Patents

Literature

56results about How to "Implement automatic correction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full-automatic series verification calibrating device with pressure-resistant water meter

InactiveCN103175588APerfect database functionImprove efficiencyTesting/calibration apparatusMicrocontrollerEngineering

The invention discloses a full-automatic series verification calibrating device with a pressure-resistant water meter. The full-automatic series verification calibrating device with the pressure-resistant water meter comprises a water meter calibrating foundation mechanism, flow counting mechanisms, a counting mechanism, a pipeline and an operation system. The water meter calibrating foundation mechanism comprises a testing tube section which is formed by multiple testing straight tube sections and multiple water meters to be inspected, wherein the multiple testing straight tube sections and the multiple water meters to be inspected are connected in series at intervals; each water meter to be inspected corresponds to a flow counting mechanism; the counting mechanism comprises an electronic weighting device and a working container; the tail end of the testing tube section is guided into the working container through the pipeline; the operation system is electrically connected with the flow counting mechanisms and the electronic weighting device in a two-direction mode. The full-automatic series verification calibrating device with the pressure-resistant water meter achieves full-automatic meter inspection by utilizing remote control of a computer combined with a single chip controlling mechanism which gives priority to the filed programmable logic controller (PLC) control or an embedded system. Compared with the inspection method of a meter in the prior art, the full-automatic series verification calibrating device with the pressure-resistant water meter greatly improves using efficiency of an inspection device of the water meter and shortens inspection time of the water meter on the basis of ensuring measuring accuracy and eliminating human errors, and greatly improves working efficiency of inspection staff in a large range at the same time.

Owner:江苏远传智能科技有限公司

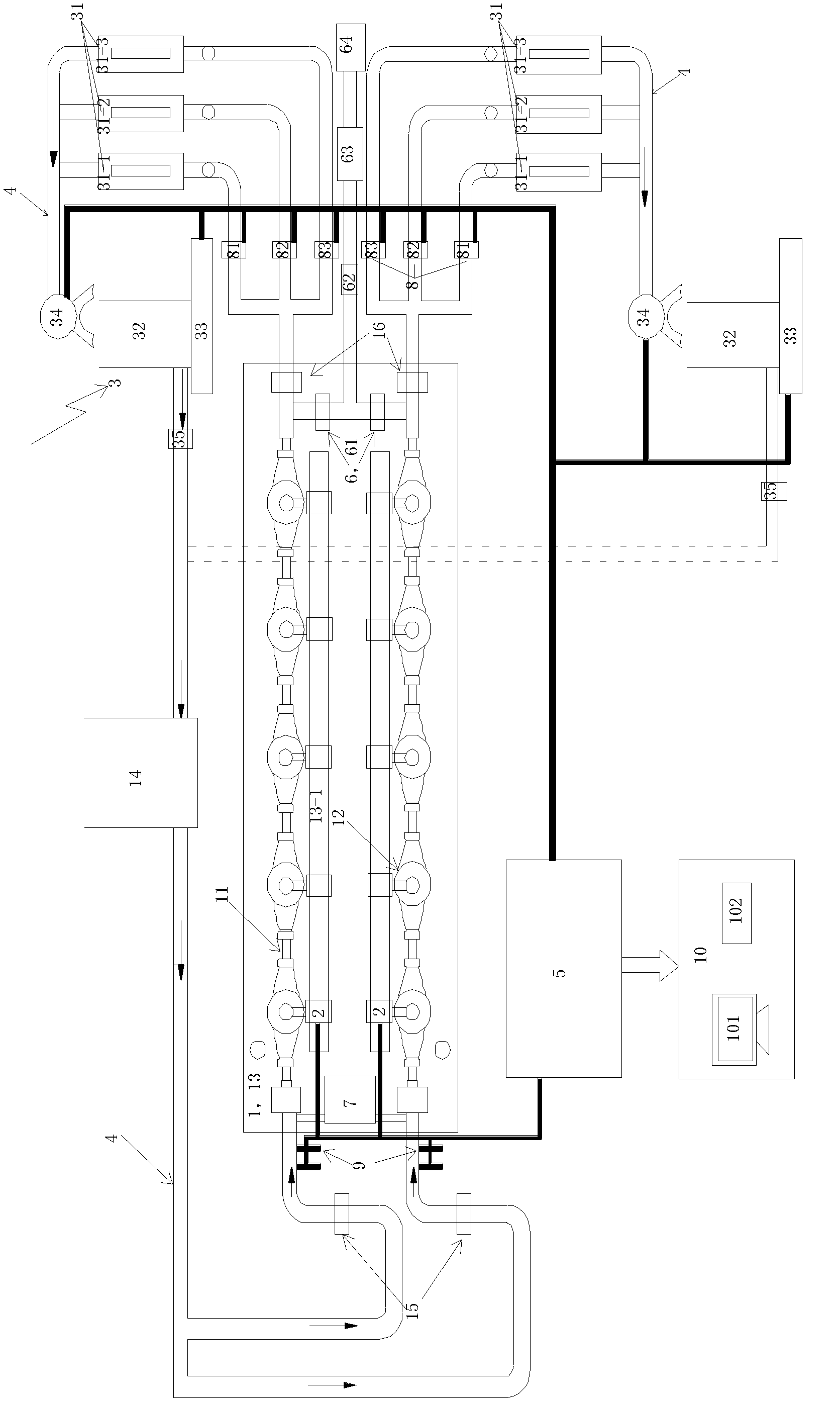

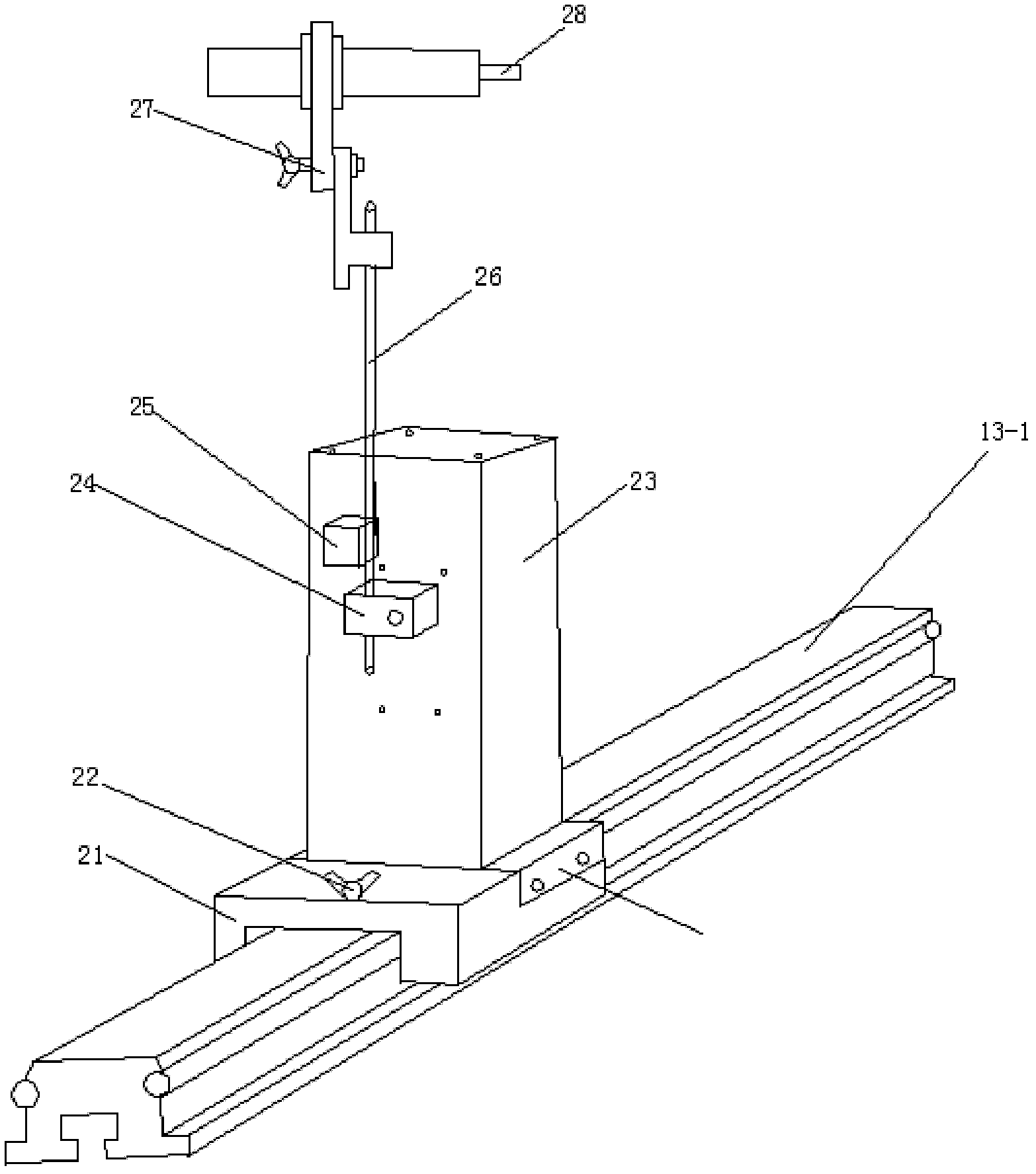

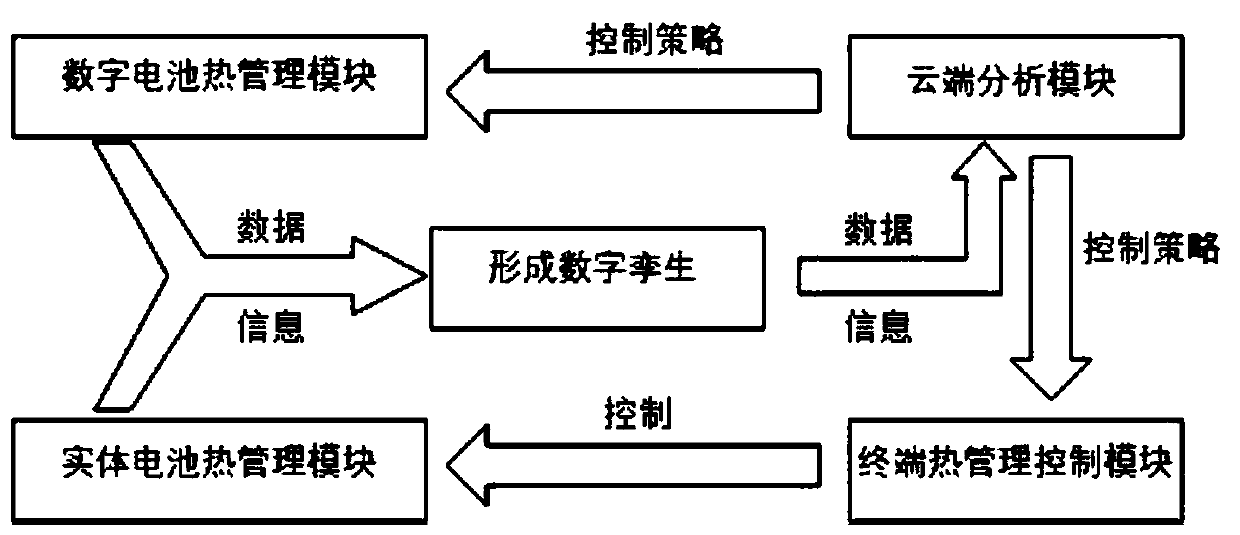

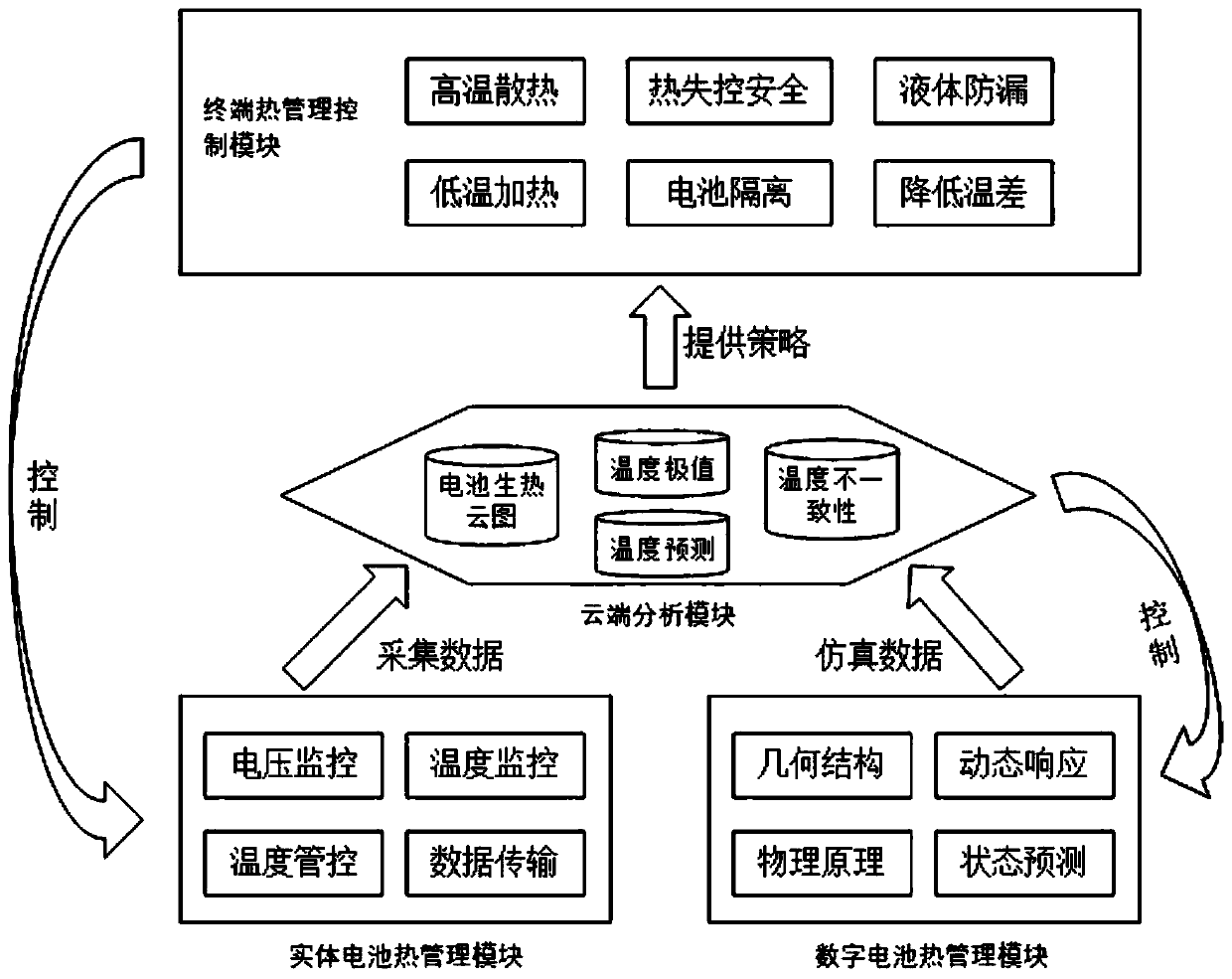

Power battery thermal management system and method

ActiveCN110532600ADelay agingImplement automatic correctionSpecial data processing applicationsPower batterySimulation

The invention relates to a power battery thermal management system and method. A power battery thermal management system based on cloud control is established by using a digital twinning technology, and meanwhile, actual operation data and simulated operation data are collected for analysis and calculation, so that a reasonable thermal management control strategy is formulated, and the effects ofdelaying battery aging and ensuring system safety are achieved.

Owner:BEIHANG UNIV

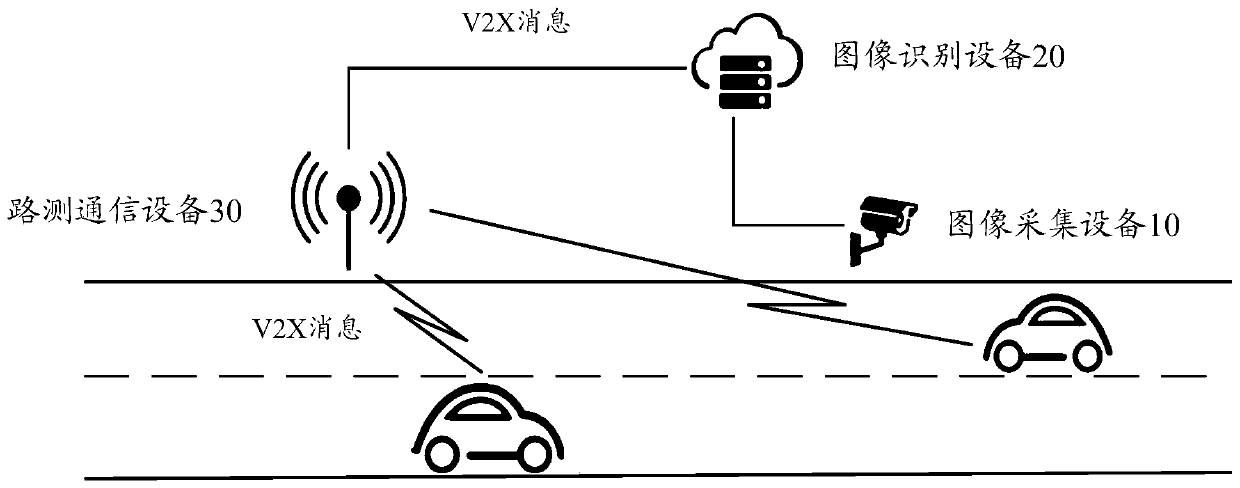

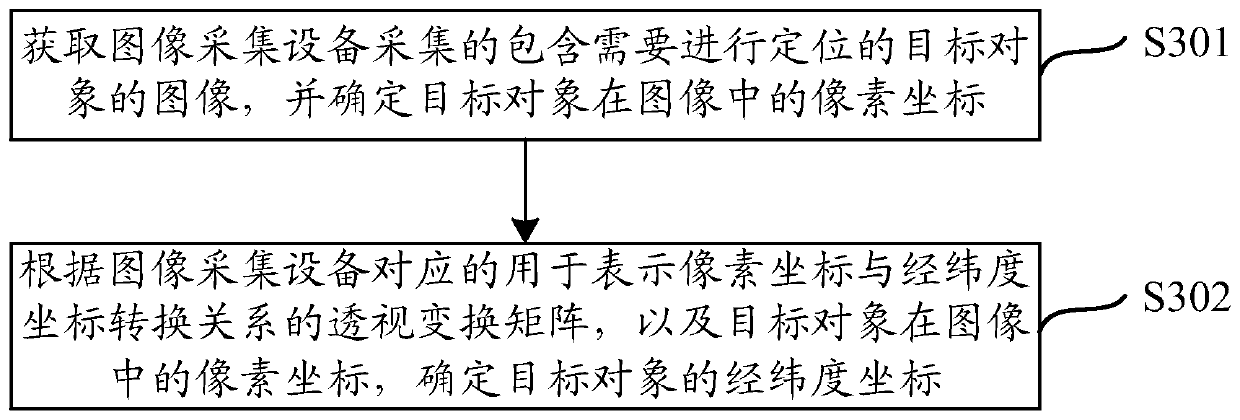

Object positioning method and device, electronic equipment and storage medium

PendingCN111046762AImplement automatic correctionReduce inaccurate positioningCharacter and pattern recognitionImaging processingComputer graphics (images)

The invention relates to the technical field of image processing, in particular to an object positioning method and device, electronic equipment and a storage medium, and aims to solve the problem that an object positioning method in the prior art is excessively limited. According to the embodiment of the invention, the method comprises the steps: obtaining an image which is collected by image collection equipment and contains a to-be-positioned target object, and determining the pixel coordinates of the target object in the image; and determining longitude and latitude coordinates of the target object according to the perspective transformation matrix corresponding to the image acquisition device and the pixel coordinates of the target object in the image. According to the embodiment of the invention, the longitude and latitude coordinates corresponding to the pixel coordinates of the target object in the image are determined through the perspective transformation matrix correspondingto the image acquisition device to complete the positioning of the target object, and the installation position of the image acquisition device is not strictly limited. Moreover, the perspective transformation matrix corresponding to the image acquisition equipment is determined according to pixel coordinates and latitude and longitude coordinates of a plurality of reference points, but selectionof the reference points is not strictly limited, so that the limitation is relatively low.

Owner:TENCENT TECH (SHENZHEN) CO LTD

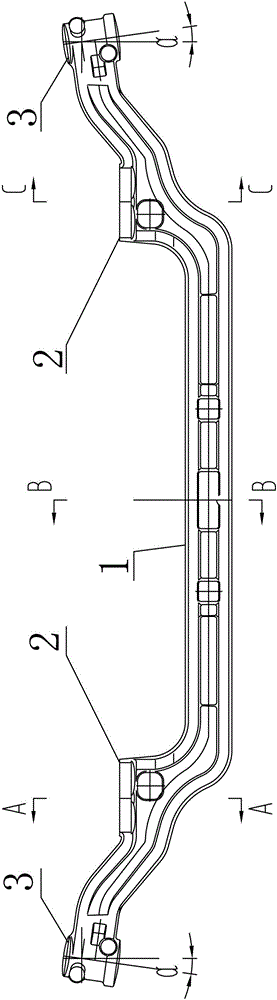

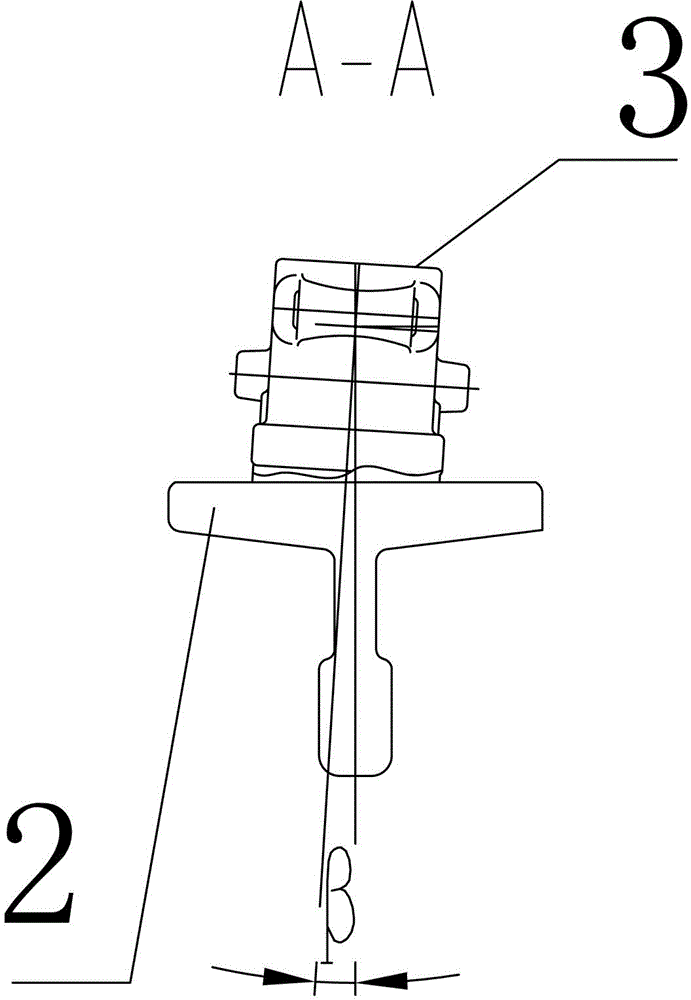

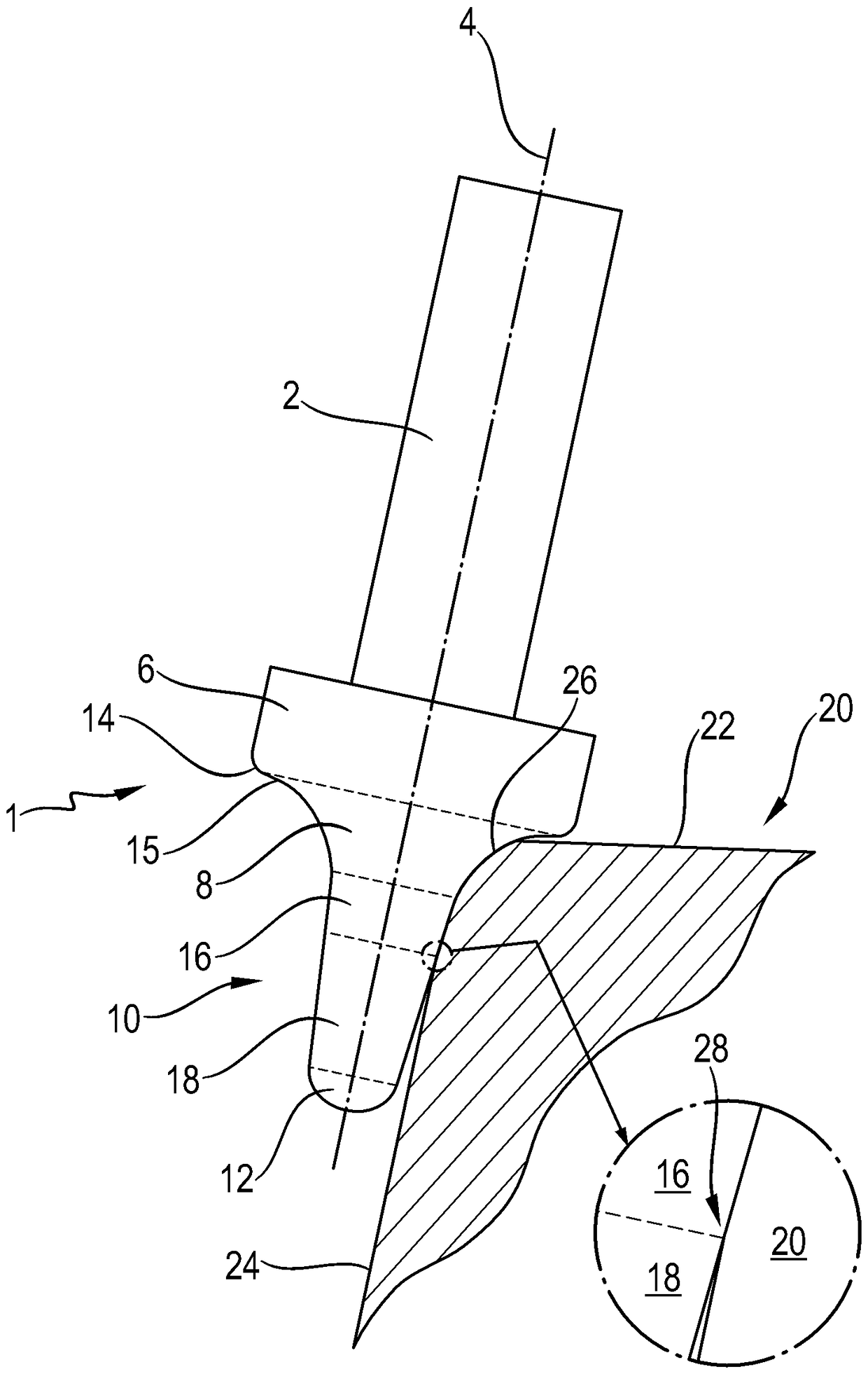

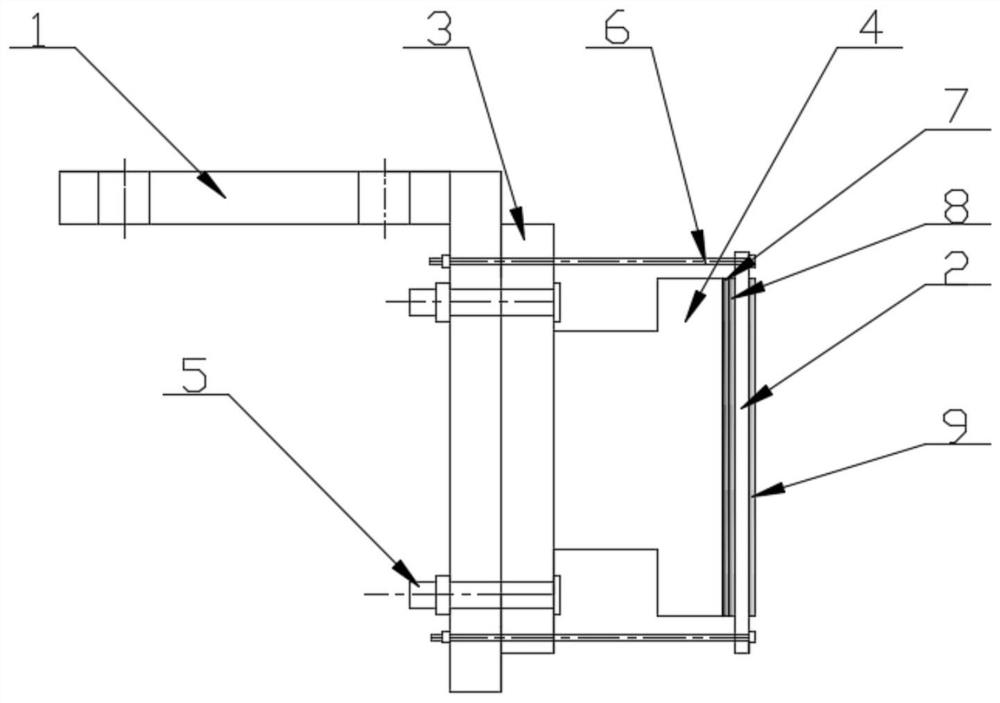

Special front shaft machining clamp capable of automatically aligning caster angle and inward camber

InactiveCN104924123ASuperiorReduce distortionAutomatic control devicesFeeding apparatusFistCaster angle

The invention provides a special front shaft machining clamp capable of automatically aligning a caster angle and an inward camber. The caster angle and the inward camber of a workblank are automatically aligned within a certain amount of deformation of the workblank of a front shaft, a front shaft leaf spring face is directly milled after alignment is performed, and a coordinated system using the aligned front shaft leaf spring face as the positioning basis is built and used as the basis during subsequent machining. According to the scheme, the clamp comprises a front shaft H-shaped beam portion auxiliary supporting structure, an H-shaped beam portion auxiliary clamping structure, a clamping H-shaped beam portion, a wedge iron self-locking clamping unit, a manual thread clamping unit, a floating supporting device and an inward camber correcting unit, wherein the front shaft H-shaped beam portion auxiliary supporting structure can abut against the front shaft H-shaped beam portion so as to play a supporting role, the H-shaped beam portion auxiliary clamping structure can compress the portion above the front shaft H-shaped beam portion, the clamping H-shaped beam portion is matched with the H-shaped beam portion auxiliary supporting structure, the wedge iron self-locking clamping unit is arranged at the rear portion of the front shaft leaf spring face, the manual thread clamping unit is arranged at the front portion of the front shaft leaf spring face and used in cooperation with the wedge iron self-locking clamping unit to clamp the front shaft leaf spring face portion, the floating supporting device is arranged at the lower portion of the front shaft leaf spring face, and the inward camber correcting unit is arranged at the position of a front shaft left fist face and used for correcting the front shaft inward camber.

