Machining track movement planning method based on sine square acceleration prospect

A technology of machining trajectory and motion planning, applied in the direction of electrical program control, digital control, etc., can solve problems such as large vibration excitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The algorithm will be described in detail below in conjunction with the accompanying drawings, so that the advantages and characteristics of the algorithm can be more easily understood by those skilled in the art, so as to make a clearer definition of the protection scope of the algorithm.

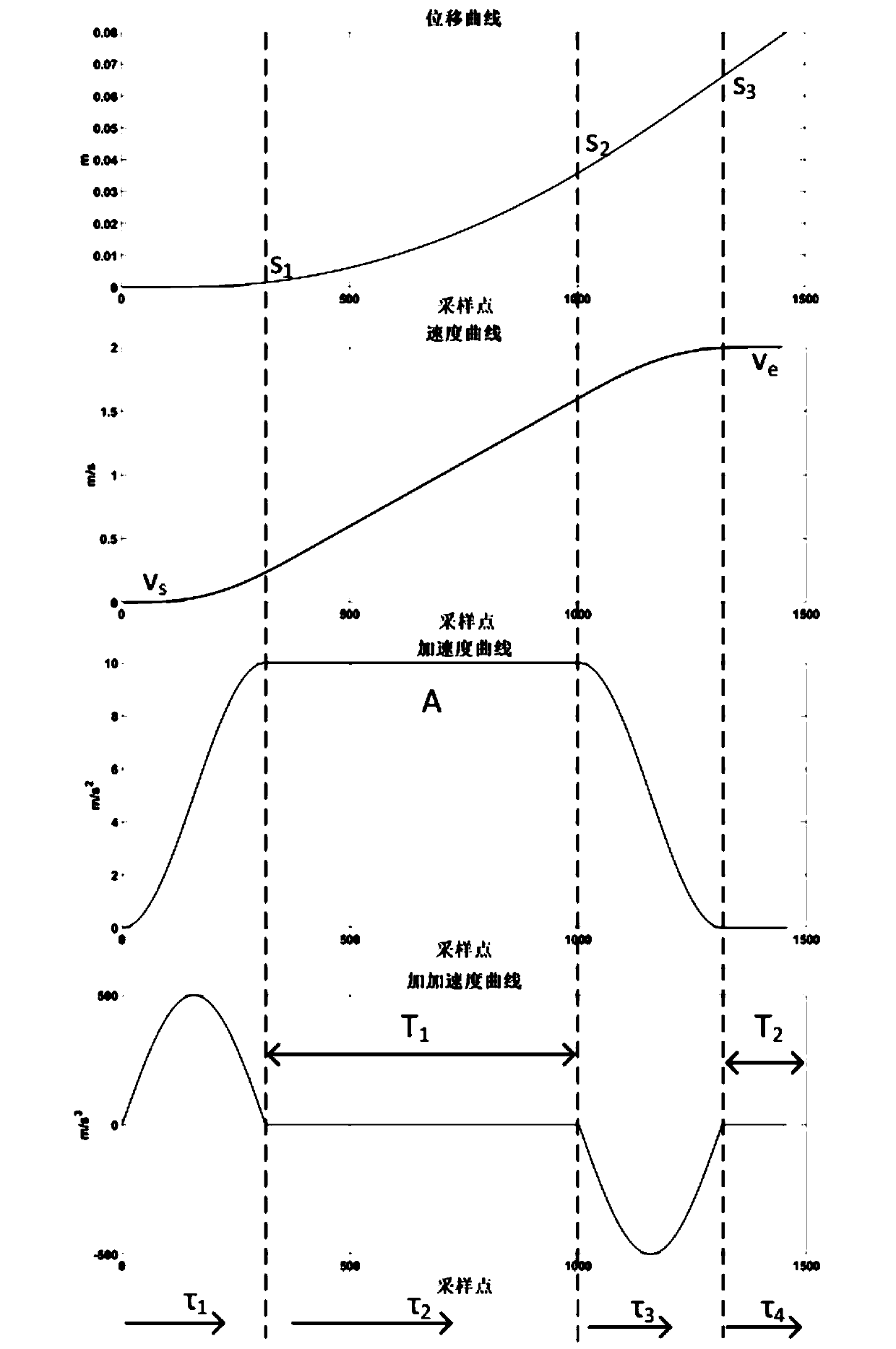

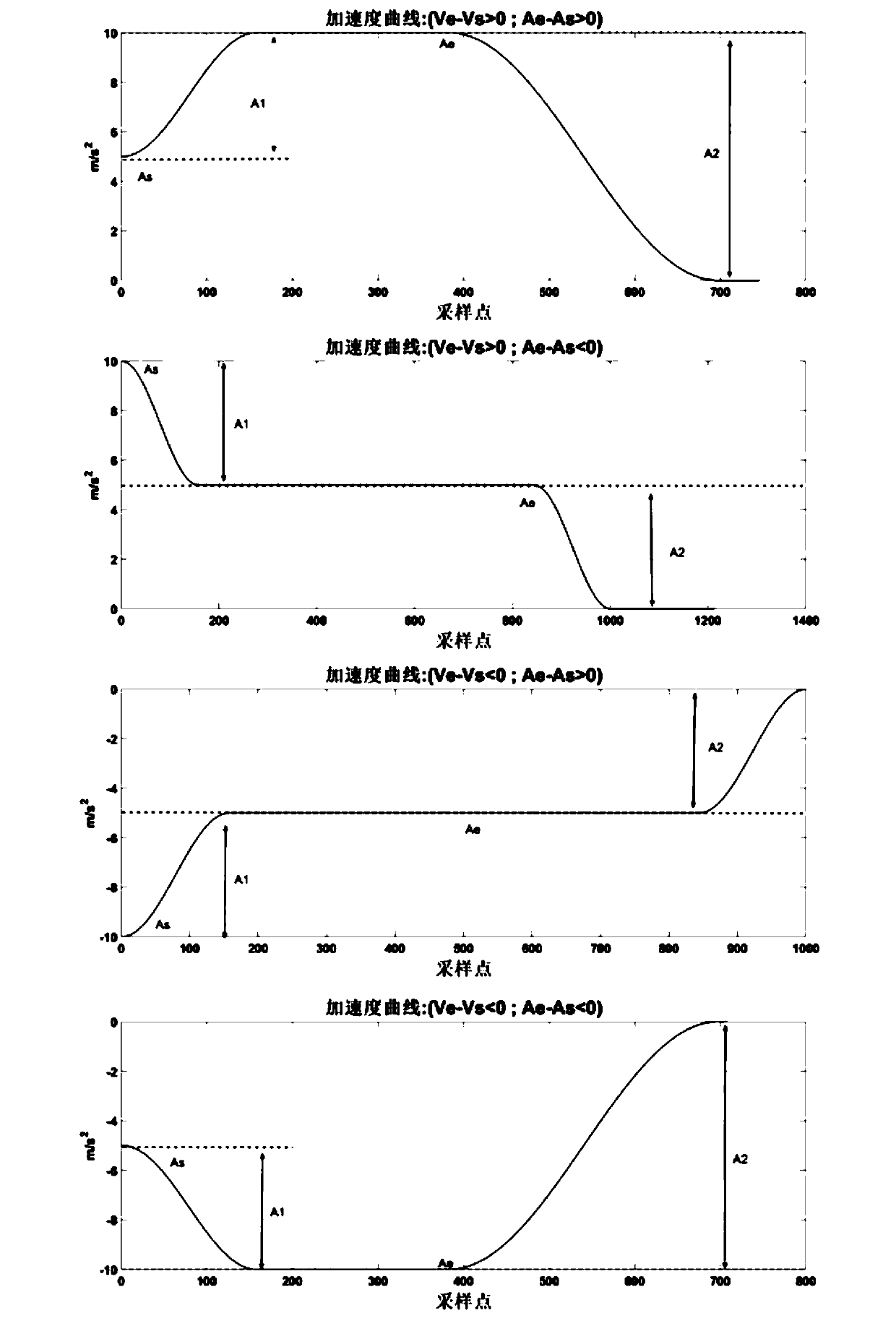

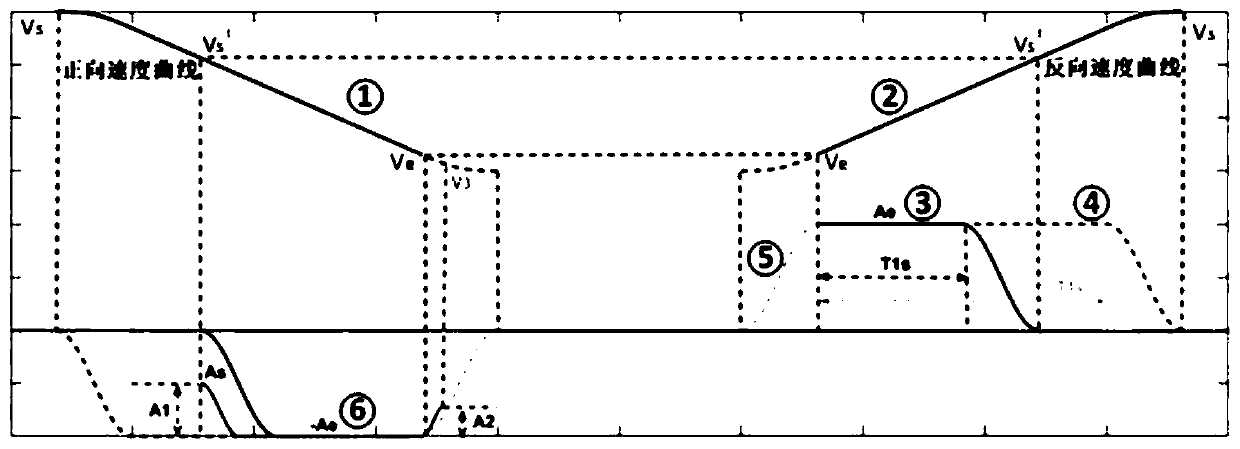

[0059] This algorithm is suitable for all motion planning applications, figure 1 is based on the traditional sine 2 Accelerated motion curve. We call the basic element of the motion planning algorithm a planning segment that satisfies the initial velocity v s to drive out of the speed limit V e , to complete the planning with path length l, jerk limit J, and speed limit A, and a planning segment takes time T and is divided into four segments. The first paragraph and the third paragraph respectively have sine 2 half cycle acceleration, the second stage is the uniform acceleration stage, the acceleration is equal to A, and the elapsed time is T 1 , the fourth stage is the constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com