Universal clamp device for vane overall length machining

A fixture device and blade technology, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency and long production cycle, and achieve the effects of simple structure, improved production efficiency and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

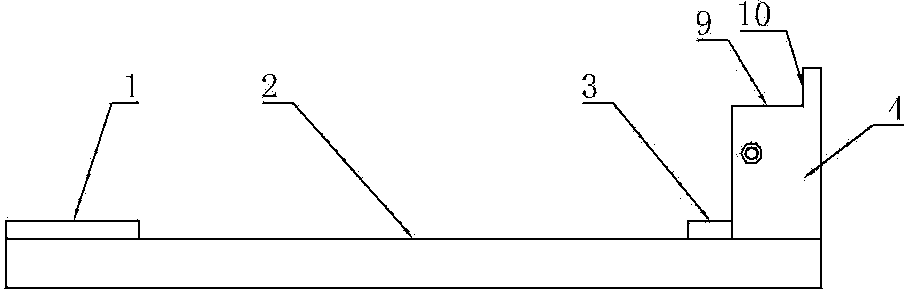

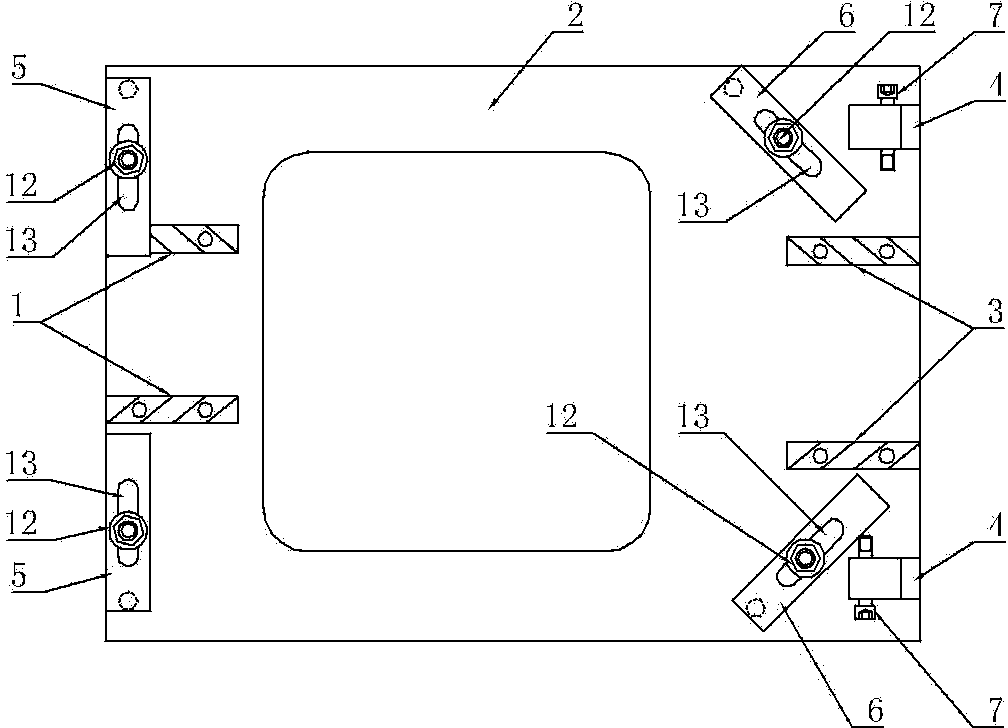

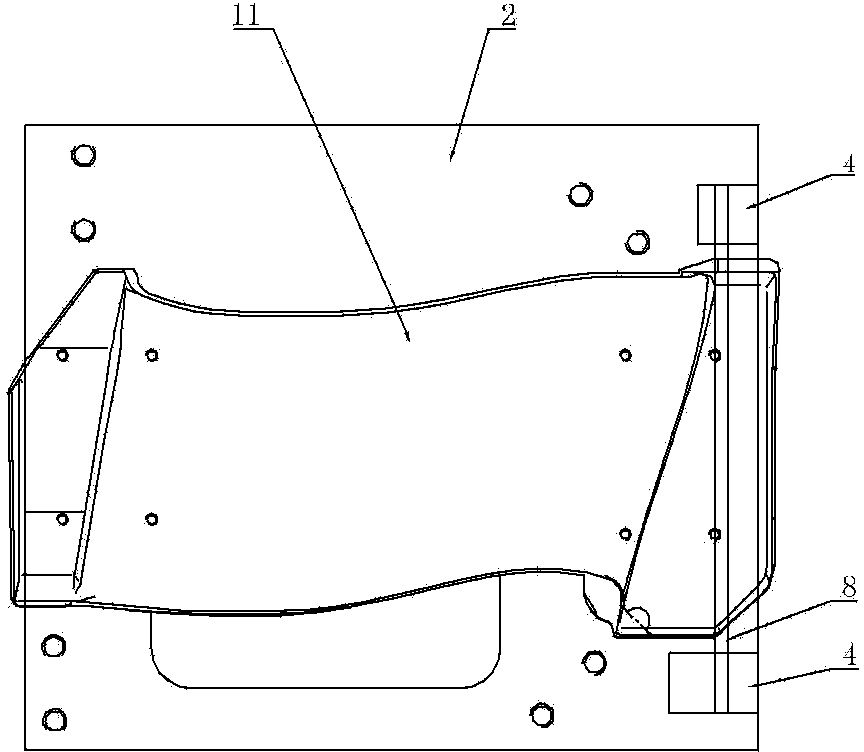

[0012] See Figure 1 ~ Figure 3 , the universal fixture device of the present invention, which includes a base 2, the crown support plate 1 and the blade root support plate 3 are respectively installed at the two lateral ends of the base 2, and the blade crown support plate 1 and the blade root support plate 3 are both provided with two, On the base 2, on the longitudinal outer ends of the two crown struts 1 and the two blade root struts 3, a crown pressing plate 5 and a blade root pressing plate 6 are installed respectively; on the base 2, on the two blade root struts 3 Blade root clamping seats 4 are respectively installed on the longitudinal outer ends, and the top surface of the blade root clamping seats 4 is provided with an inverted L-shaped groove 9, and the alignment block 8 for longitudinal positioning of the blade forging is placed on the two blade root clamping seats. 4 in the reverse L-shaped groove 9 and close to the inner groove wall 10 of the reverse L-shaped gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com