Patents

Literature

77results about How to "Reducing time and cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

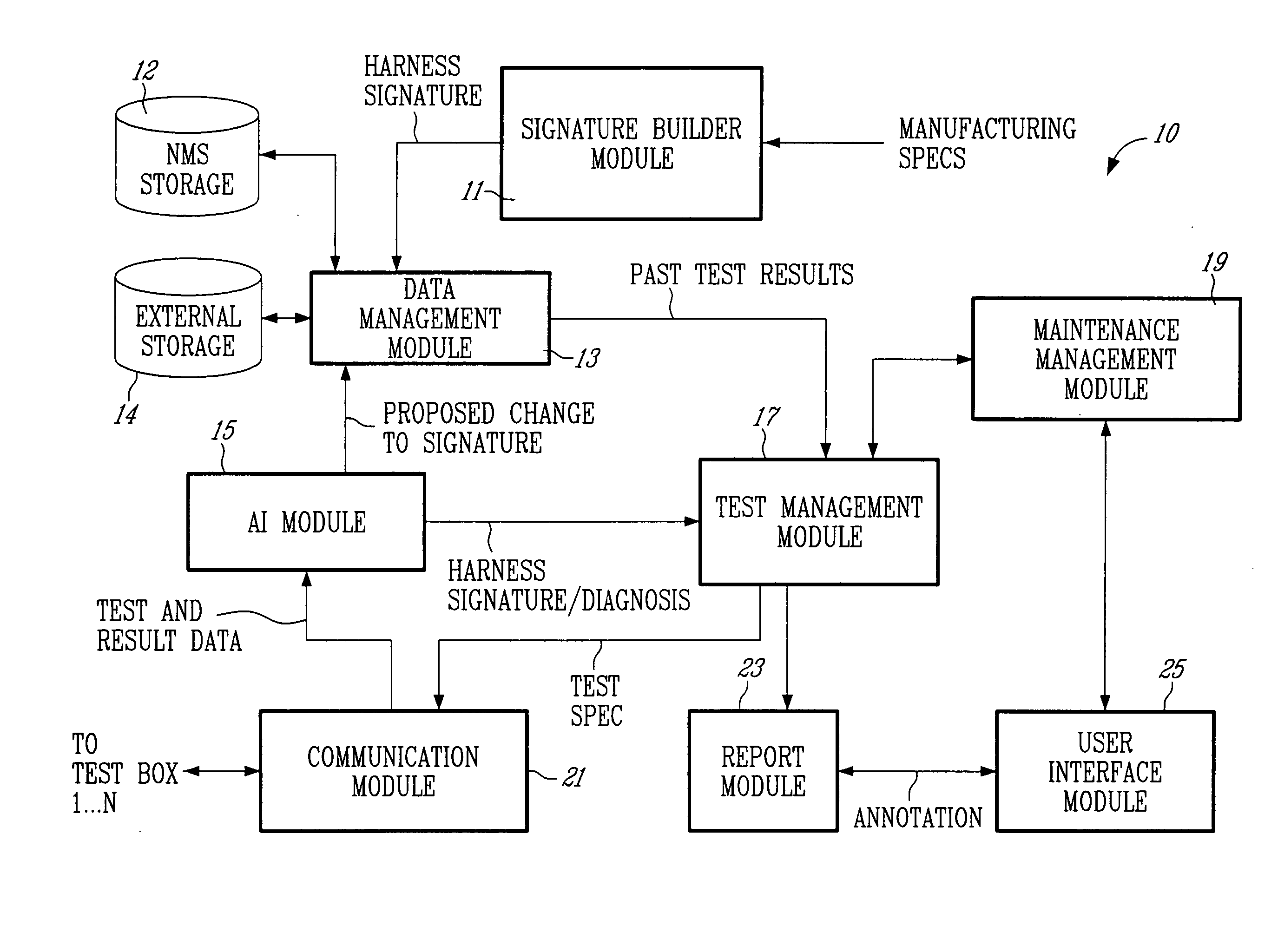

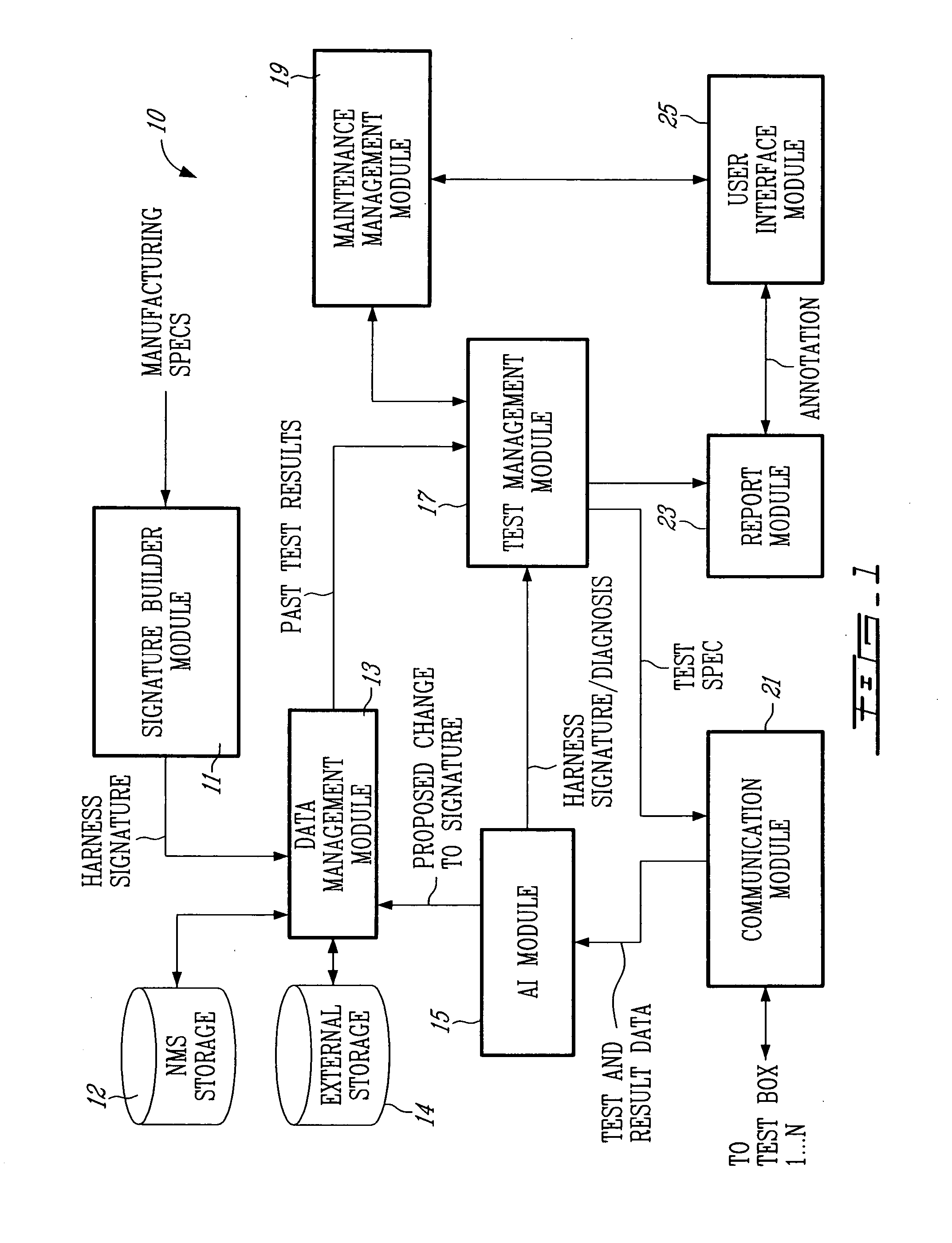

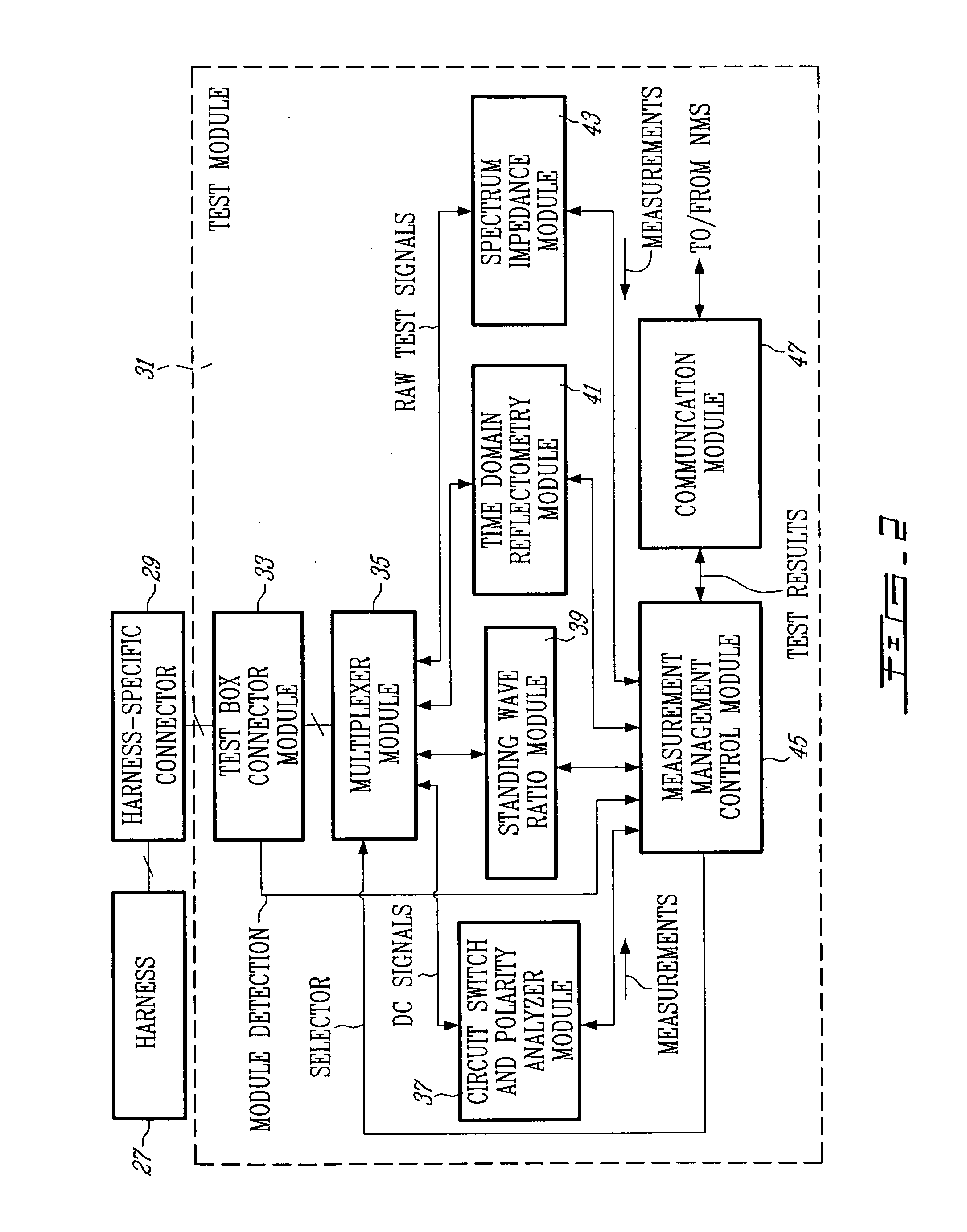

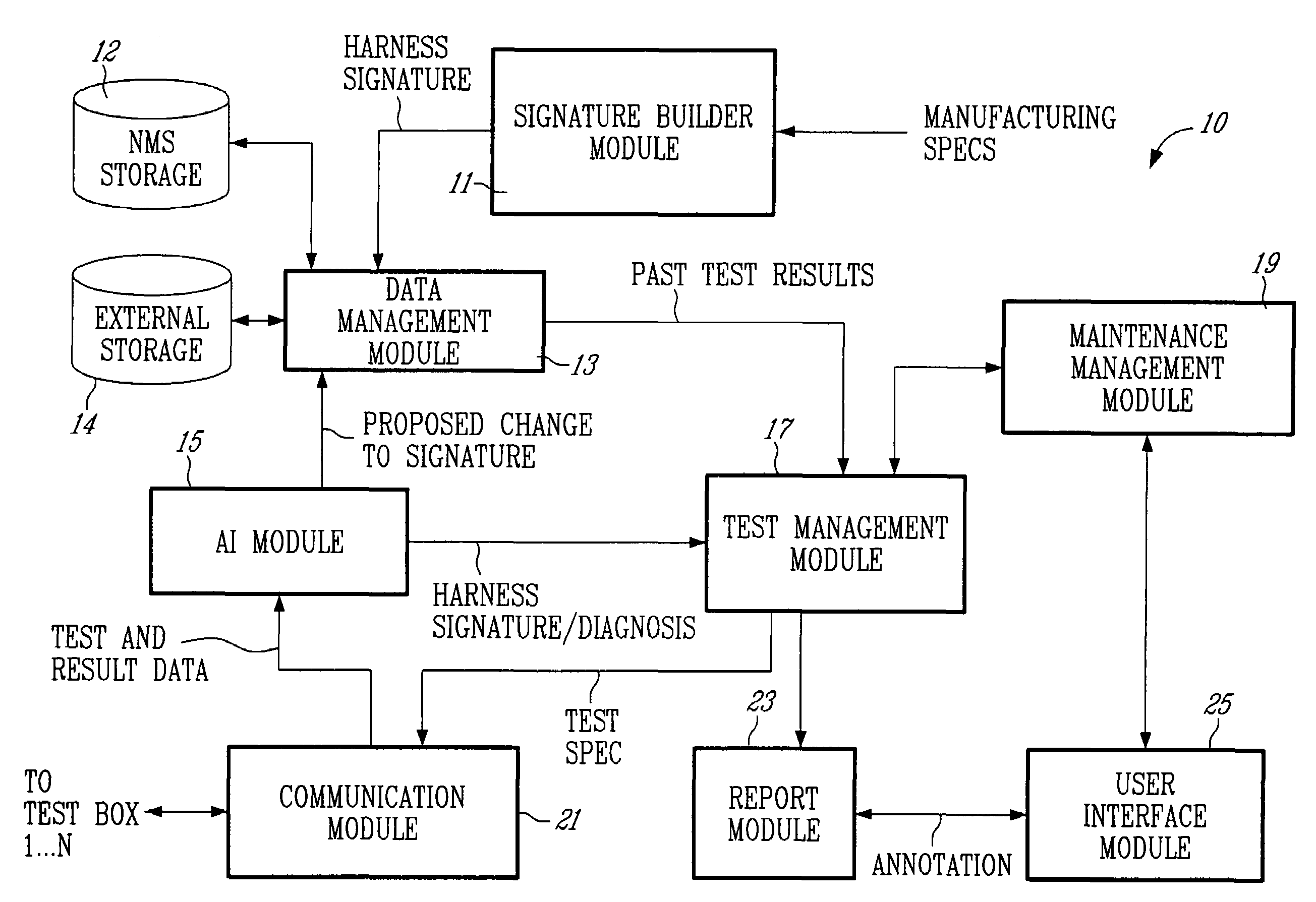

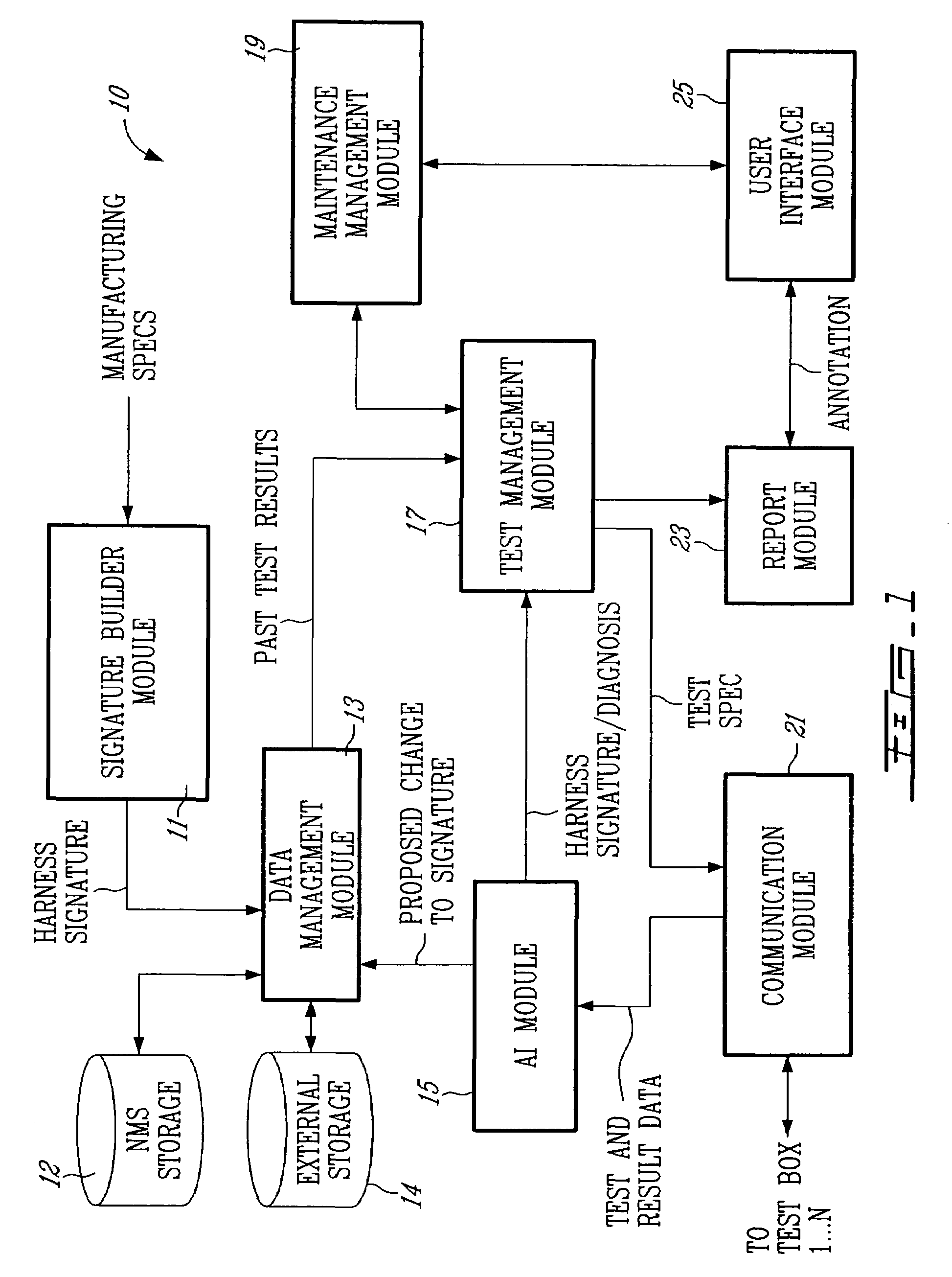

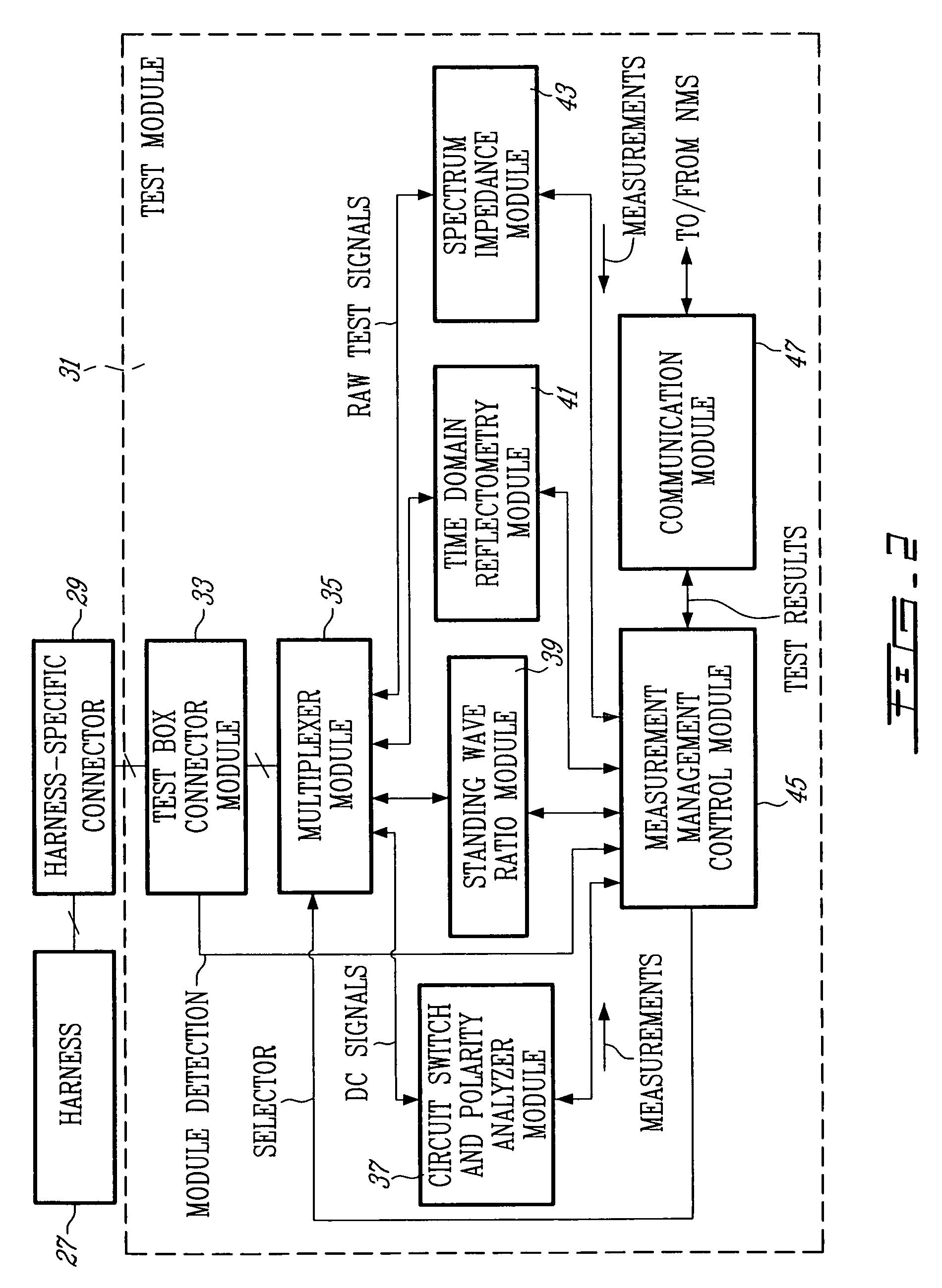

Wireless portable automated harness scanner system and method therefor

ActiveUS20060043976A1Shorten the timeLow costResistance/reactance/impedenceFault location by conductor typesTest measurementEngineering

A method for testing an installed wiring harness is provided. The method comprises providing a signal source testing module at a first node in the wiring harness and a measurement termination testing module at a second node in the wiring harness. A central management module for controlling the testing modules coordinates the testing modules to send testing signals for performing tests and recording test measurements of the installed wiring harness. The testing modules send the test measurements to the management module.