Owner:ANYANG INST OF TECH

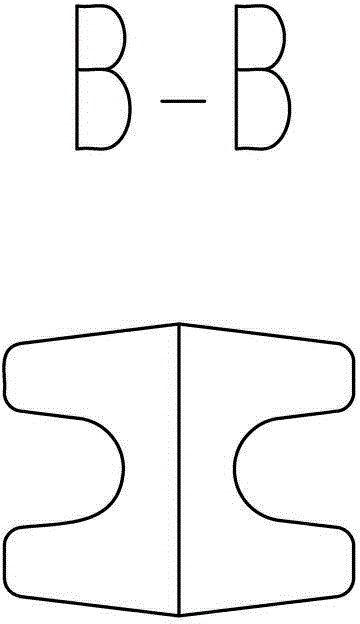

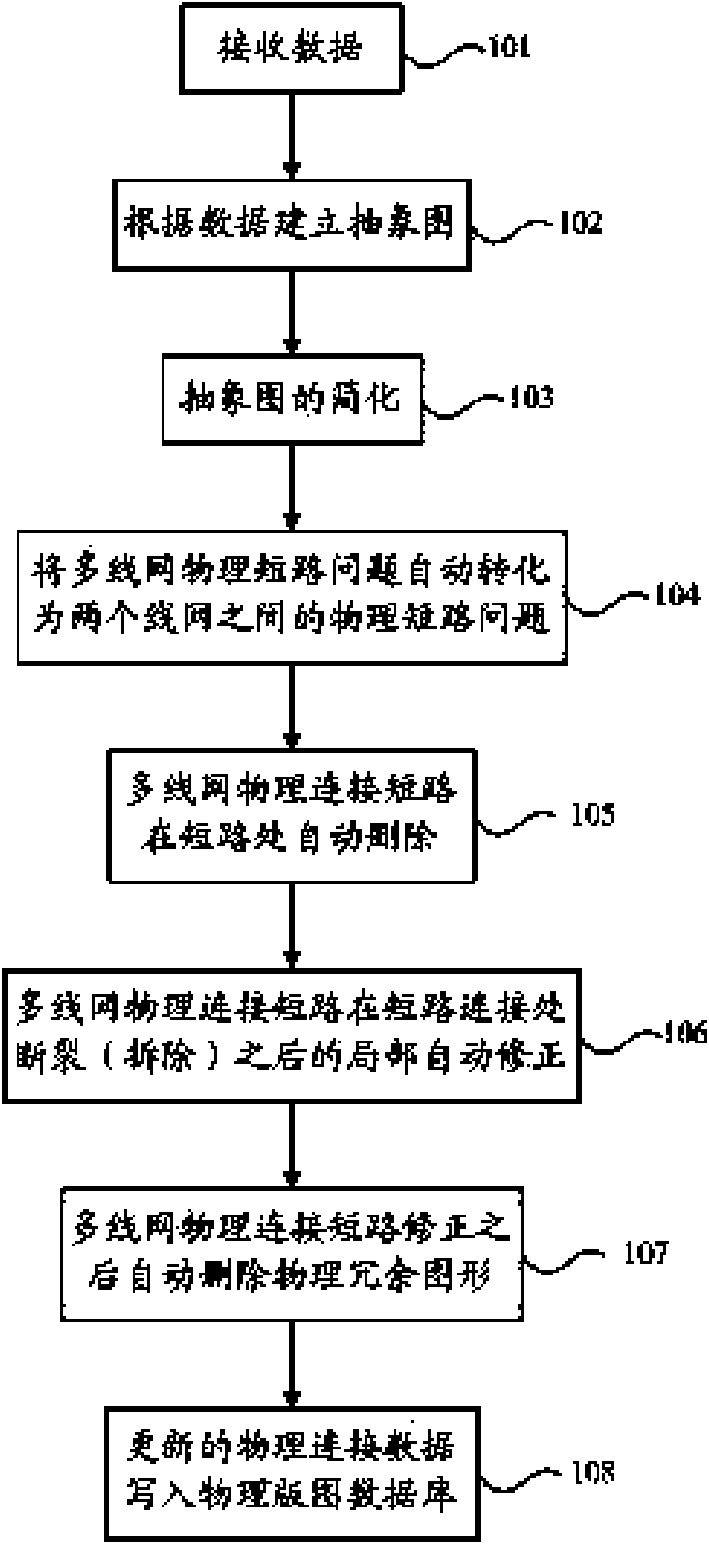

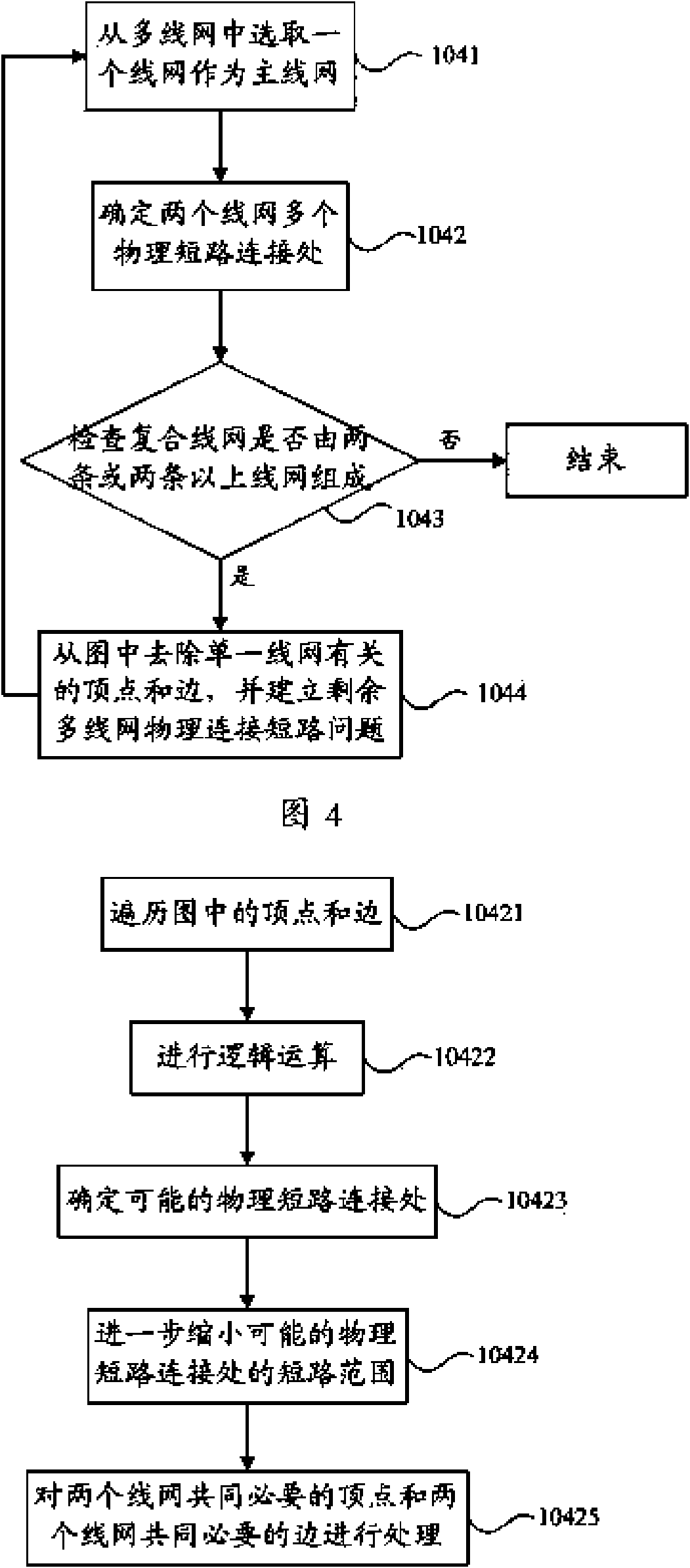

Automatic positioning method for physical short circuit positions among multiple line networks

ActiveCN102117350AImprove design efficiencyAutomatically achieve automatic positioningSpecial data processing applicationsComputer architectureNetwork on

The invention discloses an automatic positioning method for physical short circuit positions among multiple line networks, and belongs to the technical field of electronic design automation. The method comprises the following steps of: receiving a circuit diagram / circuit network table, physical layout data and layout versus schematic (LVS) result data; and establishing an abstract diagram according to the circuit diagram / circuit network table, the physical layout data and the LVS result data, and simplifying the abstract diagram so as to complete automatic positioning of physical connection short circuits of the multiple line networks on the simplified abstract diagram. By using the method, automatic positioning of the physical short circuits among the multiple line networks during integrated circuit physical layout design can be automatically realized to replace a designer to manually seek the physical short circuit positions on the physical layout, so that the design efficiency of the physical layout is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

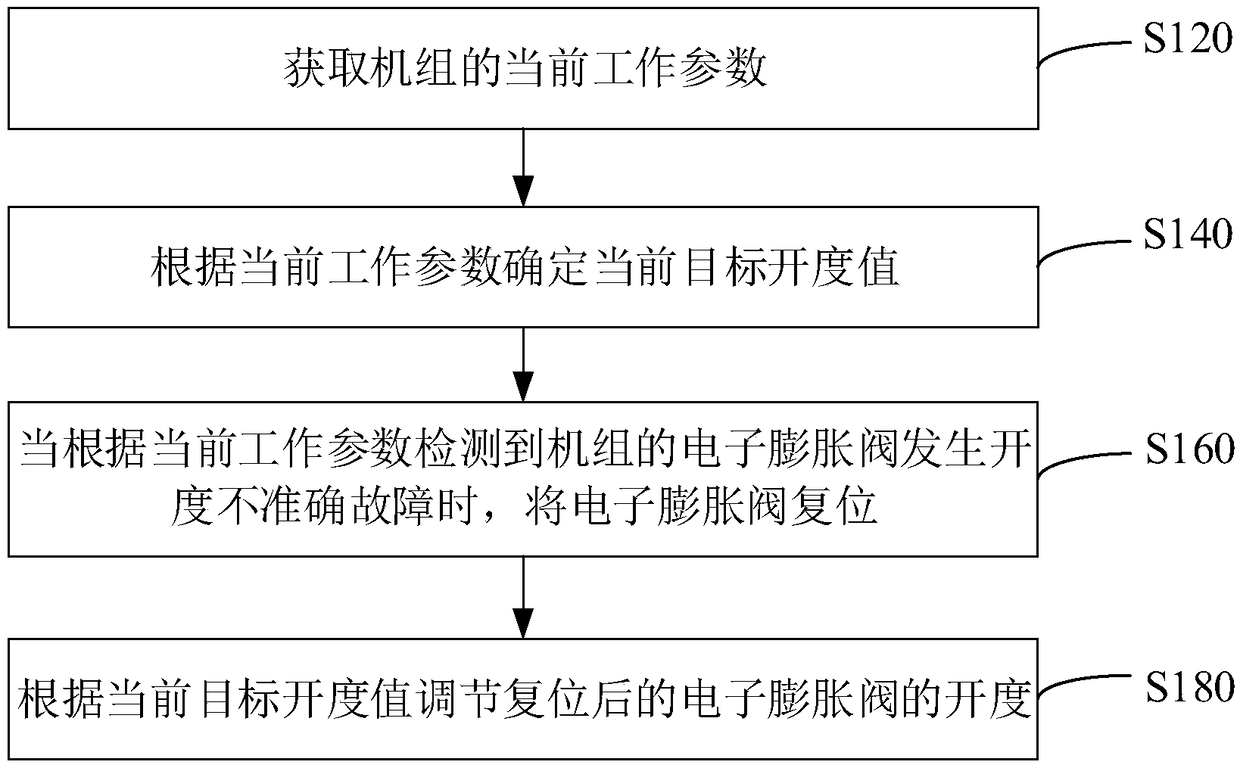

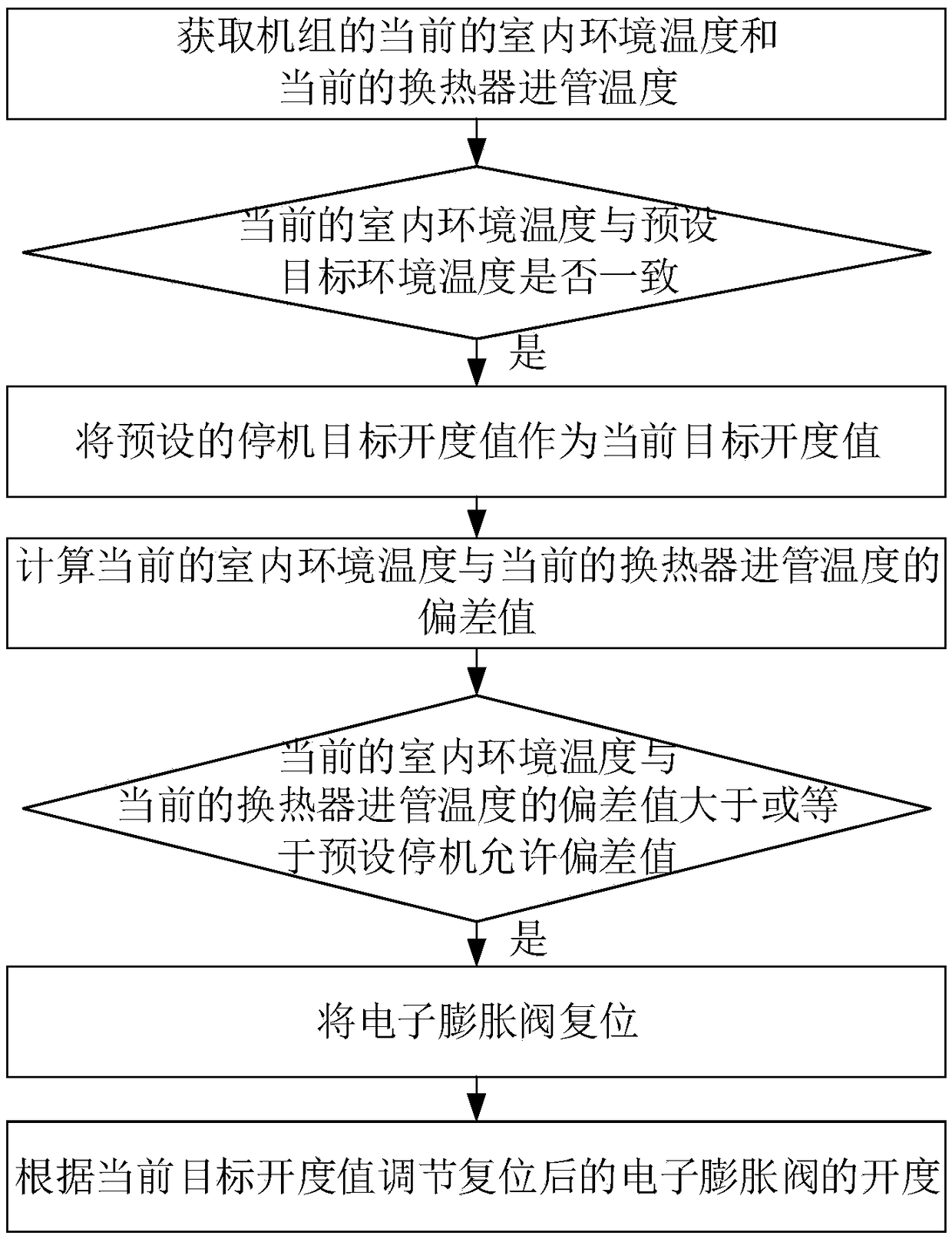

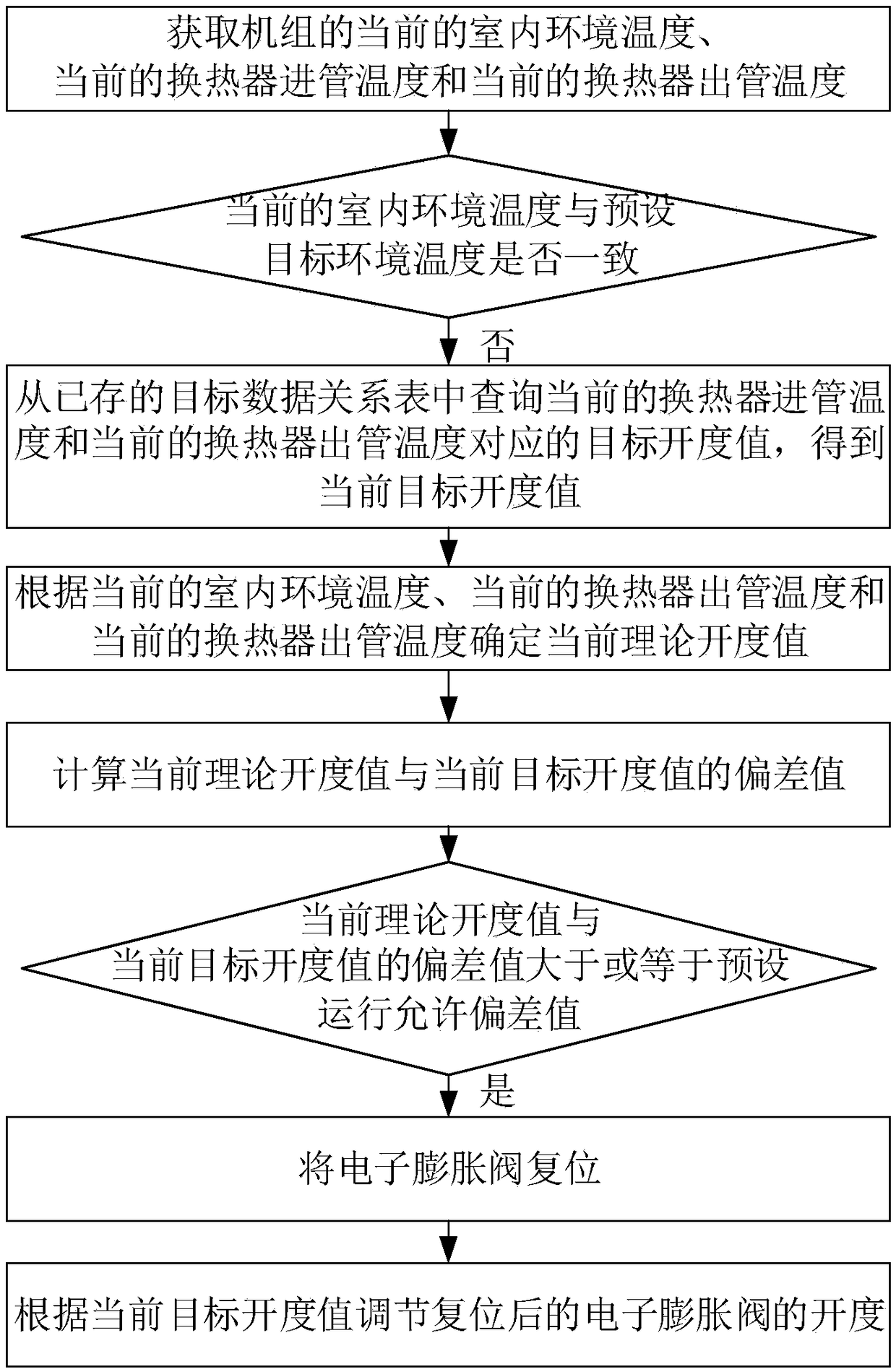

Electronic expansion valve opening degree correction method for unit, control device and air conditioning system

ActiveCN109373653AImprove accuracyImprove operational reliabilityMechanical apparatusSpace heating and ventilation safety systemsCorrection methodControl equipment

The invention relates to an electronic expansion valve opening degree correction method for unit, a control equipment and an air conditioning system. The method for correcting the opening degree of the unit electronic expansion valve comprises the following steps of acquiring the current working parameters of the unit; confirming the current target opening degree value according to the current working parameters; resetting the electronic expansion valve when the opening degree of the electronic expansion valve of the unit is not accurate according to the current working parameters; adjusting the opening degree of the reset electronic expansion valve according to the current target opening value. According to the electronic expansion valve opening degree correction method for unit, the control equipment and the air conditioning system, the accuracy of the opening degree of the electronic expansion valve can be improved, so that the operation reliability of the unit is improved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

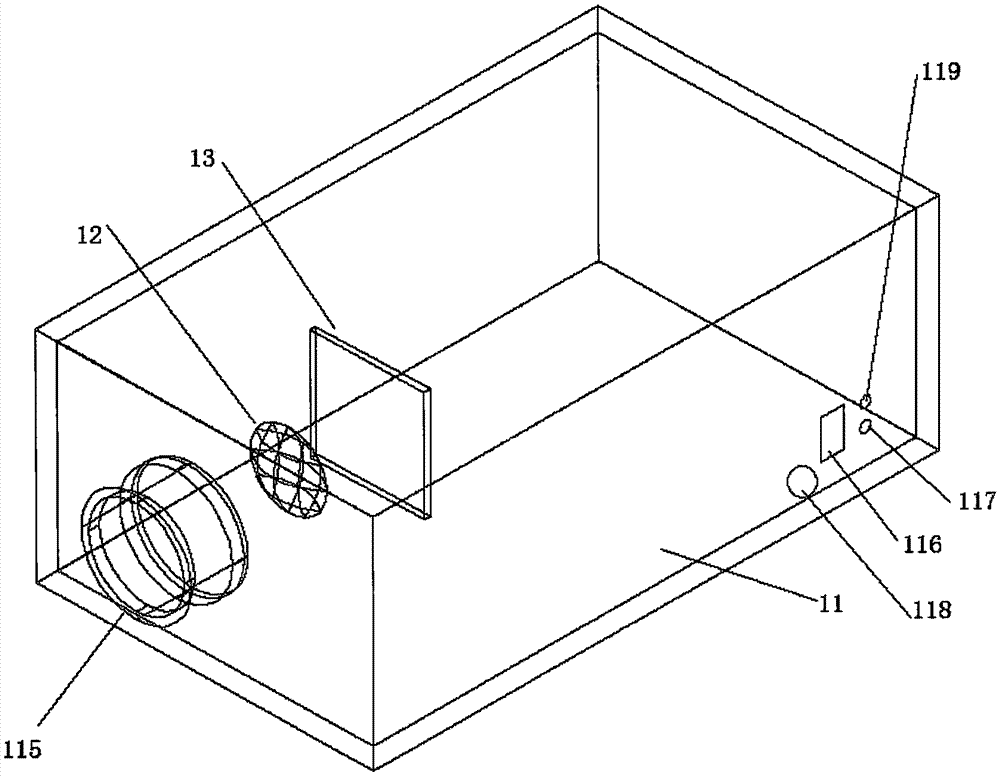

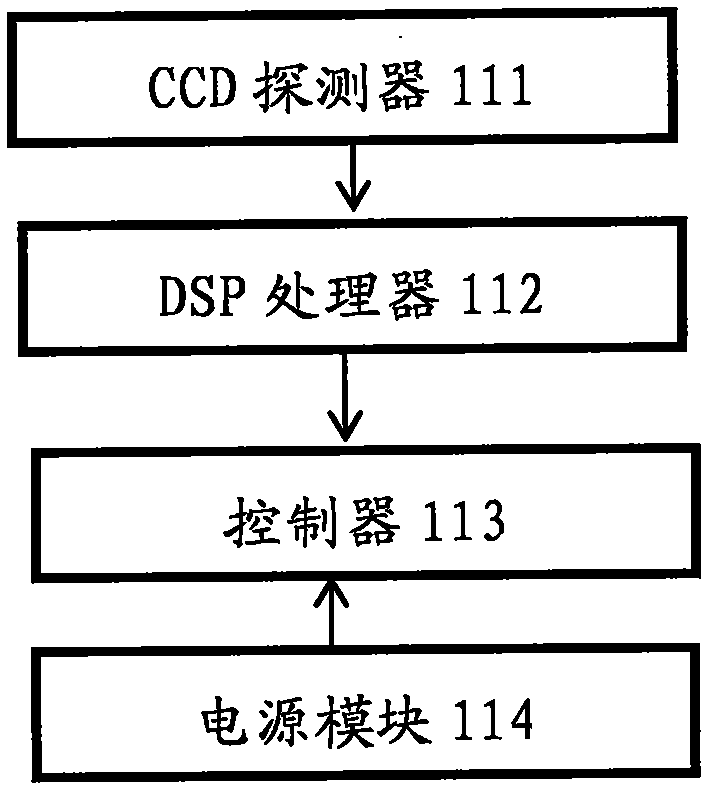

Imaging spectrometer based on liquid crystal tunable optical filter and full spectrum range automatic acquiring method

InactiveCN105444883AHigh resolutionRealize automatic acquisitionRadiation pyrometrySpectrum investigationCamera lensSpectral bands

The invention provides an imaging spectrometer based on a liquid crystal tunable optical filter. The imaging spectrometer comprises a spectrometer and a remote control device, which are in a communicated connection. The spectrometer comprises a housing, an optical lens, and a liquid crystal tunable optical filter. A CCD detector, a DSP processor, and a power supply module are disposed in the housing. The optical lens is disposed on the outer part of the housing, and the tunable optical filter is disposed on the rear part of the optical lens. The reflected light of the object can be tuned and filtered by the liquid crystal tunable optical filter after passing through the optical lens. The imaging spectrometer is advantageous in that the liquid crystal tunable optical filter is used for the core beam splitting, and the CCD detector can be used as the digital light sensing element, and the DSP processor is used as the calculation and control unit; the high-resolution spectral images can be realized, and the tuning of the spectral bands can be realized by controlling the liquid crystal tunable optical filter; by adopting the interaction between the DSP processor and the remote control device, the automatic acquisition of the spectrums and the automatic correction of the calculated parameters can be realized; the use is convenient, and the costs are low.

