Patents

Literature

313results about How to "Eliminate human error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

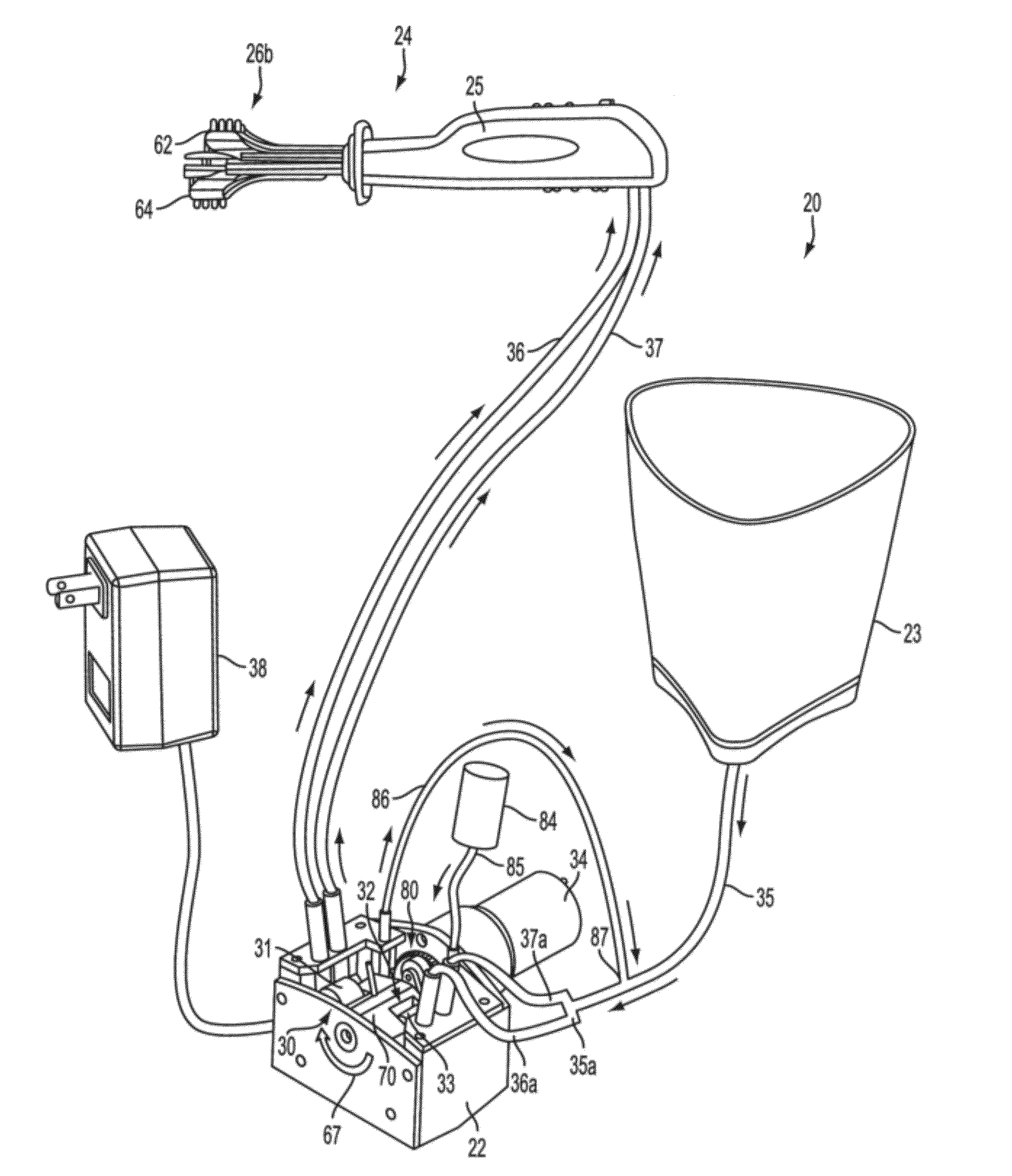

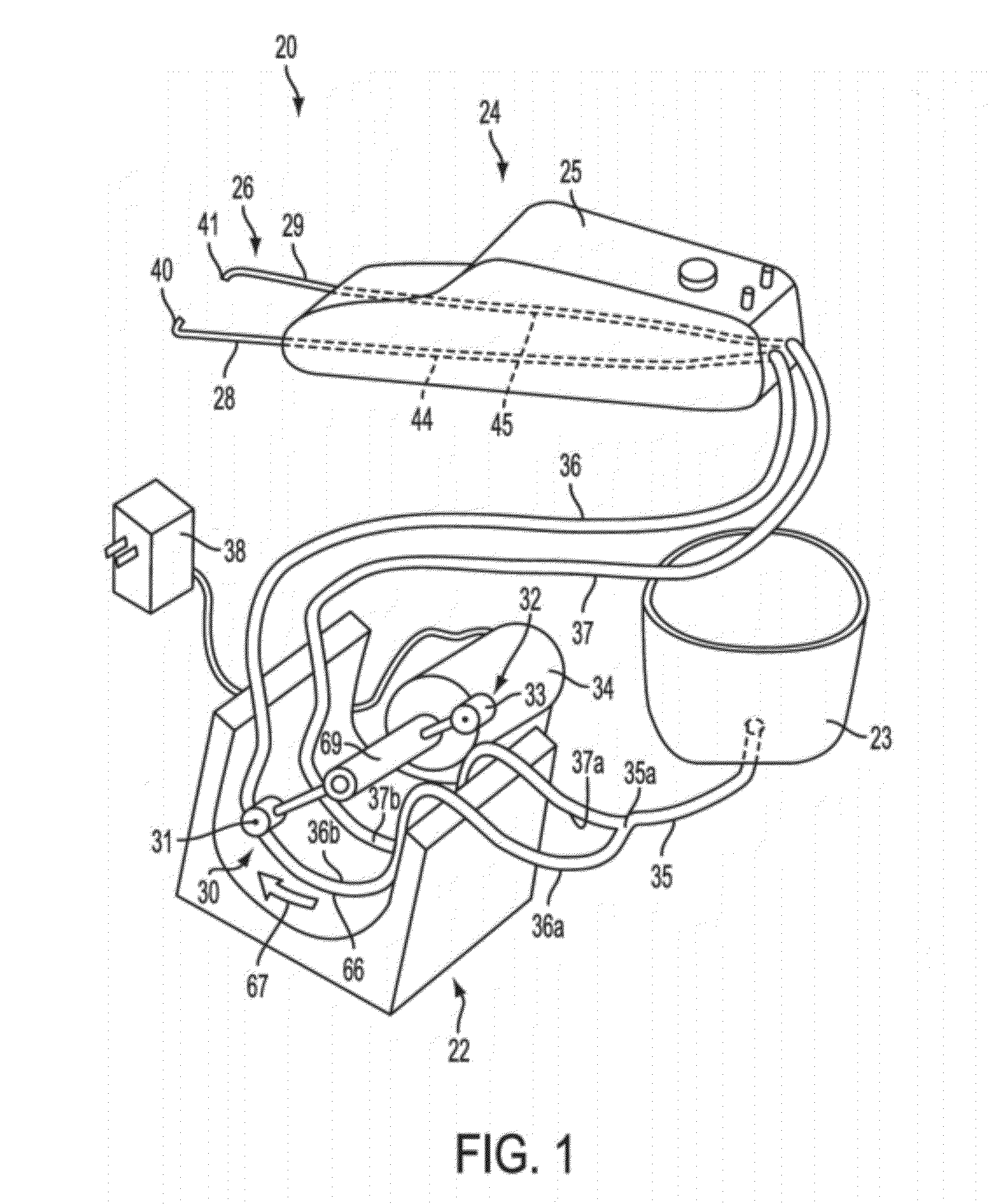

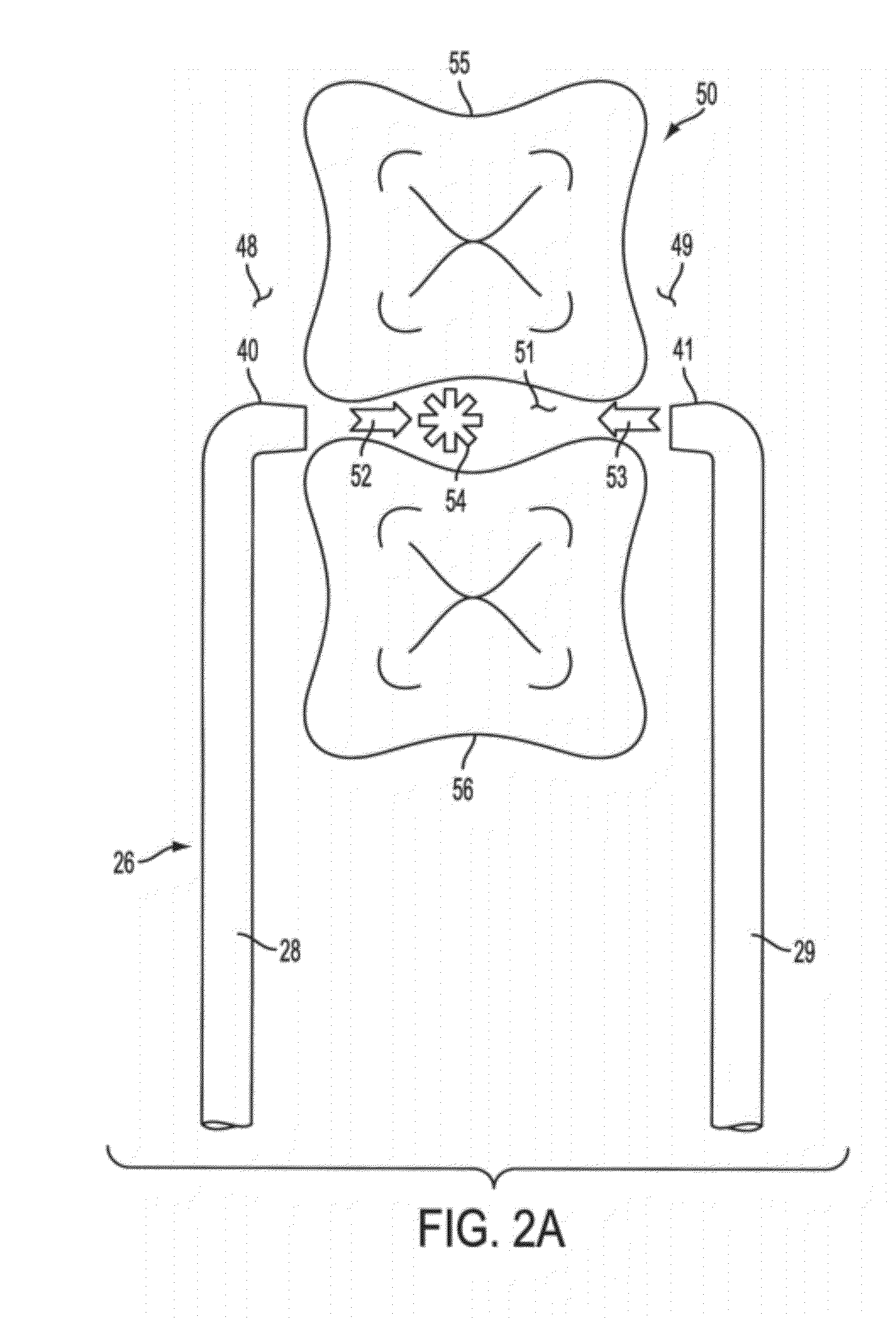

Oral Irrigation and/or Brushing Devices and/or Methods

InactiveUS20120064480A1Promotes Oral HealthPrecise positioningGum massageBristleBrush deviceDentistry

An integrated or combined oral care device having an oral cleaning device including a handle, and one or more cleaning head assemblies and a fluid irrigation assembly attached or attachable to the oral cleaning device.

Owner:CRA LABS

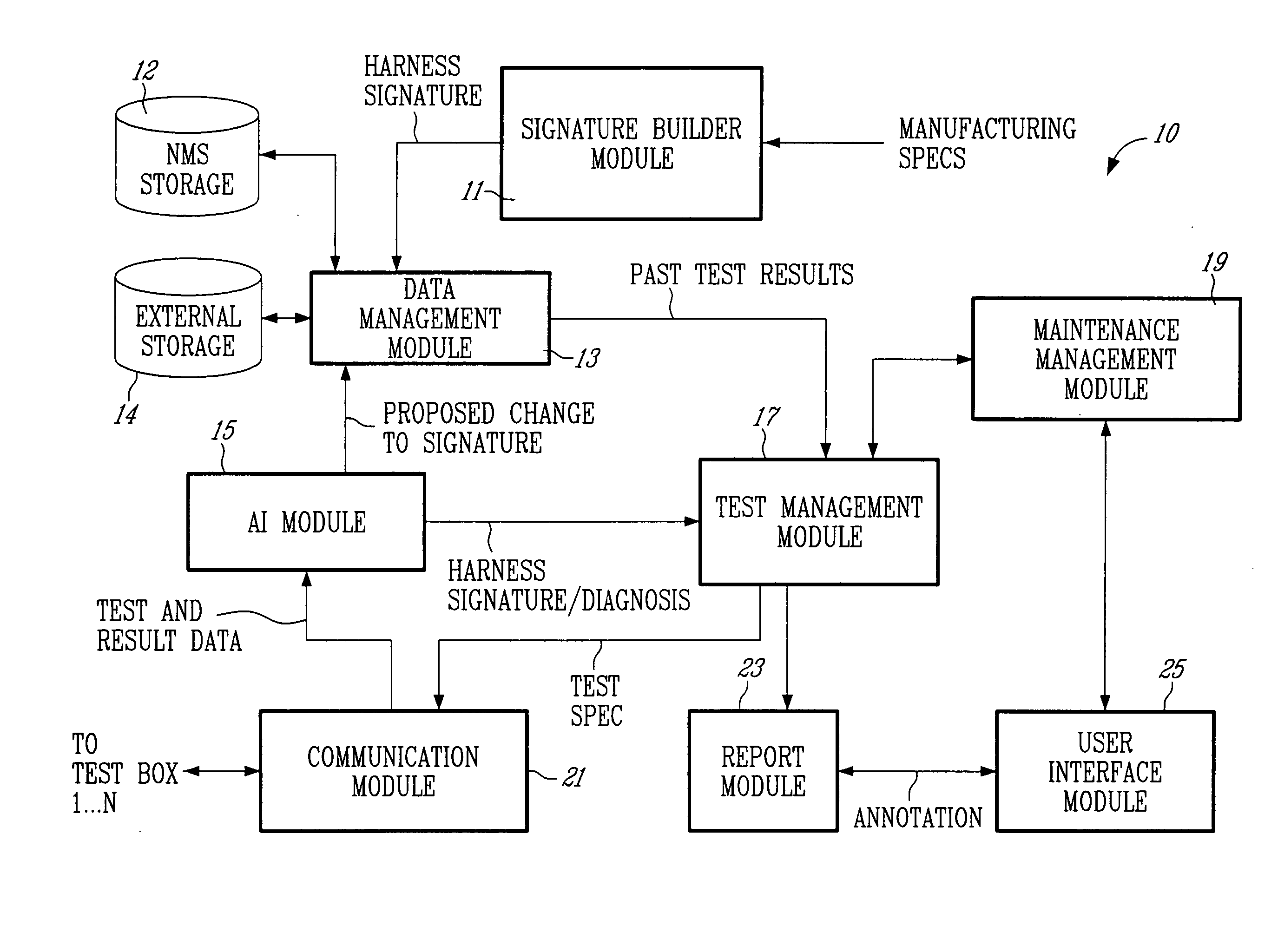

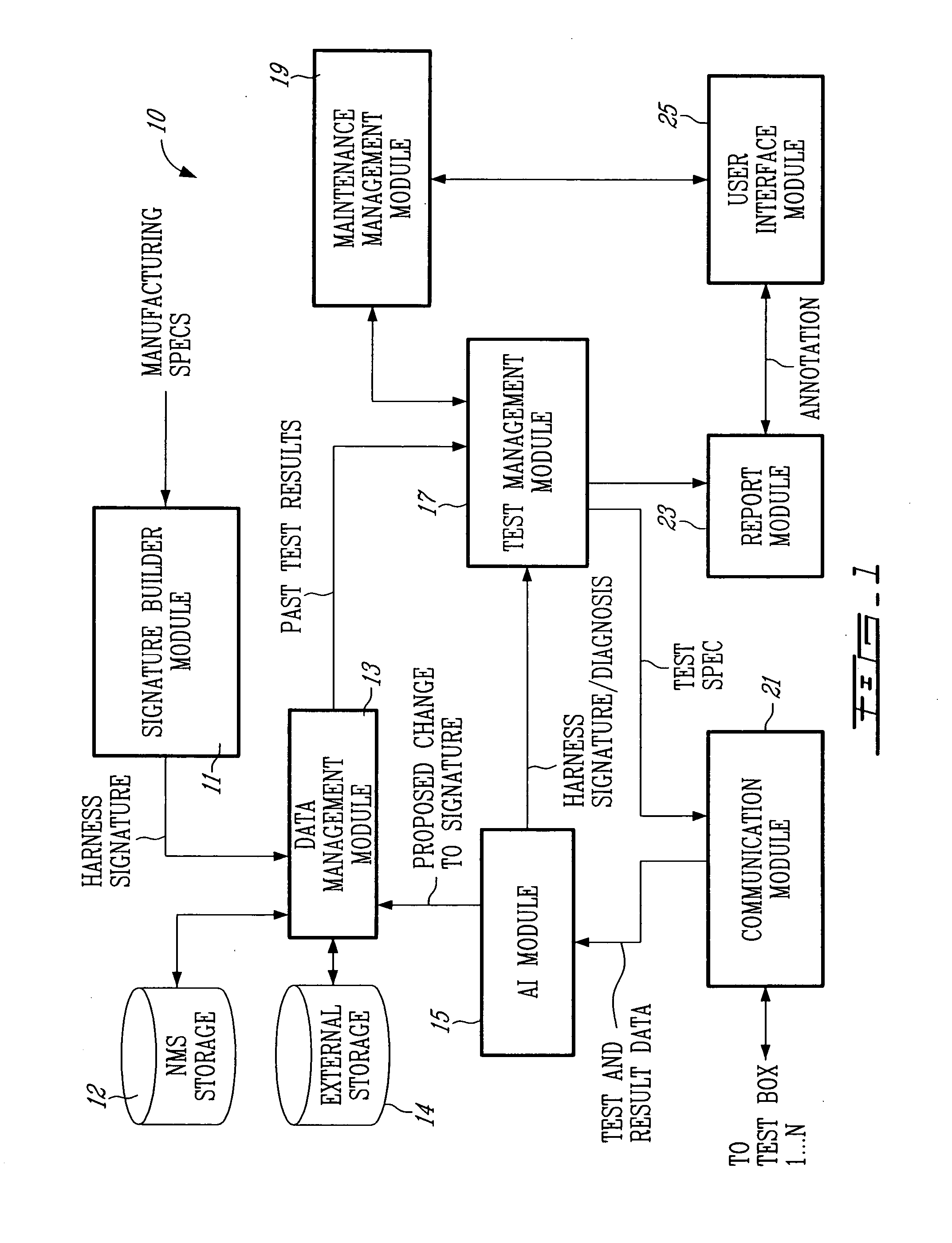

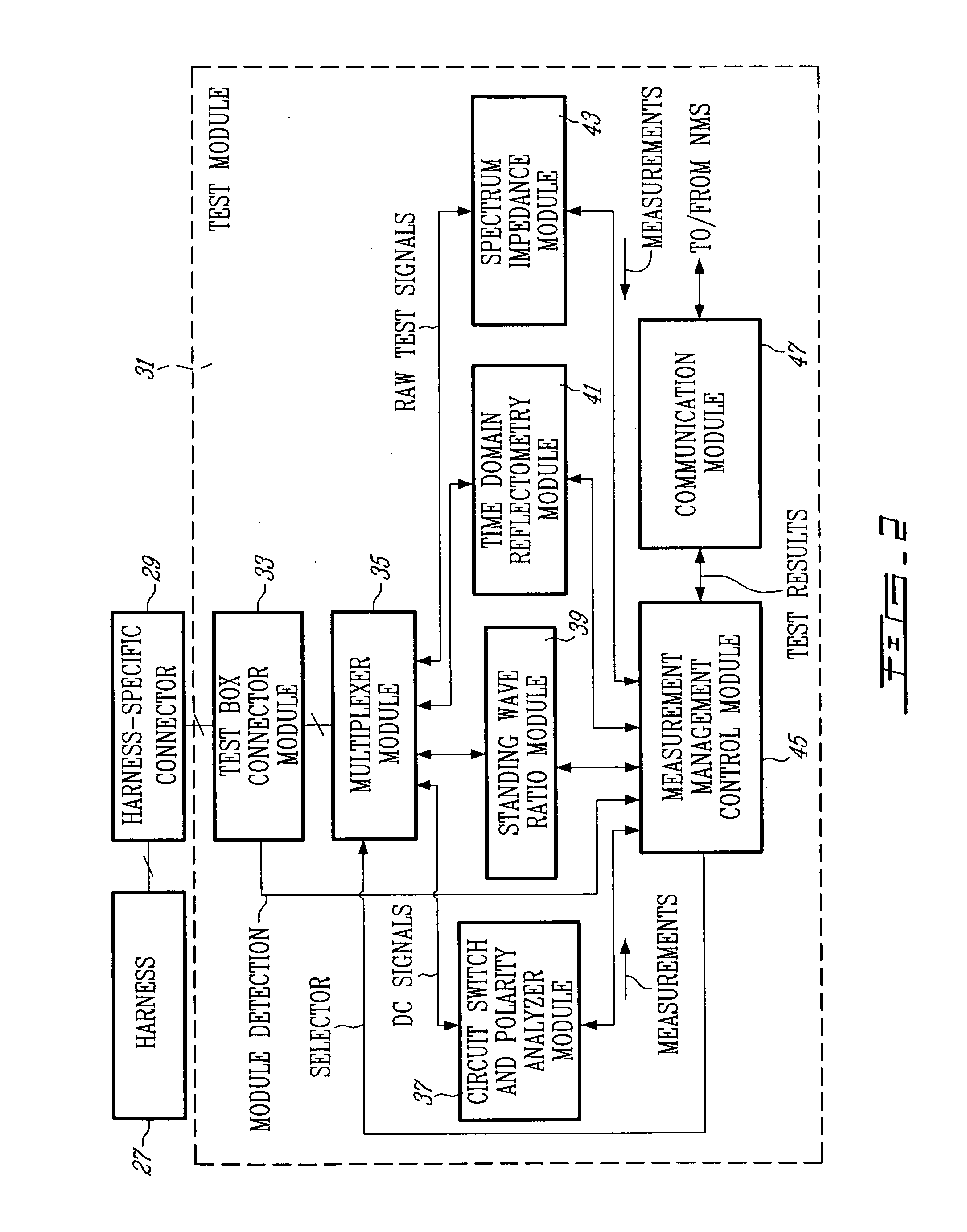

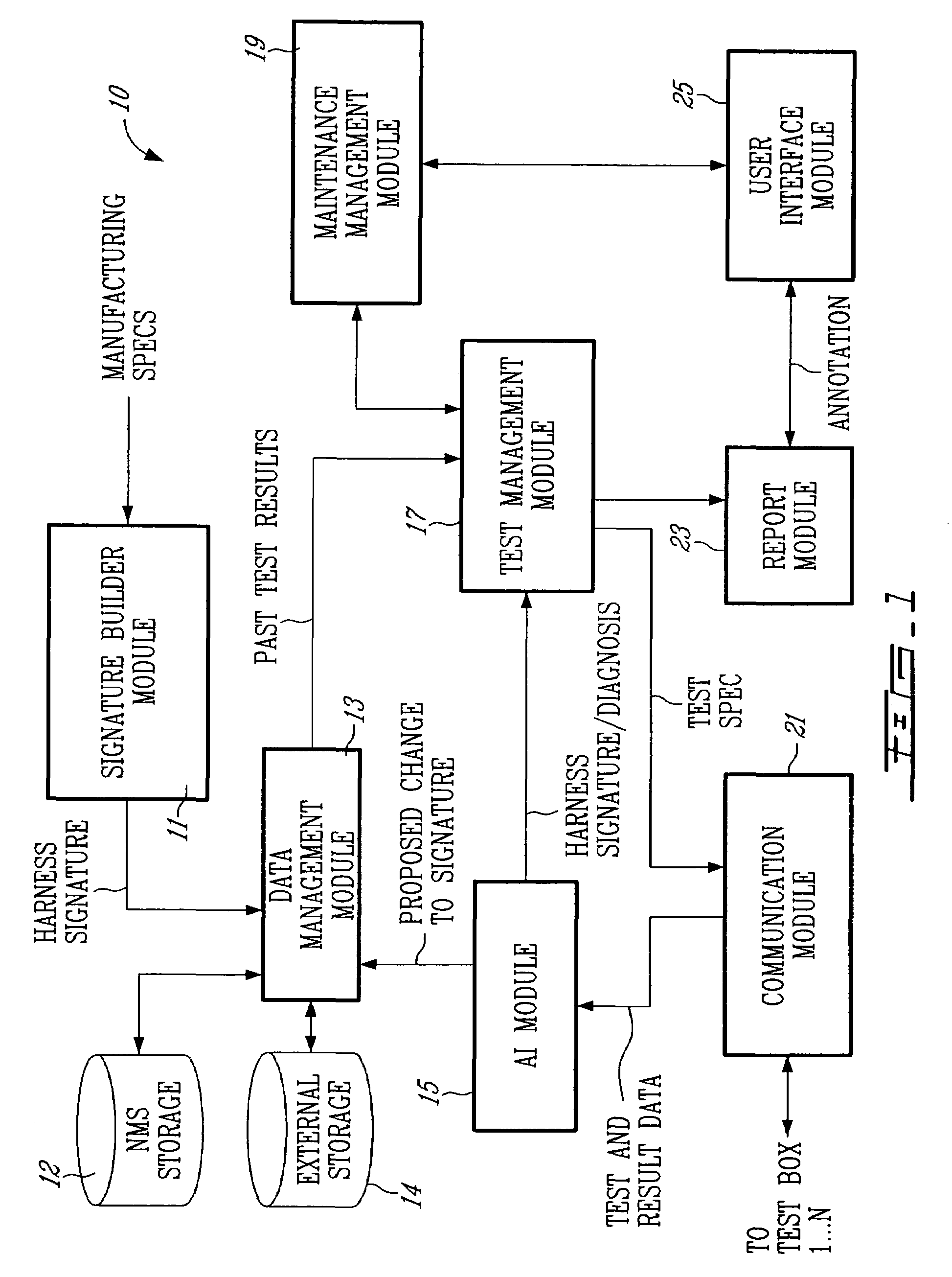

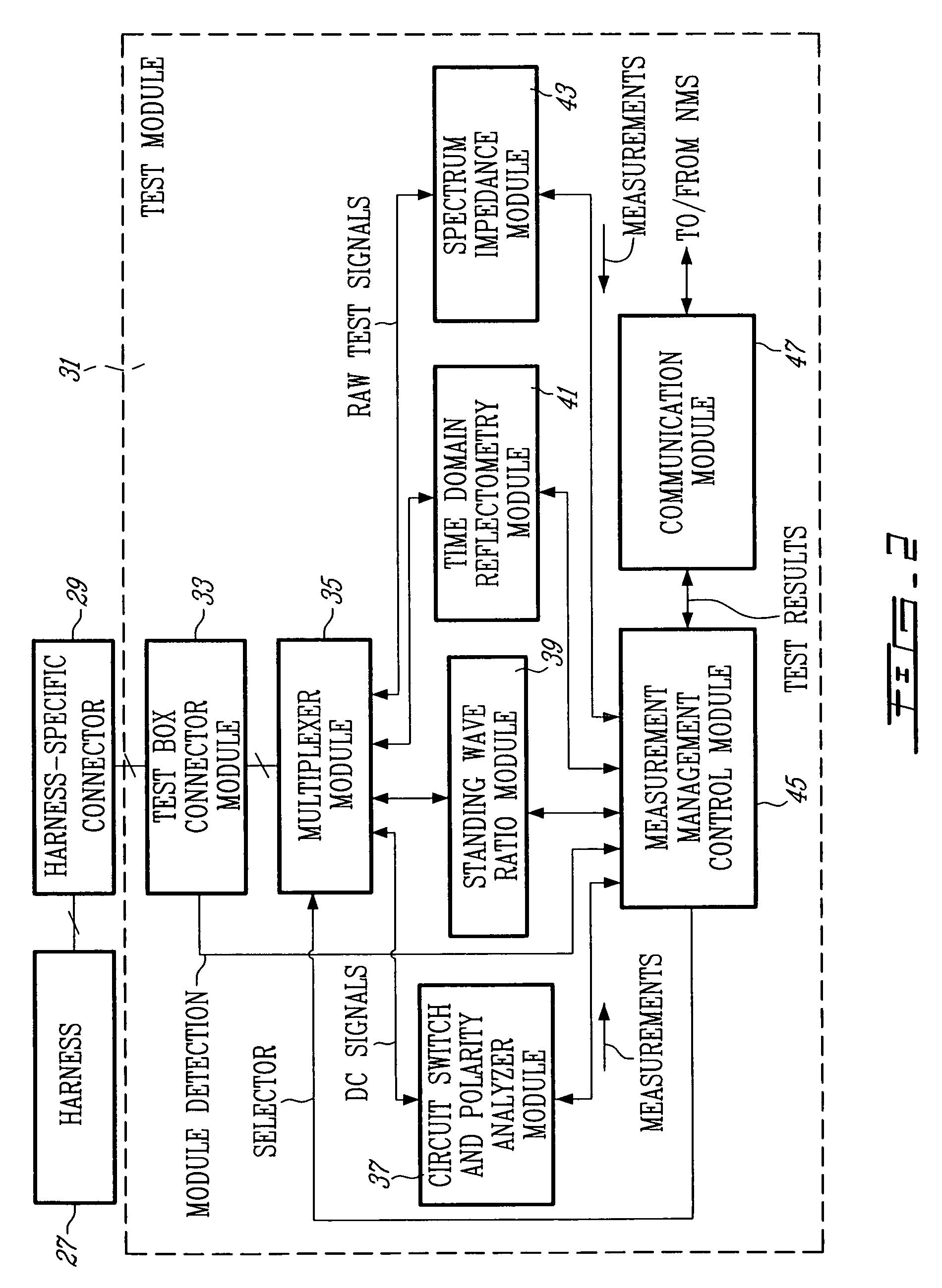

Wireless portable automated harness scanner system and method therefor

ActiveUS20060043976A1Shorten the timeLow costResistance/reactance/impedenceFault location by conductor typesTest measurementEngineering

A method for testing an installed wiring harness is provided. The method comprises providing a signal source testing module at a first node in the wiring harness and a measurement termination testing module at a second node in the wiring harness. A central management module for controlling the testing modules coordinates the testing modules to send testing signals for performing tests and recording test measurements of the installed wiring harness. The testing modules send the test measurements to the management module.