Owner:ZIOTA TECH

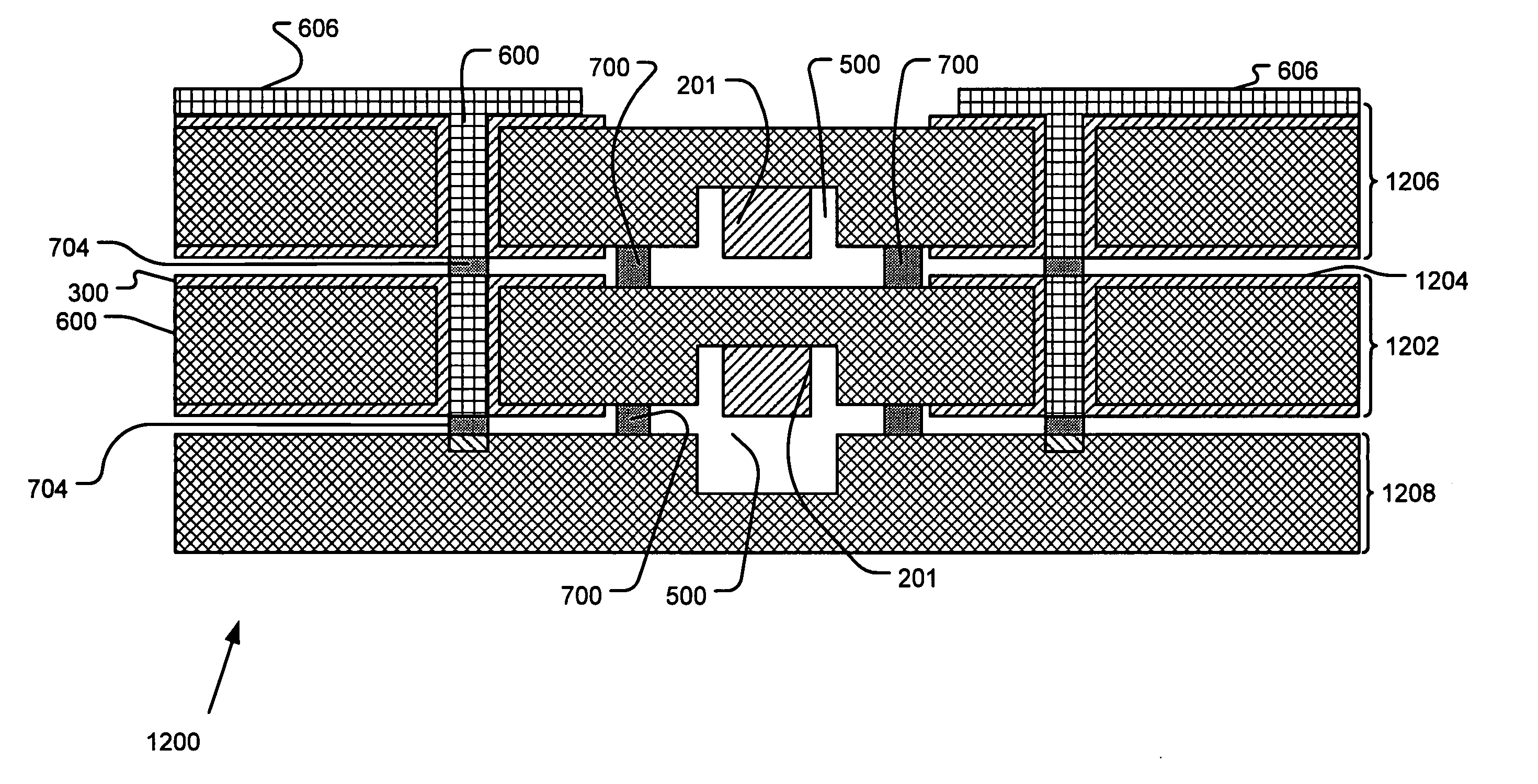

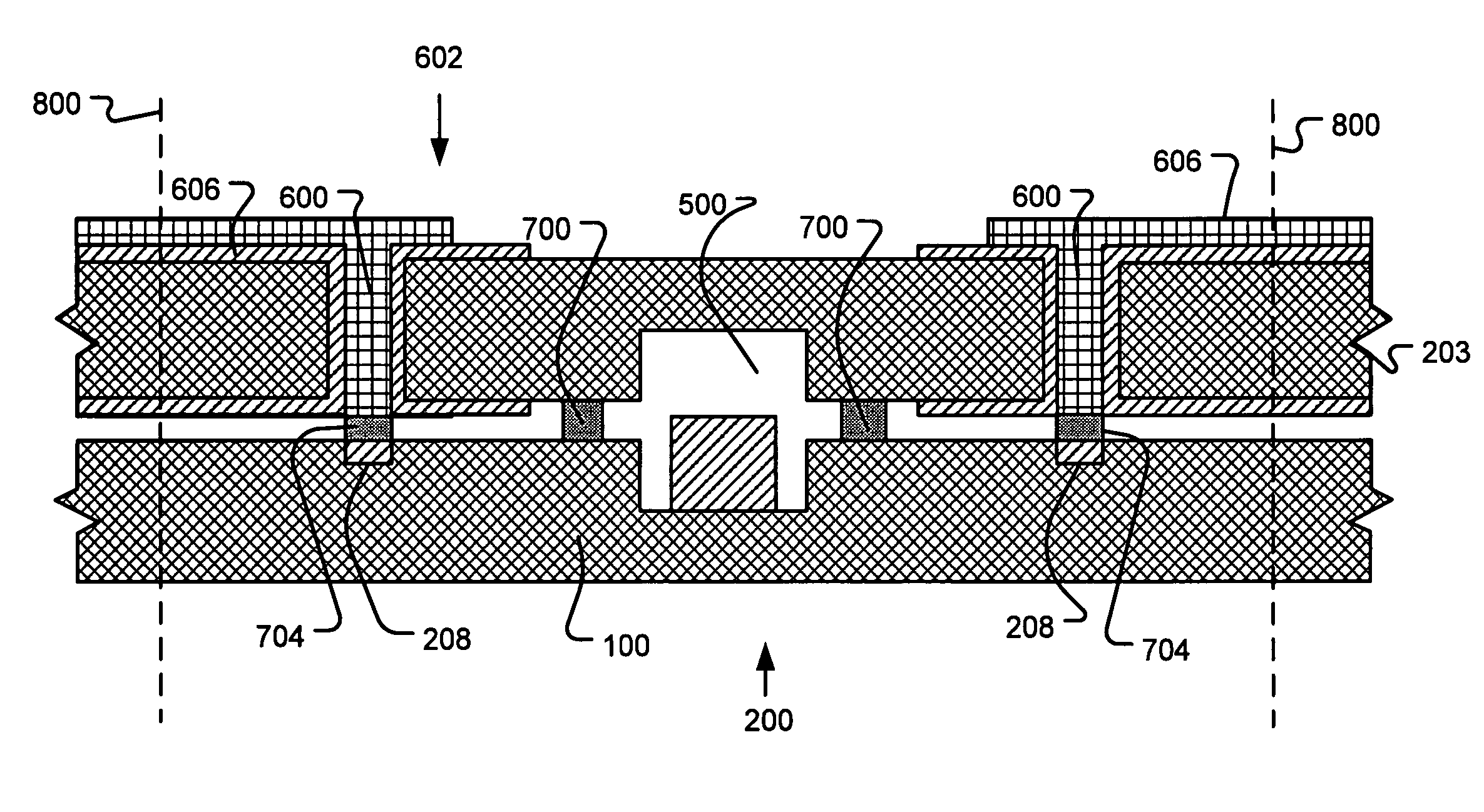

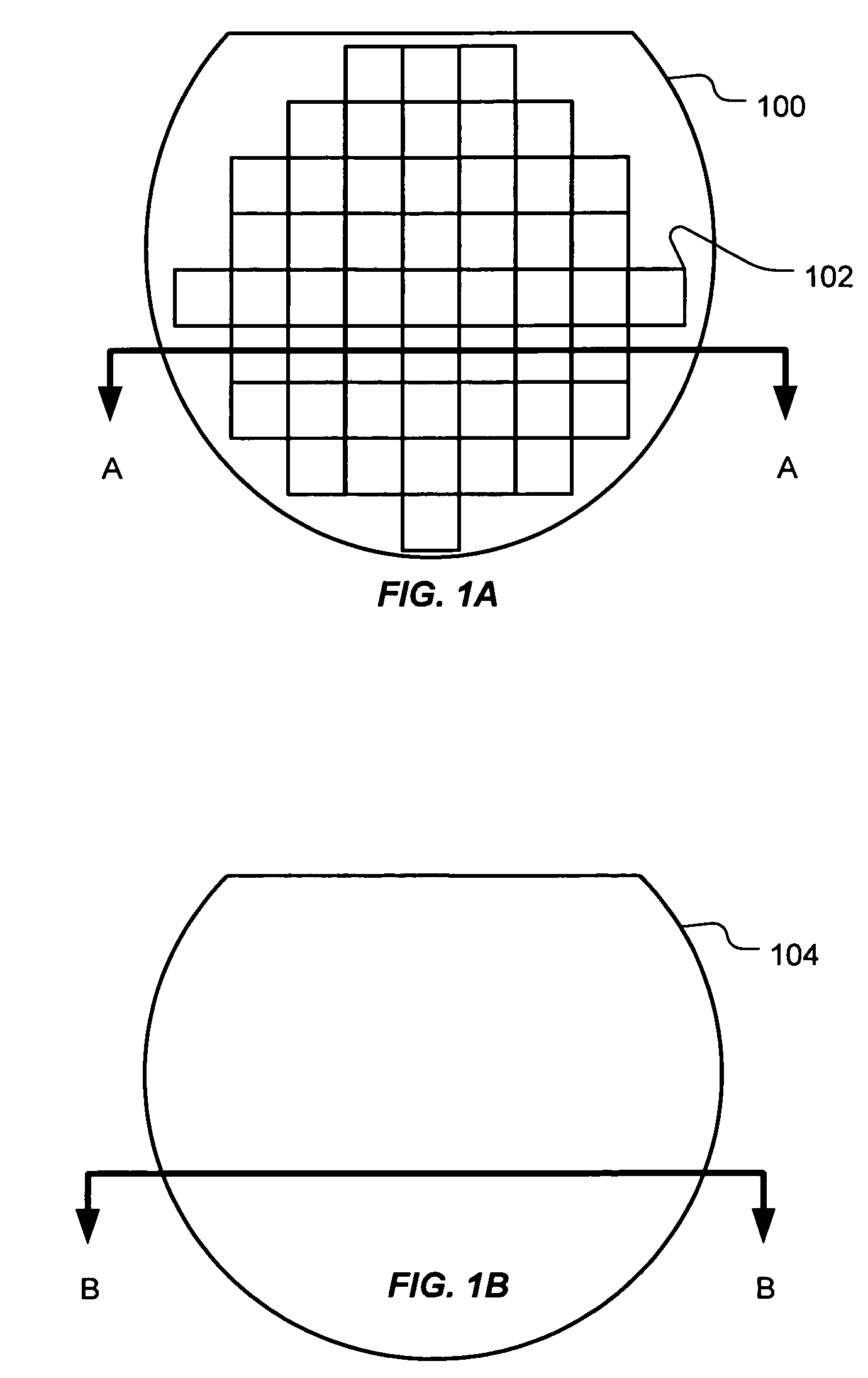

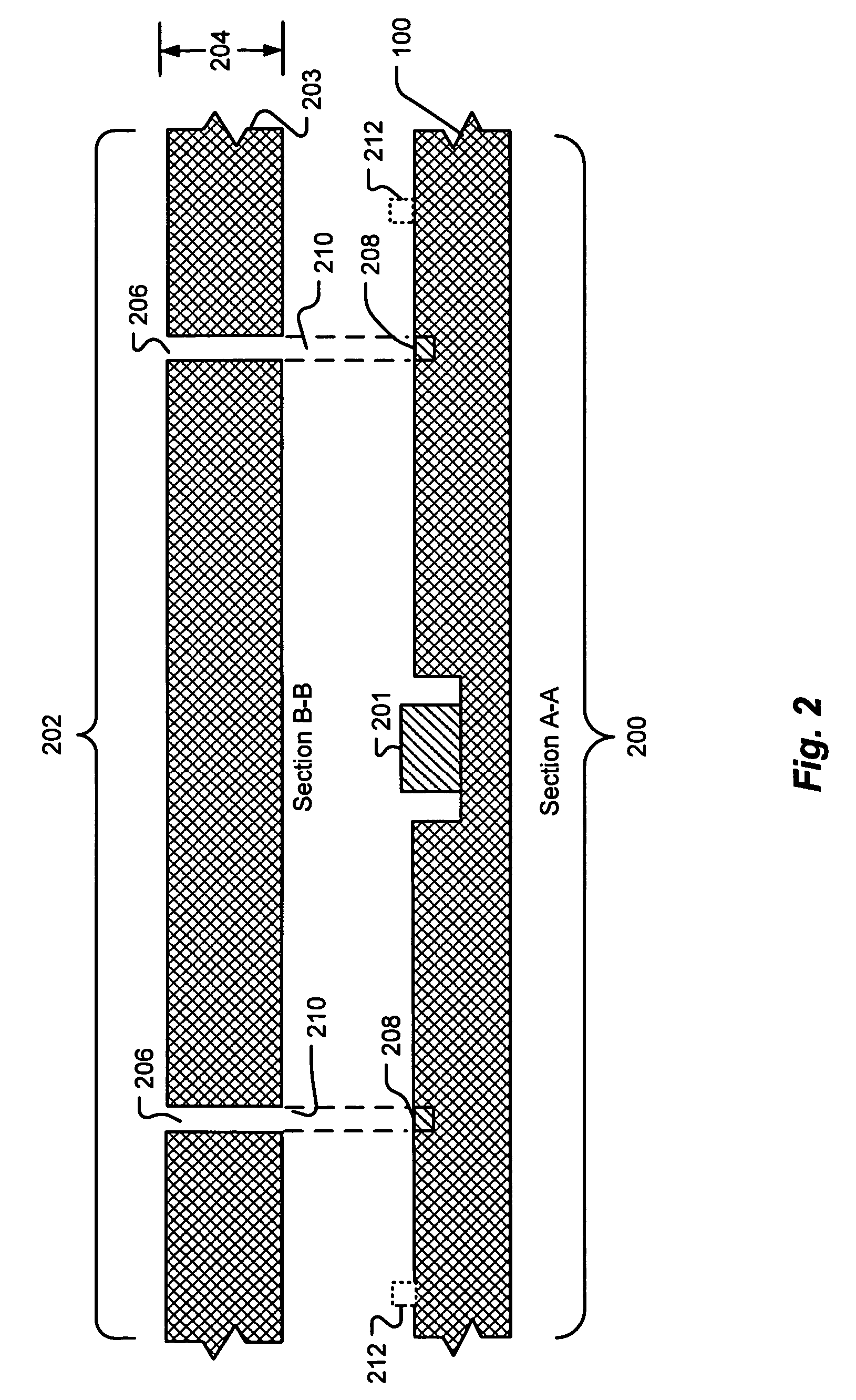

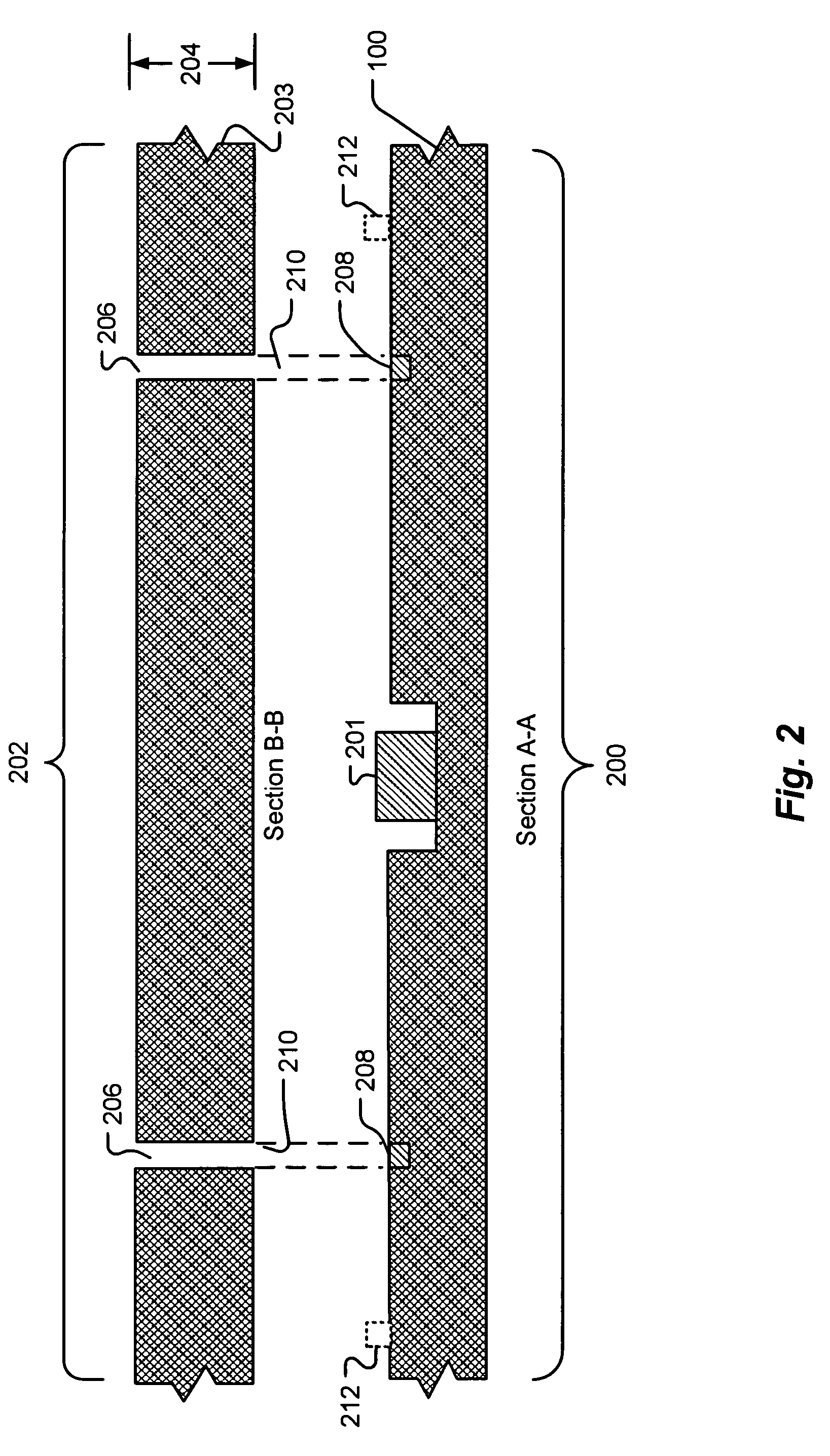

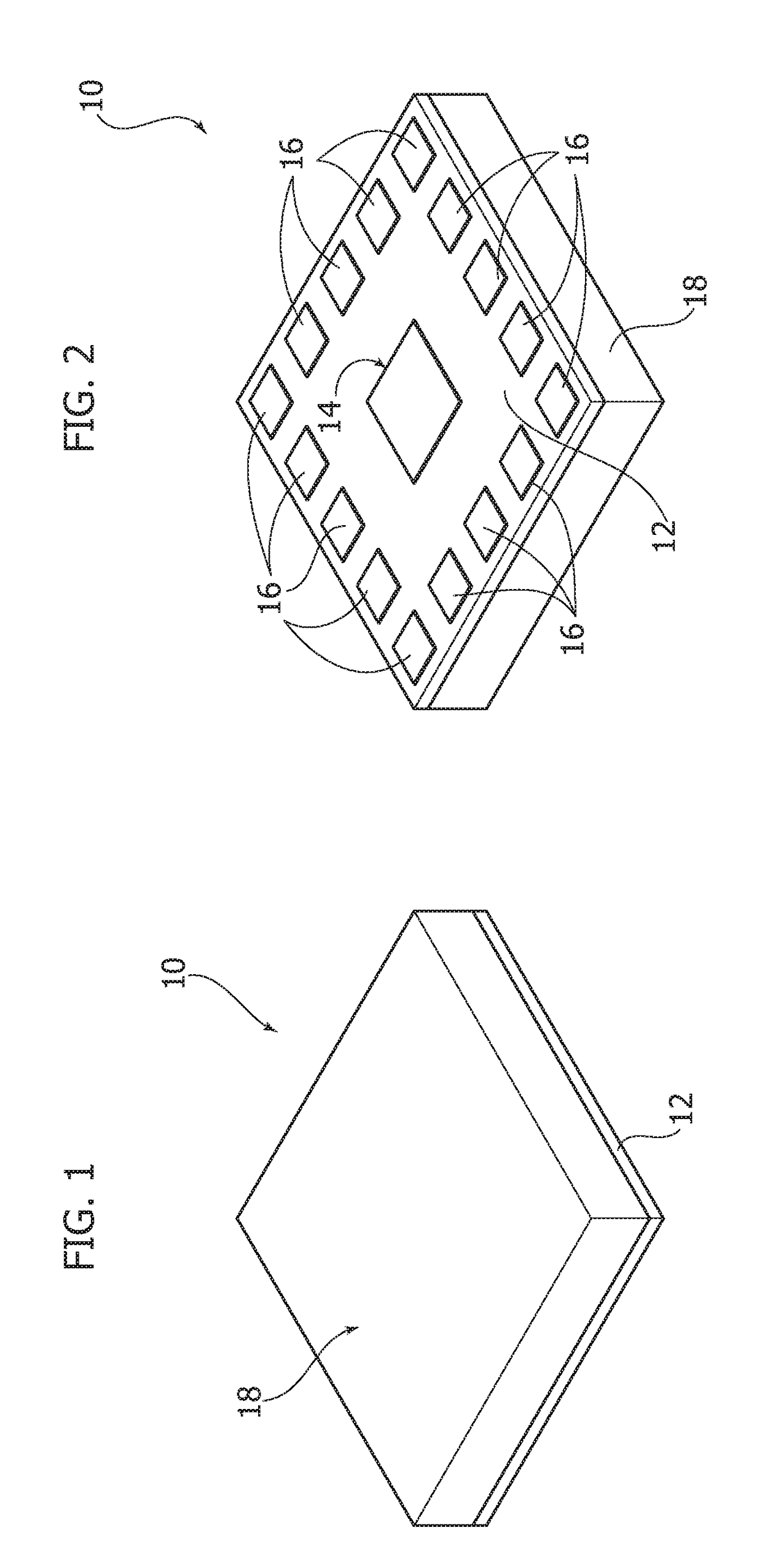

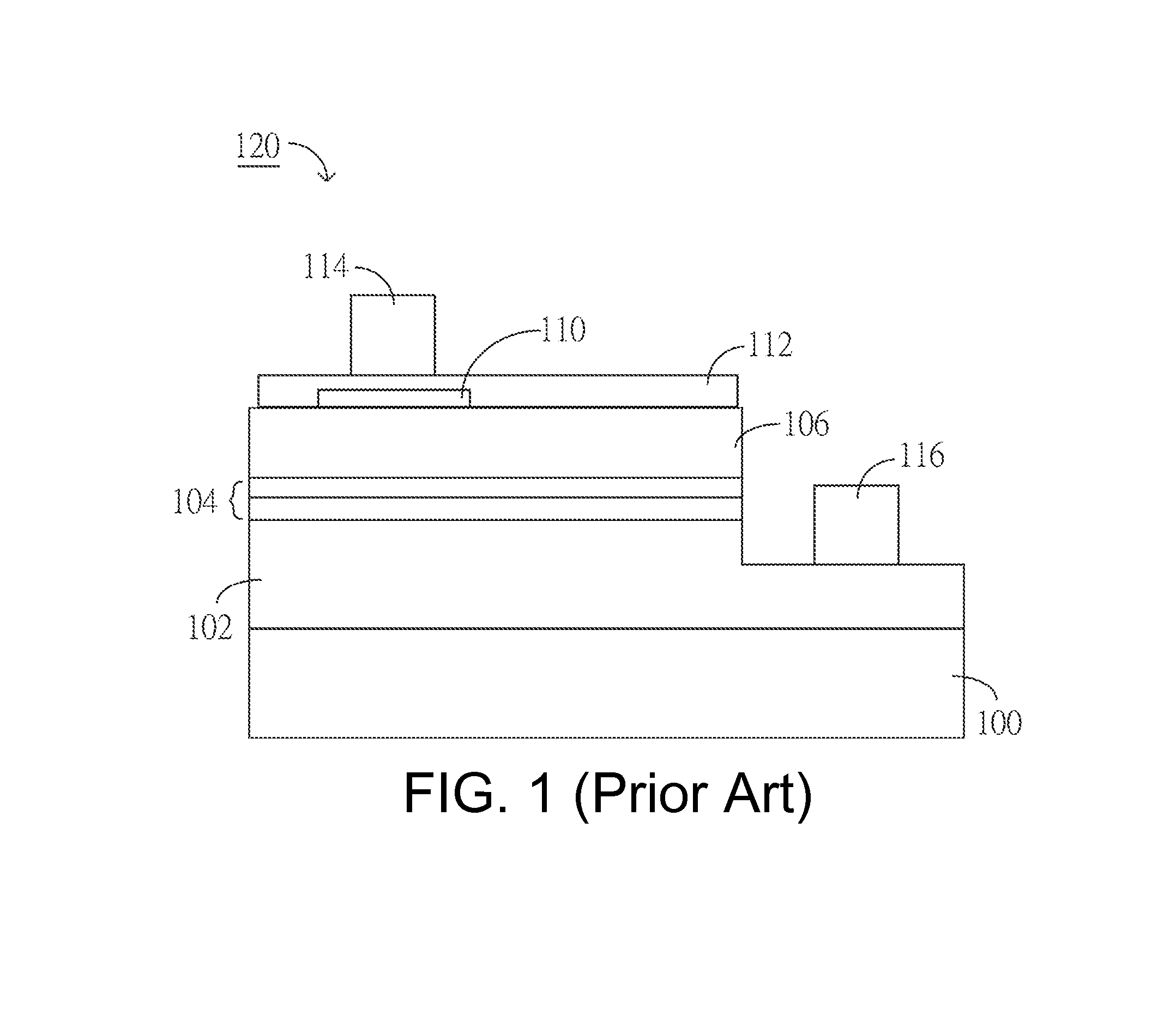

Chip-scale package for integrated circuits

ActiveUS20060216857A1Good adhesionReducing time and costSemiconductor/solid-state device detailsSolid-state devicesContact padEngineering

A chip-scale packaged IC is made by bonding one or more singulated die chips (from an IC wafer) to a common substrate, such as a single cap wafer (or a portion thereof) and cutting (singulating) the substrate to yield individual, chip-scale packaged ICs. Alternatively, each die chip is bonded to an individual, pre-cut cap. Electrically conductive paths extend through the cap wafer, between wafer contact pads on the surface of the cap and electrical contact points on the IC wafer. Optionally, the cap wafer contains one or more die. The IC wafer can be fabricated according to a different technology than the cap wafer, thereby forming a hybrid chip-scale packaged IC. Optionally, additional “upper-level” cap wafers (with or without die) can be stacked to form a “multi-story” IC.

Owner:MEMSIC

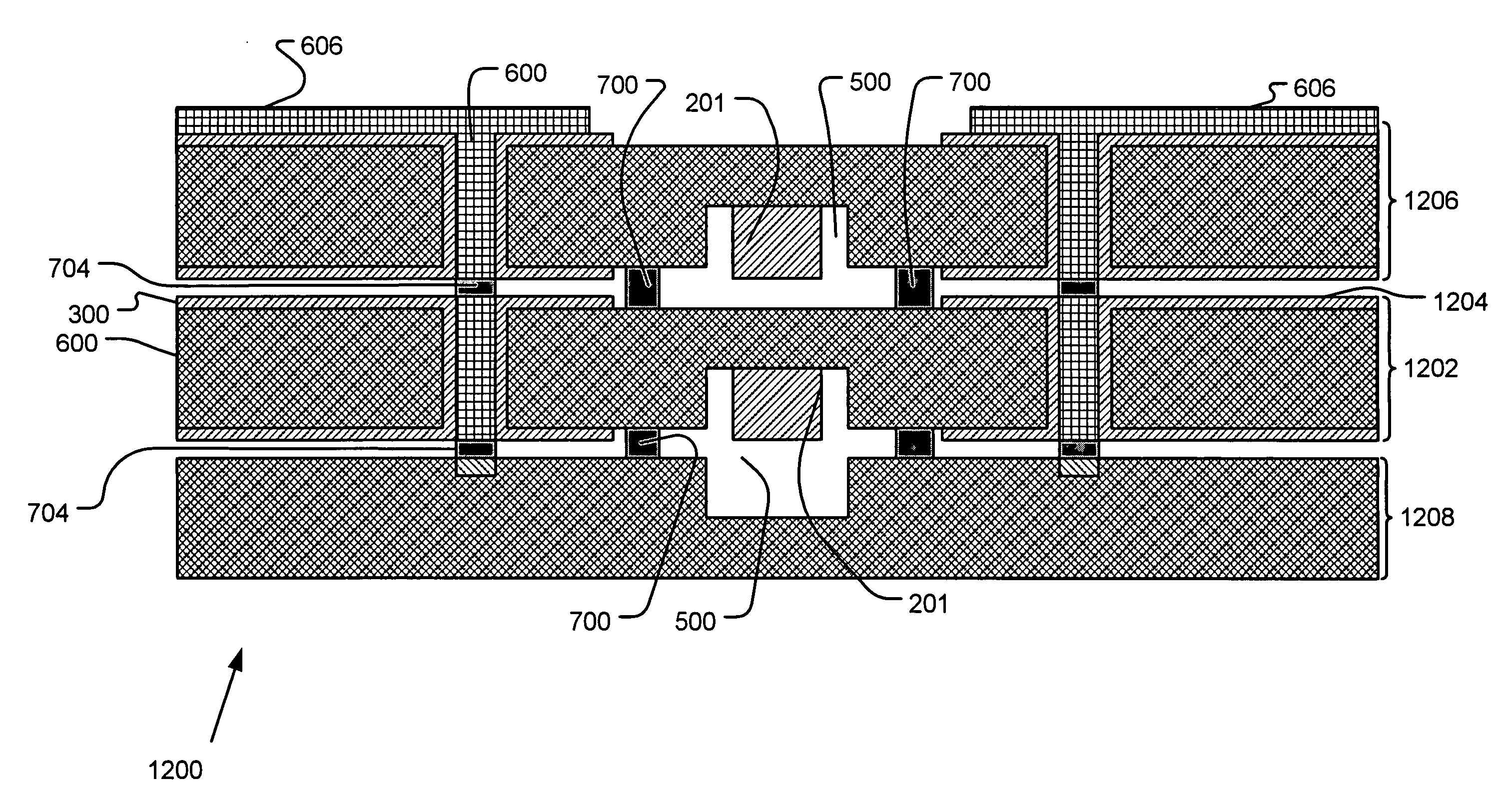

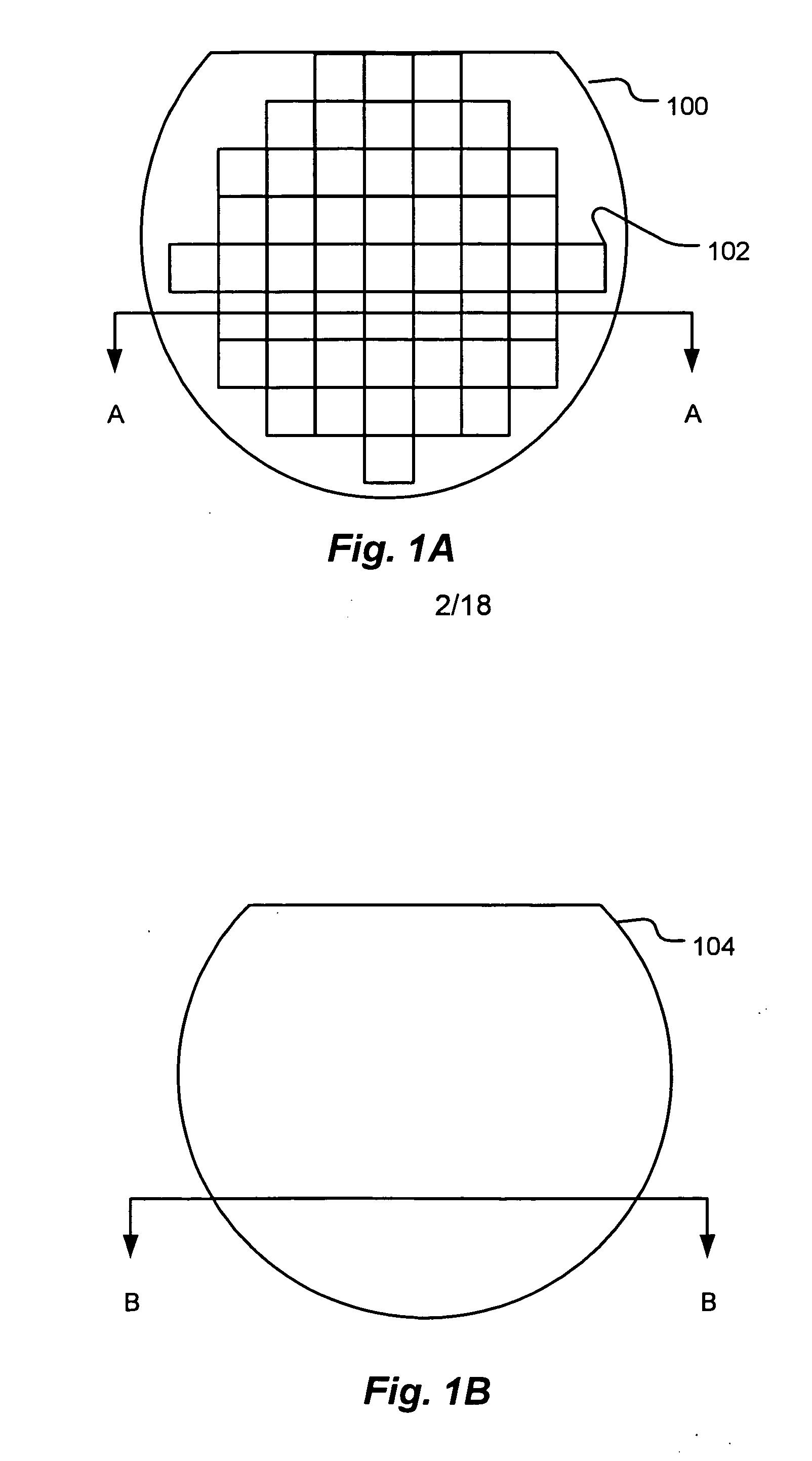

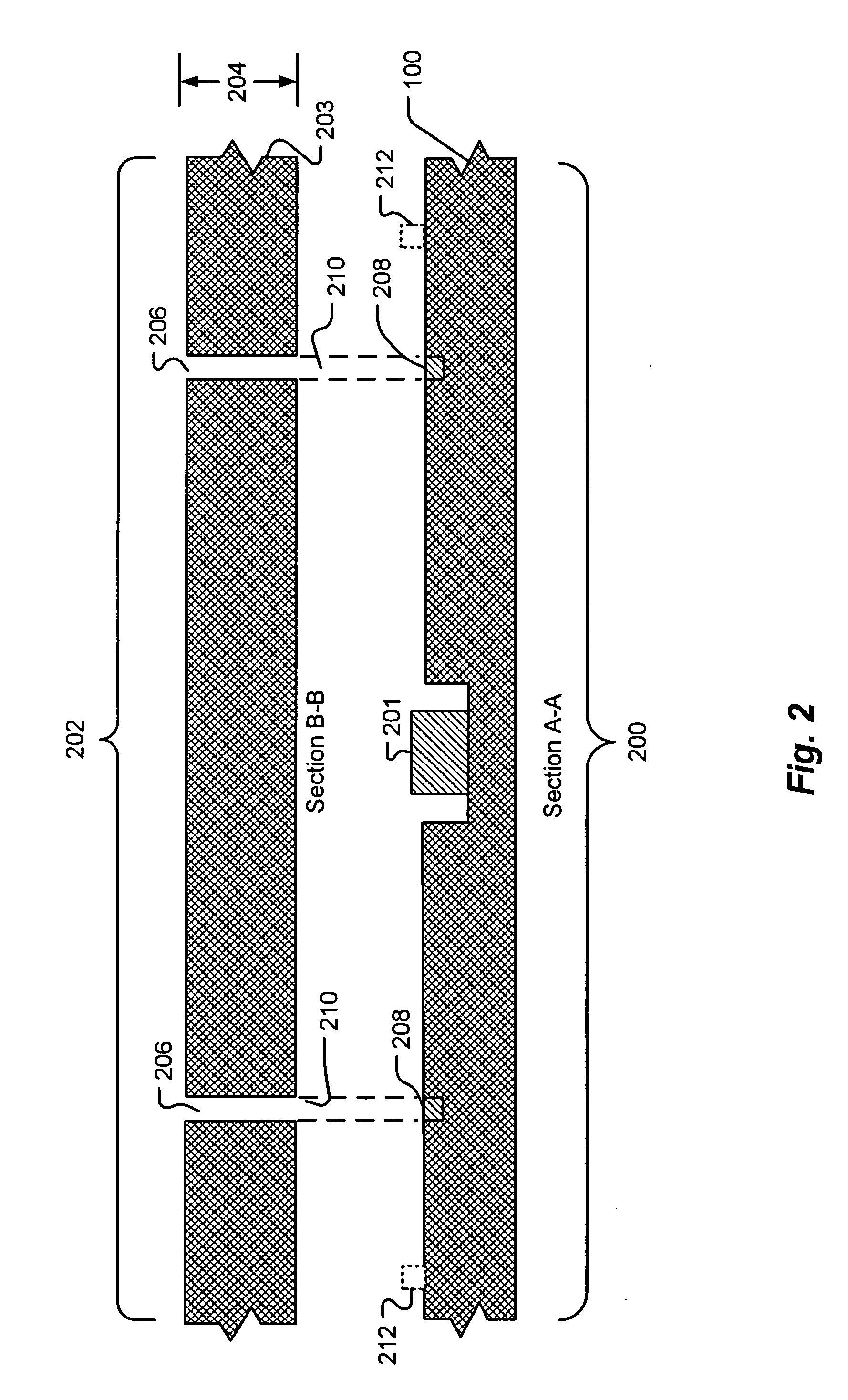

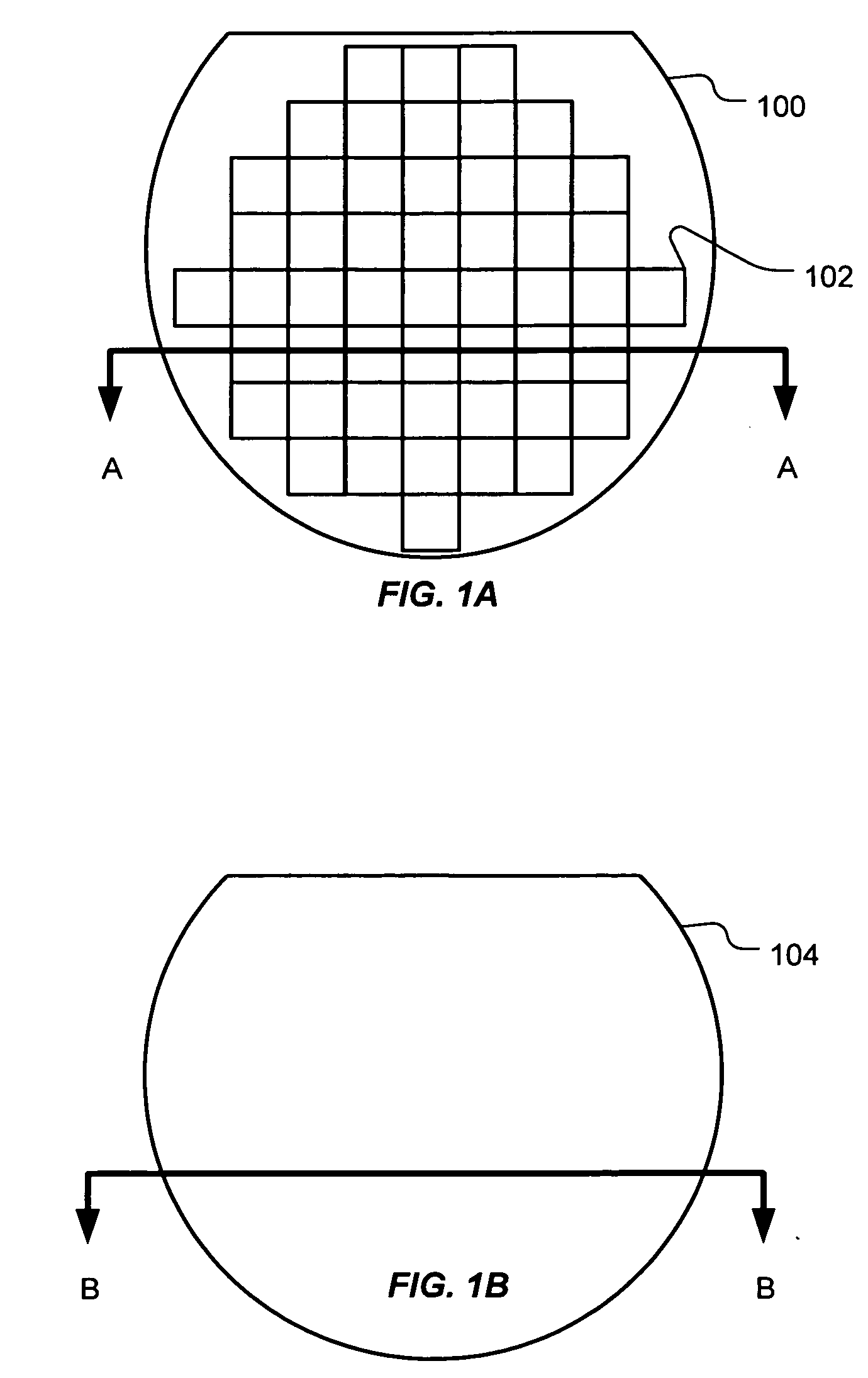

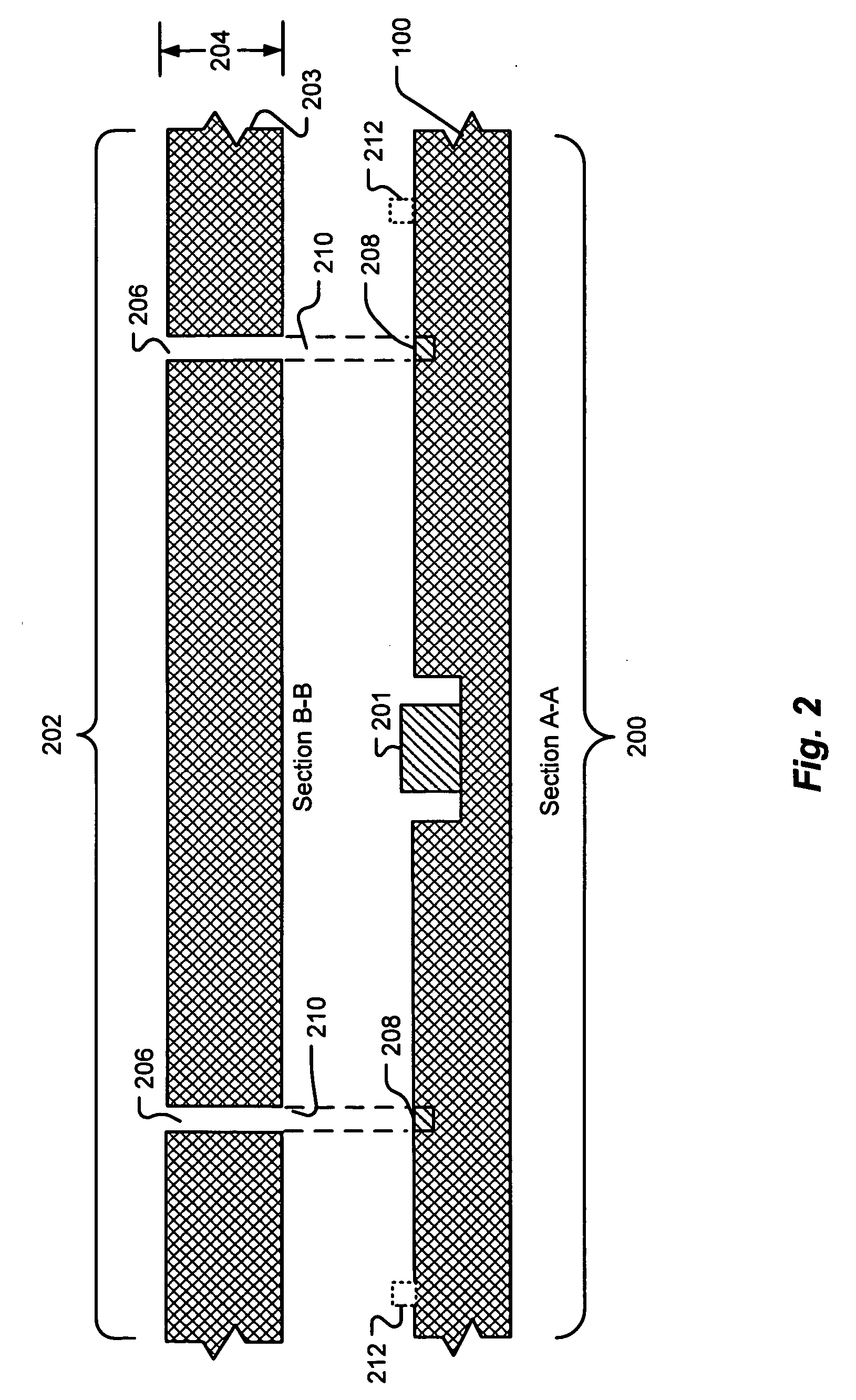

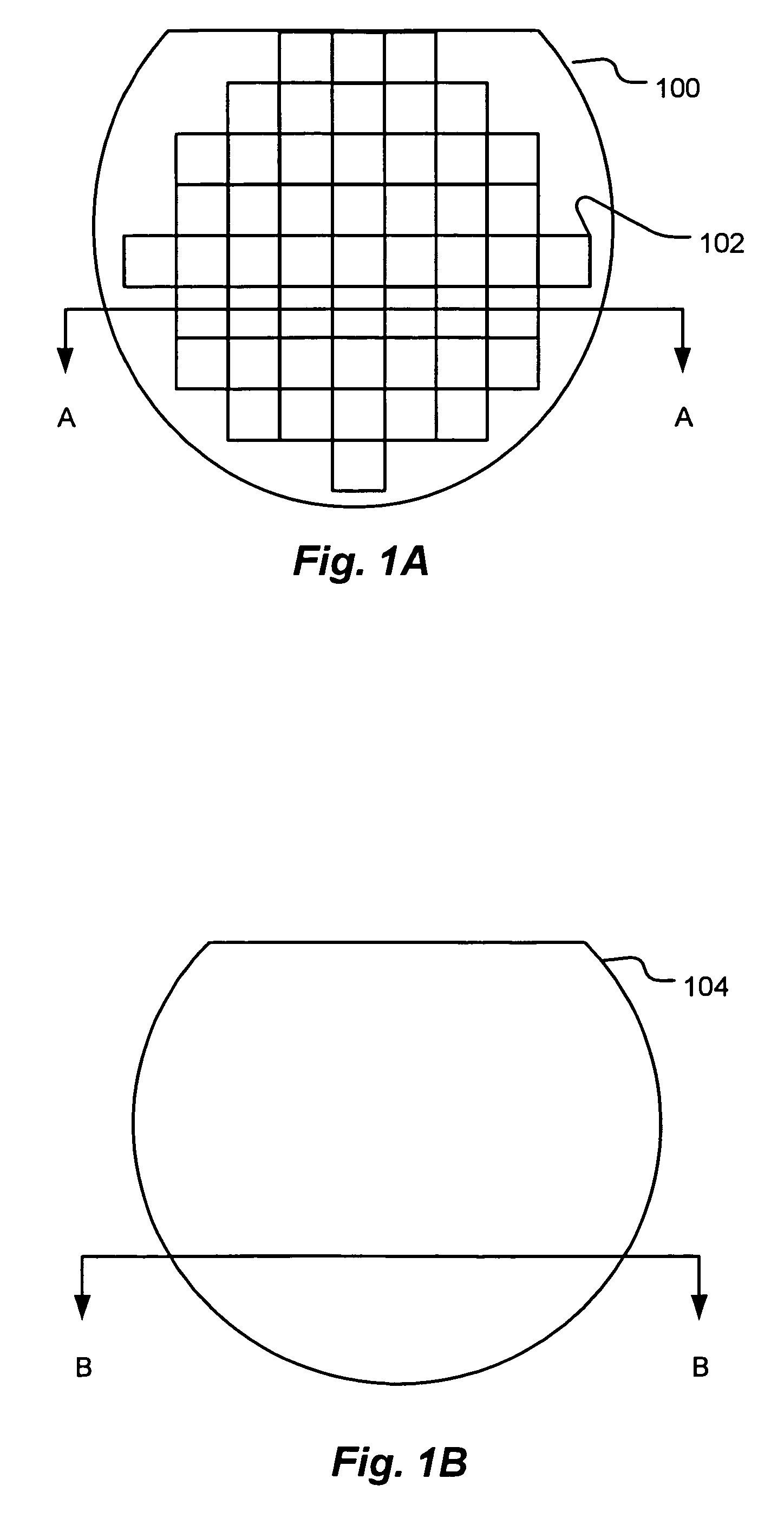

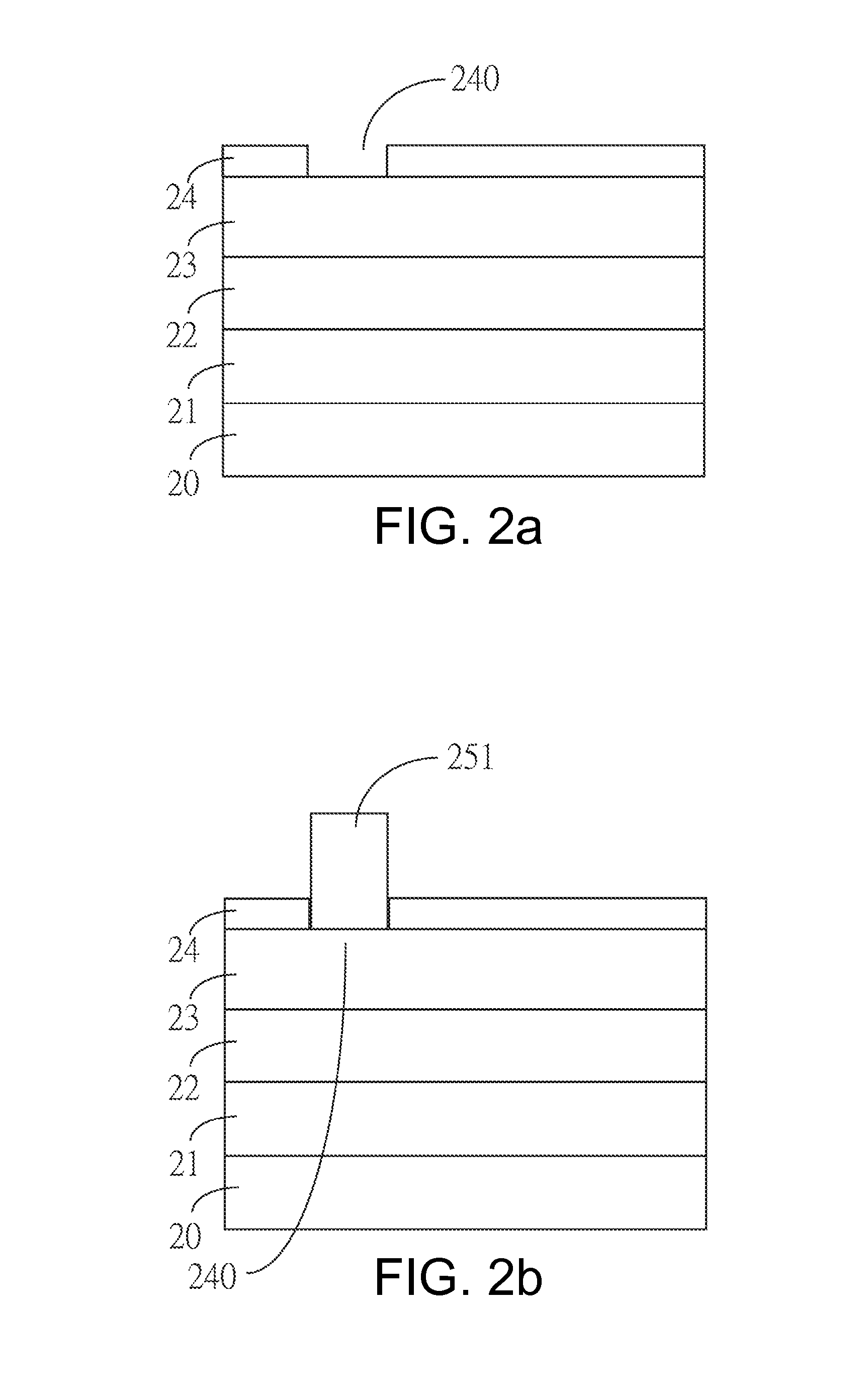

Wafer-level package for integrated circuits

ActiveUS20060216856A1Good adhesionReducing time and costSemiconductor/solid-state device detailsSolid-state devicesContact padEngineering

A wafer-level packaged IC is made by attaching a cap wafer to the top of an IC wafer before cutting the IC wafer, i.e. before singulating the plurality of die on the IC wafer. The cap wafer is mechanically attached and electrically connected to the IC wafer, then the die are singulated. Electrically conductive paths extend through the cap wafer, between wafer contact pads on the top surface of the cap and electrical contact points on the IC wafer. Optionally, the cap wafer contains one or more die. The IC wafer can be fabricated according to a different technology than the cap wafer, thereby forming a hybrid wafer-level package. Optionally, additional “upper-level” cap wafers (with or without die) can be stacked to form a “multi-story” IC.

Owner:MEMSIC

Wireless portable automated harness scanner system and method therefor

ActiveUS7368919B2Reducing time and costEliminate human errorResistance/reactance/impedenceFault location by conductor typesComputer moduleTest measurement

A method for testing an installed wiring harness is provided. The method comprises providing a signal source testing module at a first node in the wiring harness and a measurement termination testing module at a second node in the wiring harness. A central management module for controlling the testing modules coordinates the testing modules to send testing signals for performing tests and recording test measurements of the installed wiring harness. The testing modules send the test measurements to the management module.