Owner:WUHAN MAISHIWEI OPTOELECTRONICS TECH CO LTD

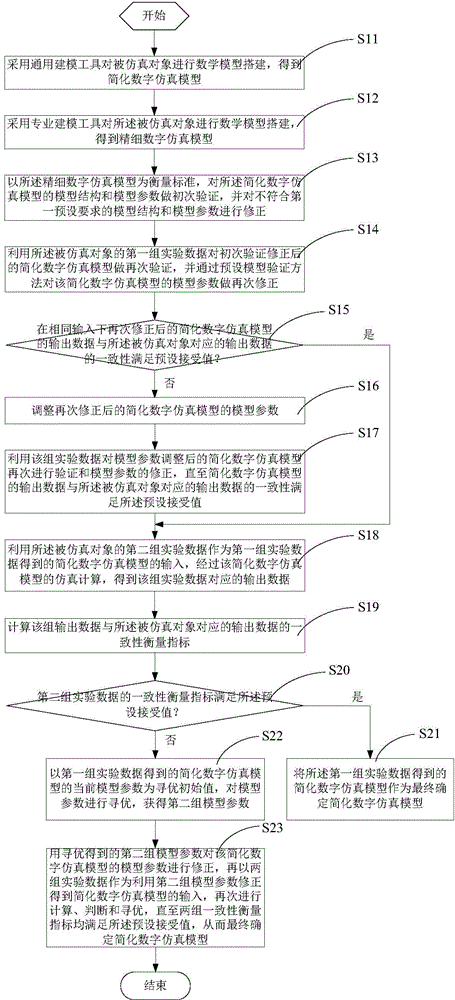

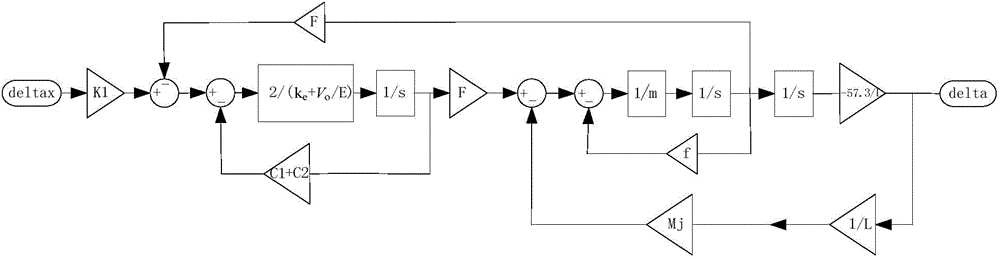

Digital simulation model correcting method and system

ActiveCN104615840AImplement automatic correctionImprove correction efficiencySpecial data processing applicationsSimulationModel parameters

The invention discloses a digital simulation model correcting method and a digital simulation model correcting system. The digital simulation model correcting method comprises the following steps: after a general modeling tool and a professional modeling tool acquire a simplified digital simulation model and an exquisite digital simulation model of a simulated object respectively, firstly, performing preliminary verification and model structure and parameter correction on the simplified digital simulation model by using exquisite digital simulation model; secondly, performing verification and model parameter correction on the corrected simplified digital simulation model by using a first group of experimental data of the simulated object till the obtained simplified digital simulation model meets requirements on measurement indexes for model verification under the group of experimental data; thirdly, performing verification and model parameter correction on the simplified digital simulation model meeting the first group of experimental data by using a second group of experimental data of the simulated object till the obtained simplified digital simulation model meets requirements on measurement indexes for model verification under the two groups of experimental data, and thus finally determining the simplified digital simulation model.

Owner:BEIJING RUNKE GENERAL TECH

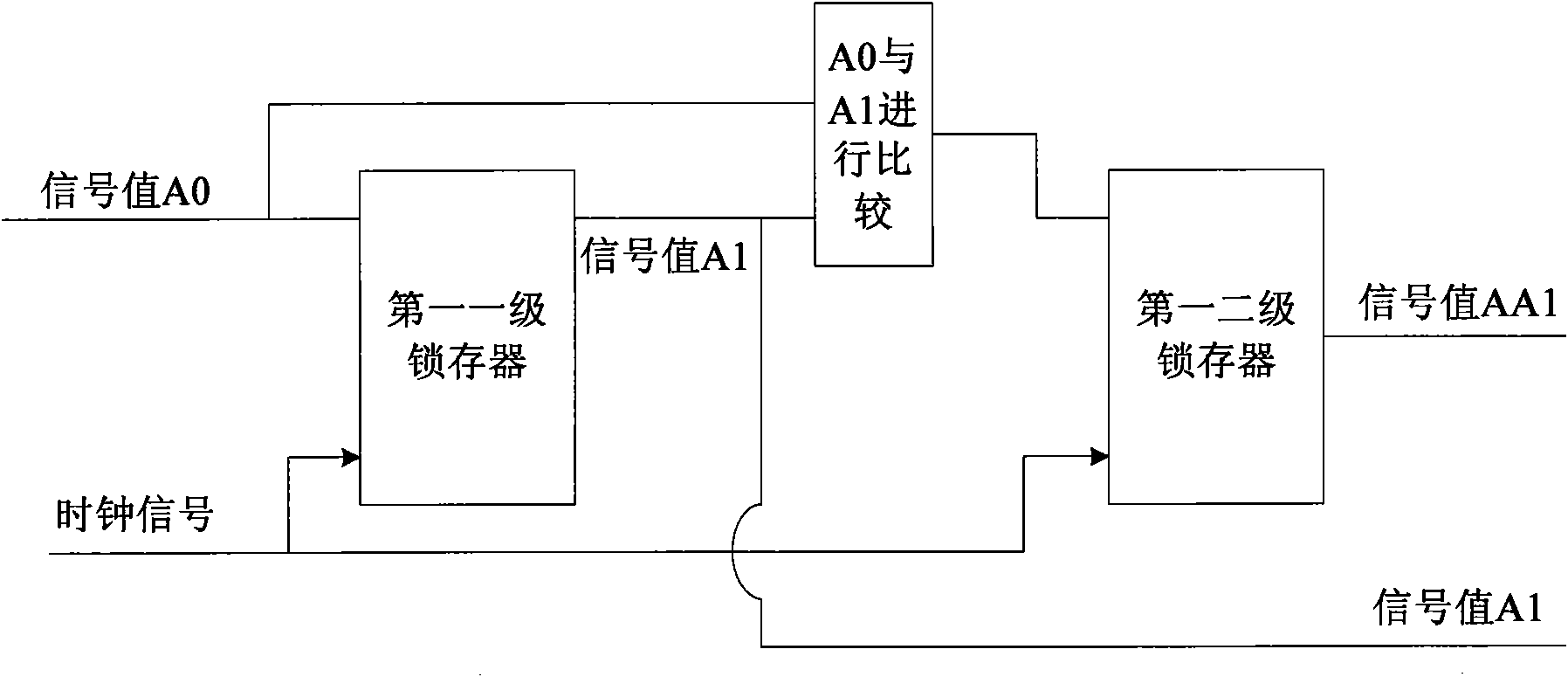

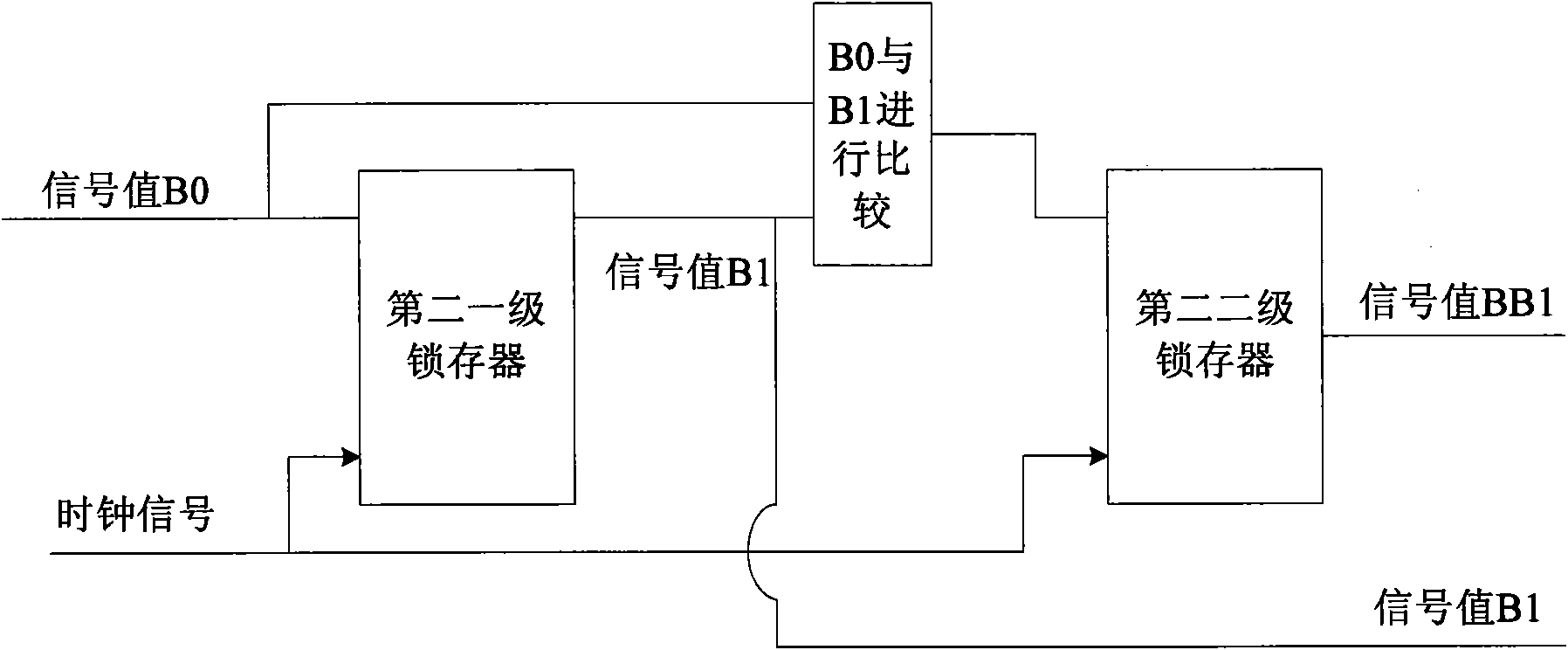

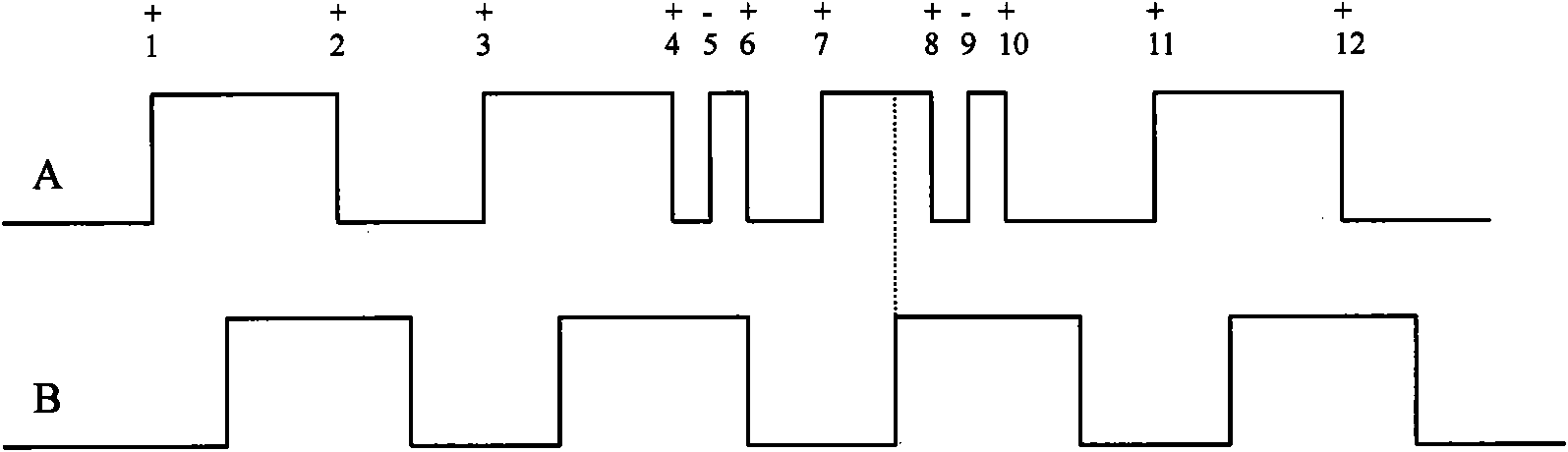

Processing method of interference signals in decoding process of digital coder

InactiveCN101660925AEliminate the effects ofEffective filteringMitigation of undesired influencesElectricityDigital filter

The invention discloses a processing method of interference signals in decoding process of a digital coder, which can effectively filter an interference signal with smaller width in pulse signals A and B by inducing one external clock signal the frequency of which is more than 3 times, but less than 10 times of the maximum frequency of the pulse signal A or B generated and outputted by the digitalcoder and taking the external clock signal as the clock signal of each-grade latch of a first digital filter and a second digital filter, and can guarantee not to change phase position factors of thepulse signals A and B; while for the interference signal with larger width, if the pulse signal B is high level when the pulse A is jumped from high level to lower level, then the attribute value isincreased by 1; however, if the pulse signal B is still high level when the interference signal stops and the pulse signal A is jumped from low level to high level, then the attribute value is reducedby 1, thus being capable of effectively eliminating the influences of the interference signal with larger width on the pulse signals, thereby leading a final attribute value to be more accurate.

Owner:NINGBO UNIV

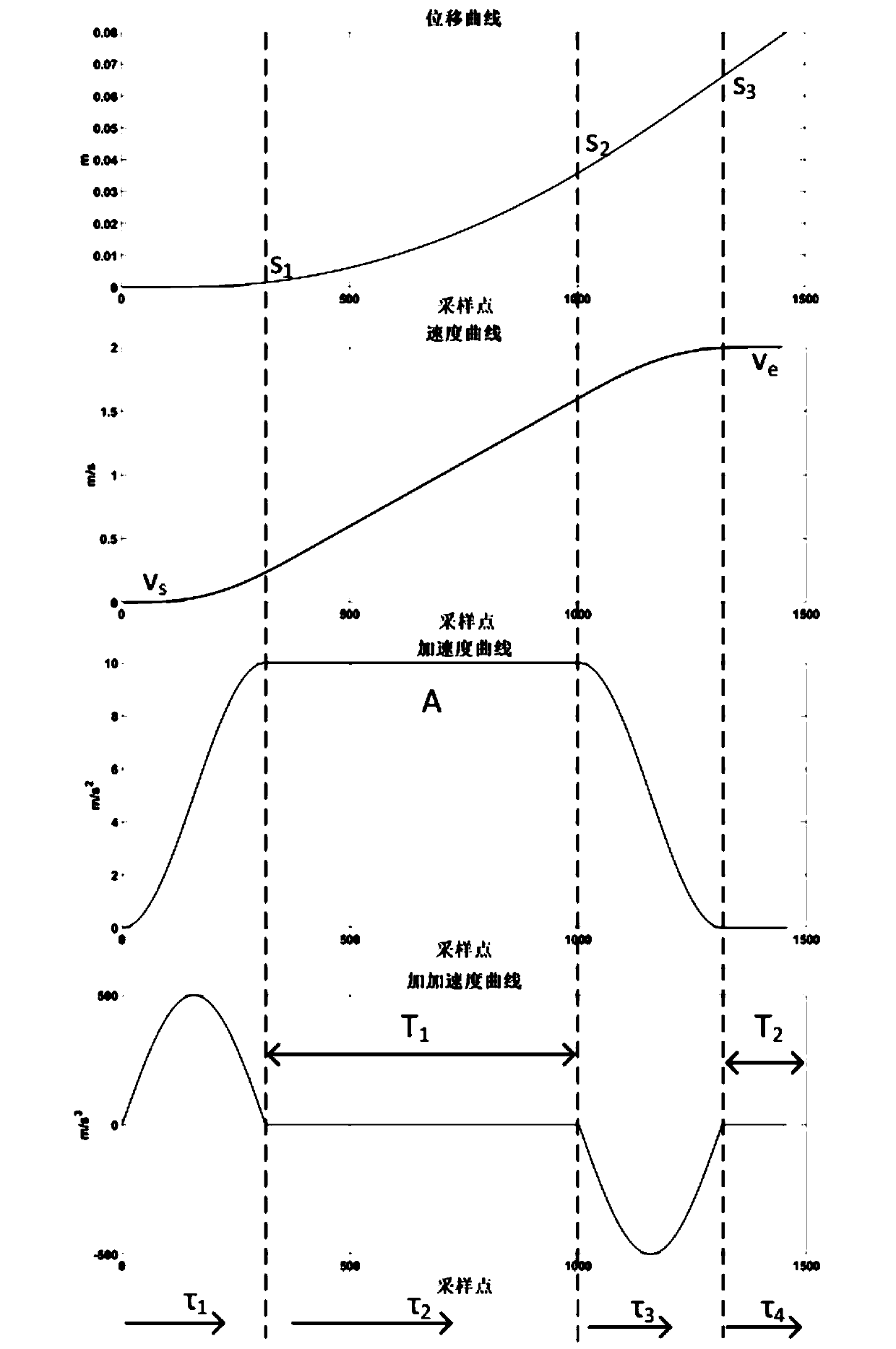

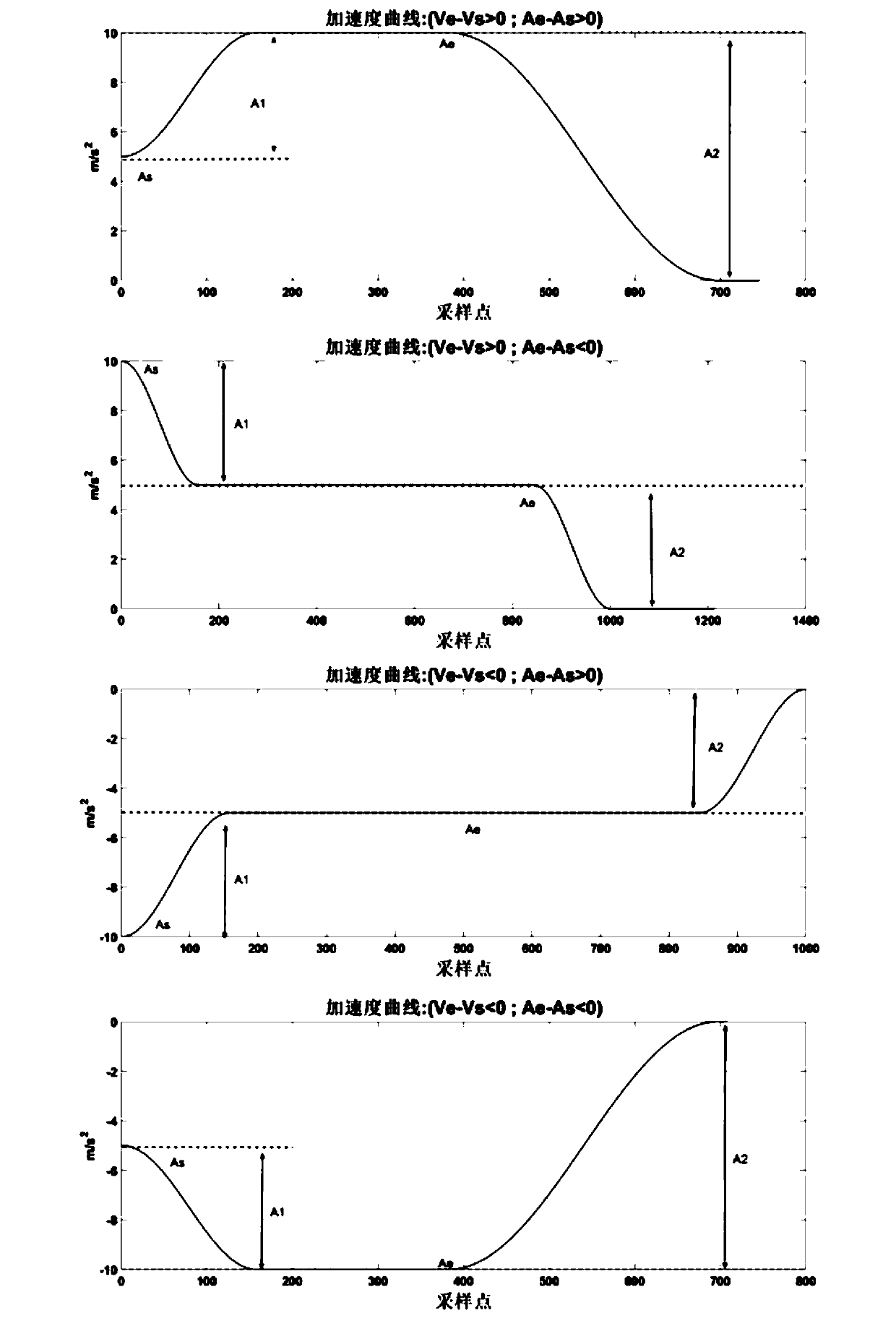

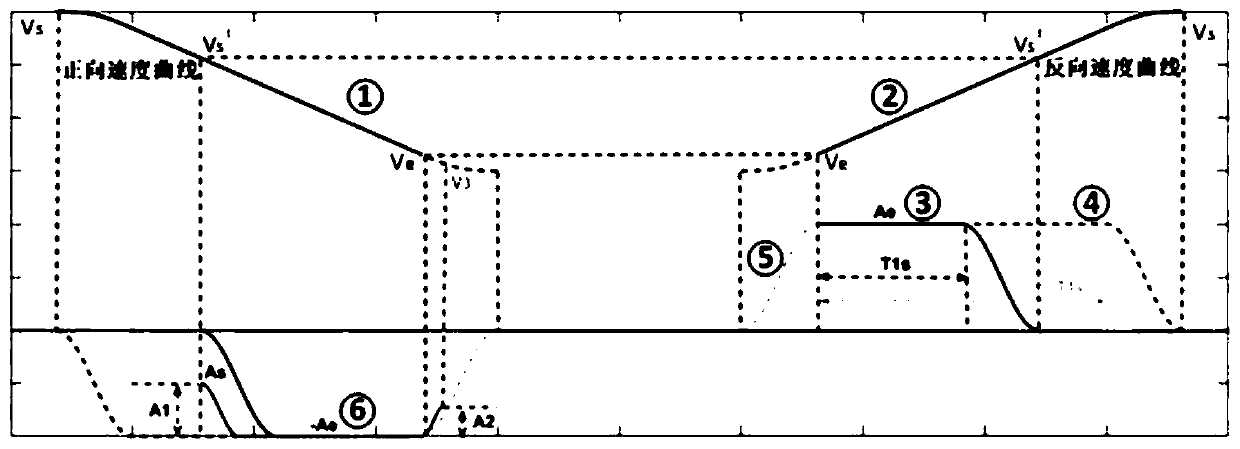

Machining track movement planning method based on sine square acceleration prospect

ActiveCN110134065AAcceleration continuousReduce vibration excitationNumerical controlMachine toolMovement planning

The invention discloses a machining track movement planning method based on sine square acceleration prospect. The method comprises the following steps: firstly realizing accelerated acceleration continuing by adopting a way that the acceleration is sine2, and reducing system excitation; secondly, judging rationality of a set parameter, analyzing shorter path and like special conditions, thereby realizing the automatic correction of the parameter when the path and speed limitation is satisfied, wherein the movement planning of the path in any length can be accomplished under a limitation condition; splitting acceleration and deceleration processes, and allowing the acceleration at each of two ends of a planning section to be non-zero, thereby avoiding the frequent acceleration and deceleration of the motor, and reducing the vibration excitation on a mechanical system; and finally designing a reverse planning algorithm, performing prospecting on the speed at the deceleration section andthe acceleration, thereby realizing any acceleration and deceleration planning demands on a specified path, wherein the speed acceleration change is stable and smooth, and the machining quality and machining efficiency of the mechanical equipment are improved.

