Special front shaft machining clamp capable of automatically aligning caster angle and inward camber

A special fixture and front axle technology, used in manufacturing tools, metal processing, automatic control devices, etc., can solve the problems of low efficiency of manual line drawing and alignment, and achieve good coplanarity, reliable clamping and high processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

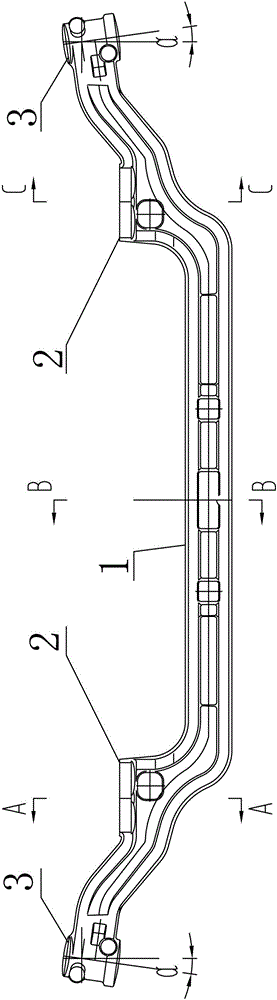

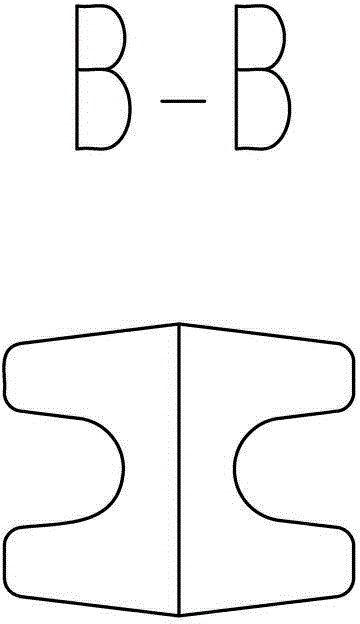

[0029] Depend on Figure 1-Figure 10 Given, including the auxiliary support structure of the I-beam part of the front axle, which can withstand the I-beam part 1 of the front axle to play a supporting role;

[0030] The auxiliary clamping structure of the I-beam part, which can be pressed on the top of the I-beam part 1 of the front axle, and cooperates with the auxiliary support structure of the I-beam part to clamp the I-beam part 1;

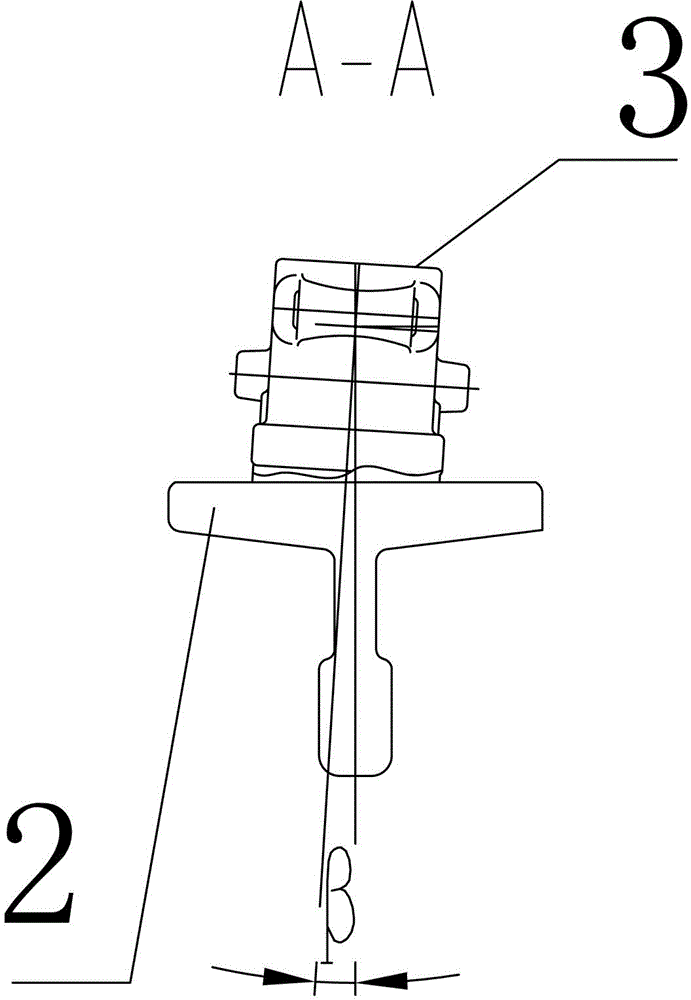

[0031] The wedge iron clamping unit placed at the rear of the leaf spring surface 2 of the front axle, the manual thread clamping unit placed at the front of the leaf spring surface 2 of the front axle and the wedge iron self-locking clamping unit to clamp the leaf spring surface of the front axle , the floating support device placed on the lower part of the leaf spring surface 2 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com