Owner:ZIOTA TECH

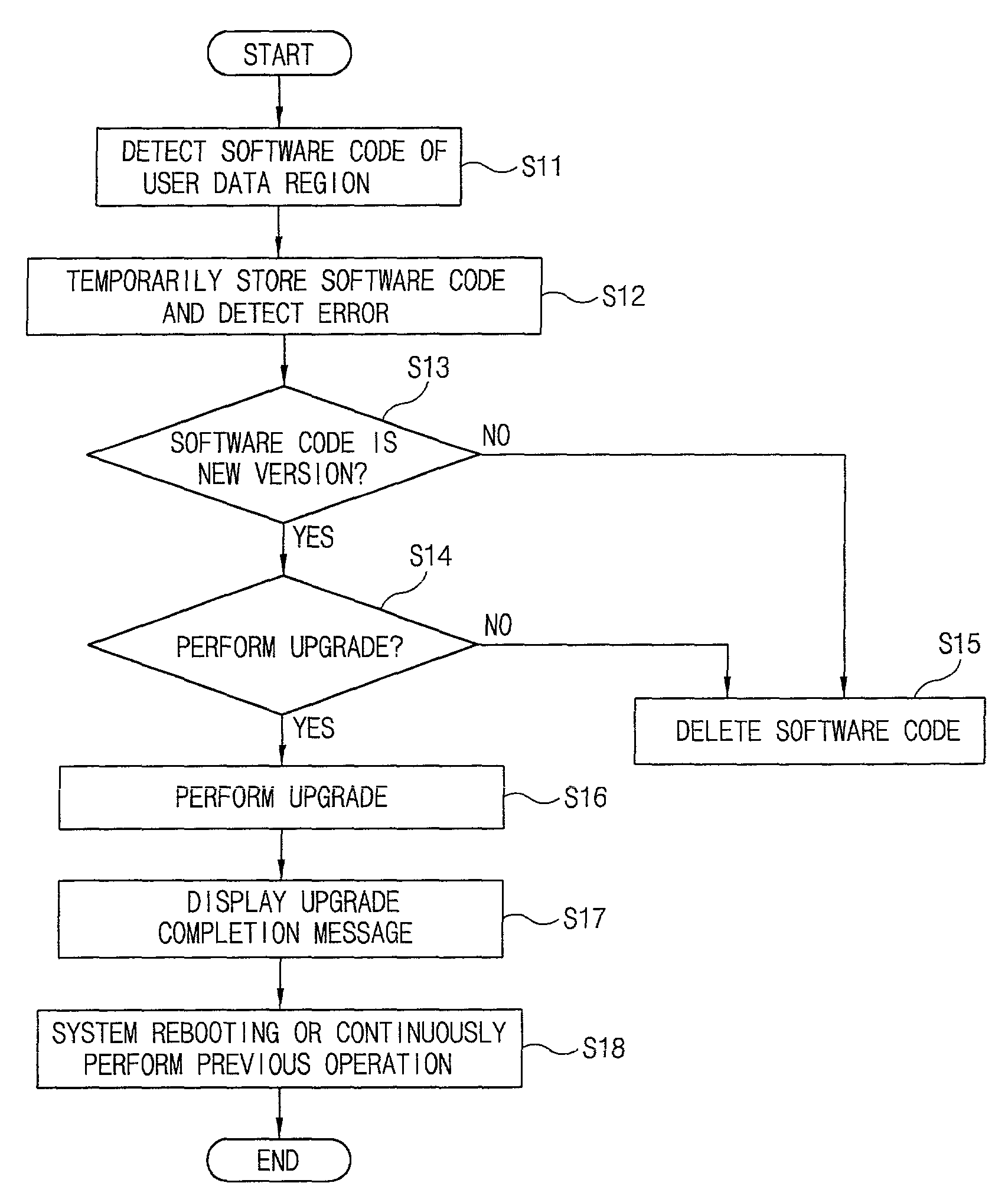

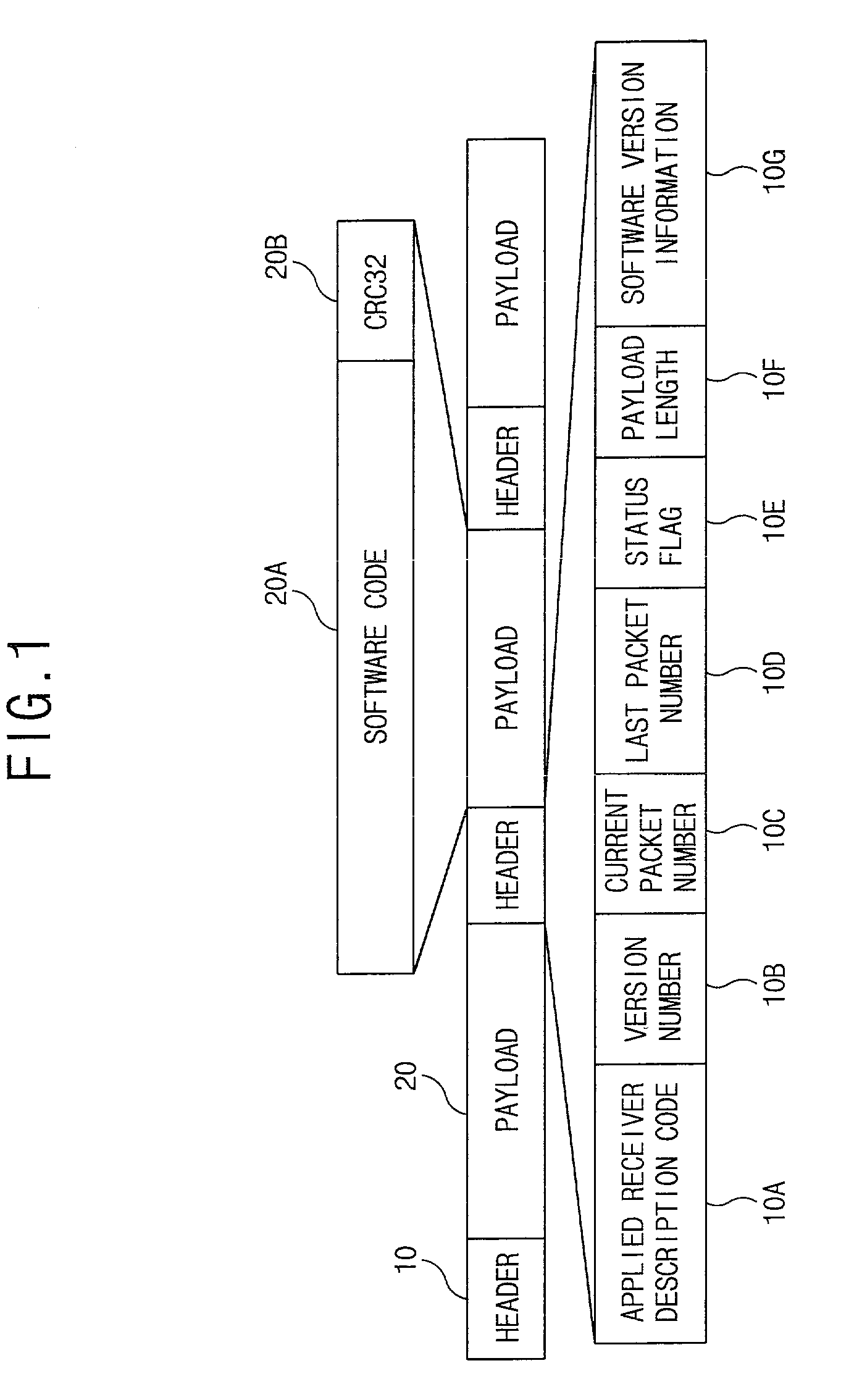

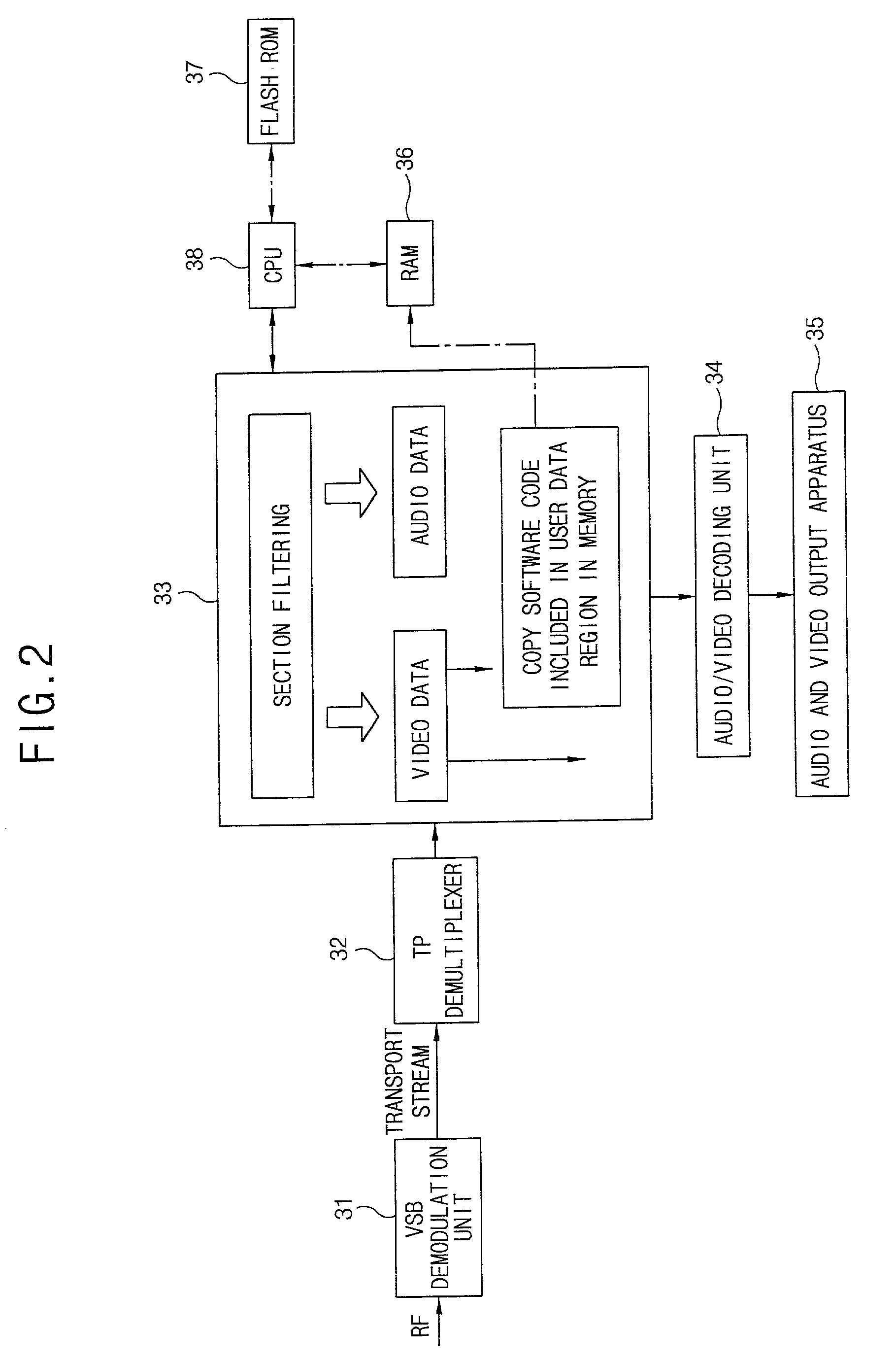

Apparatus and method for upgrading software

InactiveUS7051325B2Shorten the timeLow costTelevision system detailsBroadcast information characterisationSoftware engineeringDigital broadcasting

An apparatus and method for upgrading a software, including a version comparing unit for comparing a version of a software code and a version of a previously installed software code to determine a newer version and an upgrade processing unit for installing the software by abstracting software data in the software code, can automatically install an upgraded system software in a corresponding apparatus for receiving digital broadcasting by detecting the code of the system software simultaneously included in an advertisement broadcasting and an advertisement broadcasting signal.

Owner:LG ELECTRONICS INC

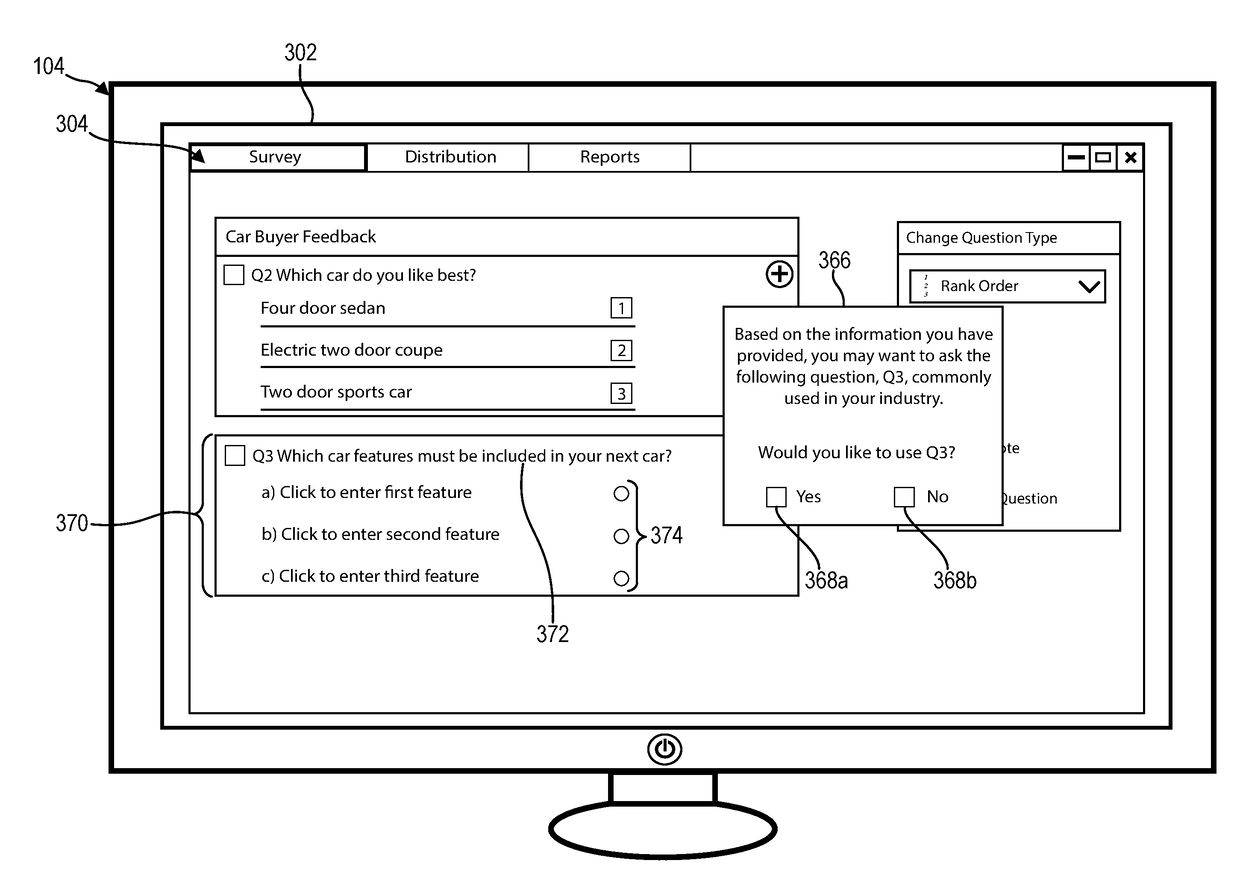

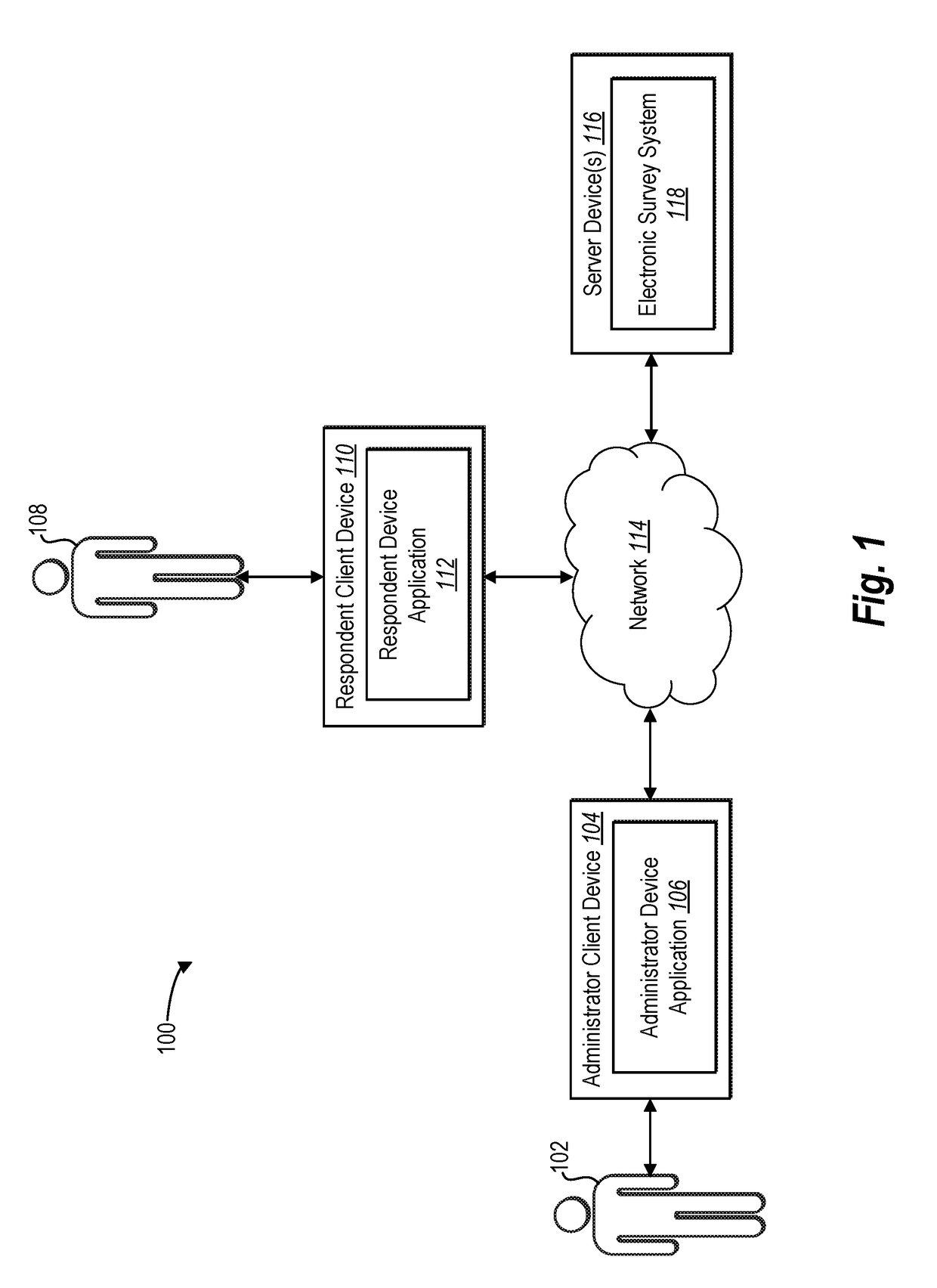

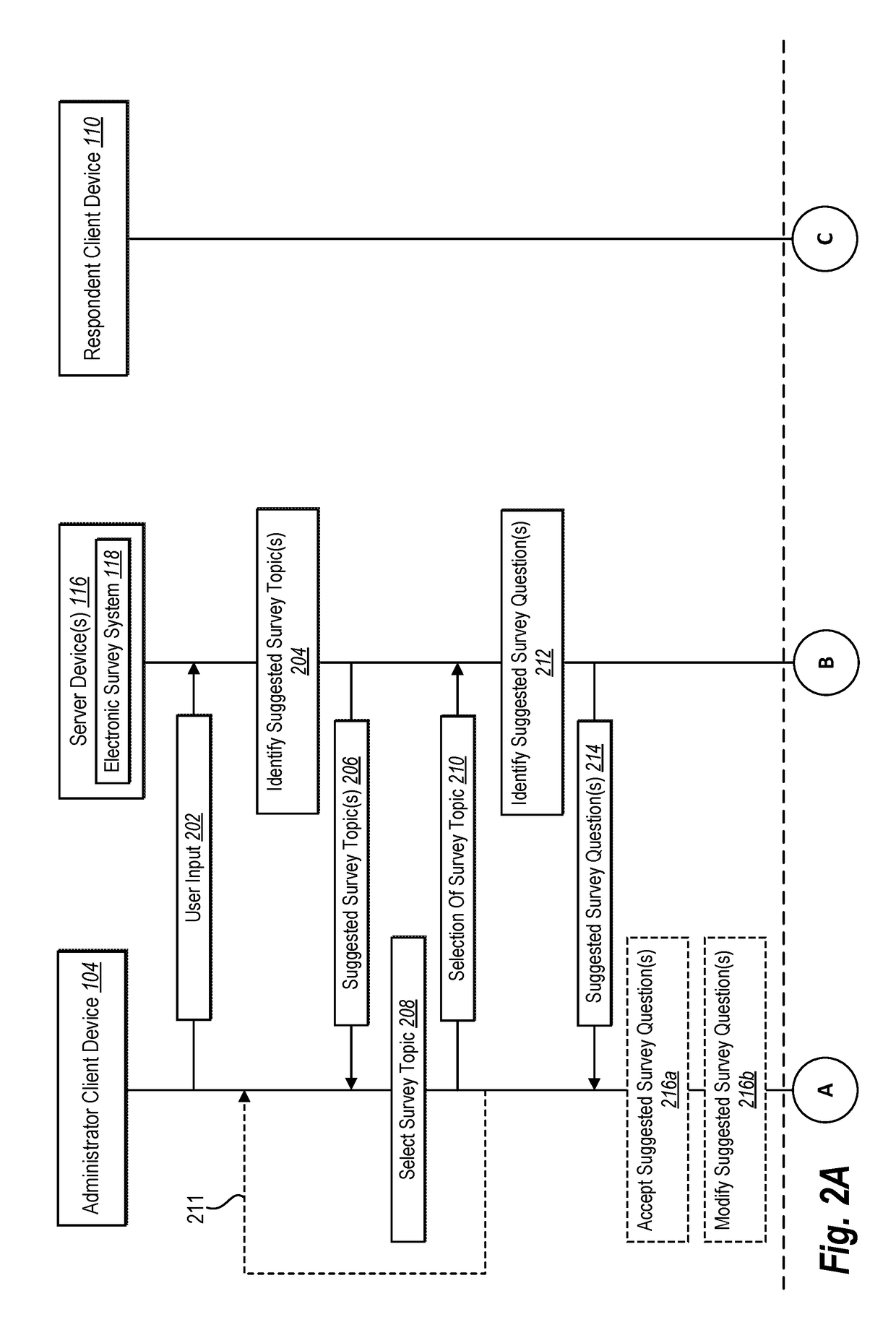

Guiding creation of an electronic survey

ActiveUS20180122256A1Easy and efficient creationReliable dataNatural language data processingElectrical appliancesUser inputCovering system

This disclosure generally covers systems and methods that provide guidance to create an electronic survey. In some embodiments, the systems and methods identify and provide a suggested survey topic—with a corresponding option to create an electronic survey—based on user input. In some embodiments, the systems and methods identify and provide one or more suggested electronic survey questions based on user input. In such embodiments, the systems and methods provide, for example, components of suggested electronic survey questions, previously composed and benchmarking electronic survey questions, or suggested revisions to electronic survey questions. In addition, the systems and methods can provide entire premade electronic surveys based on receiving user input from a survey administrator.

Owner:QUALTRICS

Wafer-level package for integrated circuits

ActiveUS7262622B2Reducing time and costSemiconductor/solid-state device detailsSolid-state devicesContact padIntegrated circuit design

Owner:MEMSIC

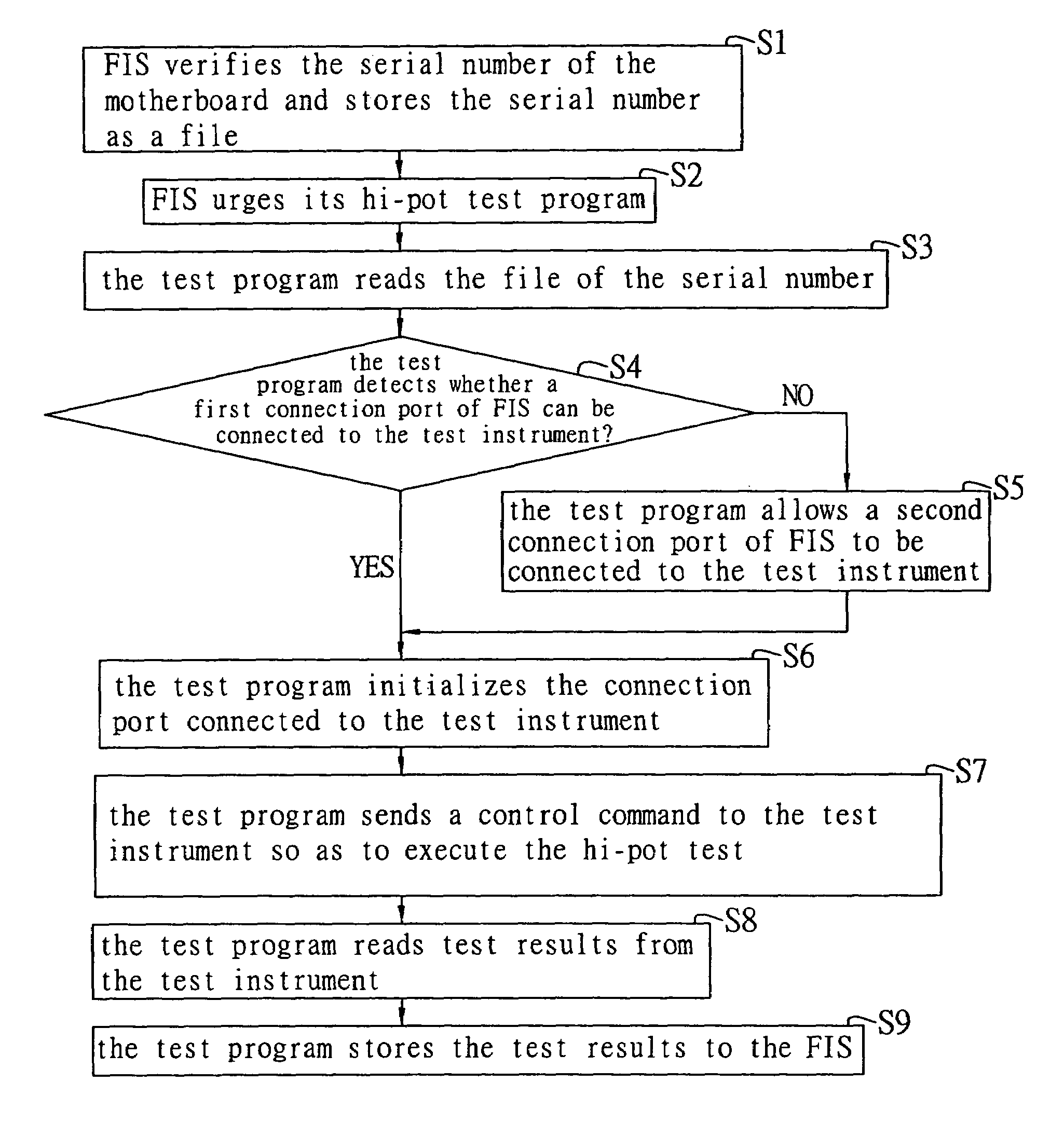

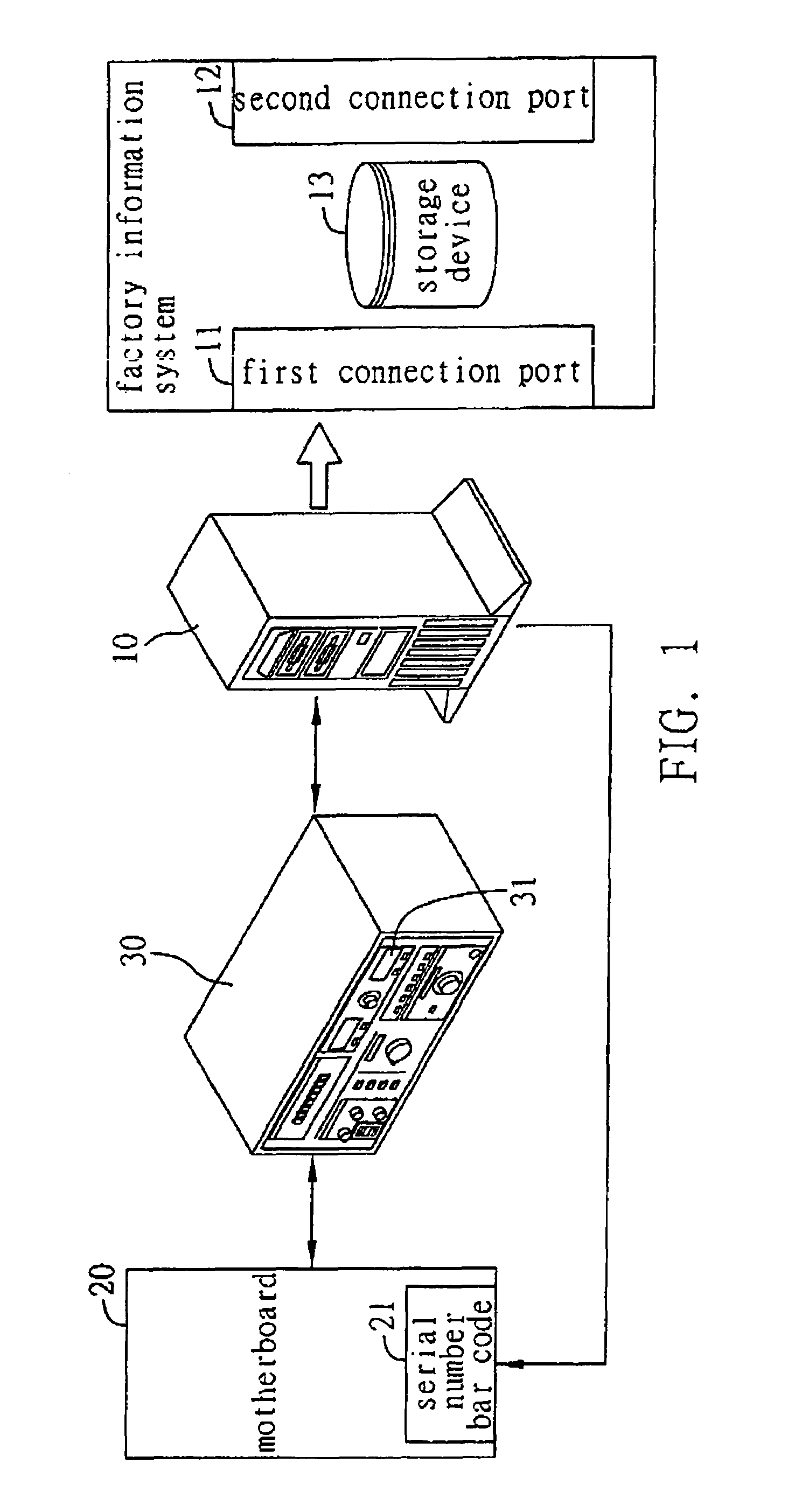

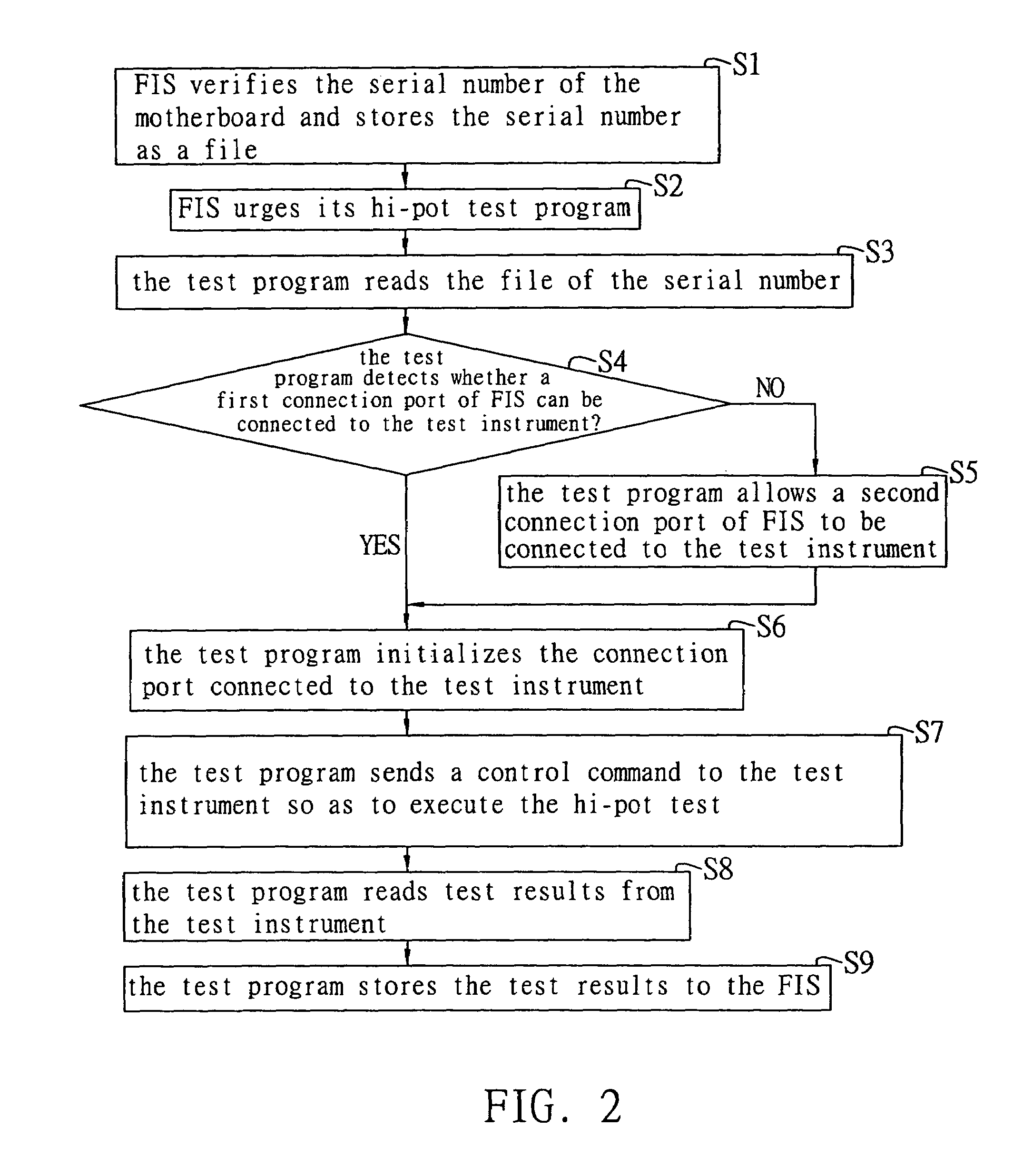

Automated test method

InactiveUS7020571B2Accurate and efficientQuality and safe operationResistance/reactance/impedenceCurrent/voltage measurementComputer hardwareElectrical devices

An automated test method for performing a hi-pot test procedure for an electrical device through the use of a test program installed in a factory information system (FIS) and a test instrument connected to the FIS. The test program sends a control command to the test instrument that in turn executes the hi-pot test for the electrical device. Test results are obtained by the test program from the test instrument and sent to the FIS. The test results are stored in the FIS for future reference.

