Cross-field shrink-fit device and method for limiting magnetic flux losses

A technology of magnetic flux and equipment, used in metal processing equipment, induction heating, manufacturing tools, etc., to achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

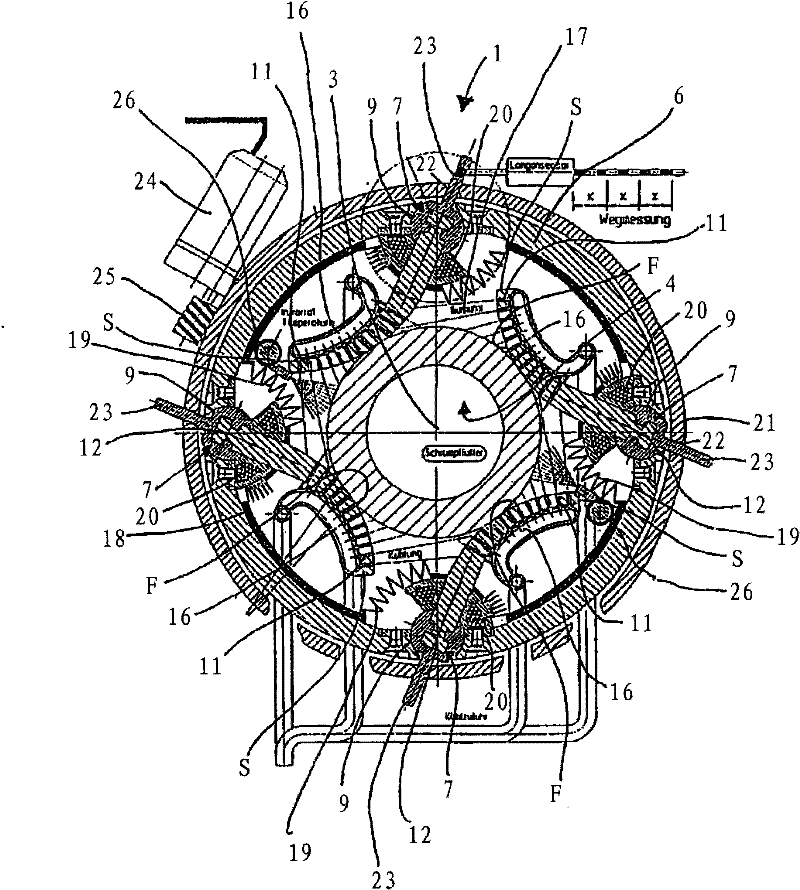

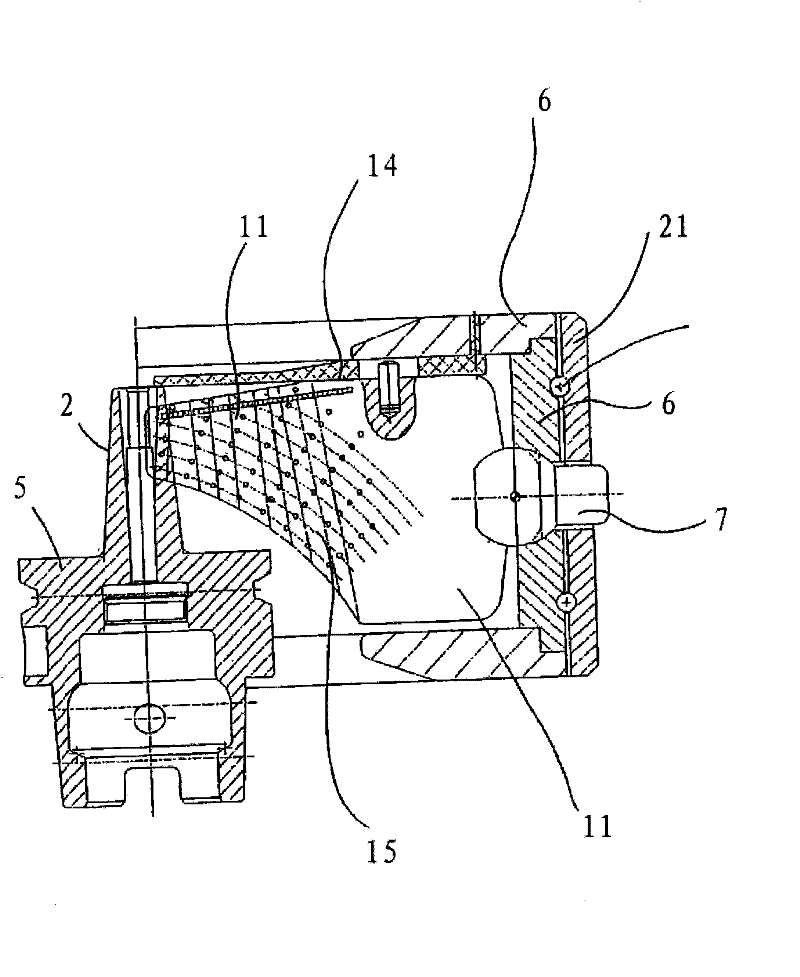

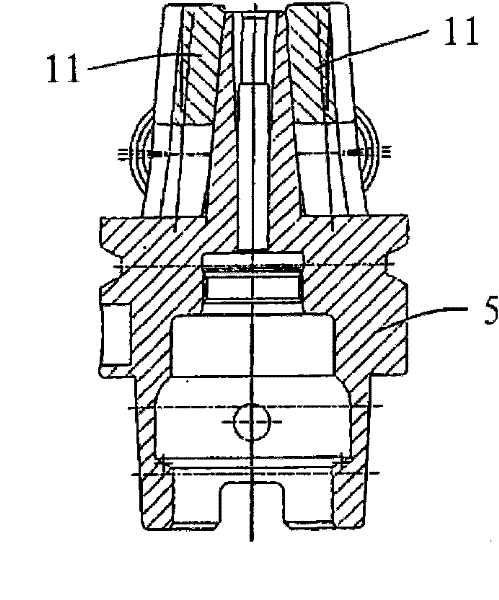

[0045] figure 1 An embodiment illustrating the basic principle of the device according to the invention is shown, here with reference to a chuck device for holding tools. Said device will then be referred to simply as an "induction clip device". The apparatus is provided with or incorporates a controller (not shown) which controls the pole pieces in a particular manner as will be described in detail below so that no substantially short magnetic flux occurs between adjacent pole pieces.

[0046] exist figure 1In , a cross-section of a sleeve section of a holding tool chuck, not shown in detail, is designated by reference number 2 . The sleeve section 2 rotates symmetrically with respect to the working axis of rotation 3 of the clamping tool chuck, in addition to the unbalance caused by tolerances, which cannot be completely avoided but is tolerable, the sleeve section 2 includes the receiver bore 4, the tool The shaft is inserted or can be inserted into the receiver bore 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com