Owner:XI AN JIAOTONG UNIV

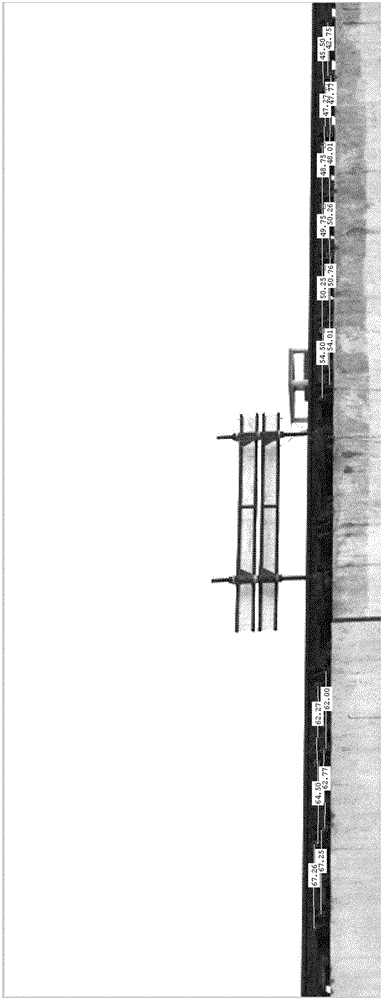

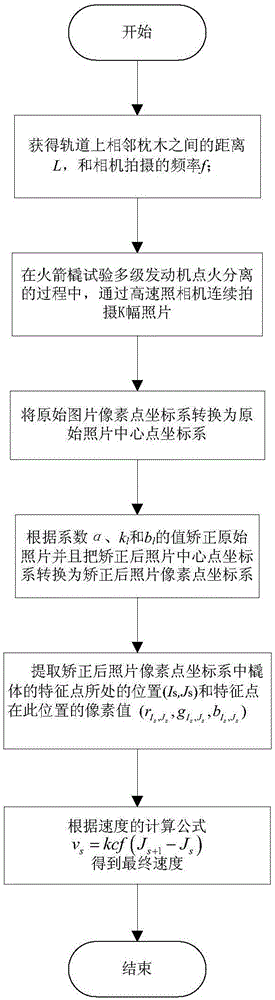

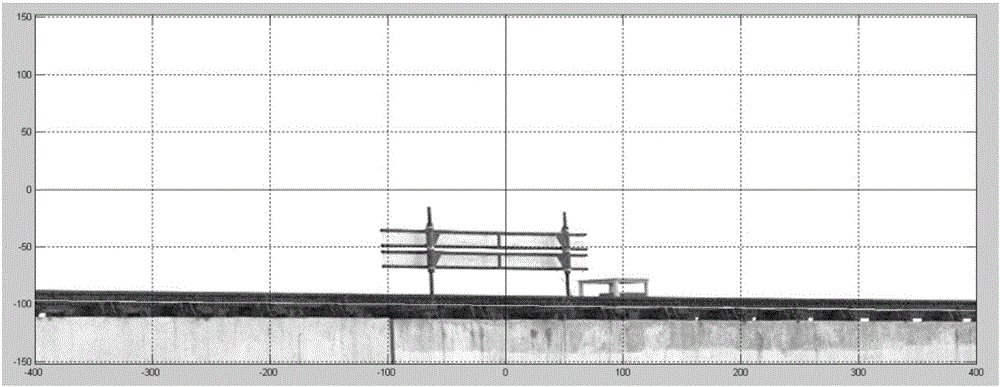

Image-based speed measurement method for rocket sled

ActiveCN106771320AOvercoming measurement inaccuraciesHigh measurement accuracyDevices using optical meansCritical positionRocket

The invention provides an image-based speed measurement method for a rocket sled. A high-speed camera is used for shooting an operation process of a sled body continuously; and after completion of a test, pitching and orientation information correction of the high-speed camera relative to a track, sled body feature point extraction, and operation speed calculation are carried out, thereby completing measurement of the operation speed of the sled body. The method has advantages of high speed measurement precision, simple and clear idea, and easy programming implementation. With the method, the speed measurement precision of the key position in the rocket sled test can be improved.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

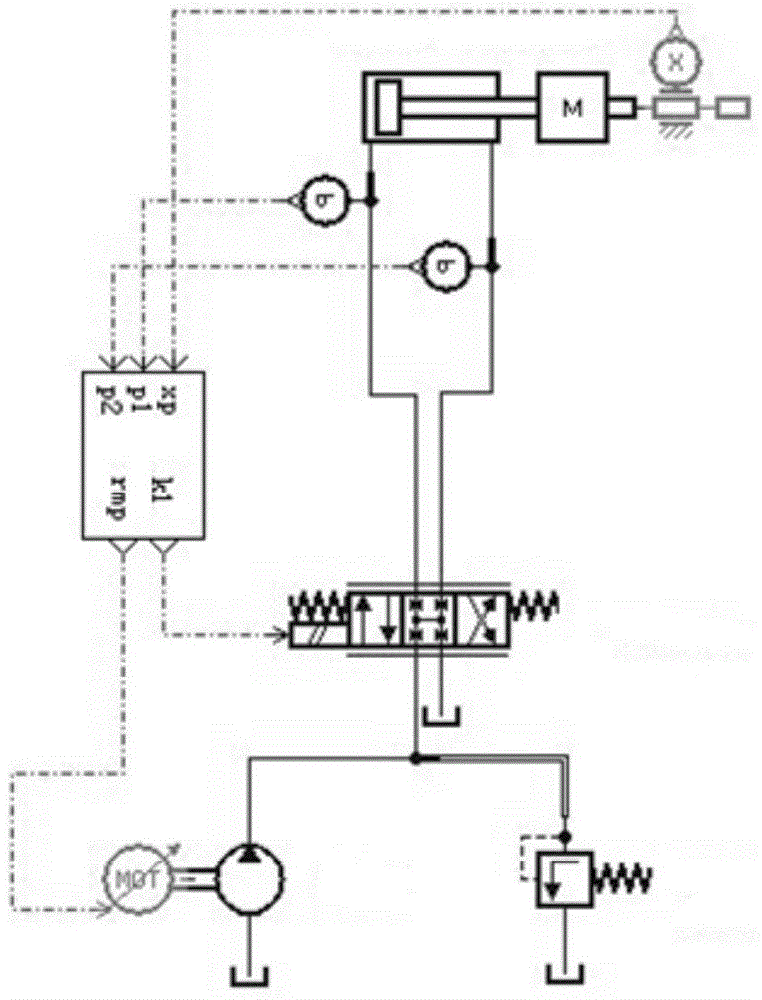

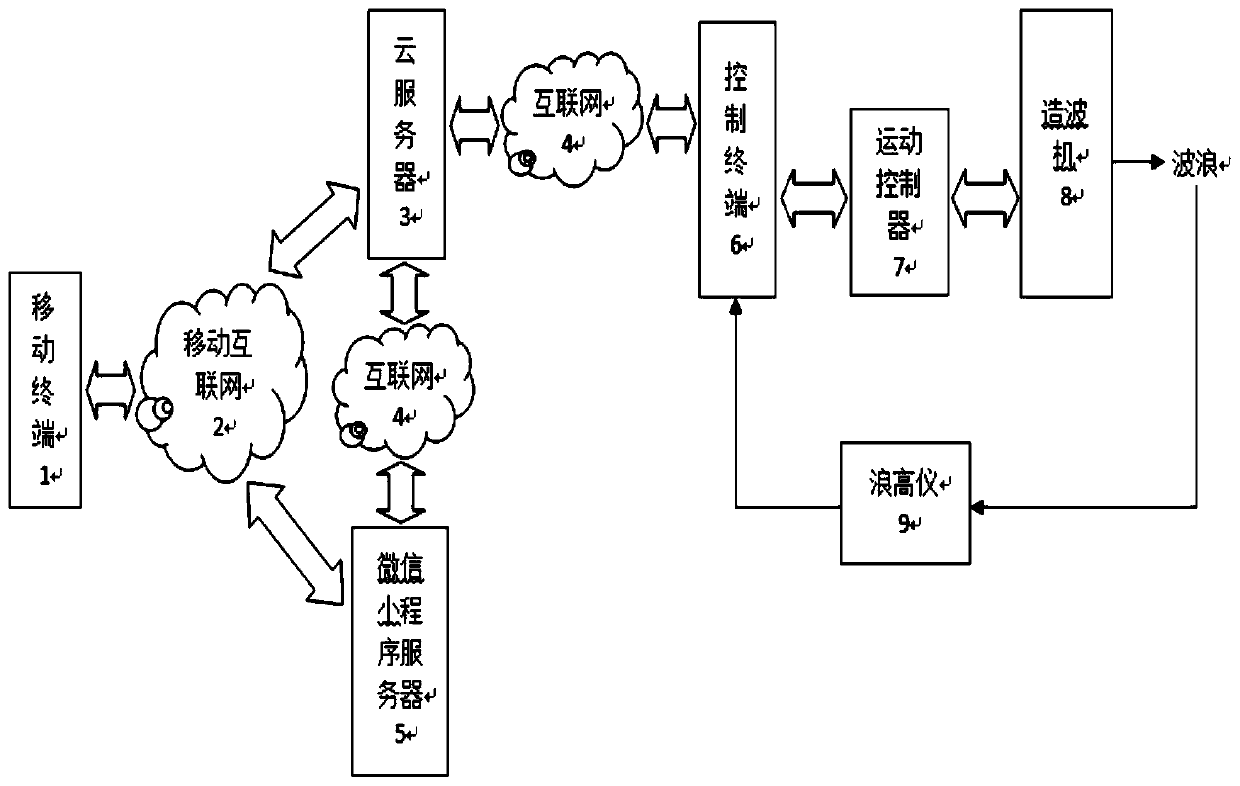

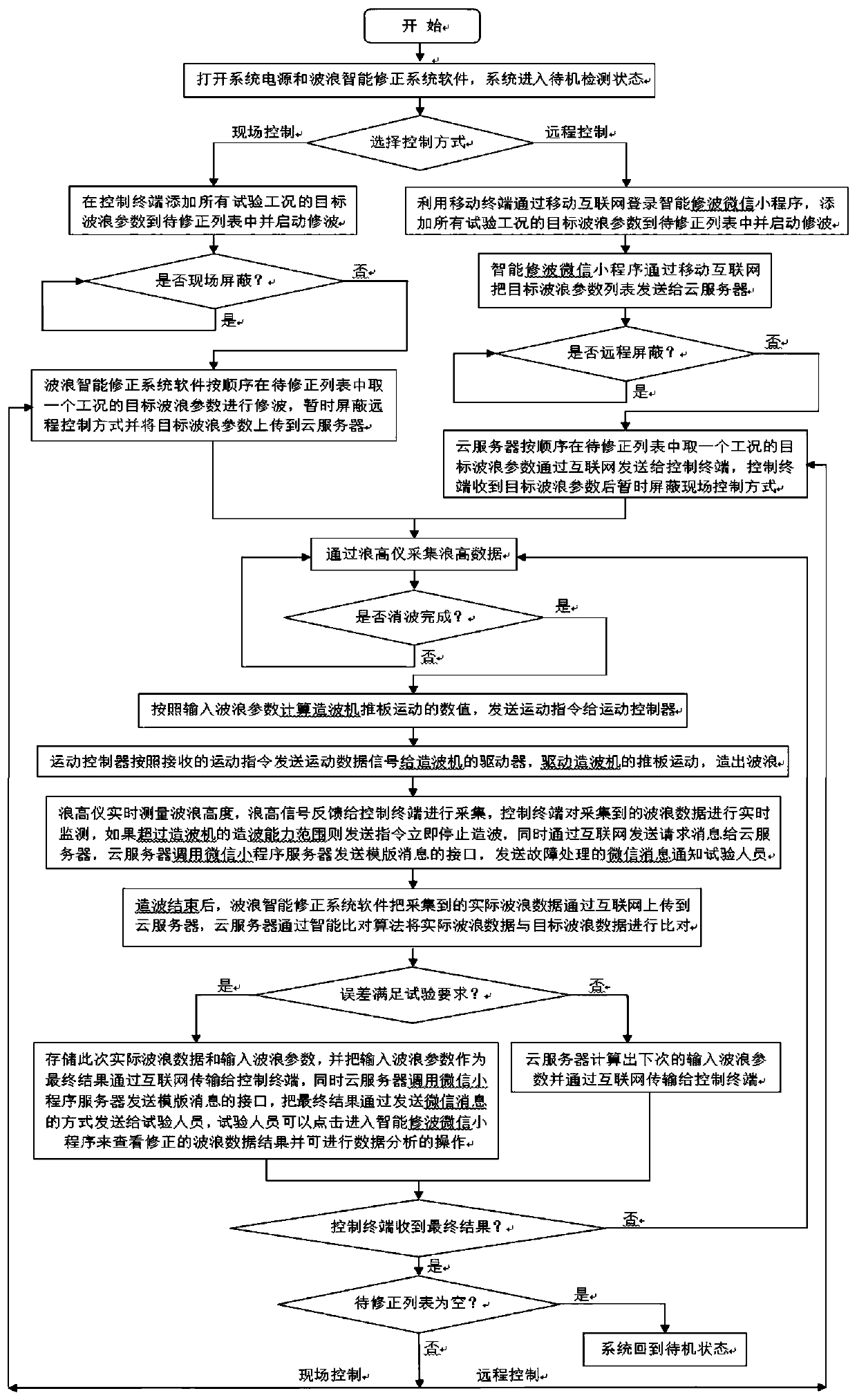

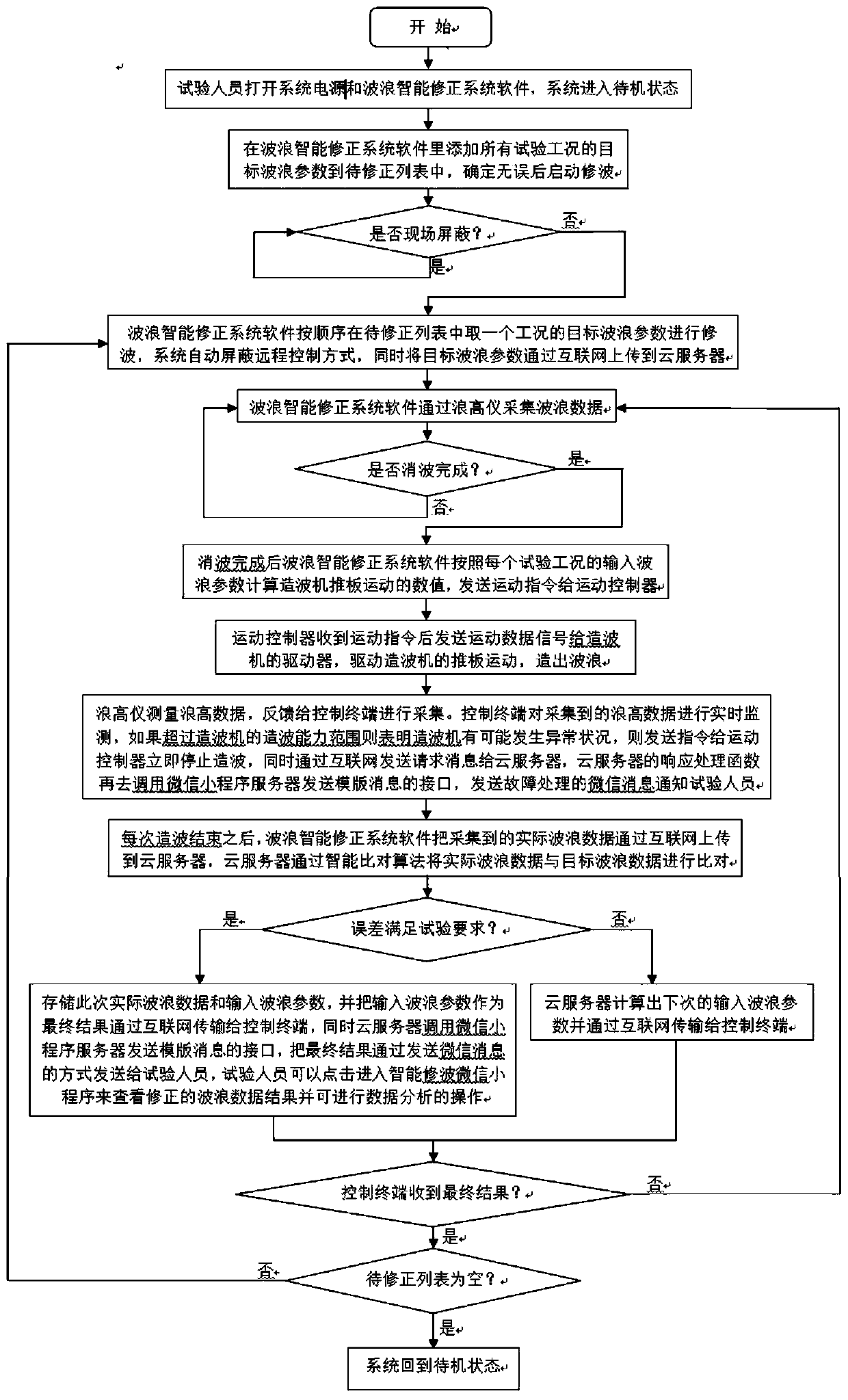

Ship model test pool wave intelligent correction system and correction method based on cloud service

ActiveCN111307413AImplement automatic correctionLive viewHydrodynamic testingMarine engineeringMotion controller

The invention discloses a ship model test pool wave intelligent correction system based on cloud service. The ship model test pool wave intelligent correction system comprises a control terminal, a motion controller, a wave maker, a wave height meter, a cloud server, a WeChat applet server and a mobile terminal. The control terminal is connected with the motion controller through an RJ-45 interface. The motion controller is connected with the wave maker through a CAN bus, the wave height meter is arranged in a ship model test pool and connected with the control terminal through a USB interface, the cloud server is connected with the control terminal through the Internet, and the mobile terminal is connected with the cloud server through the mobile Internet. Intelligent remote wave modulation is achieved, collected actual wave parameters are automatically corrected, wave data can be checked in real time, the unattended wave modulation process is achieved, corresponding fault-tolerant protection measures are taken, and the requirement for wave modulation before a ship model test pool test is met. The invention further discloses a correction method of the ship model test pool wave intelligent correction system based on the cloud service.

Owner:JIANGSU UNIV OF SCI & TECH

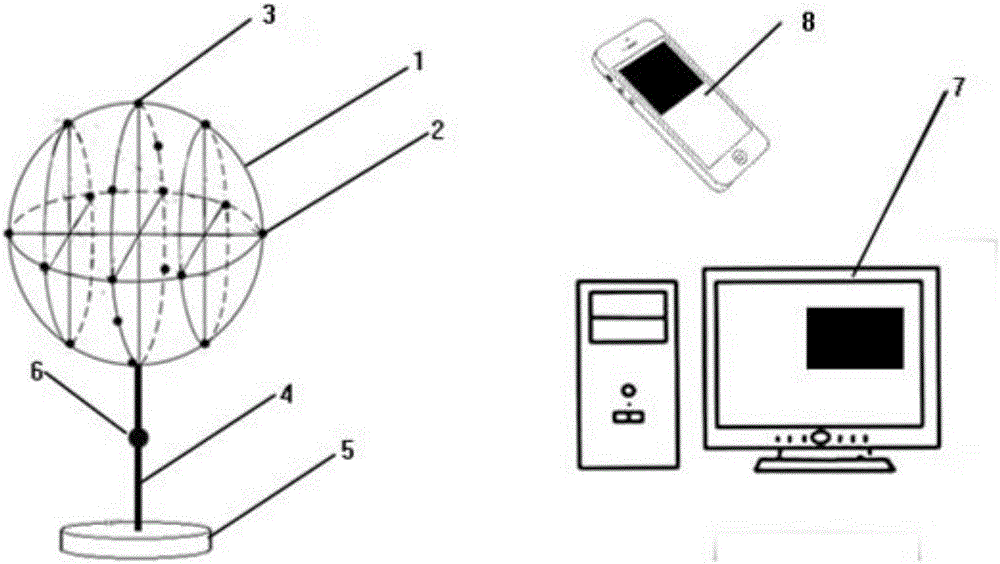

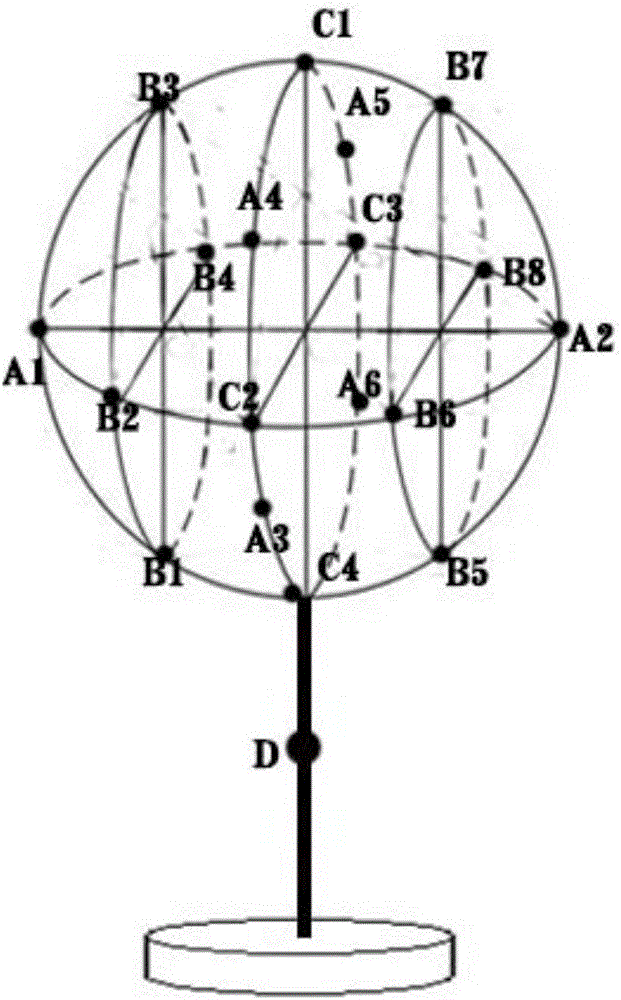

Air speed ball integration system

ActiveCN105974152AIncrease flexibilityReduce mistakesFluid speed measurementIntegrated systemsEngineering

The invention relates to an air speed ball integration system. The system includes an air speed detection ball and a client terminal. The air speed detection ball is a double layer plastic ball. Pressure sensors and temperature sensors are distributed on the outer ball housing. A thin rod with a pedestal is connected with the ball body. A humidity sensor is mounted on the thin rod. The inner ball housing is therein provided with a power supply module, a signal amplifying module, a filtering module, a data selection module, a control module, a data transceiving module and the like. A client terminal is provided with a data receiving module, a data cache module, a data storage module, a data correcting module, a data analyzing module, a display module and a control module. The system provided by the invention directly and conveniently displays the acting force of fluid on the surface of an object and the distribution and change of fluid flow speed and provides a set of effective tool for measuring air speed and air direction. The system provided by the invention can display the rule of mutual action of fluid and object when being applied to teaching and experiments and can realize accurate measurement of air speed and air direction when being applied to practical engineering measurement.

