Three-valve injection dispensing machine

A technology of enzyme dot machine and camera, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of slow drive response, low production efficiency, low efficiency, etc., and achieve the effect of high precision and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

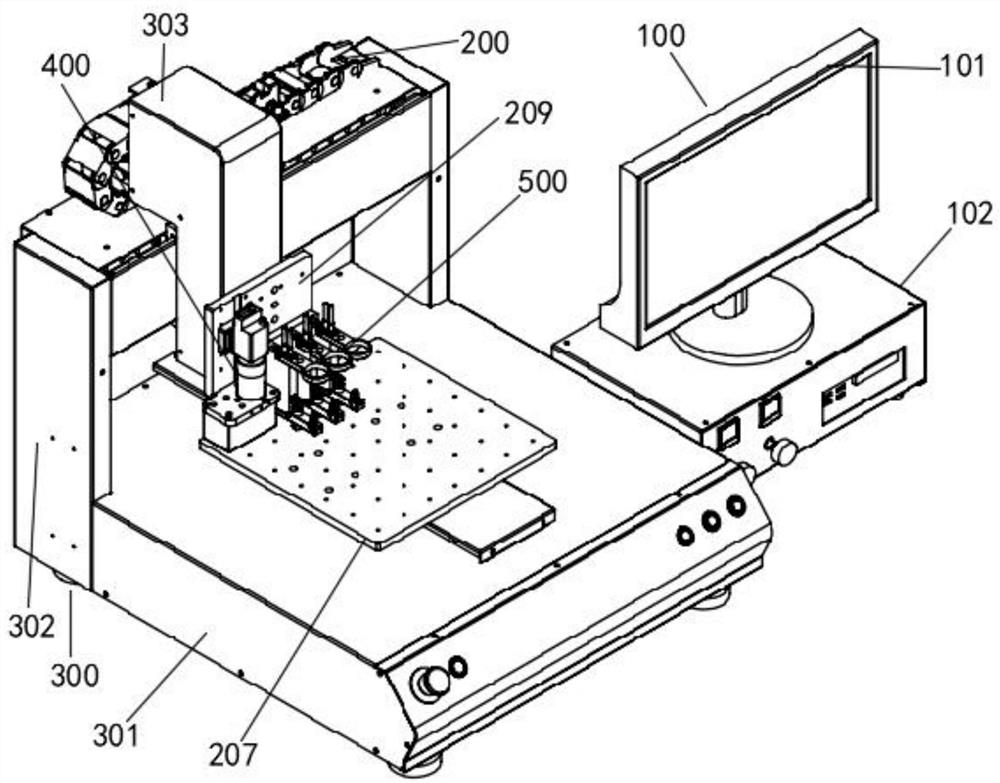

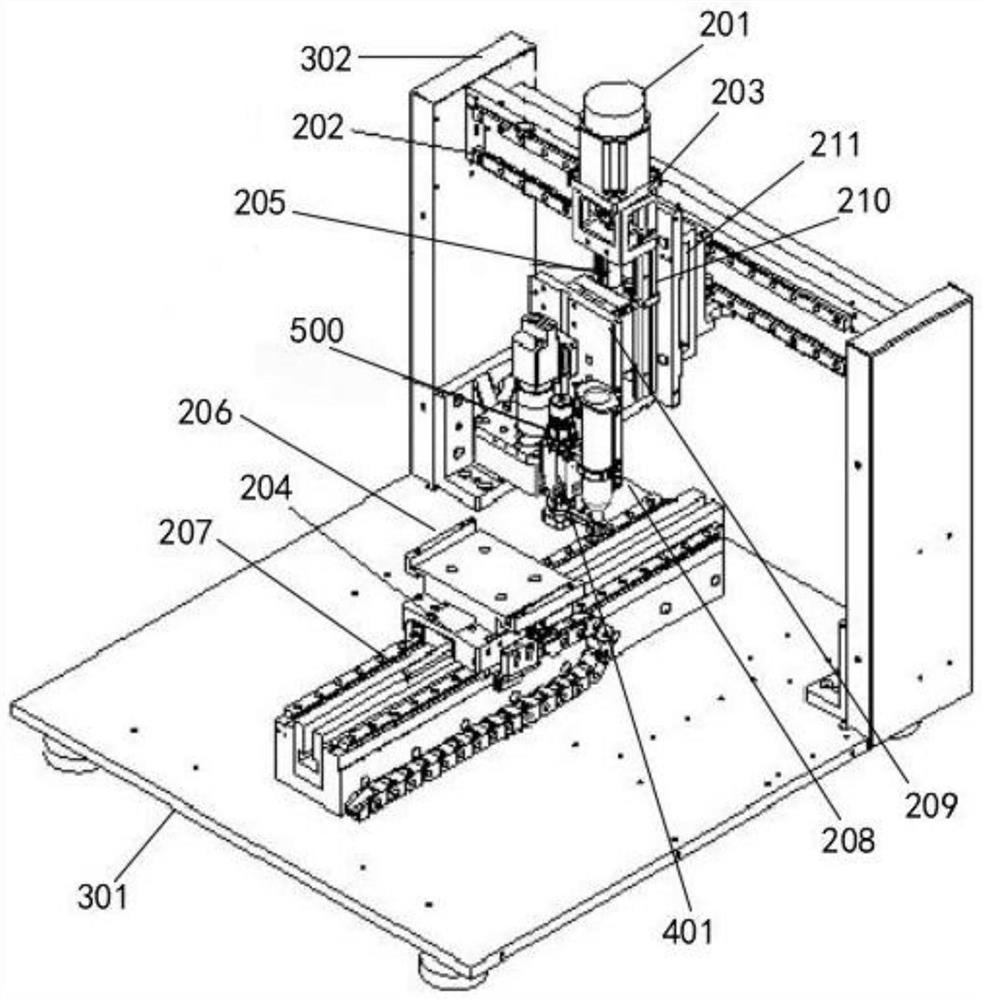

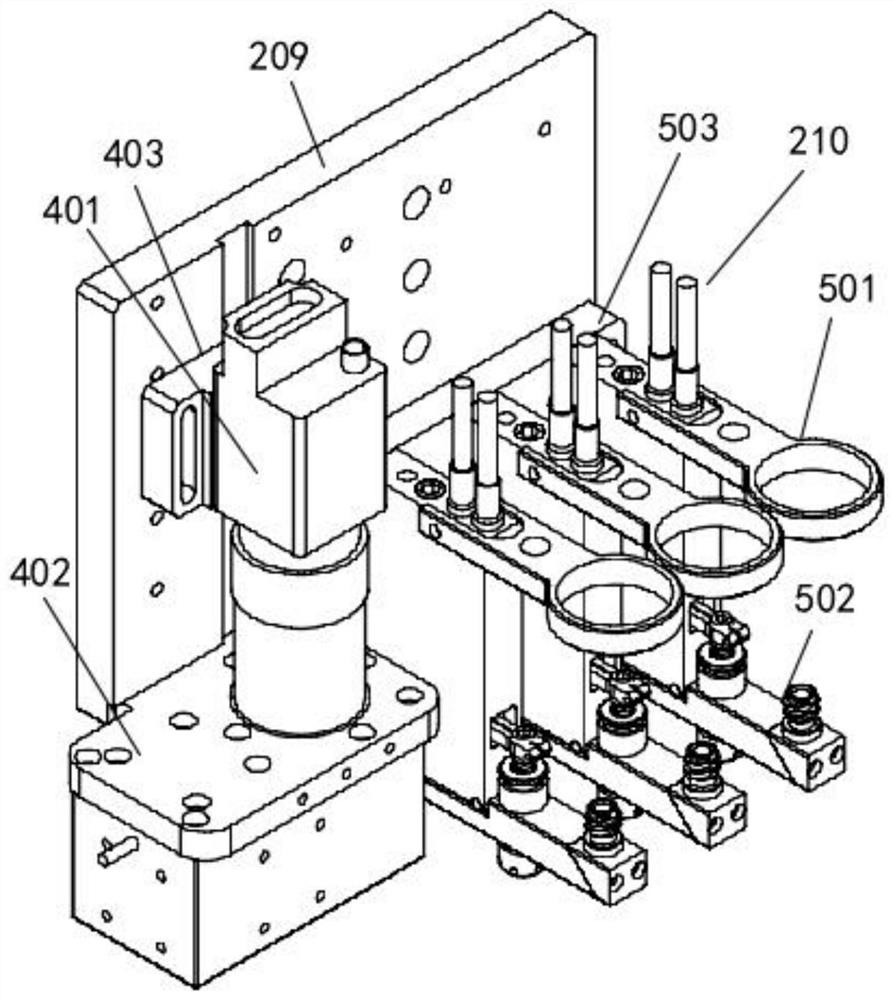

[0033] Refer to the attached Figure 1-6 , the three-valve injection spotting enzyme machine of this embodiment, comprising a drive unit 100, a power unit 200, a support unit 300, a lighting unit 400 and an enzyme spotting unit 500;

[0034] Further, the driving device 100 includes a display screen module 101, a computer module 102, a software interface module 103, a program editing module 104, a point enzyme parameter module 105, a configuration option module 106, a system correction module 107, a line drawing module 1051, and a point module 1052 , a camera correction module 1071, a camera nozzle offset correction module 1072 and a camera laser offset correction module 1073, specifically, the drive device 100 includes a computer module 102, a display screen module 101, a software interface module 103, a program editing module 104, Point enzyme parameter module 105, configuration option module 106 and system calibration module 107, the computer module 102 is electrically conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com