Owner:ZIOTA TECH

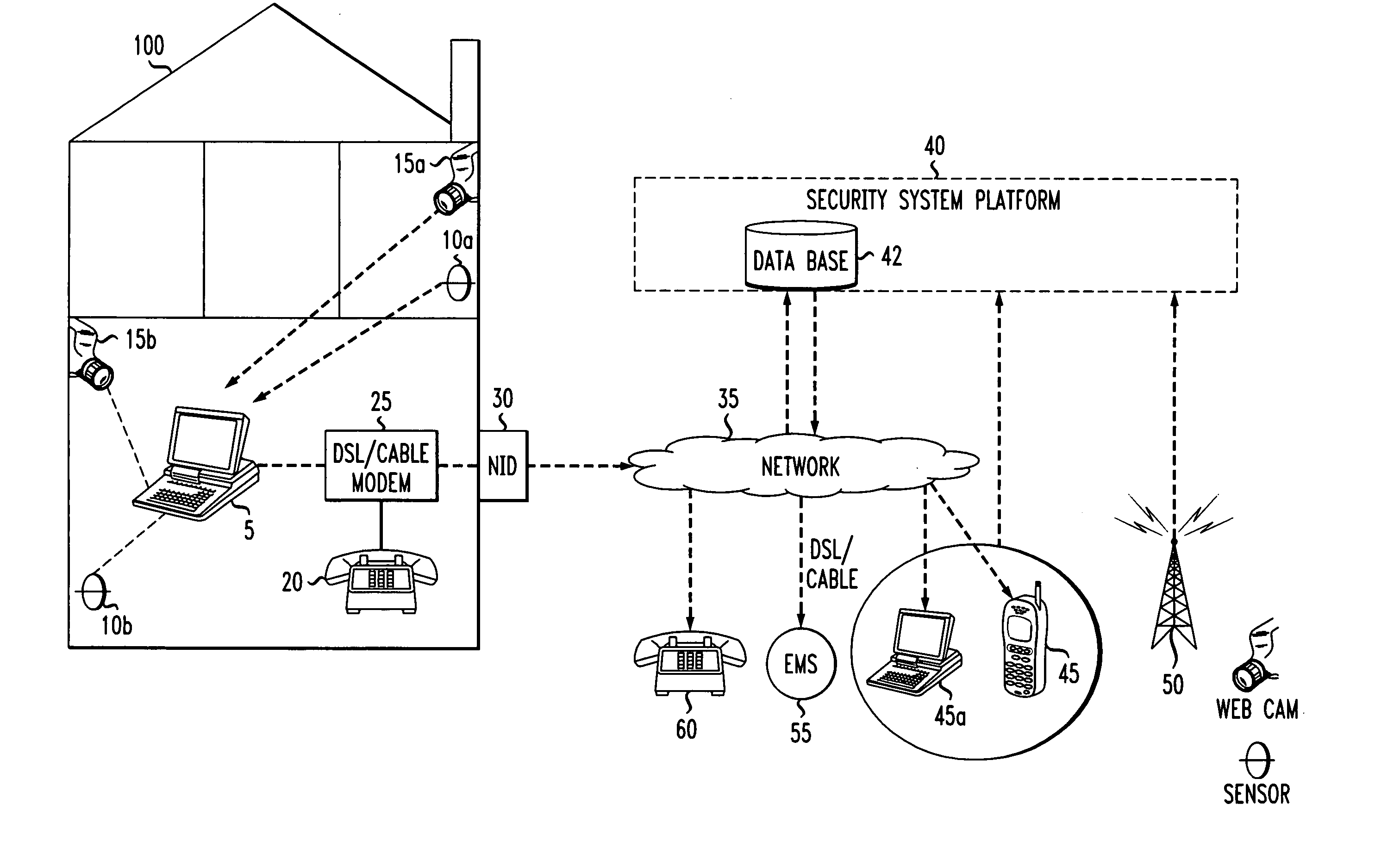

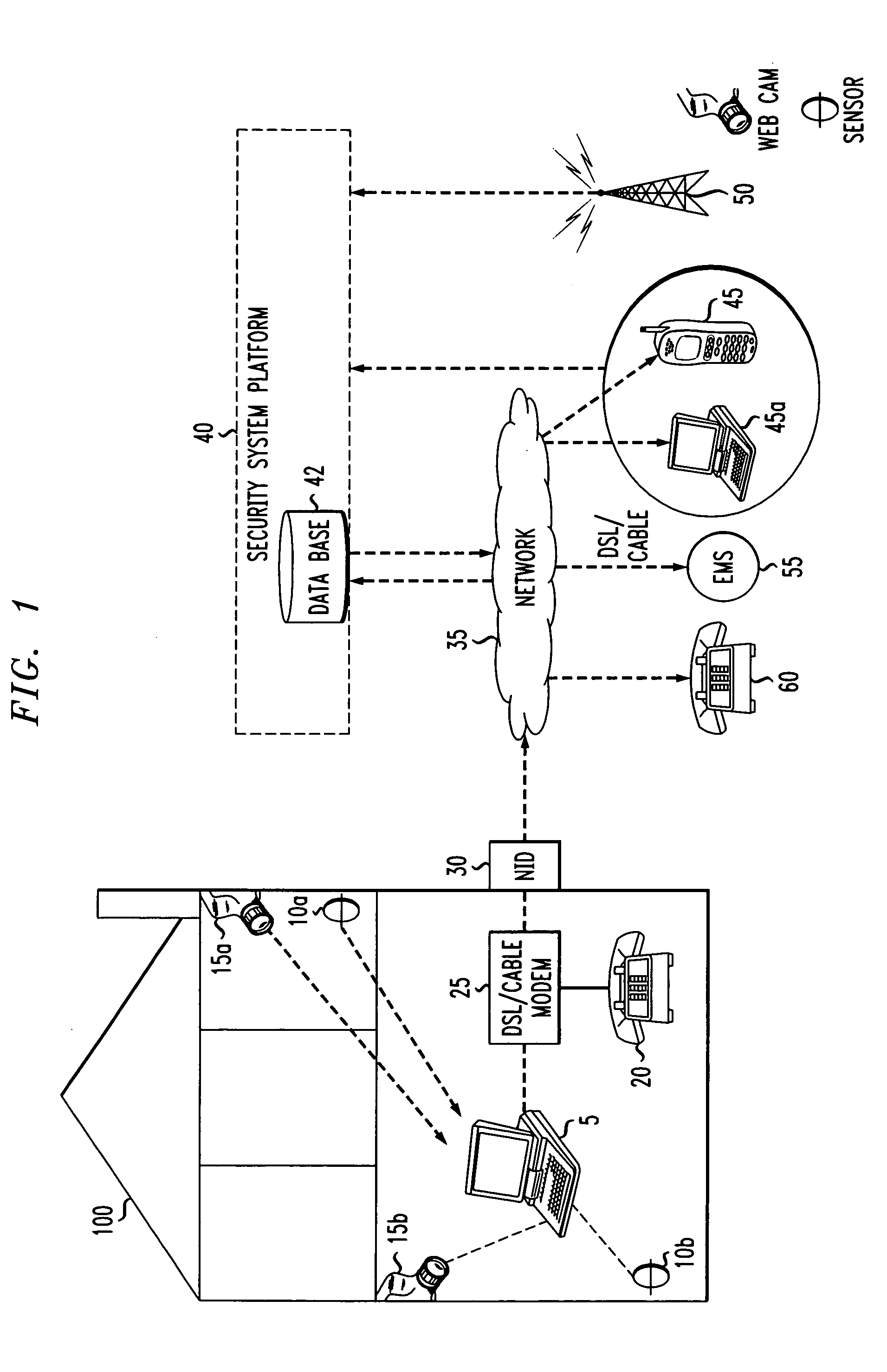

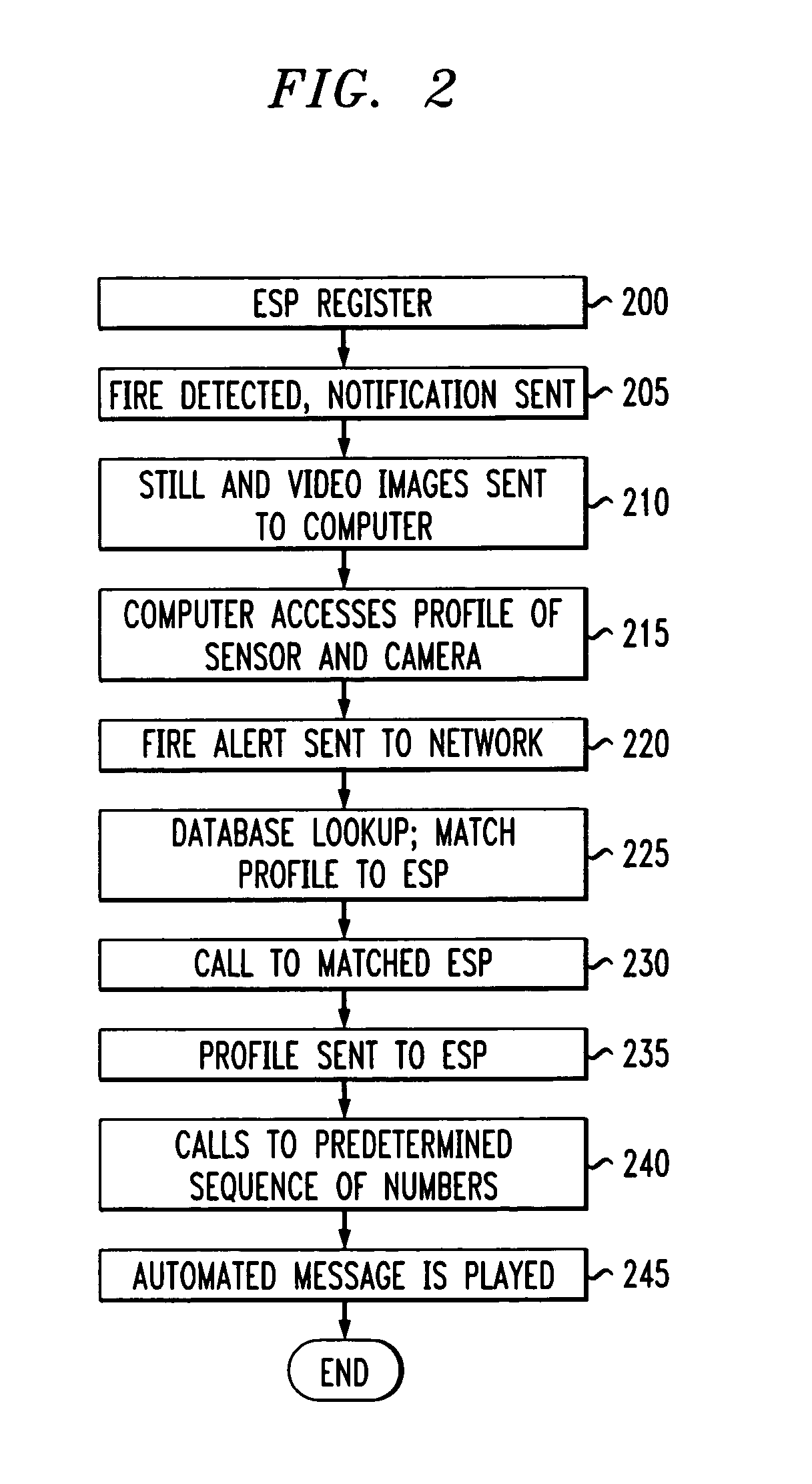

Home security administration platform

InactiveUS6943682B1Error delayShorten the timeBurglar alarm electric actuationService personnelHome security

A network may receives tracking information of various emergency services personnel, so that when a security breach has occurred at a residence or place of business, the network receives a surveillance profile from a home computer that is disposed where the detector is located, and dispatch the most geographically appropriate emergency services personnel as determined based on the tracking information. The surveillance profile may include its address, location within the residence of place of business, and a physical description or layout of the premises in which the sensor is located. Then, a verification protocol is initiated by calling a predetermined sequence of telephone numbers set by the subscriber to the security system. Dispatching of the appropriate emergency services personnel includes the network accessing a security platform database to find corresponding emergency services personnel to respond to the detected security breach in accordance with the information received in the surveillance profile.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

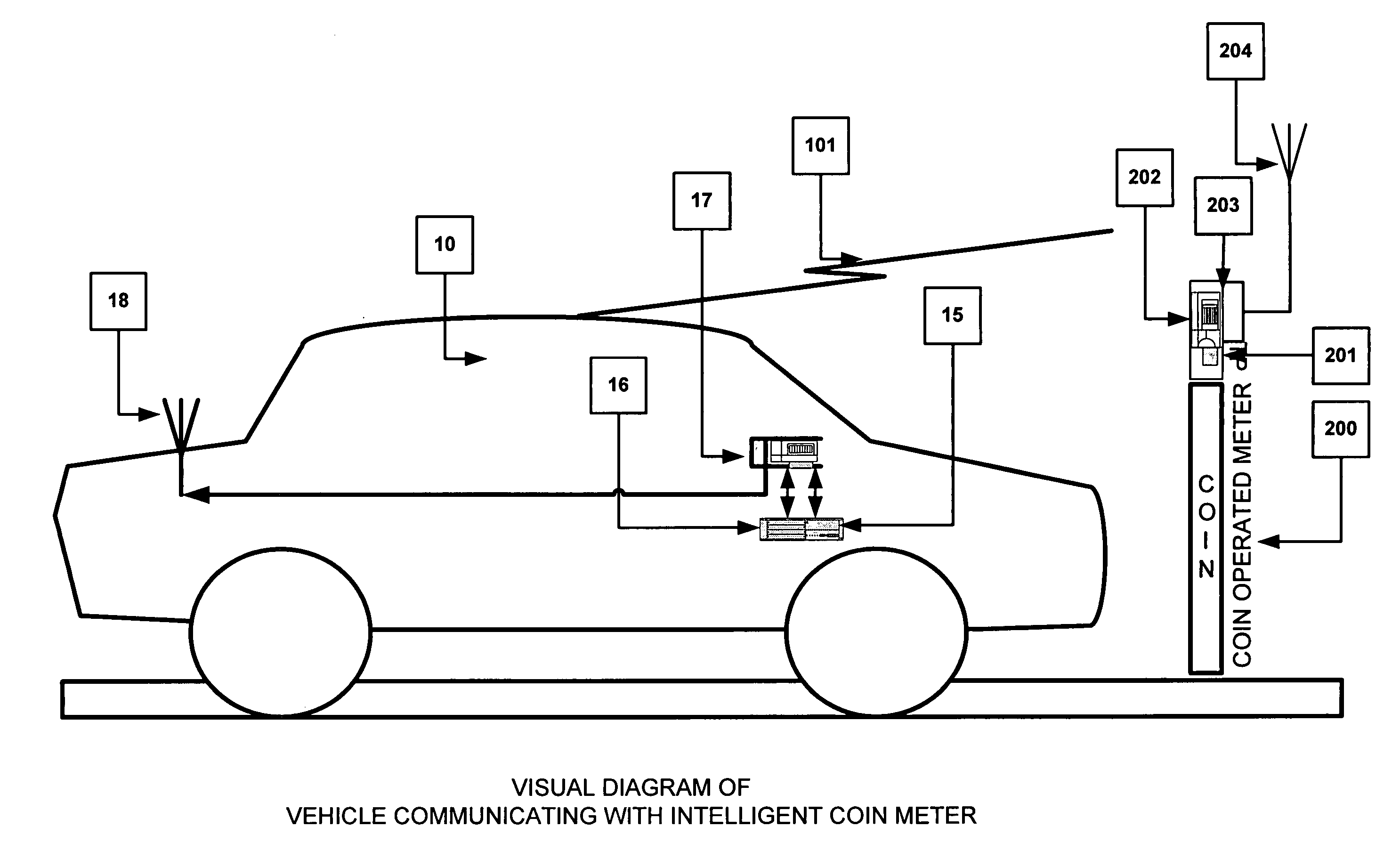

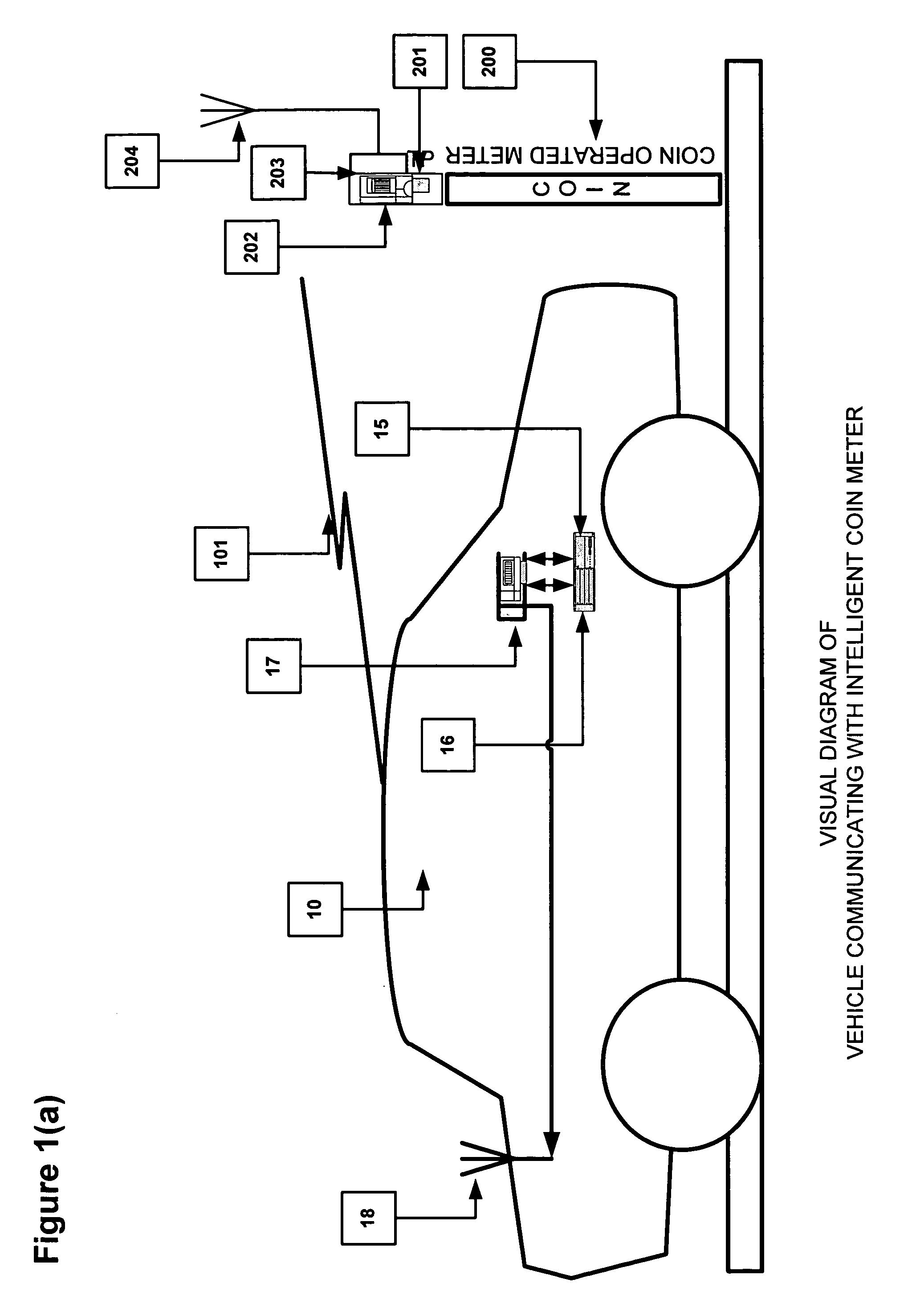

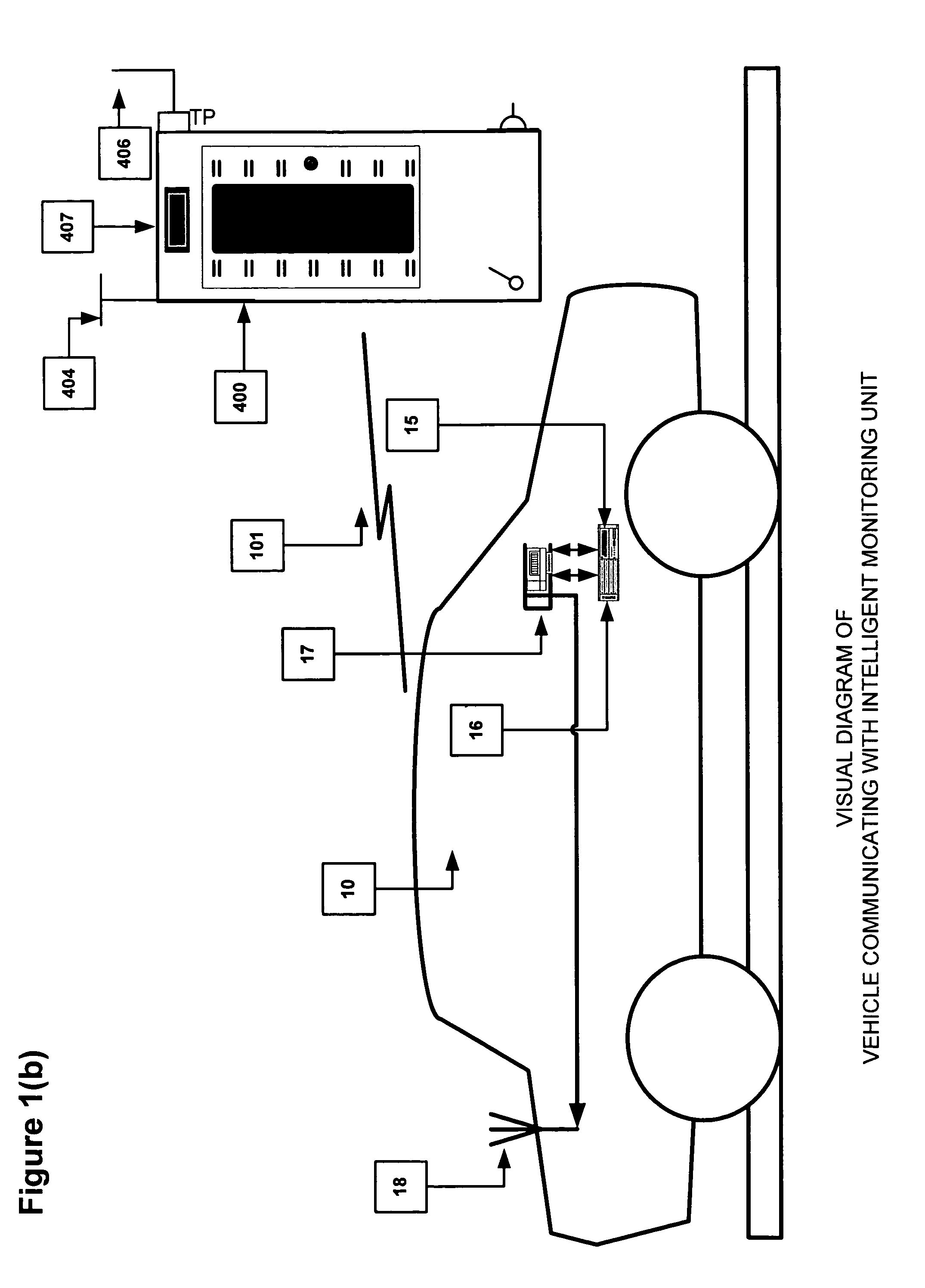

Automobile communication and registry system

InactiveUS7230545B2Increase incomeFacilitate the enforcement of parkingElectric signal transmission systemsTicket-issuing apparatusTransceiverVehicle identification

The invention is directed to method and system for providing automatic vehicle registration and control via transceiver-facilitated wireless communication of a unique vehicle identification code and a vehicle location code from a vehicle.