Owner:INVENTEC CORP

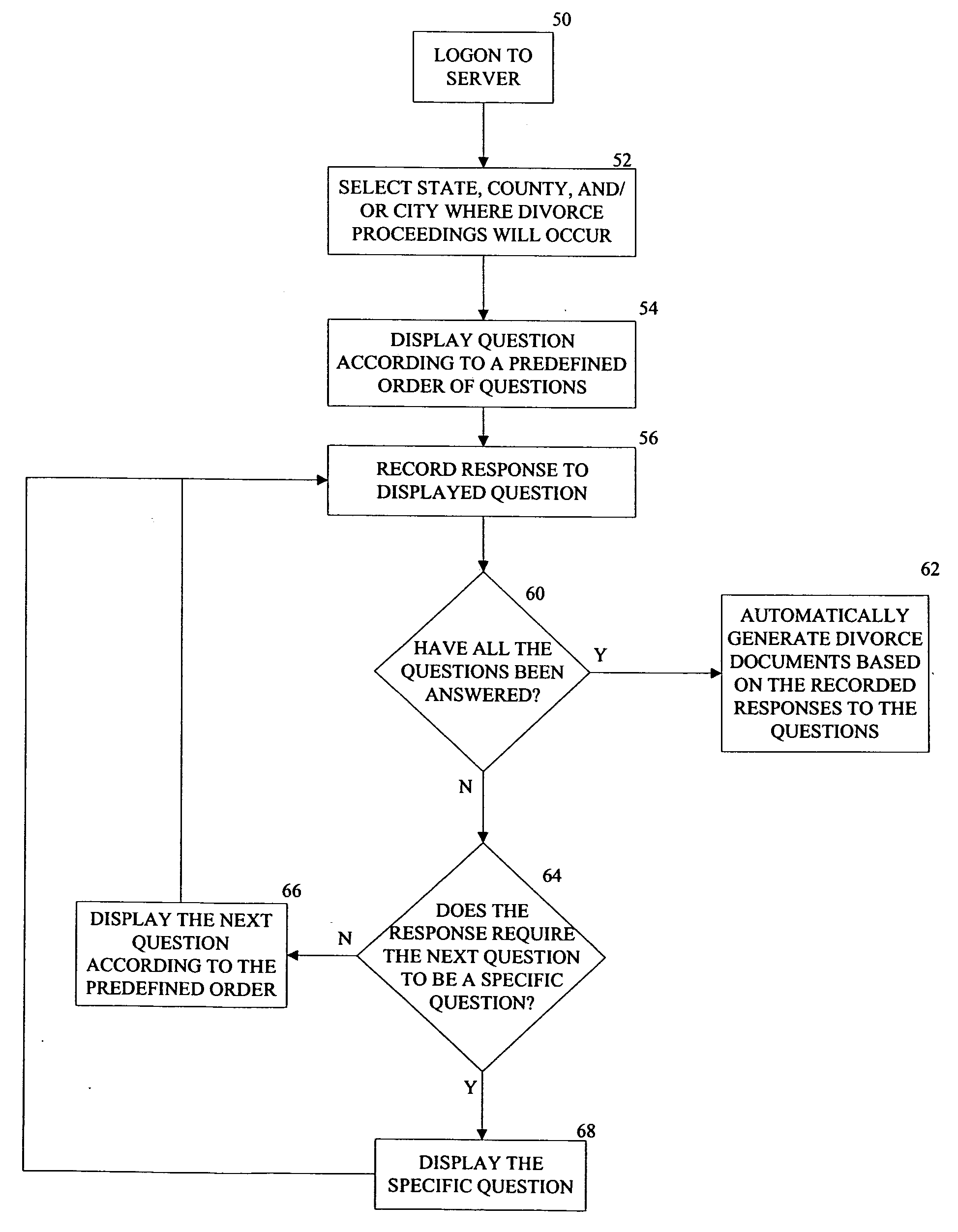

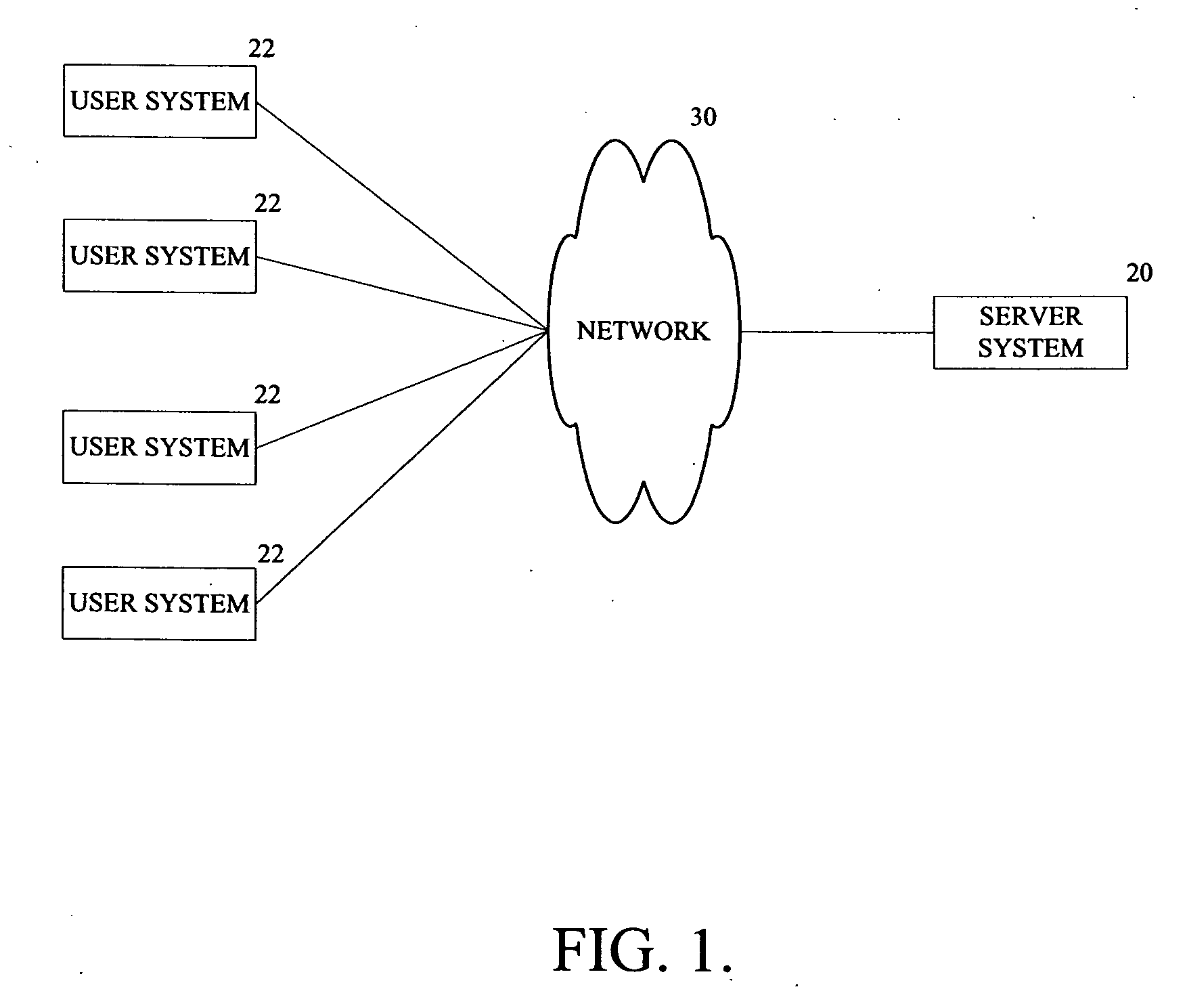

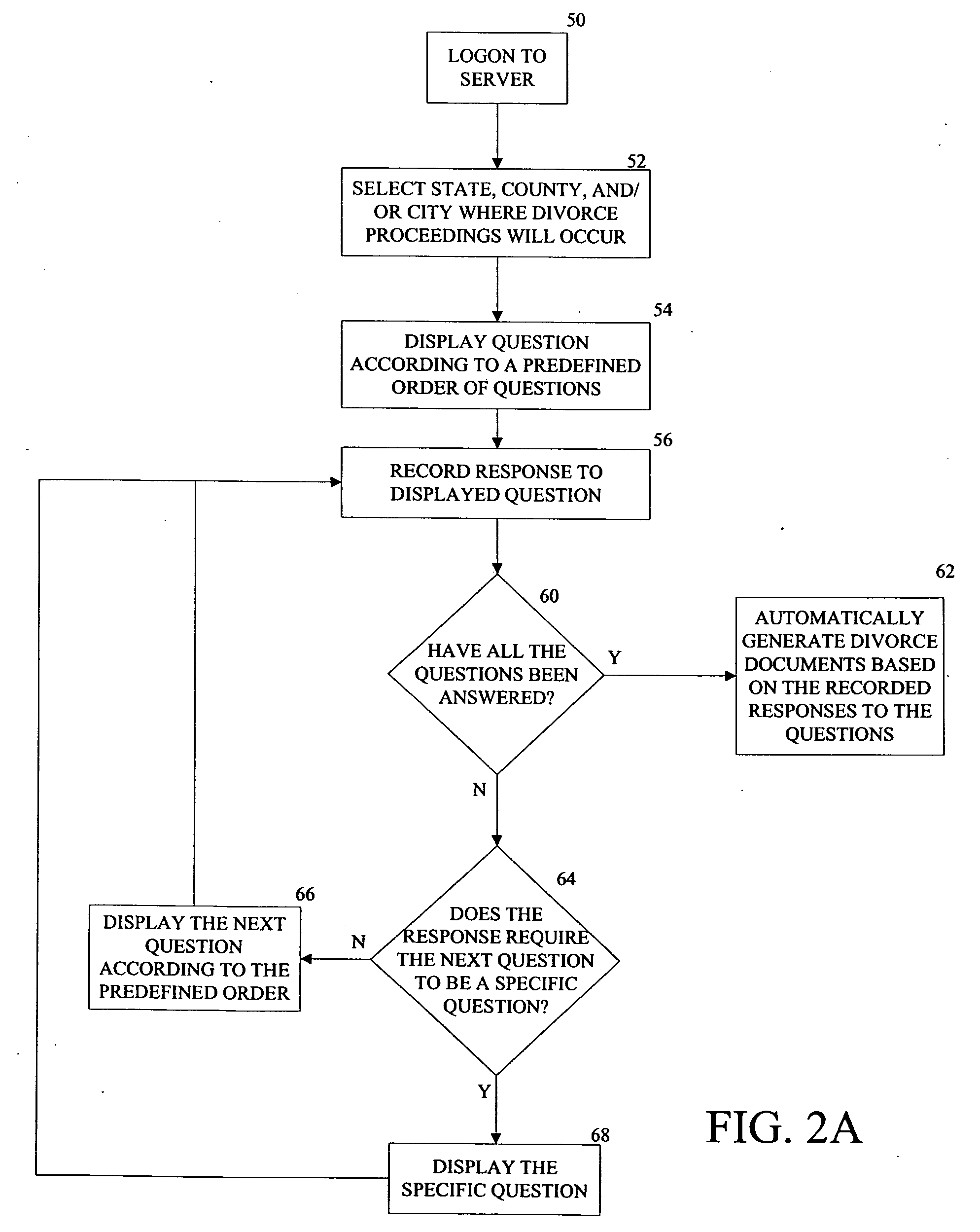

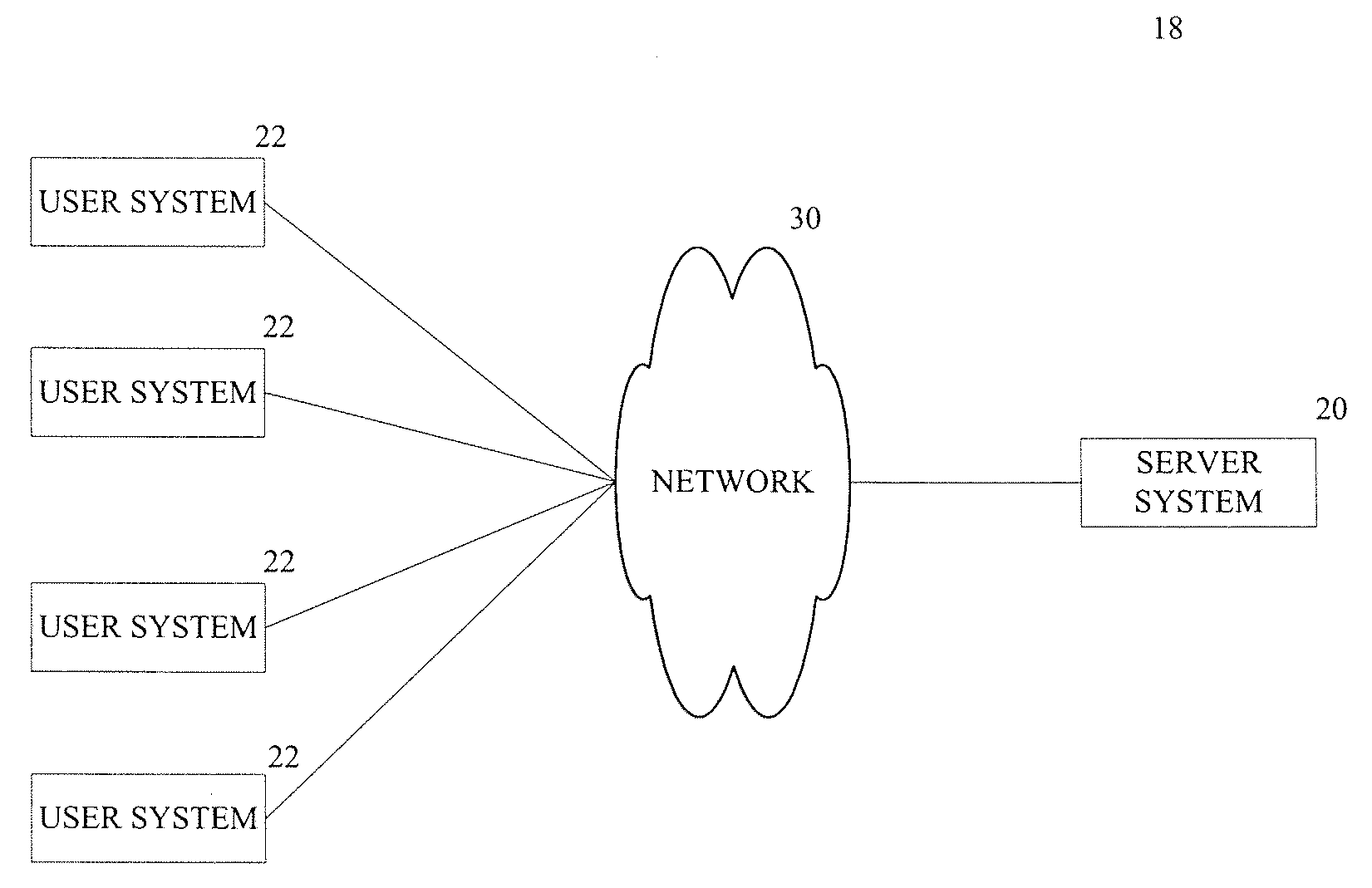

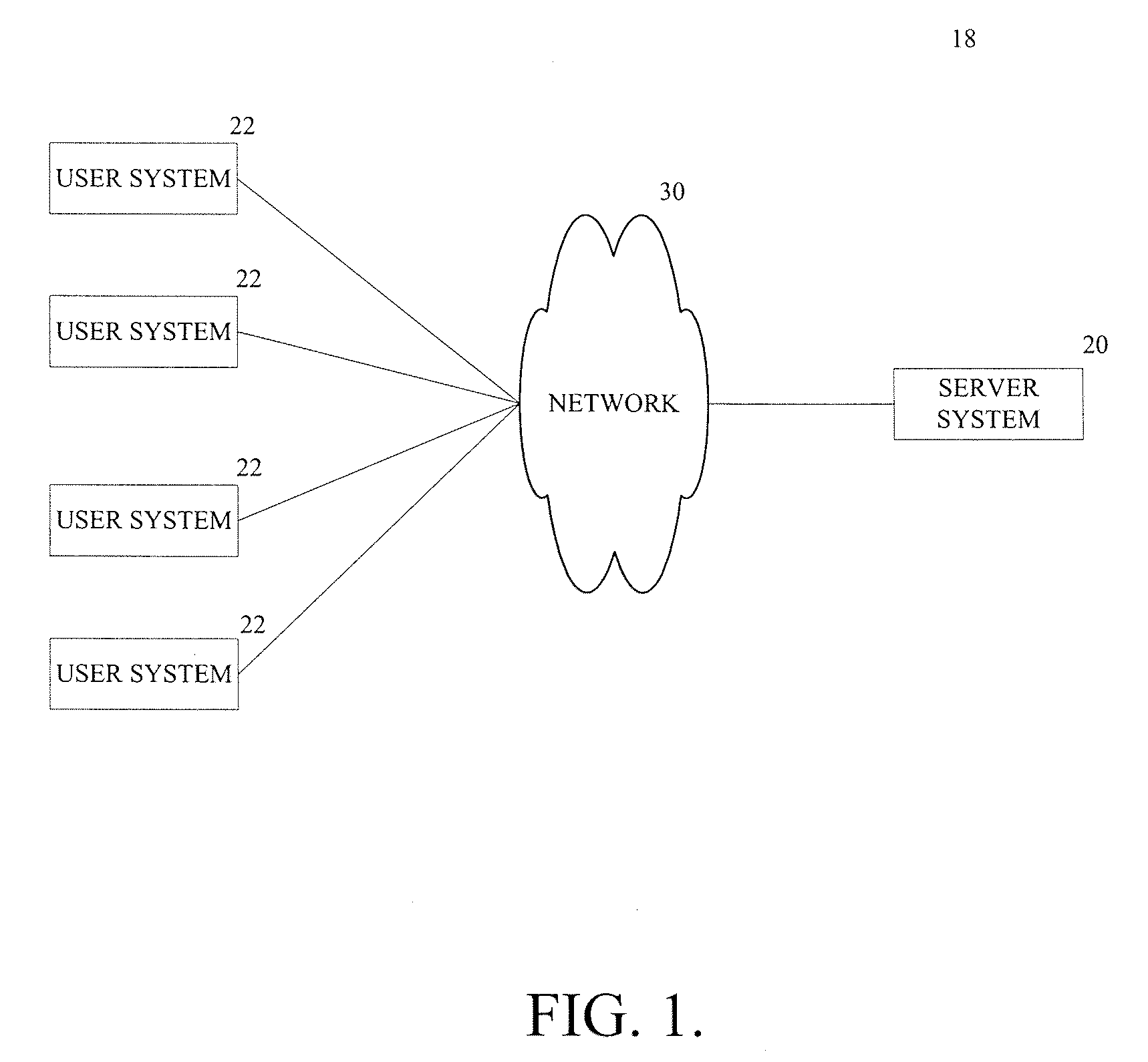

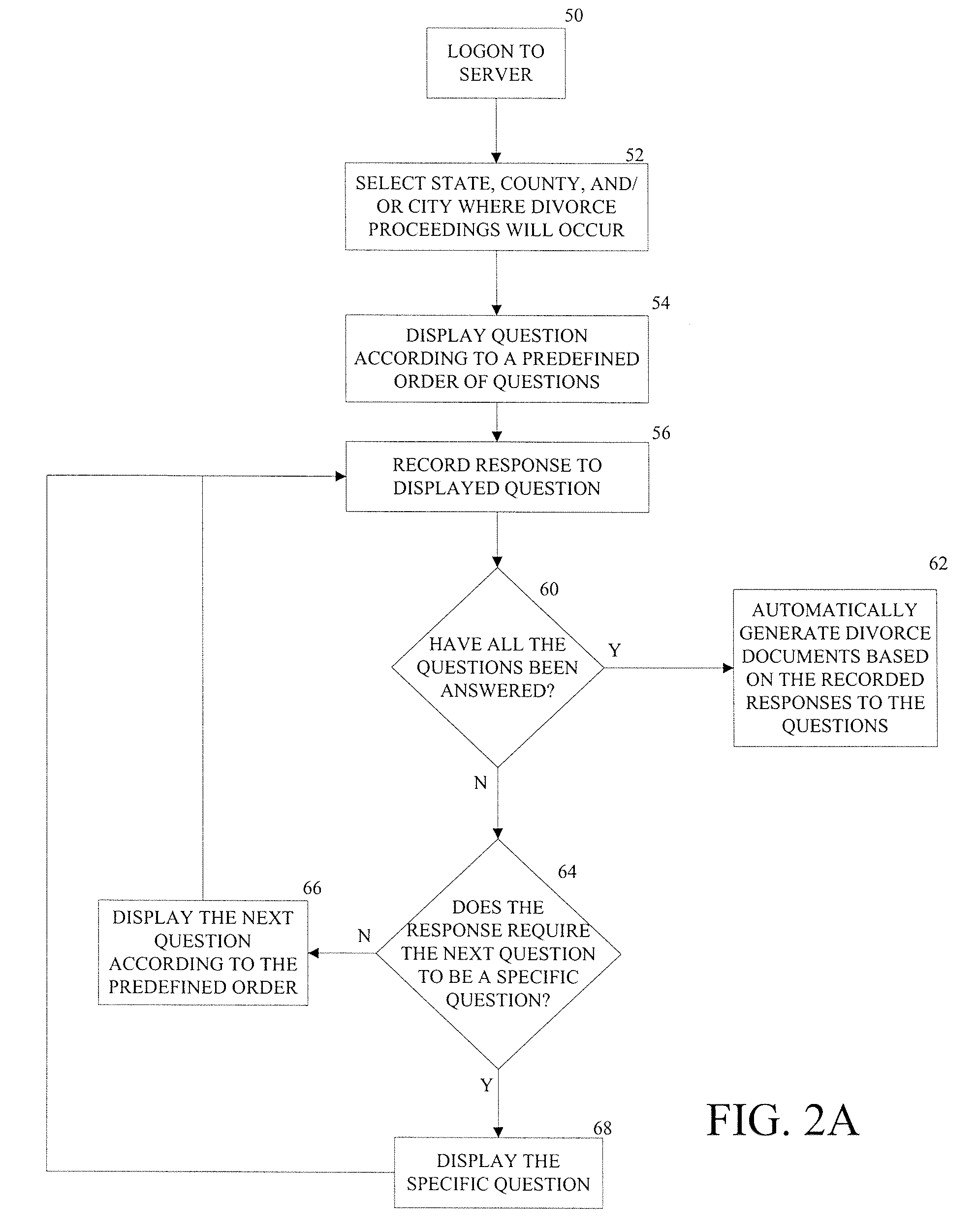

Legal document generating system

InactiveUS20070011190A1Reducing time and costNatural language translationData processing applicationsGraphicsGraphical user interface

A system and method for generating divorce proceedings or other paperwork. The system includes a server computer system and a user computer system coupled to a network. The server computer system includes a memory that stores location-based divorce proceeding rules, and a processor with a graphical user interface component. The user computer system includes a user interface component coupled to a processing component. The user interface component presents the graphical user interfaces generated by the graphical user interface component and receives responses to the presented graphical user interfaces. The responses include a selection for the location for the divorce proceedings. The received responses are sent to the server computer system. The graphical user interface component generates graphical user interfaces based on at least one of the location selection or other received responses. The processor automatically generates completed divorce documents based on the received responses.

Owner:FINNEY RANDOLPH L

Chip-scale package for integrated circuits

ActiveUS7295029B2Reducing time and costSemiconductor/solid-state device detailsSolid-state devicesContact padIntegrated circuit layout

A chip-scale packaged IC is made by bonding one or more singulated die chips (from an IC wafer) to a common substrate, such as a single cap wafer (or a portion thereof) and cutting (singulating) the substrate to yield individual, chip-scale packaged ICs. Alternatively, each die chip is bonded to an individual, pre-cut cap. Electrically conductive paths extend through the cap wafer, between wafer contact pads on the surface of the cap and electrical contact points on the IC wafer. Optionally, the cap wafer contains one or more die. The IC wafer can be fabricated according to a different technology than the cap wafer, thereby forming a hybrid chip-scale packaged IC. Optionally, additional “upper-level” cap wafers (with or without die) can be stacked to form a “multi-story” IC.

Owner:MEMSIC

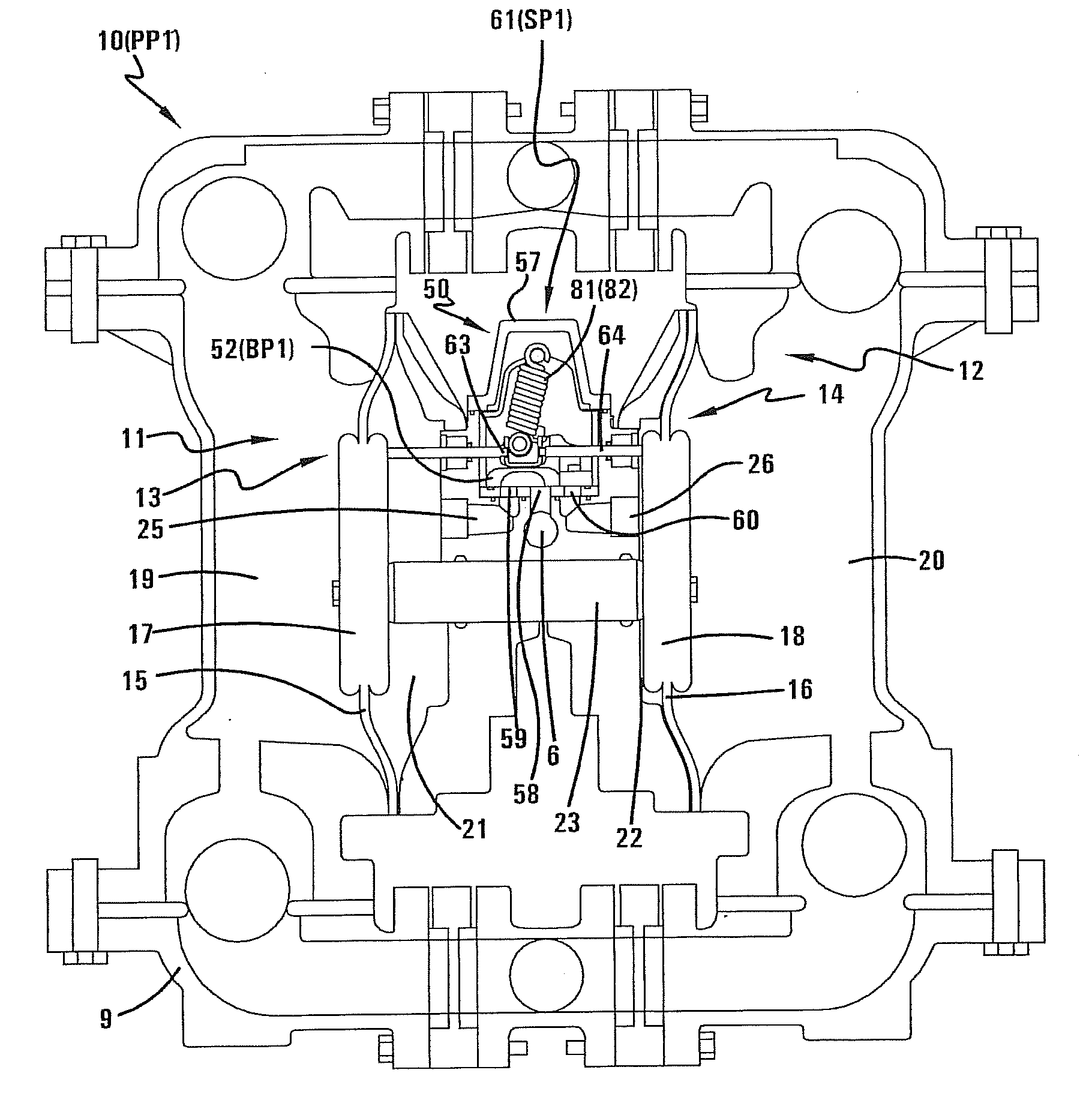

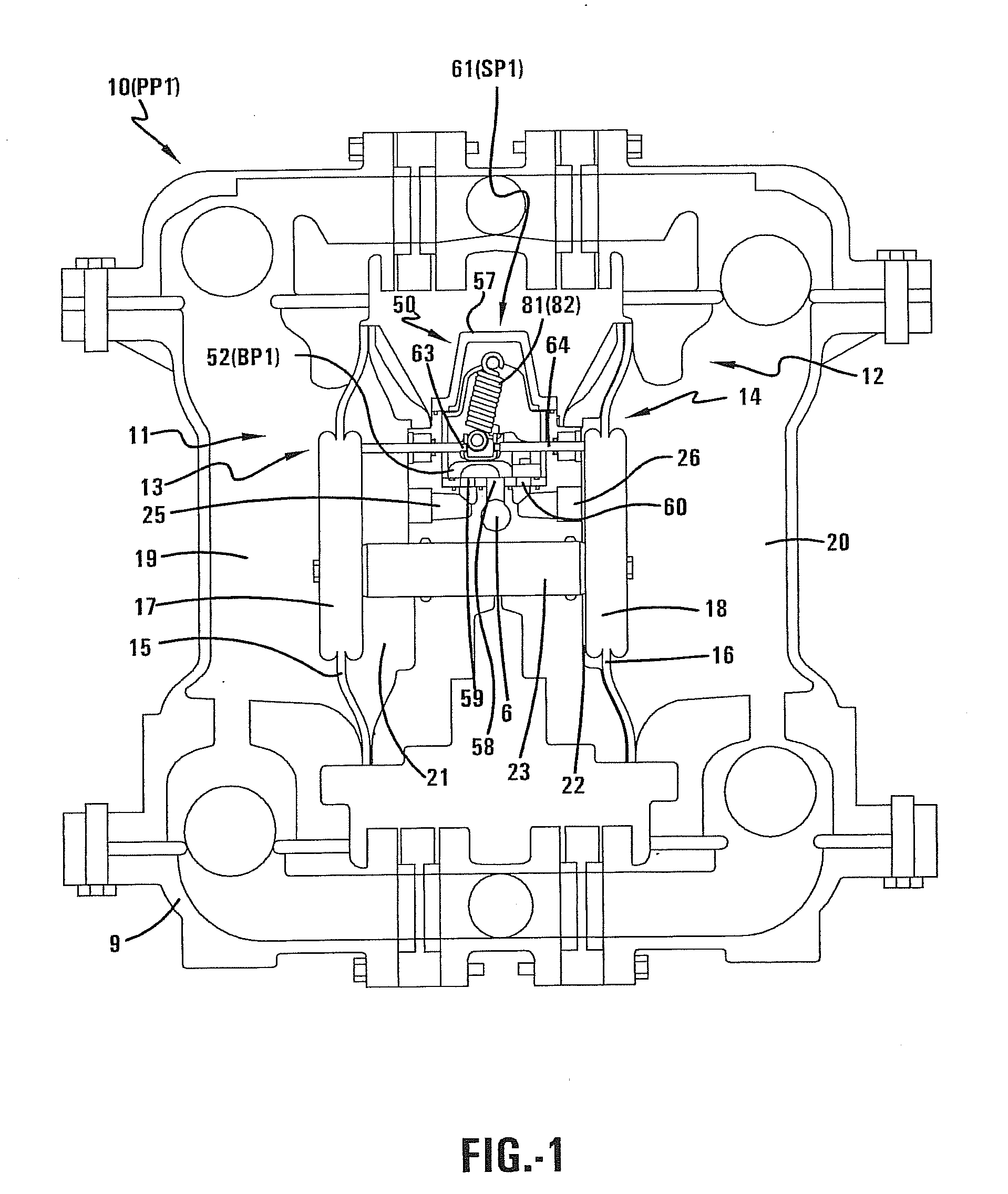

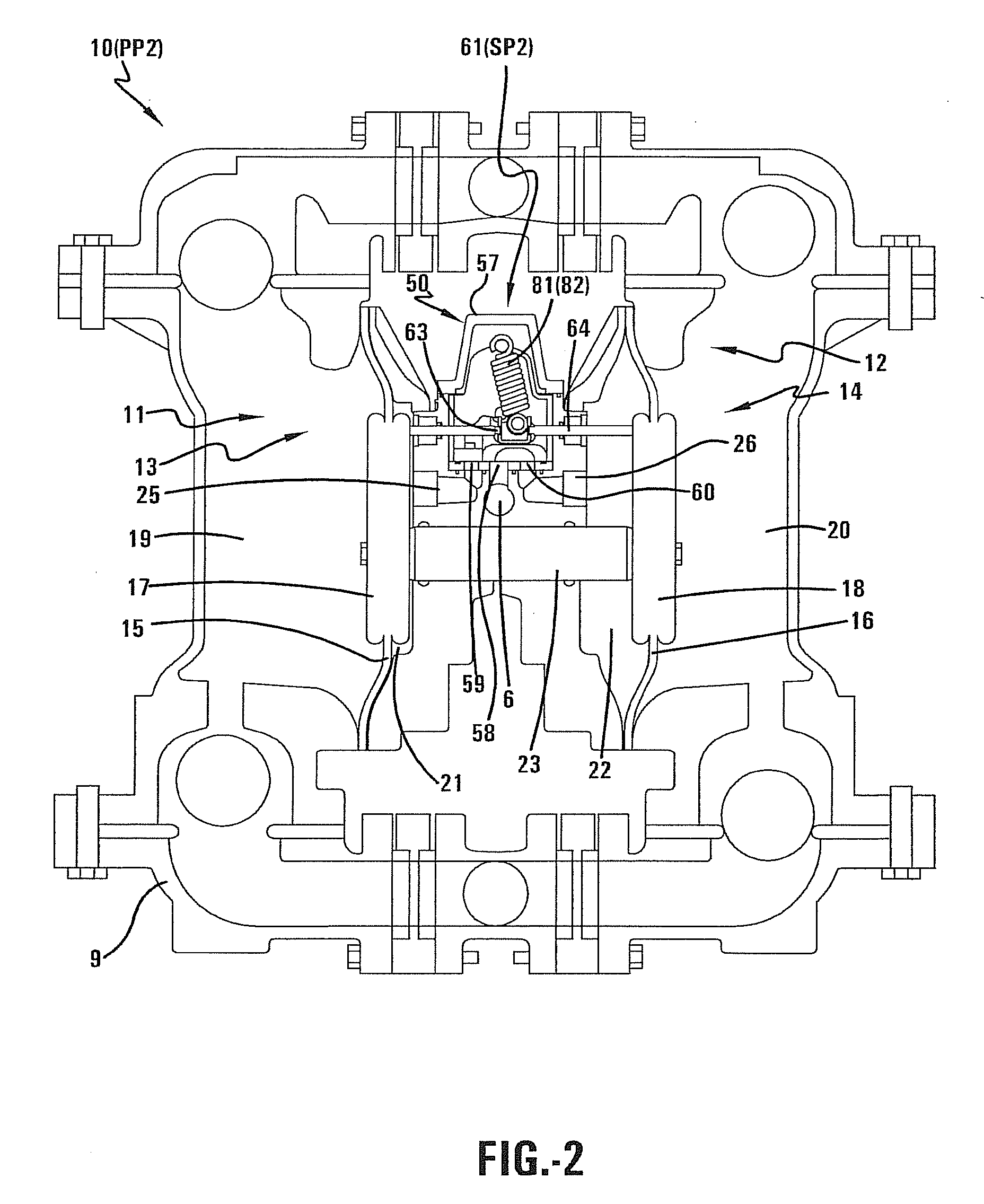

Air operated double diaphragm over center valve pump

InactiveUS20100215519A1Sacrificing longevitySacrificing performanceOperating means/releasing devices for valvesFlexible member pumpsDiaphragm pumpEngineering

An air operated double diaphragm pump comprising an air valve mechanism. The air valve mechanism may comprise a single valve system that replaces the two valve system found in conventional air operated double diaphragm pumps. The position of the valve may be determined by the diaphragm motion of the pump up to a stall position. A spring-loaded mechanical actuation may complete the valve action from the stall position to the final or end of stroke position of the pump.

Owner:WARREN RUPP INC

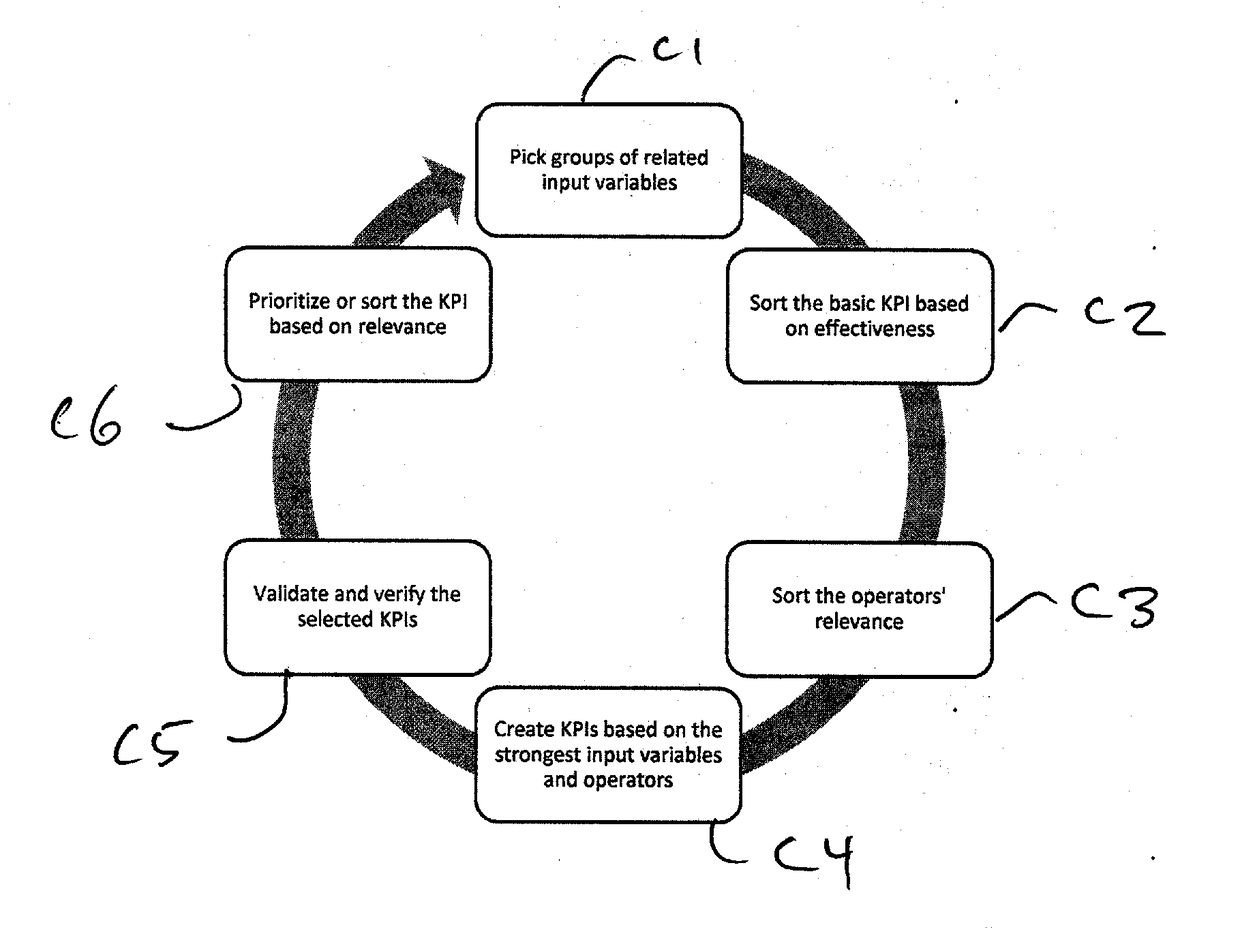

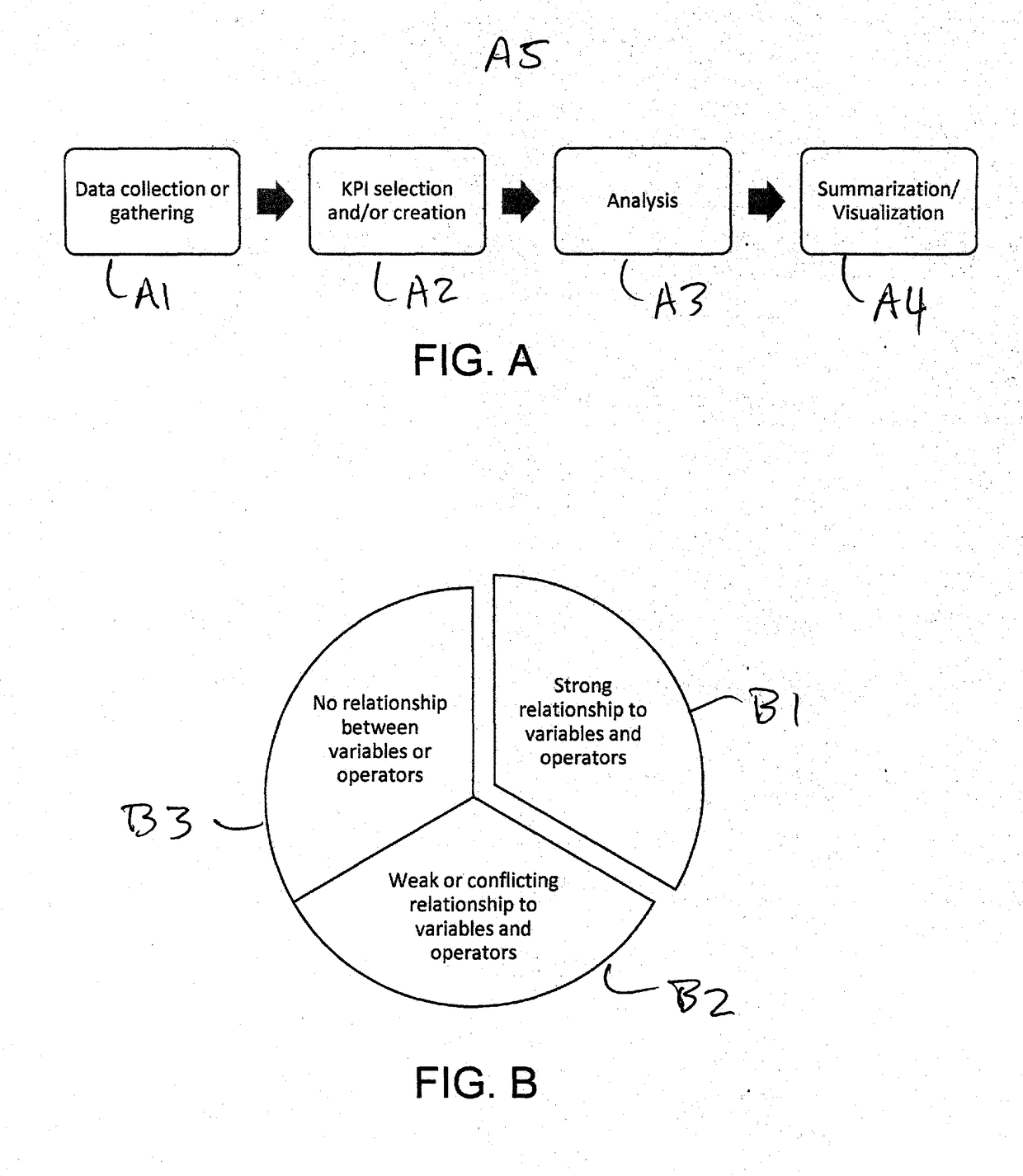

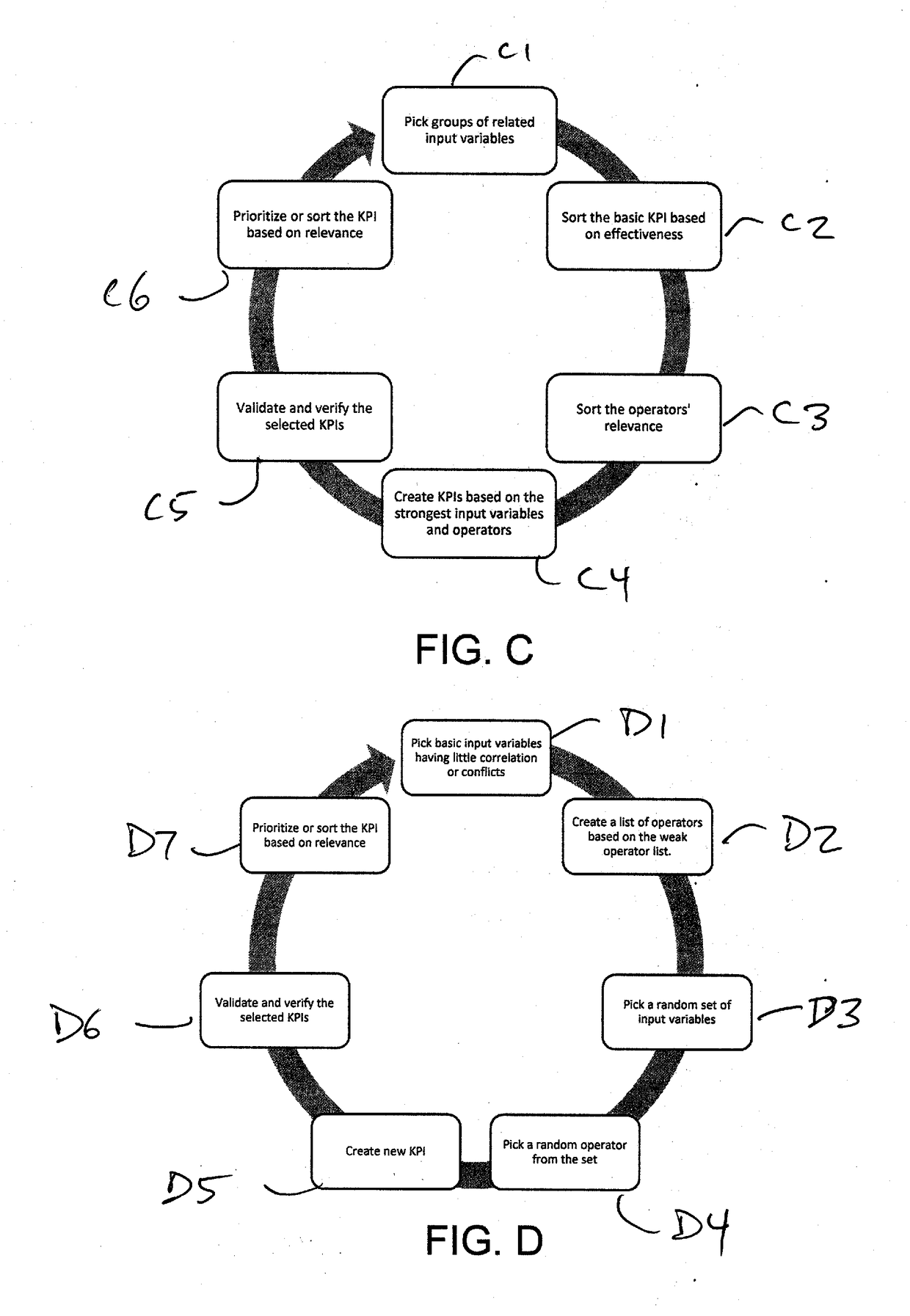

System and method for automated key-performance-indicator discovery

ActiveUS20170351689A1Reducing data setReduce search spaceDigital data information retrievalEnsemble learningTheoretical computer scienceNatural language

Various methods and systems of statistical data processing and natural-language-processing are disclosed. According to one embodiment, an intelligent, automated KPI-discovery method uses existing machine-learning algorithms and Natural Language Processing (NLP) for extraction and construction of KPIs.