Owner:SOUTHEAST UNIV

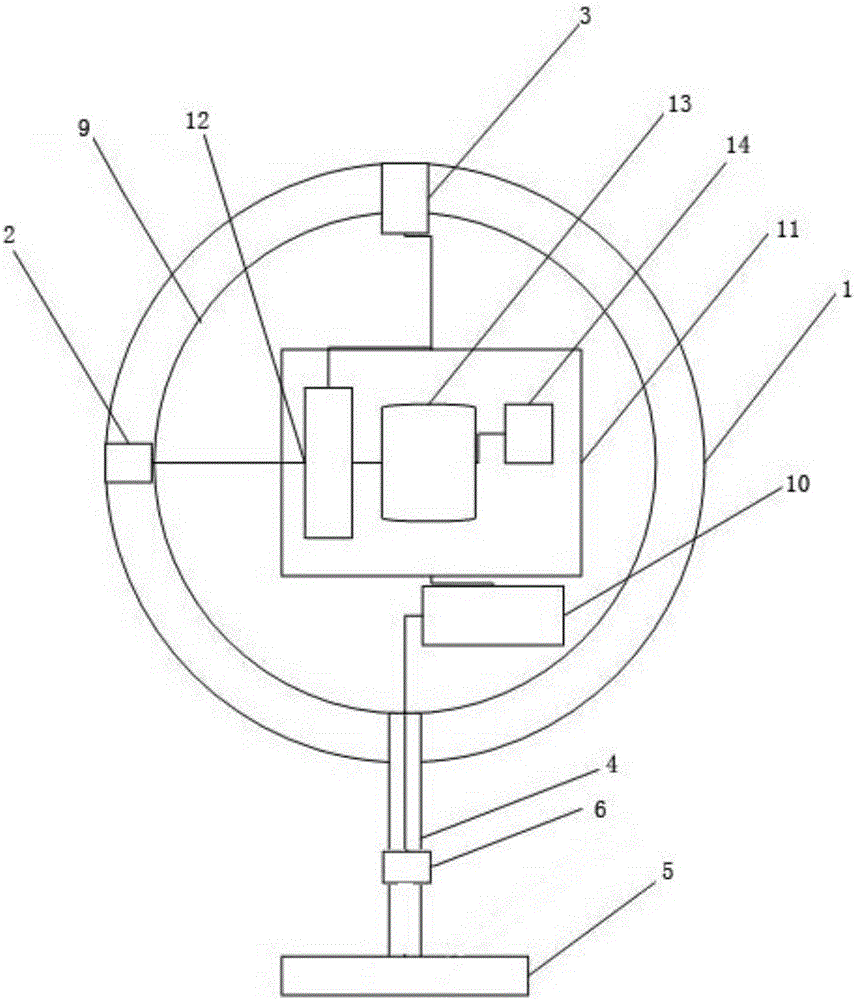

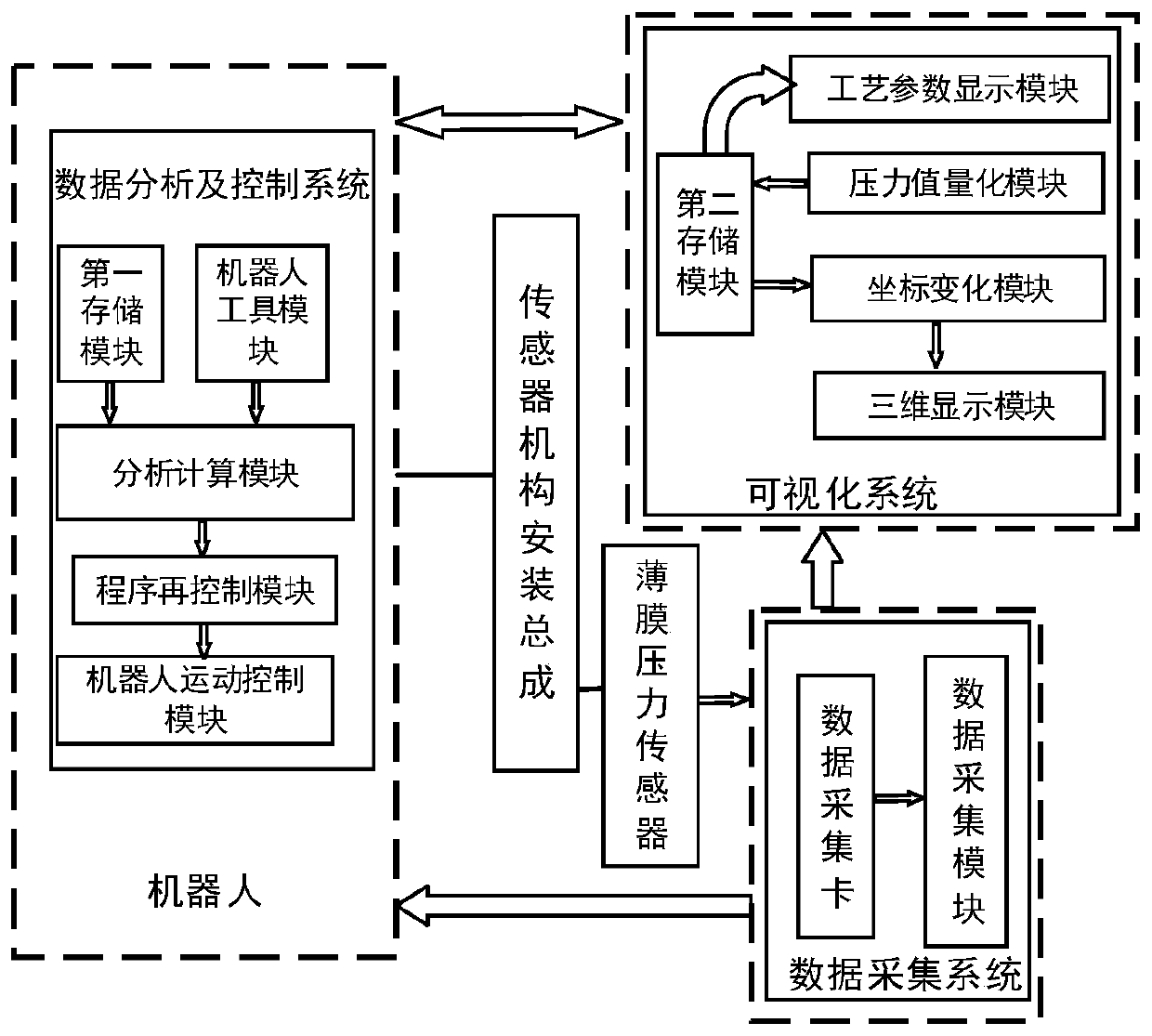

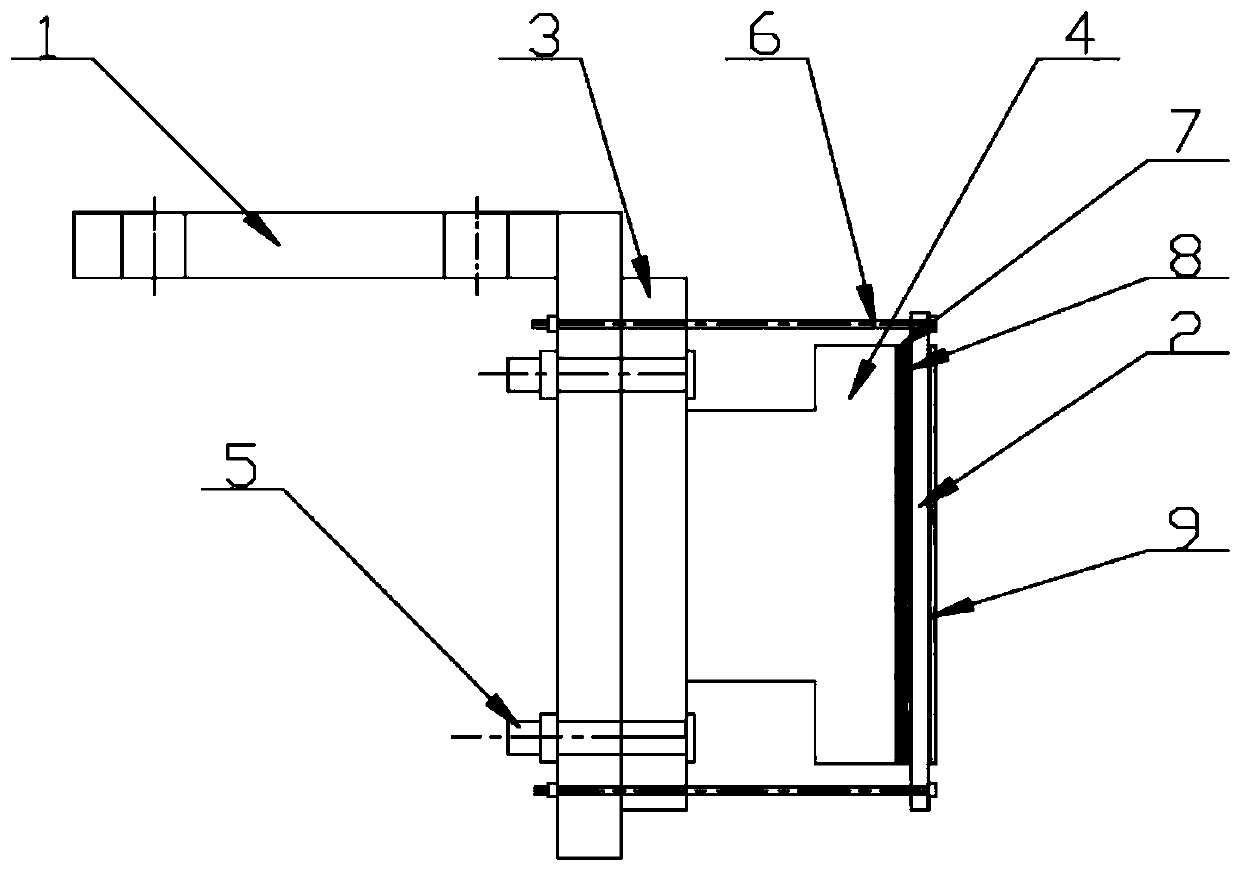

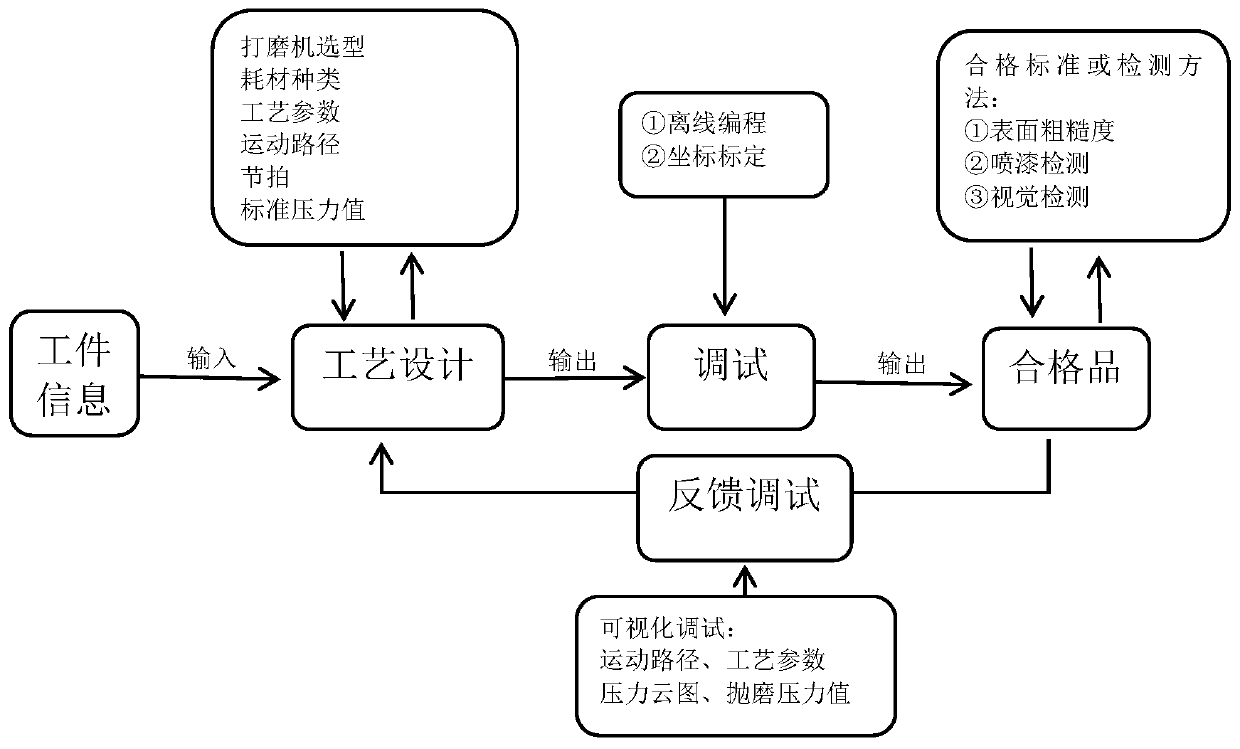

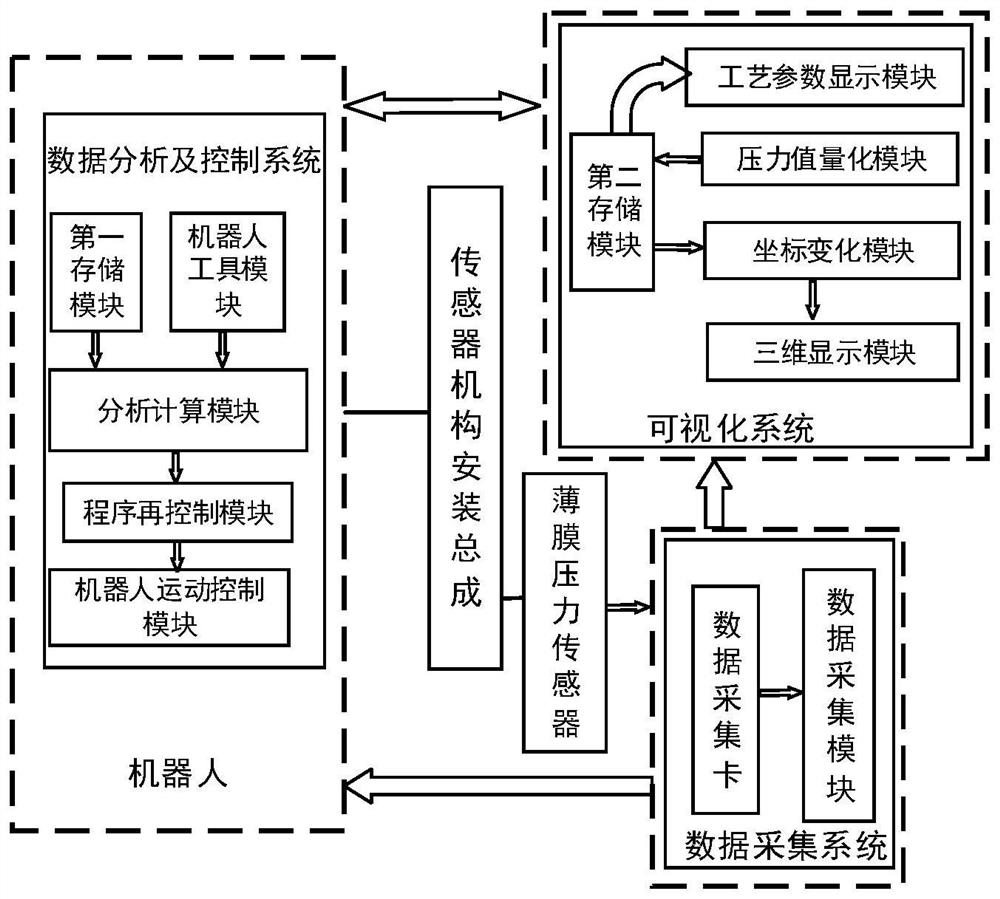

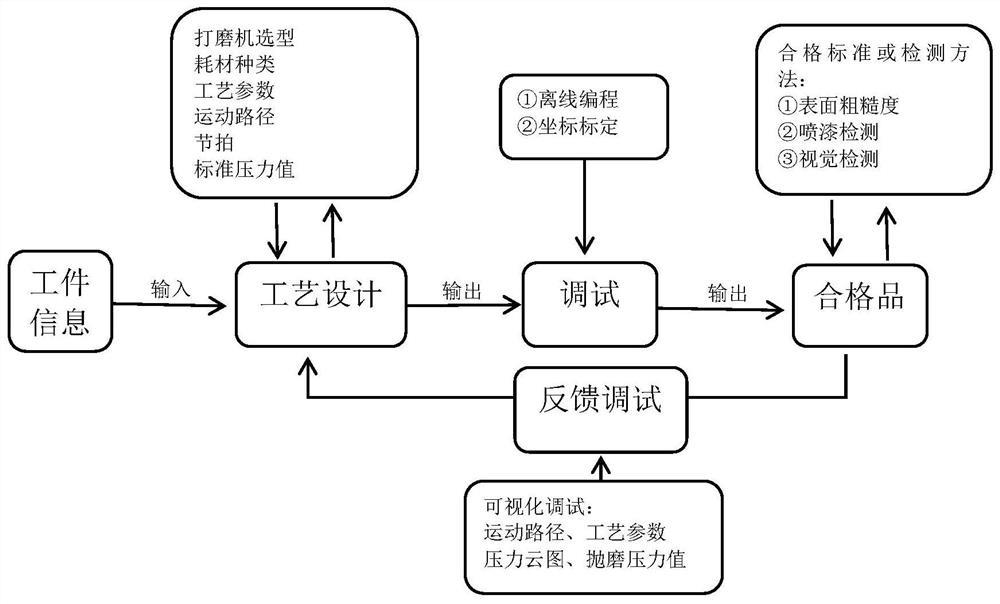

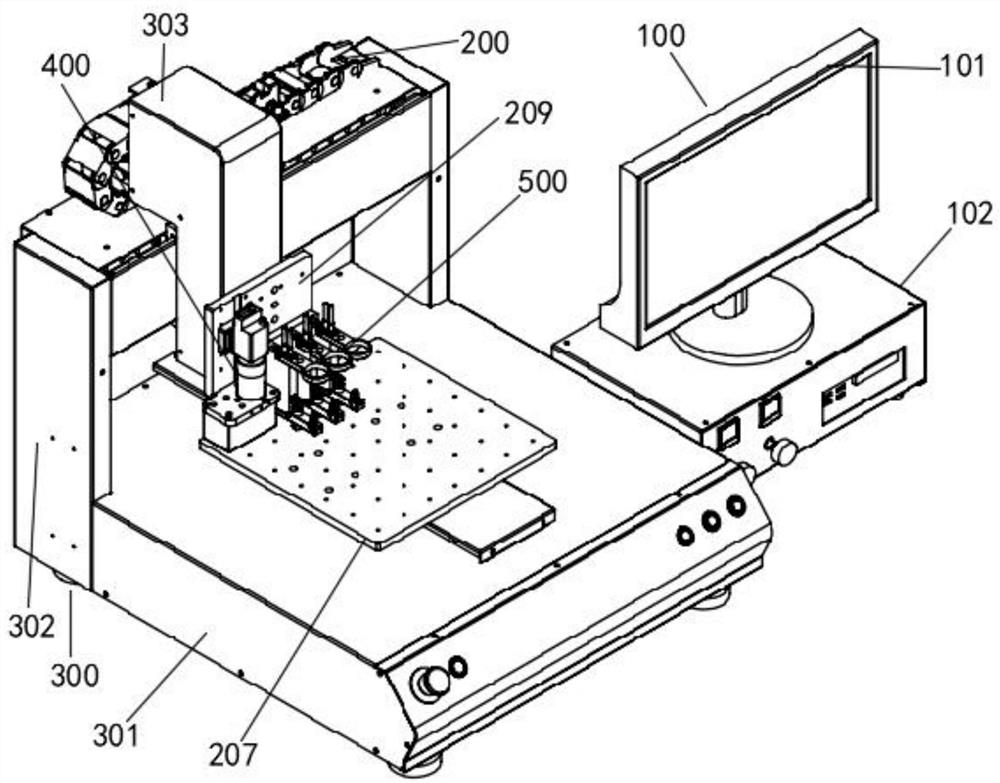

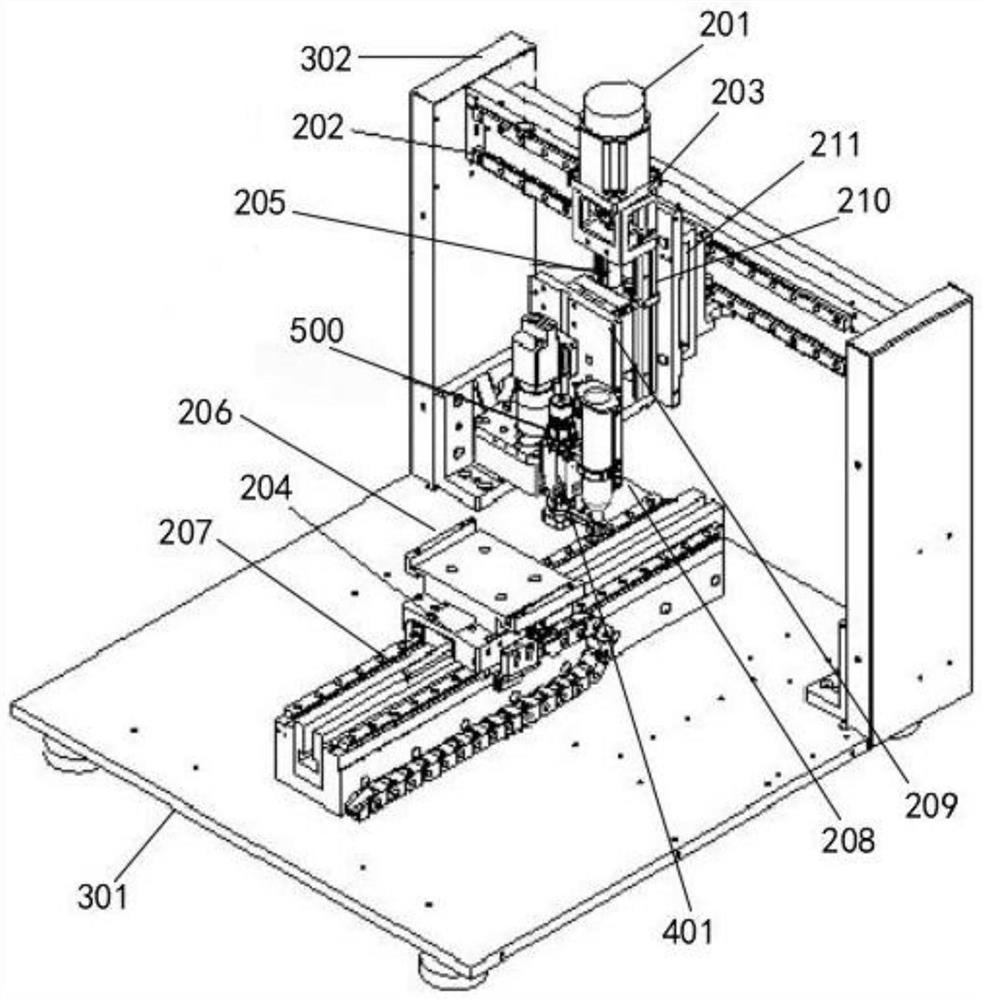

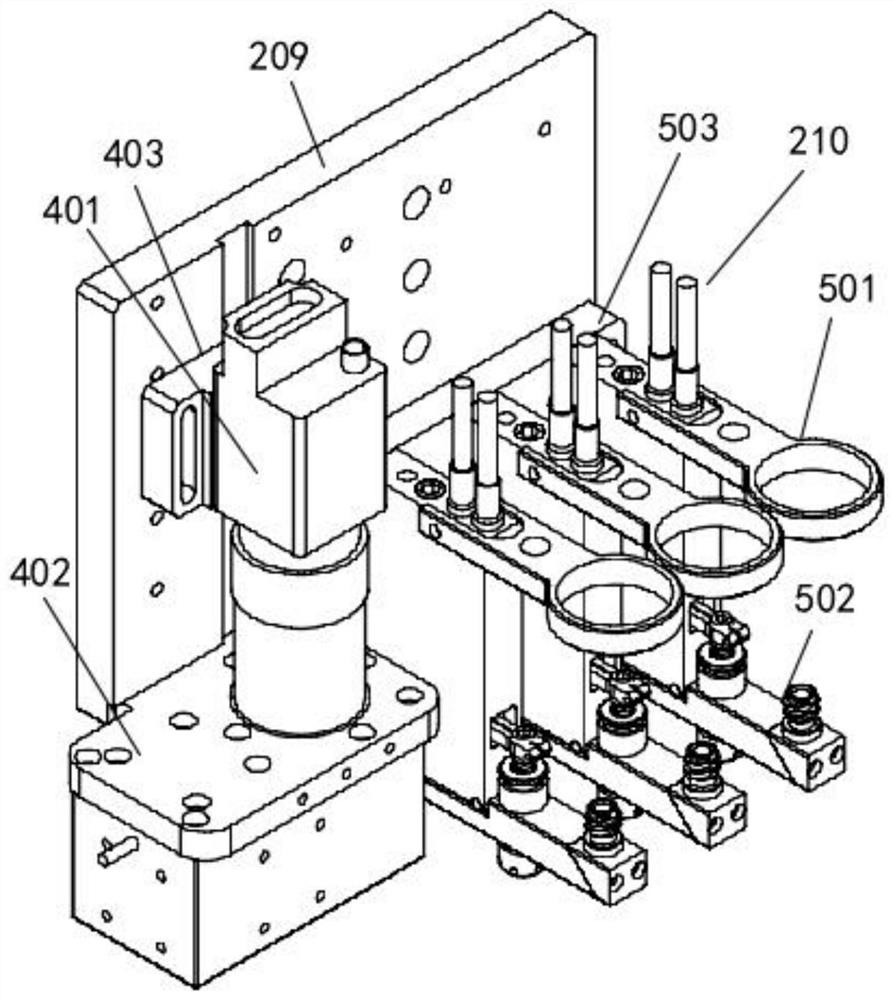

Grinding debugging system

ActiveCN110587472AAchieve installationAchieve drawingGrinding feed controlAutomatic grinding controlControl systemCurrent point

The invention relates to a grinding debugging system. The grinding debugging system comprises a robot, a film pressure sensor, a sensor mounting mechanism assembly, a data acquisition system, a data analysis and control system and a visualization system. The sensor mounting mechanism assembly is used for fixing a grinding head and the sensor to the tail end of the robot and the tail end of a grinding head correspondingly. The data acquisition system is used for collecting multiple actual pressure values, obtained by the sensor, of a current point location and obtaining a pressure nephogram. The data analysis and control system is used for conducting analysis on the pressure nephogram, the quantified actual pressure values and the prestored standard pressure value and conducting real-time correction on a motion control program in the robot. The visualization system is used for quantifying the multiple pressure values and conducting visual display according to the analysis result. The grinding debugging system can automatically modify the motion control program according to the analysis result and obtain the corrected technological parameters of the grinding head. The motion controlprogram can be migrated into multiple similar grinding robots, and the grinding debugging cost and time are remarkably reduced.

Owner:重庆智能机器人研究院 +1

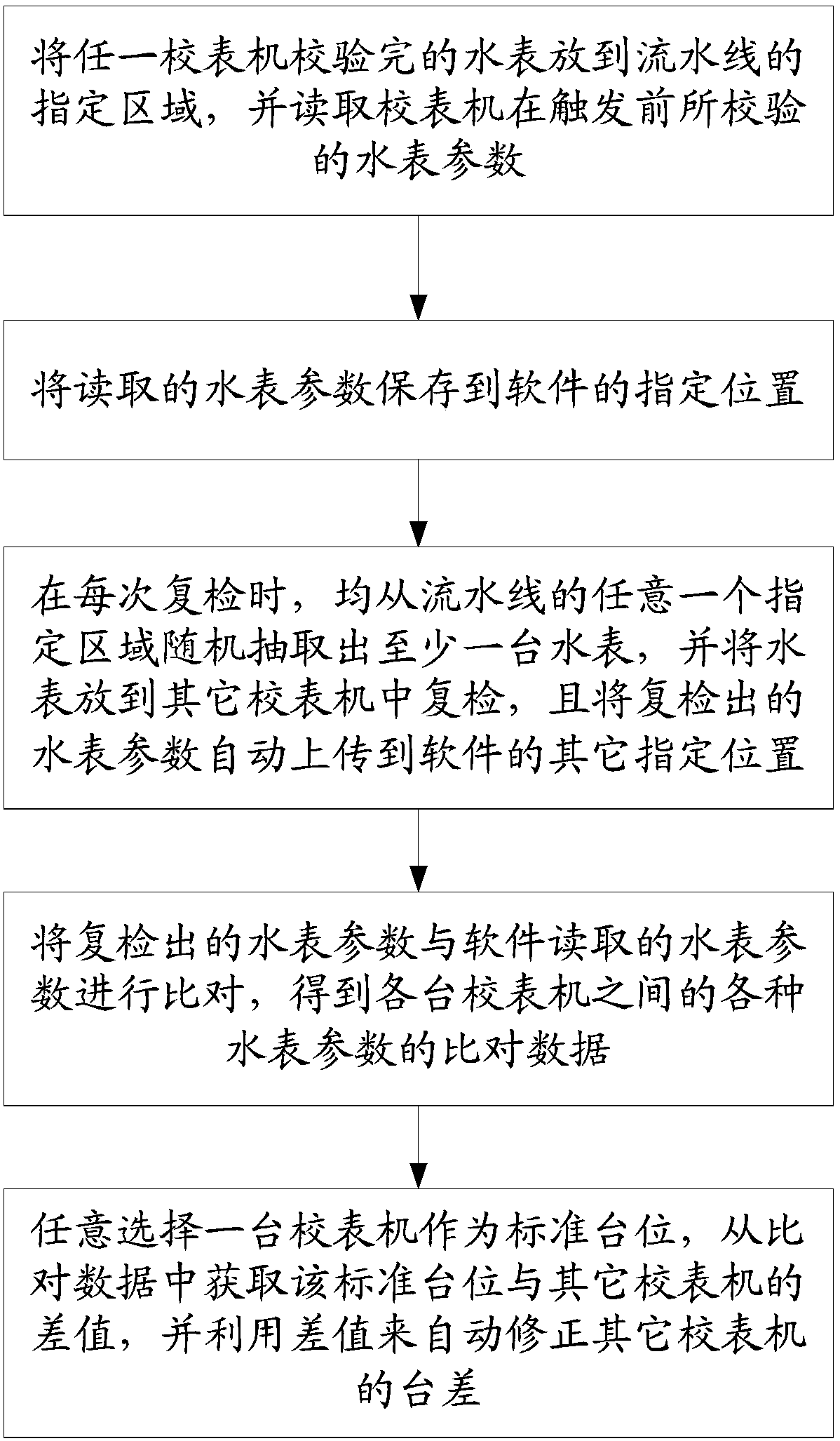

Method for automatically correcting difference of meter calibration machines by means of comparison

ActiveCN108534869AImplement automatic correctionThe verification result is accurateTesting/calibration for volume flowAssembly lineComputer science

The invention provides a method for automatically correcting difference of meter calibration machines by means of comparison. The method includes placing water meters calibrated by an optional meter calibration machine in specified regions of assembly lines and reading water meter parameters calibrated by the meter calibration machine before the meter calibration machine is triggered; storing theread water meter parameters at specified locations of software; randomly extracting at least one water meter from an optional specified region of the assembly lines during each re-inspection, re-inspecting the water meters in the other meter calibration machines, and automatically uploading re-inspected water meter parameters to other specified locations of the software; comparing the re-inspectedwater meter parameters to the water meter parameters read by the software to obtain comparison data of the diversified water meter parameters between the various meter calibration machines; arbitrarily selecting a meter calibration machine to be used as a standard station, acquiring difference values of the standard station and the other meter calibration machines from the comparison data and automatically correcting the difference of the other meter calibration machines by the aid of the difference values. The method has the advantages that the difference can be automatically timely corrected by the aid of the method, and accordingly the efficiency can be greatly improved.