Owner:NATTEL GROUP

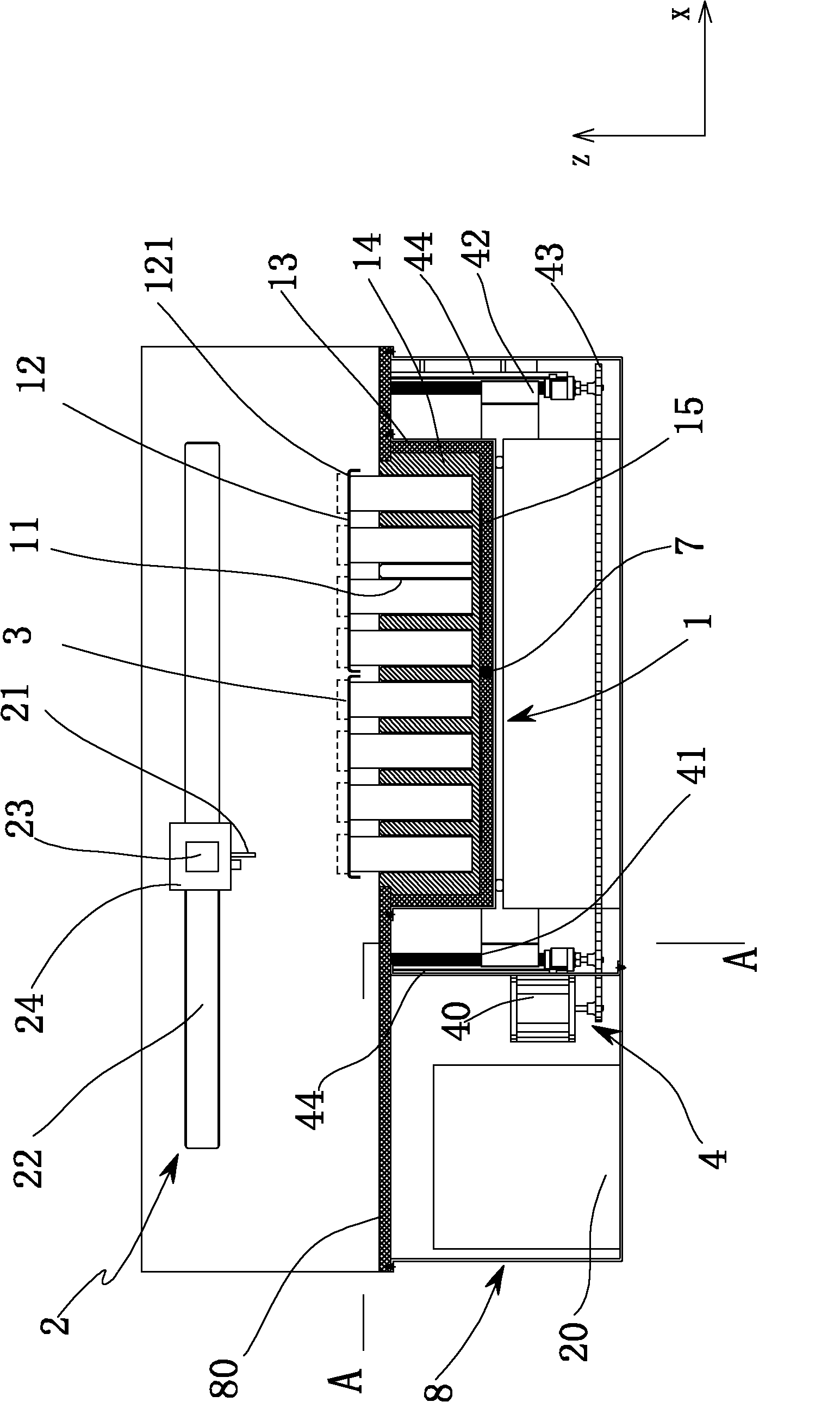

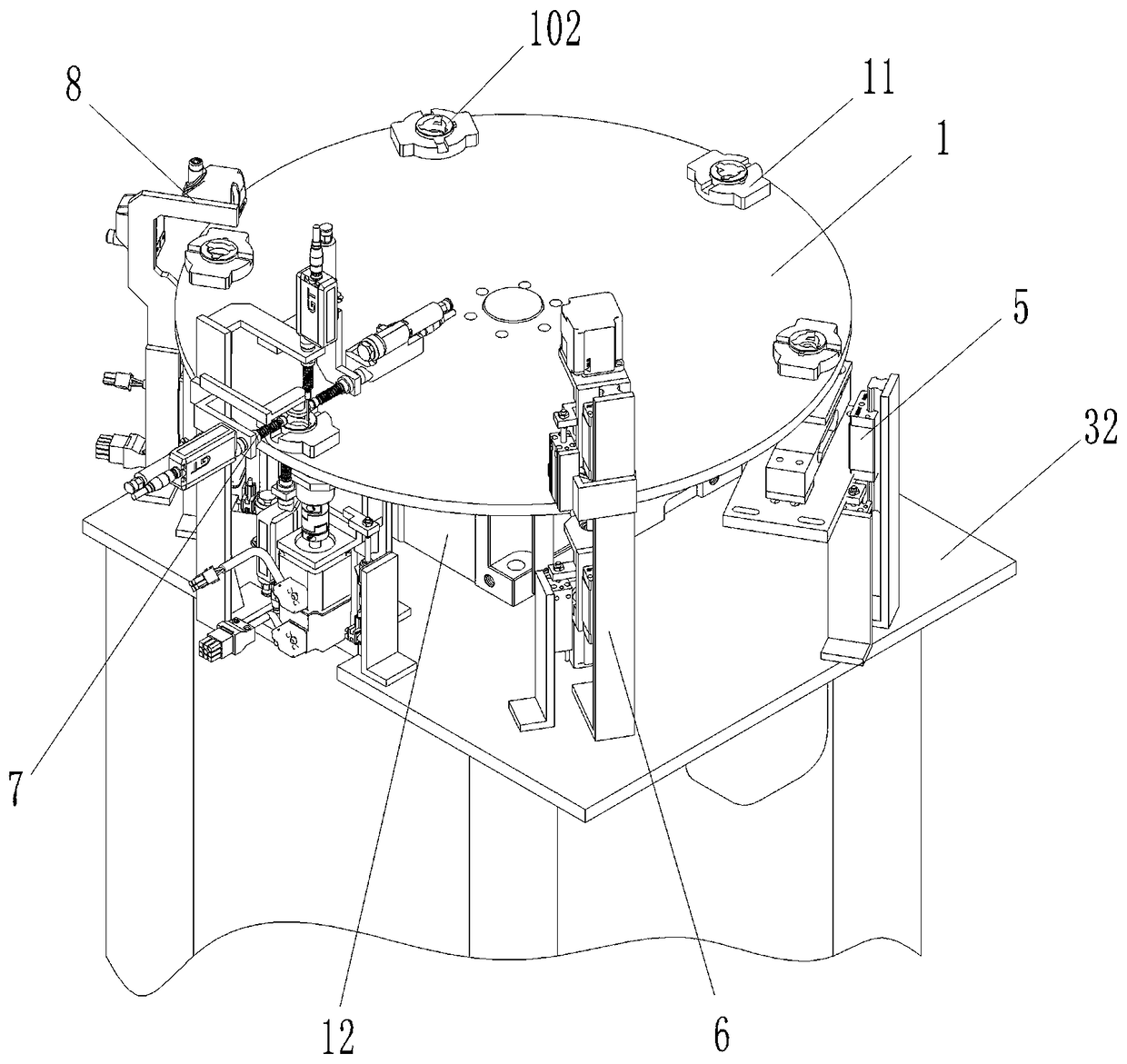

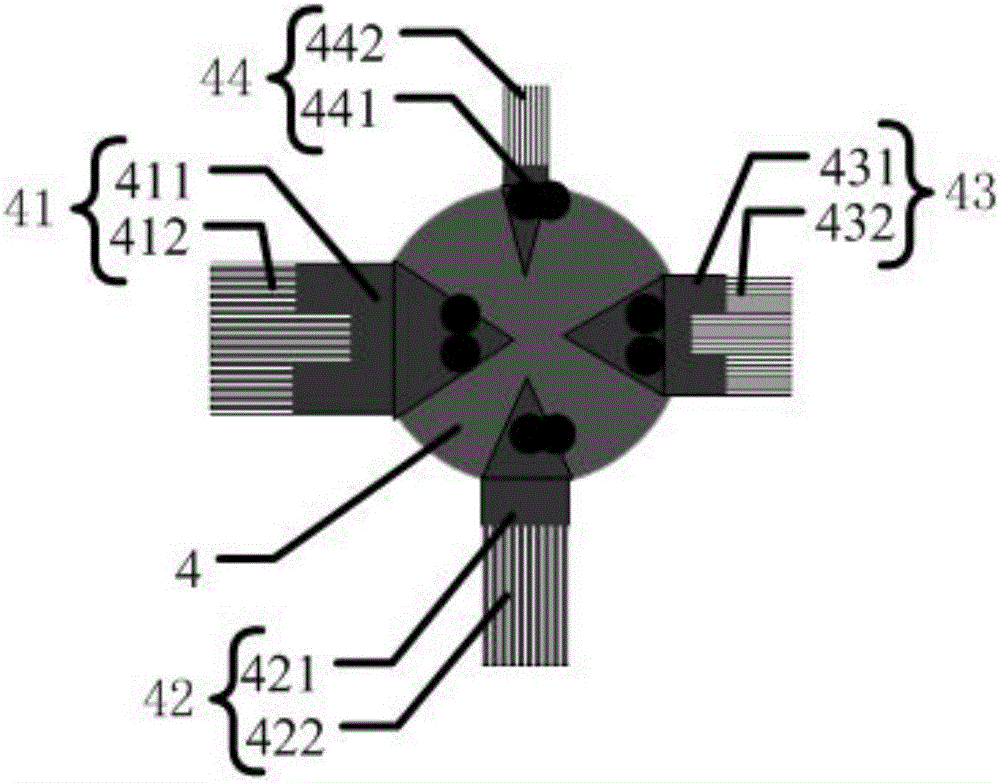

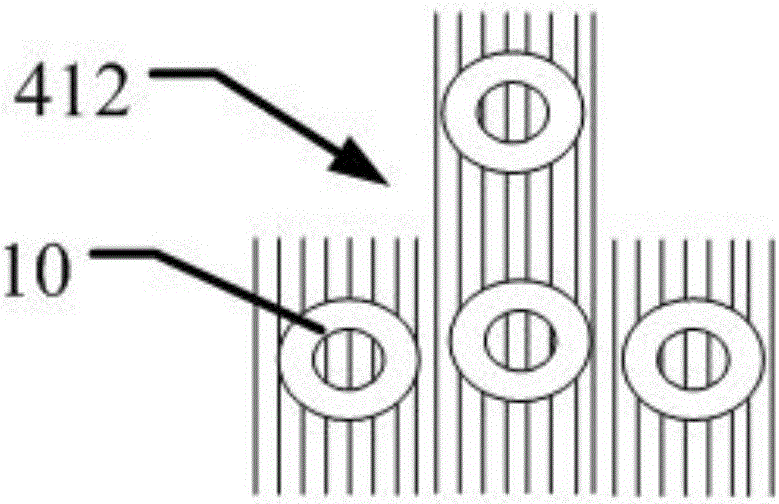

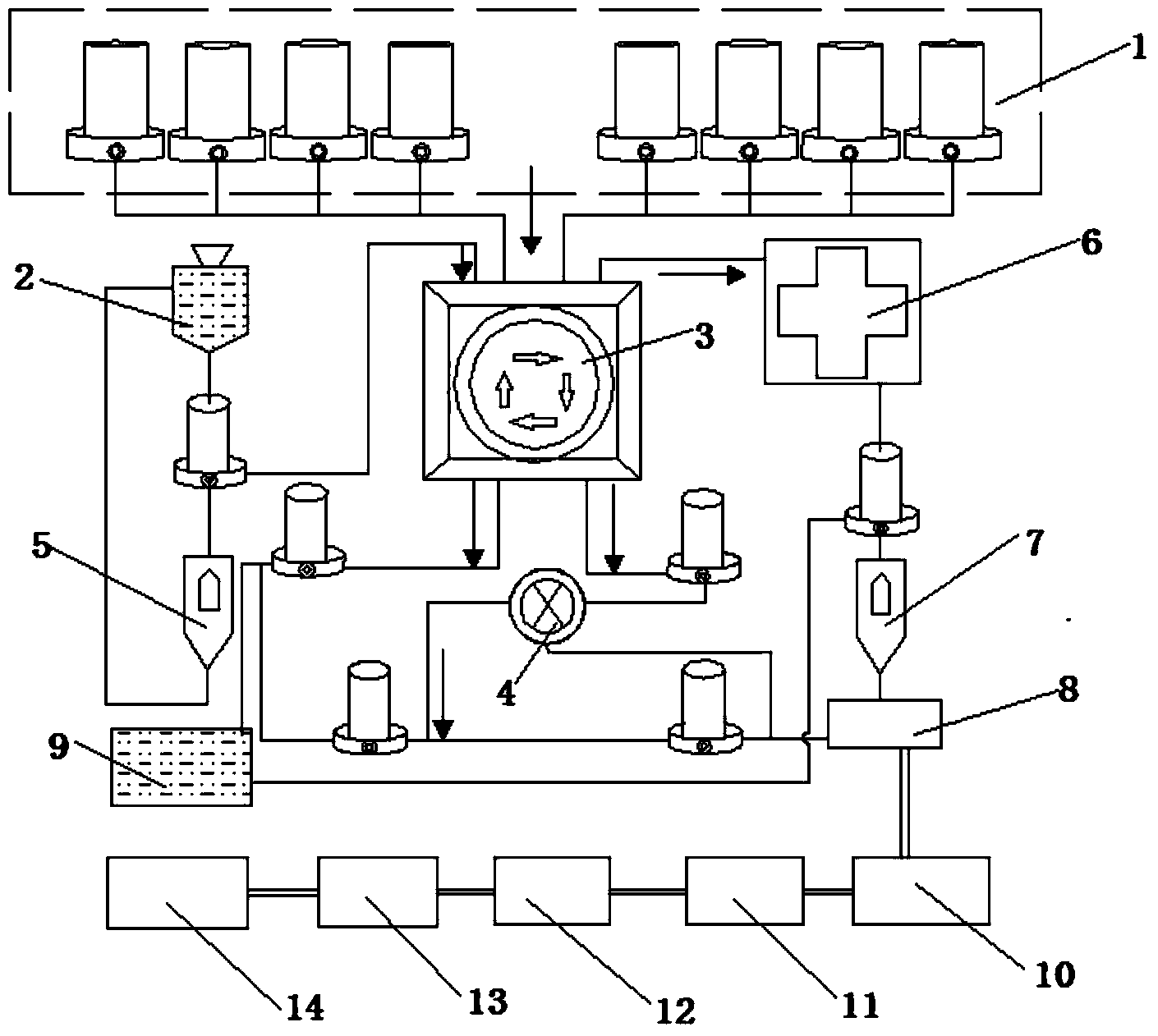

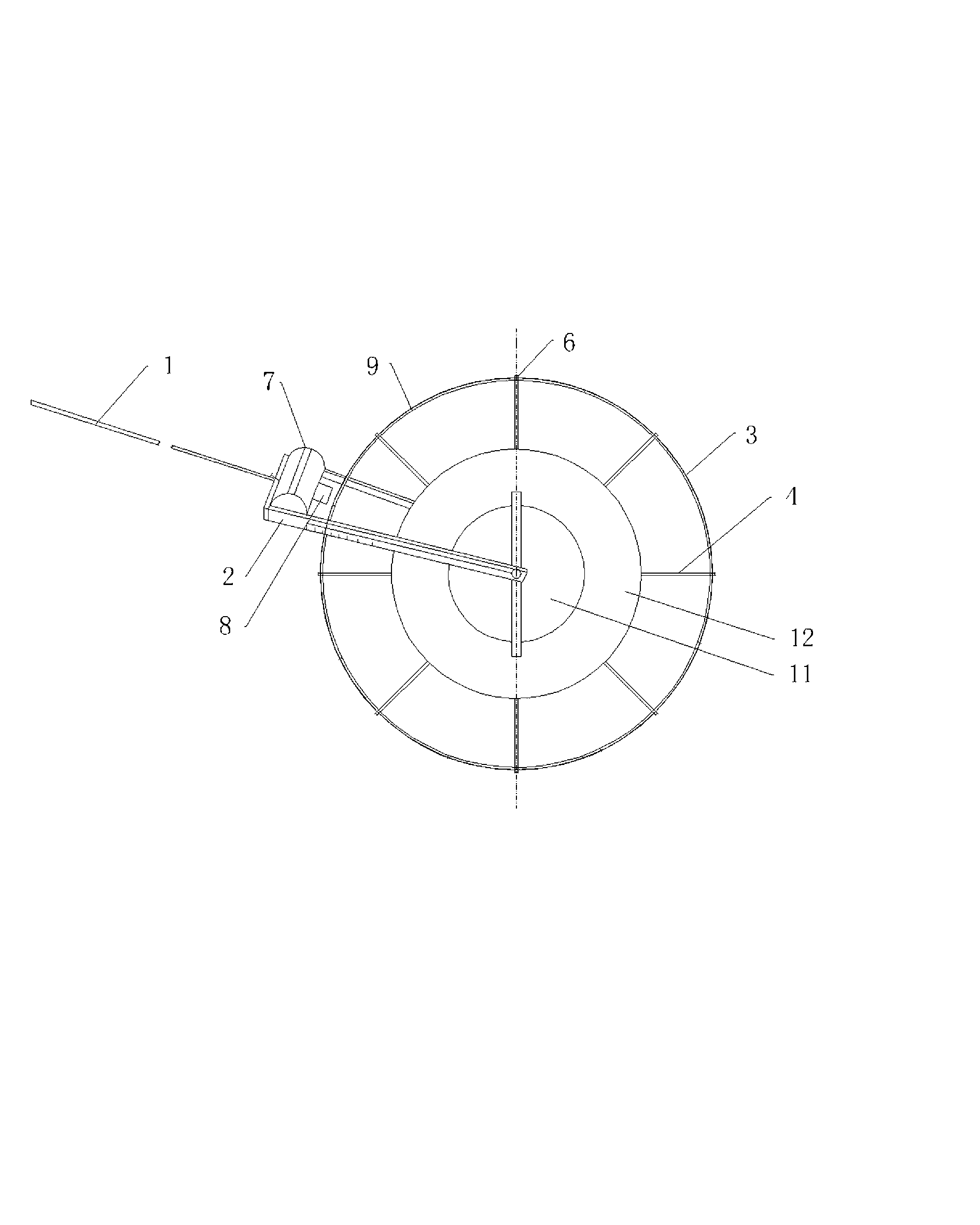

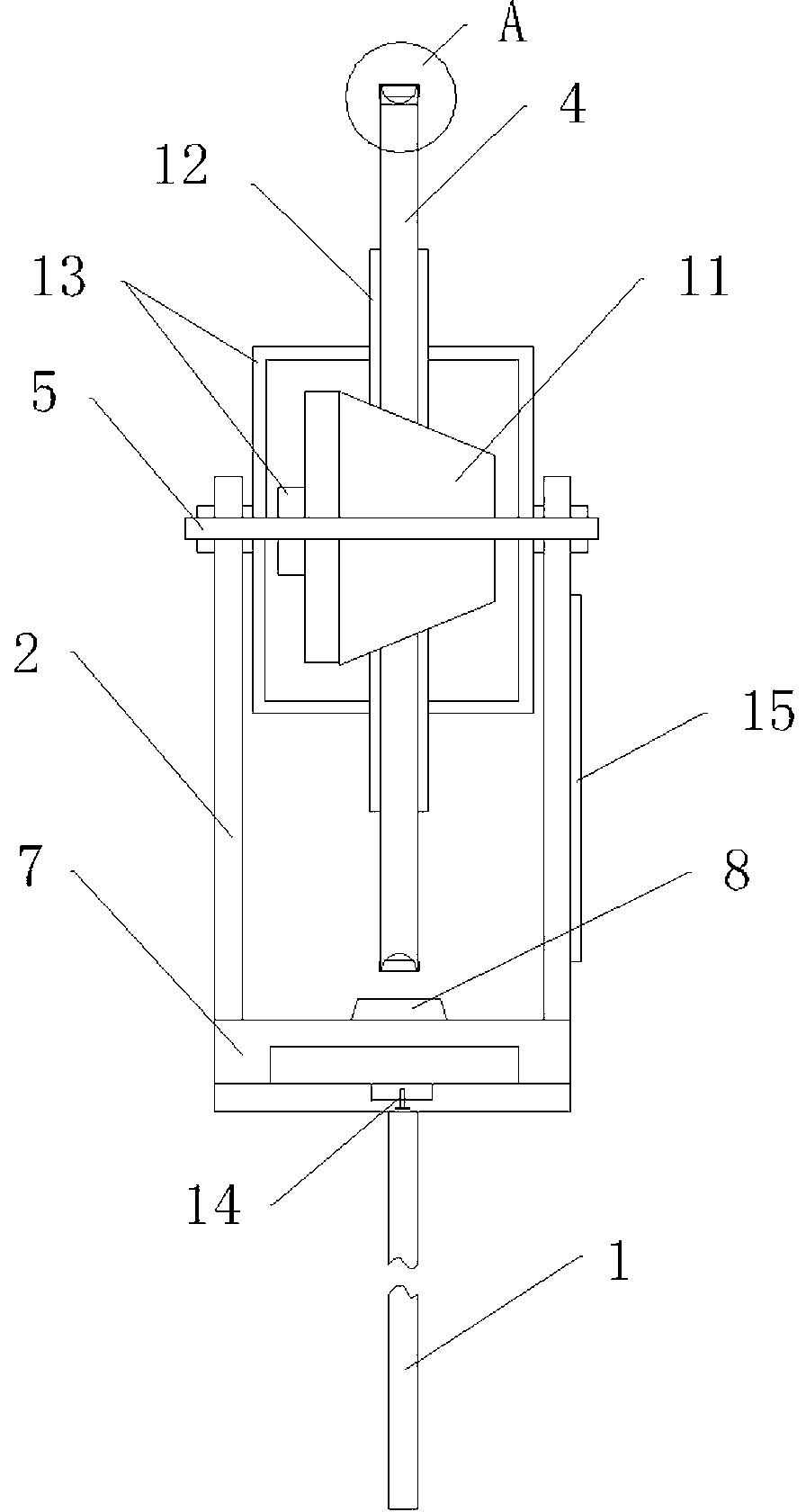

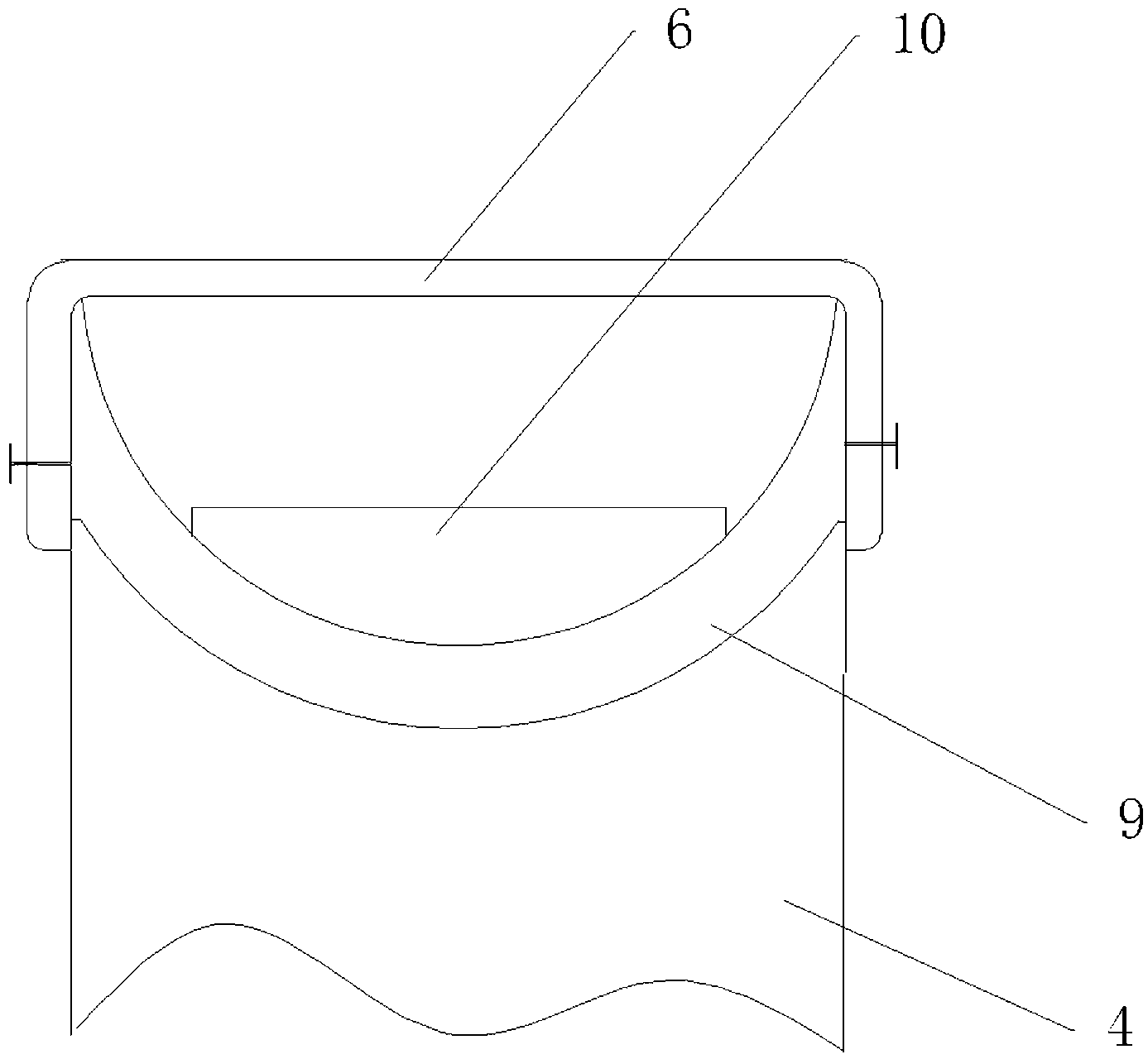

Sample digestion processing device

ActiveCN102095628AReduce harmEliminate human errorPreparing sample for investigationHeat conductingEngineering

The invention provides a sample digestion processing device, which comprises a frame, a heater and a solvent supply mechanism, wherein the heater is provided with more than one test tube accommodating hole; test tubes can be arranged in the test tube accommodating holes; the solvent supply mechanism is provided with a feeding nozzle which is arranged above the heater, can move transversely and / orlongitudinally in the horizontal plane, and is connected with a solvent storage chamber; and the heater and the solvent supply mechanism are respectively arranged on the frame; a test tube bracket isarranged on the heater; through holes corresponding to the test tube accommodating holes of the heater is formed on the test tube bracket; the heater comprises a heat-insulating tank body, and a heatconducting body arranged in the heat-insulating tank body; the test tube accommodating holes are formed on the heat conducting body; and the test tubes are arranged in the test tube bracket and the test tube accommodating holes. In the sample digestion processing device, the solvent is fed by the solvent supply mechanism, the sample is digested not by a manual wet digestion method, and the devicecan realize the quick digestion processing of quantitative solvents and samples added into the test tubes.

Owner:BEIJING POLYTECH INSTR

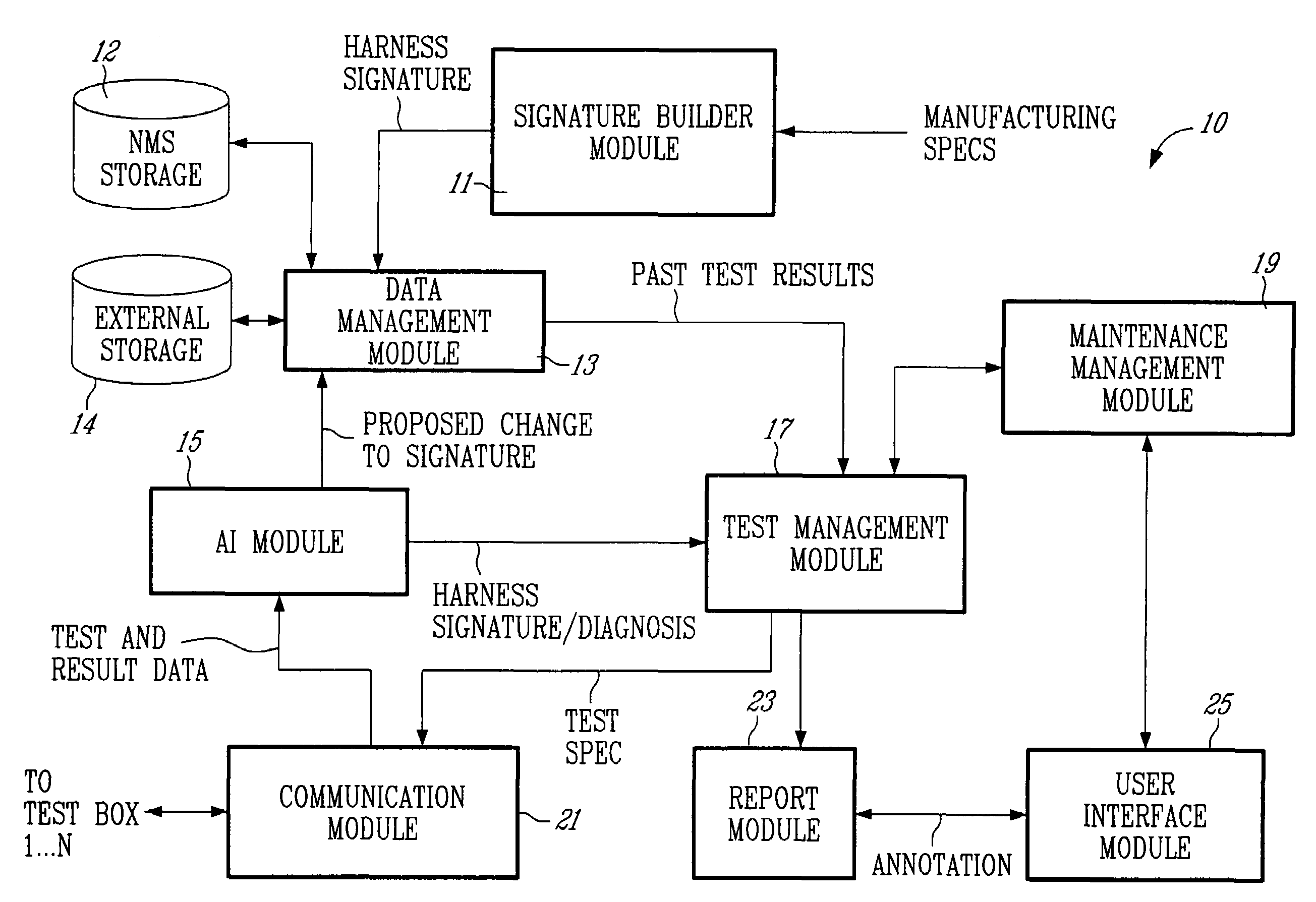

Wireless portable automated harness scanner system and method therefor

ActiveUS7368919B2Reducing time and costEliminate human errorResistance/reactance/impedenceFault location by conductor typesComputer moduleTest measurement

A method for testing an installed wiring harness is provided. The method comprises providing a signal source testing module at a first node in the wiring harness and a measurement termination testing module at a second node in the wiring harness. A central management module for controlling the testing modules coordinates the testing modules to send testing signals for performing tests and recording test measurements of the installed wiring harness. The testing modules send the test measurements to the management module.

Owner:ZIOTA TECH

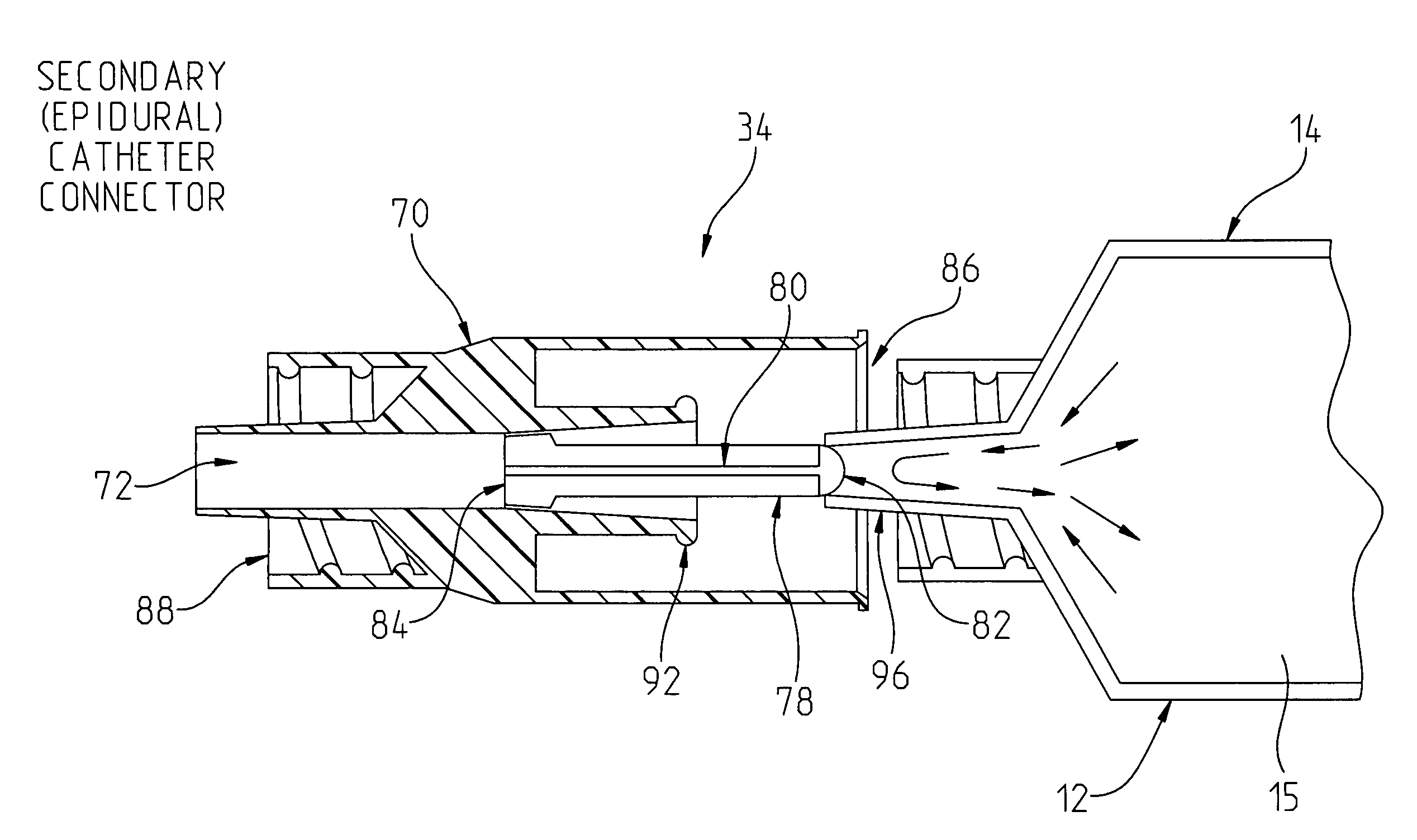

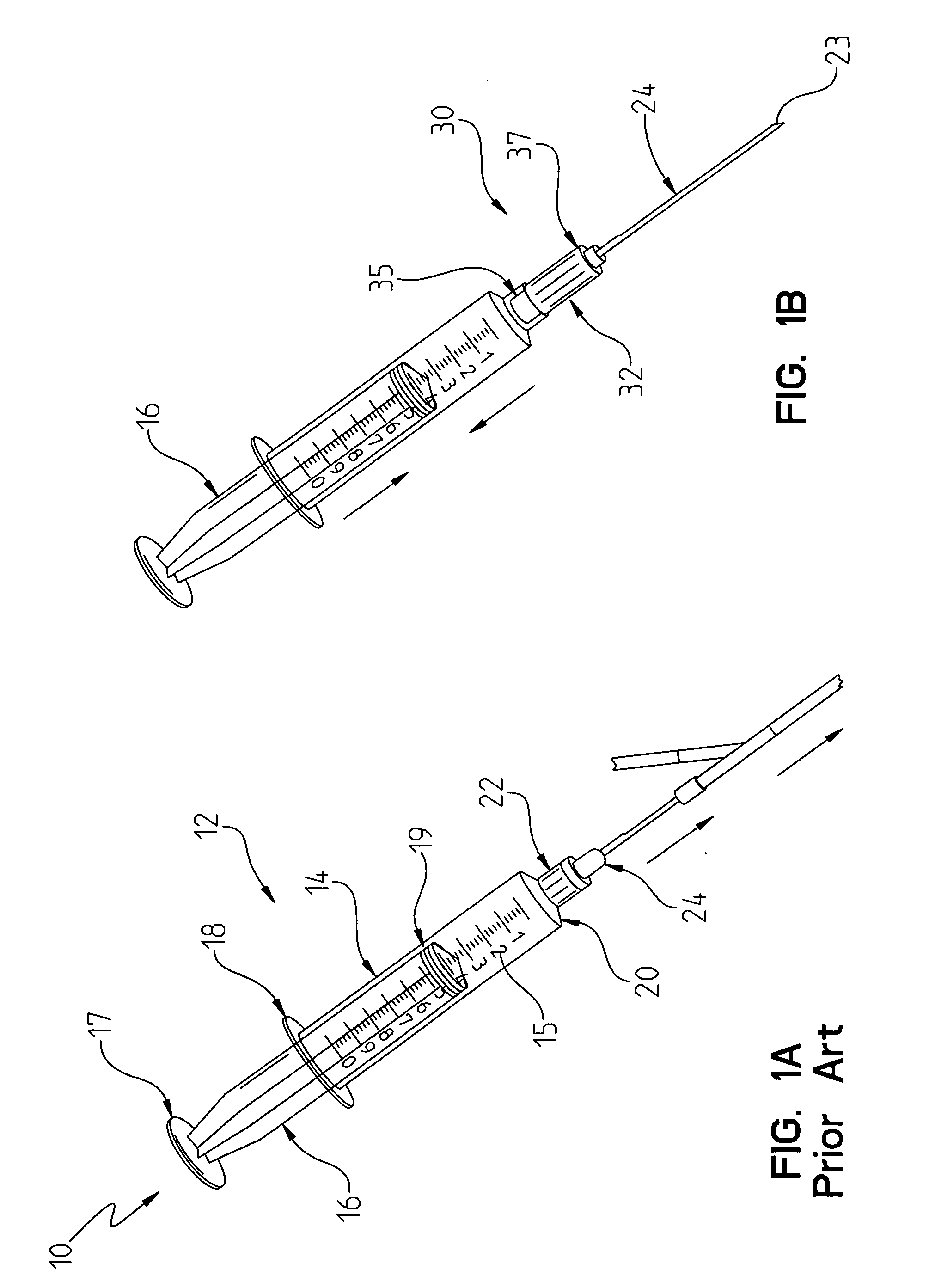

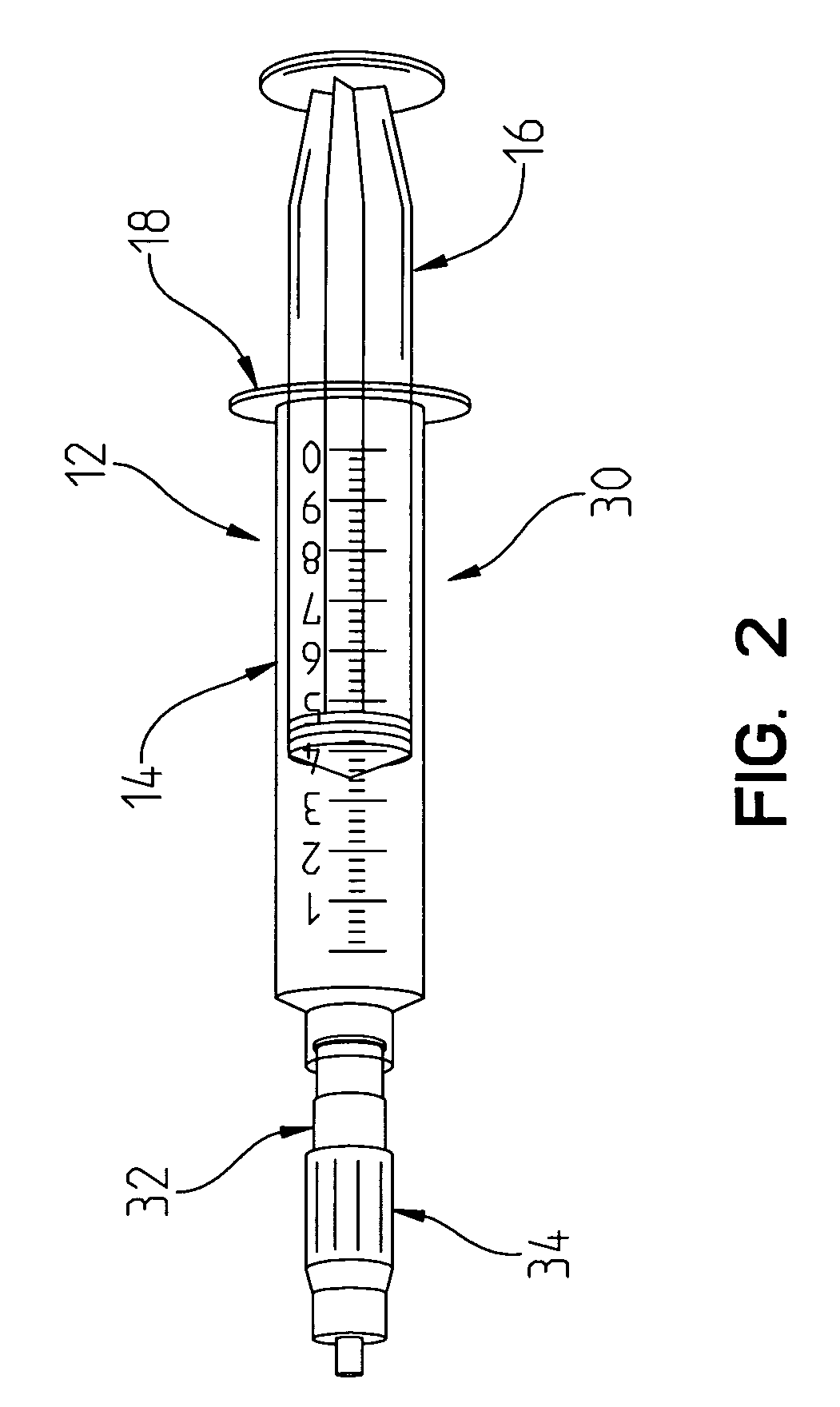

Epidural anesthetic delivery system

A connector is provided for use in an anesthesia delivery system for coupling an anesthesia dispensing container to an anesthesia delivery catheter. The connector includes a first connector member and a second connector member. The first connector member includes a body member having a proximal end that is capable of being operably coupled to an anesthesia dispensing container. The first connector member also includes a distal end capable of being selectively coupled to the second connector member. The body further includes a fluid passageway having a proximal end and a distal end. The fluid passageway extends between the proximal end and the distal end of the body member. A check valve is disposed in the fluid passageway. The check valve is configured to: (a) permit the flow of fluid between the distal end and the proximal end of the fluid passageway regardless of whether the first connector member is coupled to the second connector member; (b) permit the flow of gas between the proximal end and the distal end of the fluid passageway regardless of whether the first connector member is coupled to the second connector member; and (c) permit the flow of fluid between the proximal end and the distal end of the fluid passageway only when the first connector member is coupled to the second connector member.

Owner:CARDENAS JUAN

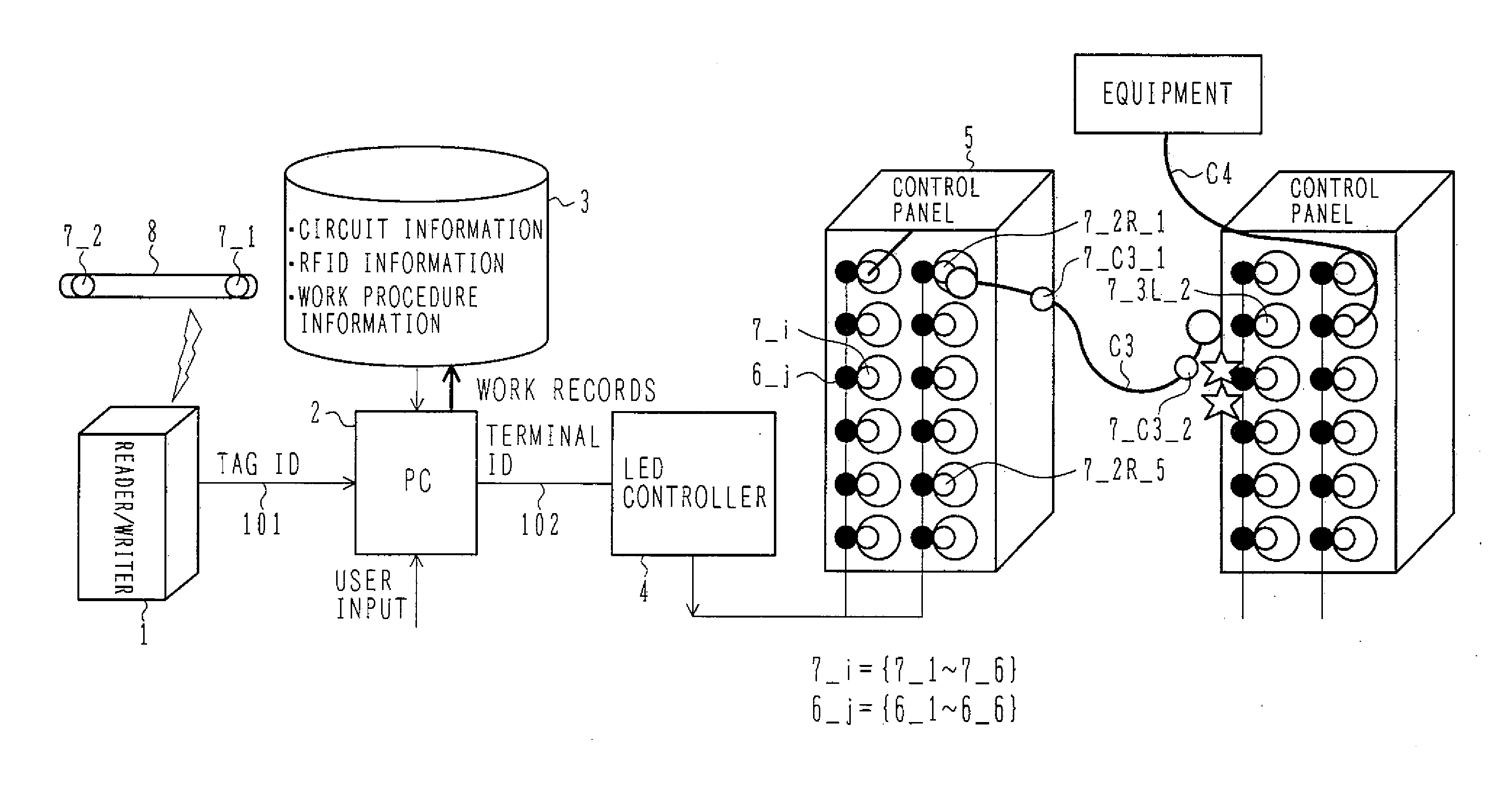

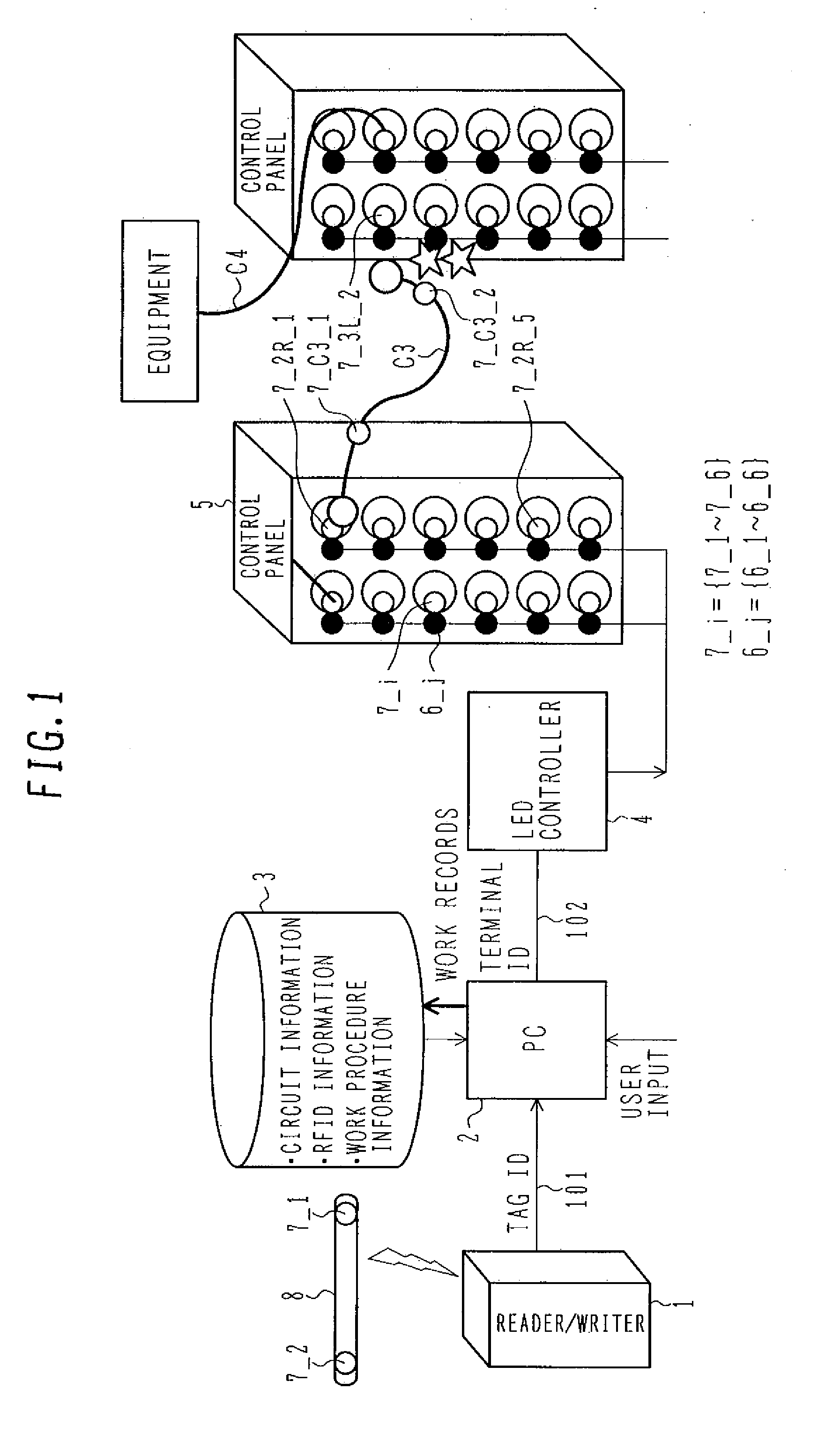

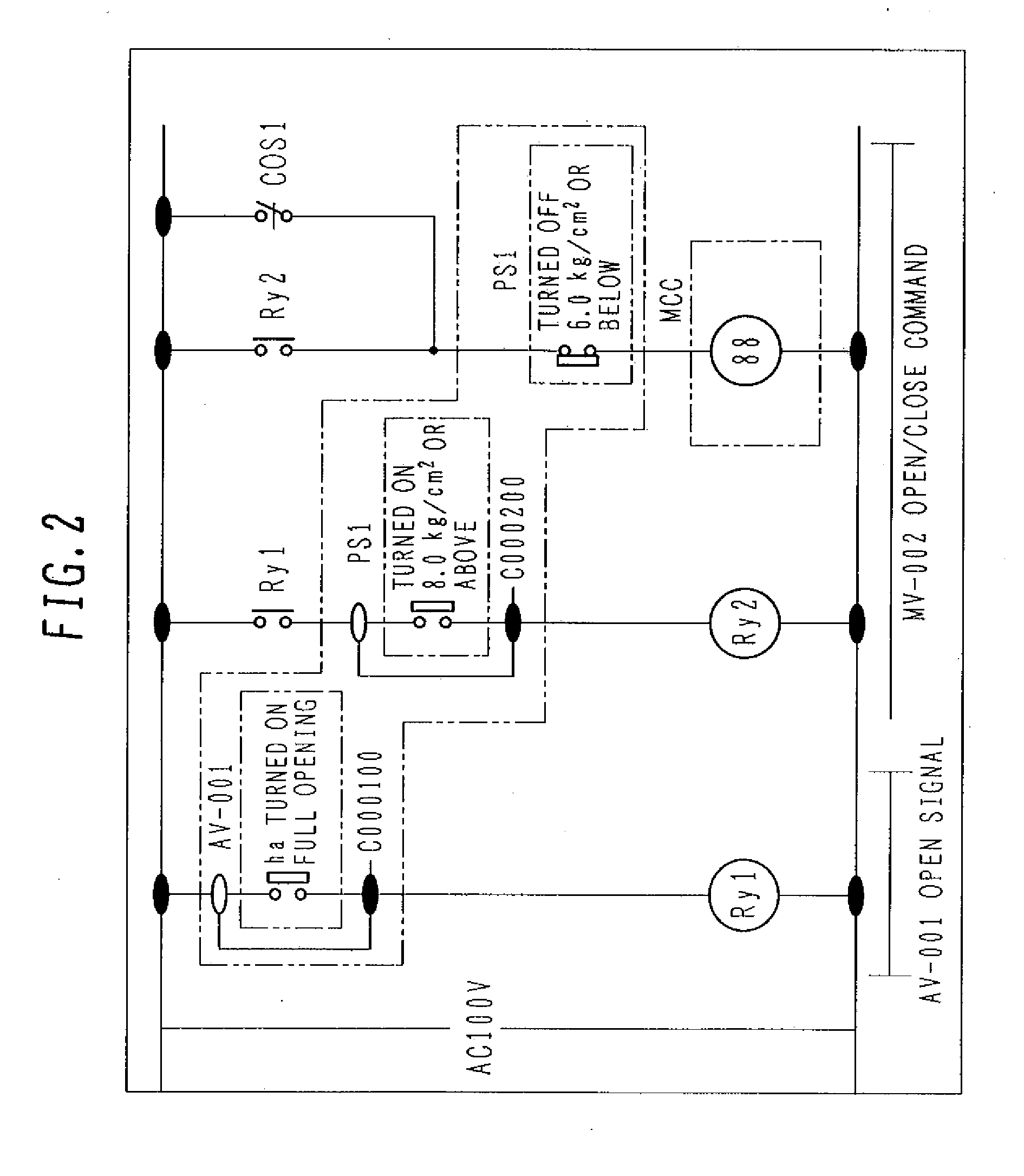

RFID system, RFID cable system, and RFID cable laying method

ActiveUS20070102505A1Eliminate human errorGuaranteed to workData processing applicationsElectric signalling detailsTest proceduresElectric cables

When an RFID is attached to an object to assist testing operations, the following problems are encountered; (1) the RFID of write type tends to cause a failure and is troublesome due to the necessity of rewrite each time the situation is changed, (2) the incorporation of the reader function in a terminal block increases the cost, and (3) the known techniques are targeted for only the connecting operation and are not adapted for a sequence test that takes the most expense in time and effort. The operations are aided by using an RFID reader and a terminal having the function for accessing a database of circuit information, RFID information, and test procedure information.