Owner:AVLINO

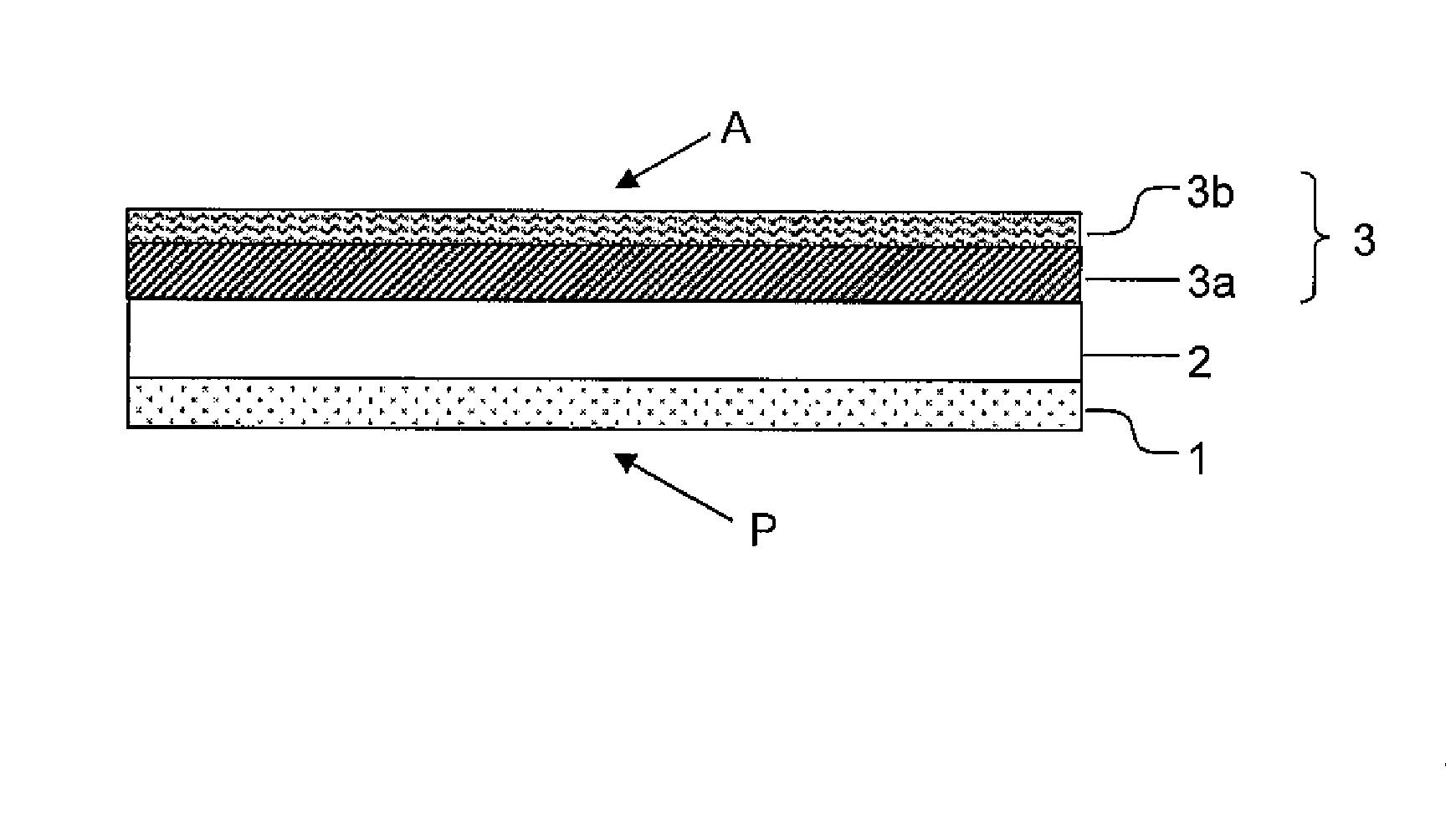

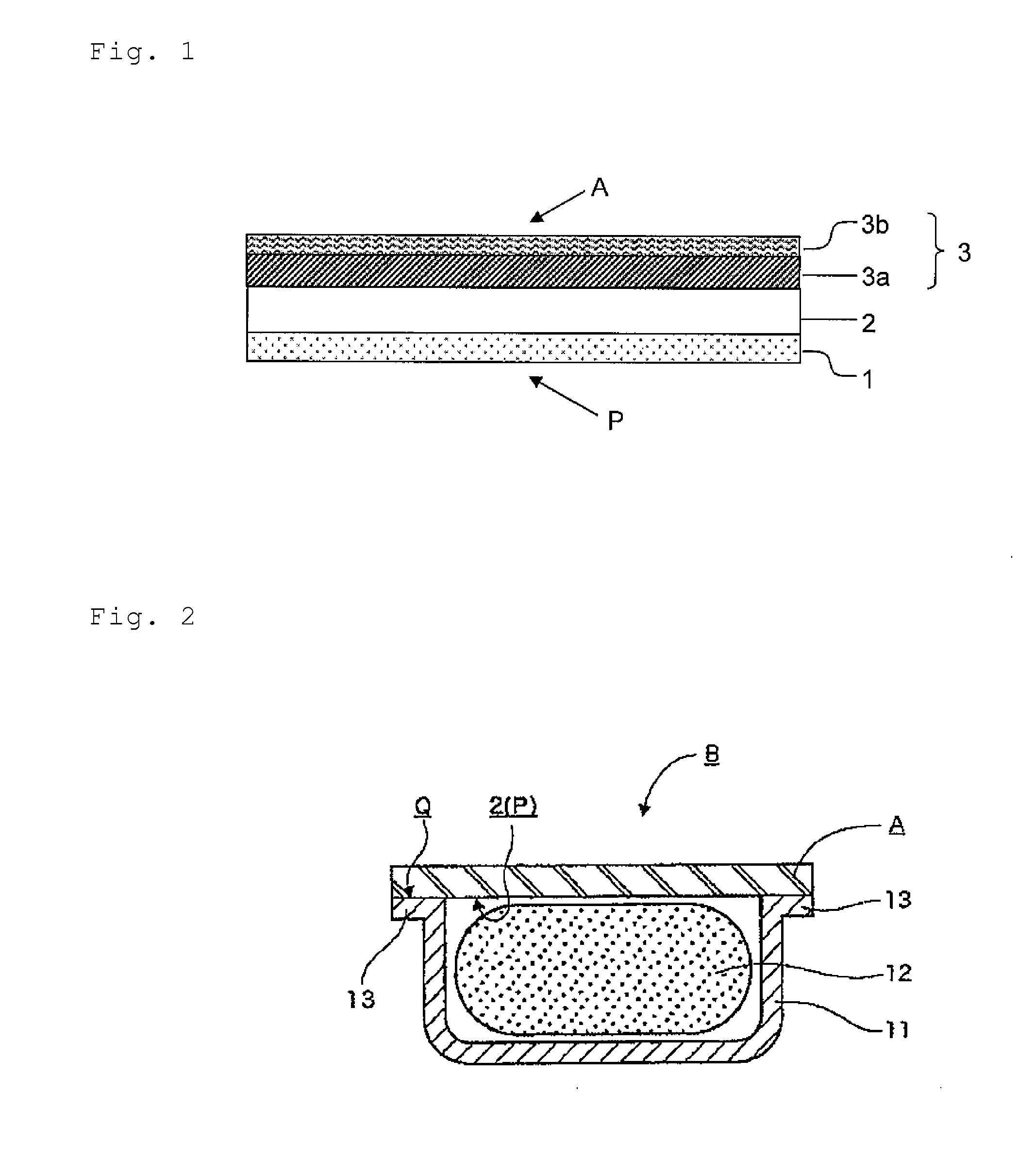

Cover material for packaging container for retortion

ActiveUS20150053680A1Shorten the timeLow costCapsDomestic sealsPolytetramethylene terephthalatePolyethylene terephthalate glycol

Provided is a cover material for packaging contains for retort sterilization which comes to exhibit excellent sealing strength through low-temperature, short-time heat sealing. The cover material for packaging containers for retort sterilization is constituted of a multilayered laminate obtained by superposing a base layer, an interlayer, and a sealing layer in this order, and is characterized in that the base layer is constituted of a laminated film obtained by laminating a polyethylene terephthalate film or polybutylene terephthalate film to an aluminum foil and the aluminum foil of the base layer has been laminated to the interlayer with a polyurethane-based adhesive or a polyester-based adhesive, and that the aluminum foil has a thickness of 7-40 μm, the polyethylene terephthalate film or the polybutylene terephthalate film has a thickness of 6-18 μm, the interlayer has a thickness of 10-100 μm, and the sealing layer has a thickness of 3-20 μm.

Owner:DAI NIPPON PRINTING CO LTD

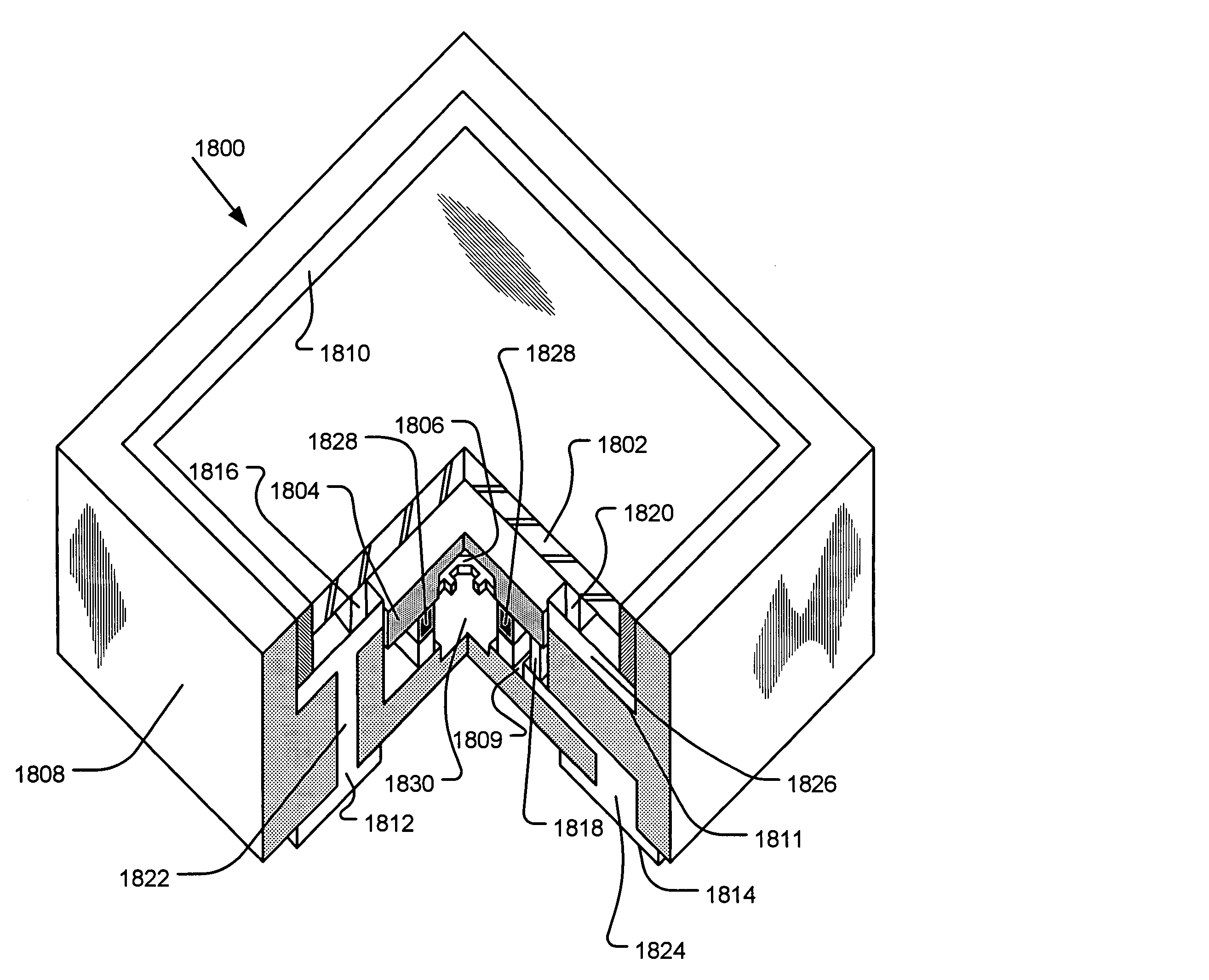

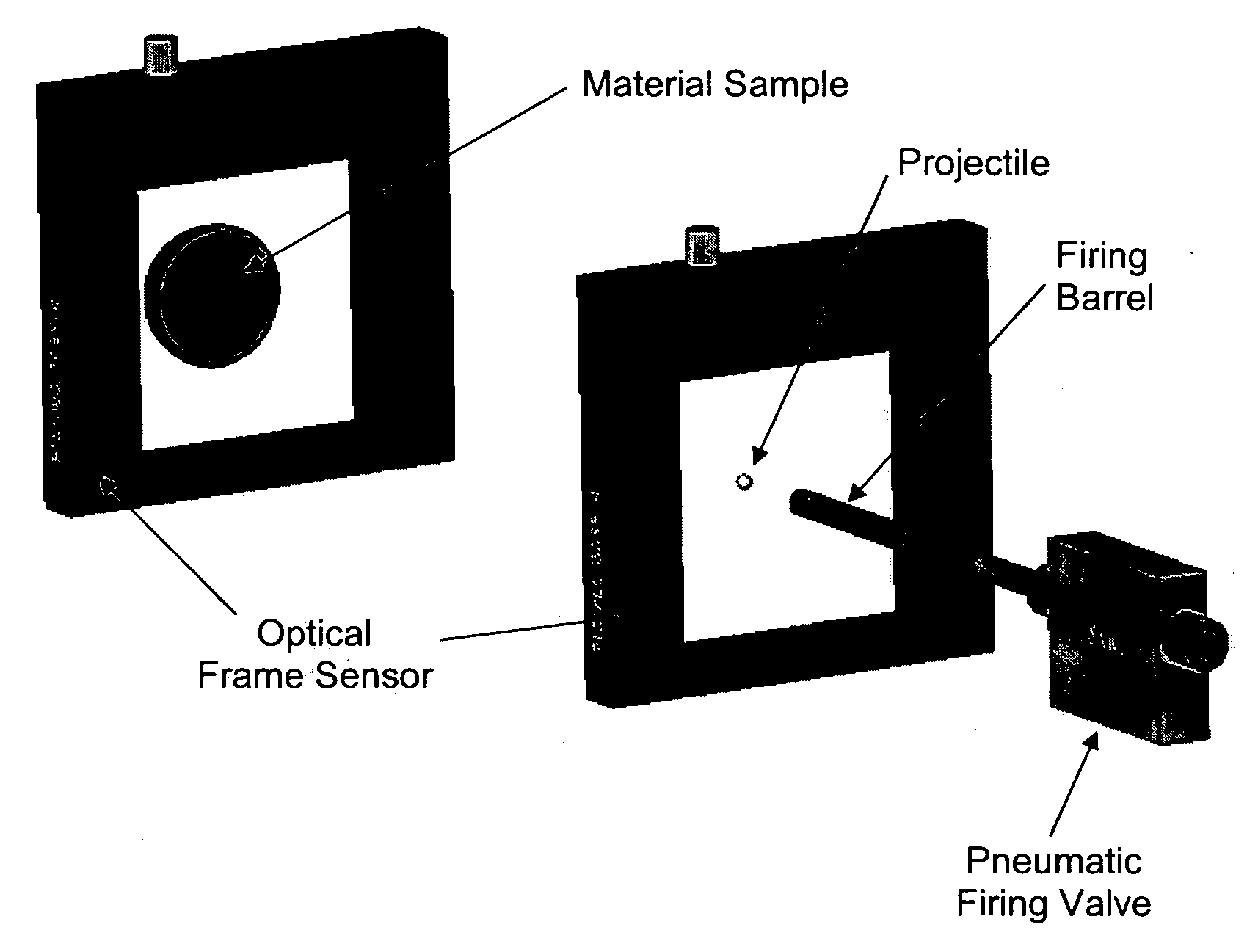

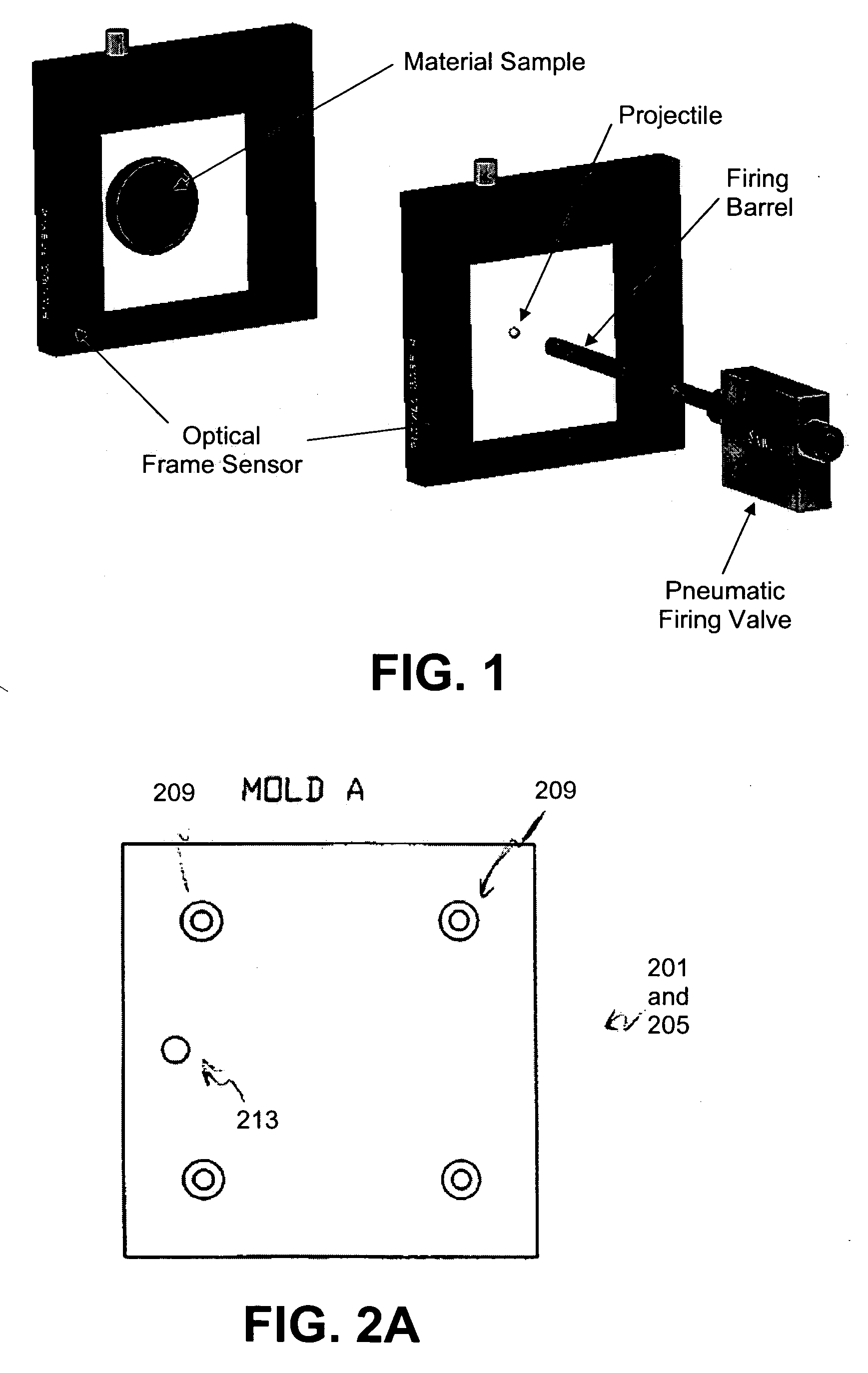

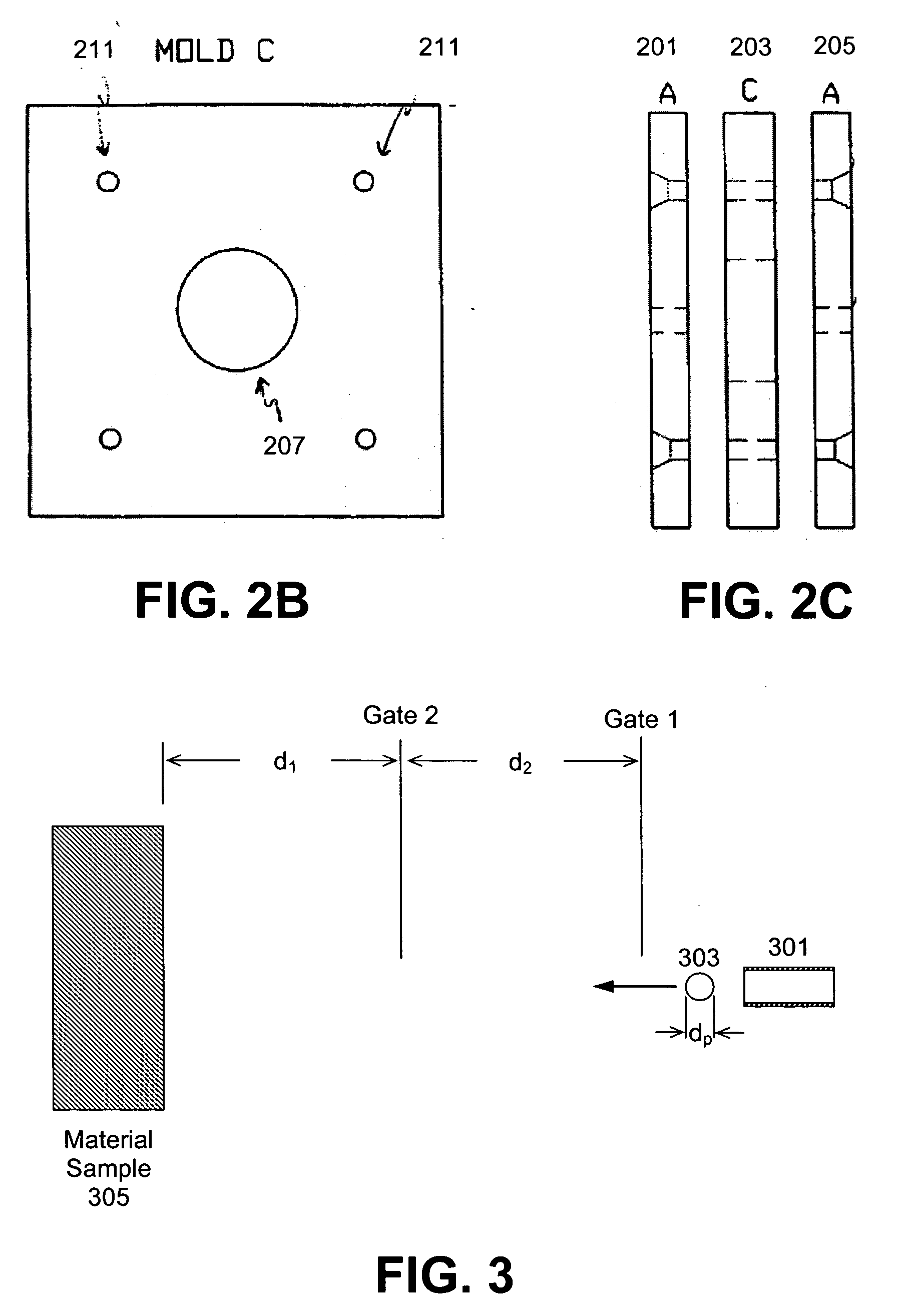

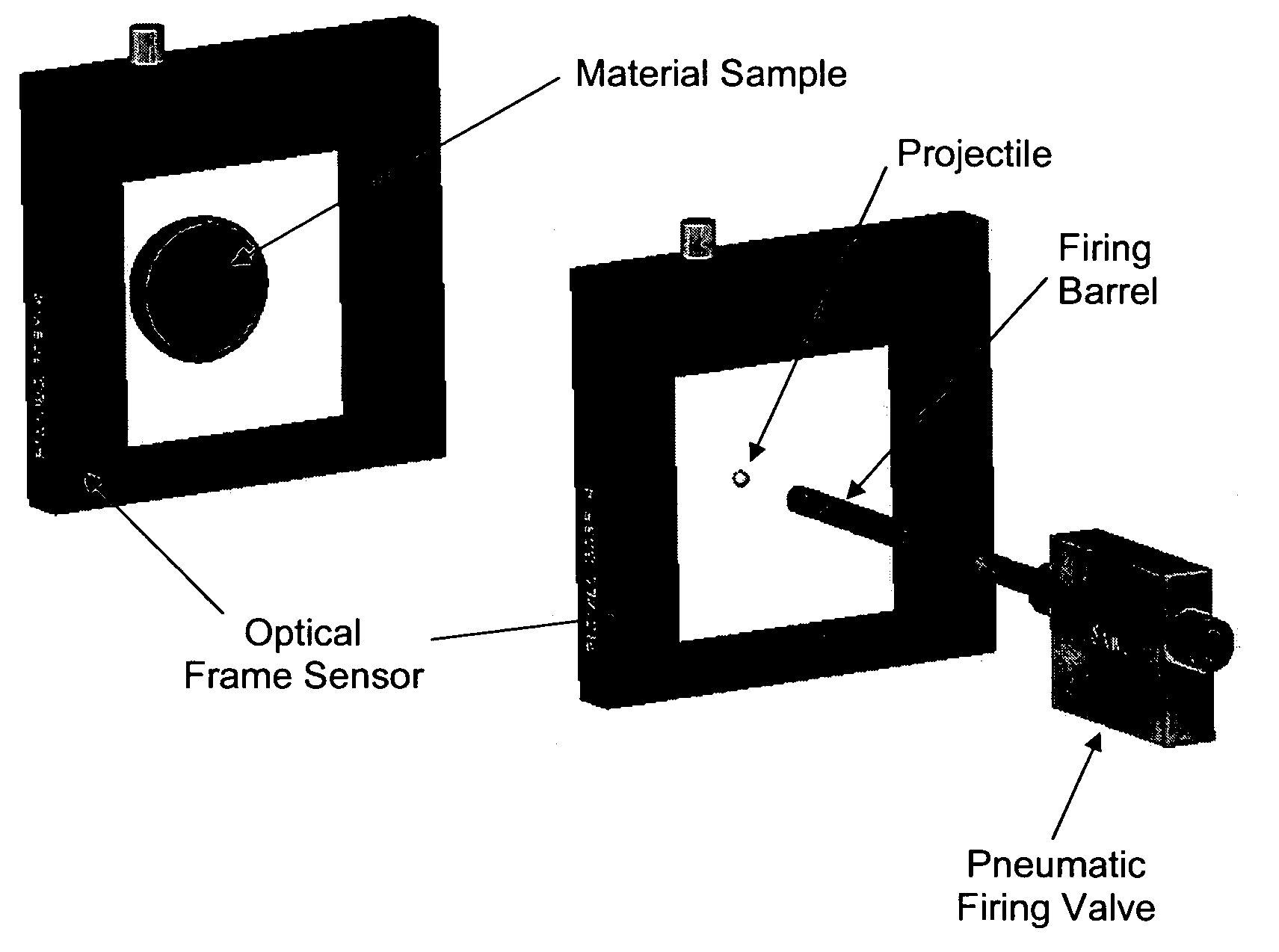

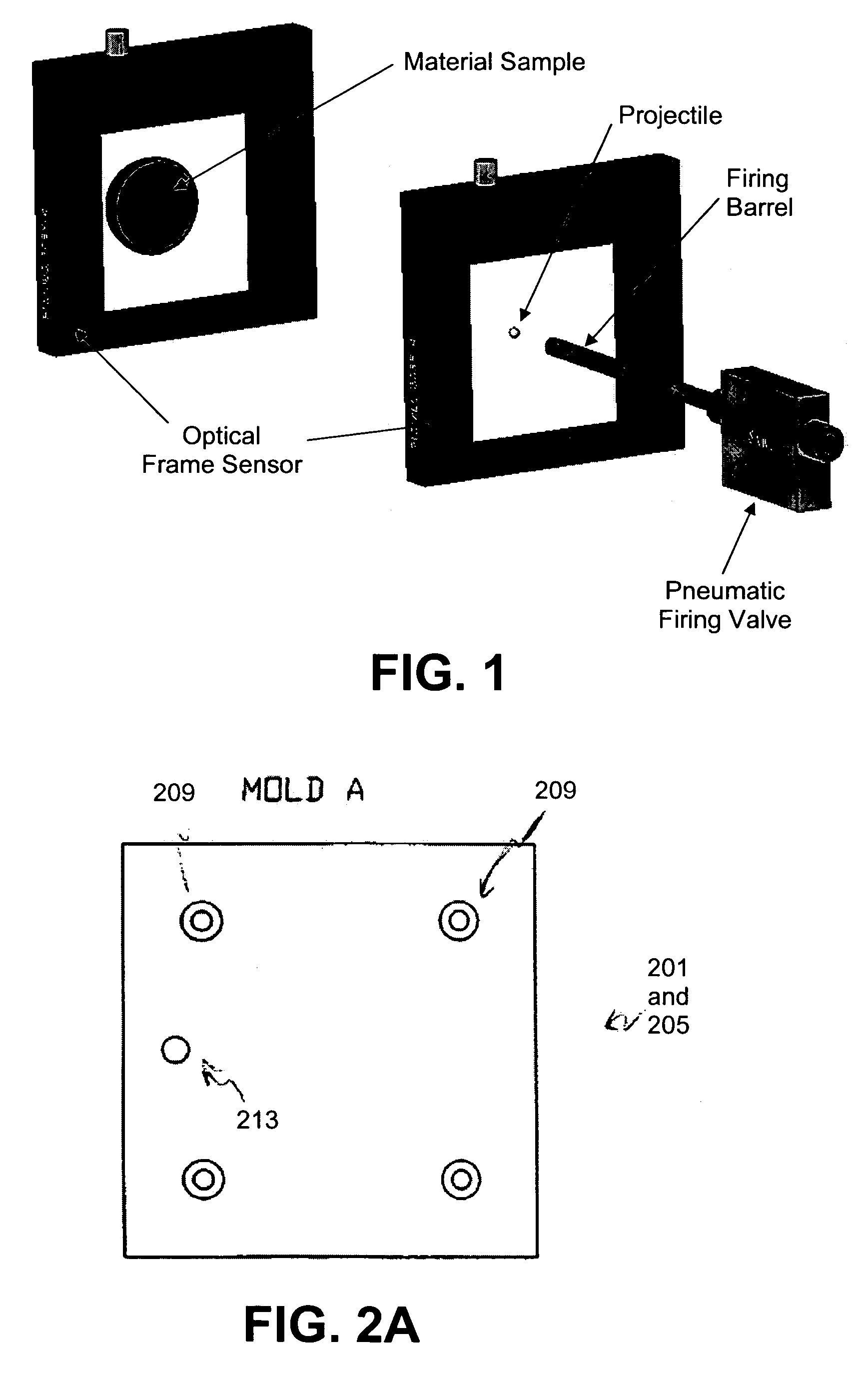

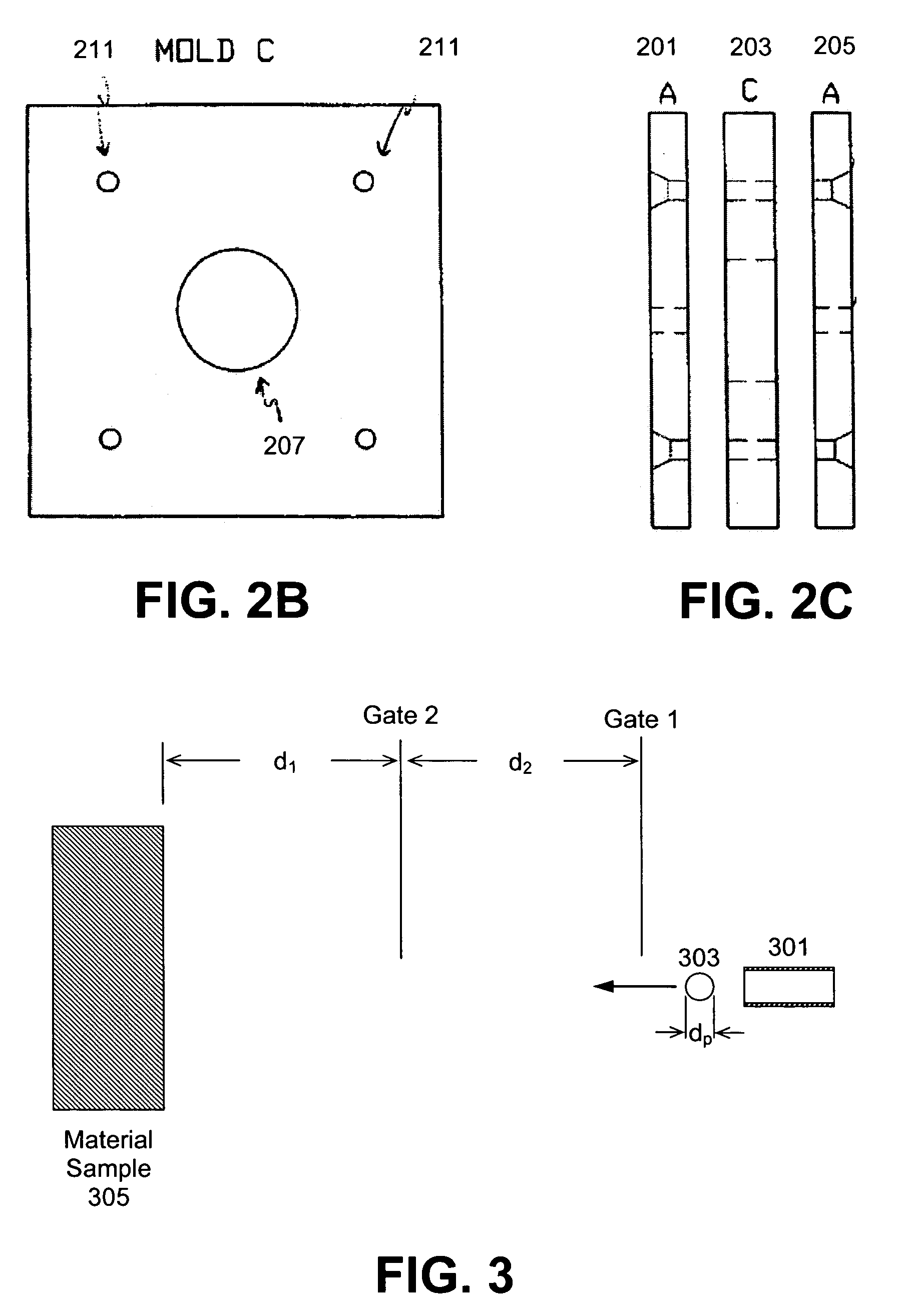

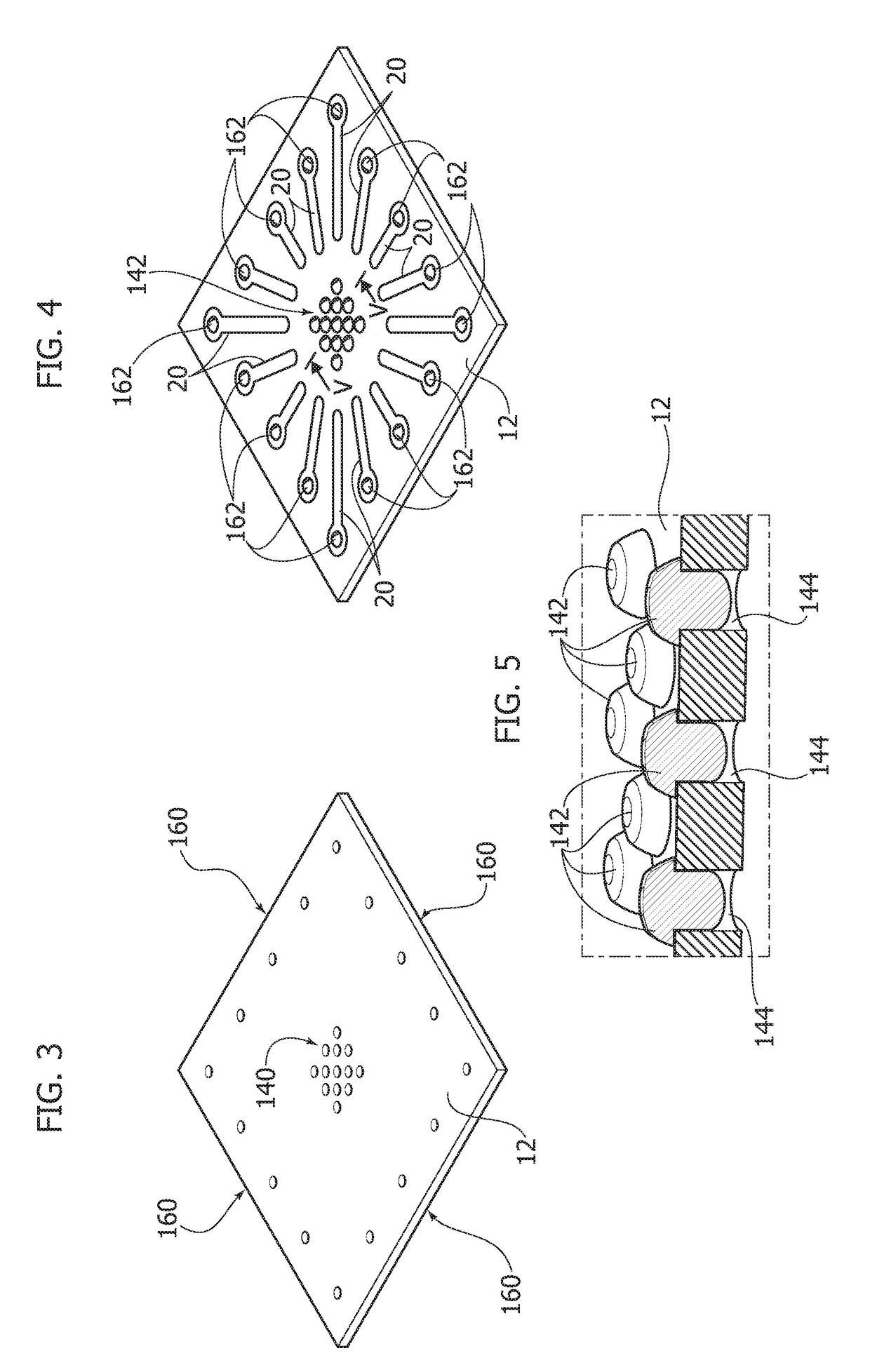

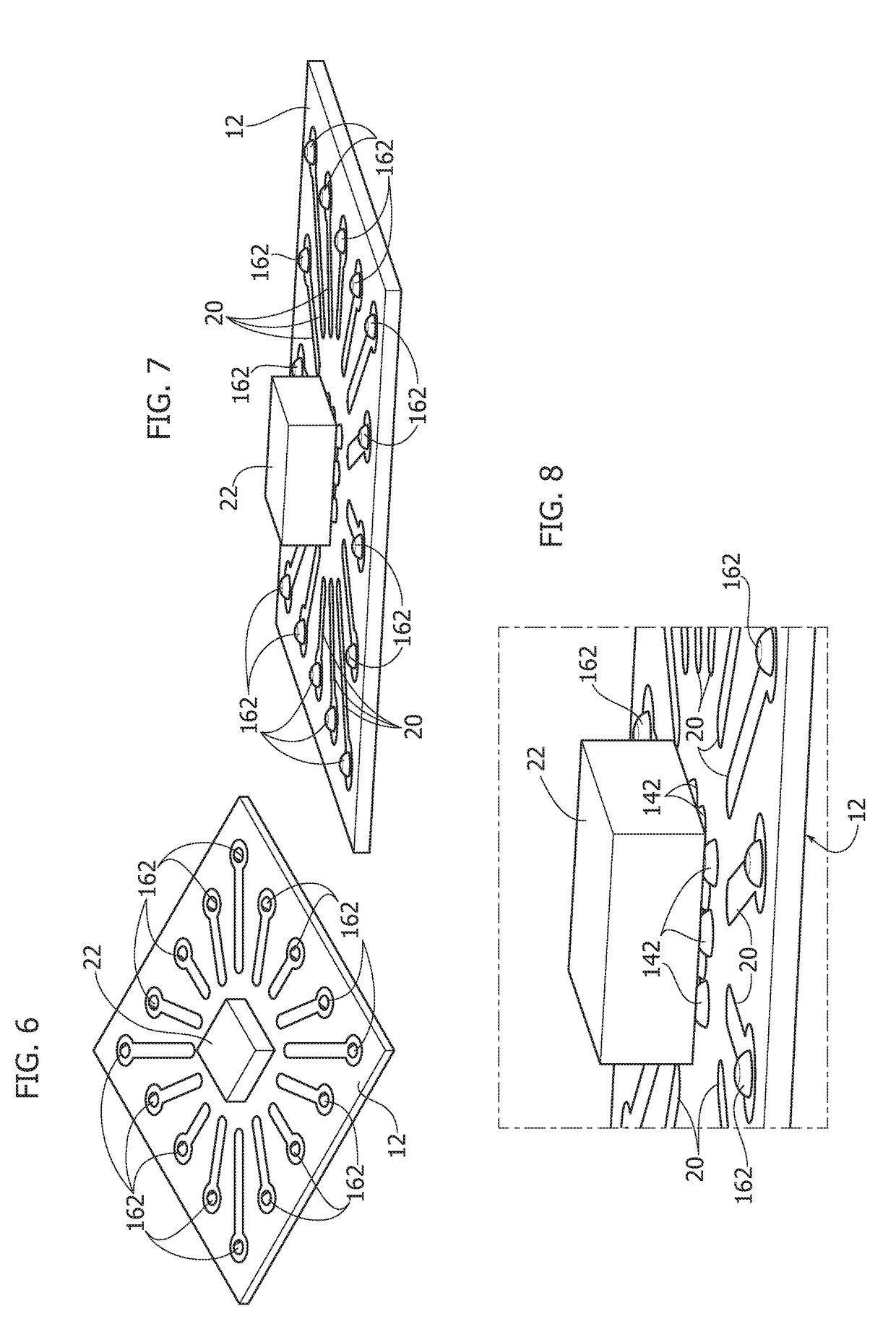

High speed resiliometer

InactiveUS20060032288A1The testing process is simpleShorten the timeAcceleration measurementInvestigating material hardnessReverse orderEngineering

An apparatus and method for testing the physical properties of a material is disclosed. Preferably, the physical properties that may be tested include, but are not limited to, the COR of a material. Accordingly, the apparatus includes a projectile that may be capable of being propelled towards a material sample. The projectile is preferably aimed and fired through a tubular barrel towards the material sample. The tubular barrel preferably comprises a propulsion system that controls pneumatic energy via a pneumatic valve. At least two sensors are placed between the tubular barrel and the material sample in order to detect the passage of the projectile. It is desired that the sensors are placed at precise, discrete positions. As the projectile passes through the field of view of each sensor, the time is recorded to a memory, for example, a counter timer board. The projectile may then impact the material sample, which may preferably be held in place by a fixation device. The fixation device is preferably a holding slot, which may be backed by an infinite mass cylinder. Upon rebounding from the material sample, the projectile passes back through the field of view of the sensors in reverse order, allowing the sensors to capture and record the time of passage to a memory, such as a counter timer board. The physical properties of the material sample may be calculated by a processing device that is operatively connected to at least a portion of the apparatus.

