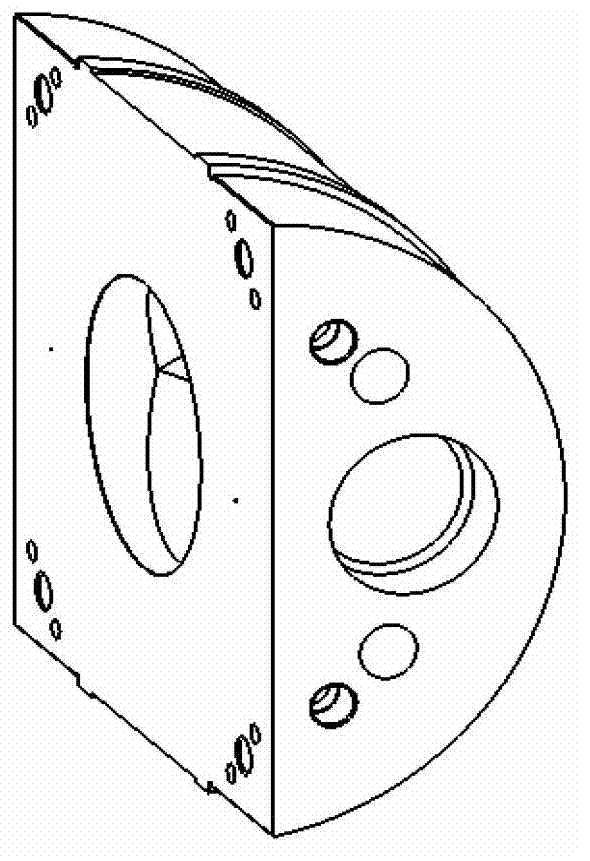

Surface grinding fixture and method for processing semi-circular pump swash plate

A flat and semi-circular grinding technology, applied in the direction of grinding workpiece supports, etc., can solve the problems of low processing efficiency and cumbersome clamping of grinding planes, and achieve the effect of improving processing efficiency, stable and reliable clamping positioning, and simplifying the adjustment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