Owner:SANCHUAN WISDOM TECH CO LTD

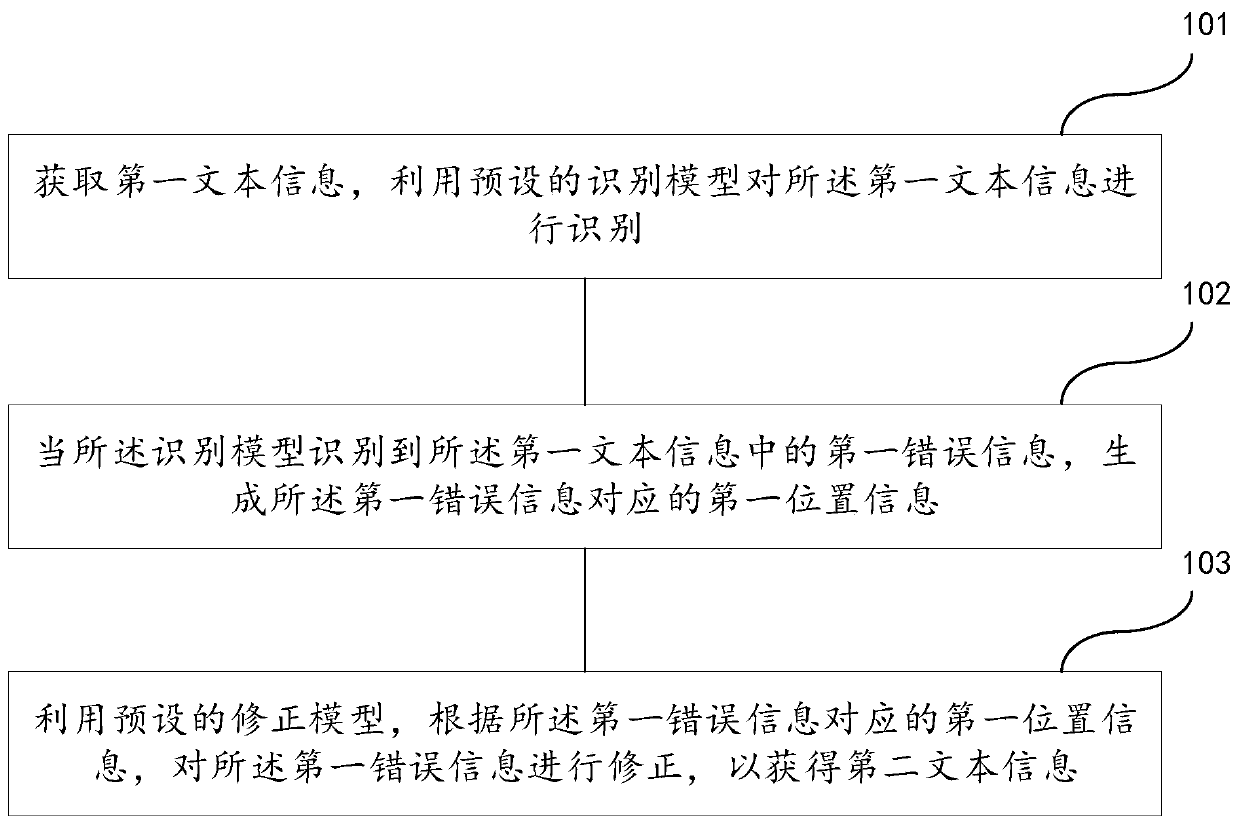

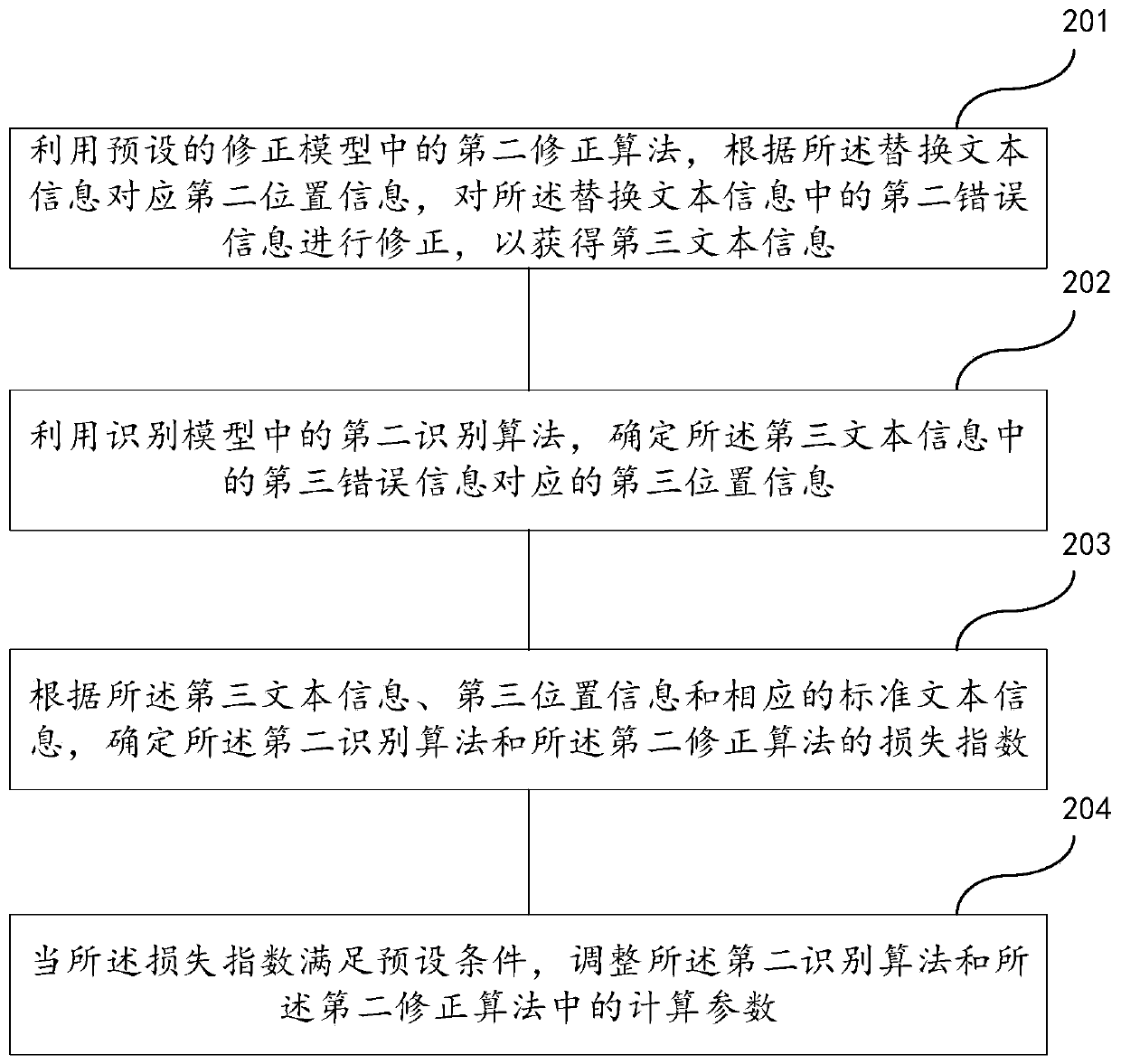

Text correction method and device, readable medium and electronic equipment

PendingCN111178049AImplement automatic correctionQuality improvementNatural language data processingMedical reportsAlgorithmError location

The invention discloses a text correction method and device, a readable medium and electronic equipment, and the method comprises the steps: obtaining first text information, and recognizing the firsttext information through a preset recognition model; when the recognition model recognizes first error information in the first text information, generating first position information corresponding to the first error information; correcting the first error information by using a preset correction model according to first position information corresponding to the first error information to obtainsecond text information. According to the method, the error position of the first text information is determined through the recognition model, and the error in the first text information is correctedthrough the correction model, so that the first error information possibly occurring in the medical text is automatically corrected, the quality of the digitized medical text is improved, and the accuracy of subsequent data analysis is ensured.

Owner:BEIJING MEDICAL CROSS THE CLOUD TECH CO LTD

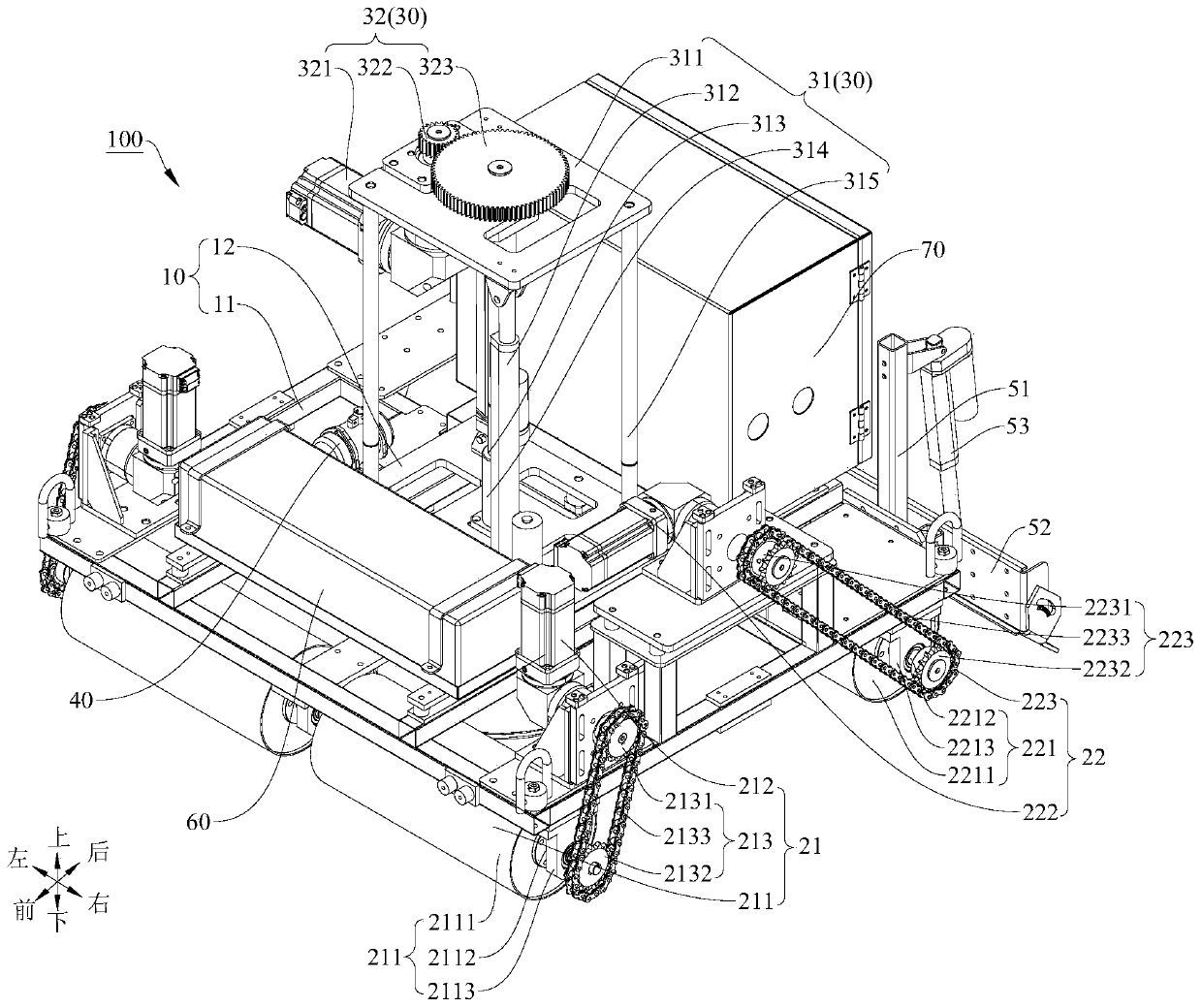

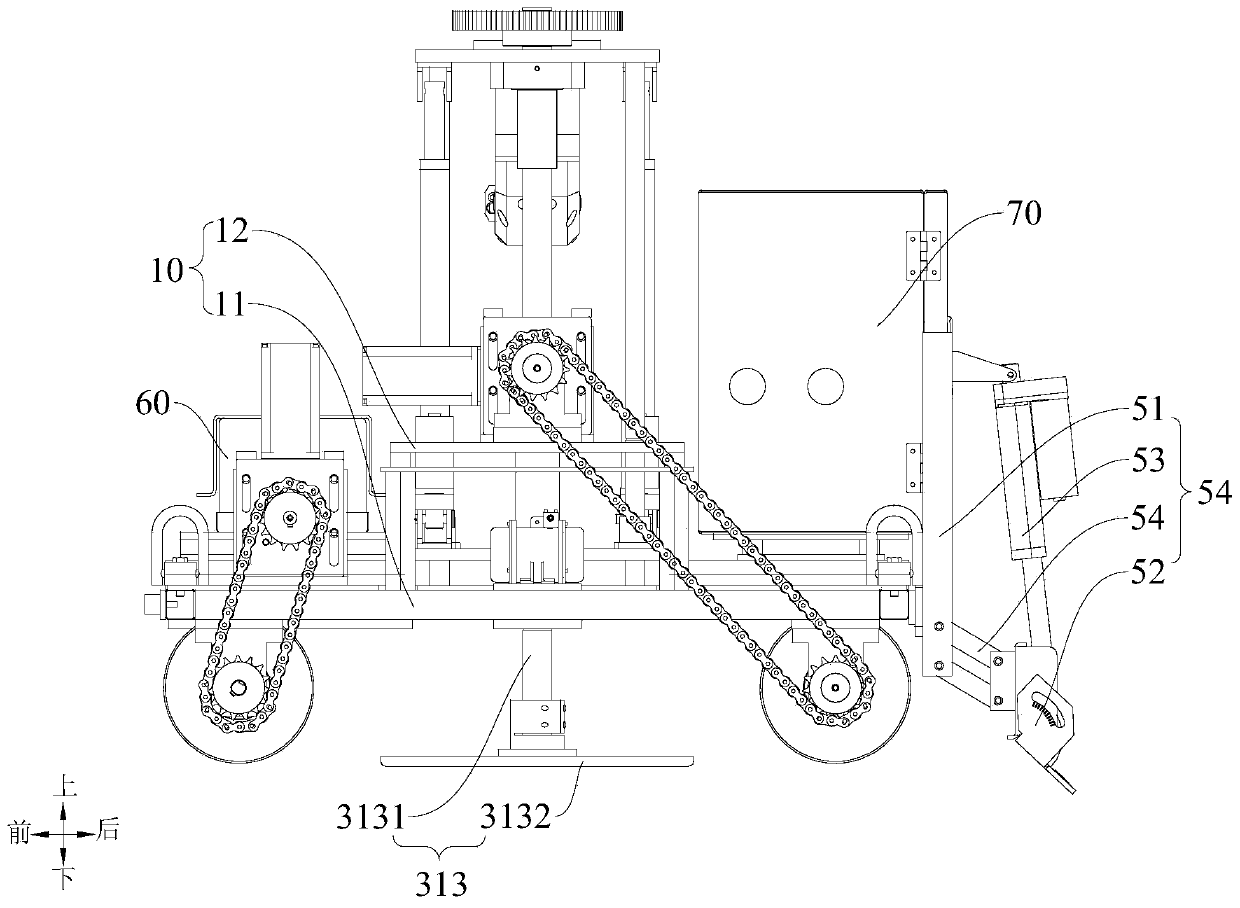

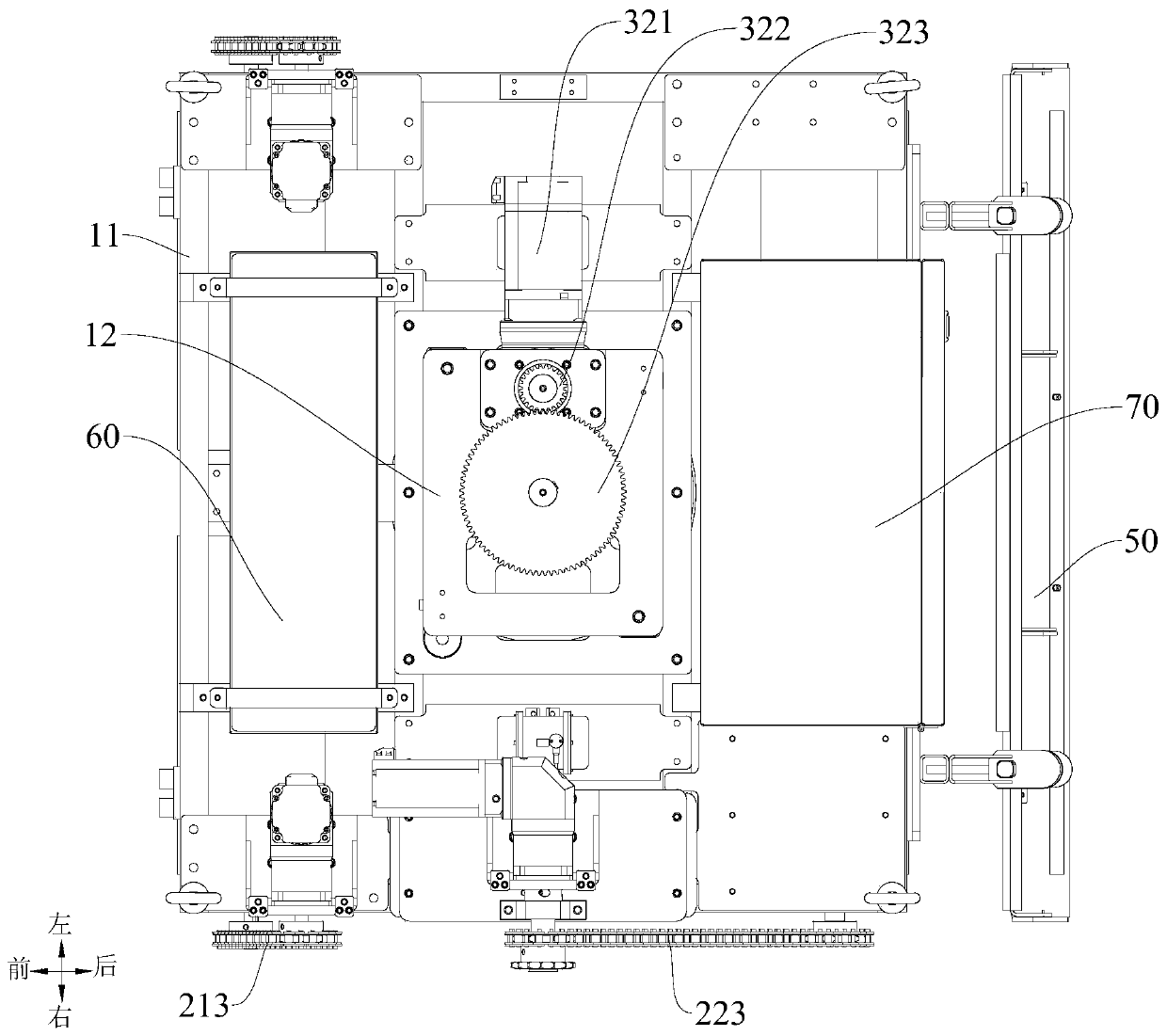

Trowelling robot

InactiveCN110541550AEasy trowelingImplement automatic correctionBuilding constructionsControl systemChassis

The invention discloses a trowelling robot. A rack, a travelling device and a lifting steering device are included; the rack comprises a bottom frame and an installing plate, and the installing plateis arranged on the bottom frame; the travelling device comprises first rolling wheel mechanisms and a second rolling wheel mechanism which are both arranged on the bottom frame; the first rolling wheel mechanisms are in two sets, and the two first rolling wheel mechanisms are arranged on the two sides in the travelling direction of the bottom frame, and each comprise a first roller and a first driving piece; each first driving piece is connected with the corresponding first roller so that the first roller can be driven to rotate; and the lifting steering device is arranged on the installing plate, and aims to make the rack and the traveling device rotate after the rack and the travelling device are lifted up, and therefore the travelling direction of the robot is adjusted. According to thetrowelling robot, the first rolling wheel mechanisms of the travelling device are arranged into two sets in a spaced manner in the travelling direction, and a movement trajectory can be automaticallycorrected in cooperation with a control system of the robot, so that an actual travelling trajectory is consistent with an expected trajectory.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

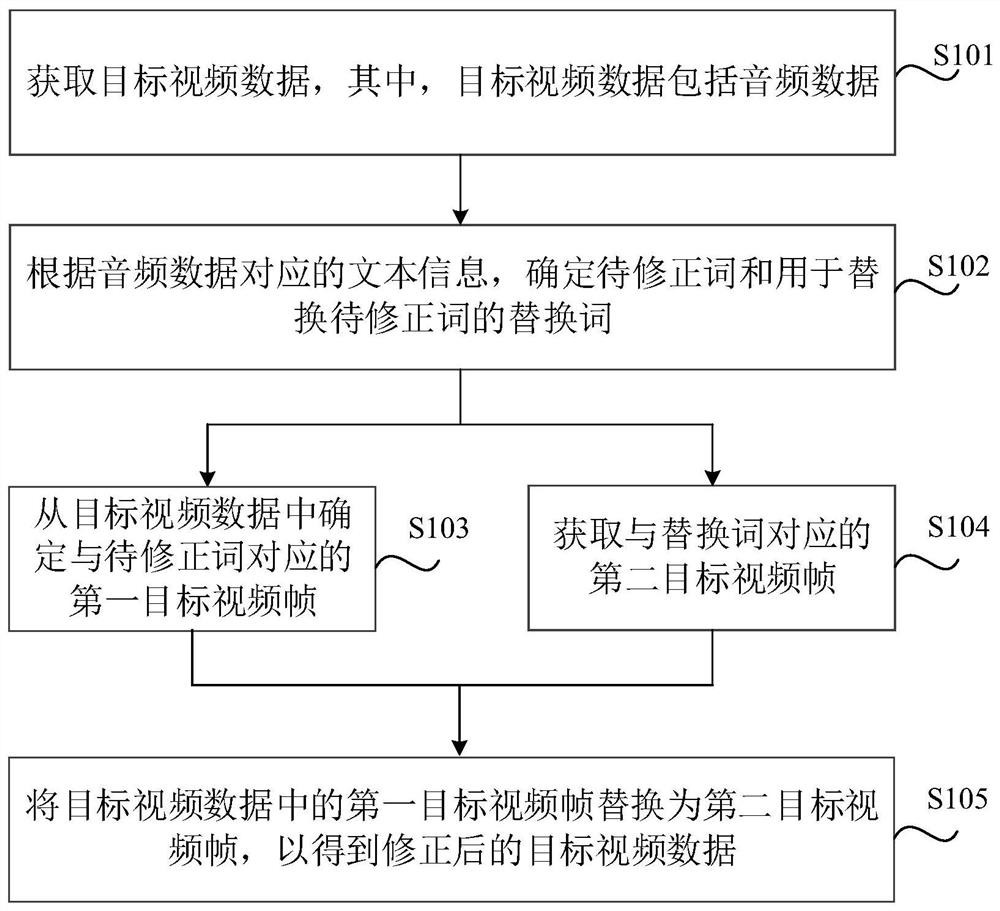

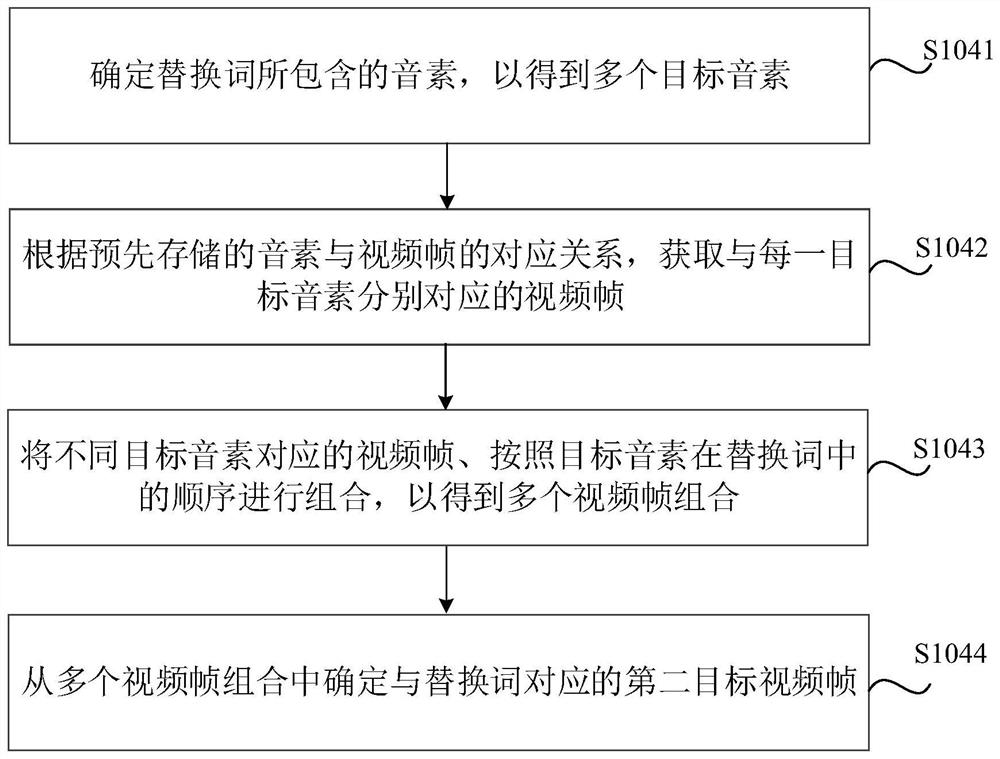

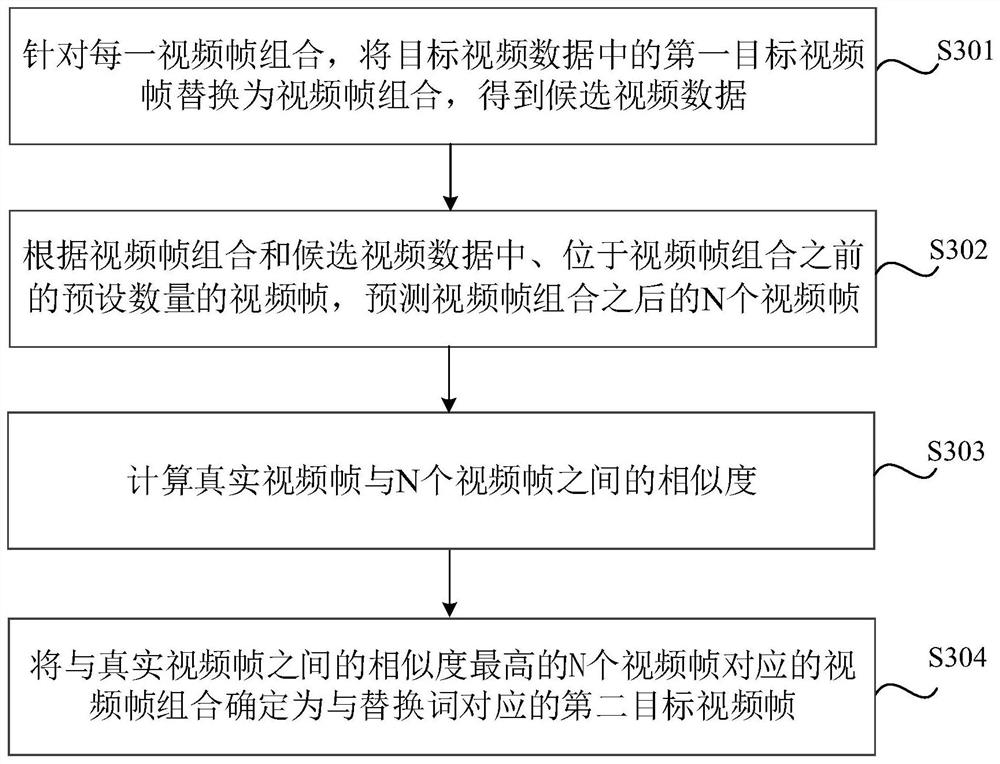

Video correction method and device, readable medium and electronic equipment

ActiveCN111935541AImplement automatic correctionApply bulk fixesImage enhancementImage analysisData packComputer graphics (images)