Owner:ACUSHNET CO

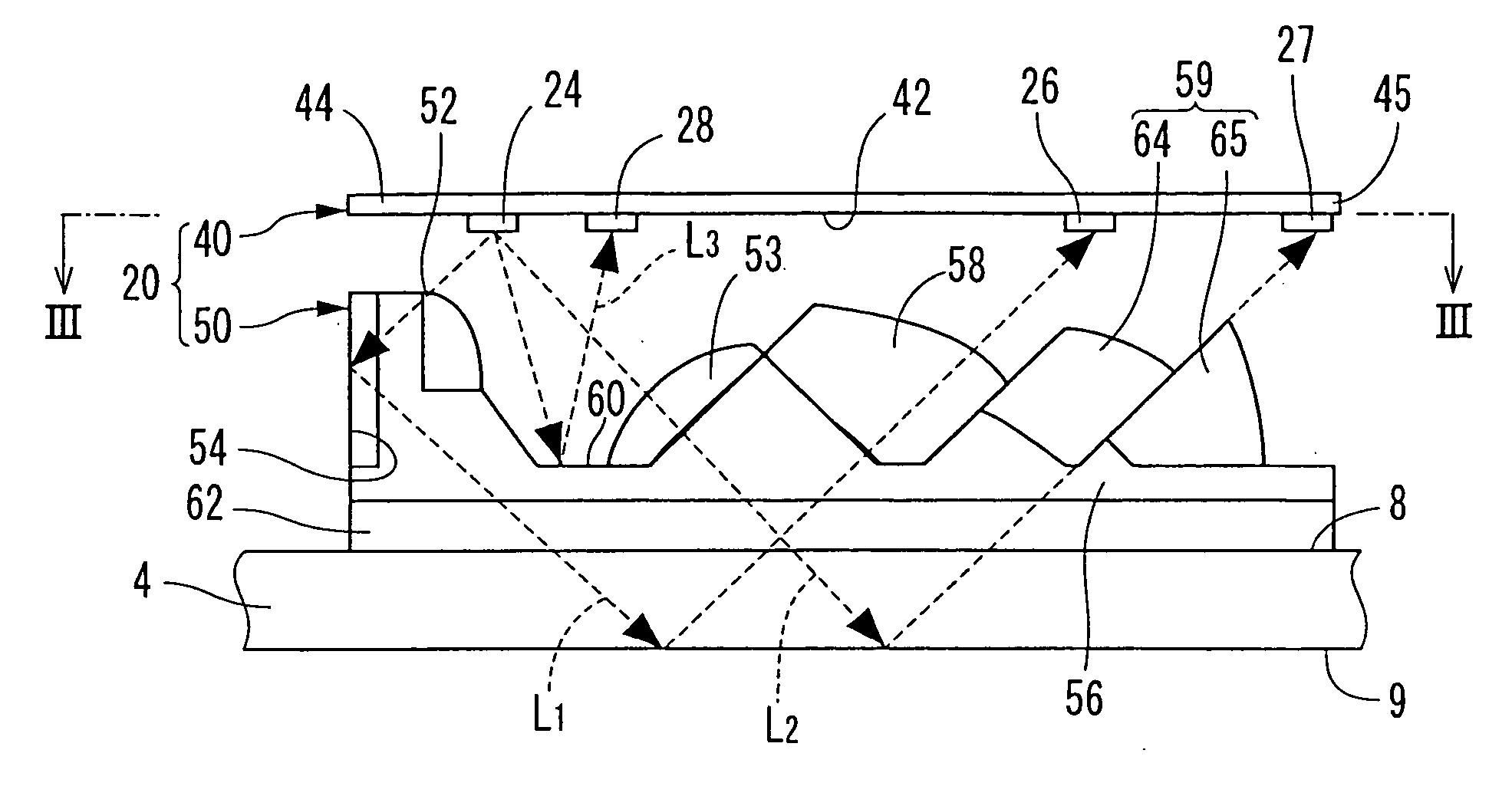

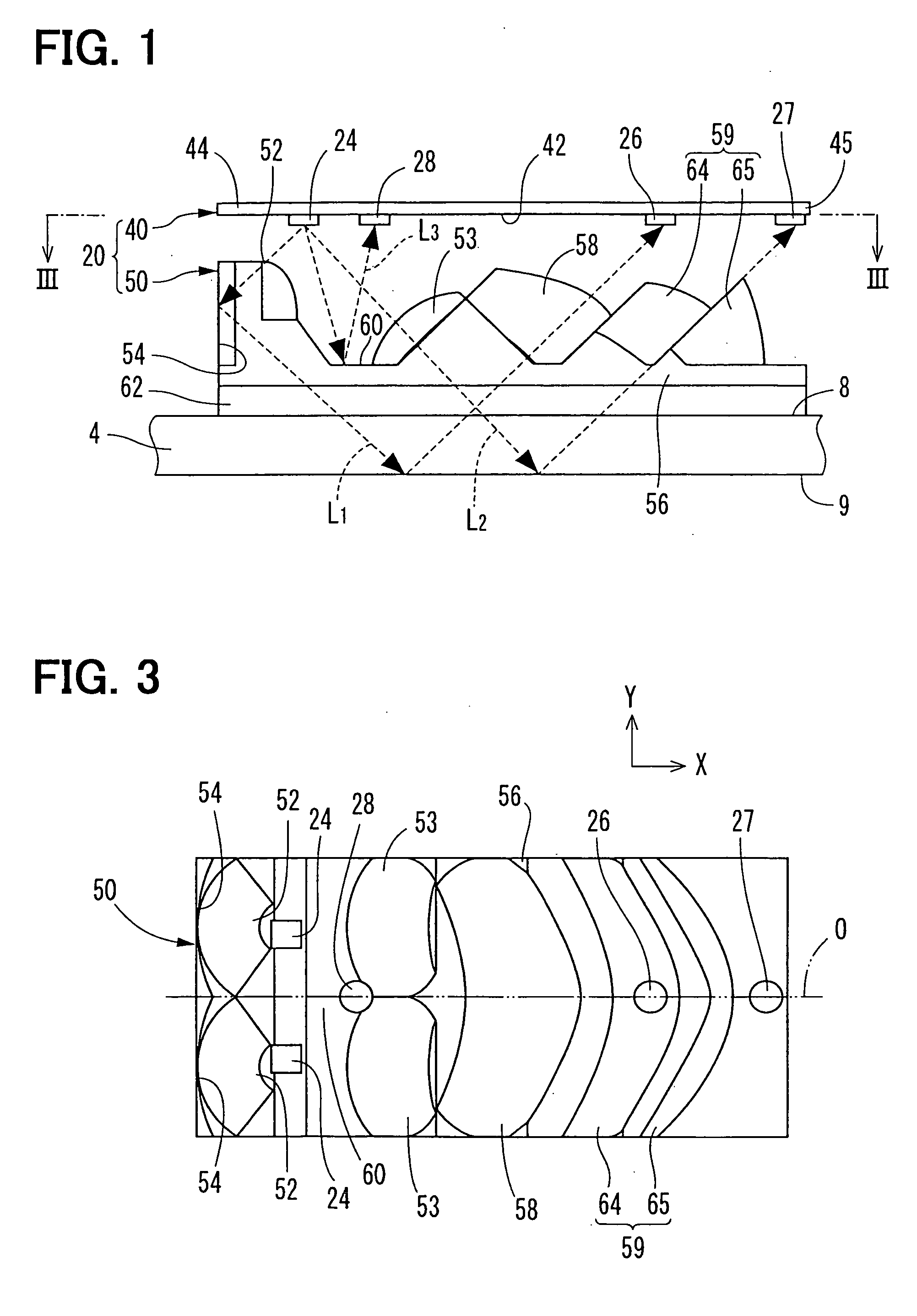

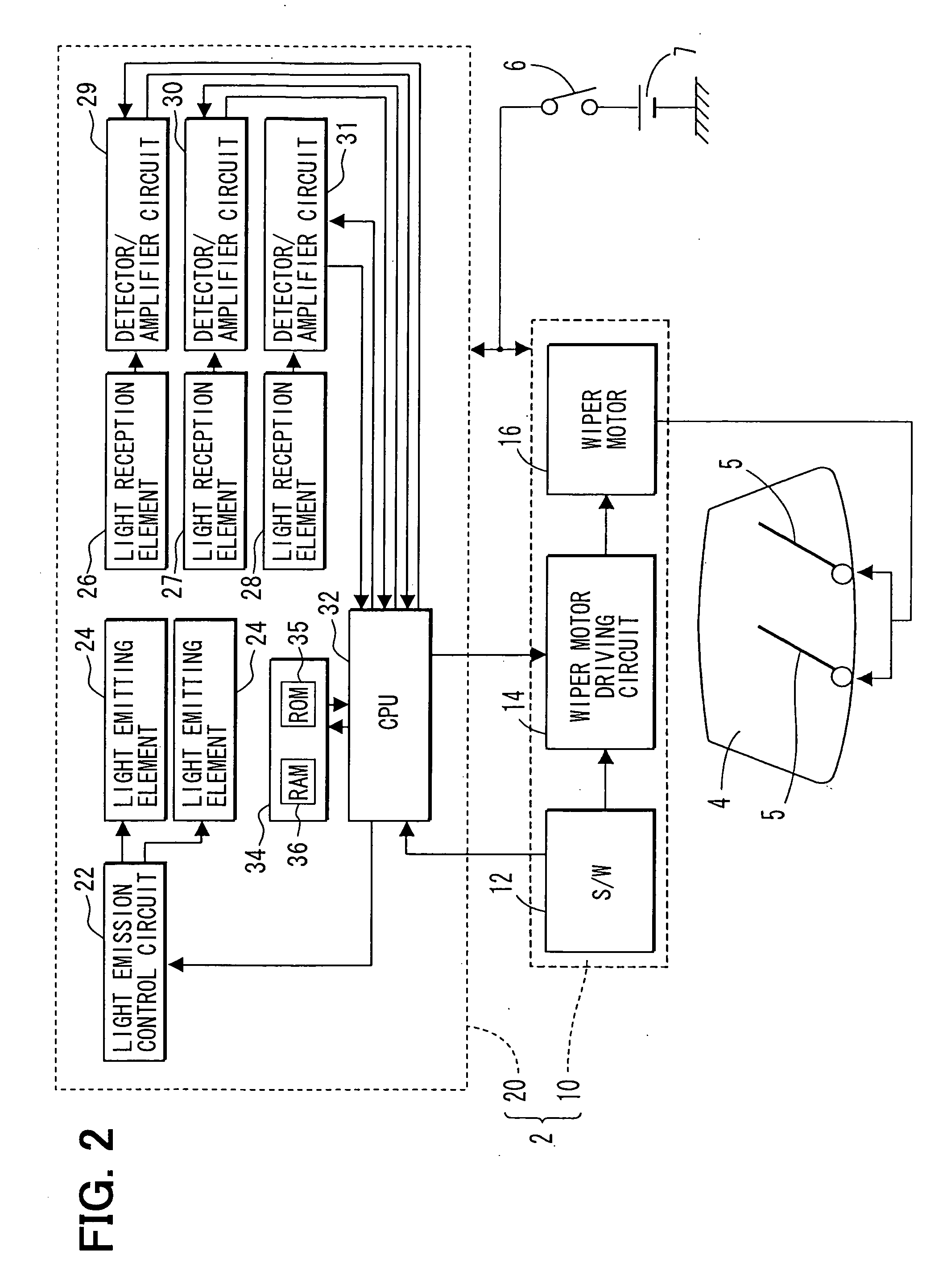

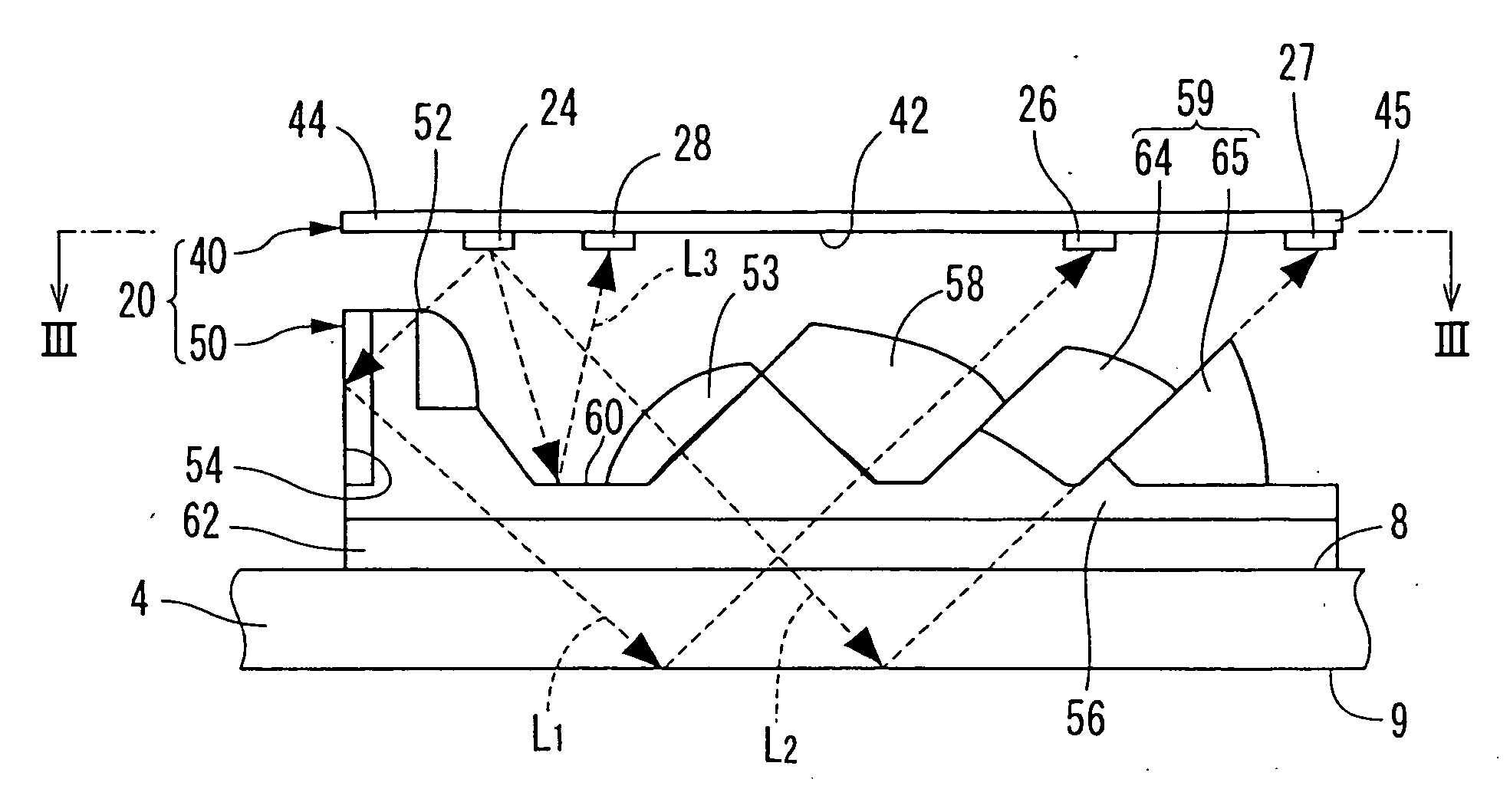

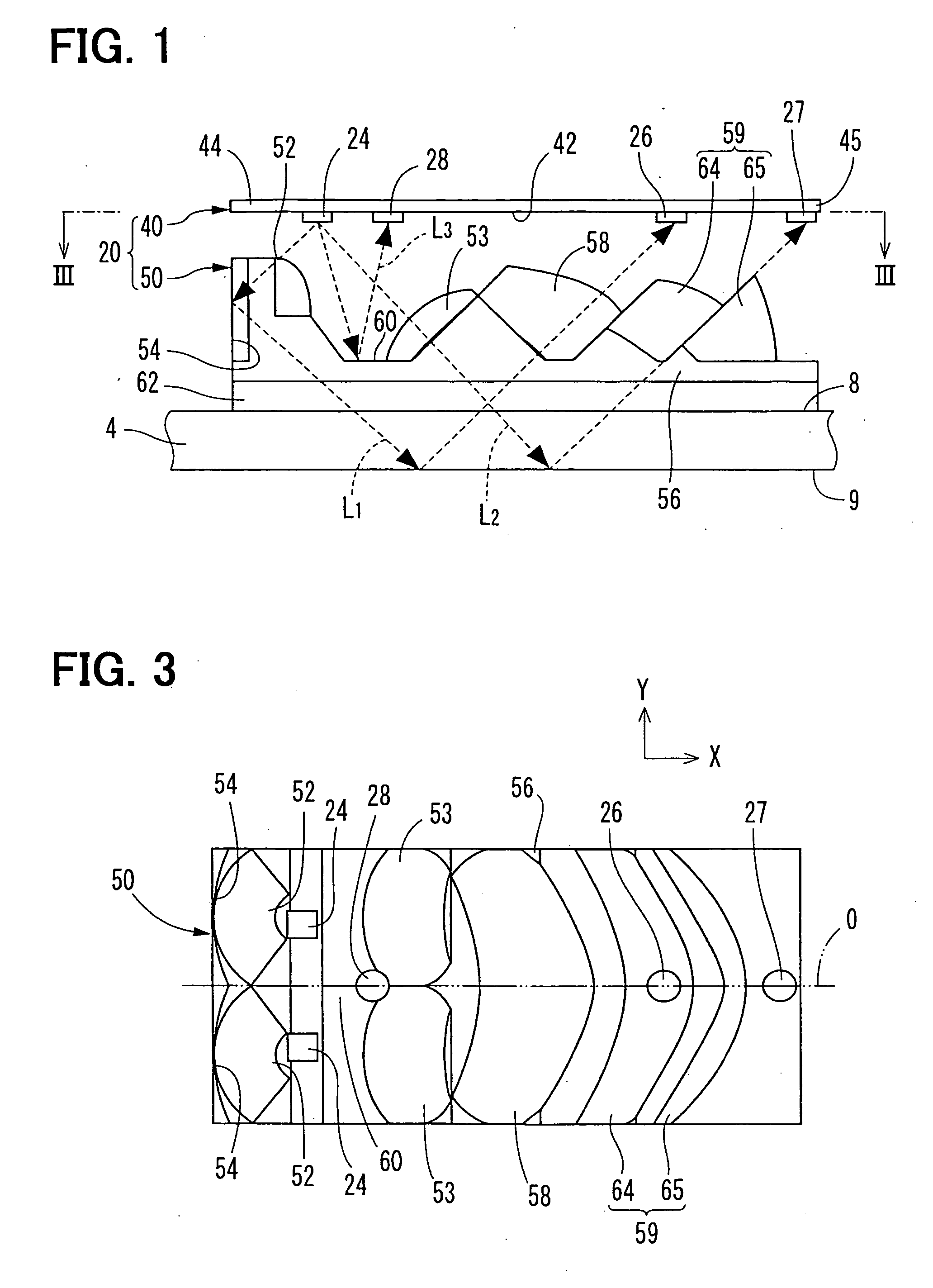

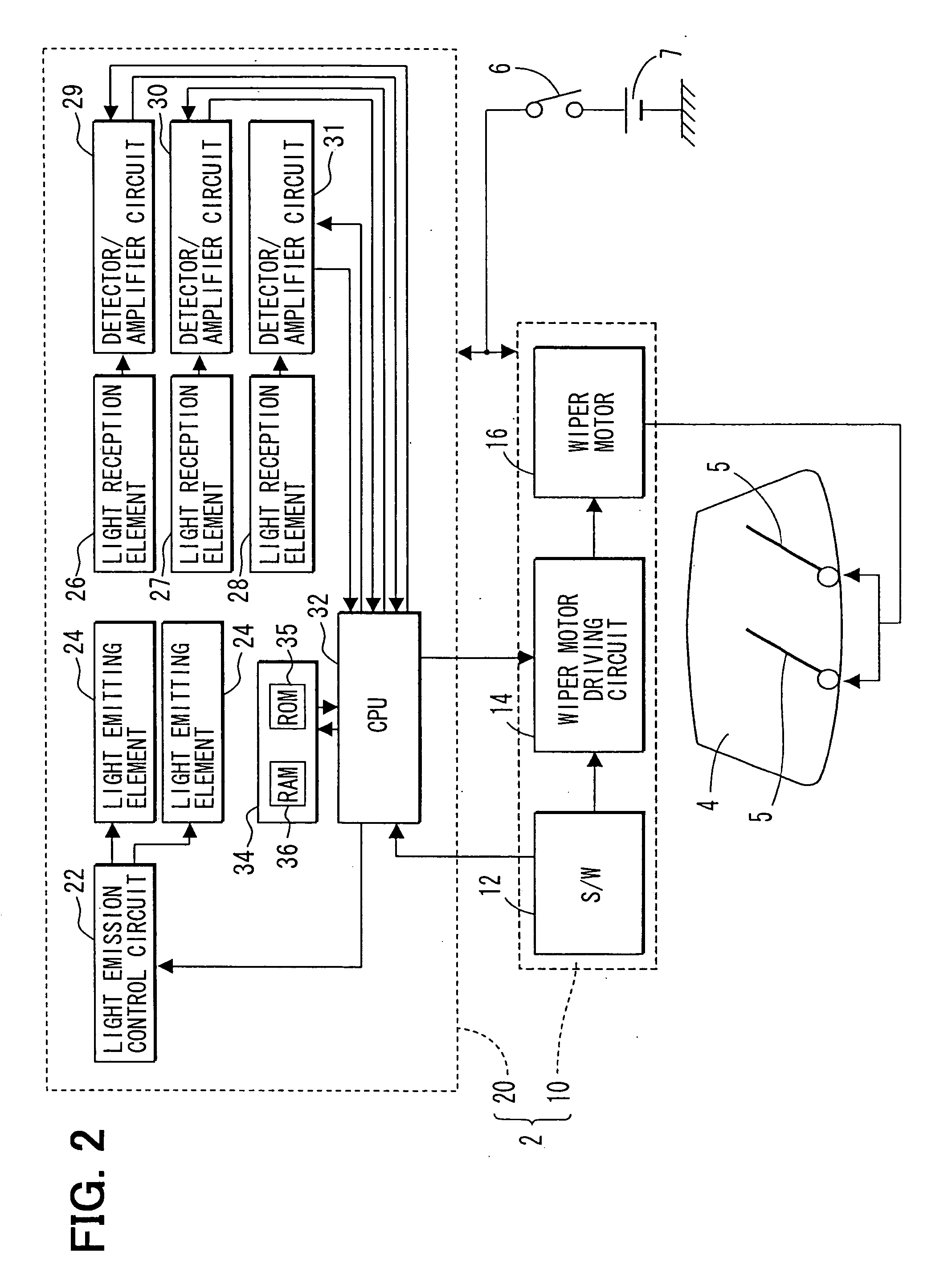

Sensor device and wiper controller

ActiveUS20060076524A1Improve accuracyGood value for moneyMotor/generator/converter stoppersDC motor speed/torque controlLight emissionPhysics

A sensor device for detecting wetting on a windshield includes a light emission element for emitting a light, a first light reception element for receiving the light in a first light path that includes reflective redirection by the windshield, and a second light reception element for receiving the light in a second light path that does not include reflective redirection by the windshield. The sensor device uses a ratio of the amount of the received light by the first light reception element and the amount of the received light by the second light reception element to determine wetting on the windshield.

Owner:DENSO CORP

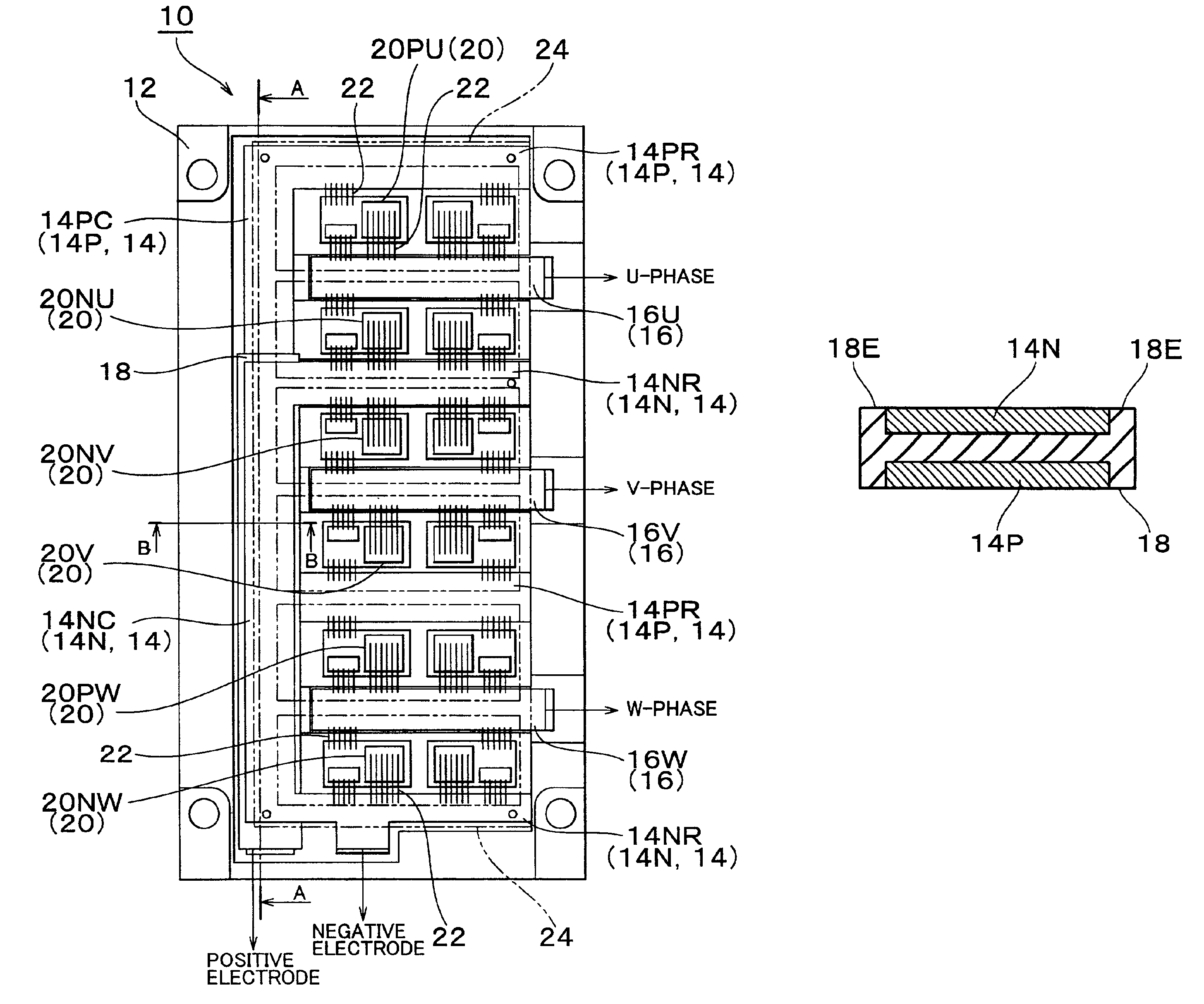

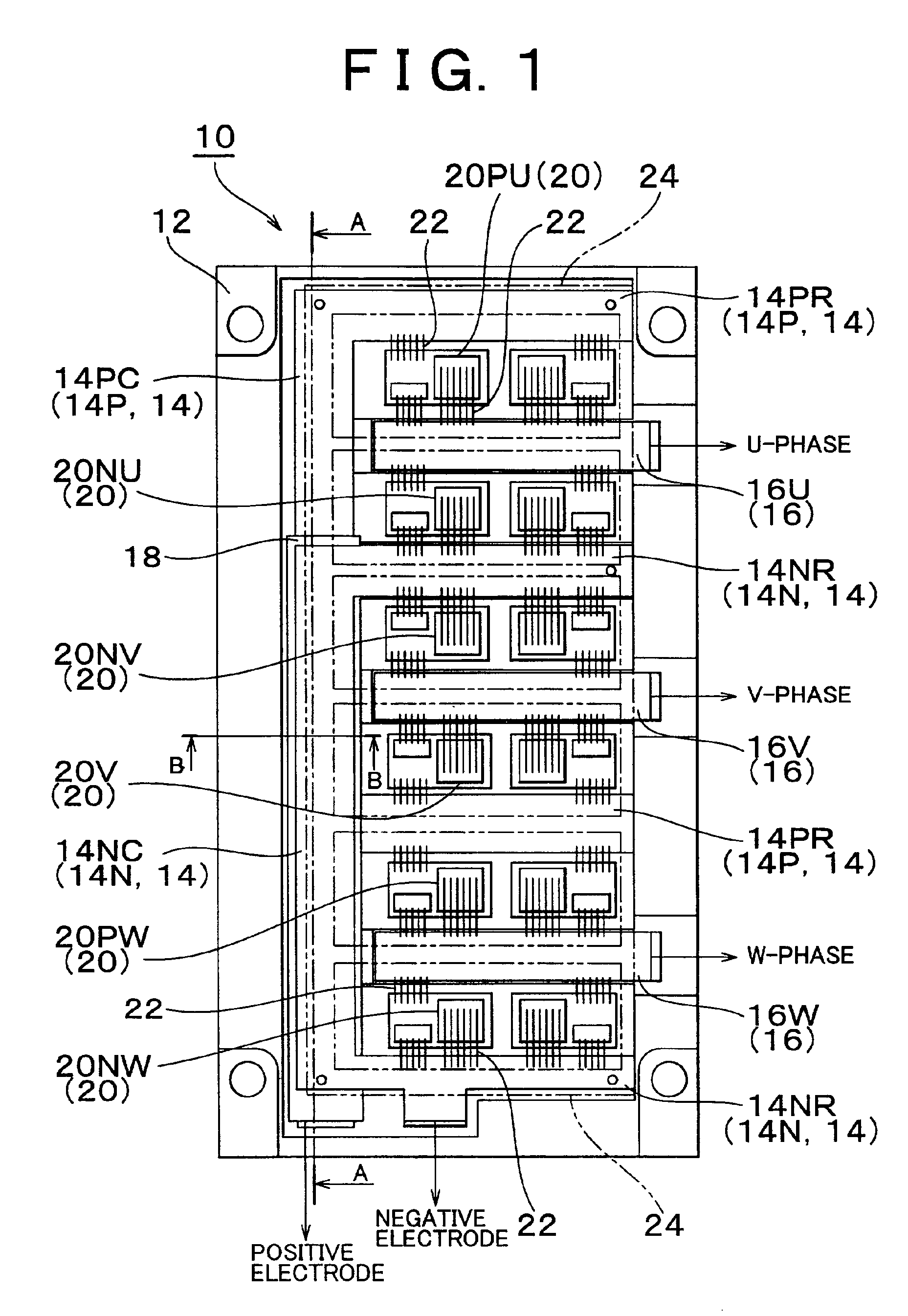

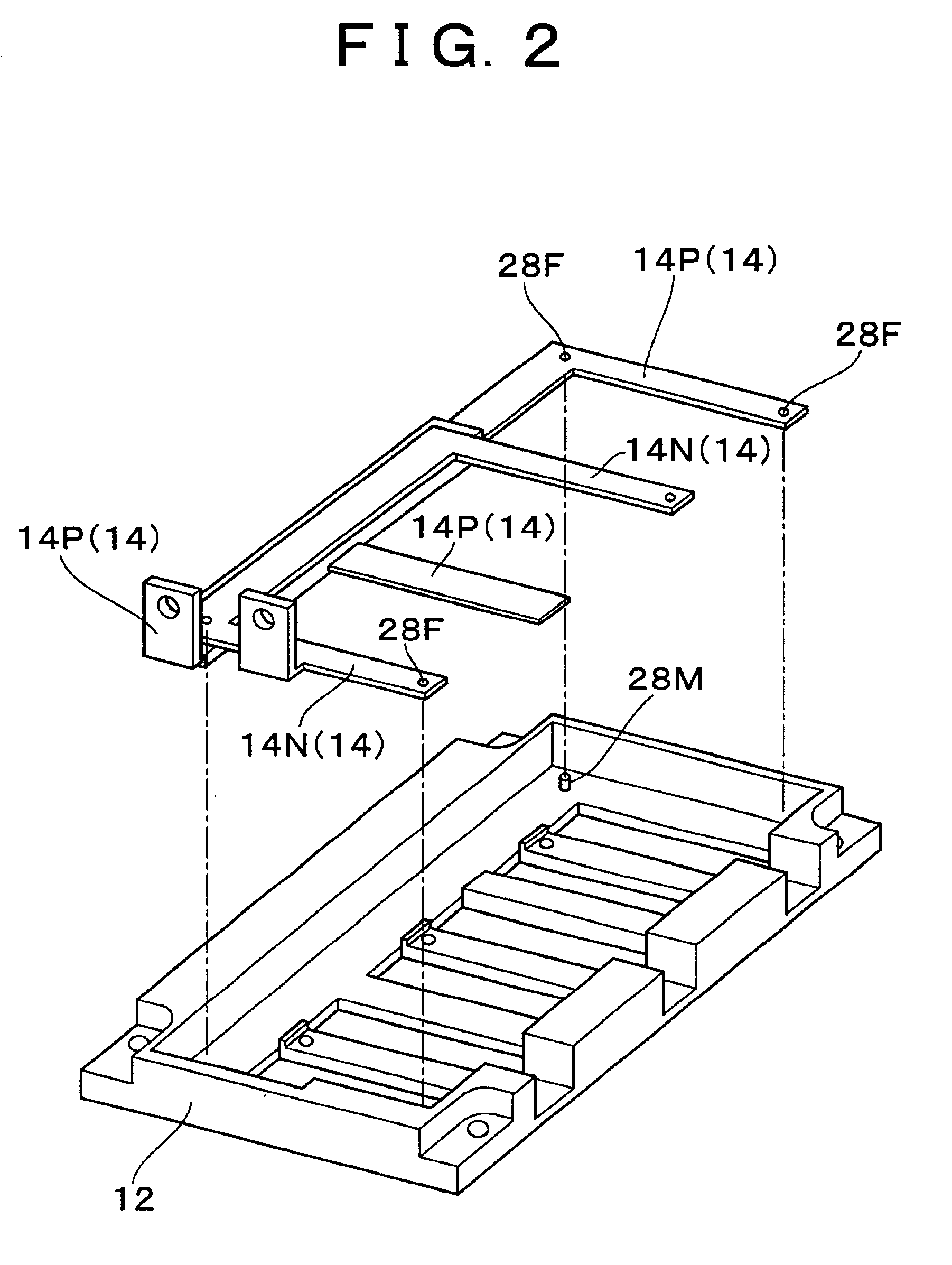

Switching circuit

InactiveUS6884953B2Reducing time and costAvoid deformationConversion constructional detailsSolid-state devicesFlexural strengthInductance

In a switching circuit, at least two bus bars are fixed with an insulator interposed therebetween and secured to a substrate of the switching circuit. Being combined with the bus bars, the insulator serves not only to insulate those bus bars but also to enhance the bending rigidity and bending strength of the switching circuit. As current flows in one of the bus bars in a direction opposite to a direction in which current flows in the other bus bar, the inductance of the bus bars is reduced, resulting in the decreased fly-back voltage generated upon switching operation.

