Deburring and rounding device

A rounding and deburring technology, which is applied in the direction of gear teeth, manufacturing tools, mechanical equipment, etc., can solve the problems of excessive distance, high investment cost, and inability to realize tangential transition, etc., and achieve automatic contact and simple device technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

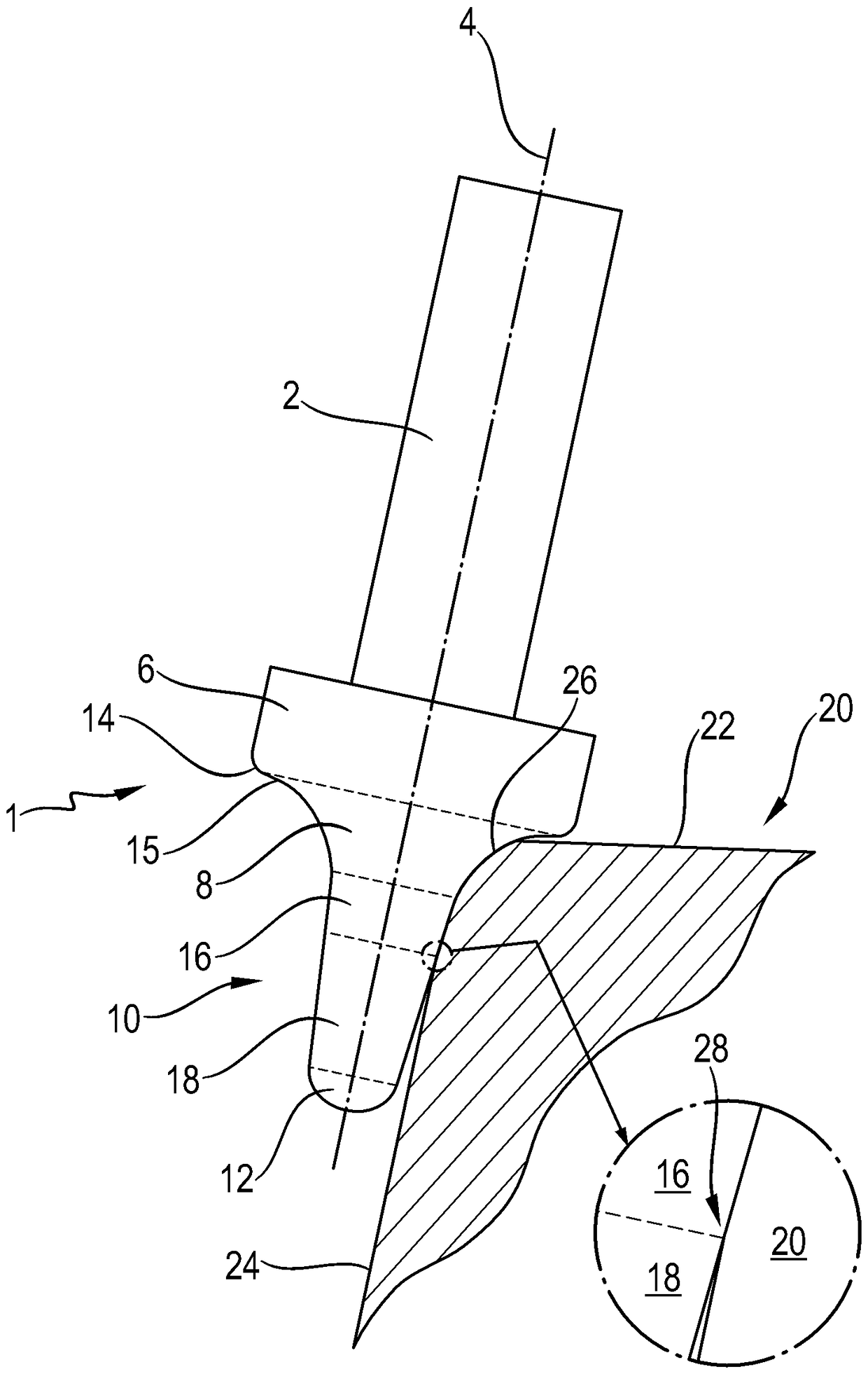

[0029] The milling head 1 is fastened to a rod 2 , which is driven in rotation about an axis of rotation 4 by an industrial robot, not specifically shown, and can be positioned and pivoted largely freely in space here.

[0030] Starting from the shank 2, the milling head 1 has the following rotationally symmetrical sections, which jointly and integrally form the milling head 1: a base section 6, an outer section adjoining the base section 8. A cone section 10 adjacent to said outer section and finally a head section 12 adjacent to said cone section. The base section 6 forms the region of the milling head 1 with the largest diameter and is substantially cylindrical. In the region of the transition to the outer section 8 , the base section 6 has a convex rounded corner 14 . Viewed in longitudinal section of the milling head 1 , the outer section 8 is concavely curved, so that its diameter decreases significantly from the radius 14 through its outermost edge region 15 in the dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com