The invention relates to a video correction method and device, a readable medium and electronic equipment. The method comprises the following steps: acquiring target video data, wherein the target video data comprises audio data; determining a to-be-corrected word and a replacement word for replacing the to-be-corrected word according to text information corresponding to the audio data; determining a first target video frame corresponding to the to-be-corrected word from the target video data; obtaining a second target video frame corresponding to the replacement word; and replacing the firsttarget video frame in the target video data with the second target video frame to obtain corrected target video data. Therefore, automatic video correction can be realized, time and labor are saved, convenience and quickness are realized, and the method is suitable for batch correction of videos.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

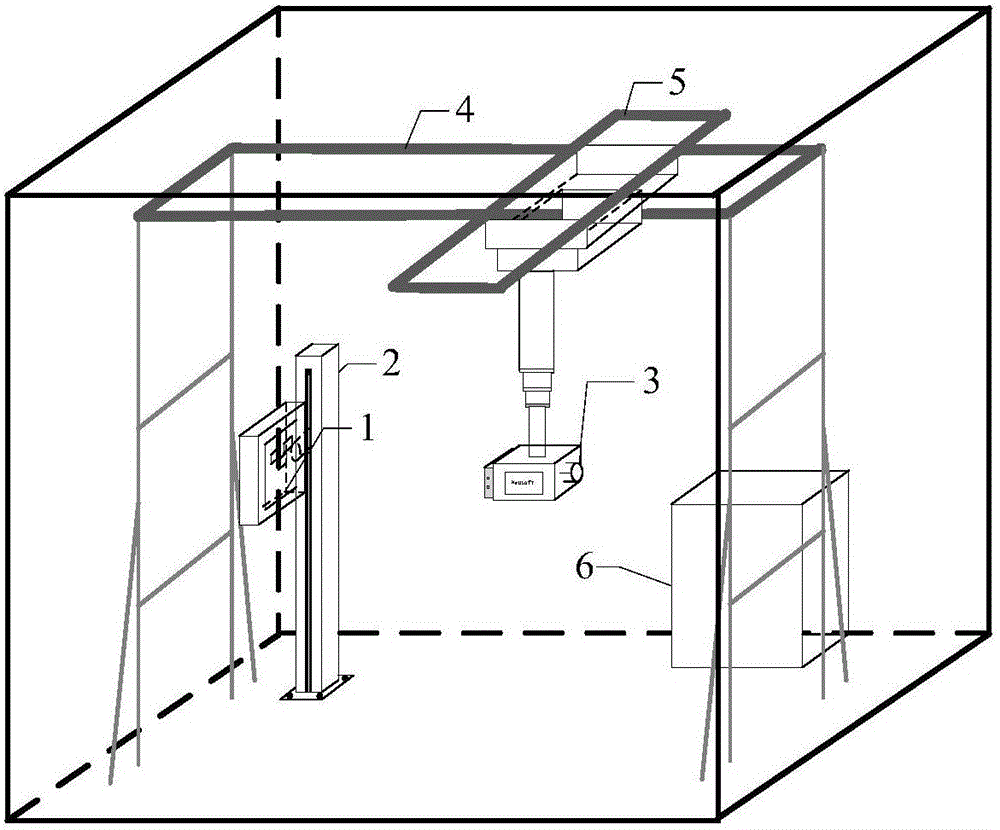

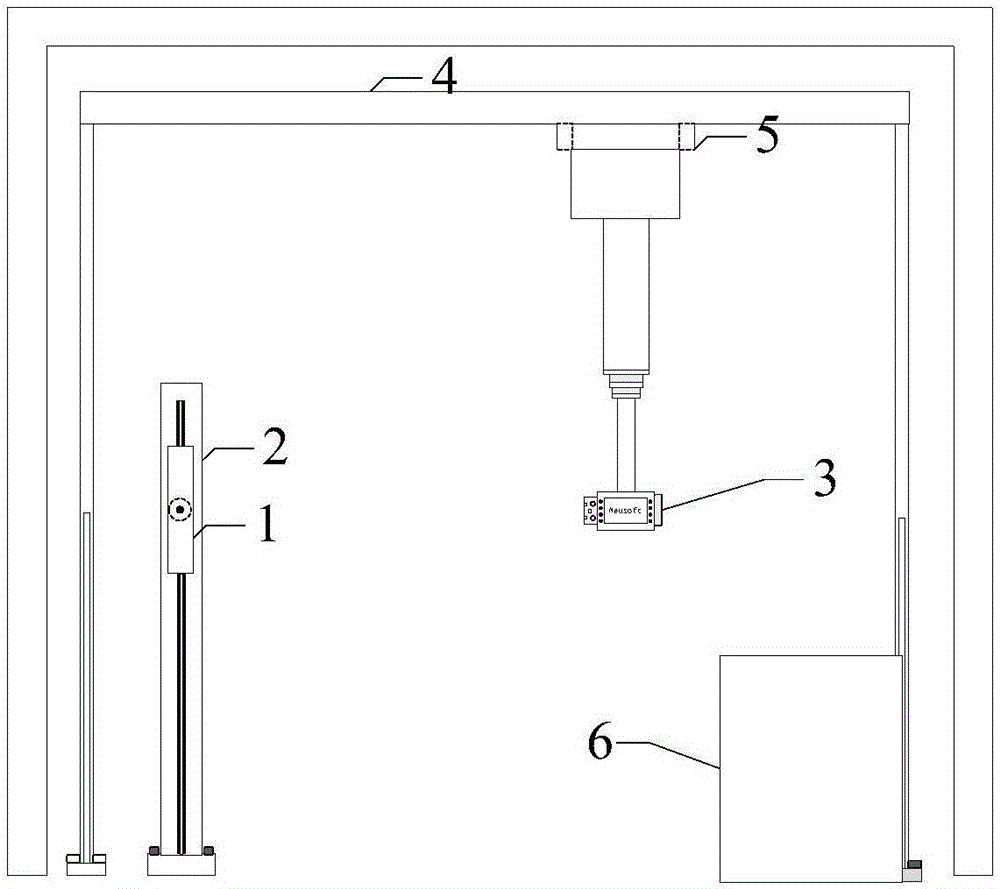

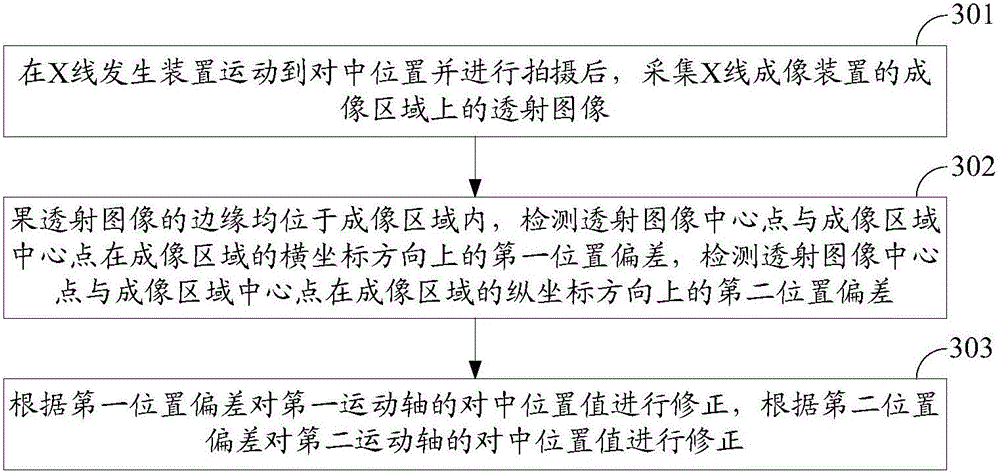

Correction method and device for achieving centering movement

InactiveCN106419941AGuaranteed accuracyImplement automatic correctionRadiation diagnosticsX-rayVertical axis

The invention discloses a correction method and device for achieving centering movement. The correction method and device are used for correcting the centering position automatically. The method comprises the steps that after an X-ray generation device moves to the centering position for shooting, a transmission image in an imaging region of the X-ray generation device is collected; the centering position is determined according to a centering position value of the first motion axis and a centering position value of the second motion axis; the first motion axis is parallel to the abscissa axis of the imaging region, and the second motion axis is parallel to vertical axis of the imaging region; if edges of the transmission image are all located in the imaging region, a first position deviation of the transmission image center point and the imaging region center point in the abscissa axis direction of the image region is detected, and a second position deviation of the transmission image center point and the imaging region center point in the vertical axis direction of the image region is detected; the centering position value of the first motion axis is corrected according to the first position deviation, and a centering position value of the second motion axis is corrected according to the second position deviation.

Owner:NEUSOFT MEDICAL SYST CO LTD

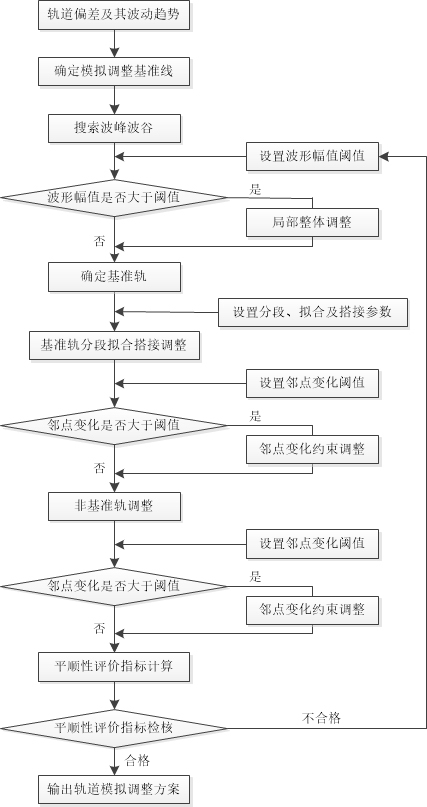

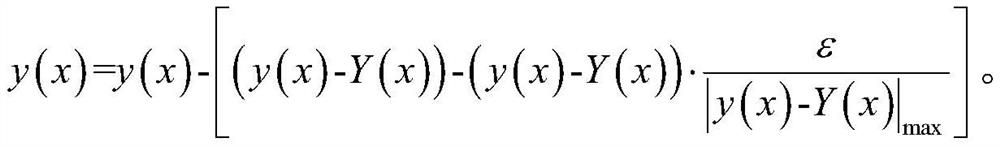

Automatic simulation adjustment method for high-speed railway ballastless track

PendingCN111950116AAutomated Simulation Tuning ImprovementsAutomated simulation tuning method improvementsGeometric CADDesign optimisation/simulationTrackwaySimulation

The invention relates to an automatic simulation adjustment method for a ballastless track of a high-speed railway. The method comprises the following steps: determining a track simulation adjustmentdatum line; searching all wave crest or wave trough intervals according to the simulation adjustment datum line and the deviation oscillogram; and establishing constraint conditions, and carrying outautomatic simulation adjustment on the ballastless track. The method solves the problems that an existing ballastless track simulation adjustment method is prone to being affected by the level of technicians and subjective factors, so that the automation degree is low (frequent manual fastener-by-fastener repeated adjustment is needed), the scheme quality is uneven, the adjustment amount is large,and the fastener replacement rate is high. A core technical support is provided for establishment and long-term maintenance of the high-smoothness state of the track.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Deburring and rounding device

InactiveCN105269053BGood roundAutomatic contactMilling cuttersMilling equipment detailsMilling cutterEngineering

The present invention relates to a deburring and rounding device, and particularly a deburring and rounding device for the edge of a complex formed workpiece. For a gear, the edge of the complex formed workpiece occurs, for example, between the end face and the tooth flank. The device includes an industrial robot. The industrial robot guides a rotary milling head along the edge of the complex formed workpiece. The milling head is designed thus, and therefore the extremely weak edge persists even if the guiding is performed accurately.

Owner:ZF FRIEDRICHSHAFEN AG

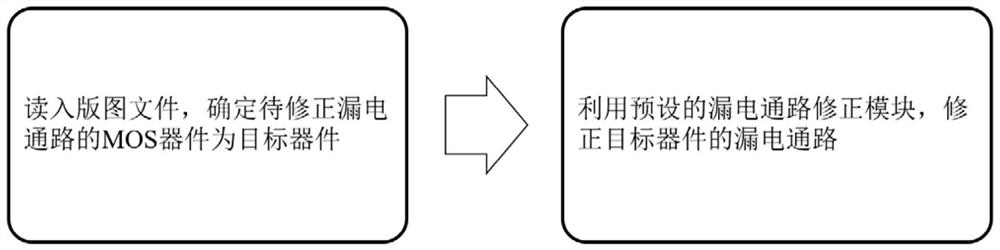

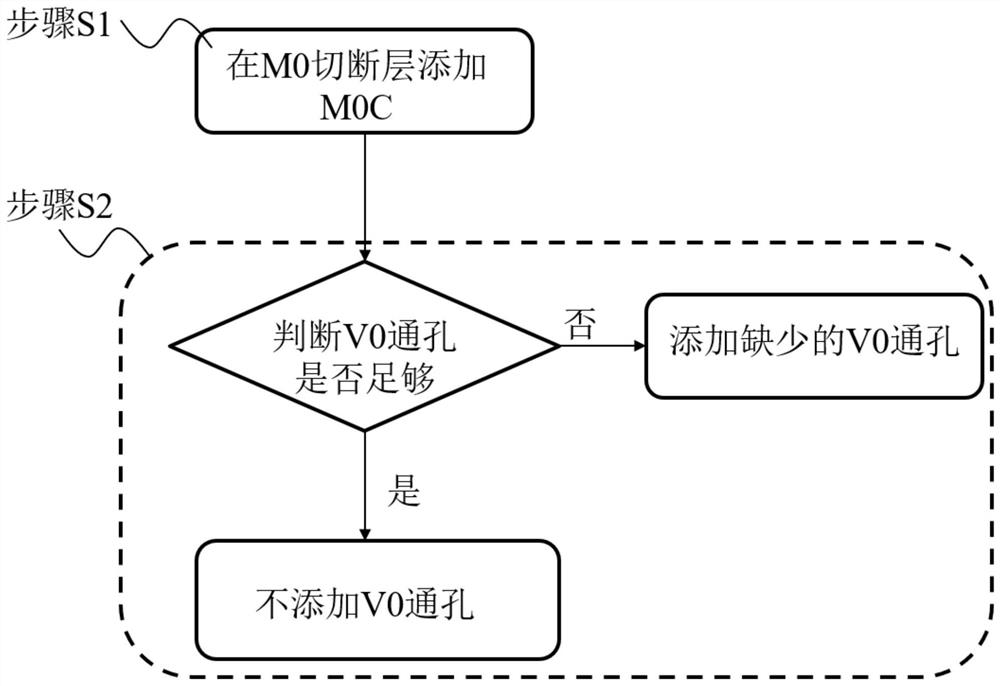

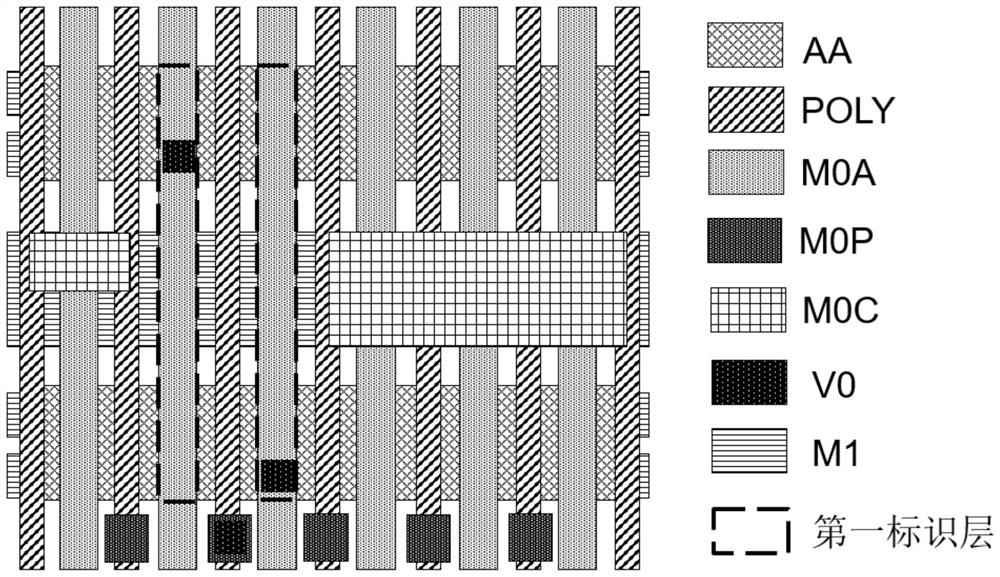

Method for automatically correcting electric leakage path of MOS device

ActiveCN113657071AIncrease authenticityImprove manufacturing levelComputer aided designSpecial data processing applicationsLayoutComputer science

The invention provides a method for automatically correcting an electric leakage path of an MOS device. The method comprises the following steps of: reading a layout file, and automatically correcting by utilizing a preset electric leakage path correction module; and defining a correction mode of the MOS device with the electric leakage path in the electric leakage path correction module: adding an M0C to an M0 cut-off layer, and adding a lacked V0 through hole. The problem that the electrical property test of the MOS device is influenced by generation of an electric leakage path is effectively solved, and the authenticity of the electrical property test of the device is improved; and the method is simple in steps, does not depend on manual operation and experience, saves manpower and working hours, reduces the process research and development cost, solves the problems that manual correction is time-consuming and the error risk is high, is better in reliability of an automatic correction result, and facilitates the improvement of the manufacturing level and the overall quality of a product.

Owner:SEMITRONIX

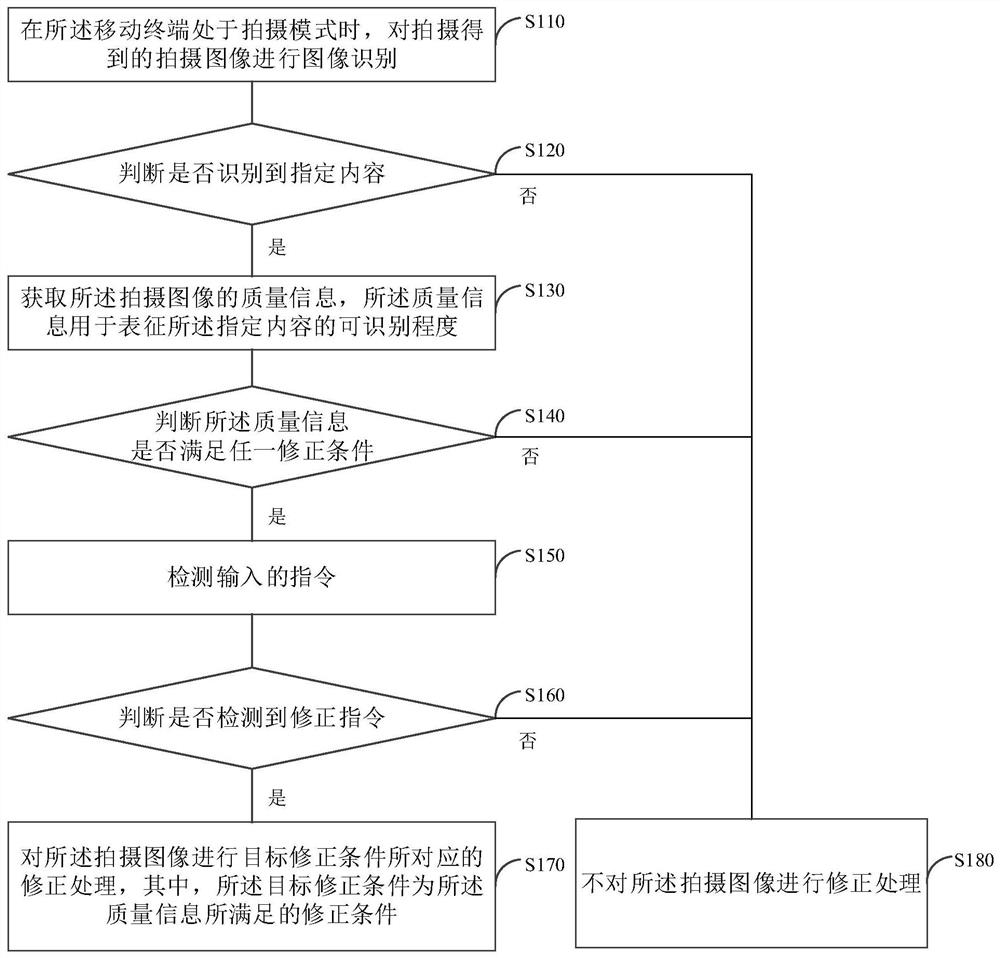

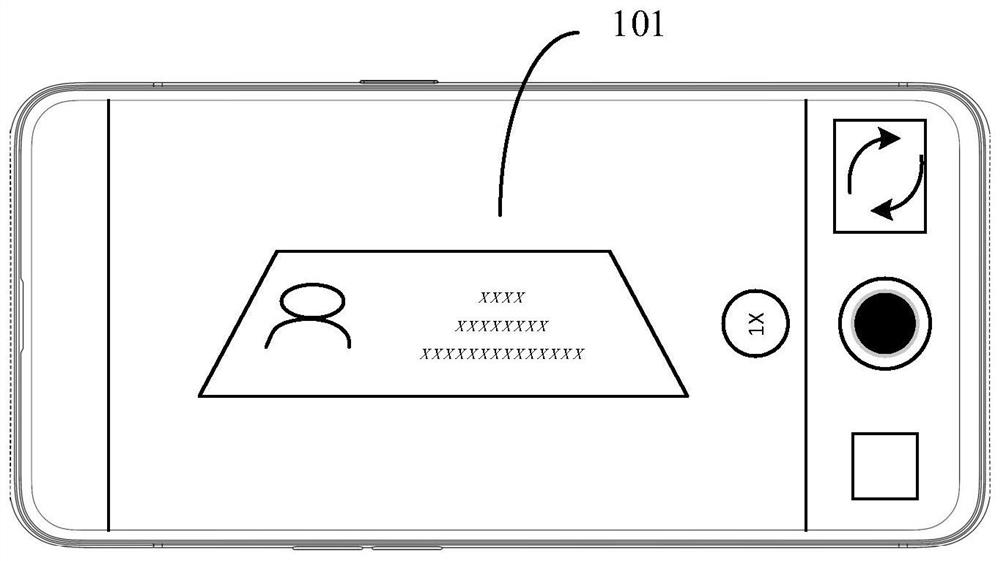

Method, device, mobile terminal and storage medium for processing captured images

ActiveCN111491106BImplement automatic correctionImprove photo experienceTelevision system detailsColor television detailsImaging processingComputer graphics (images)

The application discloses a method and device for processing captured images, a mobile terminal and a storage medium, and relates to the technical field of image processing. The method is applied to a mobile terminal, and the method includes: when the mobile terminal is in the shooting mode, image recognition is performed on the captured image obtained by shooting; when the specified content is recognized, the quality information of the captured image is acquired, and the quality information is used to represent the quality of the specified content Recognizable degree; when the quality information satisfies any correction condition, detect the input instruction; when the correction instruction is detected, perform correction processing corresponding to the target correction condition on the captured image, wherein the target correction condition is satisfied by the quality information Modify the conditions. This application can automatically obtain the quality information of the captured image when the mobile terminal captures the captured image containing the specified content, and automatically judge whether to correct the captured image according to the quality information and user input instructions, which improves the user's ability to take pictures experience, avoiding repeated photos.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

