Automatic carrier band winding and collecting system

A carrier tape and reeling technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of carrier tape and electronic components damage, low efficiency of carrier tape rewinding, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

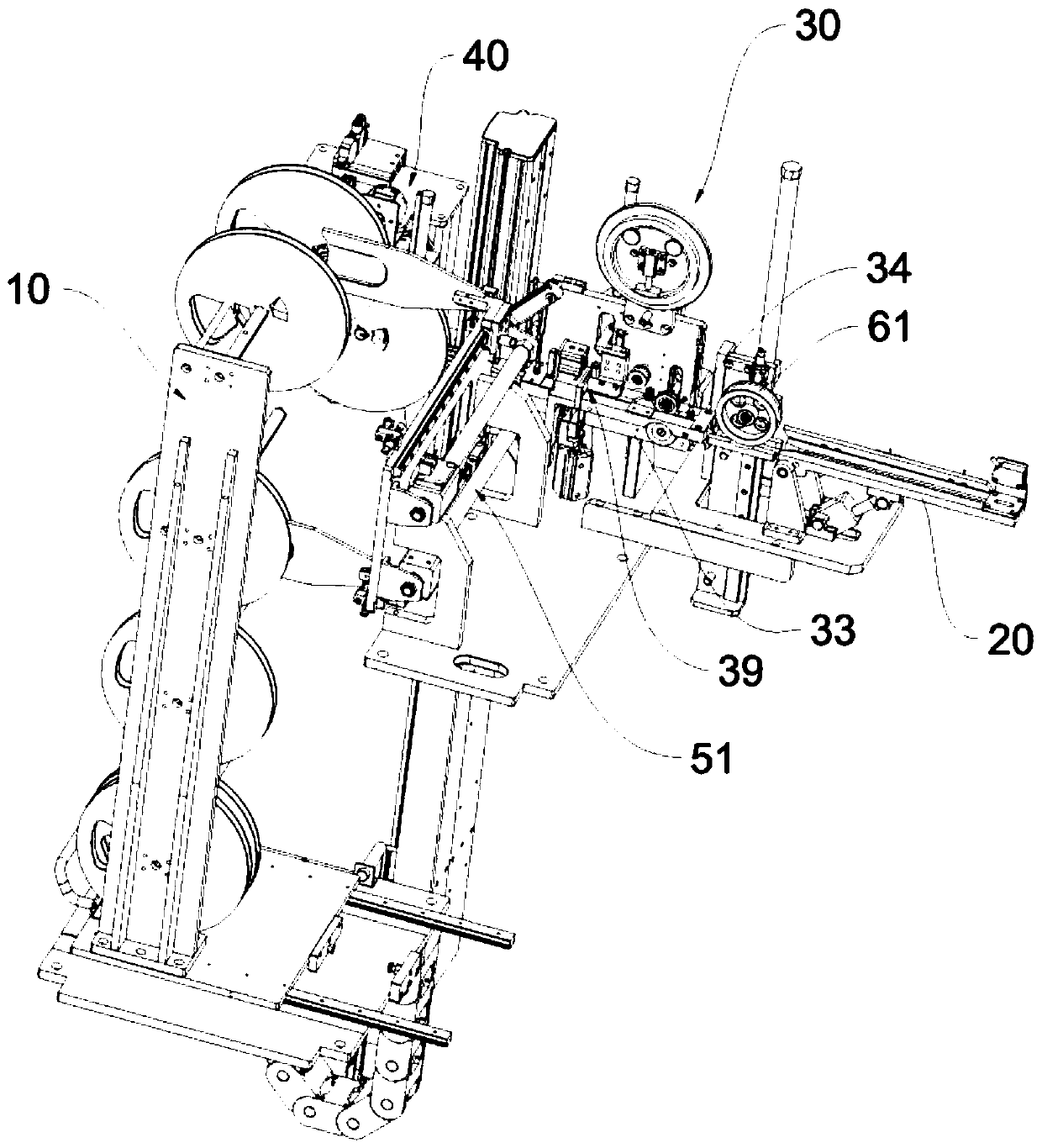

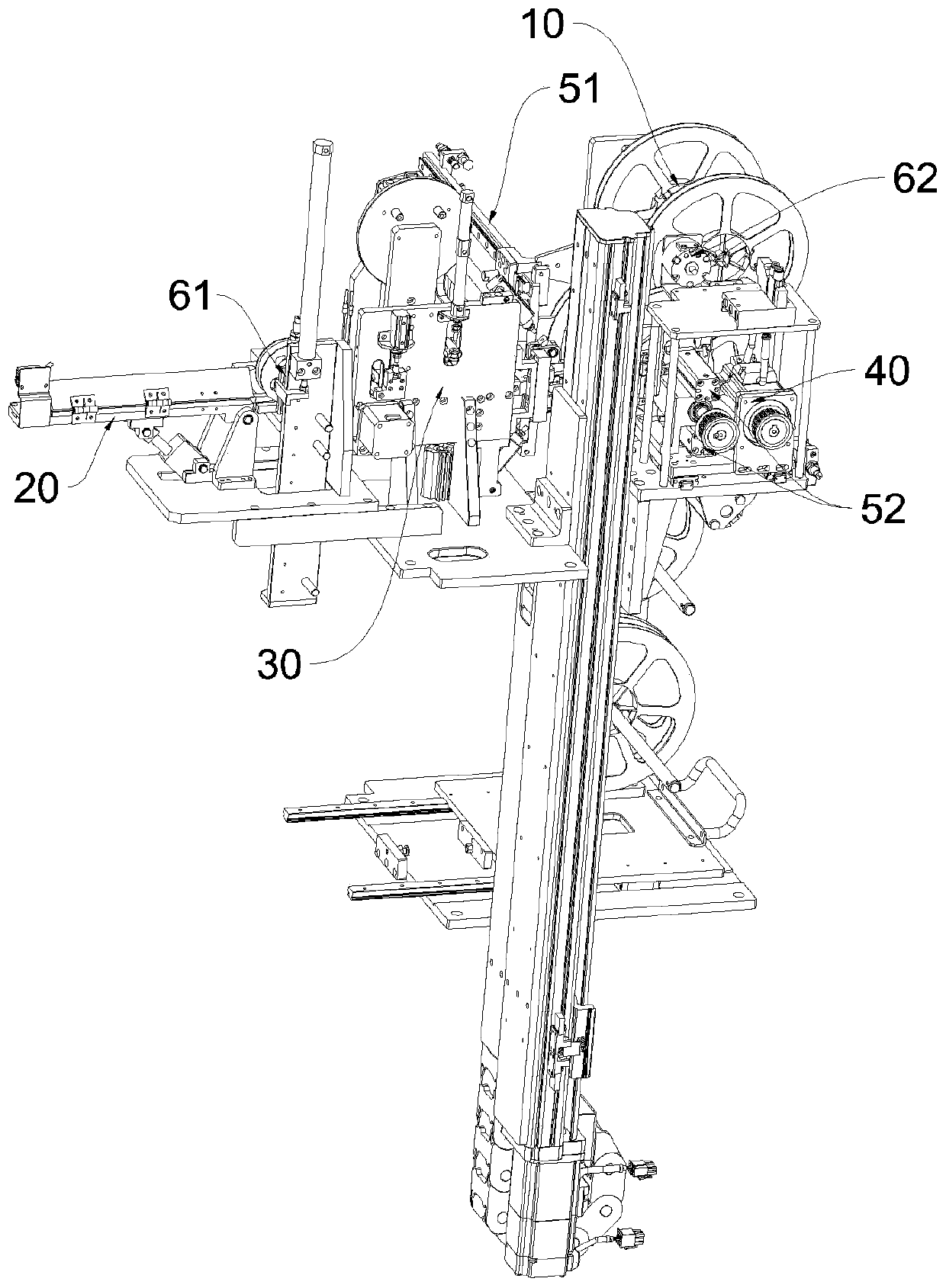

[0064] See figure 1 , the automatic winding and rewinding system of the carrier tape of the present invention, which includes

[0065] The tray storage device 10 is used to store empty trays before winding and full trays after winding;