Owner:HITACHI LTD

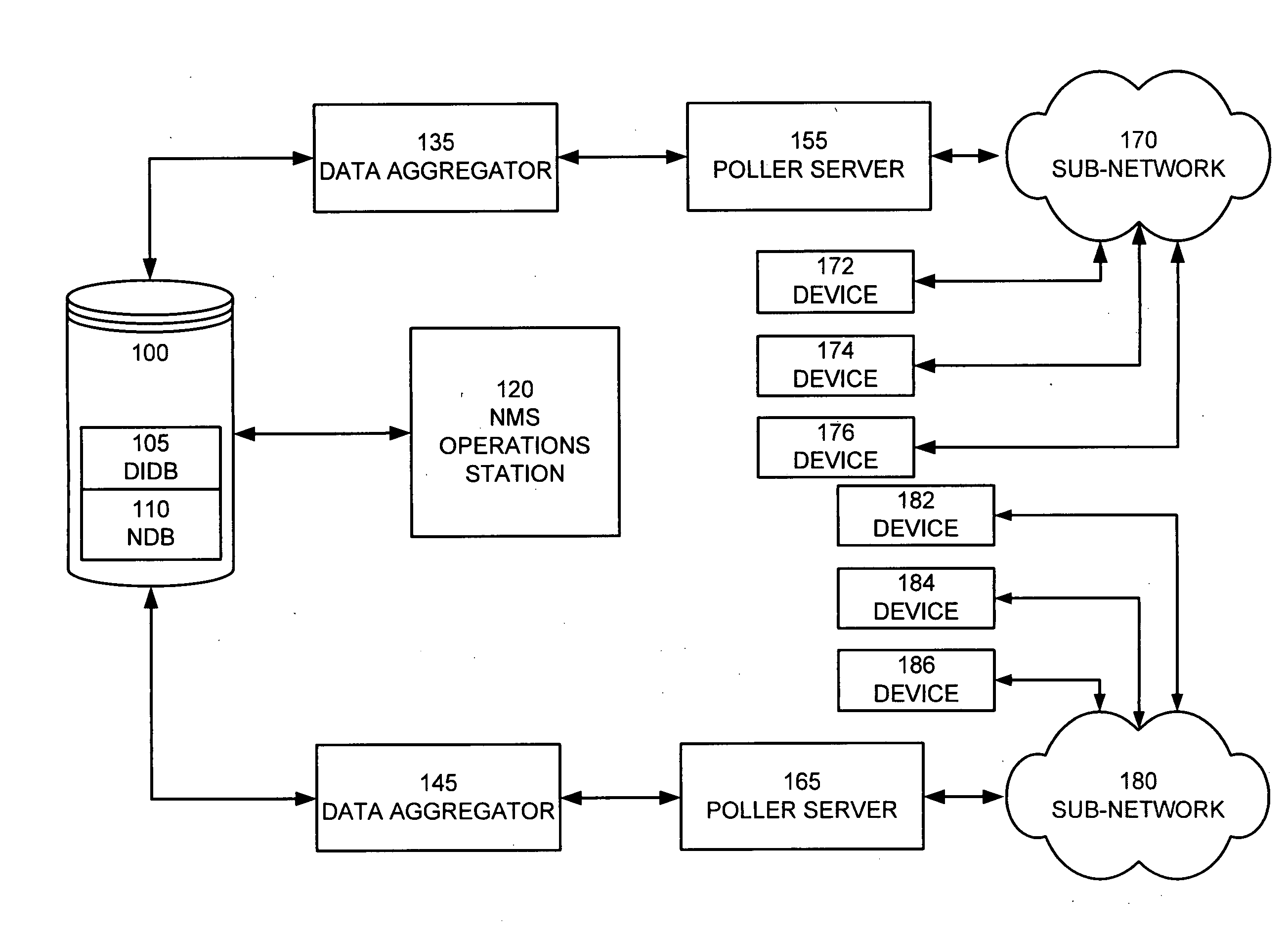

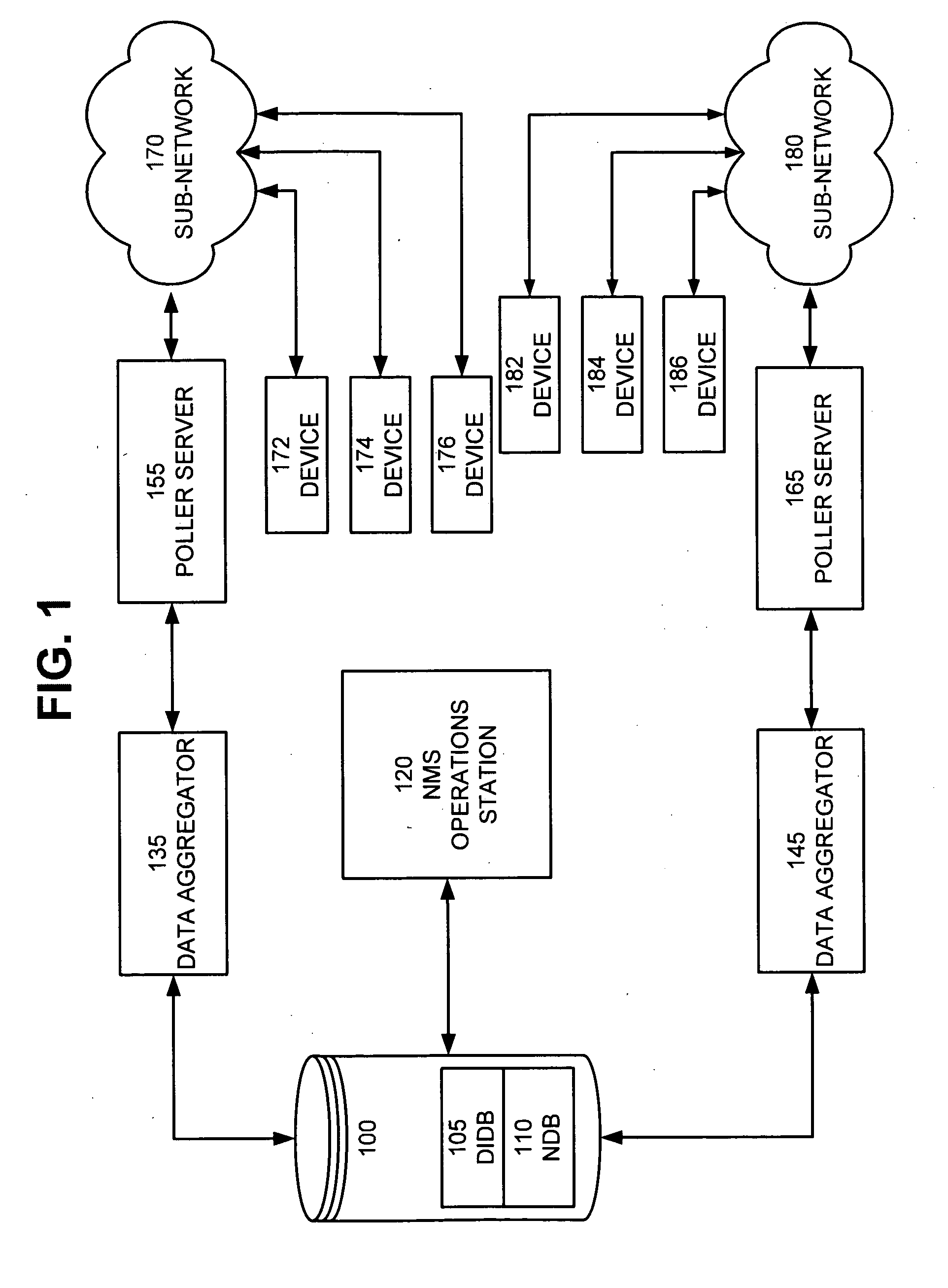

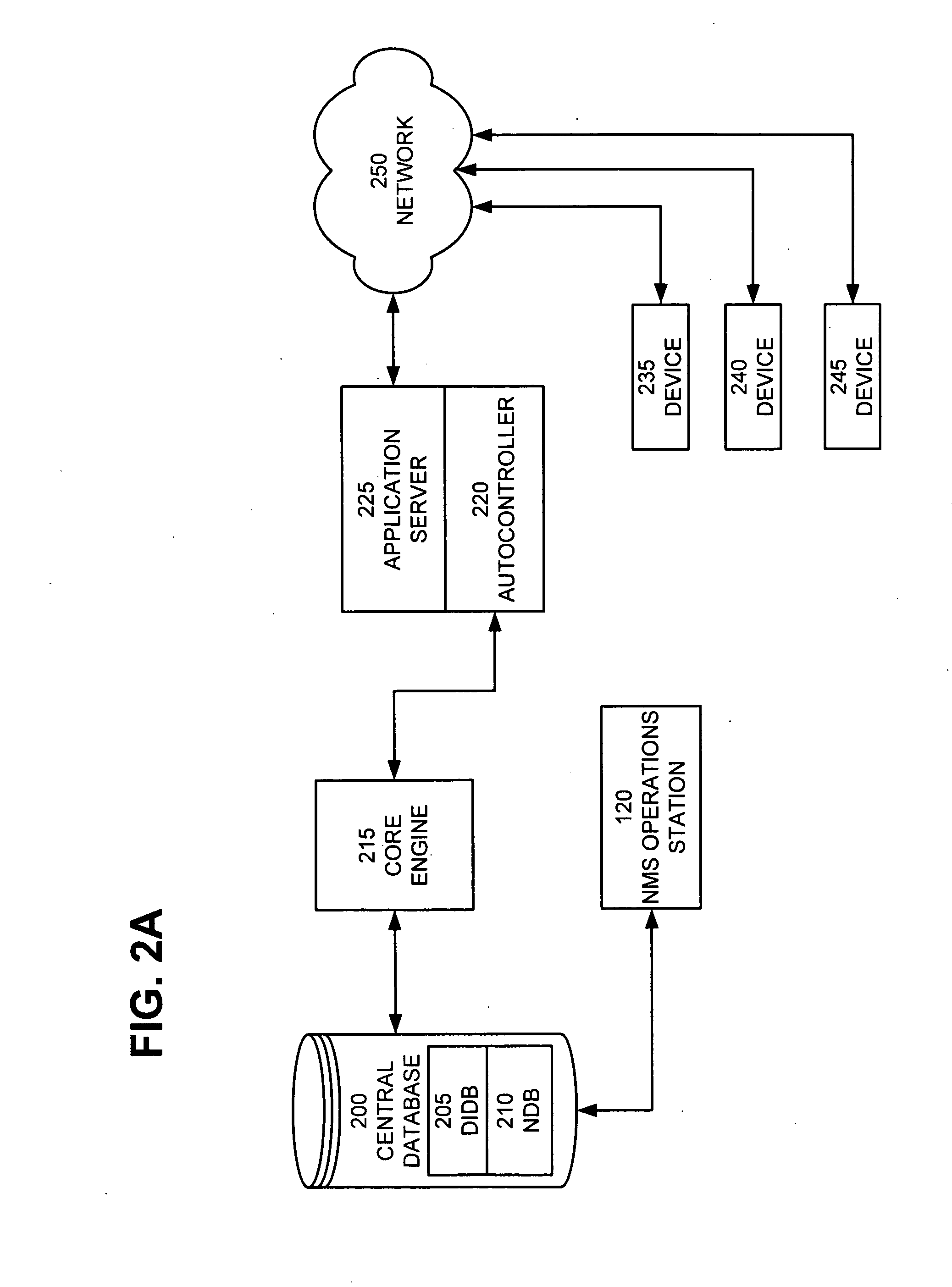

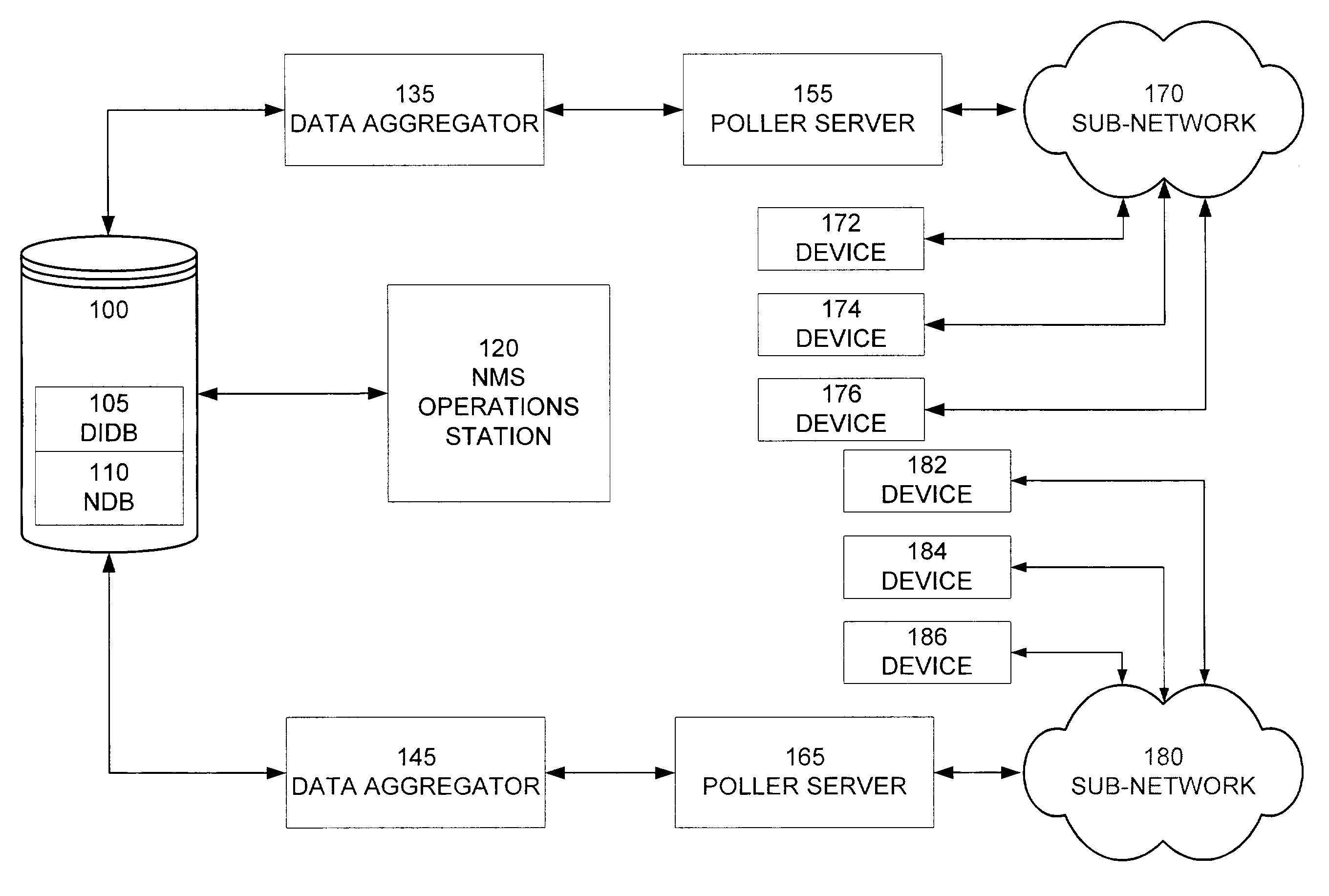

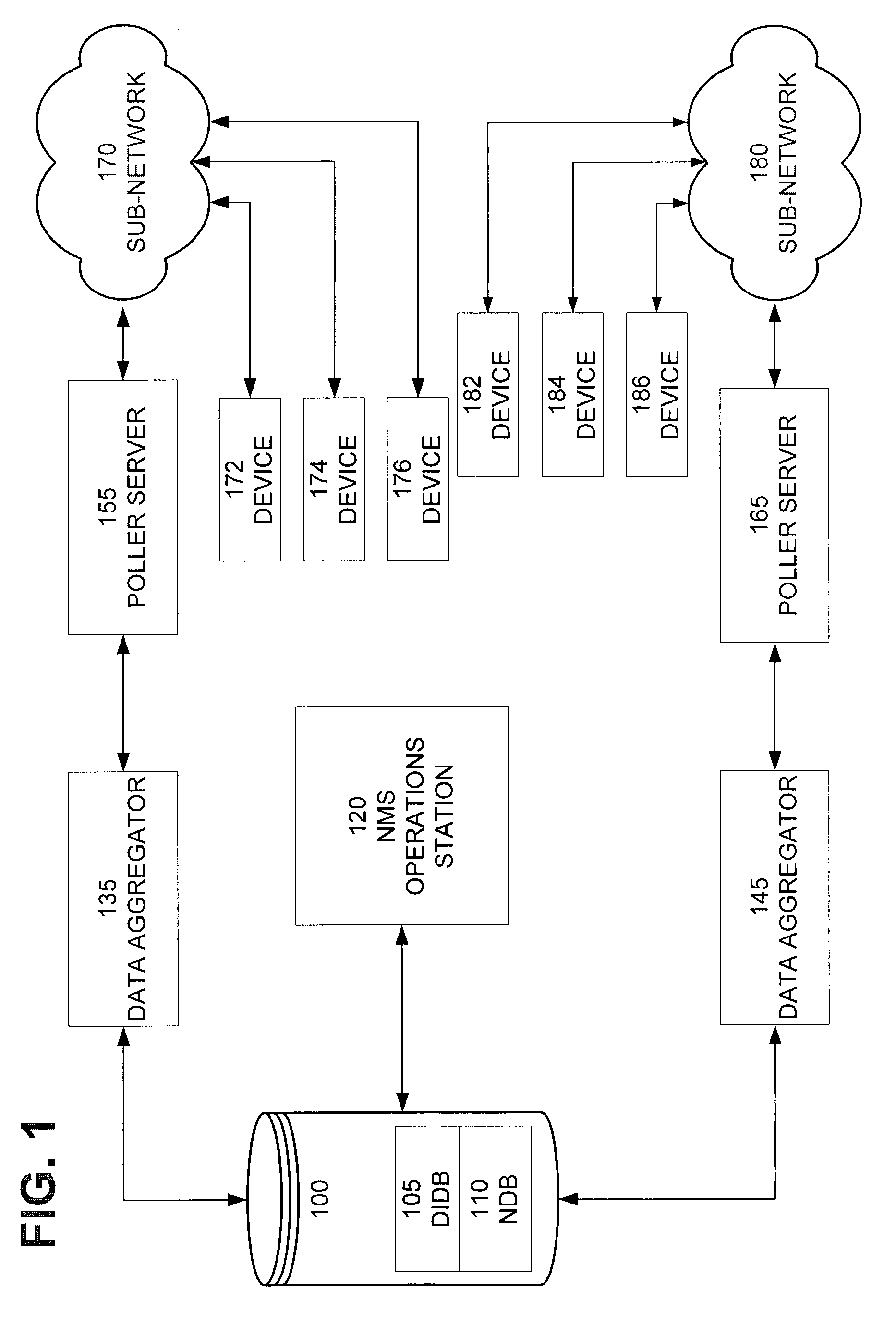

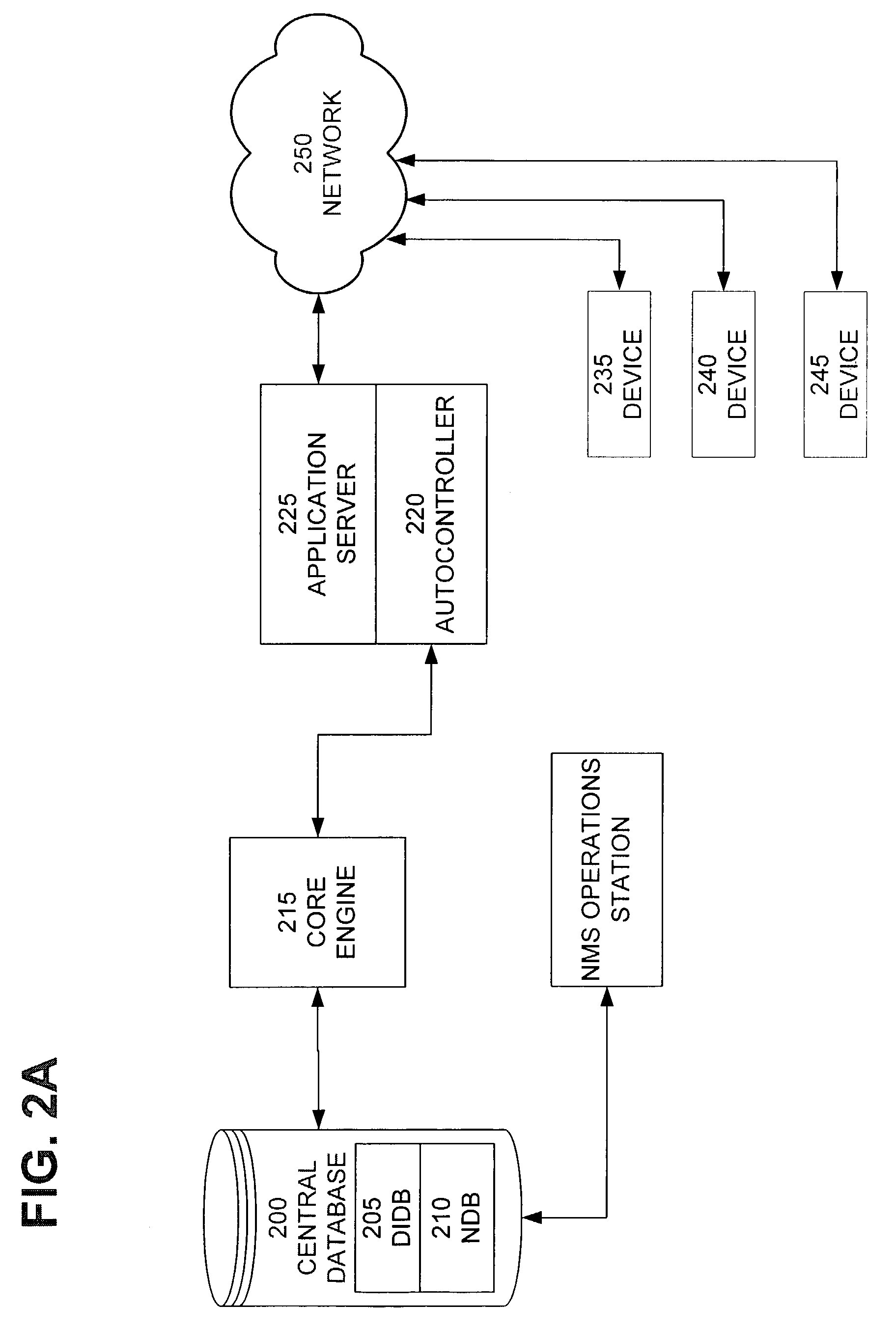

System and Method for Synchronizing the Configuration of Distributed Network Management Applications

InactiveUS20090204699A1Eliminate human errorShorten the timeDigital computer detailsData switching networksChange managementNetwork management application

Owner:TIME WARNER CABLE ENTERPRISES LLC

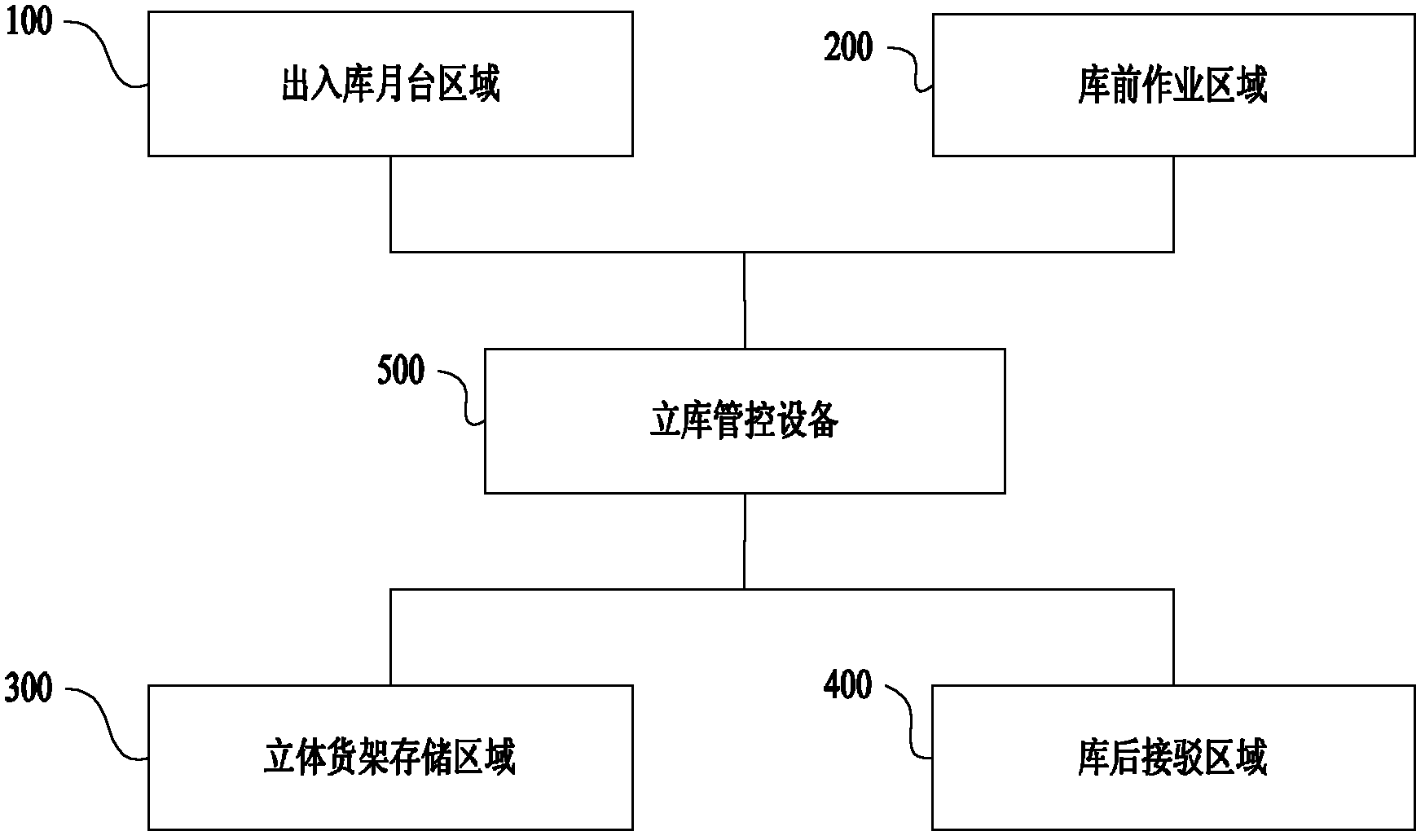

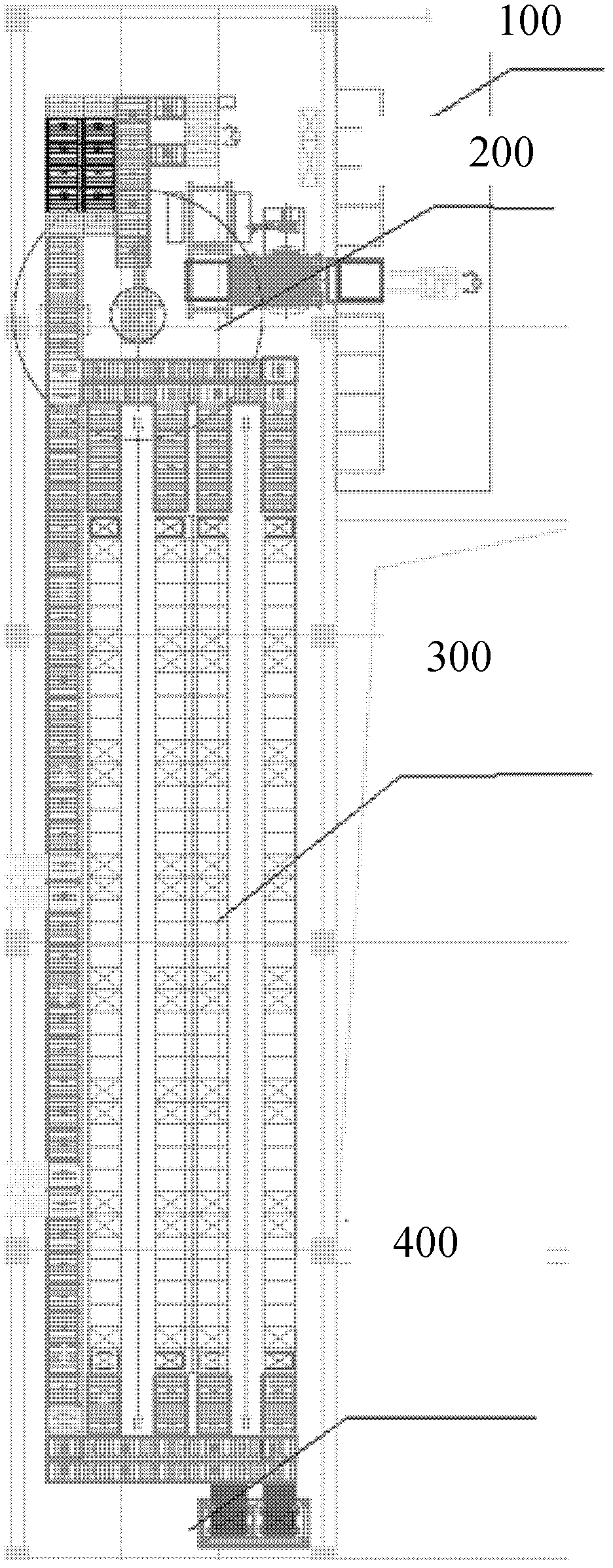

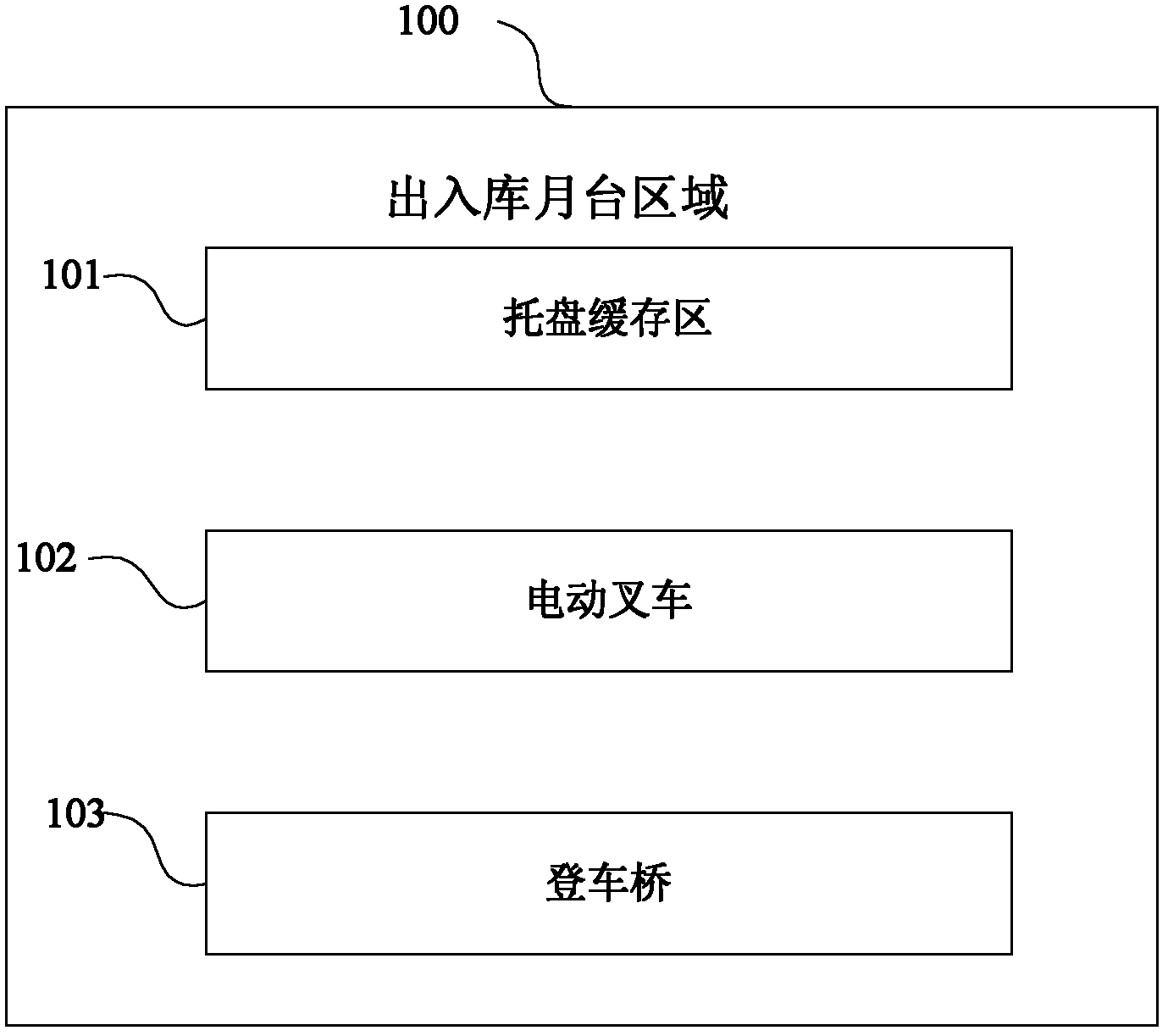

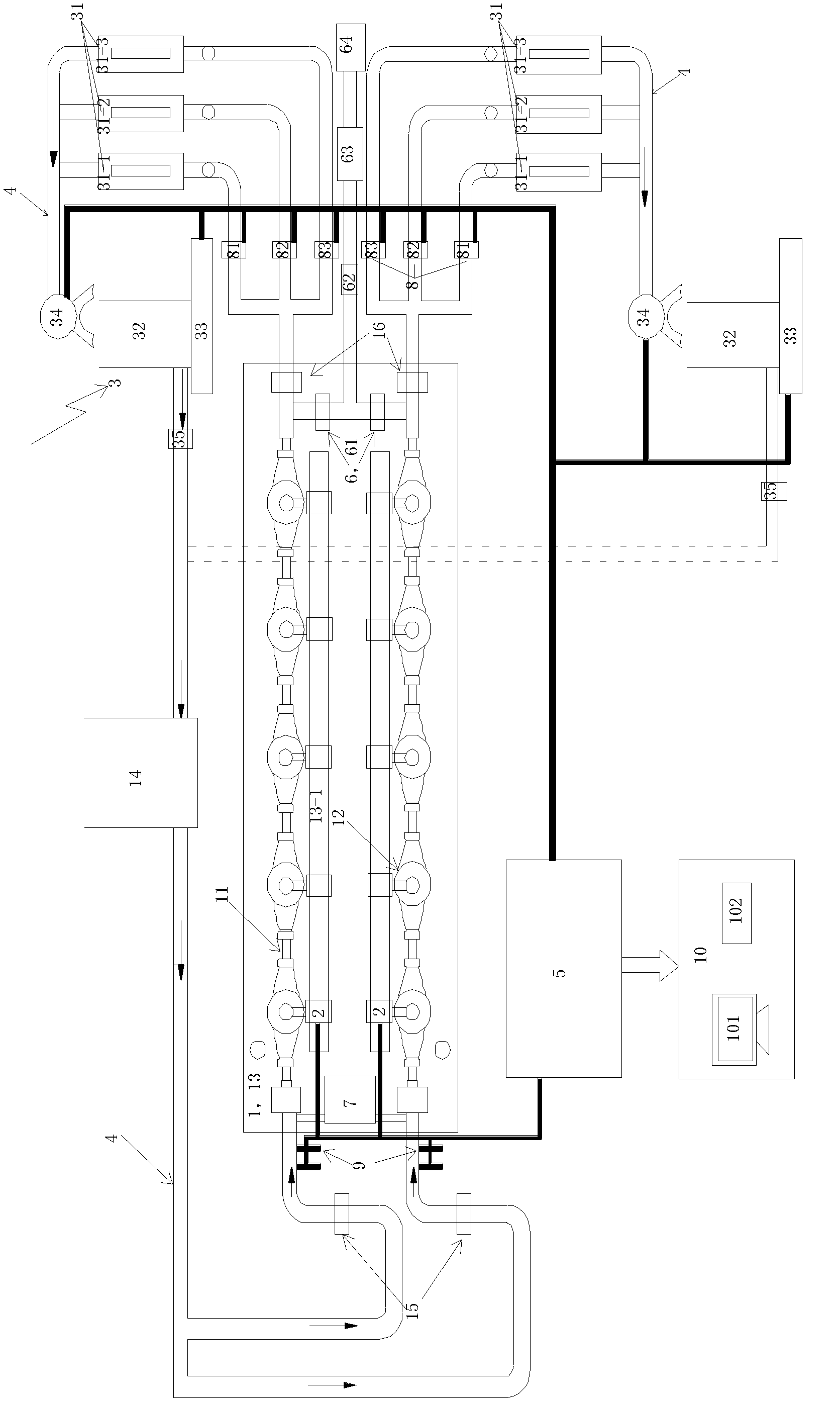

Intelligent stereoscopic storage system for electric energy metering device

An embodiment of the invention provides an intelligent stereoscopic storage system for an electric energy metering device. The intelligent stereoscopic storage system comprises a warehouse-out and warehouse-in platform area, a pre-warehousing operation area, a stereoscopic rack storage area, a post-warehousing connection area and stereoscopic warehouse control equipment, wherein the warehouse-out and warehouse-in platform area, the pre-warehousing operation area, the stereoscopic rack storage area and the post-warehousing connection area are respectively connected with the stereoscopic warehouse control equipment. By the aid of the warehouse-out and warehouse-in platform area, the pre-warehousing operation area, the stereoscopic rack storage area, the post-warehousing connection area and the stereoscopic warehouse control equipment in the intelligent stereoscopic storage system, automated storage of the electric energy metering device is realized, seamless butt joint of the intelligent stereoscopic storage system and an automated calibration assembly line is also realized, and human errors caused by manual storage and sorting are eliminated.