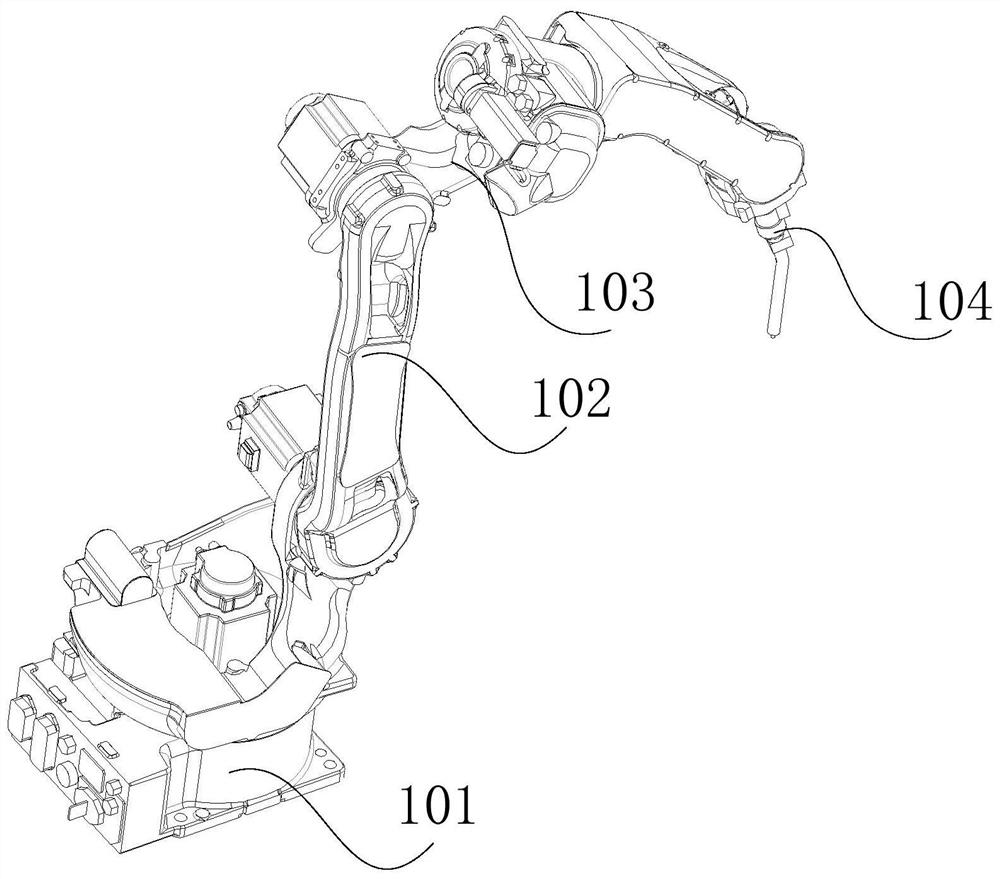

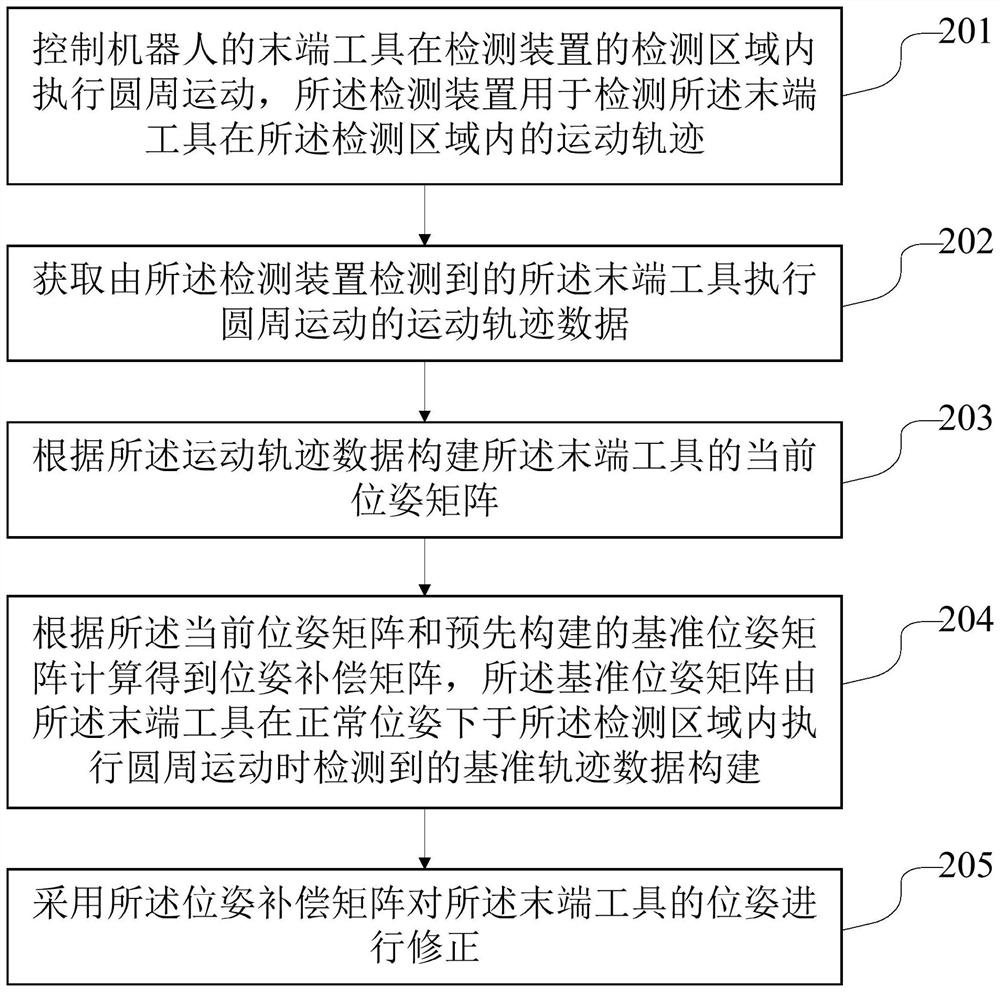

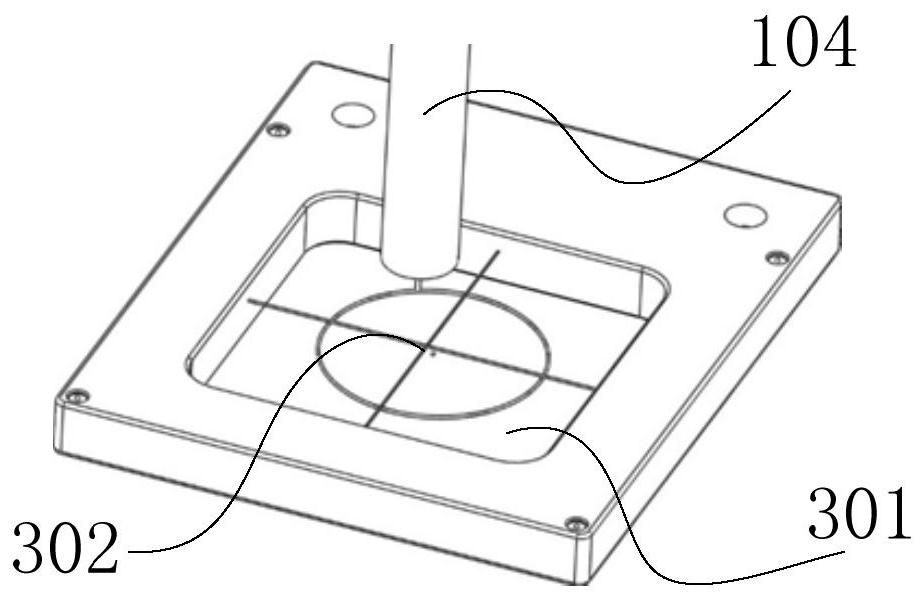

A method and device for correcting the pose of a robot end tool

ActiveCN111844130BImplement automatic correctionSave human resourcesProgramme-controlled manipulatorPattern recognitionRobotics

The present application relates to the field of robot technology, and provides a method, device, terminal device and storage medium for correcting the pose of a robot end tool. The method includes: obtaining motion trajectory data corresponding to a motion trajectory generated by the end tool of the robot performing circular motion within the detection area of the detection device; constructing a current pose matrix of the end tool according to the motion trajectory data; calculating the current pose matrix and the pre-built reference pose matrix to obtain a pose compensation matrix; using the pose compensation matrix to correct the pose of the end tool. By adopting the method of the present application, the pose of the end tool can be automatically corrected to a normal pose, saving manpower and time resources.

Owner:深圳市智流形机器人技术有限公司

A grinding and debugging system

ActiveCN110587472BEasy to installImplement automatic correctionGrinding feed controlAutomatic grinding controlControl systemData acquisition

The invention relates to a grinding debugging system. The grinding debugging system comprises a robot, a film pressure sensor, a sensor mounting mechanism assembly, a data acquisition system, a data analysis and control system and a visualization system. The sensor mounting mechanism assembly is used for fixing a grinding head and the sensor to the tail end of the robot and the tail end of a grinding head correspondingly. The data acquisition system is used for collecting multiple actual pressure values, obtained by the sensor, of a current point location and obtaining a pressure nephogram. The data analysis and control system is used for conducting analysis on the pressure nephogram, the quantified actual pressure values and the prestored standard pressure value and conducting real-time correction on a motion control program in the robot. The visualization system is used for quantifying the multiple pressure values and conducting visual display according to the analysis result. The grinding debugging system can automatically modify the motion control program according to the analysis result and obtain the corrected technological parameters of the grinding head. The motion controlprogram can be migrated into multiple similar grinding robots, and the grinding debugging cost and time are remarkably reduced.

Owner:重庆智能机器人研究院 +1

Three-valve injection dispensing machine

InactiveCN112221858AHigh speedHigh precisionLiquid surface applicatorsCoatingsElectric machineControl engineering

The invention discloses a three-valve injection dispensing machine. According to the technical scheme, the three-valve injection dispensing machine comprises a driving device, wherein a supporting device is arranged on the left side of the driving device; a power device is fixedly mounted on the supporting device; a polishing device and a dispensing device are fixedly mounted on the power device;the power device comprises a first linear motor; the output end of the first linear motor is fixedly connected with a first sliding plate; one end of the first sliding plate is fixedly connected witha motor support; a limiting rod is fixedly mounted at the bottom of the motor support; and the inner wall of the motor support is fixedly connected with a servo motor. The three-valve injection dispensing machine effectively solves the problems of slow driving response, transmission errors, reverse gaps and the like of a three-shaft dispensing machine caused by existing stepping or servo motor driving, synchronous belt or screw rod transmission; three injection heads are adopted, so that independent liquid injection of three reagents can be realized; one or more injection heads can be selectedto correspondingly realize injection of one or at most three liquids; and the corresponding injection heads are respectively regulated and controlled according to actual requirements.

Owner:上海博哈寿生物科技有限公司

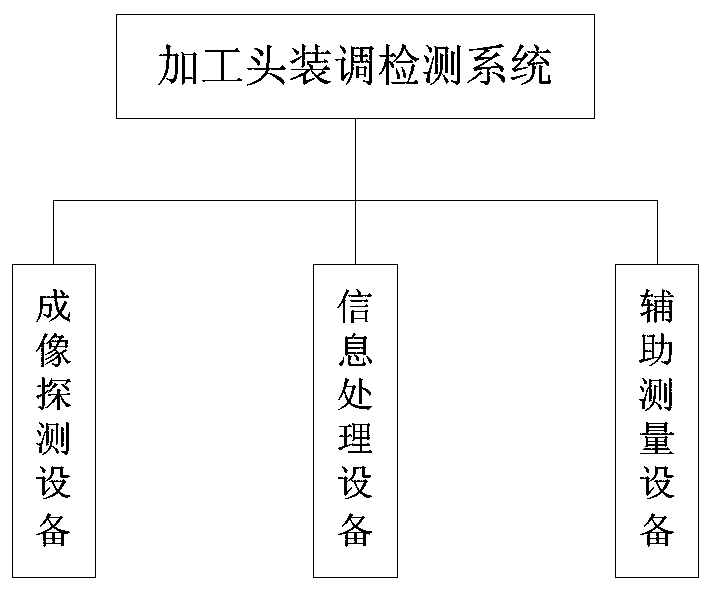

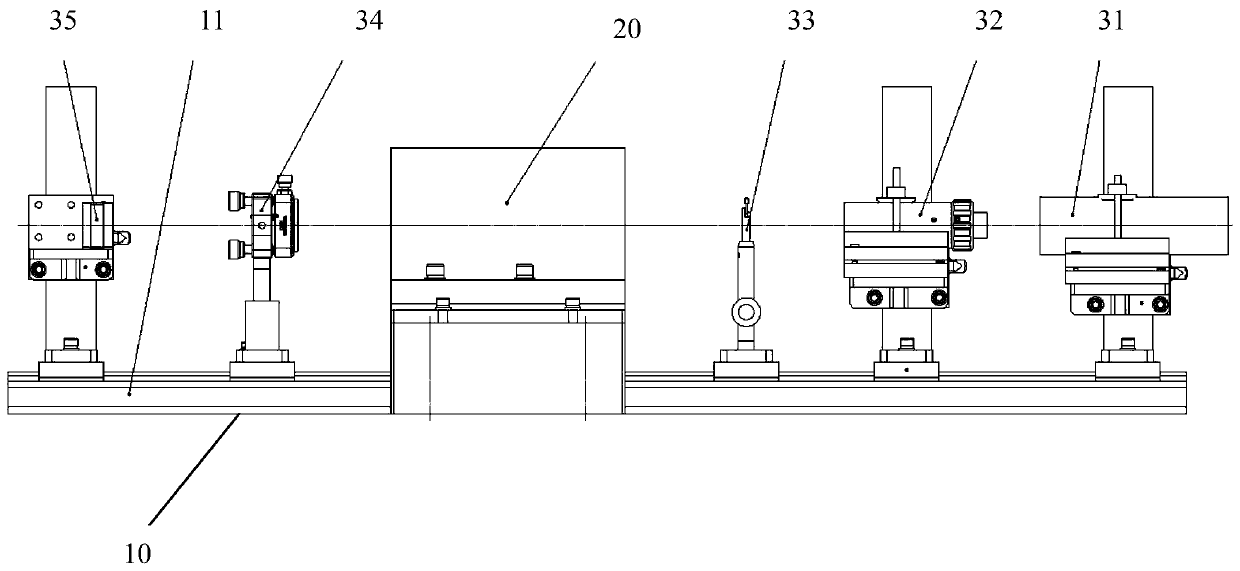

Laser scanning head installation calibration inspection system

InactiveCN108303236BReduce or avoid errorsImprove accuracyOptical apparatus testingInformation processingCamera lens

The invention discloses a mounting, calibrating and checking system for a laser scanner. The system includes a pedestal, an imaging detection device, an auxiliary measurement device and an informationprocessing device. The imaging detection device includes a laser scanner, a video microscopic lens and an area array camera. The video microscopic lens can form an image on a target face of the areaarray camera after amplifying an object. The area array camera acquires scanning information and transmits the information to the information processing device. The auxiliary measurement device includes a parallel light source, a light beam modulator, an adjustable diaphragm, a focusing lens and a calibration board mounted on the pedestal. Light beams emitted by the parallel light source cast to the target face of the camera after passing through the light beam modulator, the adjustable diaphragm, the laser scanner and the focusing lens. Accurate measurement values used for mounting, calibrating or checking the laser scanner are obtained after software algorithm treatment on the acquired image information on the target face. The system has advantages of improving accuracy of scanning information of the scanner and ensuring performance indexes of the scanner.

Owner:福建省莆田市中涵机动力有限公司

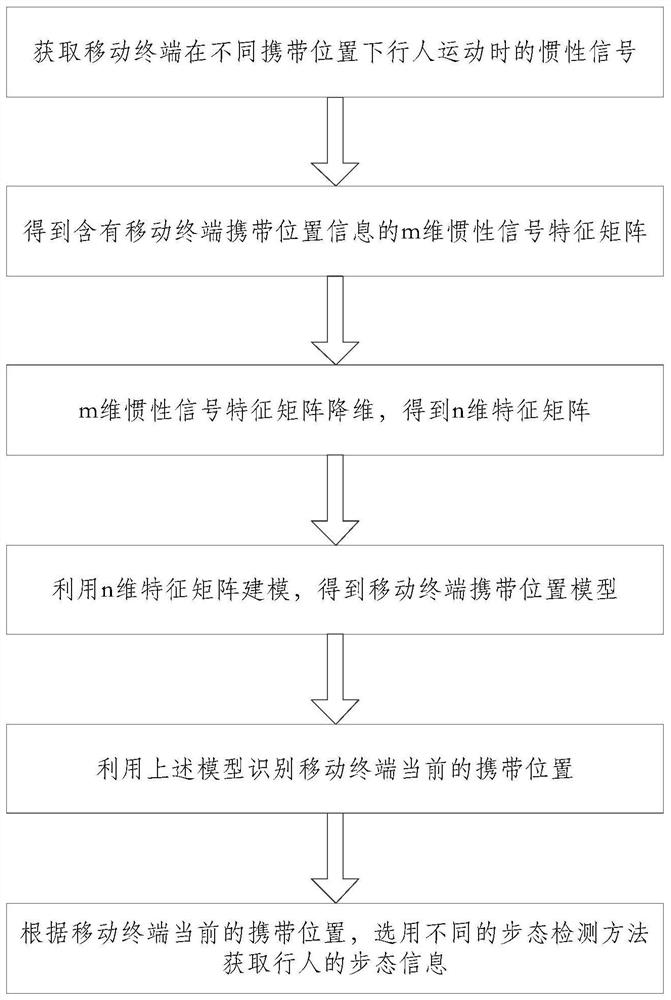

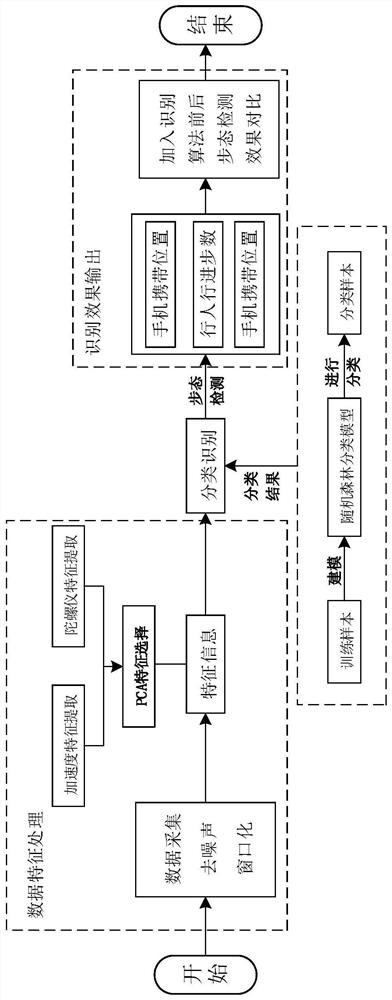

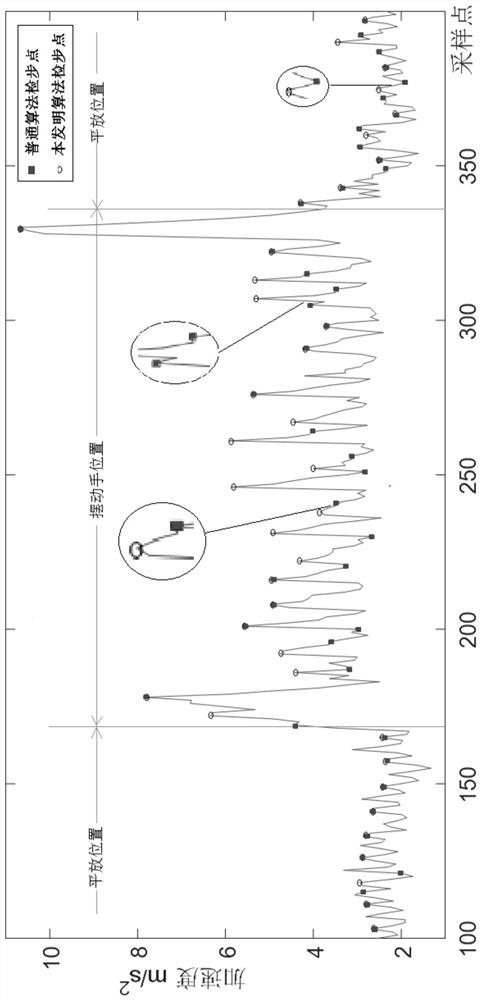

Method of improving gait detection based on mobile terminal in different carrying positions

InactiveCN109893137BRealize automatic identificationHigh precisionCharacter and pattern recognitionDiagnostic recording/measuringSimulationPedestrian

The invention discloses a method for improving gait detection based on a mobile terminal at different carrying positions, which includes the following steps: s1. Obtaining the inertial signal of the mobile terminal when pedestrians move at different carrying positions; s2. According to the inertial signal of step s1 signal to obtain the m-dimensional inertial signal feature matrix containing the mobile terminal's carrying position information; s3. to reduce the dimensionality of the m-dimensional inertial signal feature matrix to obtain an n-dimensional feature matrix; s4. to the n-dimensional feature matrix and the carrying position attribute of the mobile terminal Matrix modeling to obtain the mobile terminal carrying position model; s5. Utilize the mobile terminal carrying position model in step s4 to identify the current carrying position of the mobile terminal; s6. According to the current carrying position of the mobile terminal, select different gait detection methods to obtain Gait information of pedestrians. The invention can adapt to the change of the mobile terminal in different carrying positions, and improves the accuracy of gait detection.

Owner:SHANDONG UNIV OF SCI & TECH

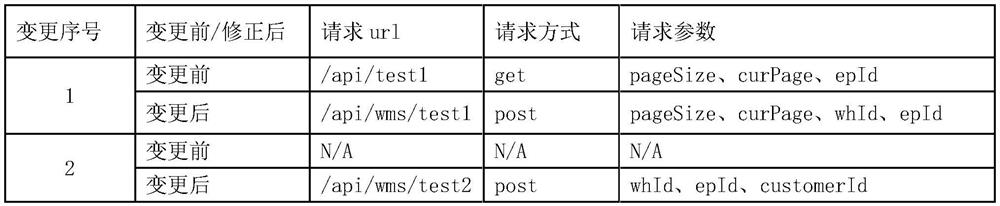

Automatic correction method for interface test case

PendingCN114116492AImplement automatic correctionUnresolved and inaccurateSoftware testing/debuggingComputer hardwareTest efficiency

The invention discloses an automatic correction method for an interface test case, which is characterized by comprising the following steps of: S1, capturing change information in two git versions by a system through a command, and storing the captured information into a file 1; s2, judging whether the change information in the file 1 has an interface change or not through a keyword, if so, screening out a change point, and entering S3; if not, finishing the correction and the like. The interface change mapping relation is obtained by capturing the git code submission record, and then the test case of the corresponding interface is automatically corrected according to the mapping relation, so that automatic correction of the interface test case is realized, and the problems that the interface change is not timely and inaccurate to inform a tester and the test efficiency is high are well solved. And after the interface is changed, a tester needs to manually change a corresponding test case, so that the correction timeliness and accuracy of the interface test case are poor.

Owner:多点(深圳)数字科技有限公司

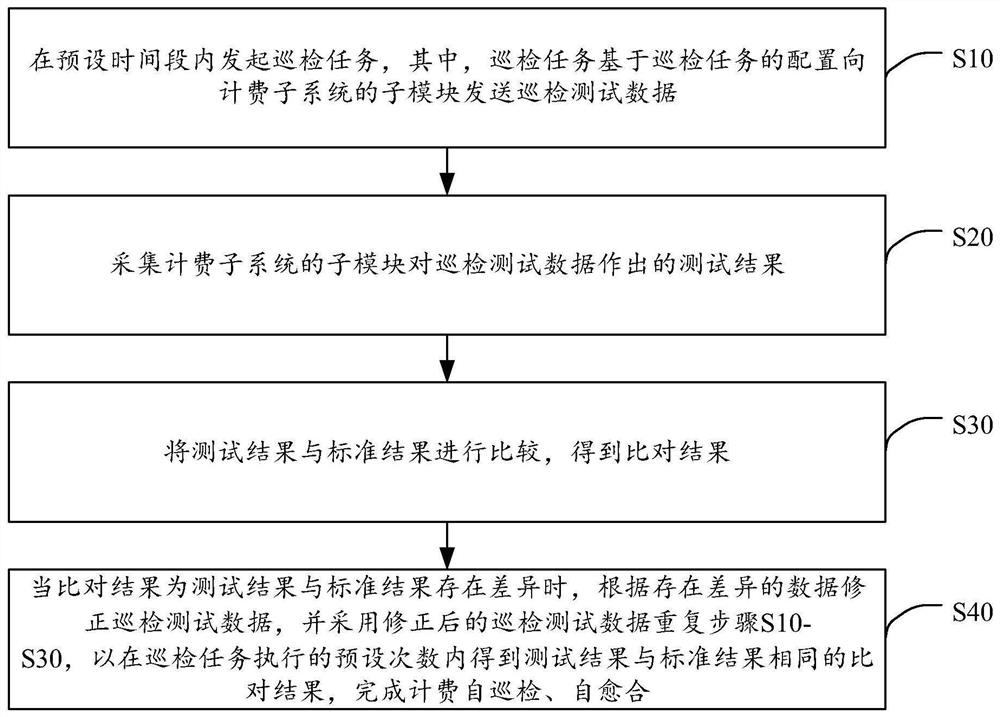

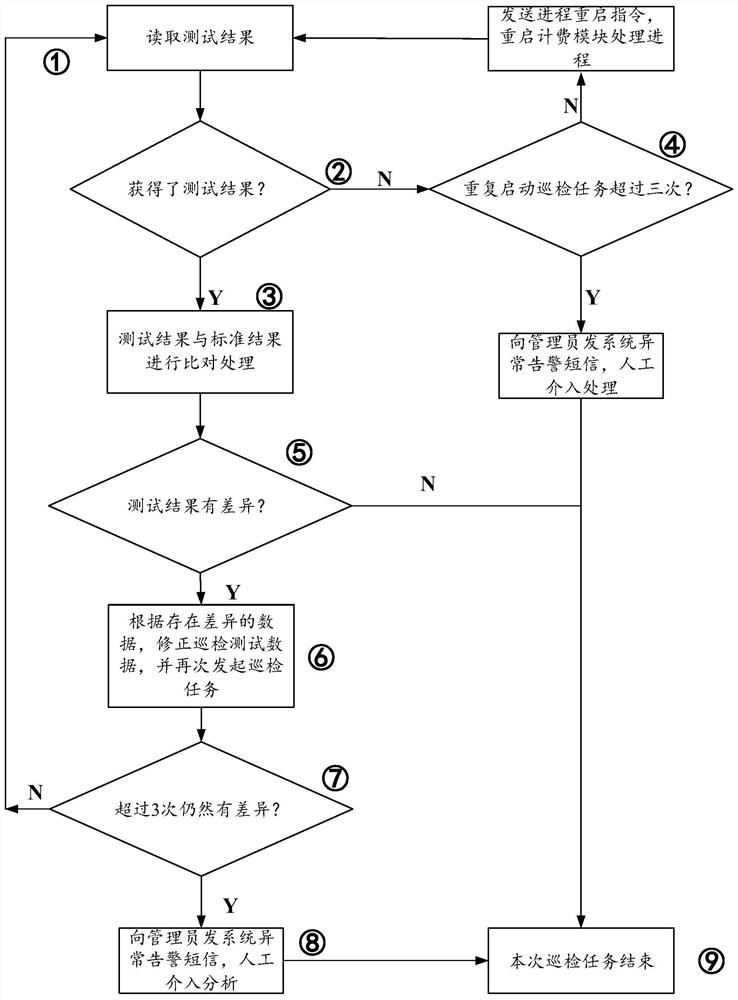

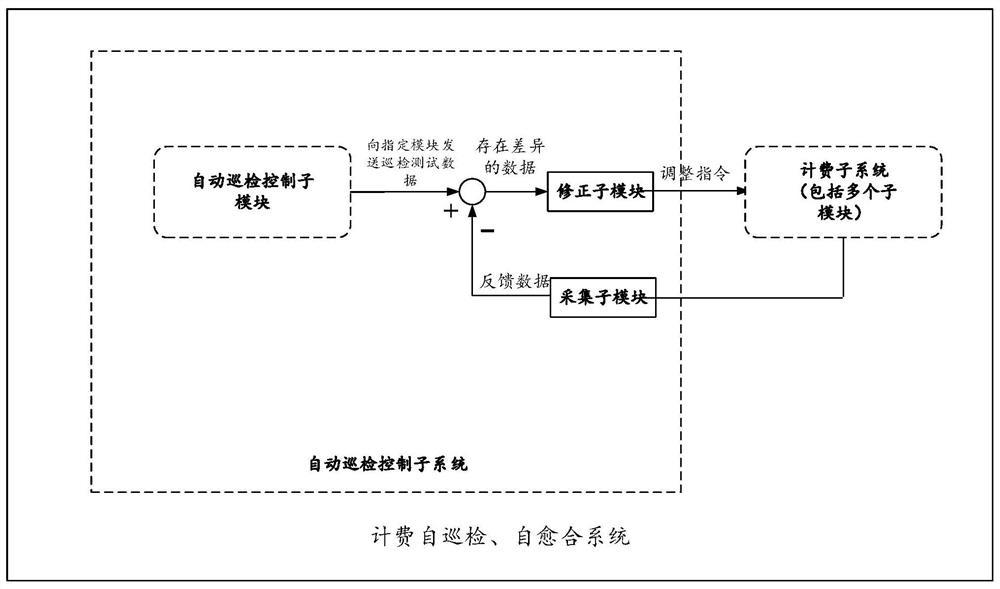

Charging self-inspection and self-healing method and device, computer equipment and storage medium

ActiveCN113452533ARealize billing self-inspectionRealize self-healing functionMetering/charging/biilling arrangementsTelephonic communicationReliability engineeringComputer engineering

The invention discloses a charging self-inspection and self-healing method and device, computer equipment and a storage medium. The charging self-inspection and self-healing method comprises the steps: initiating an inspection task within a preset time period, wherein the inspection task sends inspection test data to a sub-module of a charging subsystem based on configuration of the inspection task; acquiring a test result made by the sub-module of the charging subsystem on the inspection test data; comparing the test result with a standard result to obtain a comparison result; and when the comparison result shows that the test result is different from the standard result, correcting the inspection test data according to the data with the difference, and repeating the self-inspection step by using the corrected inspection test data so as to obtain a comparison result where the test result is the same as the standard result within the preset number of times of execution of the inspection task, thereby completing charging self-inspection and self-healing. By using the method, the charging accuracy under all charging scenes can be tested, and the charging self-inspection and self-healing functions can be realized.

Owner:CHINA MOBILE GROUP SHANDONG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com