Connecting element, assembly comprising such connecting element, and method for producing connection

A technology for connecting components and components, applied in the direction of conductive connection, electrical components, structural parts, etc., to achieve the effect of small installation space and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

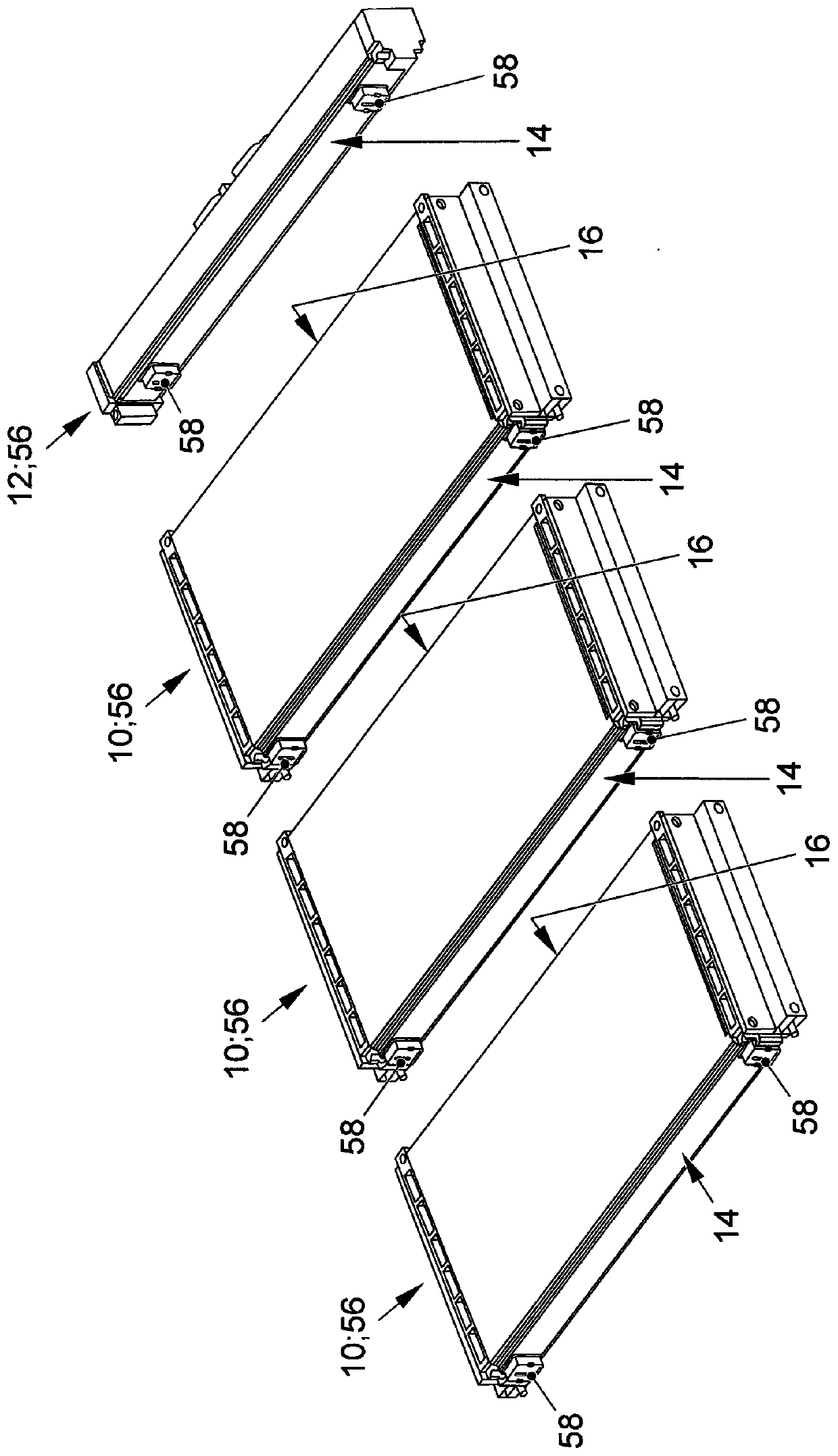

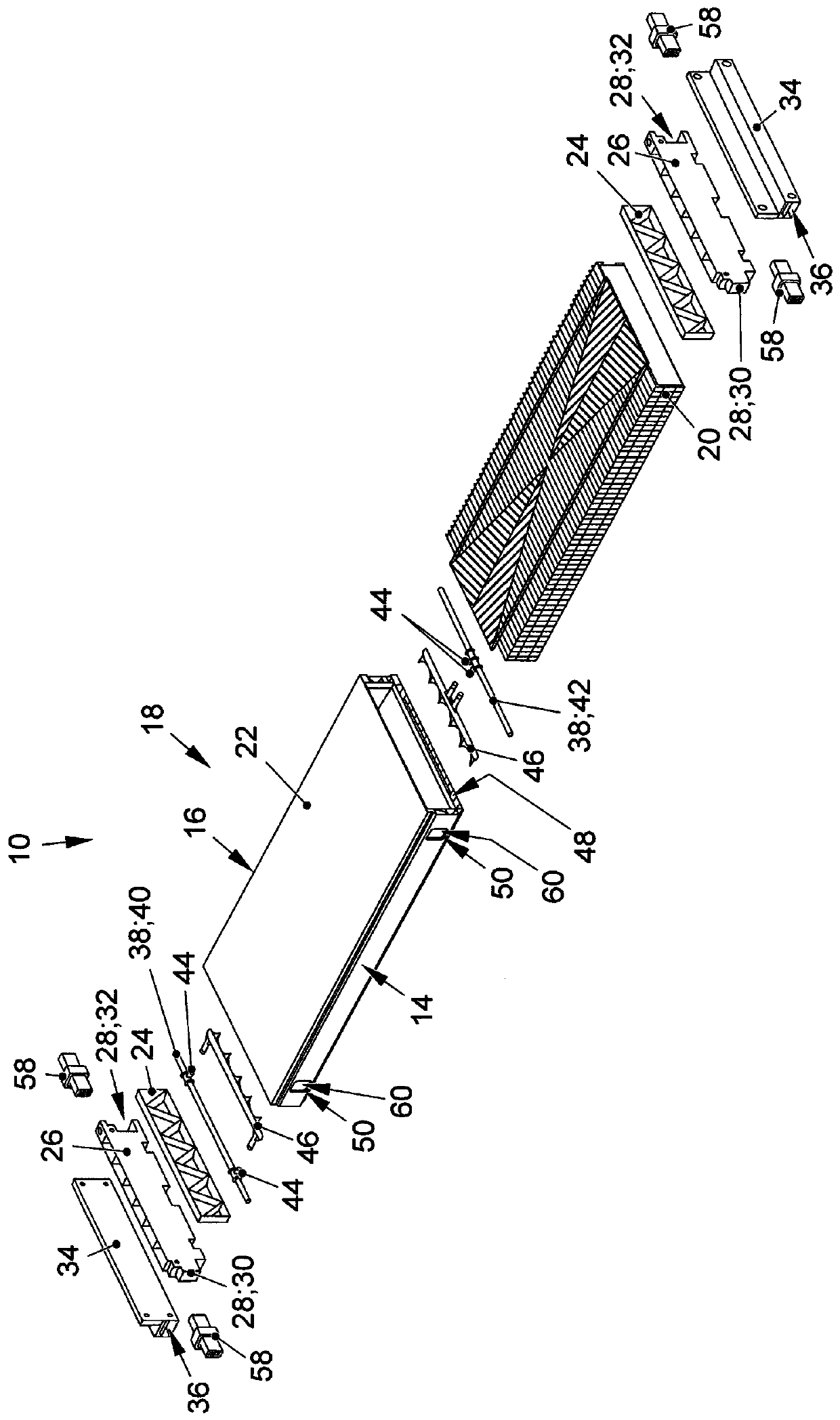

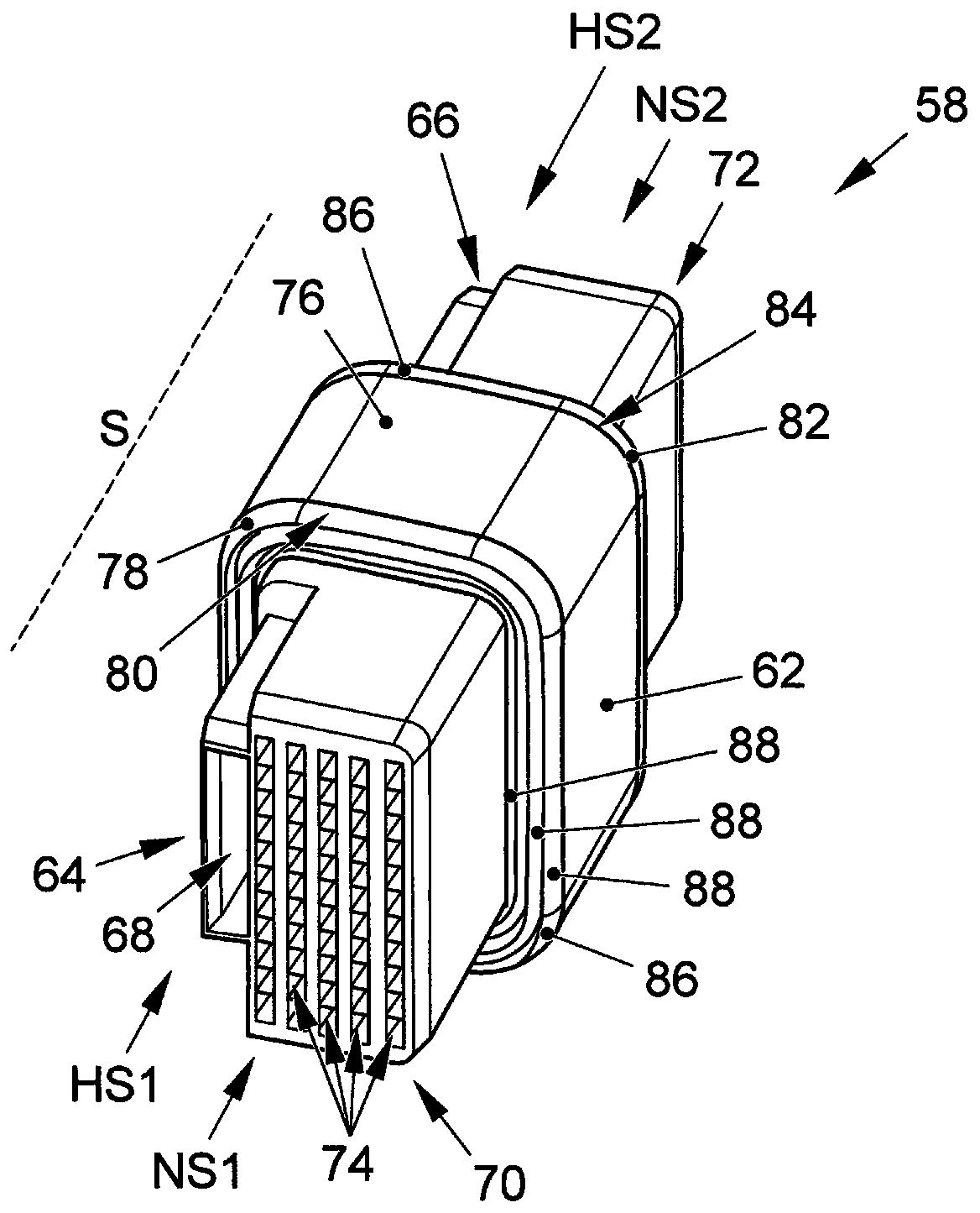

[0036] exist figure 1 shows a diagram of three structurally identical high-voltage battery modules 10 and control devices 12 before the corresponding plug connections are established. To establish the plug connection, the high-voltage battery module 10 and the control device 12 are moved toward each other in the plug connection direction (S). Each high-voltage battery module 10 has a first connection side 14 and an opposite second connection side 16, wherein when the high-voltage battery module is connected, the respectively adapted connection sides 14, 16 directly abut (cf. Figure 8 ). The control device 12 also has a first connection side 14 which abuts directly against an adapted second connection side 16 of the high-voltage battery module 10 . A plurality of high-voltage battery modules 10 are connected via a plug connection, and a high-voltage battery module 10 is connected to a control device 12 via a plug connection. In this case, the high-voltage battery module 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com