Owner:NORTH CHINA GRID MEASUREMENT CENT

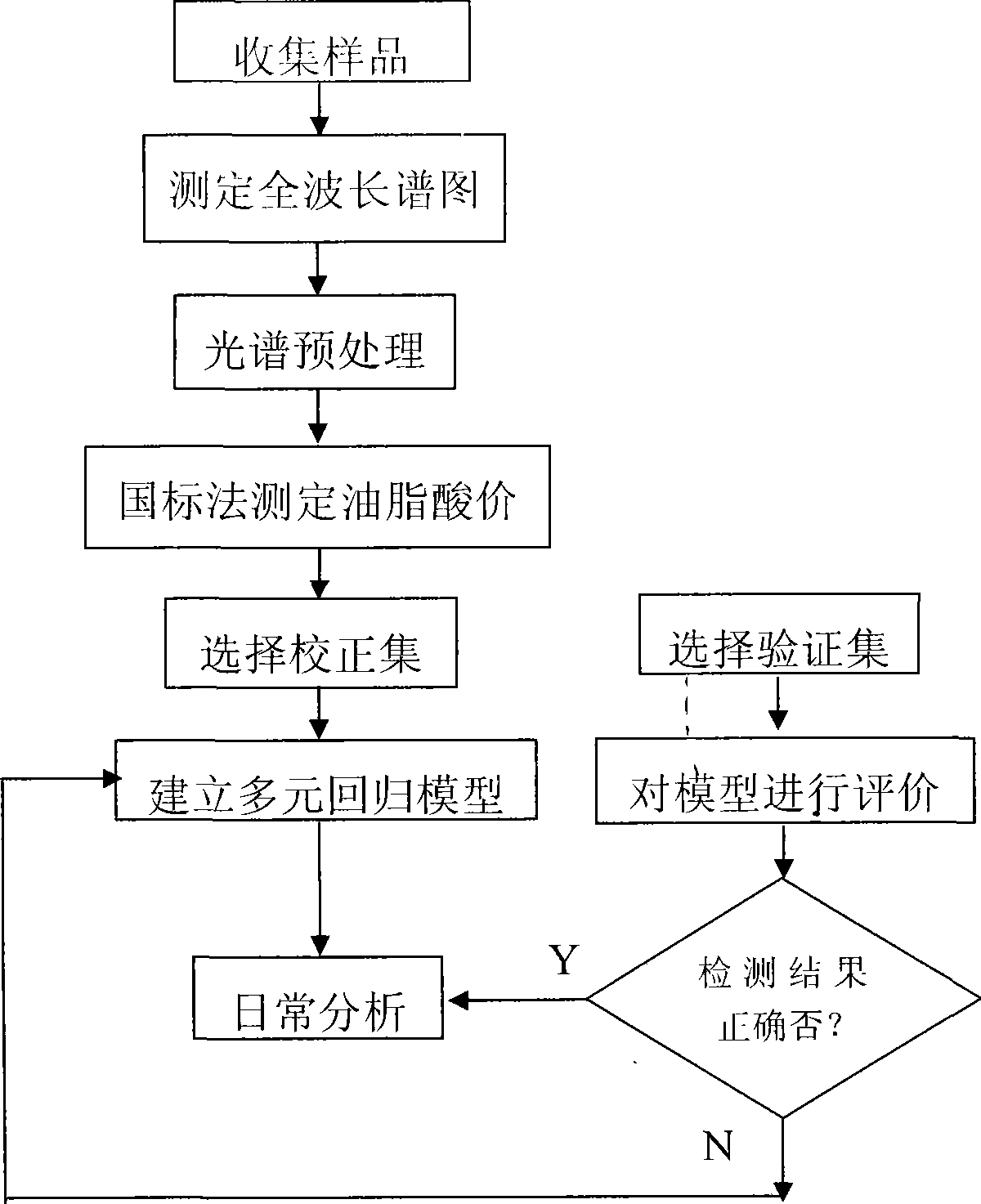

Edible fatty acid value detection method based on near-infrared spectrum analysis

InactiveCN101504363ARapid online real-time detection and analysisAccurate online real-time detection and analysisColor/spectral properties measurementsInfraredAcid value

The invention discloses a method for detecting an acid value of edible fat based on near infrared spectrum analysis. The invention relates to a method for detecting an acid value of edible fat by utilizing near infrared spectrum analysis technology, which aims to solve the problems that in the practical production, the prior laboratory detection and test method can only perform intermittent operation, fail to realize accurate and quick on-line detection and the like. The method for detecting the acid value of the edible fat by utilizing the near infrared spectrum analysis technology is realized through the following steps of: 1, establishment of a calibration set sample spectrum; 2, pretreatment of spectrum data; 3, determination of essential data; 4, establishment of a calibration model; 5, verification of the calibration model; and 6, analysis of a sample to be tested. The method can effectively eliminate personal error, shorten detection period, and realize the on-line detection and control of the acid value in the process of processing the fat.

Owner:HARBIN UNIV OF COMMERCE

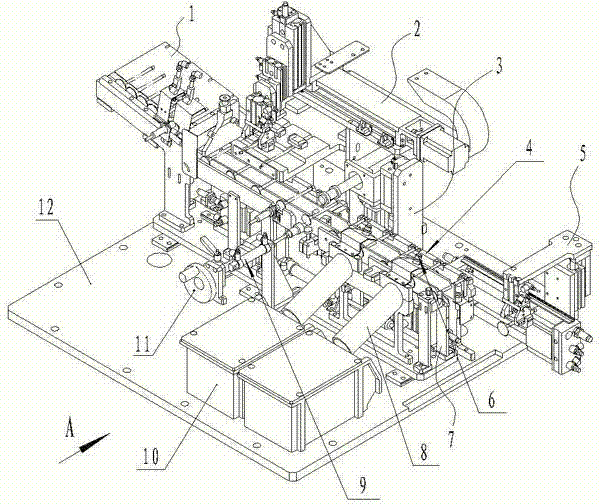

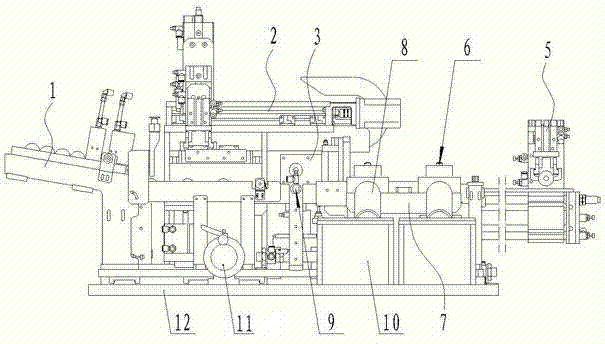

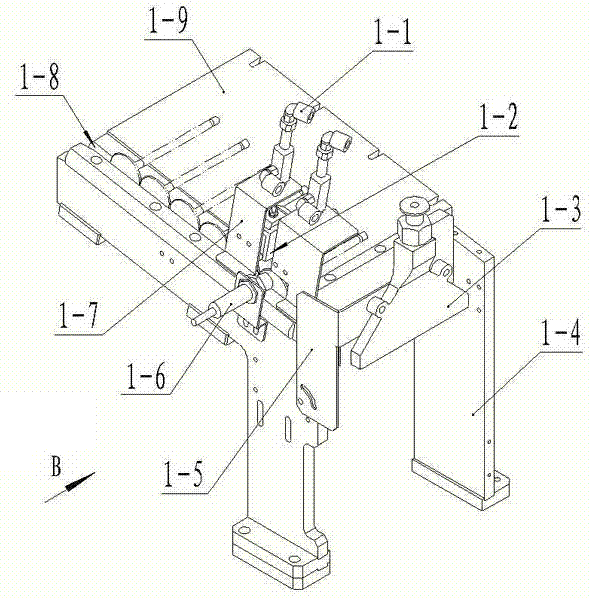

Valve rod automatic checkout device

PendingCN104713505AAvoid Inaccurate DefectsReduce labor intensityMeasurement devicesSortingSlide plateEngineering

The invention discloses a valve rod automatic checkout device, and belongs to valve rod checkout devices. The valve rod automatic checkout device saves labor, and is efficient and accurate in data. The valve rod automatic checkout device comprises a feeding mechanism, a conveying mechanism, a measurement mechanism, a positioning mechanism and the like; the feeding mechanism is formed by a retainer plate, a splitting air cylinder and a stopping gate plate; the conveying mechanism is formed by a longitudinal guide rail, a longitudinal sliding plate, a first transverse guide rail, a first transverse sliding block, a first lifting air cylinder, a first conveying plate, a second conveying plate, a second positioning plate, a first transverse air cylinder and a first positioning plate; the measurement mechanism is formed by a second transverse guide rail, a second transverse air cylinder, a second lifting air cylinder, a first vertical sliding block, a first motor, a pressing rod shaft, a positioning measuring head and a supporting block; the positioning mechanism is a pneumatic ejection rod. By means of the valve rod automatic checkout device, the labor intensity is reduced, the detection efficiency is improved, the size does not need to be manually marked, and the measurement accuracy is improved.

Owner:REACH PRECISION MEASUREMENT GUIYANG COMPANY

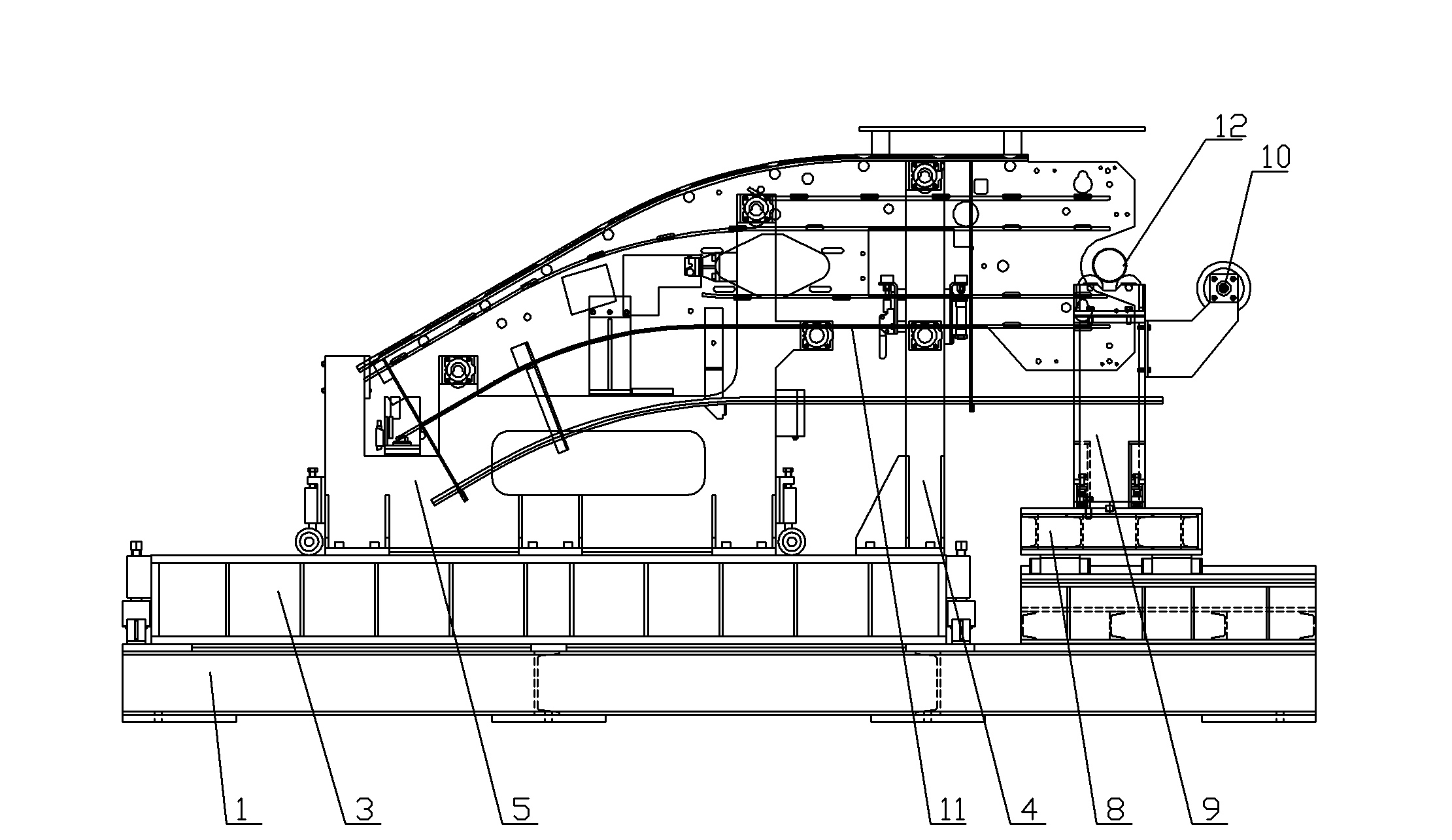

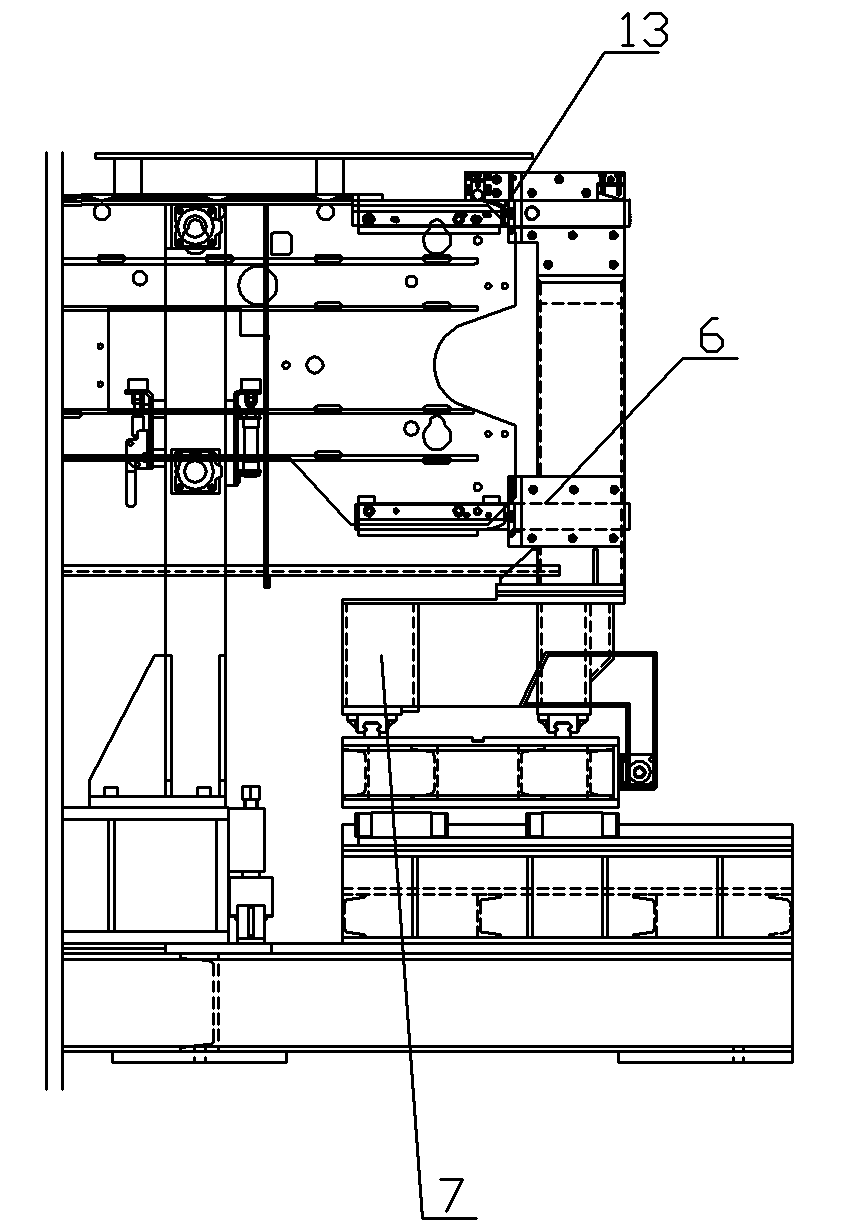

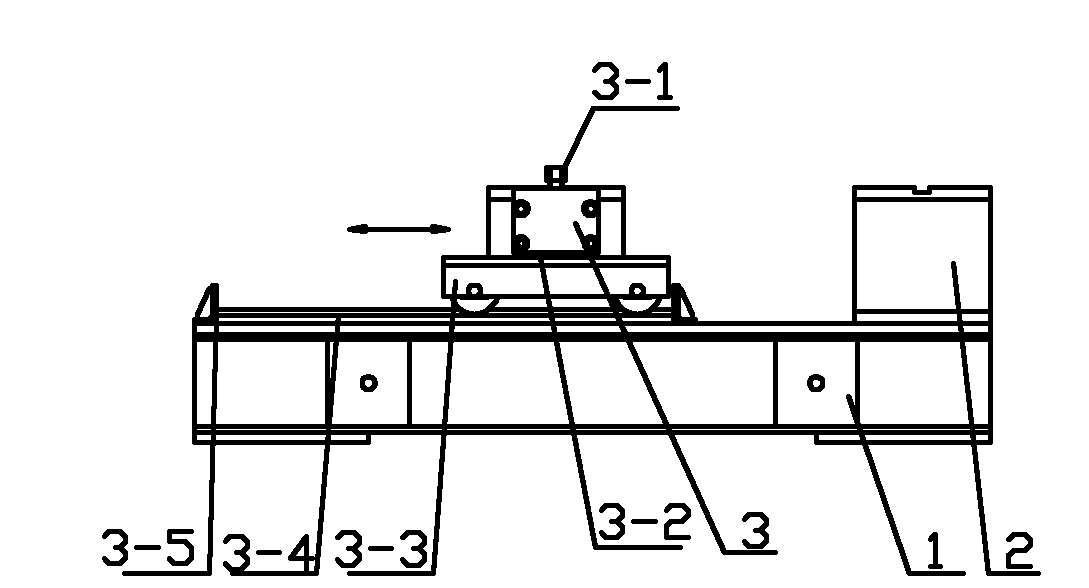

Assembly tooling for double assembly and main drive of head side plate on staircase and assembly method

ActiveCN102632382AReduce spacingLow costWelding/cutting auxillary devicesAssembly machinesAssembly lineEngineering

The invention discloses an assembly tooling for the double assembly and the main drive of a head side plate on a staircase and an assembly method. The tooling comprises a work platform, wherein a fixed reference beam, a beam capable of transversely moving, a main drive lengthways moving dolly are arranged on the work platform, and the two beams are in parallel with each other by moving the beam capable of transversely moving; and a positioning stand column and a positioning wall plate capable of lengthways moving the side plate of the staircase are respectively arranged on the two beams, gaps are remained between the corresponding positioning stand columns and positioning wall plates, and the corresponding positioning wall plates can respectively move along the beams, so that the distances between the corresponding positioning wall plates and the corresponding positioning stand columns are changed; a pair of tangential guide rail arranging seat transverse moving trolleys are distributed on the main drive lengthways moving dolly, and the tangential guide rail is transported to the installing position of the tangential guide rail on the side plate by the dolly; a left / right main drive height positioning device is further arranged on the main drive lengthways moving dolly, and the device is used for positioning the double assembly height position of the center and the side plate of the main drive axis; and a pair of driving axial centering devices is arranged on the main drive height positioning device.

Owner:HANGZHOU XO ELEVATOR

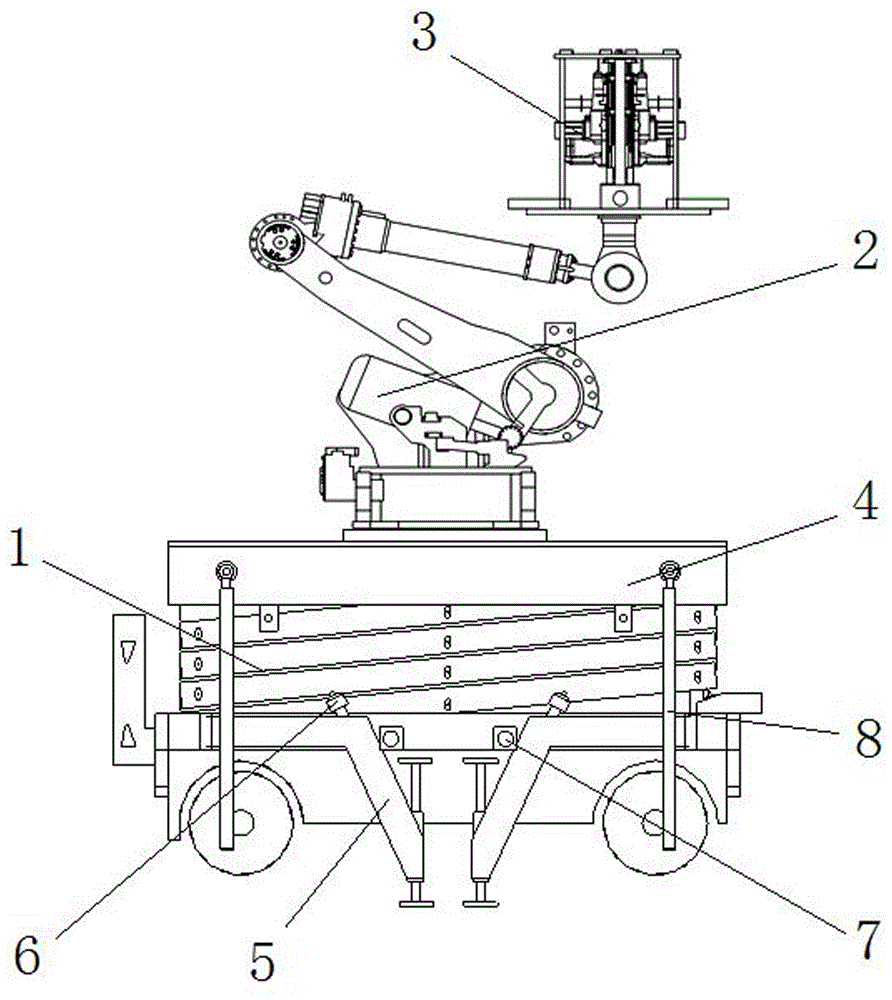

Automatic punching device and method for high-speed railway tunnel anchor implantation

InactiveCN106703689APrevent health damageEliminate human errorLifting devicesAnchoring boltsRailway tunnelLaser ranging

The invention discloses an automatic punching device and method for high-speed railway tunnel anchor implantation and solves problem that health of construction staff is damaged, punching accuracy is poor in anchor implantation, construction efficiency is low and security of the construction staff cannot be guaranteed in existing tunnel anchor implantation. Each of the front end and the rear end of a hydraulic life truck is provided with a support leg, each support leg is provided with a support ball head and a winch, each of the front end face and the rear end face of a lift platform is provided with a hydraulic telescopic rod, each of the upper and lower ends of a frame-type housing is provided with a horizontal chute, a fixing pillar is vertically arranged in the two horizontal chutes, a horizontal servo motor and vertical chutes are arranged in the fixing pillar, each of the vertical chutes is provided with an electric hammer, vertical servo motors are arranged under the electric hammers, a gravity sensor and a laser range finder are arranged at the lower end of the frame-type shell, and a radar range instrument is arranged at the upper end of the frame-type shell. By the arrangement, working accuracy is greatly improved, and danger coefficient in construction is reduced.

Owner:NORTH ENG OF THE ELECTRIFICATION BUREAU GROUP CRCC

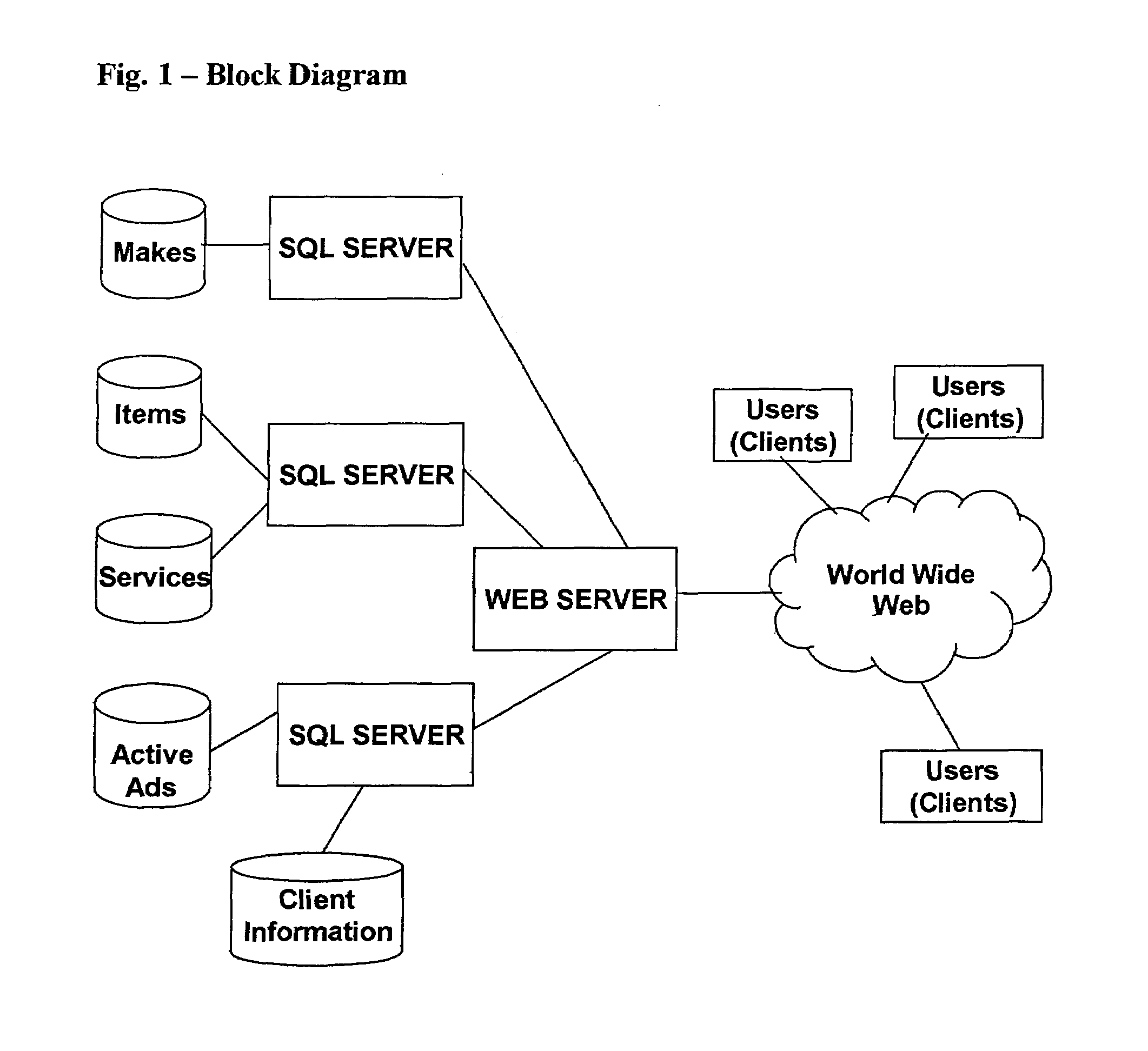

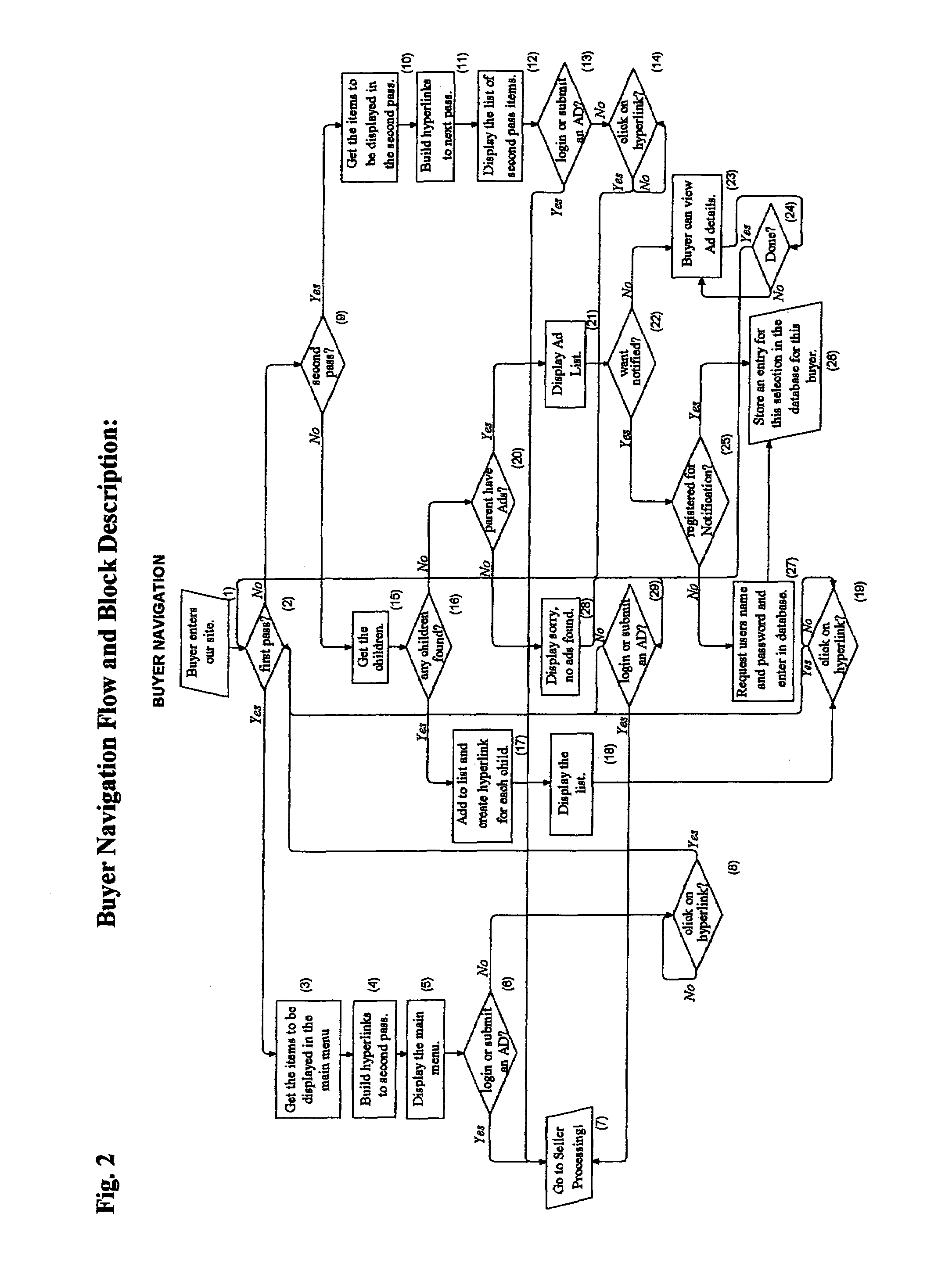

Recursive method and system for accessing classification information

InactiveUS7389252B2Reduce chanceReduce in quantityPlanar light sourcesPoint-like light sourceWeb siteBiological activation

