Plug connector for flexible conductor films

A plug connector, conductive connection technology, applied in the direction of conductive connection, connection, fixed connection, etc., can solve the problems of very thin conductor track damage, conductor track interruption, etc., to achieve simple contact, avoid cutting process, and excellent electrical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

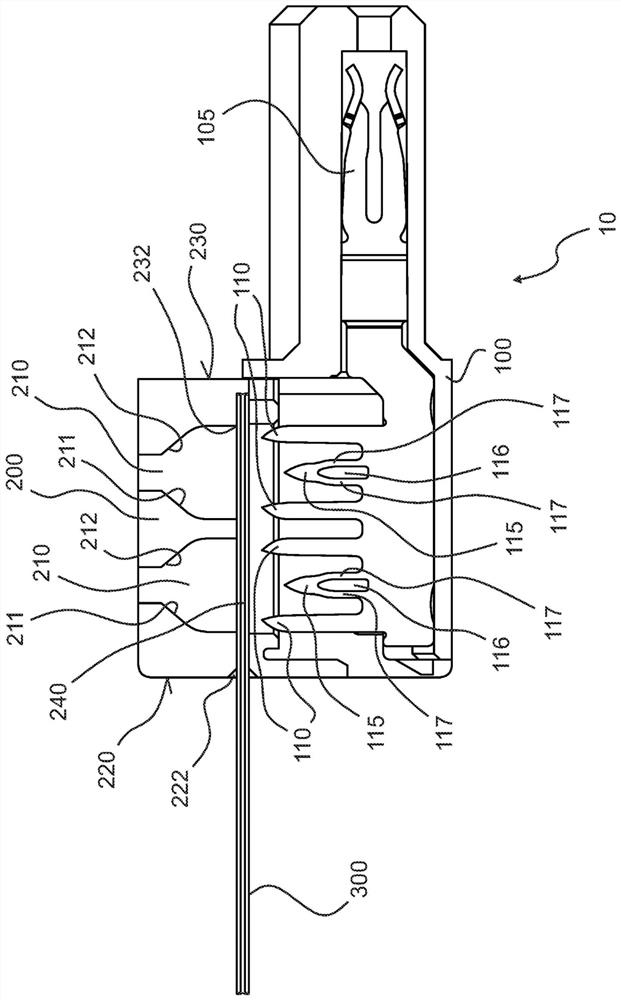

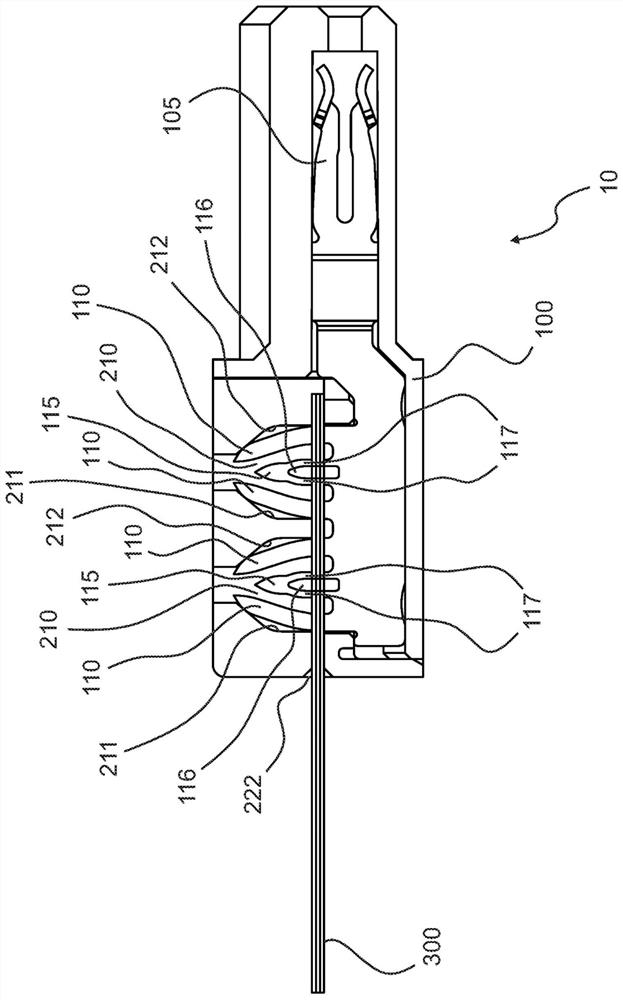

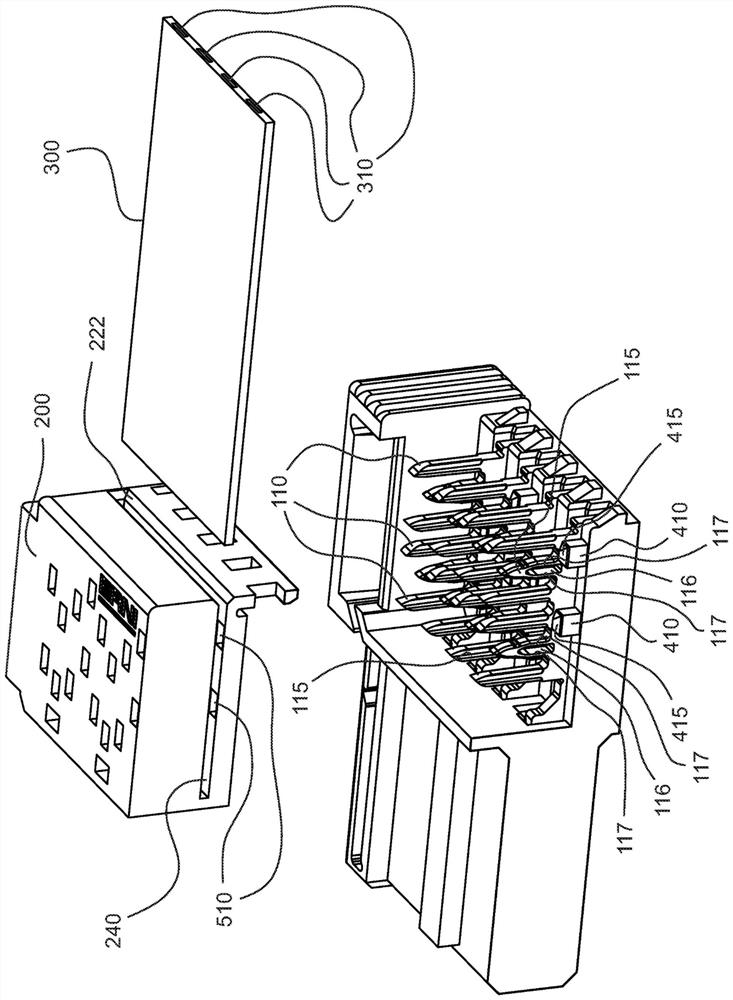

[0042] The plug connector, generally designated 10, has a housing consisting of two parts. In the first plug connector housing part 100 the plug contacts are arranged in the shape of the plug contacts 105 in a per se known manner. Blades 110 , 115 are electrically conductively connected to the plug contact 105 , said blades 110 , 115 are arranged one behind the other in a straight line, wherein in each case a shorter blade 115 is surrounded by two longer blades 110 . The shorter blade 115 has an opening 116 via which the flexibility of the blade 115 is achieved, as will be explained in more detail below.

[0043] The second plug connector housing part 200 is formed as a single part. The second plug connector housing part 200 is formed in such a way that by being inserted into a corresponding opening in the first plug connector housing part 100 it can be secured thereto and latched therewith. The second plug connector housing part 200 has an opening 222 on the side wall 220 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com