Owner:TOYOTA JIDOSHA KK +1

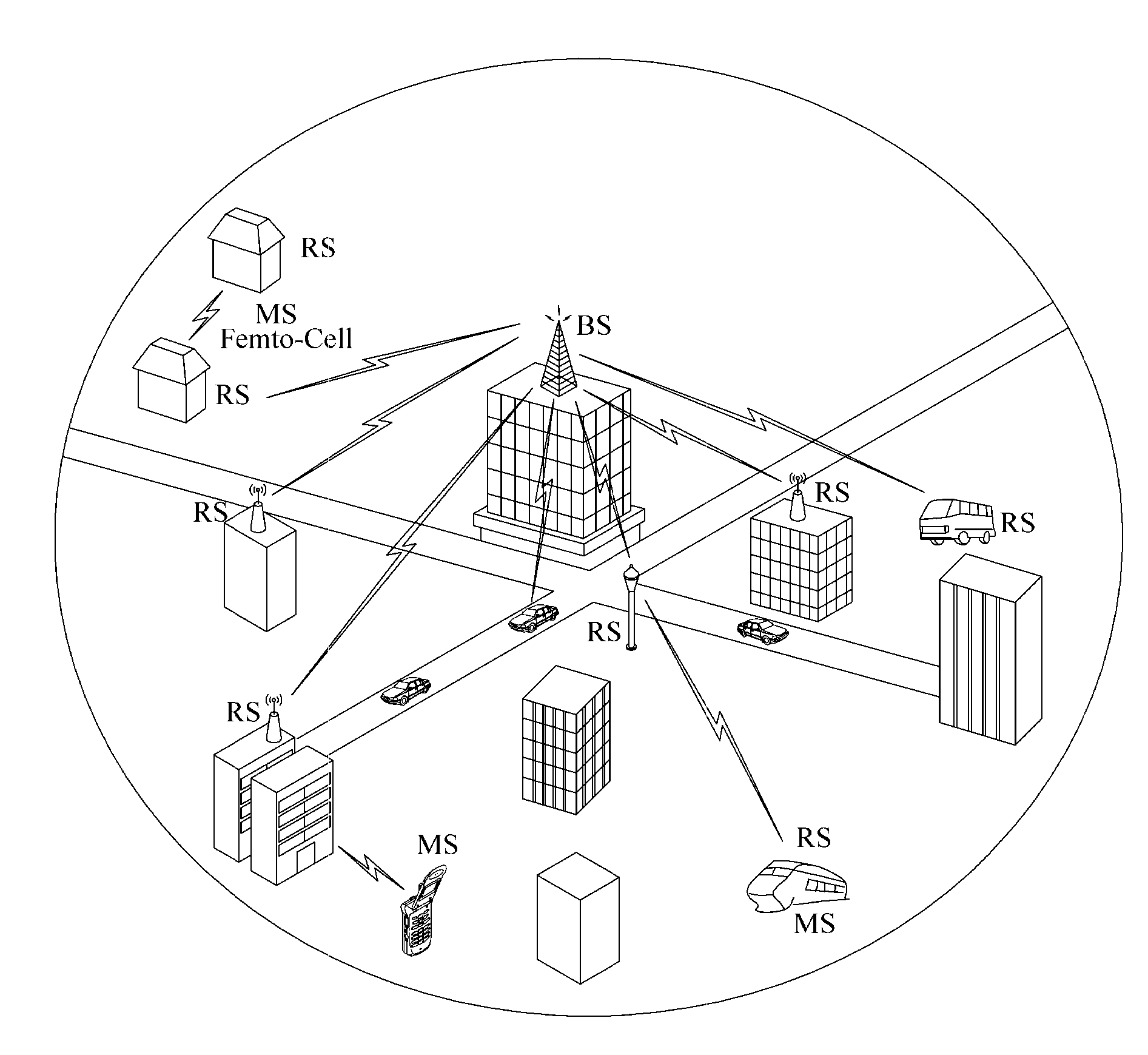

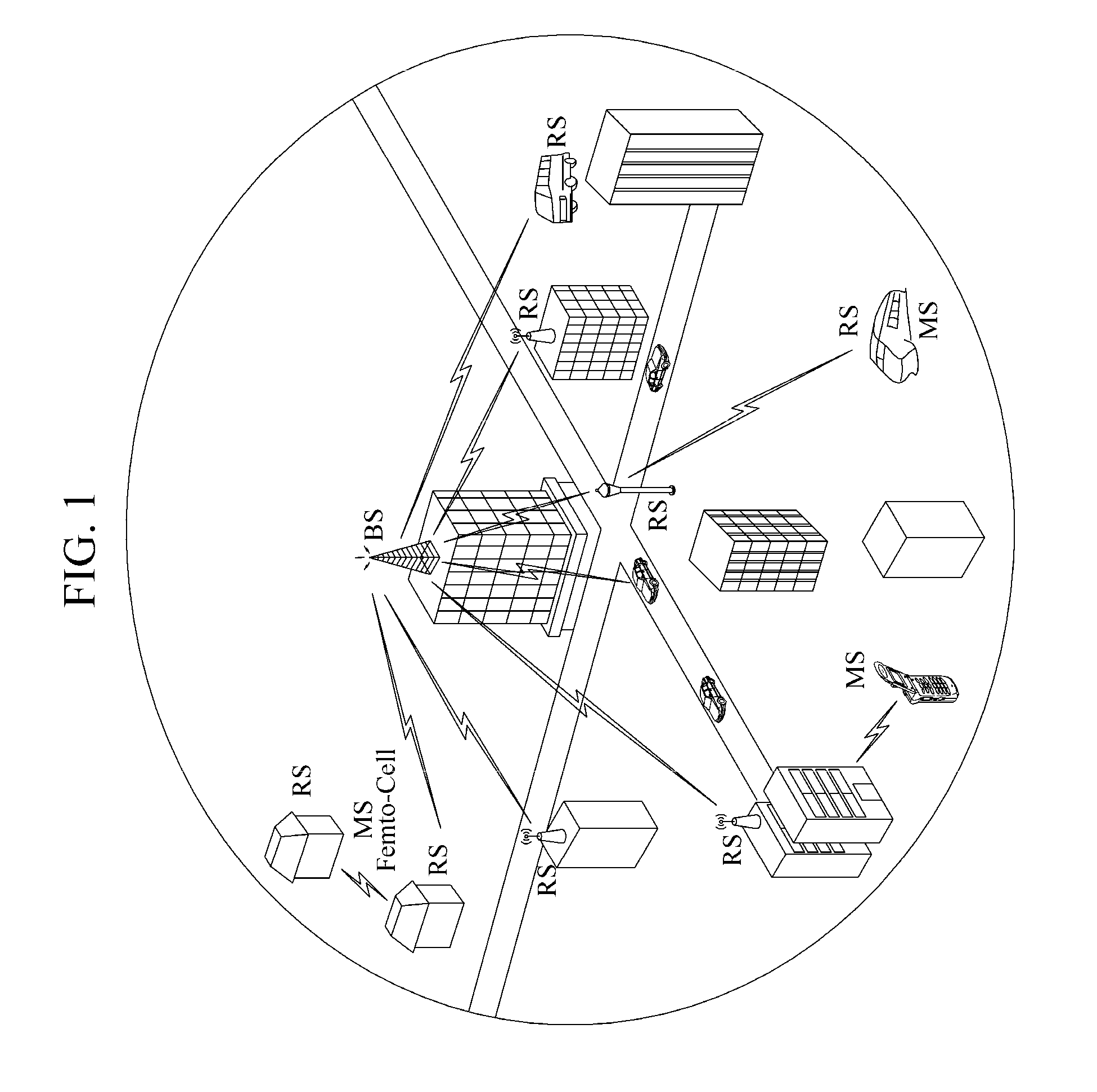

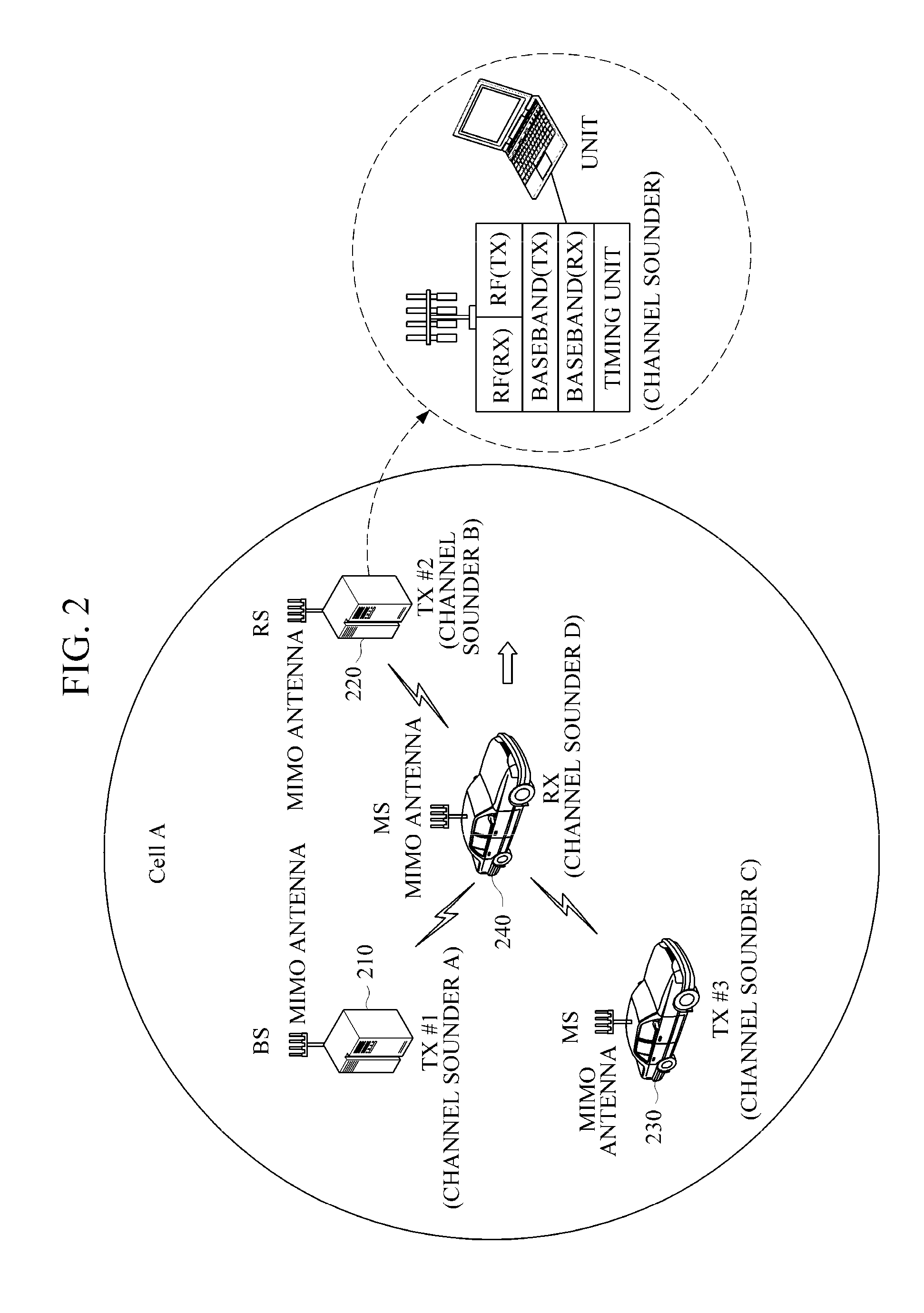

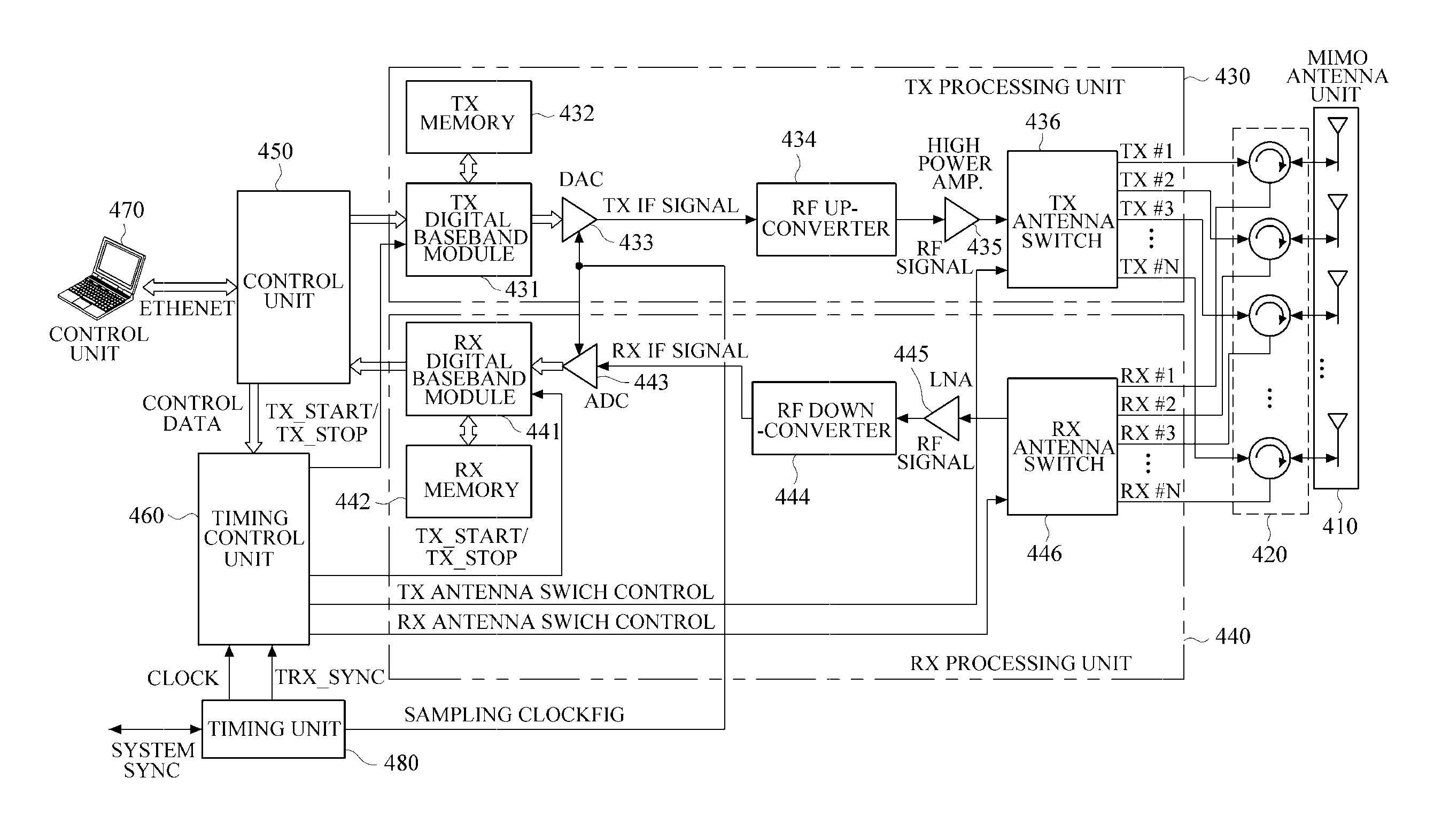

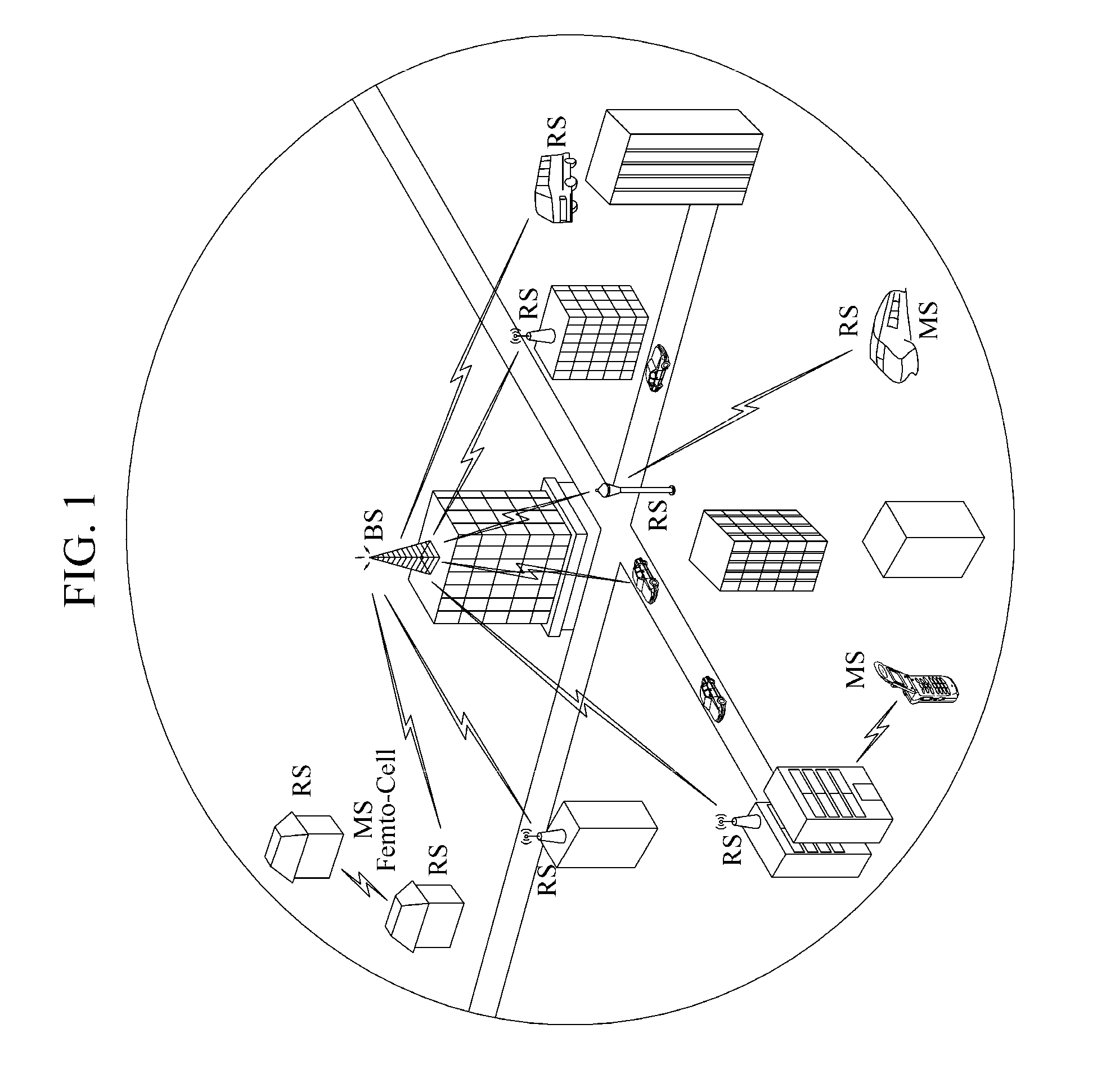

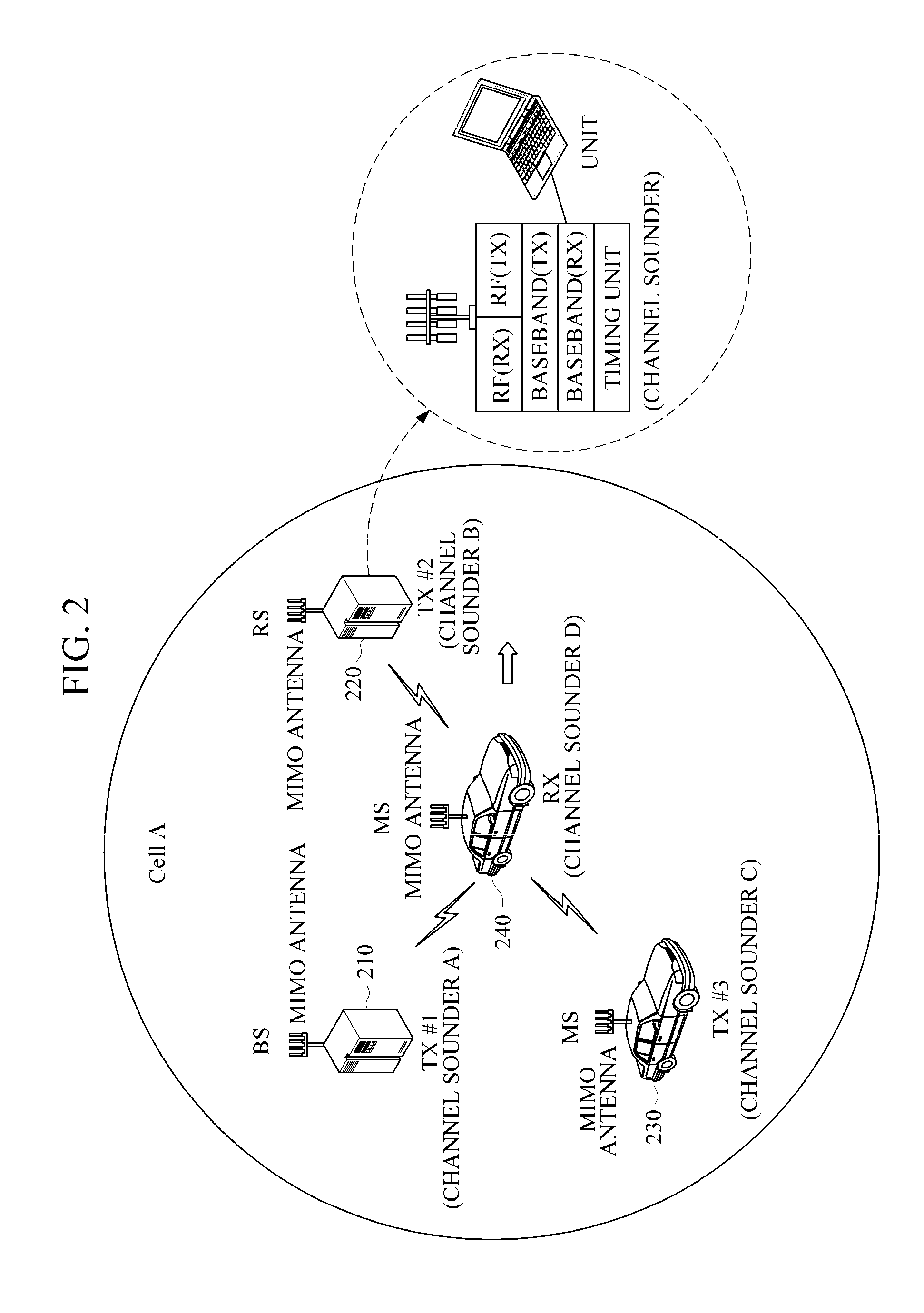

Multi-link wireless channel sounder and multi-link wireless channel measurement method thereof

ActiveUS20120155516A1Shorten the timeLow costAssess restrictionTransmission monitoringMulti inputMimo antenna

A multi-link wireless channel sounder is provided. The multi-link wireless channel sounder includes a multi-input multi-output (MIMO) antenna unit, a transmitter (TX) signal processing unit configured to transmit via the MIMO antennas one or more TX wireless channel signals to be transmitted via a wireless channel, a receiver (RX) signal processing unit configured to receive and process one or more RX wireless channel signals that are received from multiple links via the MIMO antenna unit, and a control unit configured to receive an operation mode selection signal that indicates a TX mode or an RX mode from a user and to control the TX signal processing unit or the RX signal processing unit to operate selectively in accordance with the operation mode selection signal.

Owner:ELECTRONICS & TELECOMM RES INST

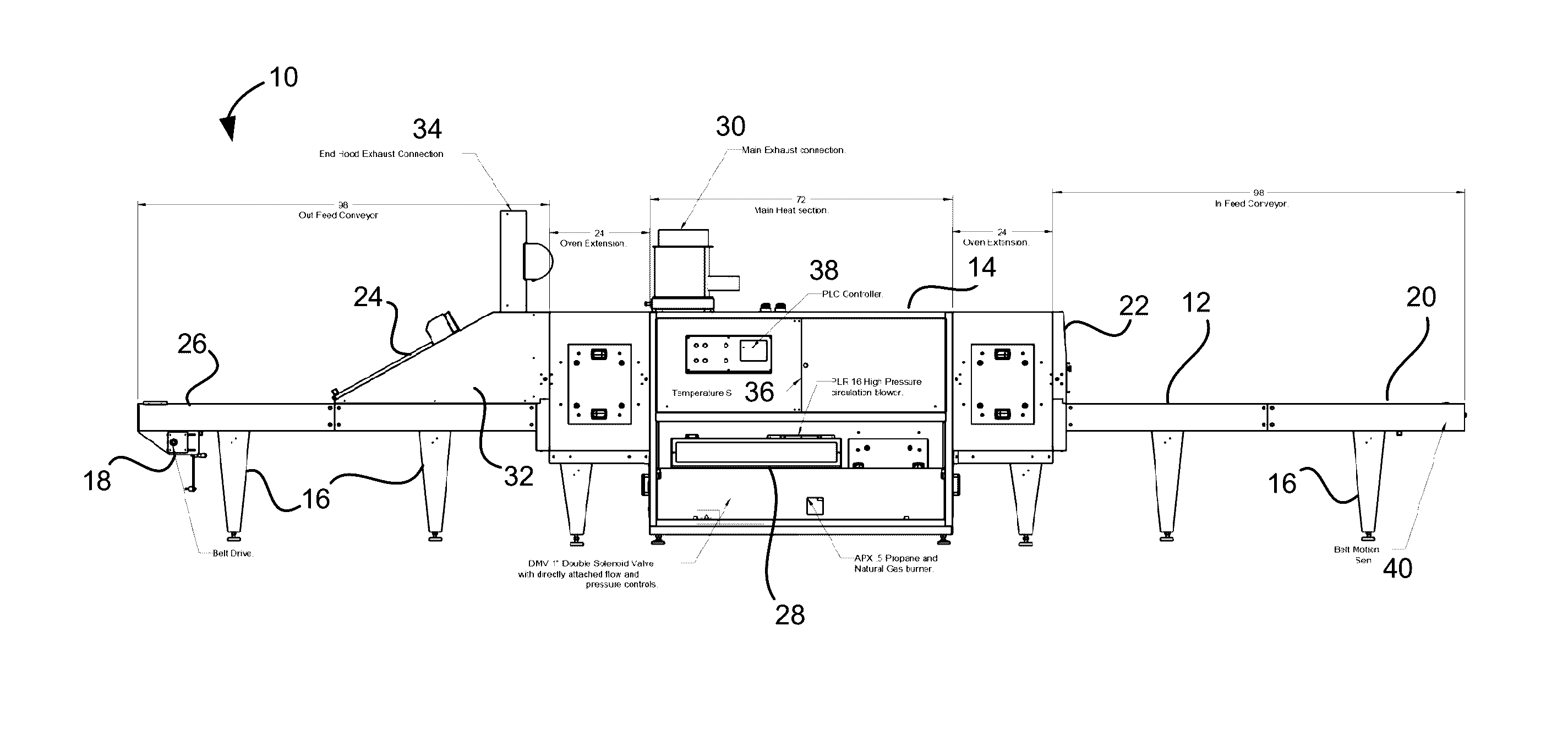

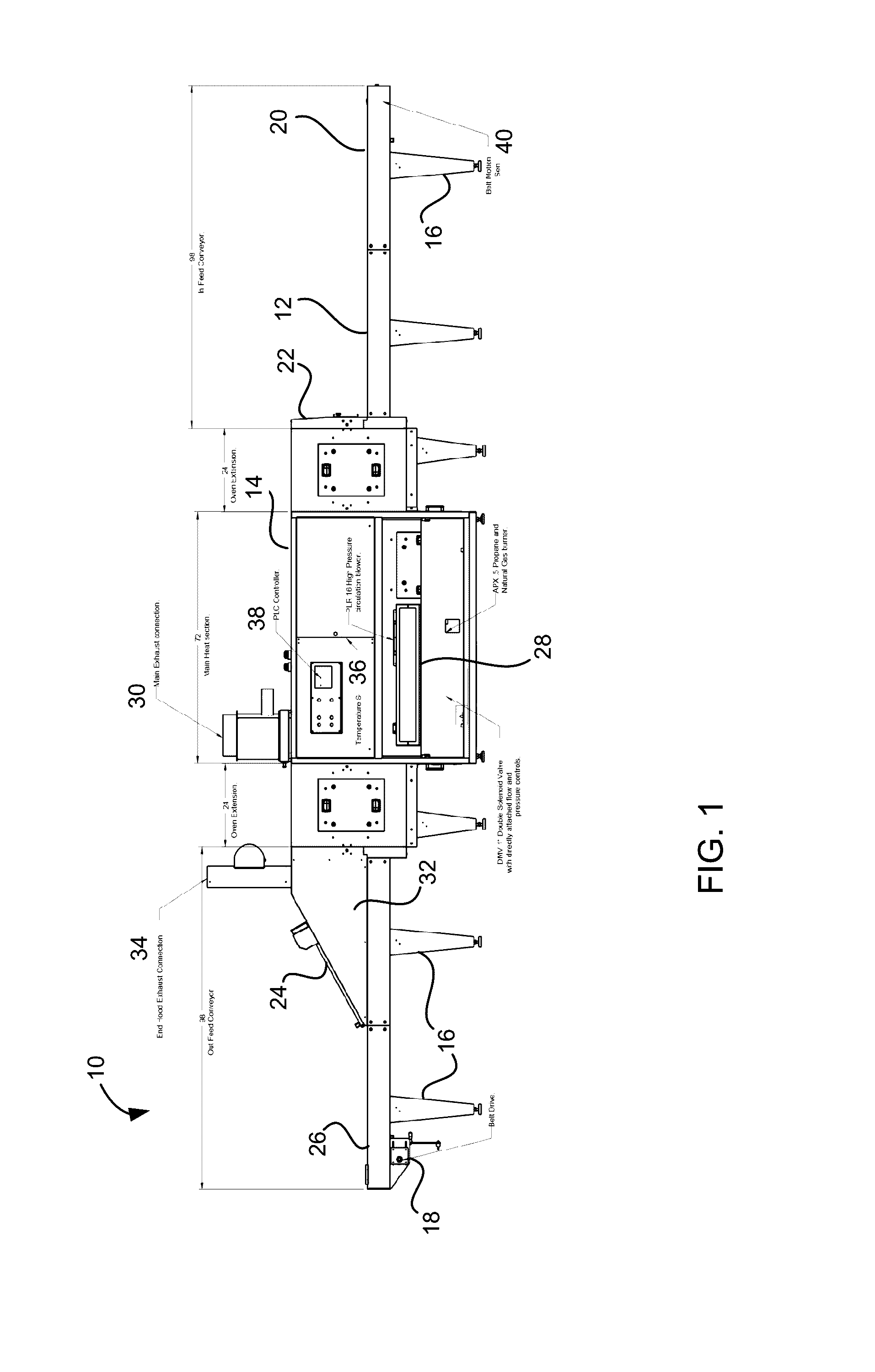

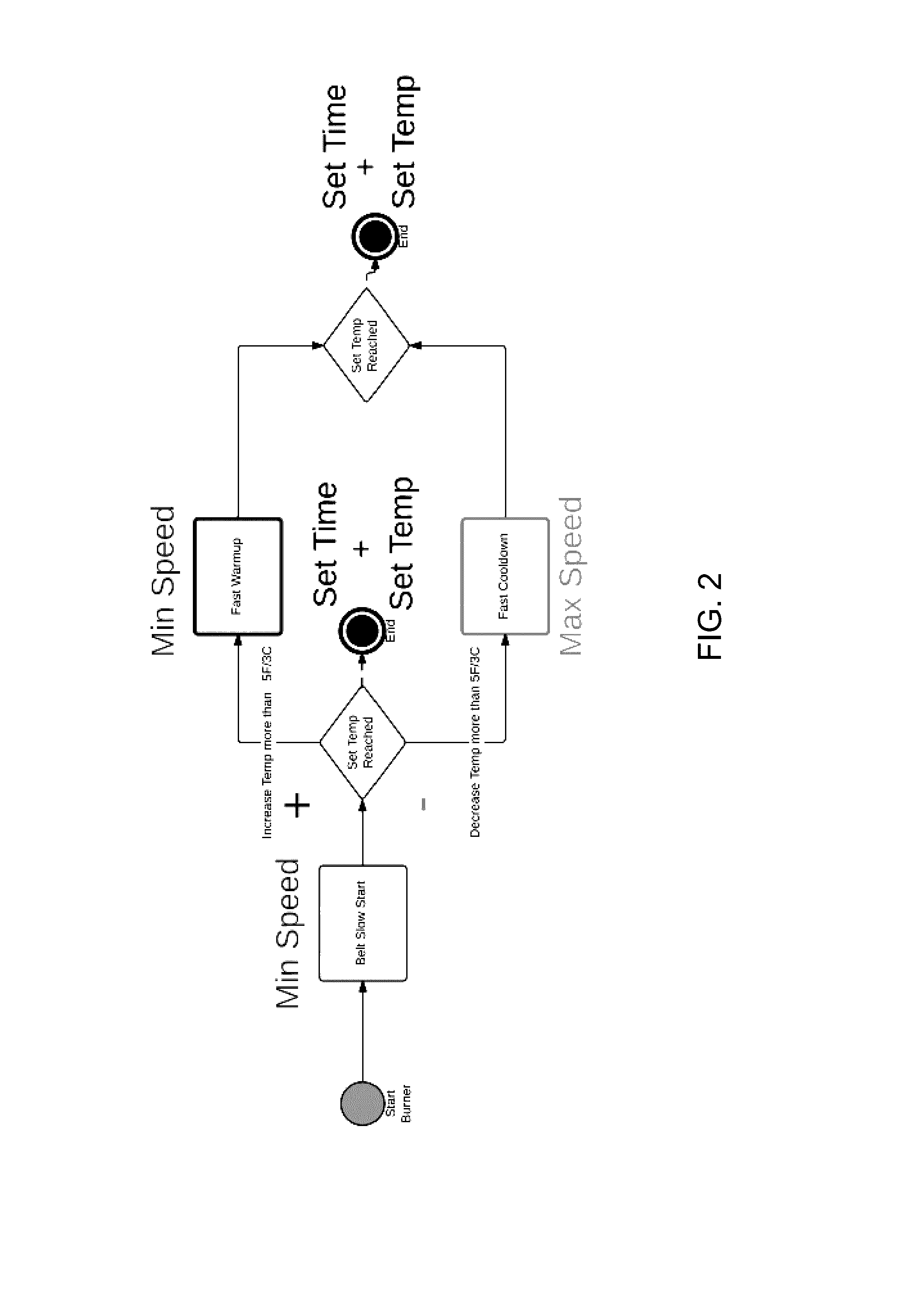

System and method for dynamically adjusting dryer belt speed

ActiveUS20170059244A1Easy temperature controlEfficiently and quickly changeDrying gas arrangementsDrying machines with progressive movementsBelt speedEngineering

A dynamically adjustable textile dryer and method of controlling a conveyor belt speed of the textile dryer is provided. The speed of the belt is utilized to more quickly adjust the temperature of the drying chamber.

Owner:M&R PRINTING EQUIP

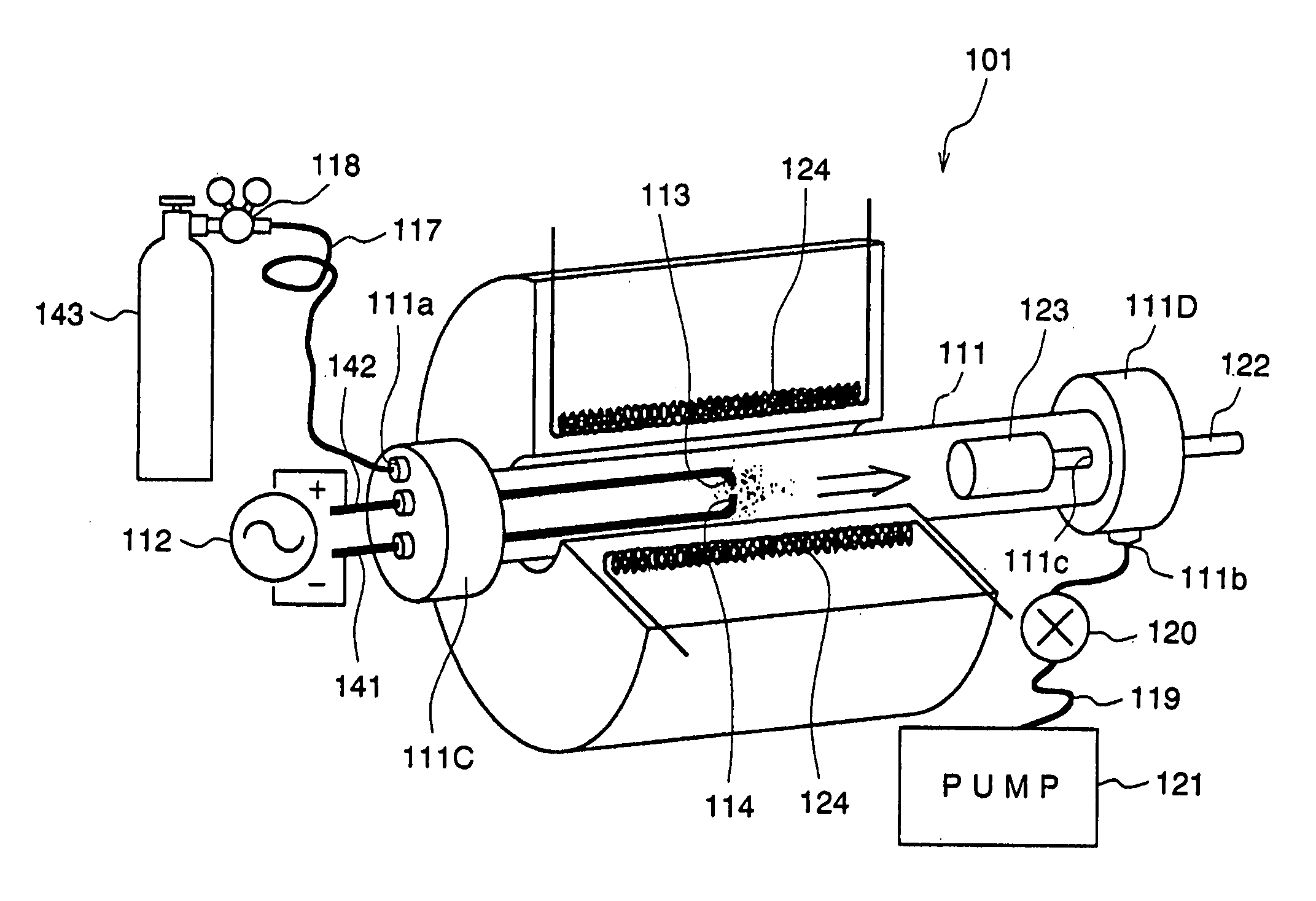

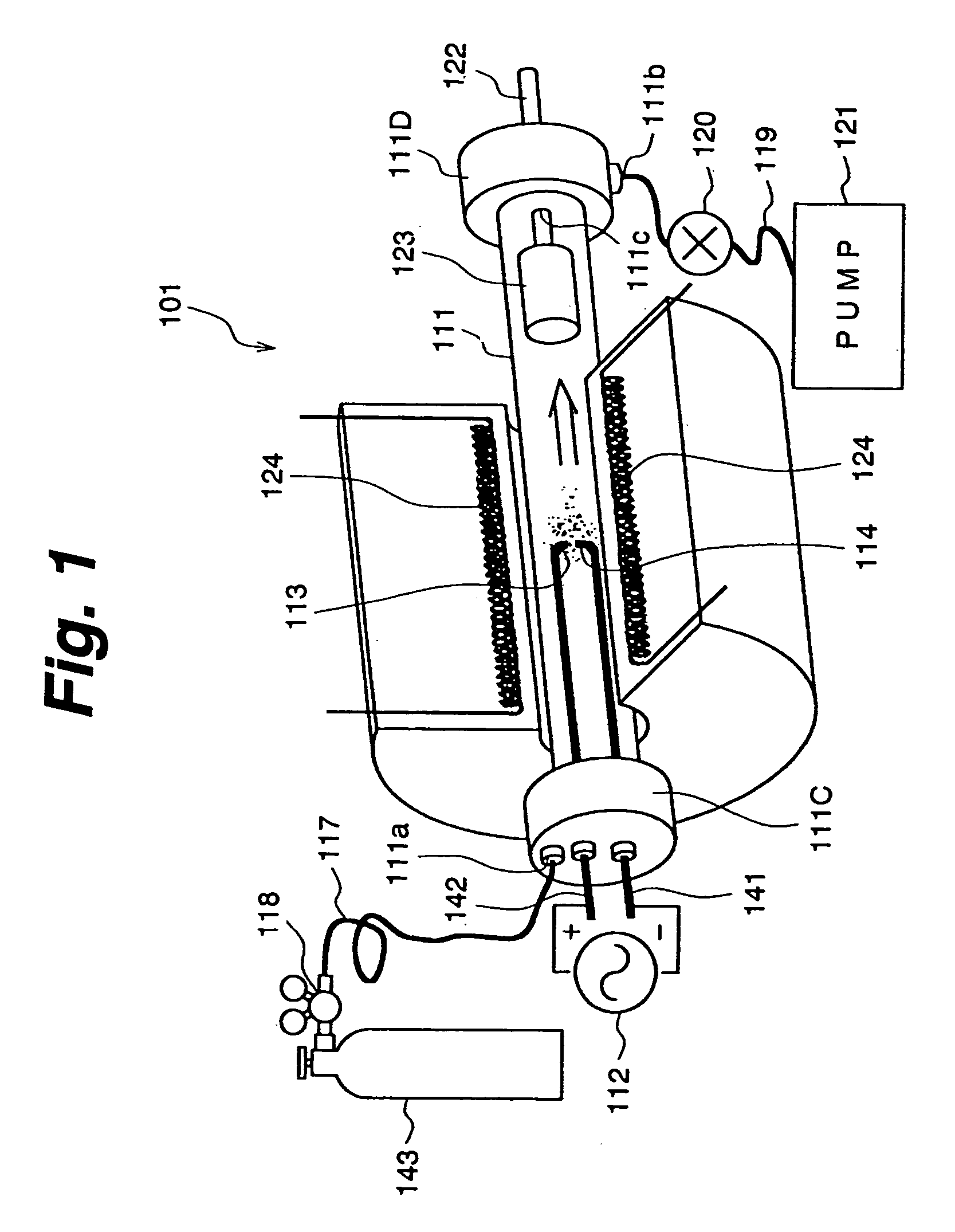

Device and method for manufacture of carbonaceous material

InactiveUS20040062992A1Increase percentageReduce impurityMaterial nanotechnologySemi-permeable membranesAtmospheric airCarbon nanotube

A carbonaceous material manufacturing apparatus includes a reaction tube and a gas supply portion. An anode and a cathode defining an arc discharge portion is place in the reaction tube, and a capturer is located provided as well to capture carbonaceous materials generated. At the location of the capturer, an RF heater is disposed around the reaction tube. In a carbonaceous material manufacturing method, carbonaceous materials generated in the arc discharge portion are transported from a gas supply portion into the reaction tube by the gas supplied into the reaction tube, then heated by a RF heater in the capturer where the carbonaceous materials are not exposed to the atmospheric air, to thereby promote removal of impurities and growth of single-walled carbon nanotubes.