Owner:ROBB ANNE E

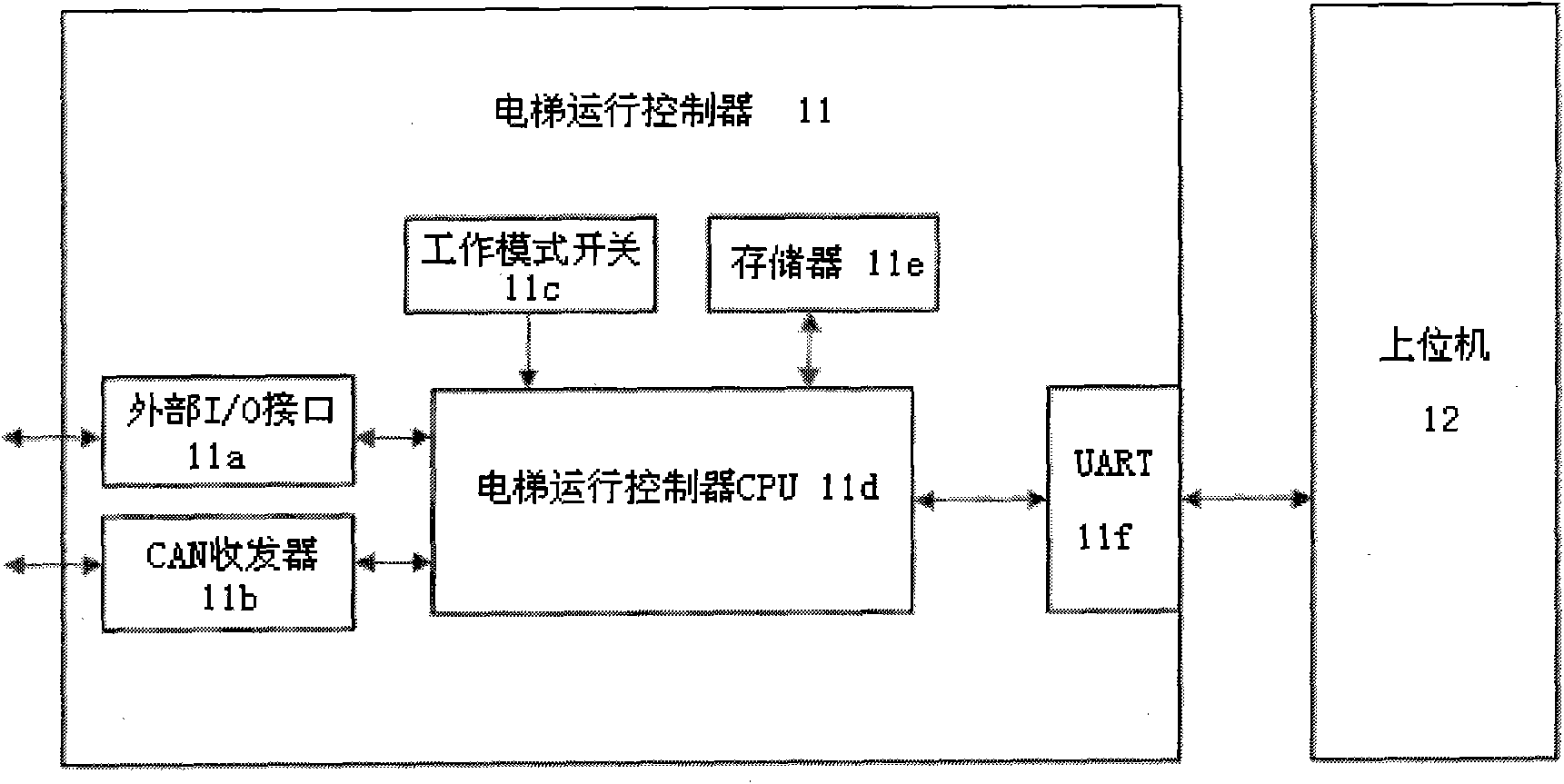

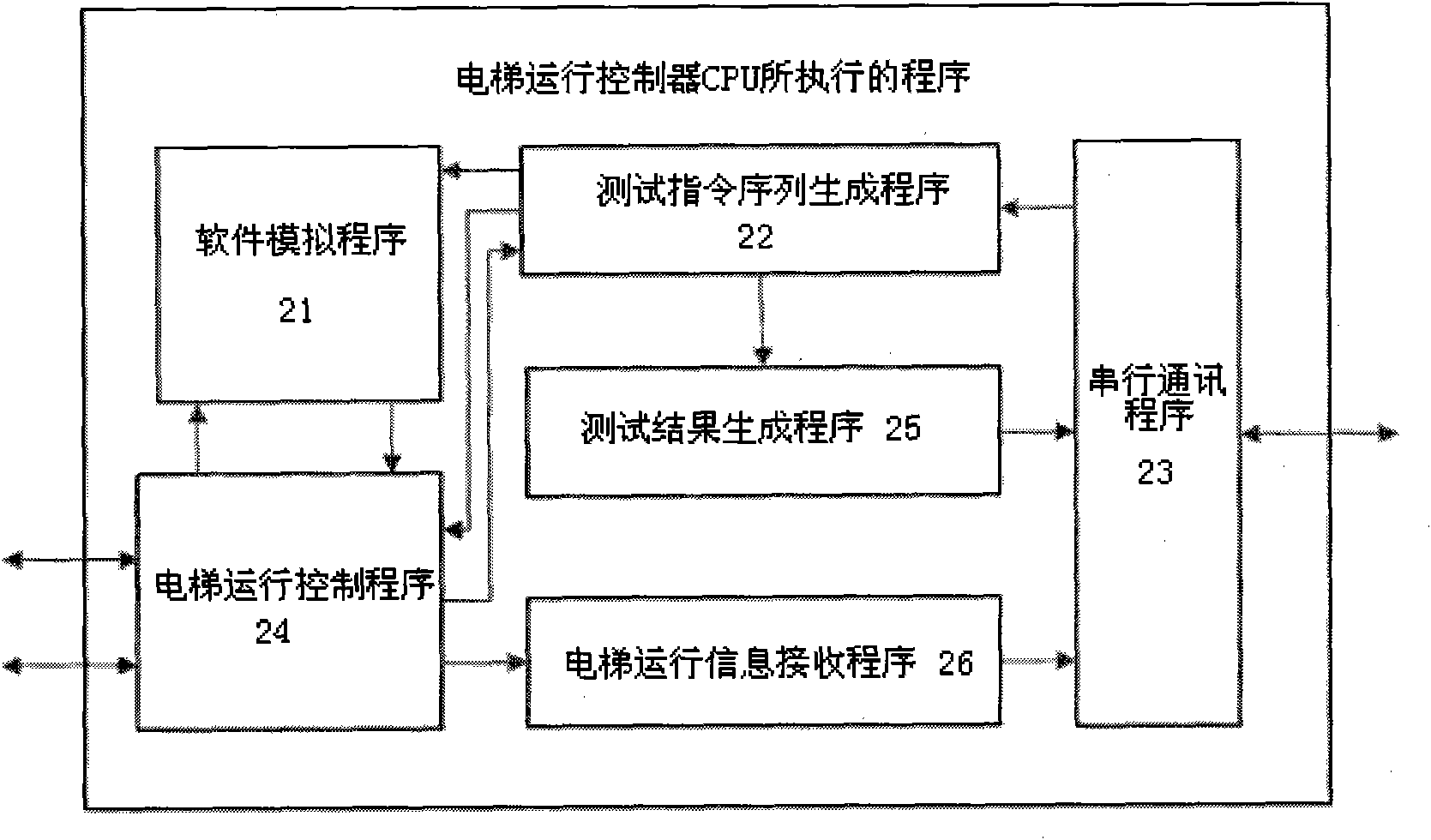

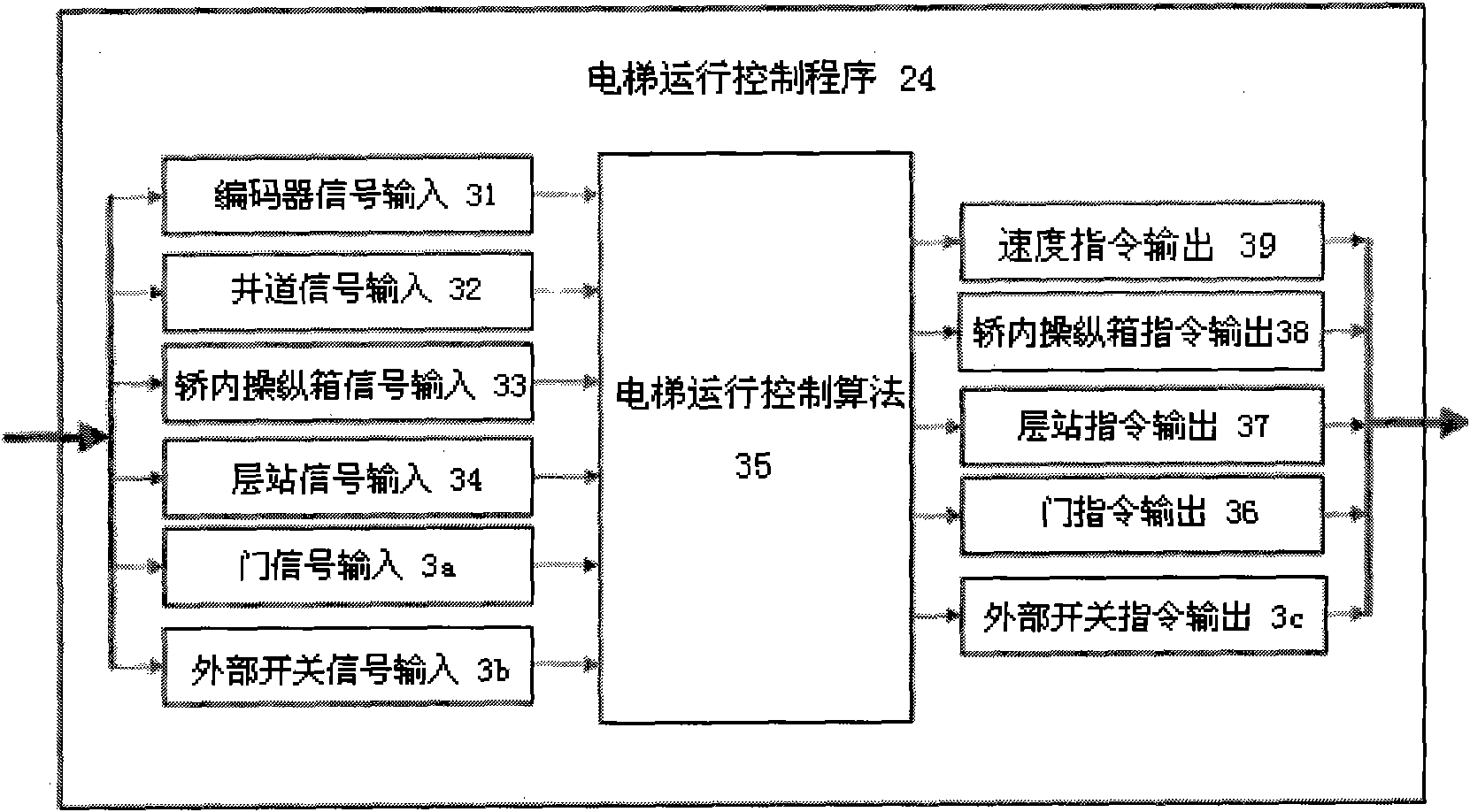

Automatic testing system of elevator running control software

ActiveCN102070054AEliminate human errorNo human intervention requiredElevatorsInstruction sequenceMaterial resources

The invention discloses an automatic testing system of elevator running control software. A host computer transmits a test item instruction to an elevator running controller according to configuration, receives a test result which is uploaded by the elevator running controller, generates a test report and also receives and displays elevator running information on a human-computer interaction interface; and the elevator running controller automatically generates a test instruction sequence according to the received test item instruction transmitted by the host computer, automatically executes testing work related to the elevator running control software according to a correct time sequence, generates a test result, uploads the test result to the host computer and also uploads the elevator running information to the host computer at regular time. Through the system, the complex testing work of the elevator running control software which is originally required to be operated by testing personnel step by step is changed to be automatically finished by the automatic testing system, manual intervention is avoided, testing efficiency is improved, and the human error of the testing work is eliminated, so that manpower and material resources are saved.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

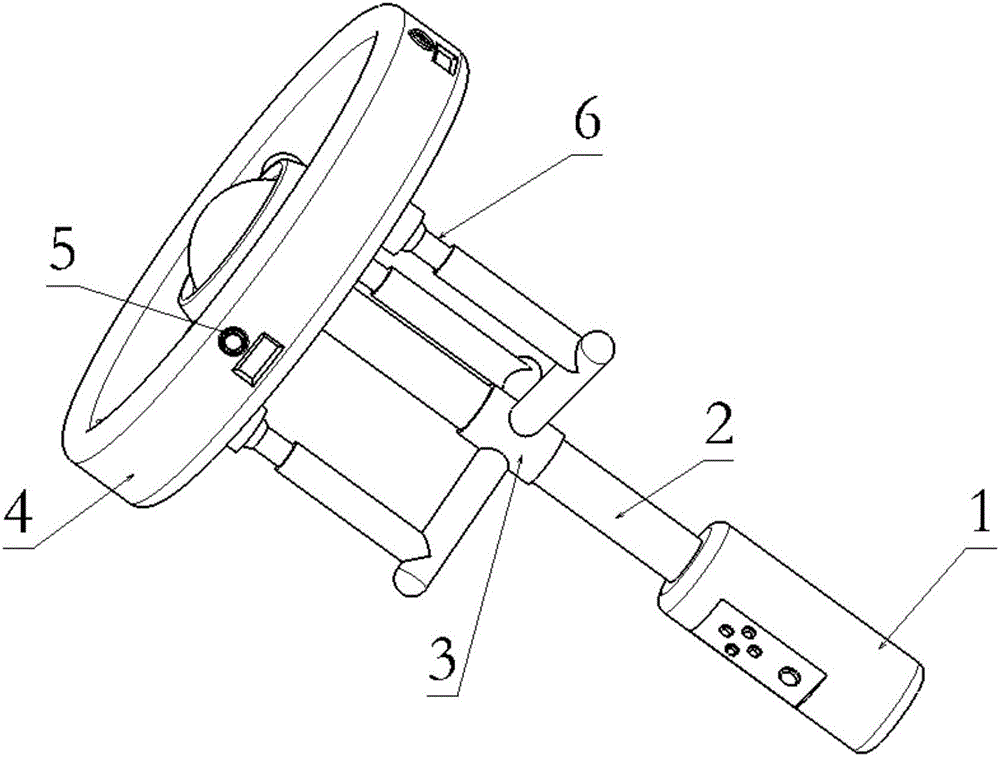

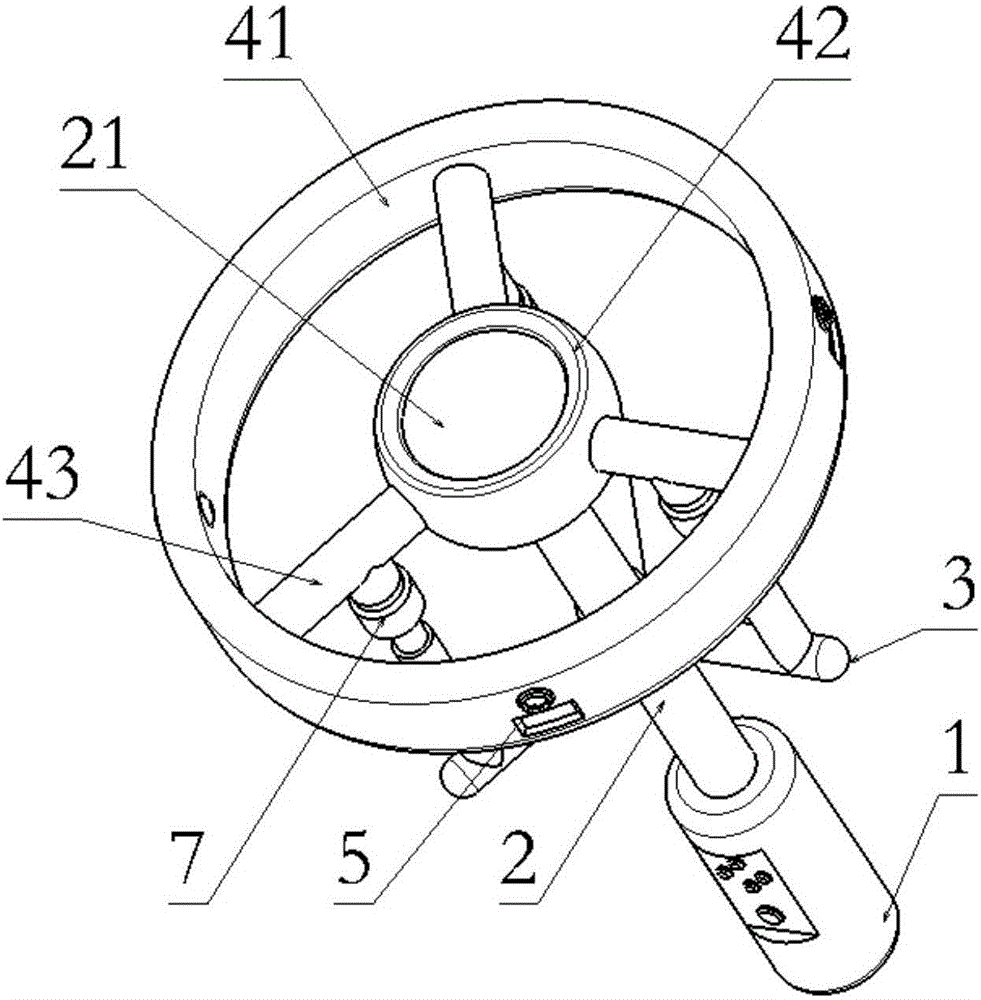

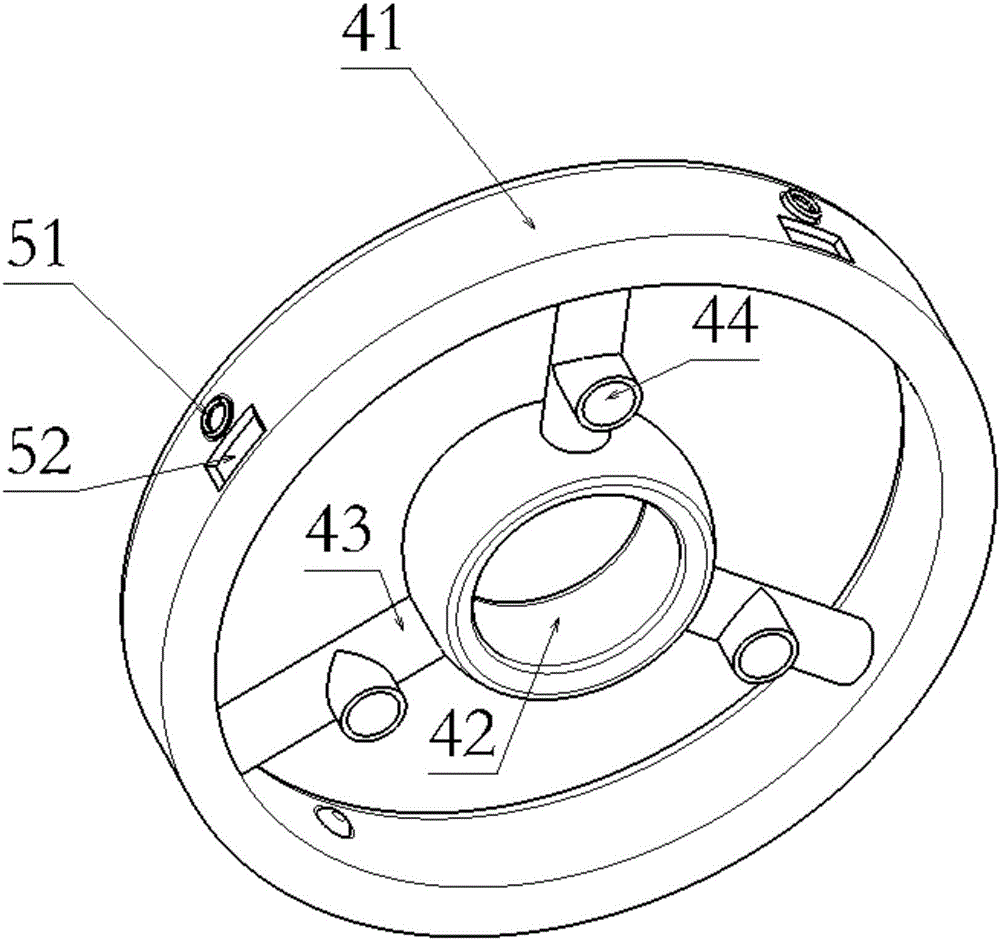

Laser inner diameter measuring instrument

ActiveCN106152956AHigh measurement accuracyThe operation process is simple and convenientUsing optical meansContinuous measurementRadial plane

The invention provides a laser inner diameter measuring instrument which comprises a handle, a main rod, a rotary fulcrum rod, a measuring ring and spherical hinges. According to the laser inner diameter measuring instrument, non-contact type laser measurement is adopted, the measuring ring is turned for continuous measurement, three laser heads measure the inner wall of a workpiece to obtain three-point distance sets, measured section plane inner diameter values corresponding to all the three-point distance sets are obtained, the minimum values in the obtained inner diameters are compared, and the radial plane inner diameter value of the workpiece is obtained. The measuring instrument is high in measurement precision, the operation process is easy and convenient, personal errors caused by traditional contact measurement are effectively eliminated, and a fast and precise measuring tool and method are provided for workpiece deep hole measurement.

Owner:IBE ELECTRONICS CO LTD

Full-automatic series verification calibrating device with pressure-resistant water meter

InactiveCN103175588APerfect database functionImprove efficiencyTesting/calibration apparatusMicrocontrollerEngineering

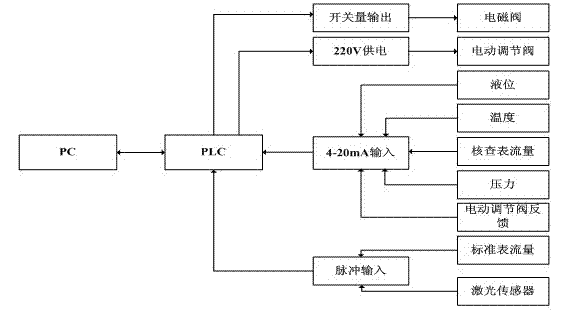

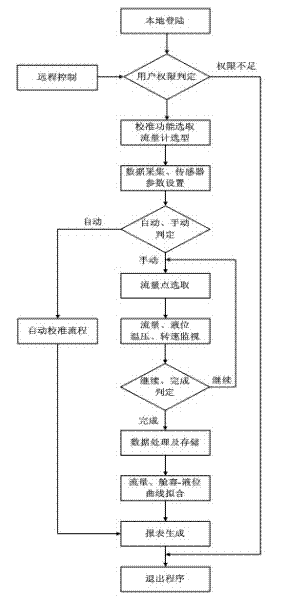

The invention discloses a full-automatic series verification calibrating device with a pressure-resistant water meter. The full-automatic series verification calibrating device with the pressure-resistant water meter comprises a water meter calibrating foundation mechanism, flow counting mechanisms, a counting mechanism, a pipeline and an operation system. The water meter calibrating foundation mechanism comprises a testing tube section which is formed by multiple testing straight tube sections and multiple water meters to be inspected, wherein the multiple testing straight tube sections and the multiple water meters to be inspected are connected in series at intervals; each water meter to be inspected corresponds to a flow counting mechanism; the counting mechanism comprises an electronic weighting device and a working container; the tail end of the testing tube section is guided into the working container through the pipeline; the operation system is electrically connected with the flow counting mechanisms and the electronic weighting device in a two-direction mode. The full-automatic series verification calibrating device with the pressure-resistant water meter achieves full-automatic meter inspection by utilizing remote control of a computer combined with a single chip controlling mechanism which gives priority to the filed programmable logic controller (PLC) control or an embedded system. Compared with the inspection method of a meter in the prior art, the full-automatic series verification calibrating device with the pressure-resistant water meter greatly improves using efficiency of an inspection device of the water meter and shortens inspection time of the water meter on the basis of ensuring measuring accuracy and eliminating human errors, and greatly improves working efficiency of inspection staff in a large range at the same time.

Owner:江苏远传智能科技有限公司

Secure Method for Delivering Regulated Items Including Drugs to a Patient

InactiveUS20110245967A1Eliminate errorHamper dispensingAcutation objectsDigital data processing detailsDrugPharmacist interventions

The present invention is generally directed to a method of dispensing regulated items, particularly drugs, directly to the patient via a dispensing system, without pharmacist intervention, that reduces human error associated with dispensing regulated items wherein a manufacturer or distributor of a regulated item establishes a dispensing system in communication with a data base wherein a prescriber is registered and enters patient data such as which regulated item is prescribed for the patient, characteristics such as sex, age, height, weight, etc., any other drugs the patient is currently taking or has a prescription for, any allergies to any particular drugs, substances, components, etc., reliable data for verifying the identity of the patient, and subsequently dispensing a regulated item directly to the patient from said dispensing system without pharmacist intervention, including communicating any necessary educational or instructional information to the patient concerning the regulated item and verifying the steps to the data base.

Owner:INSPIRION DELIVERY SCI LLC

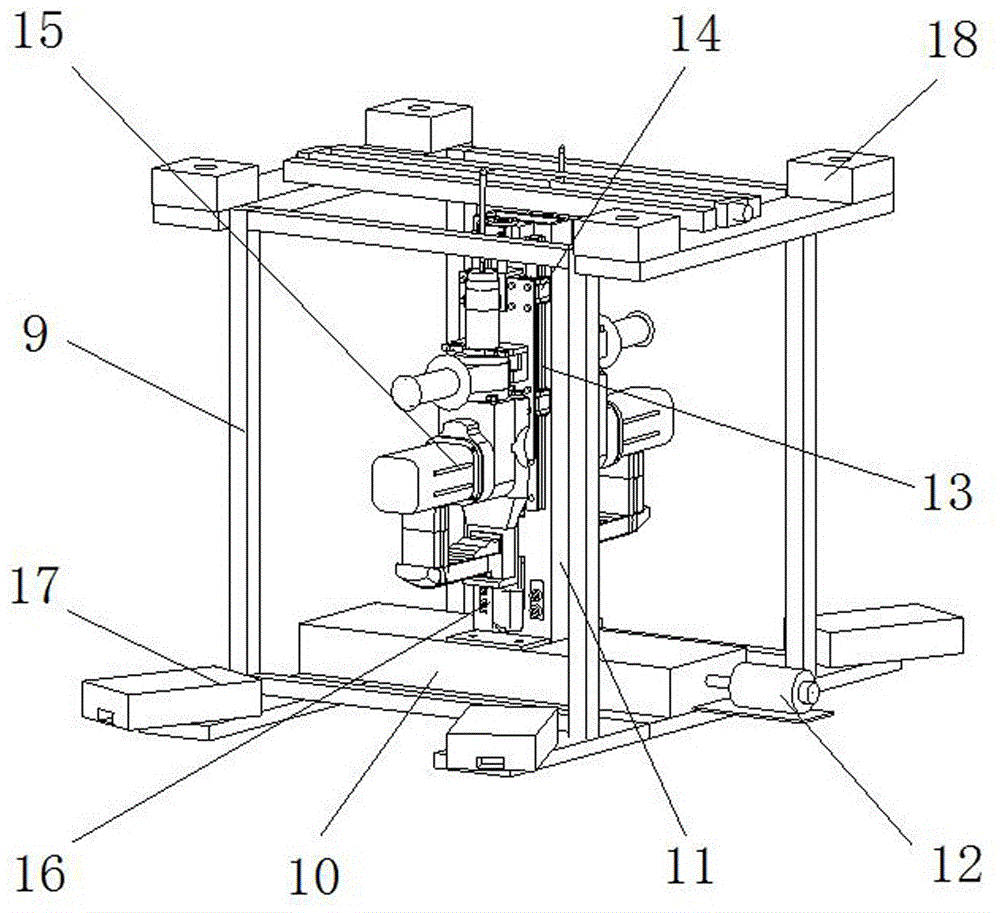

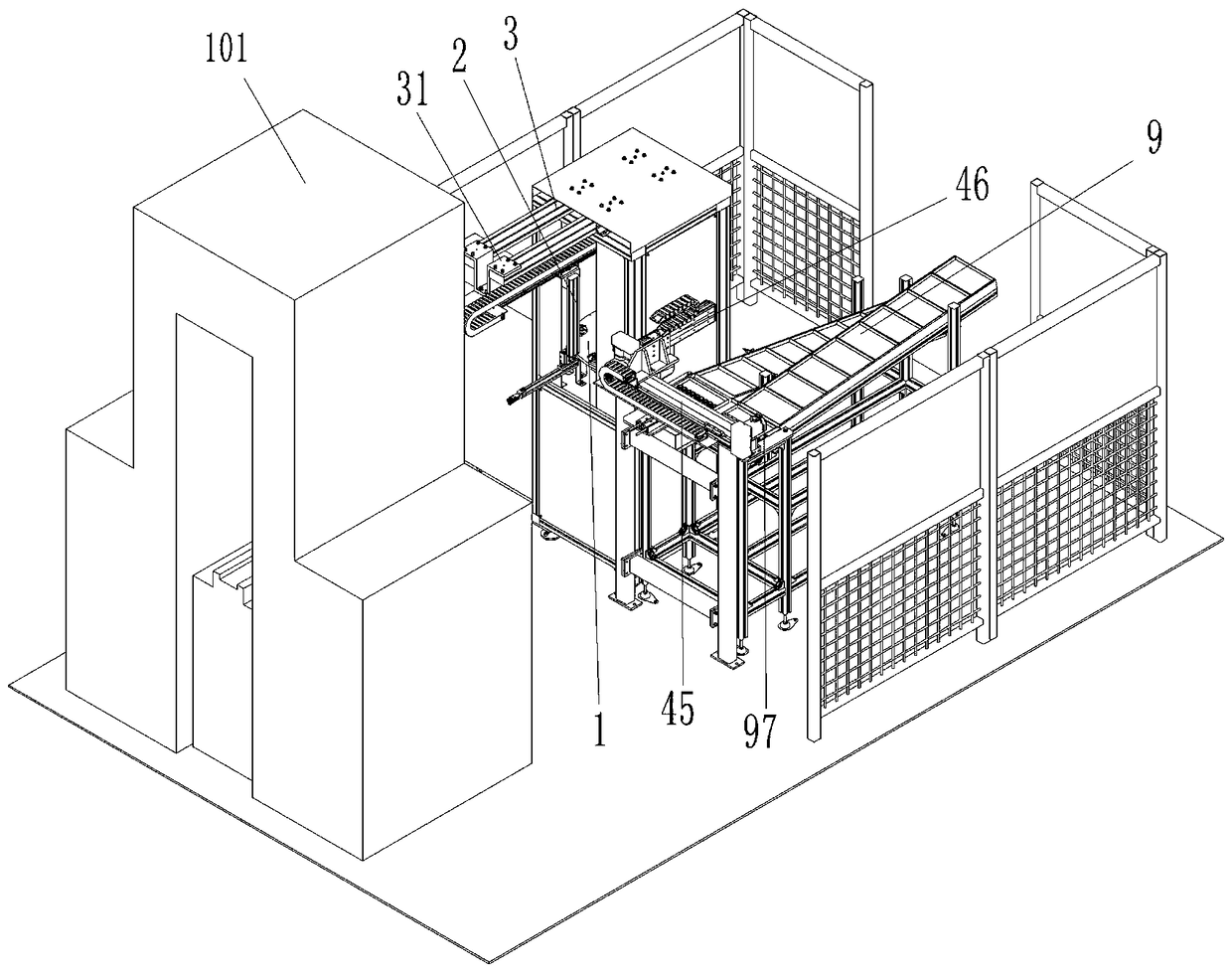

Isolator automatic online detecting system

PendingCN108942484AImprove efficiencyRealization of automatic online detectionEdge grinding machinesGrinding carriagesReciprocating motionAssembly line

The invention discloses an isolator automatic online detecting system. The isolator automatic online detecting system comprises a control management system and a rack arranged on the side of a fetching opening of a press machine, and is characterized in that the rack is provided with a feeding manipulator, an intermittent type indexing rotary table, a discharging manipulator and a material tray turnover system; the feeding manipulator is arranged on a feeding guide rail above the rotary table, and has the degree of freedom of moving to the position above a workbench of the press machine alongthe feeding guide rail to fetch materials and moving to the feeding station of the rotary table for feeding; positioning clamps matched with stations in number are evenly distributed on the edge of the rotary table; the positioning clamps form an assembly line type checking structure together with the feeding manipulator, the discharging manipulator and the stations of gauge units arranged at thestopping positions of the rotary table in a surrounding mode correspondingly; and the discharging manipulator moves in a reciprocating mode between a discharging station and the material tray turnoversystem along a cross guide rail above the material tray turnover system to form a discharging and sorting structure. Automatic detection is achieved, and the working efficiency and enterprise benefits are greatly improved.

