Full-automatic series verification calibrating device with pressure-resistant water meter

A verification device and fully automatic technology, applied in testing/calibration devices, measuring devices, instruments, etc., can solve the problems of inability to read, disordered image readings, and high computer operation requirements, and achieve the effect of improving work efficiency and use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

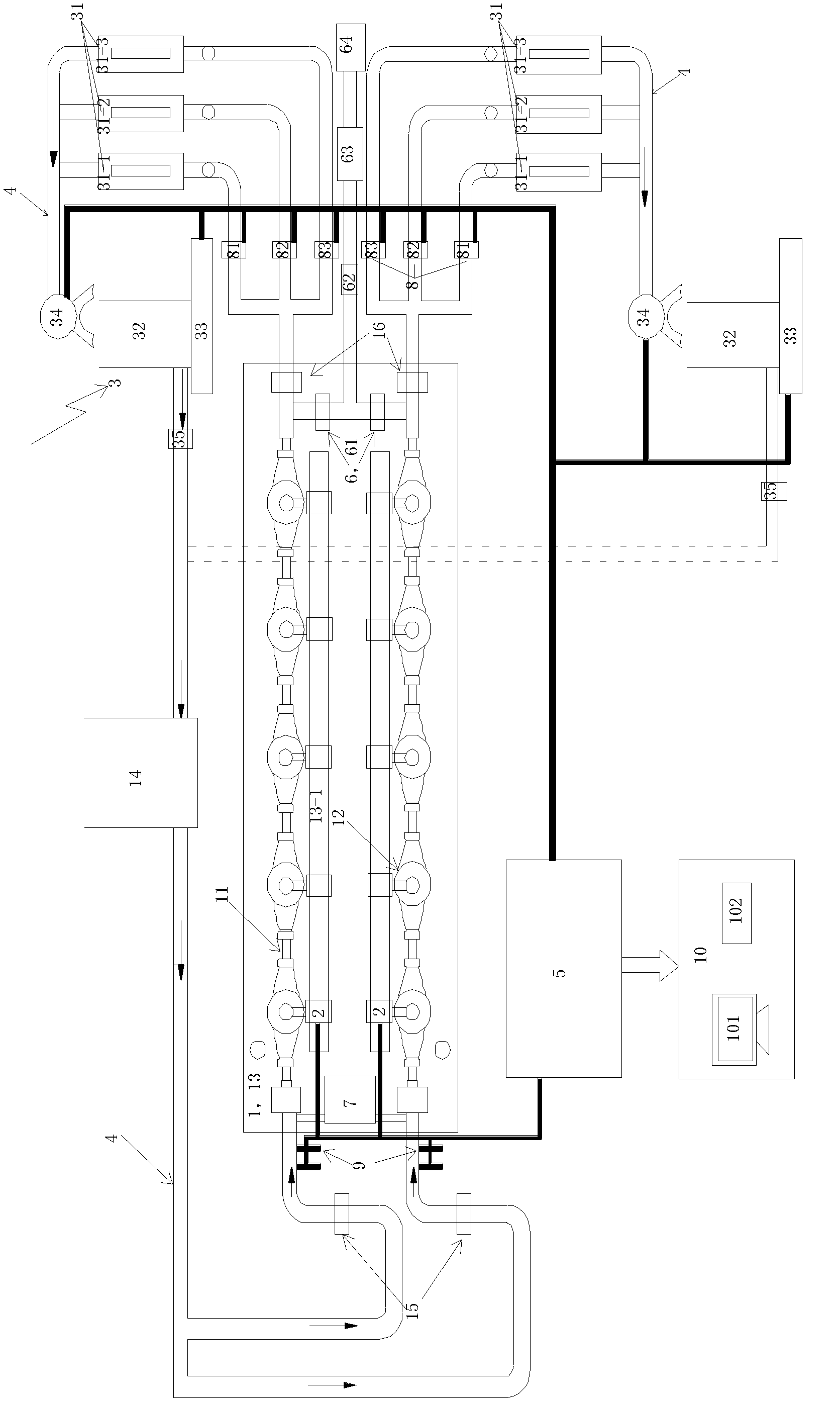

[0036] See figure 1 , the fully automatic calibrating and testing device for pressure-resistant water meters in series in this implementation example, including water meter verification basic mechanism 1, flow counting mechanism 2, metering mechanism 3, pipeline 4, control system 5, exhaust mechanism 6, automatic pressure detection Mechanism 7, measuring solenoid valve 8 and temperature sensor 9.

