Automatic simulation adjustment method for high-speed railway ballastless track

A ballastless track and high-speed railway technology, which is applied in the fields of railway car body parts, railway auxiliary equipment, railway signal and safety, etc., can solve the problems of uneven quality, high replacement rate of fasteners, low degree of automation, etc., to achieve The effect of ensuring the degree of approach, improving ride comfort, and improving overall ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below with reference to specific embodiments.

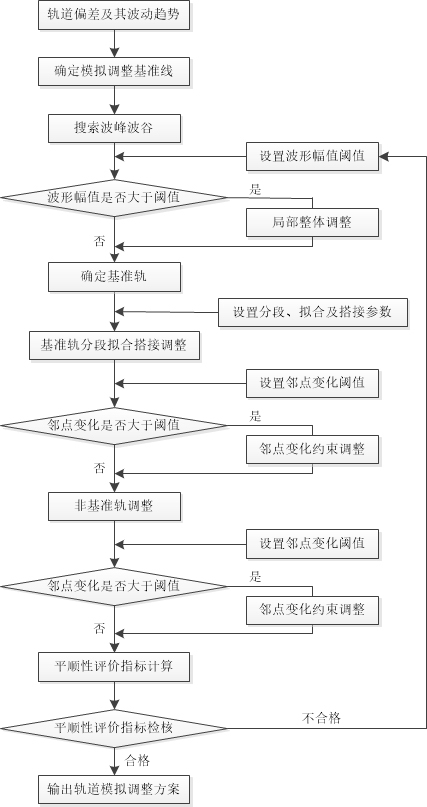

[0050] The method for automatic simulation adjustment of ballastless track of high-speed railway according to the present invention establishes the fine adjustment strategy, adjustment model and constraint conditions of ballastless track, avoids the influence of technical personnel level and subjective factors, and realizes automatic simulation adjustment of ballastless track , the specific implementation method includes the following steps:

[0051] Step 1: According to the deviation between the measured geometric parameters of the ballastless track and the theoretical design value and its overall fluctuation trend, determine the track simulation adjustment baseline.

[0052] In step one:

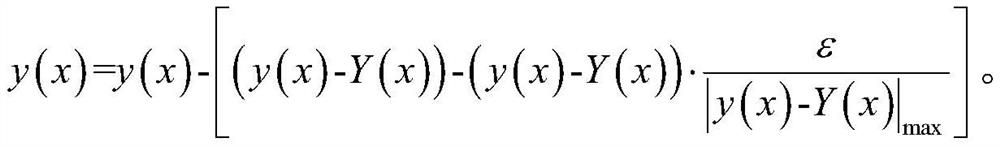

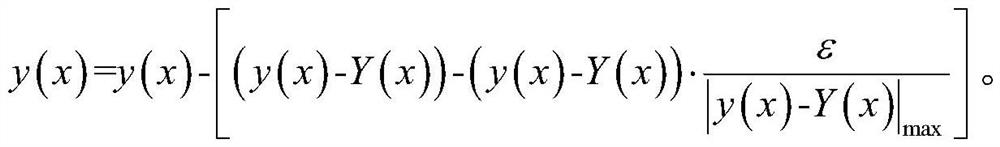

[0053] Let the deviation value of the orbit and its extremum be y(x), y min (x) and y max (x), the total number of measurement points is n, Y(x)∈[y min (x),y max (x)] is the undete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com