Diesel-engine box-body clamp

A diesel engine and fixture technology, which is applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve problems affecting product quality and low efficiency, and achieve the effects of simple structure, improved production efficiency, and high-efficiency clamping and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

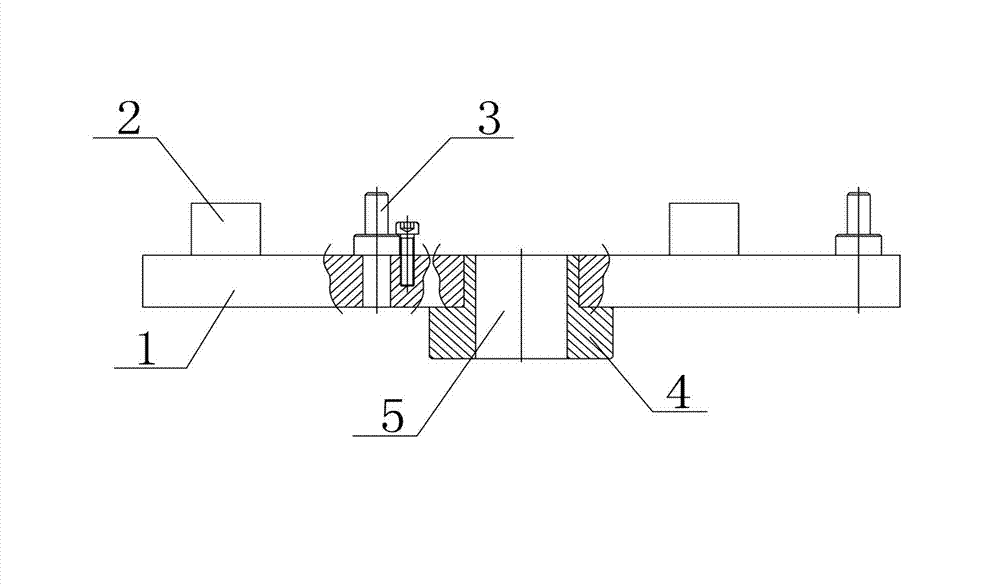

[0010] refer to figure 1 , a diesel engine box clamp, the relative position of the clamp is provided with a cylinder, the clamp includes a clamp main board 1, a positioning block 2 and a positioning pin 3 are connected to the clamp main board 1, and a positioning bushing 4 is inserted in the middle of the clamp main board 1, The positioning shaft sleeve 4 is connected to the fixture main board 1 by bolts. There is a positioning hole 5 in the positioning shaft sleeve 4. The positioning hole 5 is aligned with the position of the output shaft of the cylinder for positioning the output shaft of the cylinder.

[0011] When in use, the parts of the diesel engine box are fixed on the fixture main board 1 through the positioning block 2 and the positioning pin 3, and the output shaft of the cylinder passes through the shaft hole of the diesel engine box and the positioning hole 5 and is tightened on the tooling, and is clamped by the reciprocating motion of the cylinder. And loosen, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com