Owner:SHIJIAZHUANG RONGXIN SCI & TECH

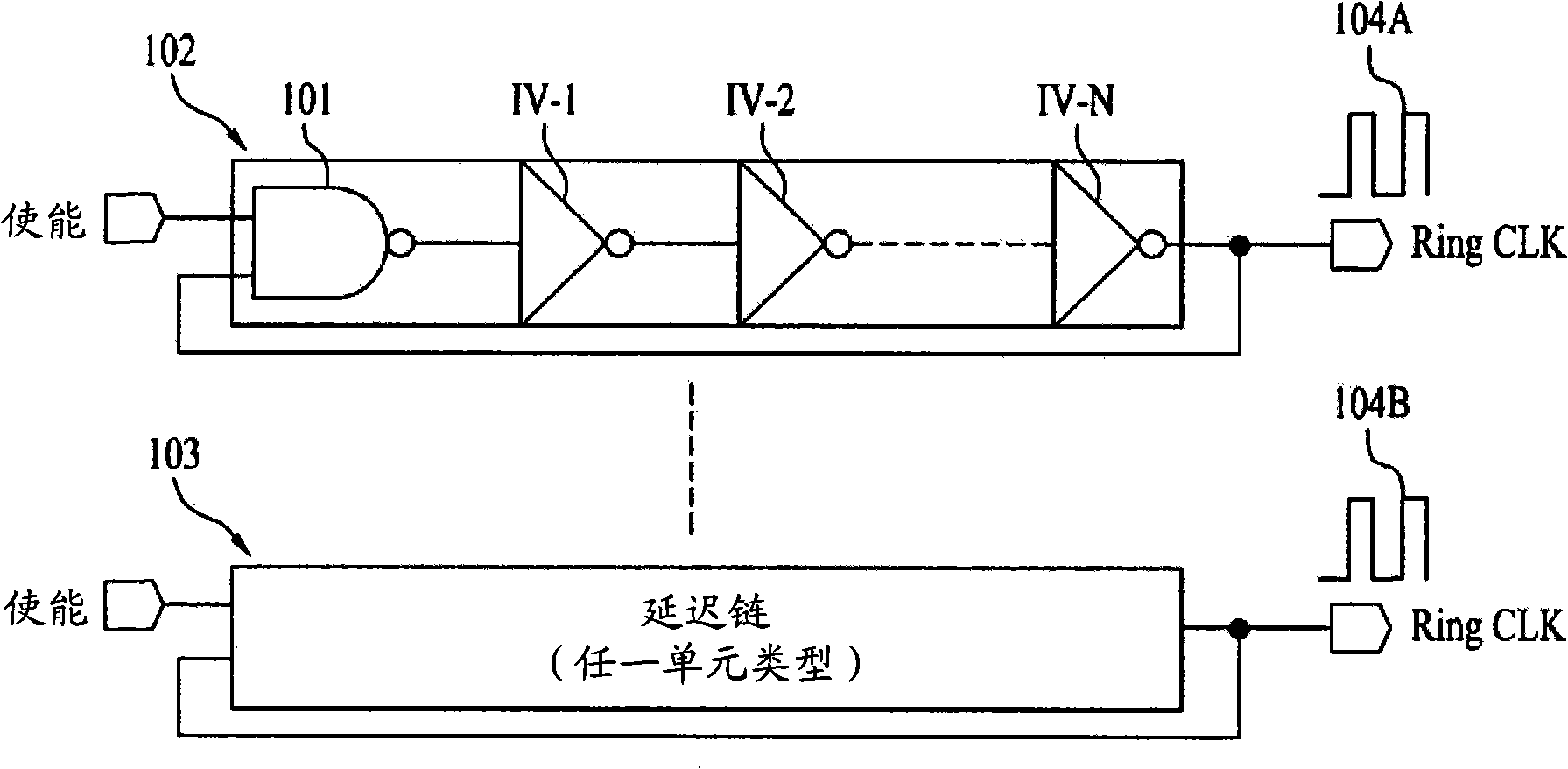

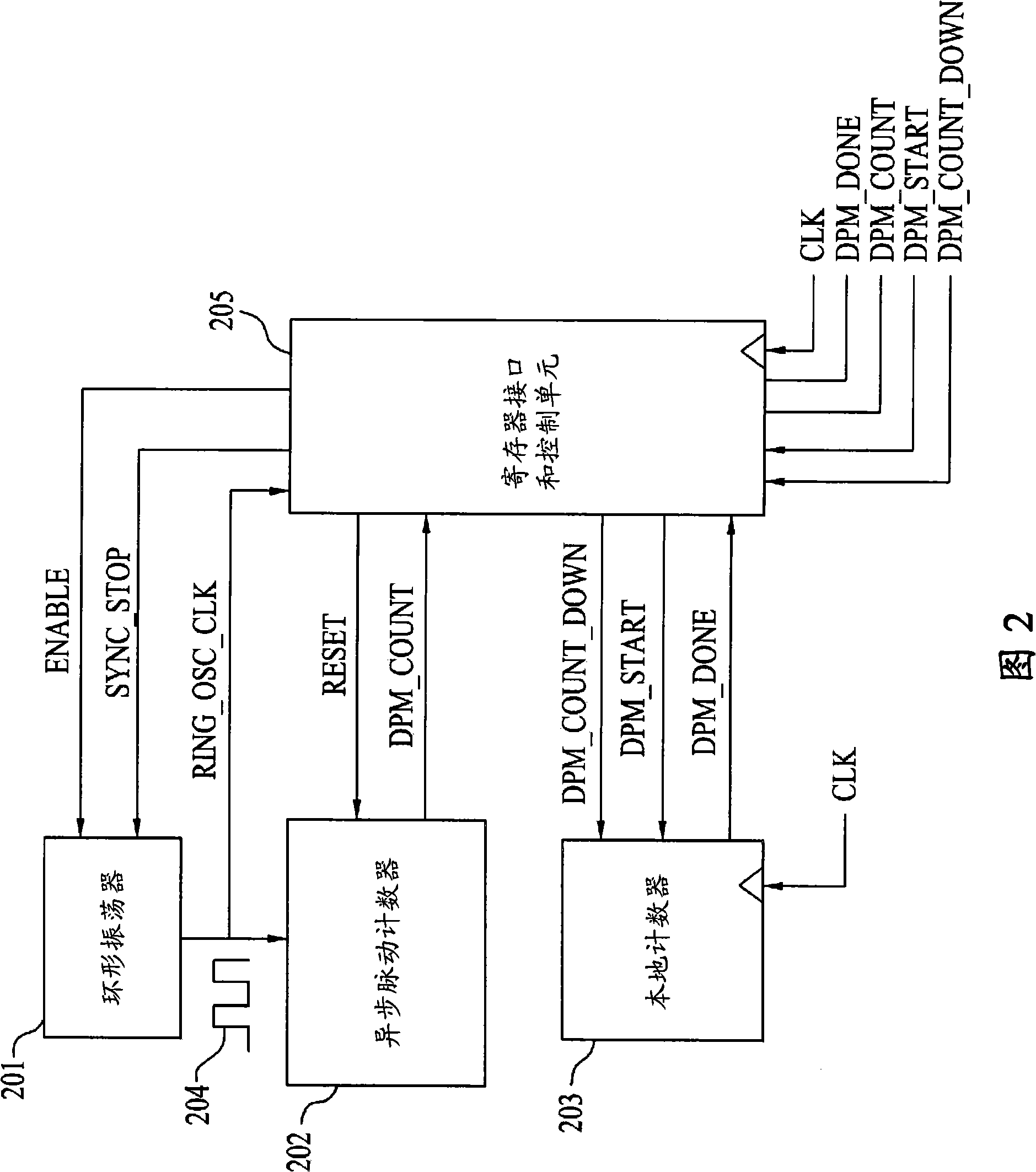

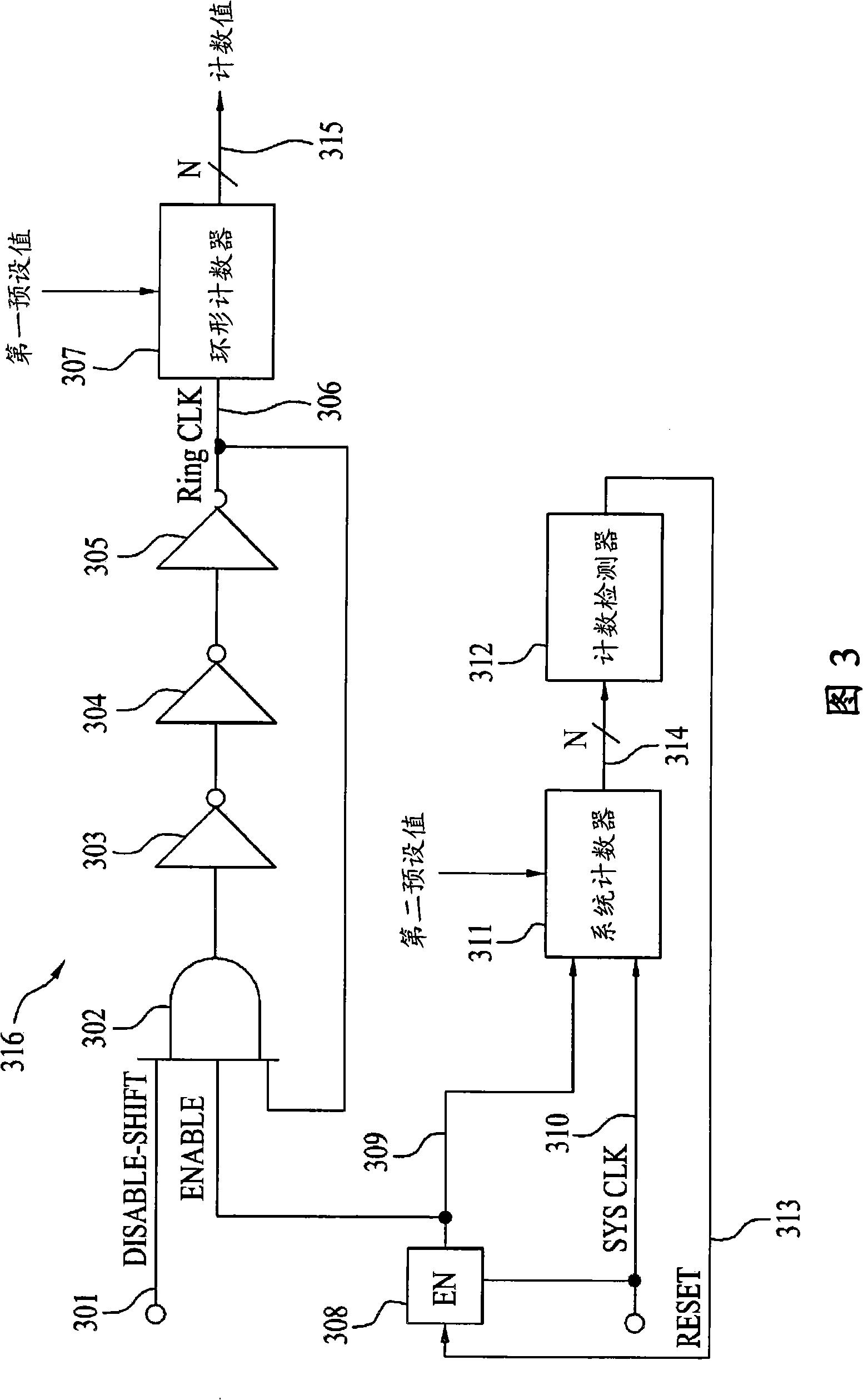

Measurement apparatus for improving performance of standard cell library

InactiveCN101334440AImprove performanceEliminate human errorElectrical testingPulse generation by logic circuitsMeasurement deviceStandard cell

The invention discloses a measurement apparatus for improving performances of standard cells in a standard cell library when verifying performance of the standard cell library through a ring oscillator among various test element groups (TEGs). A built-in circuit is used to measure and verify performance of the standard cell library through a TEG. Therefore, it is possible to effectively improve performances of the standard cells in the standard cell library. Particularly, it is possible to not only remove human errors or internal errors of equipment, but also perform the measurement more readily, rapidly and accurately. Further, it is possible to curtail the use of high-performance equipment or manpower and time required in a measurement process.

Owner:DONGBU HITEK CO LTD

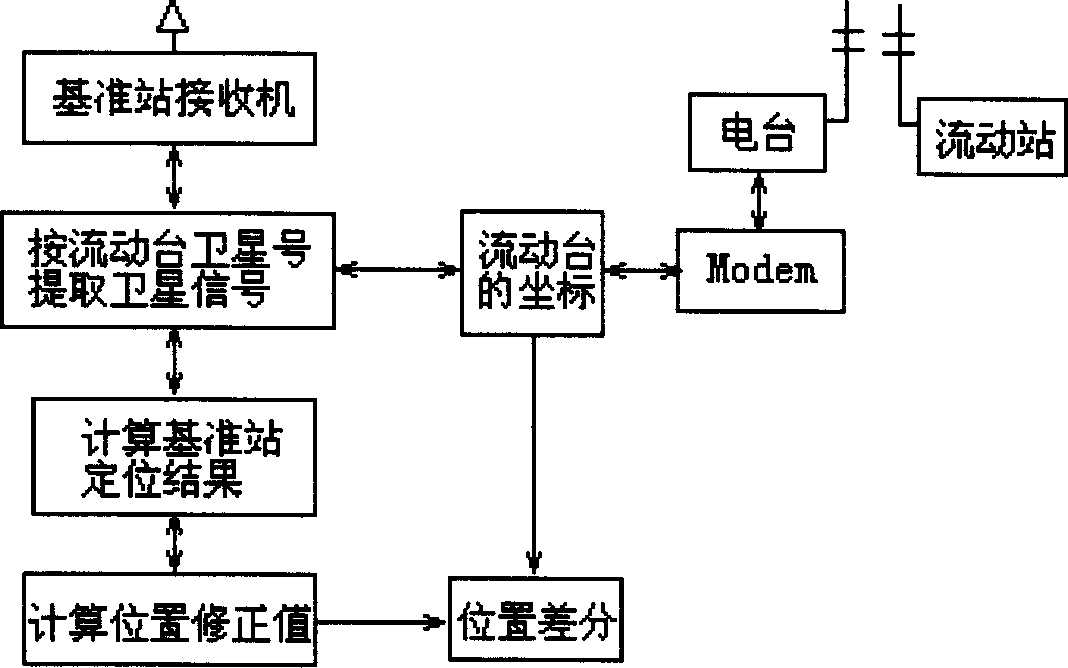

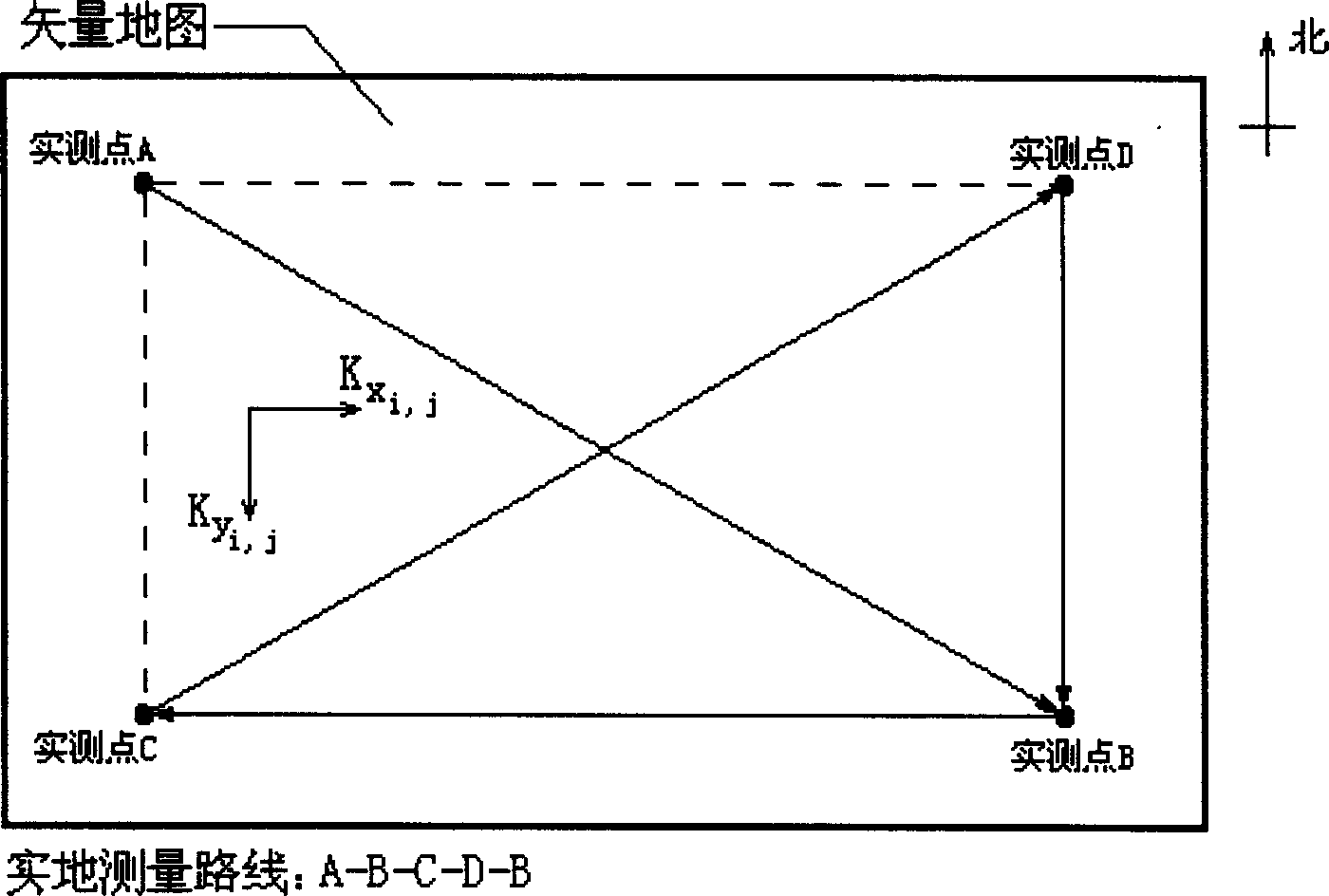

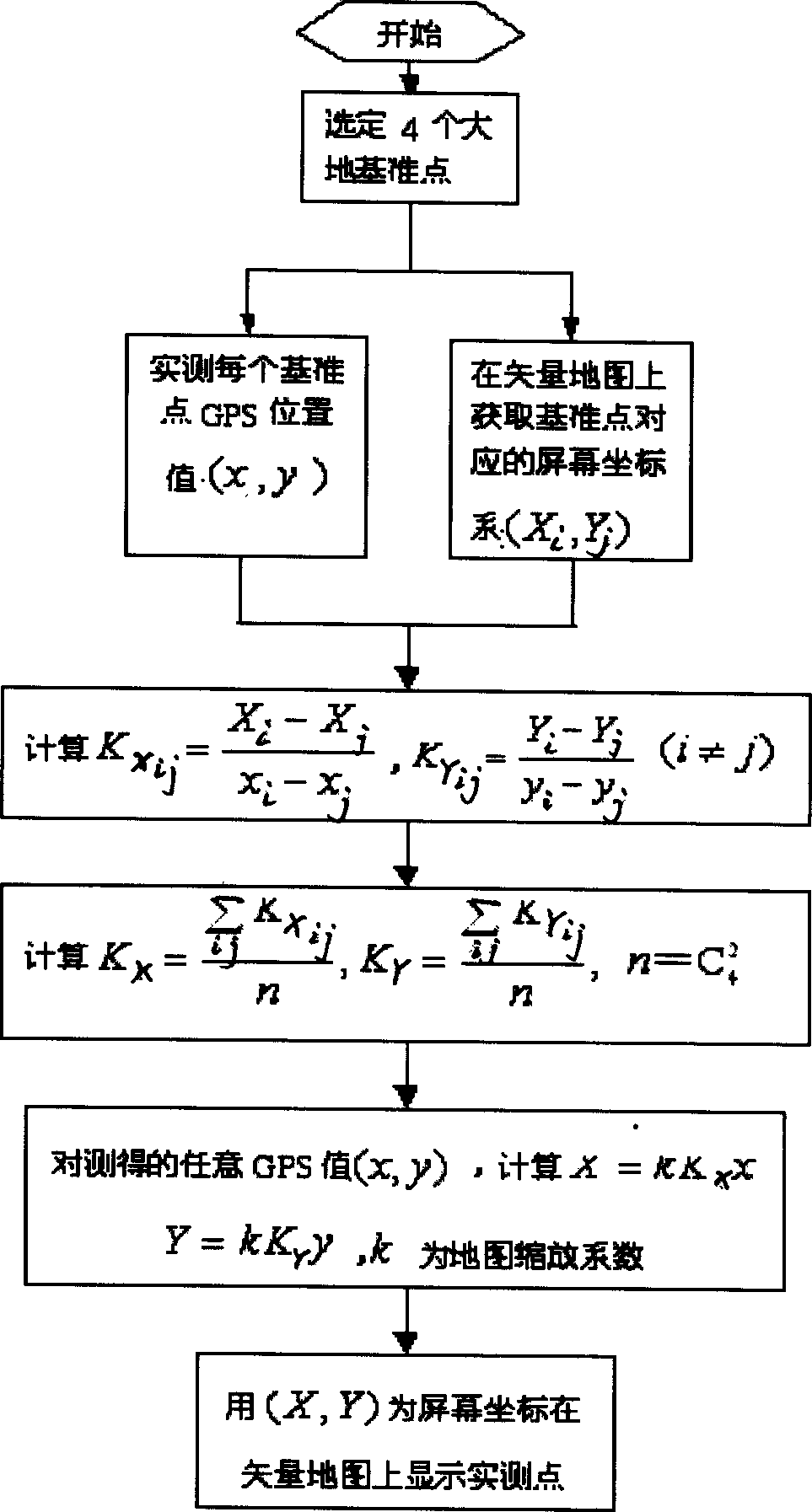

Satellite locating error processing method based on map matching

InactiveCN1455268AEliminate human errorLow costPosition fixationVehicle position indicationSatelliteMap matching

GPS is utilized to measure the four points not arranged in same line within the location area to obtain the actual measured values, which are compared with the latitude and longitude values of the corresponding points on the vector map. Thus, the transverse and longitudinal deviations of the positioning accuracy are obtained. The correction is carried out to eliminate the GPS positioning system error and the manual error in making the vector map effectively. The method does not need the equipment of communication system to transfer the difference positioning information so as to reduce the intermedium steps and lower the cost, providing the features of fast speed, high accuracy and possessing the obvious economical and social benefit.

Owner:第二炮兵工程学院对外技术服务部

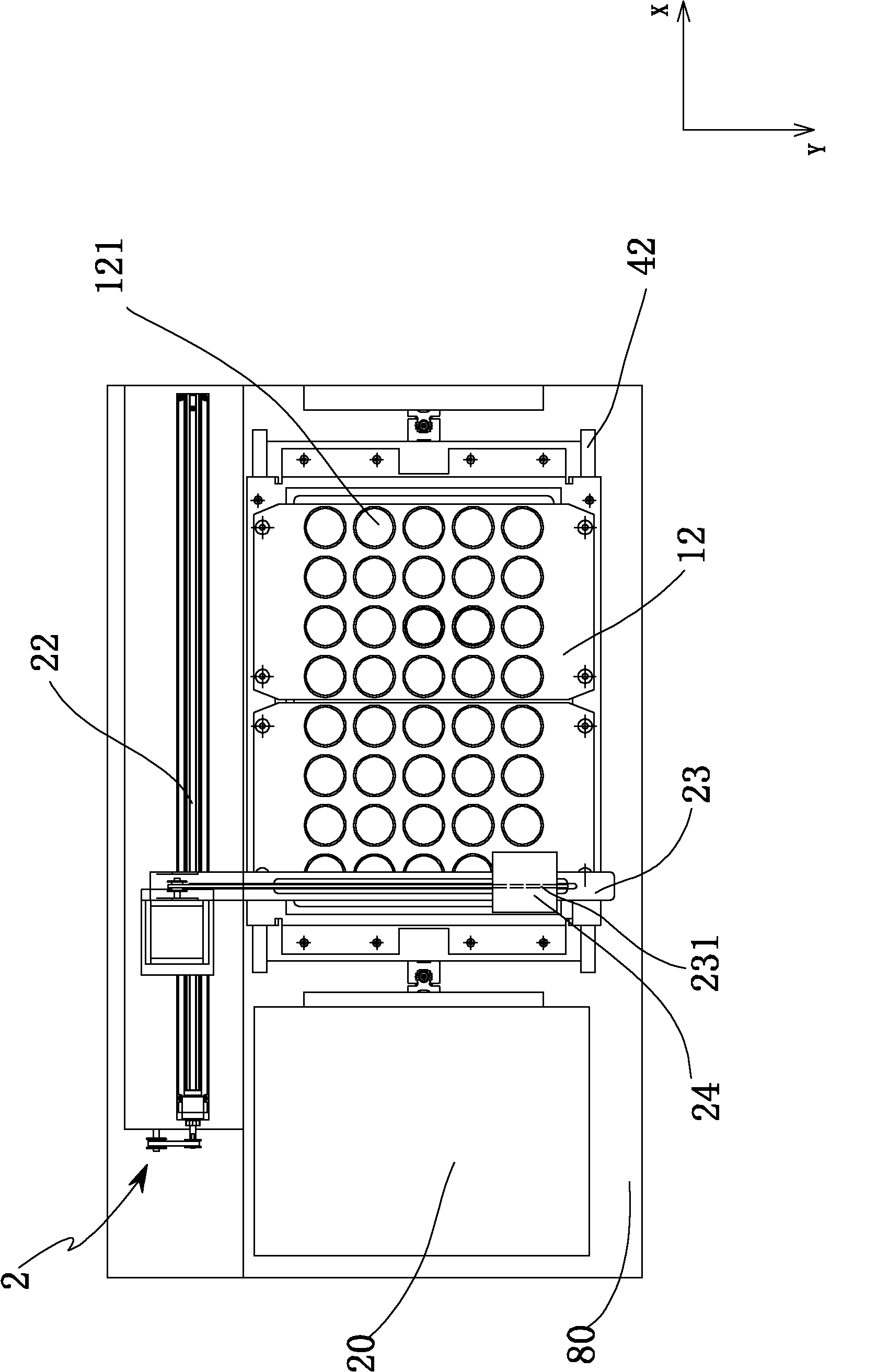

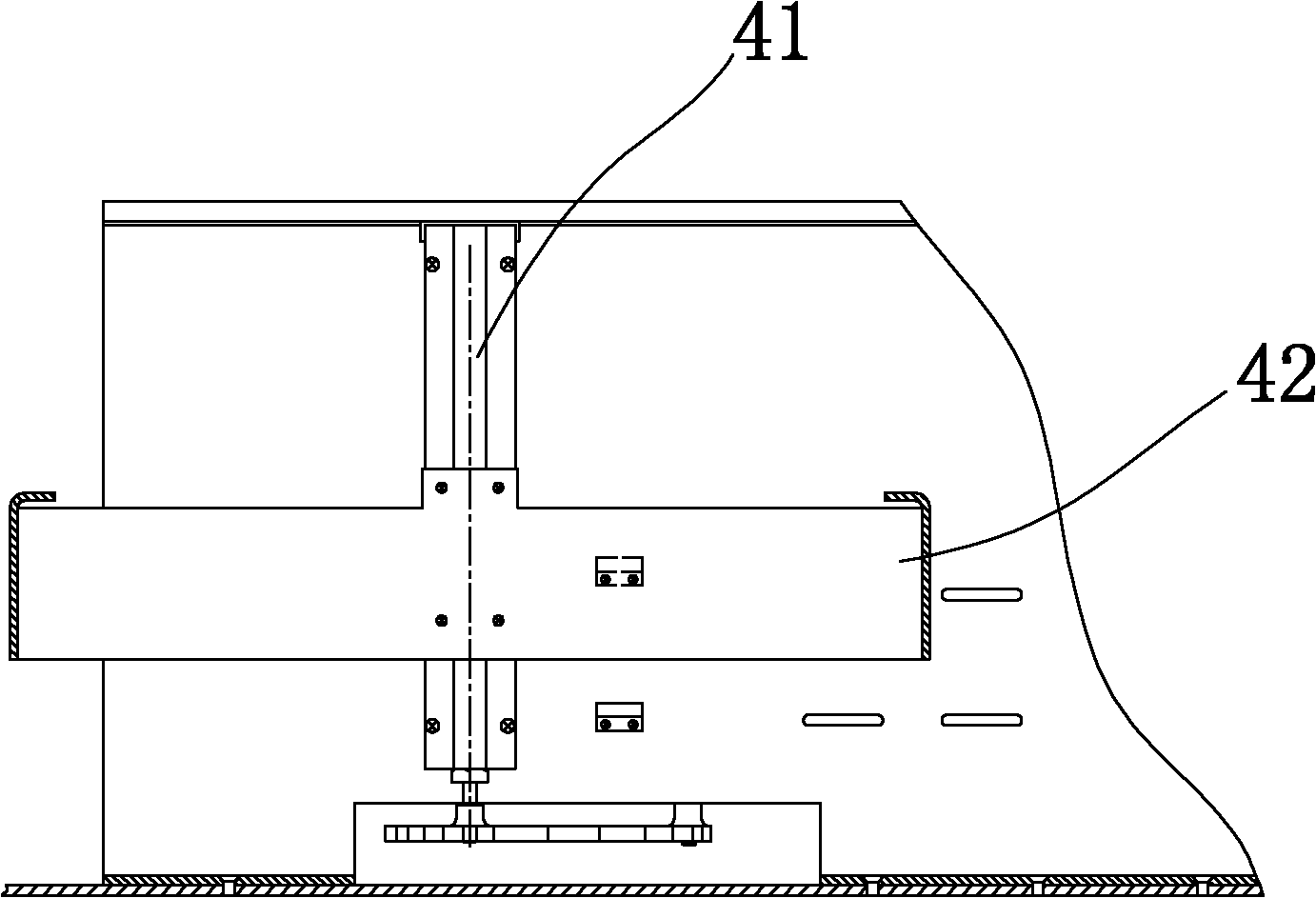

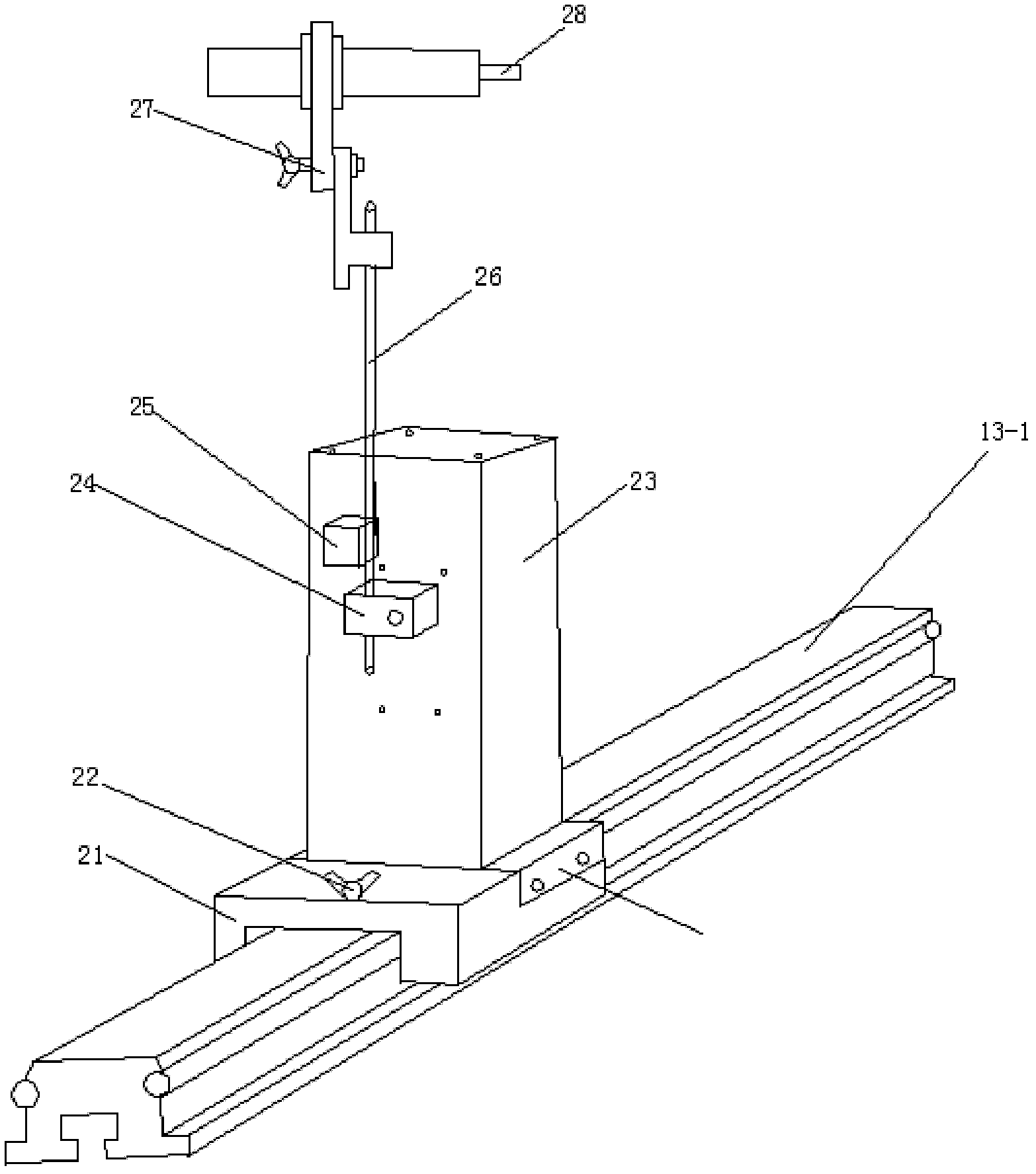

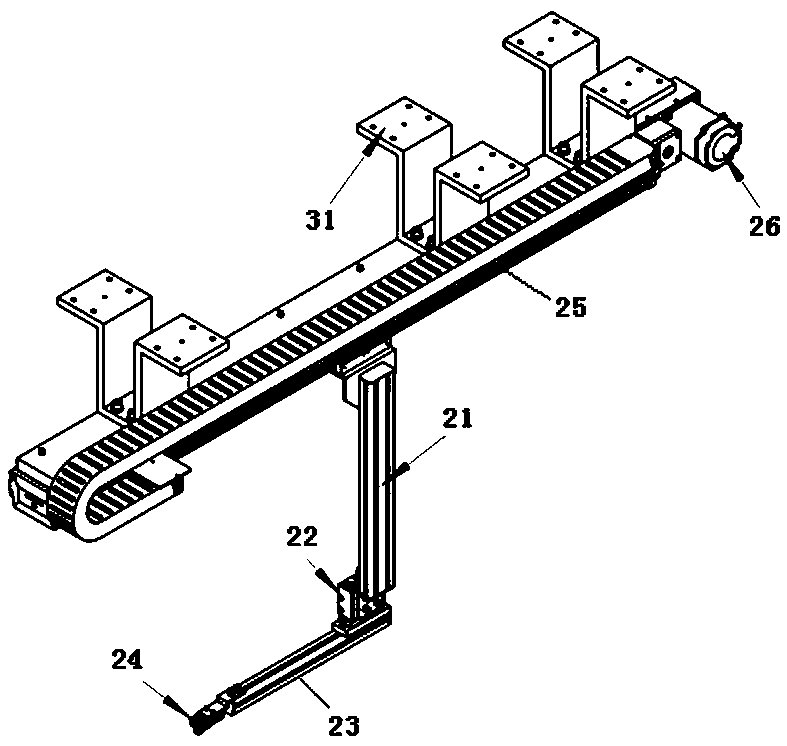

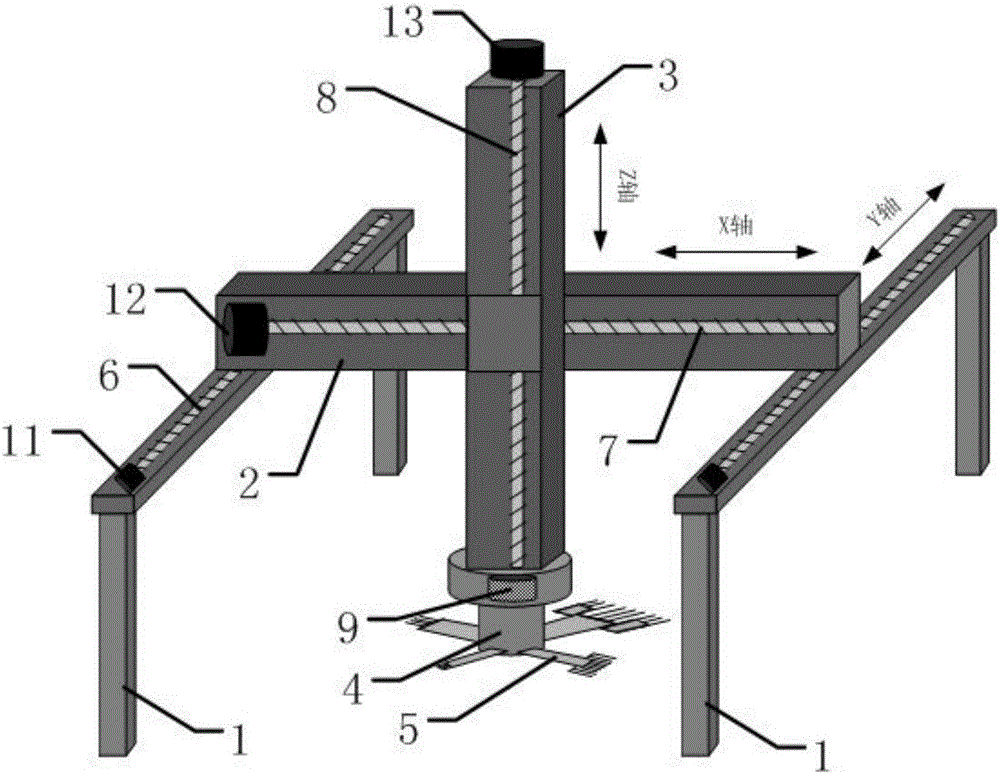

Conveying mechanism for comprehensively controlling weight, weight verification system and weight verification method

InactiveCN106315211AReduce or eliminate the impactEliminate human errorWeighing apparatus testing/calibrationConveyor partsEngineeringVerification system

The invention provides a conveying mechanism for comprehensively controlling a weight. The conveying mechanism comprises two door-shaped beams arranged side by side, and a horizontal transverse beam; a vertical longitudinal beam is arranged on the horizontal transverse beam; a manipulator is arranged at the end part of the vertical longitudinal beam; Y-axle guide mechanisms are respectively arranged on the two door-shaped beams; the horizontal transverse beam is provided with an X-axle guide mechanism; the vertical longitudinal beam is provided with a Z-axle guide mechanism; joint parts are respectively arranged on the X-axle guide mechanism and the Z-axle guide mechanism; and the manipulator includes a rotating section, multiple manipulators respectively connected with the rotating section, and a manipulator motor for driving the rotating section to rotate by 360 degrees. The manipulator has a single large fork with two stations, two large forks with four stations, a single small fork with two stations and double small forks with four stations; and each fork is a comb-shaped structure. The whole weight verification process is operated by set procedures, so that the personal error is eliminated, and the influence of linear drifting of a qualitative comparison instrument on the measurement result is effectively reduced or eliminated.