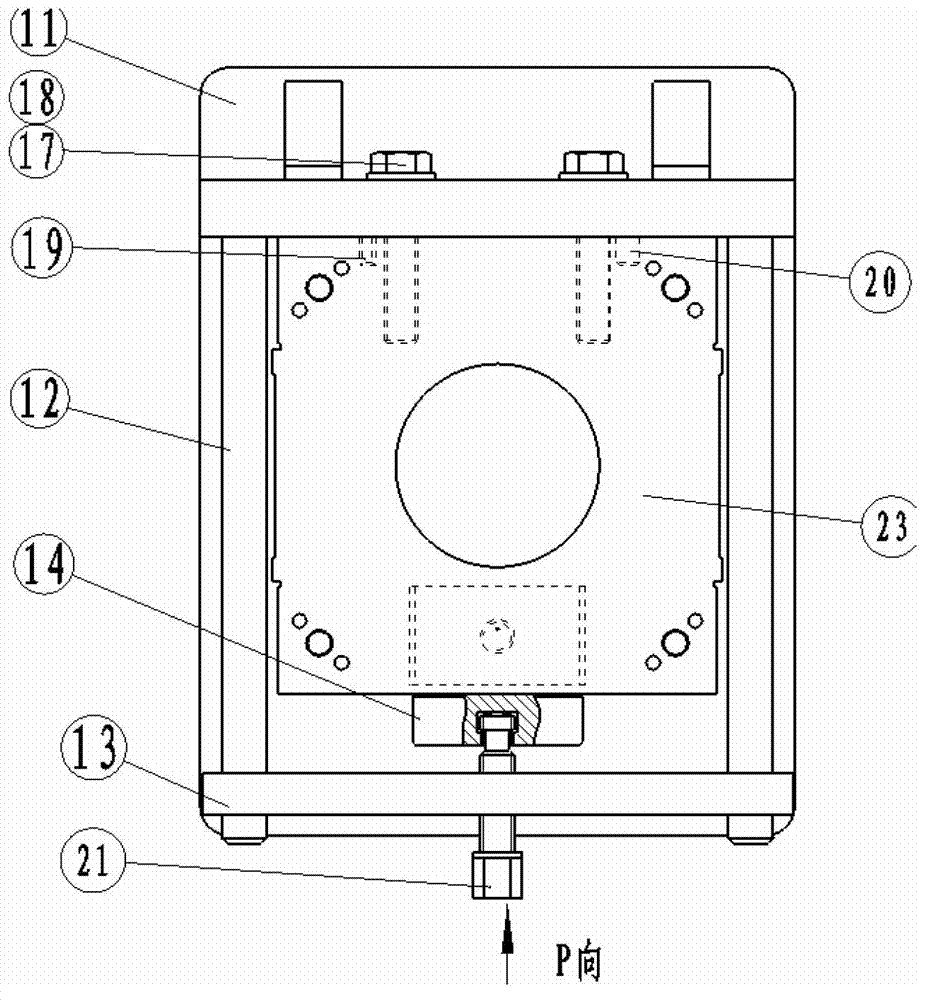

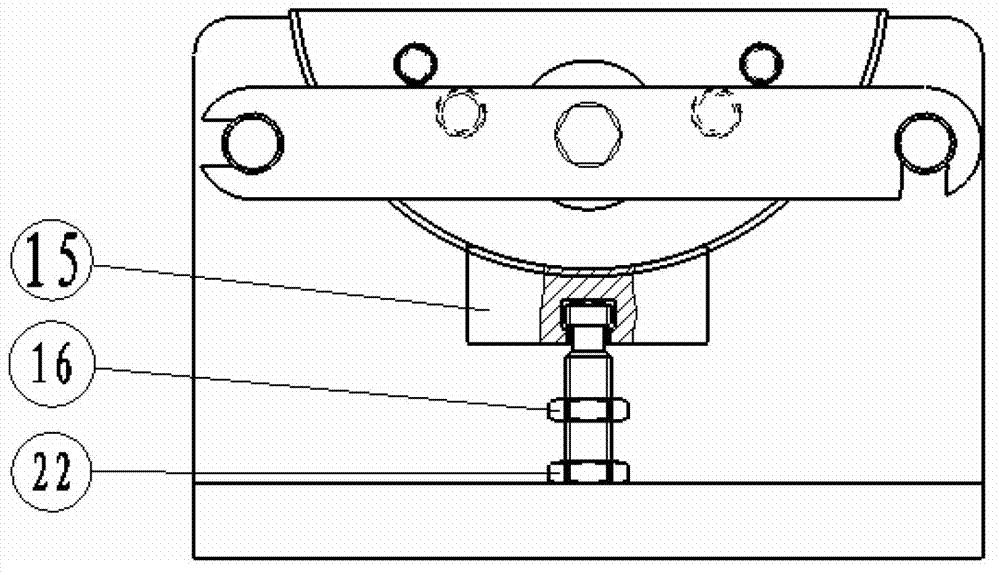

[0026] The invention provides a grinding plane fixture, which comprises a clamping body, a pressing mechanism for pressing a plane part to be ground, positioning pins and screws arranged on the clamping body; The clamp body is positioned and fixedly connected with the clamp body by screws; the plane part to be ground includes the plane to be ground; the pressing mechanism is pressed on the end face of the plane part to be ground and fixedly connected with the clamp body; the pressing mechanism includes a pillar, a pressing plate, a pressing Blocks and compression screws; the pressure plate is set on the plane of the part to be ground; the pillars are connected with the clamp body through threads, and the two pillars prop up a pressure plate as the compression support point of the parts to be processed, and the screws on the pressure plate pass through the screw The pressing force is transmitted to the pressing block, and the parts to be processed are clamped and fixed at the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com