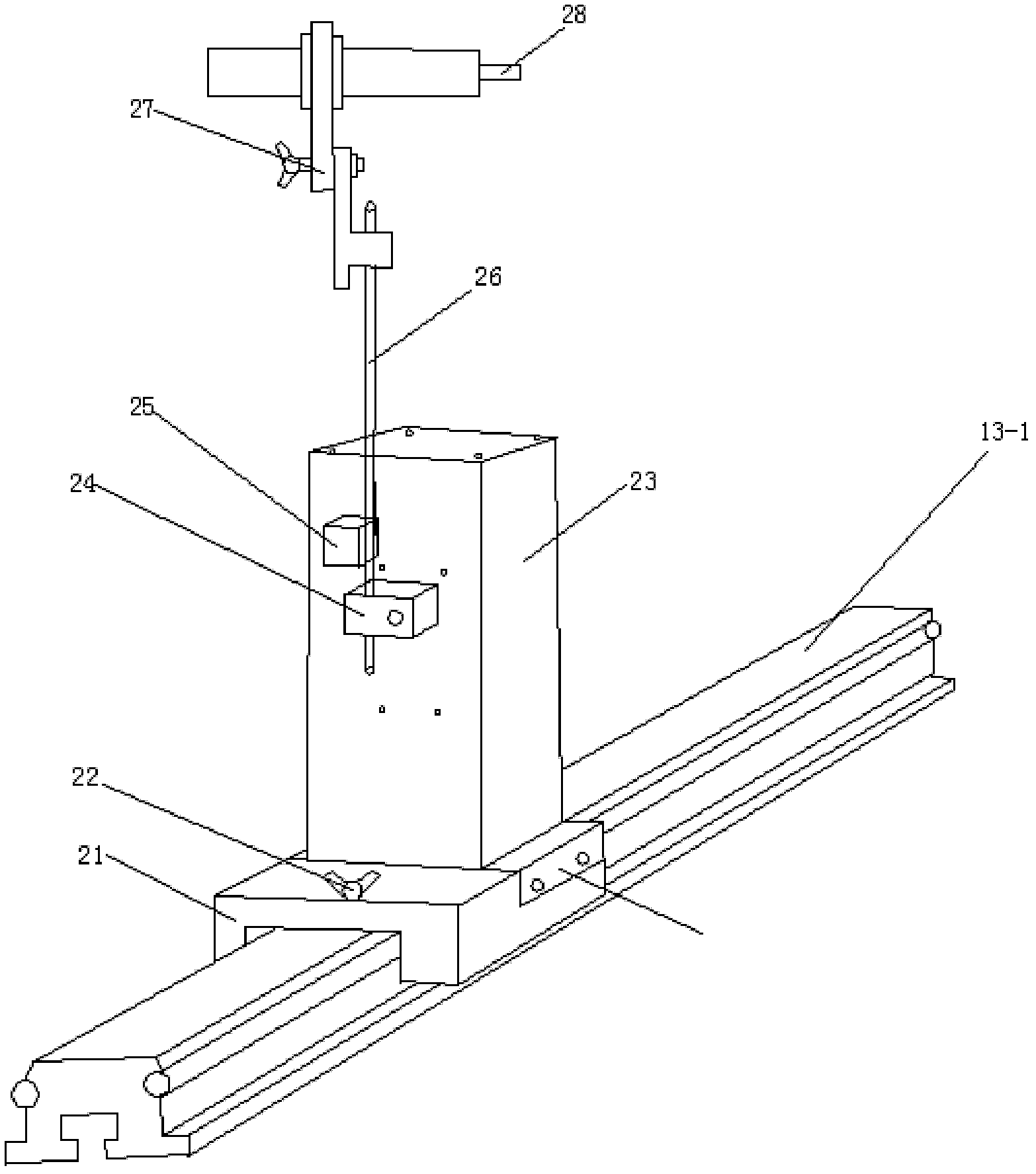

[0037] The water meter verification basic mechanism 1 includes multiple test straight pipe sections 11 and multiple water meters to be tested 12 , a meter calibration platform 13 , a standard water source device 14 , a general water inlet valve 15 and a pressure test valve 16 . Multiple test straight pipe sections 11 and multiple water meters 12 to be tested are connected in series at intervals to form a test pipe section, figure 1 There are two rows of test pipe sections in the middle, which are all set on the meter calibration platform 13, and the meter calibration platform 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com