Owner:SHANDONG MEASUREMENT SCI RES INST +1

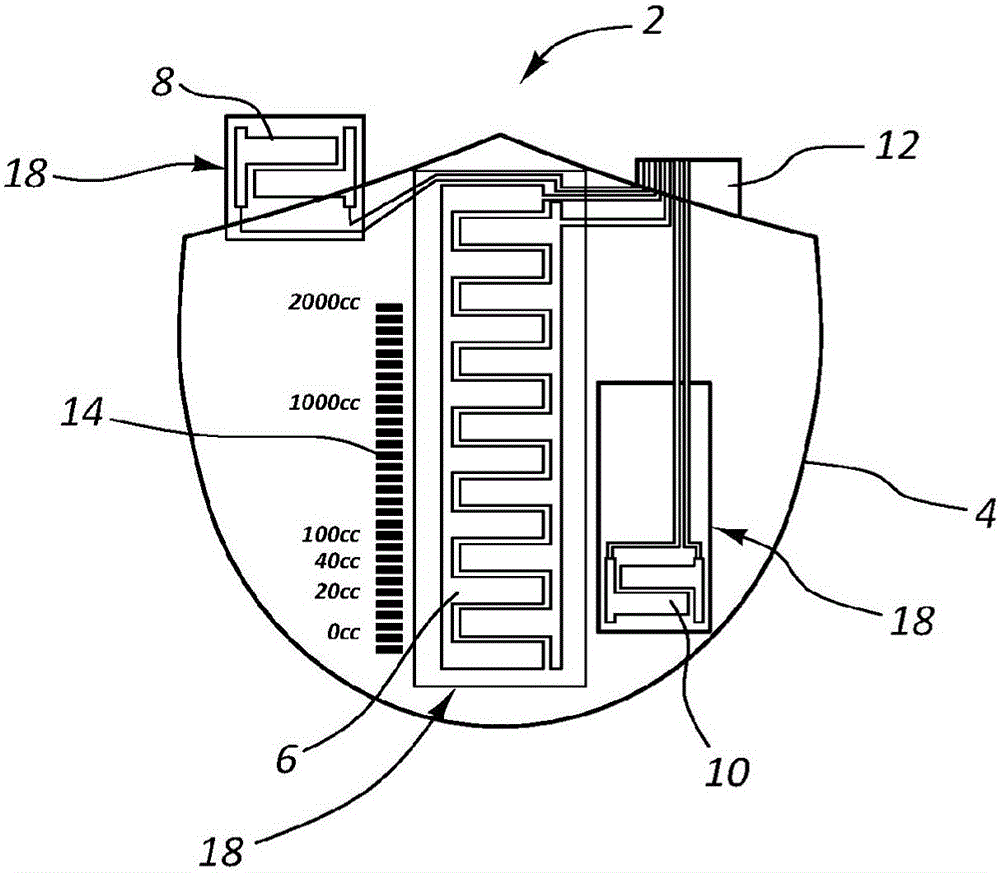

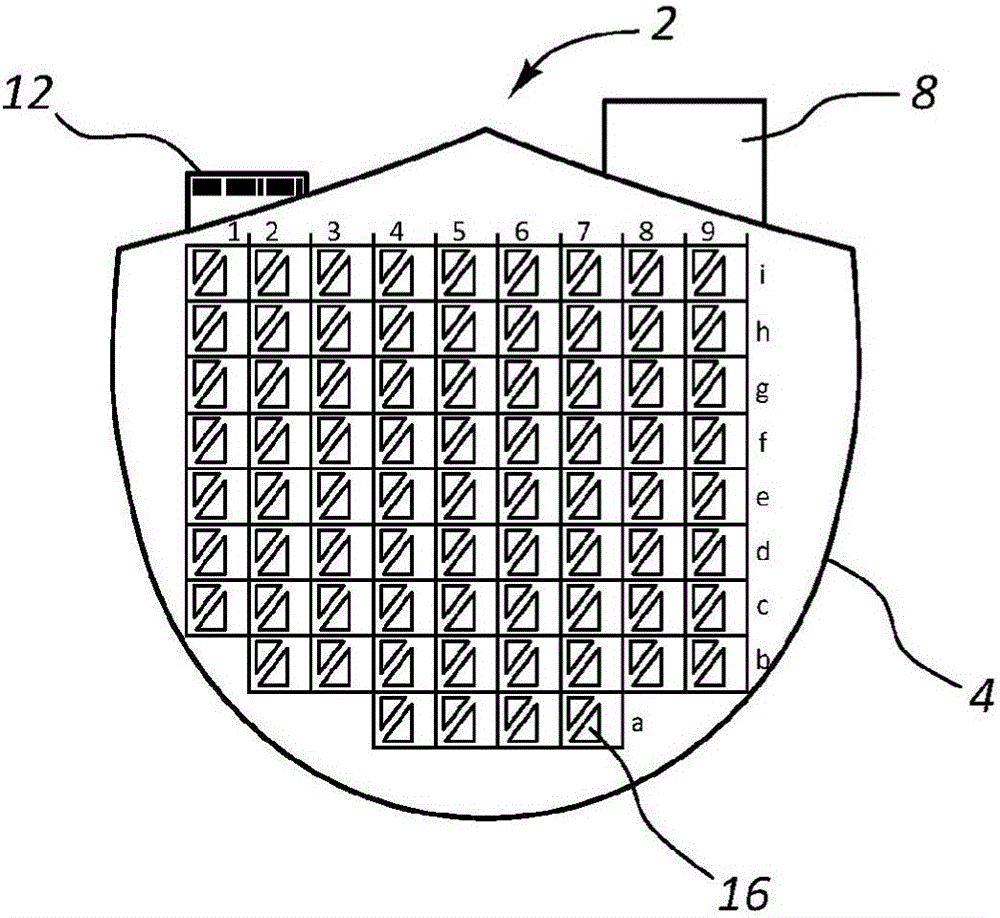

Urine monitoring systems and methods

InactiveCN105025809AShorten the timeHigh resolutionSurgeryVaccination/ovulation diagnosticsMonitoring systemMonitoring fluid output

Fluid / urine monitoring devices and / or systems are provided for monitoring fluid output, including volume and flow rate. One high resolution, low cost electronic urine monitoring device and system collects urine and includes a capacitance sensor. The capacitance of the capacitance sensor may be correlated with fluid content and be used to identify urine volume and flow rate. Another high resolution, low cost flow meter is placed in line with drainage tubing and uses a capacitance sensor to measure fluid output without collecting the fluid. Other low cost urine monitoring devices use pressure based or weight based measurement sensors to measure volume and flow rate.

Owner:CR BARD INC

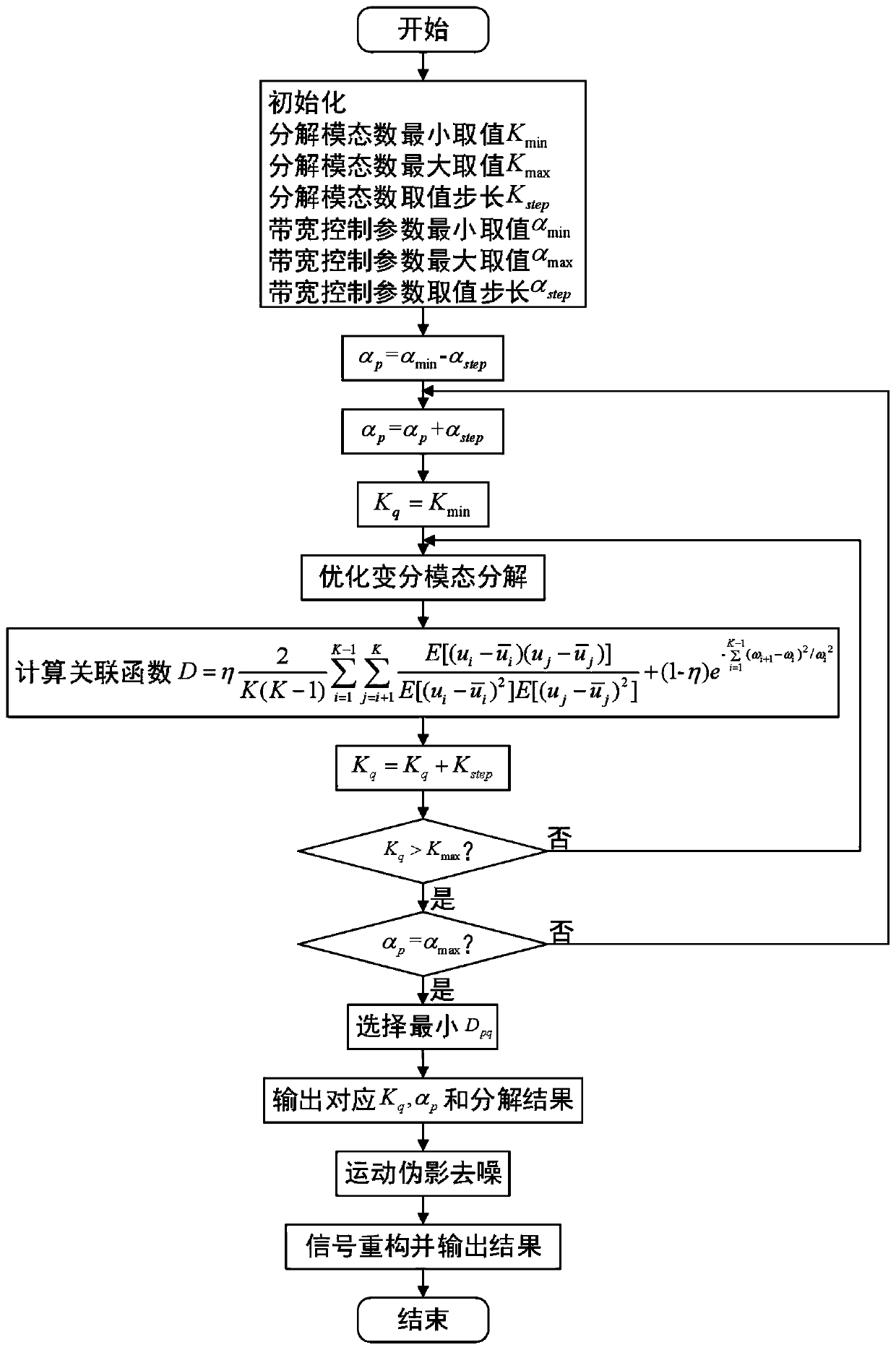

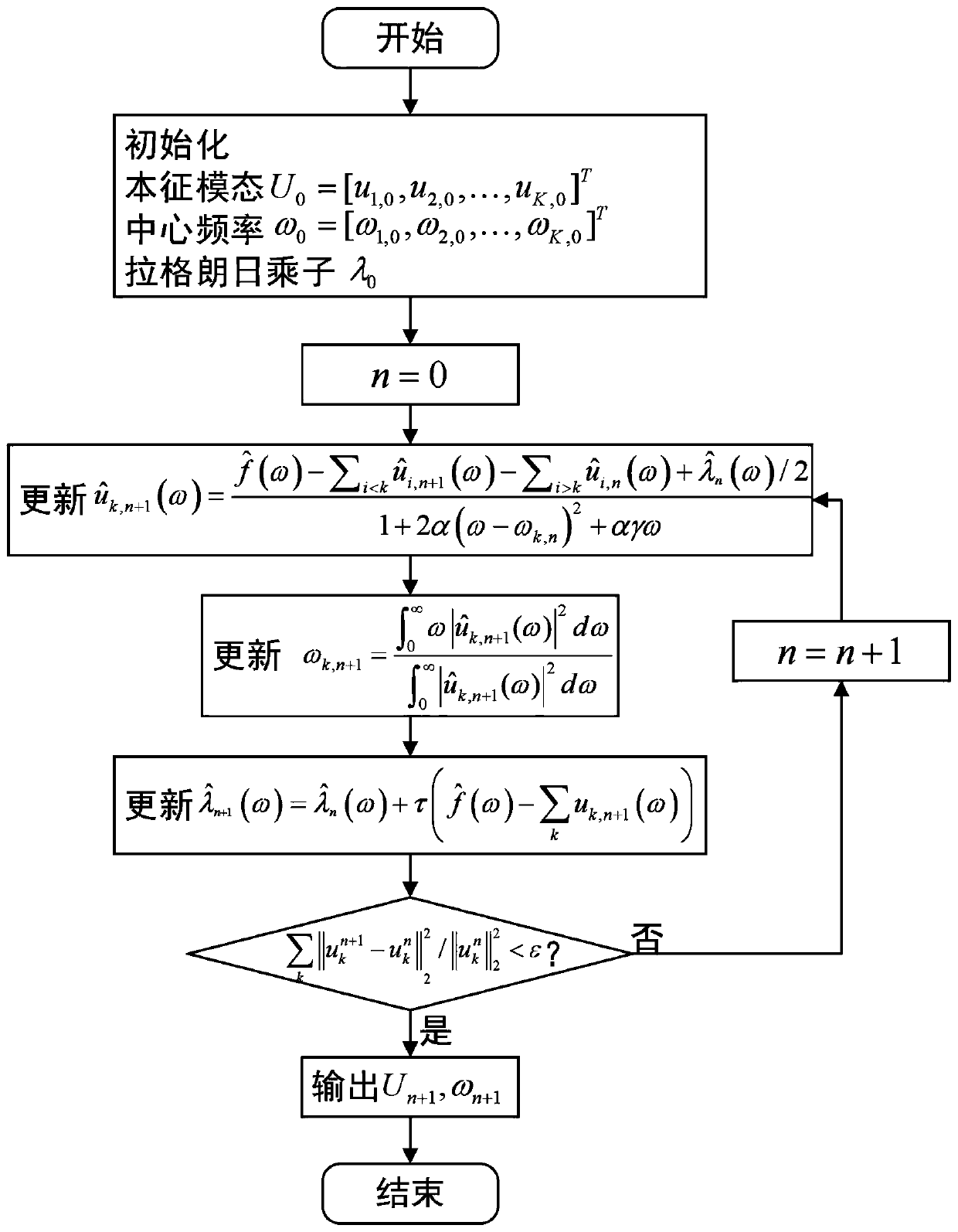

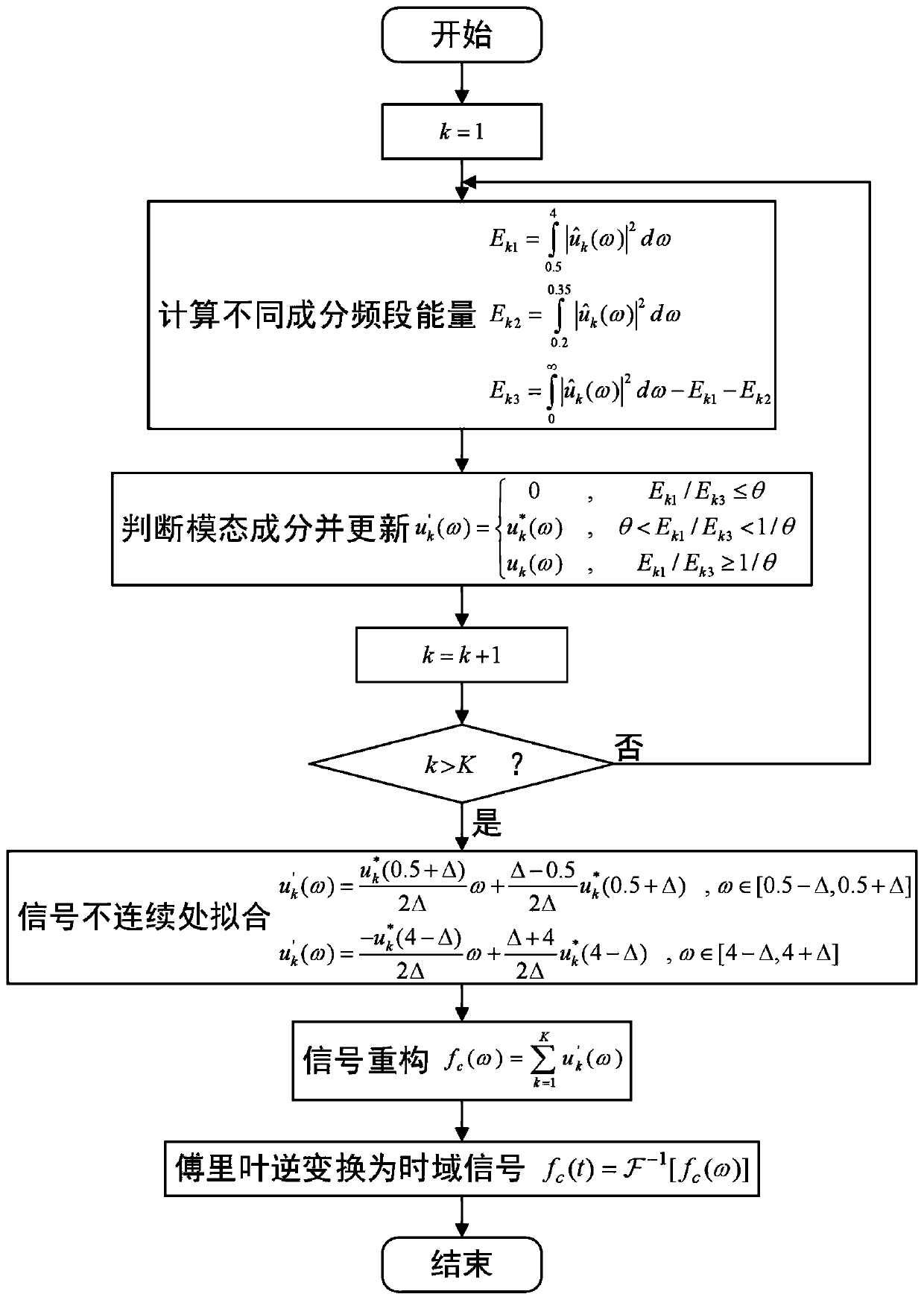

Pulse wave motion artifact removal method based on parameter adaptive optimization VMD

ActiveCN110309817AQuality improvementGood removal effectCharacter and pattern recognitionMedical equipmentRelative energyIntrinsic metric

The invention relates to a pulse wave motion artifact removal method for parameter adaptive optimization VMD, and belongs to the technical field of biomedical signal acquisition and processing. The method comprises the following steps of by optimizing an objective function of variational mode decomposition, evaluating the variational mode decomposition result by adopting a correlation coefficientwith the fusion of the intrinsic mode correlation degree and the central frequency dispersion degree; carrying out parameter adaptive optimization variational mode decomposition on a pulse wave signalto obtain an intrinsic mode [uk] of the pulse wave, and designing a denoising rule according to the relative energy of frequency bands corresponding to different components of the signal to remove the motion artifacts of the pulse wave. Compared with the prior art, the method has the advantages that the quality of pulse wave variational mode decomposition is improved, the effect of removing the motion artifacts is improved, and the data complexity in the process of removing the motion artifacts is simplified.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

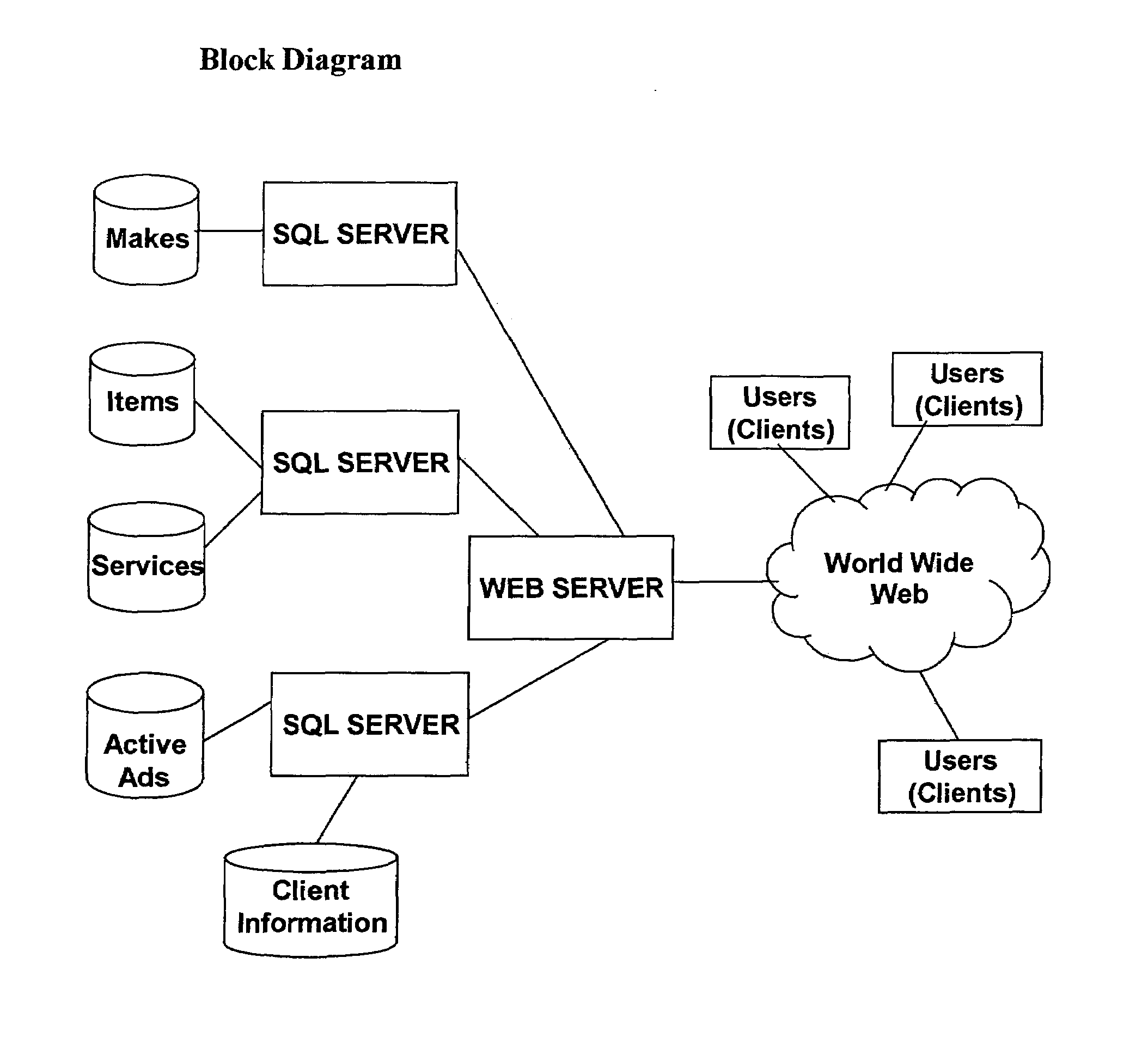

System and method for synchronizing the configuration of distributed network management applications

ActiveUS7523184B2Eliminate human errorShorten the timeDigital computer detailsData switching networksChange managementNetwork management application

A change management system to synchronize the configuration of network management applications. Traditional network management systems are maintained by hand-entering device lists into individual network management applications with no common-ties between the different applications. Whenever a network management application is changed or upgraded, it frequently becomes necessary to insure that the upgrade is populated throughout the network in order for devices to talk to one another in an error free way. The present invention is a system and method that automates the change management process in a real-time using a two-way communications model that permits a central database to affect changes on all or some network management applications / systems in the field, while also allowing those same field systems to affect the central database thereby reducing the time required for updating and monitoring a system when device changes take place.

Owner:TIME WARNER CABLE ENTERPRISES LLC

Full automatic infrared oil content analyzer

InactiveCN104345035AEnsure health and safetyReduce cross contaminationMaterial analysis by optical meansOil waterMeasurement precision

The invention provides a full automatic infrared oil content analyzer. The full automatic infrared oil content analyzer comprises a water sampling device, a magnetic agitated extraction device, an oil water separation filtering device, a waste liquid exhaust gas discharge device, an optical device, a filter amplifier, a signal processor, and a computer which are arranged in an integral cavity of the full automatic infrared oil content analyzer, and a host power supply and a controller which are connected with the water sampling device, the magnetic agitated extraction device, the oil water separation filtering device, the waste liquid exhaust gas discharge device, the optical device, the filter amplifier, the signal processor and the computer. The full automatic infrared oil content analyzer has the advantages of being high in measurement precision, convenient to operate and high in security.

Owner:TIANJIN NENGPU TECH

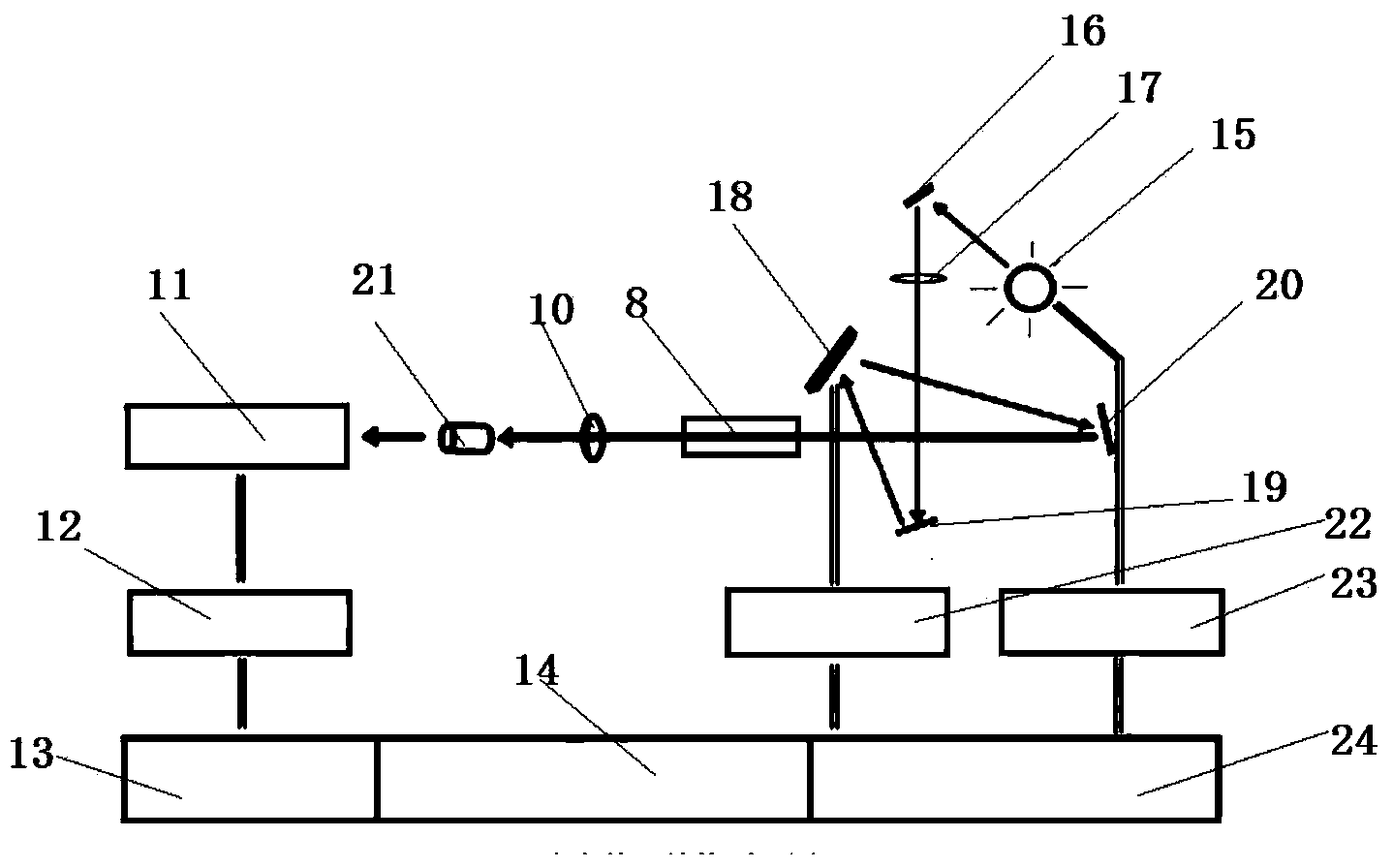

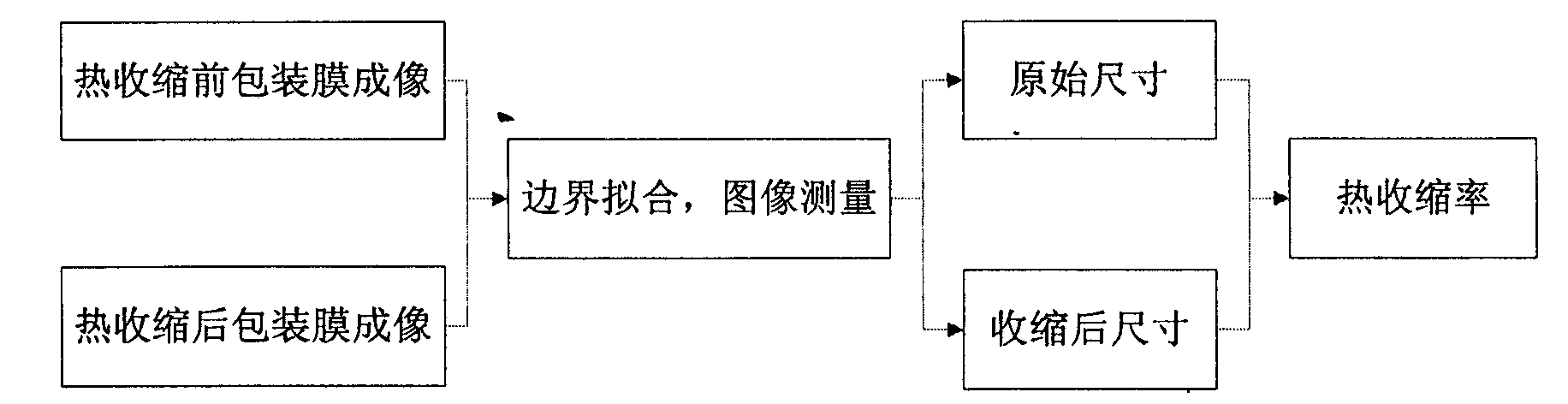

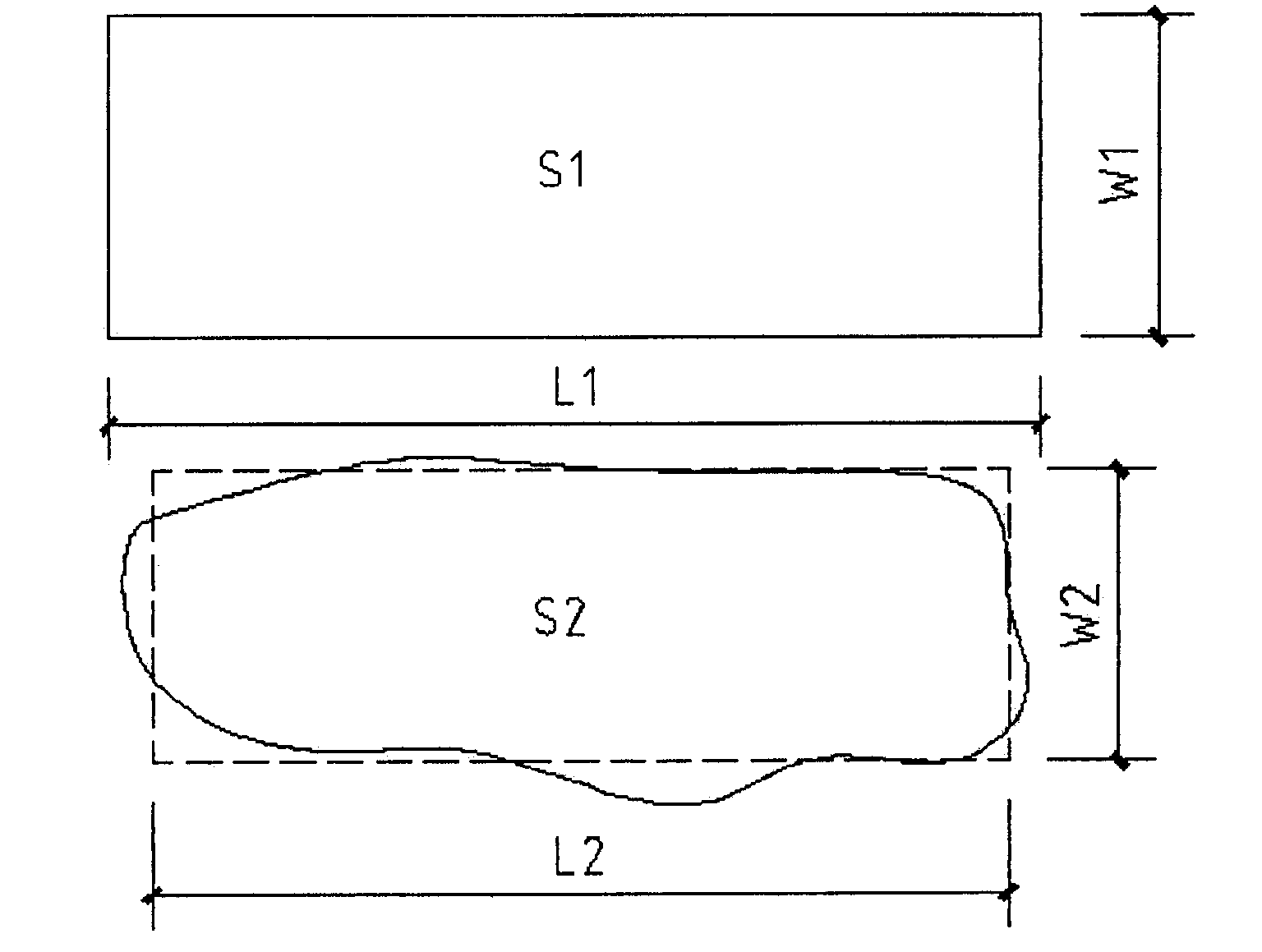

Measuring method of thermal shrinkage rate of cigarette packaging film

InactiveCN103308548AEliminate human errorAvoid duplication of investmentMaterial thermal coefficient of expansionImaging analysisShrinkage rate

The invention discloses a measuring method of a thermal shrinkage rate of a cigarette packaging film. The measuring method is characterized by comprising the steps that an image acquisition device acquires dimension parameters of the cigarette packaging film before and after certain temperature and time processing in a heating medium; images are preprocessed; boundaries of the cigarette packaging film before and after shrinkage are fitted out by image analysis software; dimension variations of the cigarette packaging film are measured by using image measuring software; and longitudinal, transverse and overall thermal shrinkage rates of the cigarette packaging film are obtained after computation. According to the measuring method, the images before and after the shrinkage of the cigarette packaging film can be extracted and subjected to necessary image preprocessing and image analysis, and the dimension parameters of the cigarette packaging film can be extracted, so that the thermal shrinkage rate of the cigarette packaging film can be accurately measured. According to the measuring method, an influence of manual measuring on a testing result in an existing method can be avoided and a personal error can be eliminated; and the measuring procedure is fully automatic, so that the measuring accuracy and the measuring precision can be improved.

Owner:CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

Steel bar spacing indicator for construction

The invention discloses a steel bar spacing indicator for construction. The steel bar spacing indicator for construction comprises a walking wheel which is capable of being held and pushed by hand and is composed of a pushing rod, a support frame, a wheel ring, wheel spokes and a wheel shaft, and is characterized in that dotting pens are arranged on the wheel ring at intervals, an ink box is arranged on the support frame, and in the rolling process of the wheel ring, the dotting pens on the wheel ring are inked and dot for indication at the same time by contacting an ink-dipping contact of the ink box. Compared with the prior art, the steel bar spacing indicator for the construction has the advantages of being rapid in indication, high in efficiency, and capable of saving manpower and improving construction speed; being accurate in indication, and capable of eliminating artificial errors and improving construction quality; being simple and convenient to operate, capable of relieving labor intensity, and capable of indicating a plane and a steel bar or a faceted surface; being simple in structure and low in cost.

Owner:赵章富

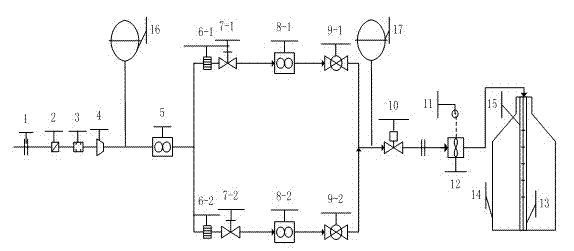

Liquid reservoir automatic calibration device and calibration method

InactiveCN102506964ASimplify workEliminate human errorTesting/calibration apparatusExhaust valveEngineering

The invention relates to a liquid reservoir automatic calibration device and a calibration method. The device comprises a filter, an exhaust valve, a pressure relieving and stabilizing valve, an ultrasonic wave flowmeter, an upper rectifier plate, an upper manual valve, an upper standard meter, an upper electromagnetic valve, a lower rectifier plate, a lower manual valve, a lower standard meter, a lower electromagnetic valve, an electric regulating valve, a laser sensor, a meter to be tested, a liquidometer, a liquid reservoir to be detected, a pressure transmitter, a first temperature transmitter and a second temperature transmitter. The device can realize the automatic reading of flow rate, liquid level, temperature pressure and regulating valve feedback signals and other signals and automatic storage and processing of data and form printing reports; and the whole process is automatically accomplished with reduced human error and improved accuracy of the device.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com