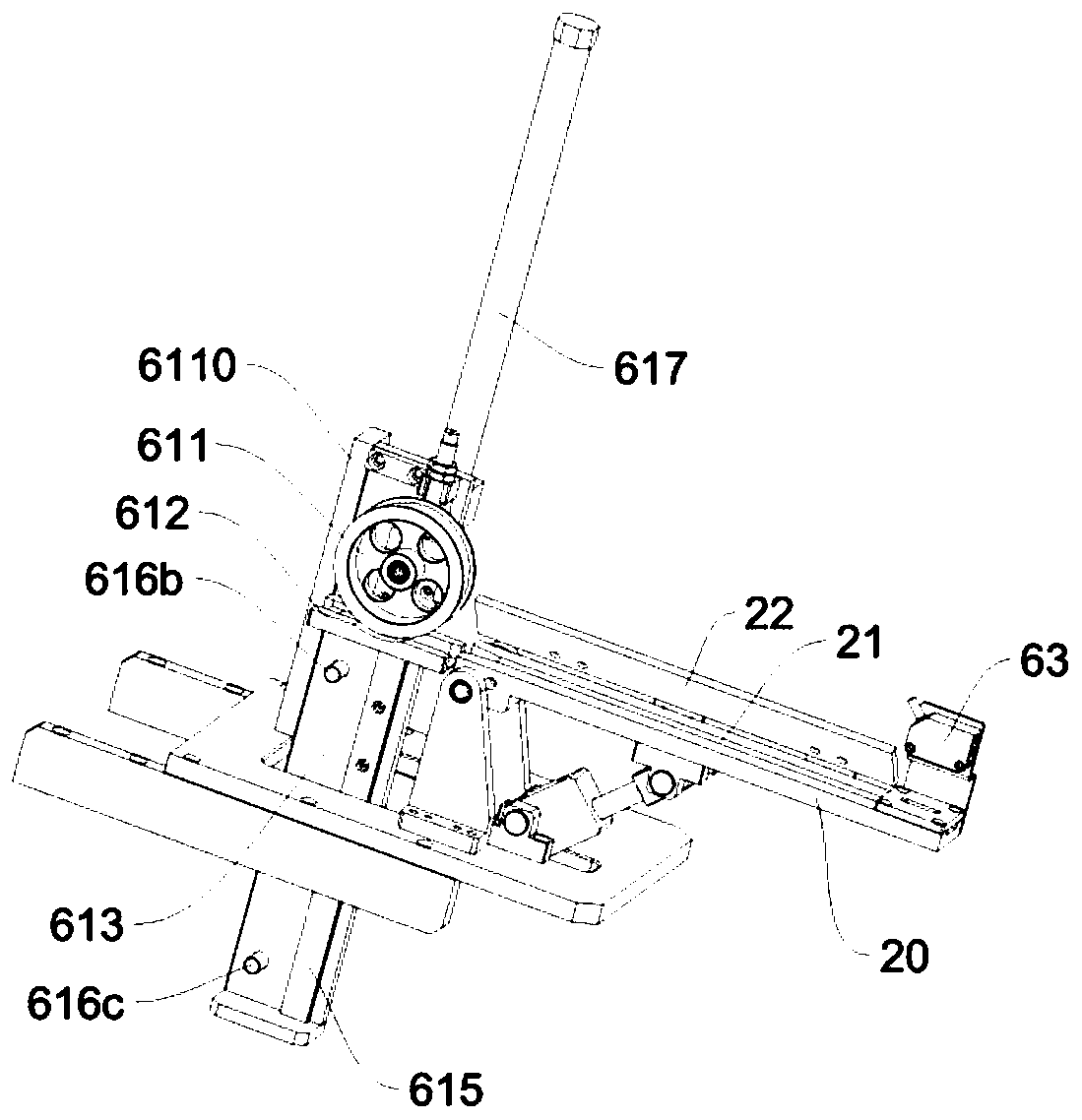

[0066] The material receiving track 20 is used for docking with the previous process equipment and receiving the carrier tape to be received from the carrier tape discharge end of the previous process equipment;

[0067] The feeding device 30 is used to transport the carrier tape received by the receiving track to the winding device;

[0068] The winding device 40 is used to wind the carrier tape from the feeding device onto an empty tray, which includes a winding servo motor that drives the tray to rotate so that the carrier tape is wound onto the tray;

[0069] The upper and lower disk devices are used to send the empty material trays above the disk storage device 10 to the winding device 40 and send the full material disks after winding o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com