Owner:SONY CORP

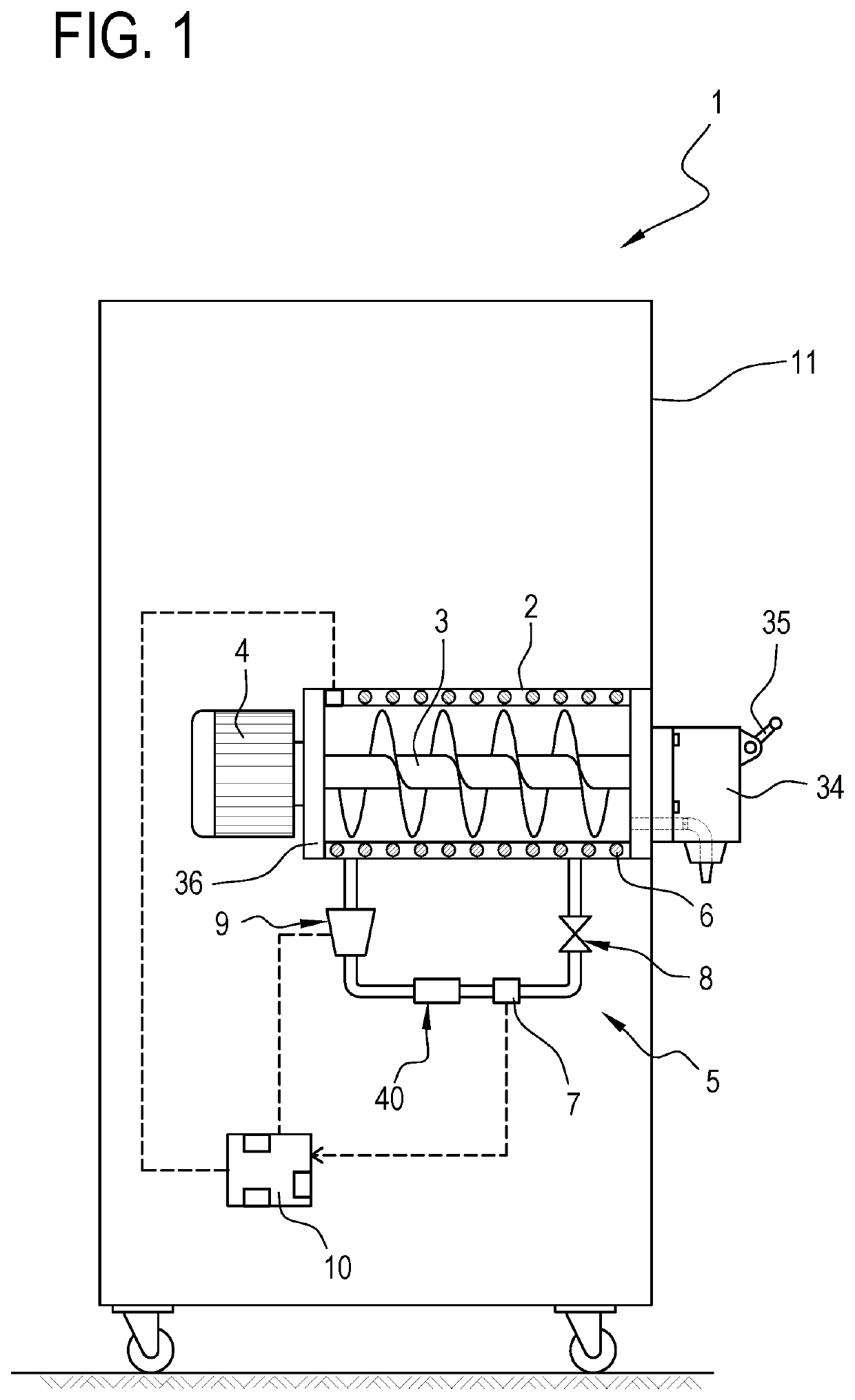

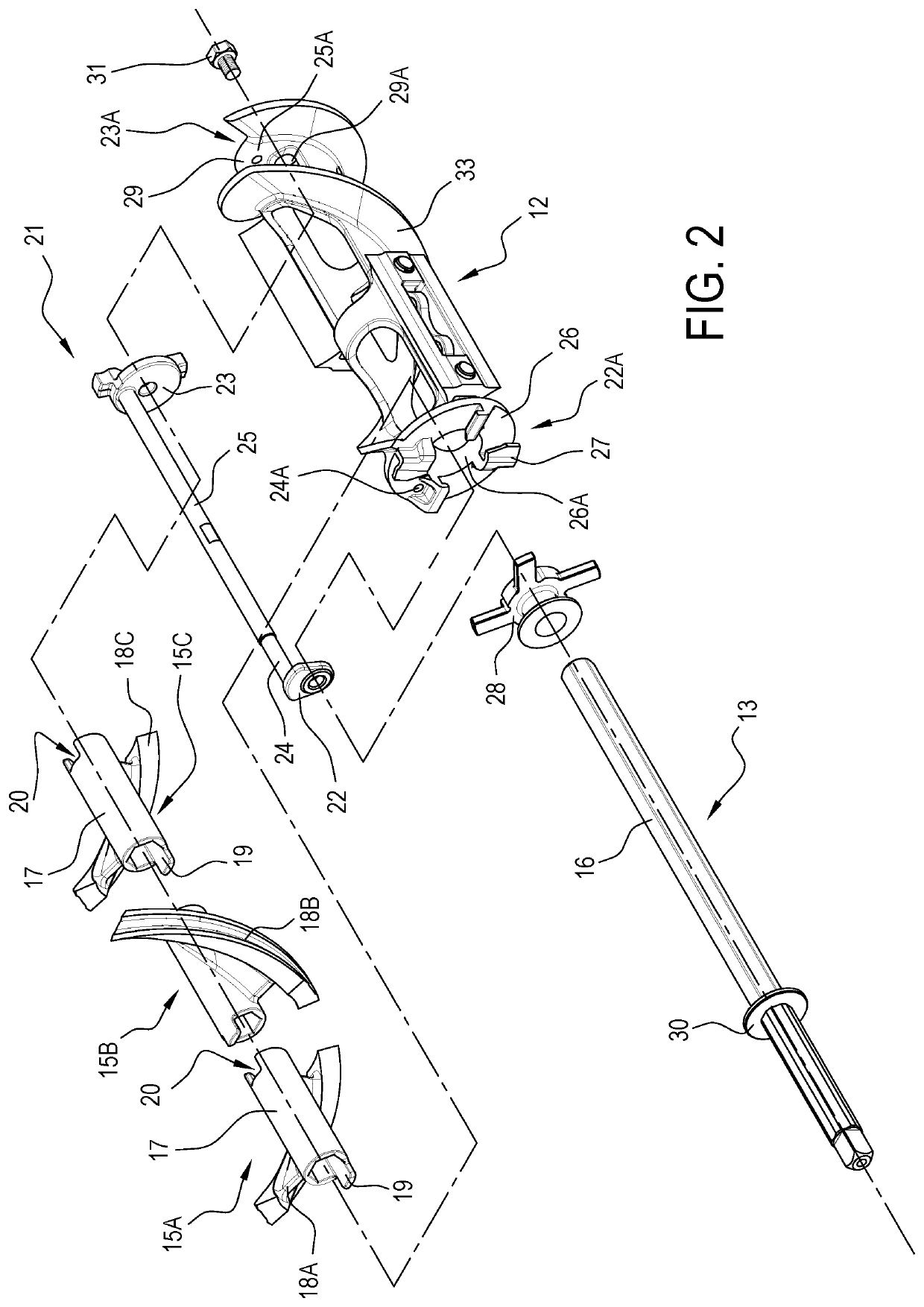

Stirring device of a machine for making liquid or semi-liquid food products

ActiveUS20200221726A1Easy to adaptLess expensiveRotary stirring mixersTransportation and packagingIce CreamsElectric machinery

A machine used for making liquid or semi-liquid food products, specifically ice cream, comprises a container for processing liquid or semi-liquid base products by means of a stirring device driven by a motor. The stirring device comprises an external mixing structure to which a shaft is fixed so that the motor can drive it in rotation. Keyed to the shaft are scraping elements which scrape the product off the inside walls of the processing container.

Owner:ALI - CARPIGIANI GROUP

High speed resiliometer

InactiveUS7127933B2Reducing time and costThe testing process is simpleAcceleration measurementInvestigating material hardnessReverse orderPneumatic valve

An apparatus and method for testing the physical properties of a material is disclosed. Preferably, the physical properties that may be tested include, but are not limited to, the COR of a material. Accordingly, the apparatus includes a projectile that may be capable of being propelled towards a material sample. The projectile is preferably aimed and fired through a tubular barrel towards the material sample. The tubular barrel preferably comprises a propulsion system that controls pneumatic energy via a pneumatic valve. At least two sensors are placed between the tubular barrel and the material sample in order to detect the passage of the projectile. It is desired that the sensors are placed at precise, discrete positions. As the projectile passes through the field of view of each sensor, the time is recorded to a memory, for example, a counter timer board. The projectile may then impact the material sample, which may preferably be held in place by a fixation device. The fixation device is preferably a holding slot, which may be backed by an infinite mass cylinder. Upon rebounding from the material sample, the projectile passes back through the field of view of the sensors in reverse order, allowing the sensors to capture and record the time of passage to a memory, such as a counter timer board. The physical properties of the material sample may be calculated by a processing device that is operatively connected to at least a portion of the apparatus.

Owner:ACUSHNET CO

Legal document generating system

InactiveUS20090164507A1Reducing time and costNatural language translationData processing applicationsGraphicsGraphical user interface

A system and method for generating divorce proceedings or other paperwork. The system includes a server computer system and a user computer system coupled to a network. The server computer system includes a memory that stores location-based divorce proceeding rules, and a processor with a graphical user interface component. The user computer system includes a user interface component coupled to a processing component. The user interface component presents the graphical user interfaces generated by the graphical user interface component and receives responses to the presented graphical user interfaces. The responses include a selection for the location for the divorce proceedings. The received responses are sent to the server computer system. The graphical user interface component generates graphical user interfaces based on at least one of the location selection or other received responses. The processor automatically generates completed divorce documents based on the received responses.

Owner:FINNEY RANDOLPH L

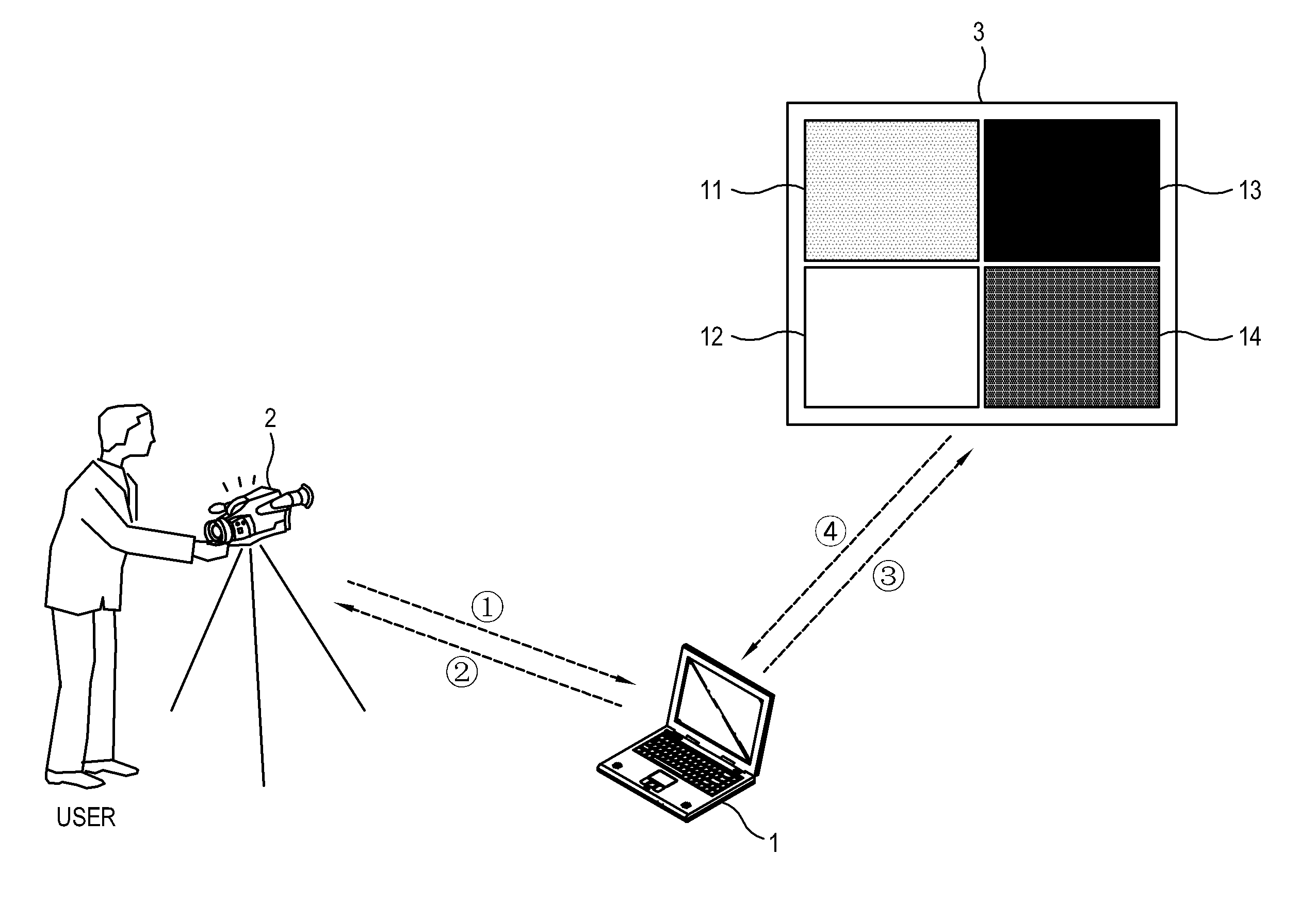

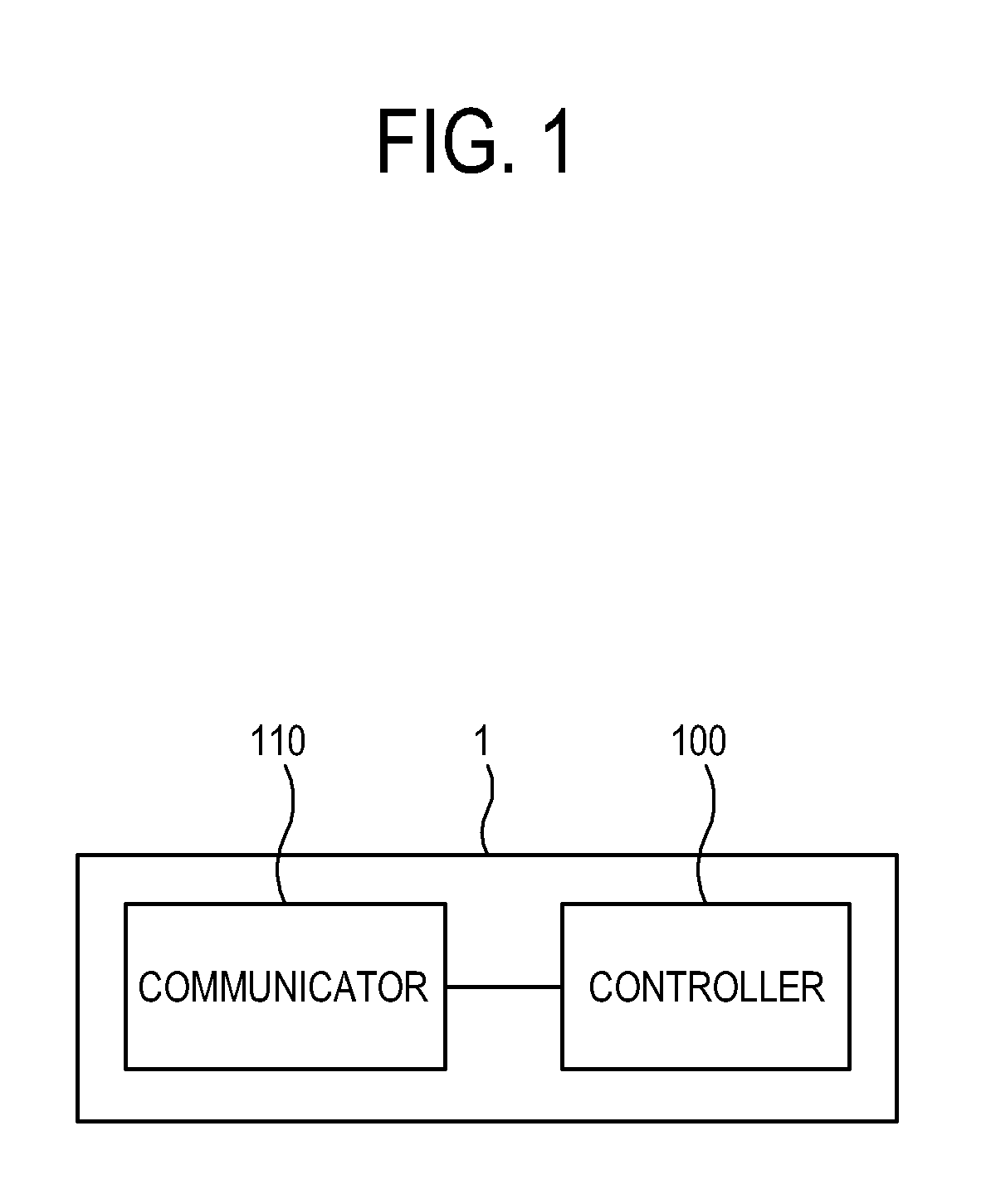

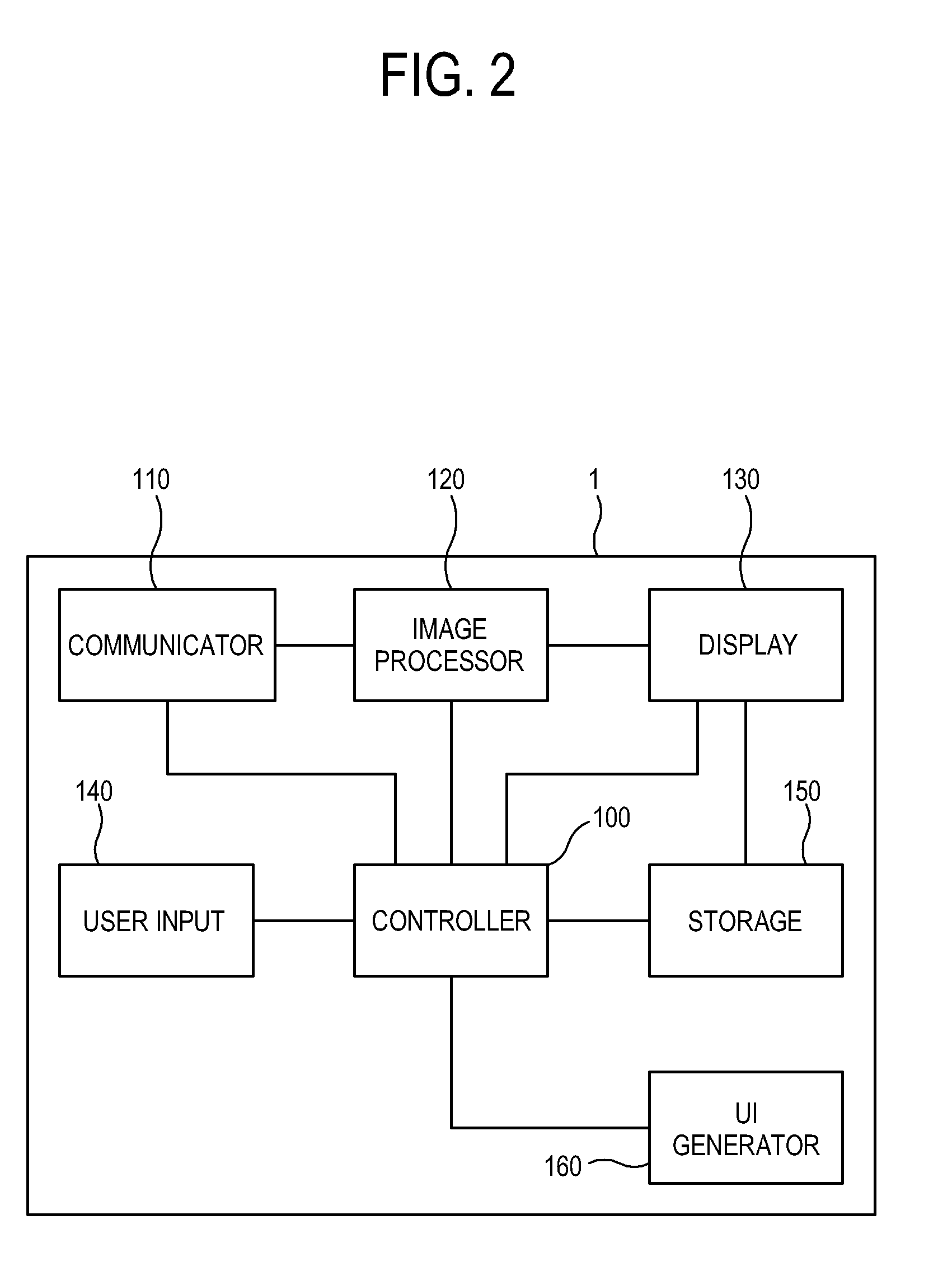

Calibration device, display system and control method thereof

InactiveUS20150221078A1Shorten the timeLow costImage enhancementImage analysisControl communicationsHuman–computer interaction

A calibration device, a display system, and methods thereof, are provided in which a plurality of display apparatuses are photographed in order to calibrate the plurality of display apparatuses. The calibration device may include a communicator configured to communicate with at least one display apparatus from among a plurality of display apparatuses of a display system, and a controller configured to control the communicator to transmit a setup value for the display apparatuses to the at least one display apparatus, and transmit, to the at least one display apparatus, a control command for calibrating the plurality of display apparatuses based on an image of the plurality of display apparatuses displaying an image, received from the an image taking device

Owner:SAMSUNG ELECTRONICS CO LTD

Semiconductor product and corresponding method

ActiveUS20190006191A1Partially fillReducing time and costSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipConductive materials

A semiconductor product such as an integrated circuit includes a laminar plastic substrate having first and second opposed surfaces and through holes extending through the substrate, electrically and / or thermally conductive material balls inserted in the through holes at the first surface of the substrate, and one or more semiconductor chips mounted at the first surface of the substrate, the semiconductor chip(s) electrically and / or thermally coupled with electrically and / or thermally conductive material balls inserted in the through holes.

Owner:STMICROELECTRONICS SRL

Multi-link wireless channel sounder and multi-link wireless channel measurement method thereof

ActiveUS9031147B2Reducing time and costImprove reliability and precisionAssess restrictionDiversity/multi-antenna systemsMulti inputMimo antenna

A multi-link wireless channel sounder is provided. The multi-link wireless channel sounder includes a multi-input multi-output (MIMO) antenna unit, a transmitter (TX) signal processing unit configured to transmit via the MIMO antennas one or more TX wireless channel signals to be transmitted via a wireless channel, a receiver (RX) signal processing unit configured to receive and process one or more RX wireless channel signals that are received from multiple links via the MIMO antenna unit, and a control unit configured to receive an operation mode selection signal that indicates a TX mode or an RX mode from a user and to control the TX signal processing unit or the RX signal processing unit to operate selectively in accordance with the operation mode selection signal.

Owner:ELECTRONICS & TELECOMM RES INST

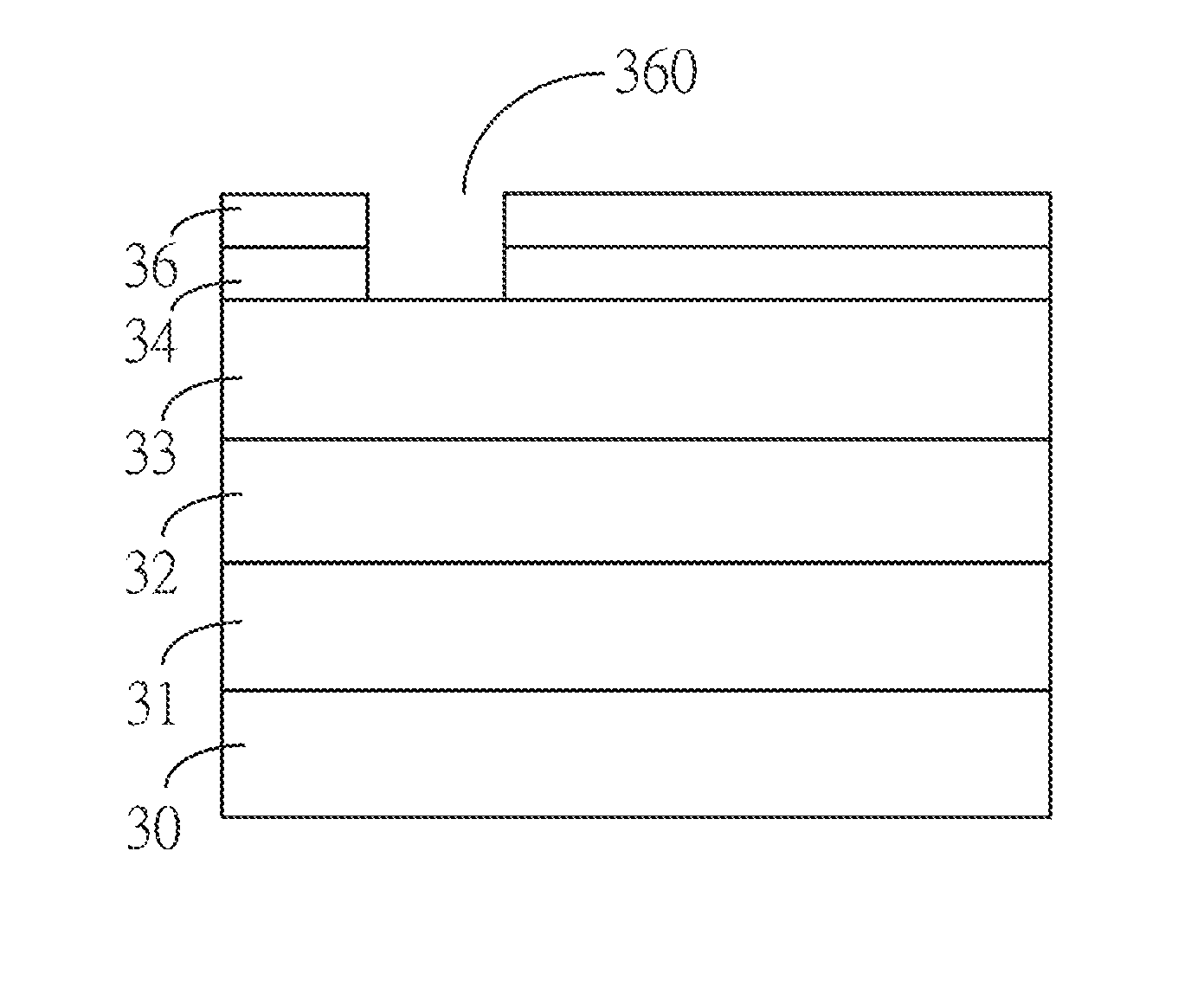

Light emitting diode structure and manufacturing method thereof

InactiveUS20140001434A1Shorten the timeLow costSemiconductor/solid-state device manufacturingSemiconductor devicesElectrode ContactLight-emitting diode

A light-emitting diode structure and a manufacturing method thereof are provided. The structure includes a semiconductor substrate, a first type semiconductor layer, a light-emitting layer, a second type semiconductor layer, an electrode contact layer, a positive electrode and a negative electrode. A stacking layer consisting of the first type semiconductor layer, the light-emitting layer, the second type semiconductor layer and the electrode contact layer is formed on the semiconductor substrate, and a first opening penetrates the electrode contact layer and exposes a part of the second type semiconductor layer. The positive electrode is formed in the first opening. A part of the first type semiconductor layer, the light-emitting layer, the second type semiconductor layer and the electrode contact layer is removed to form a platform structure. The negative electrode is formed on the exposed surface of the first type semiconductor layer.

Owner:LEXTAR ELECTRONICS CORP

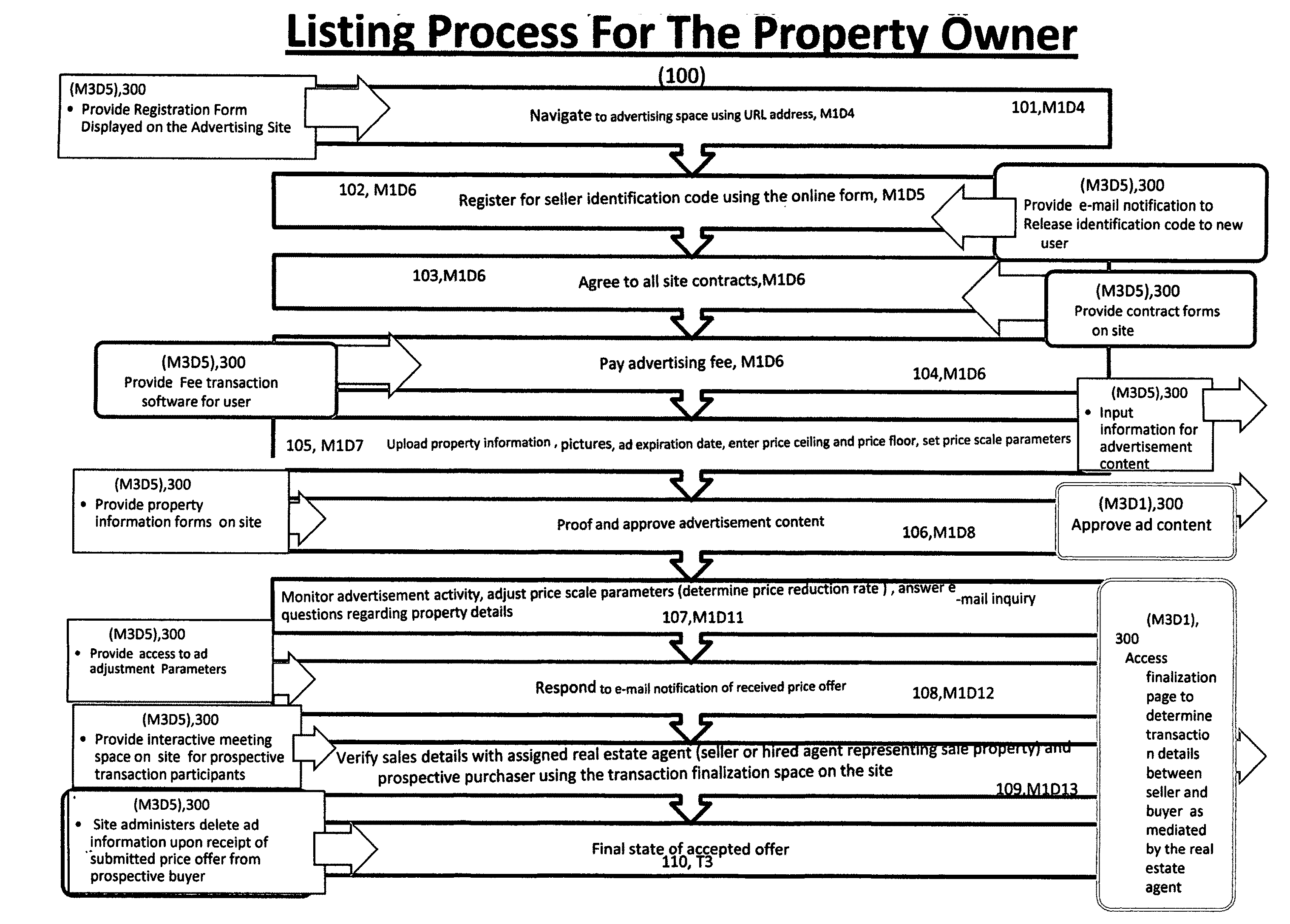

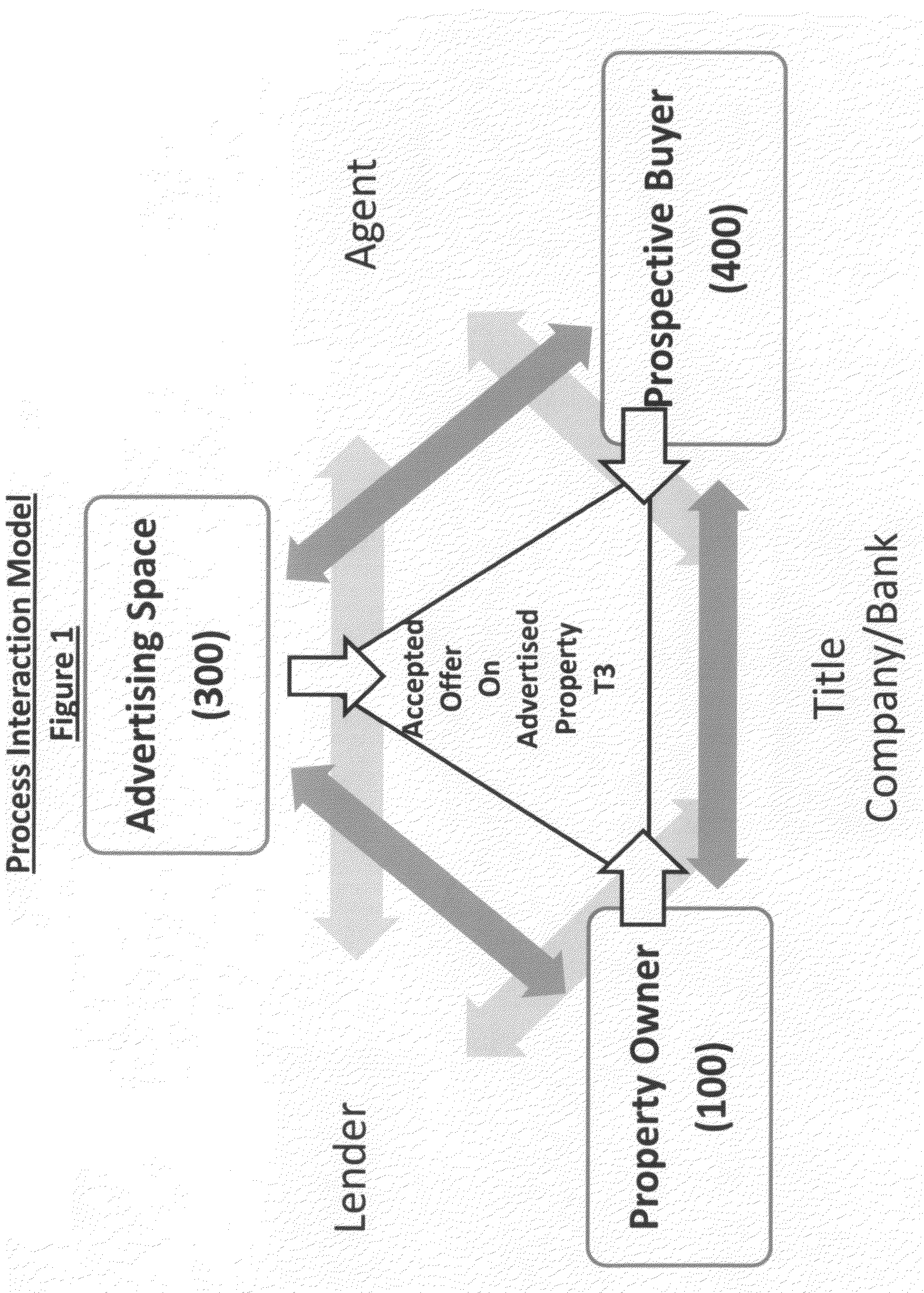

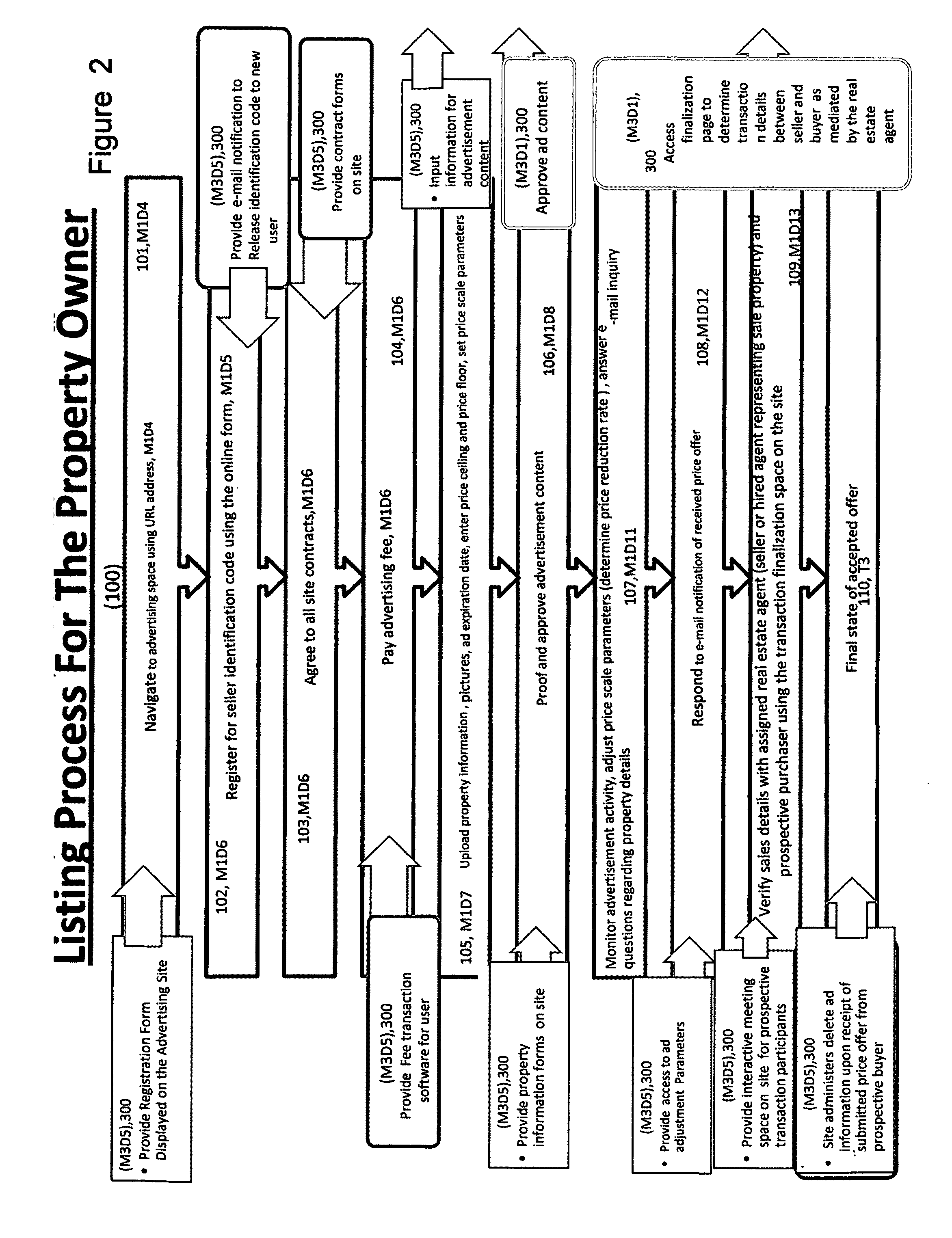

Method and system utilizing an interactive, descending, sale-price meter used to optimize negotiation-free, sales offers

InactiveUS20100088238A1Reduces time and costReduce time and costPayment architectureBuying/selling/leasing transactionsApplication softwareMonetary Amount

A method and system to determine a fair sales price for items displayed on an advertising space with connectivity to the internet. This method and system facilitates negotiation free, transactions (like, but not limited to, real-estate sales) regulated by a unique fluctuating, regressive, digitally displayed sale price in an interactive, electronic advertising space utilizing a database. The system includes algorithms that are hosted on a server such that space is provided for property owners and prospective buyers to determine an acceptable offer on advertised property. Set parameters, which regulate the sale price amount displayed on the property's advertisement. This interactive, digital / graphic, sale-price display which regressively descends at varying rates, as manipulated by the property listing representative registered with the system, until the displayed sale price is selected by a buyer. Once the buyer offer is submitted, the host application stops further price deductions and accepts the offer for closing.

Owner:BUTTERFIELD MELISSA RAE

Sensor device and wiper controller

ActiveUS20070034785A1Improve accuracyImprove efficiencyMotor/generator/converter stoppersDC motor speed/torque controlLight emissionWindshield

A sensor device for detecting wetting on a windshield includes a light emission element for emitting a light, a first light reception element for receiving the light in a first light path that includes reflective redirection by the windshield, and a second light reception element for receiving the light in a second light path that does not include reflective redirection by the windshield. The sensor device uses a ratio of the amount of the received light by the first light reception element and the amount of the received light by the second light reception element to determine wetting on the windshield.

Owner:DENSO CORP

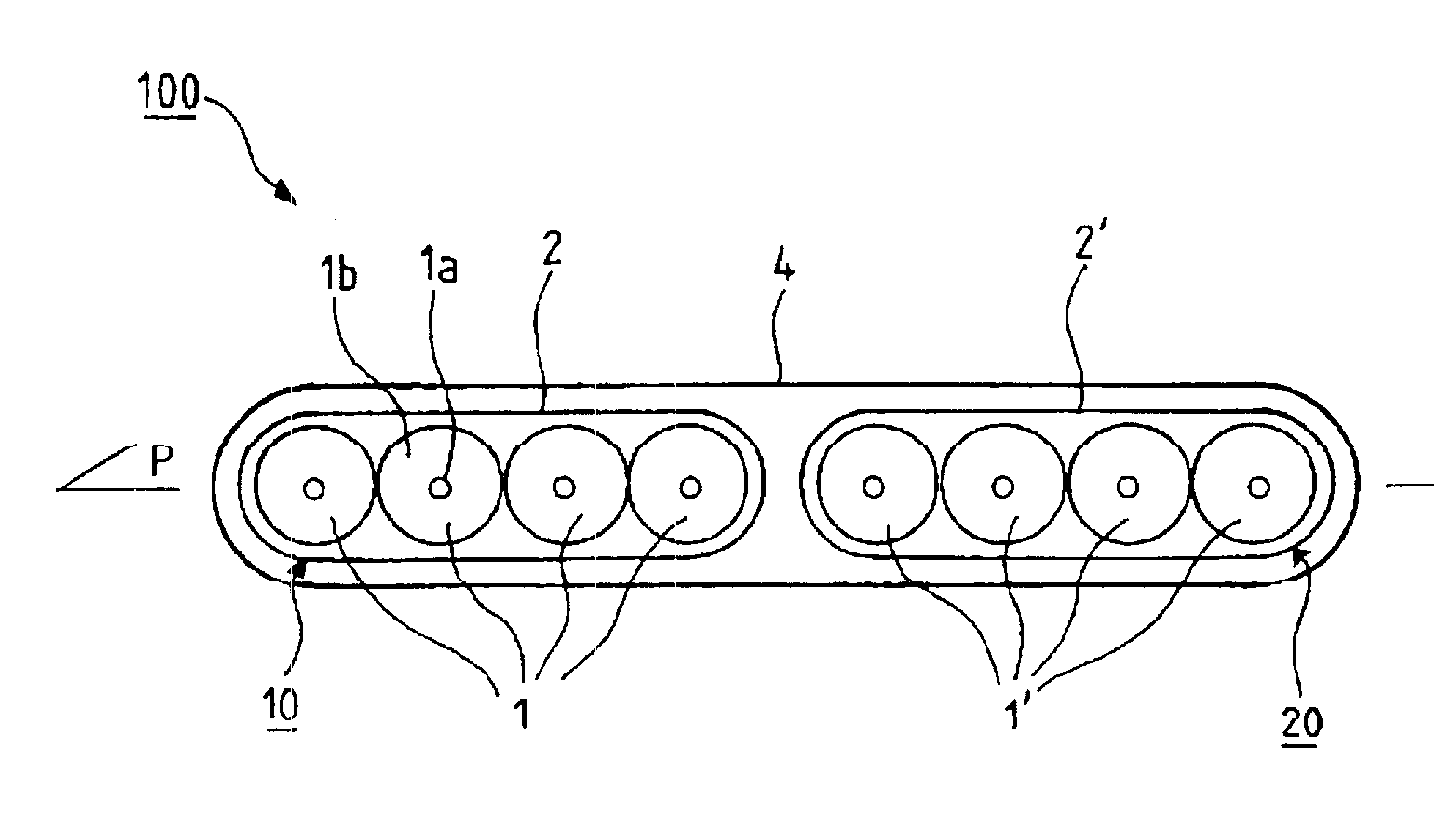

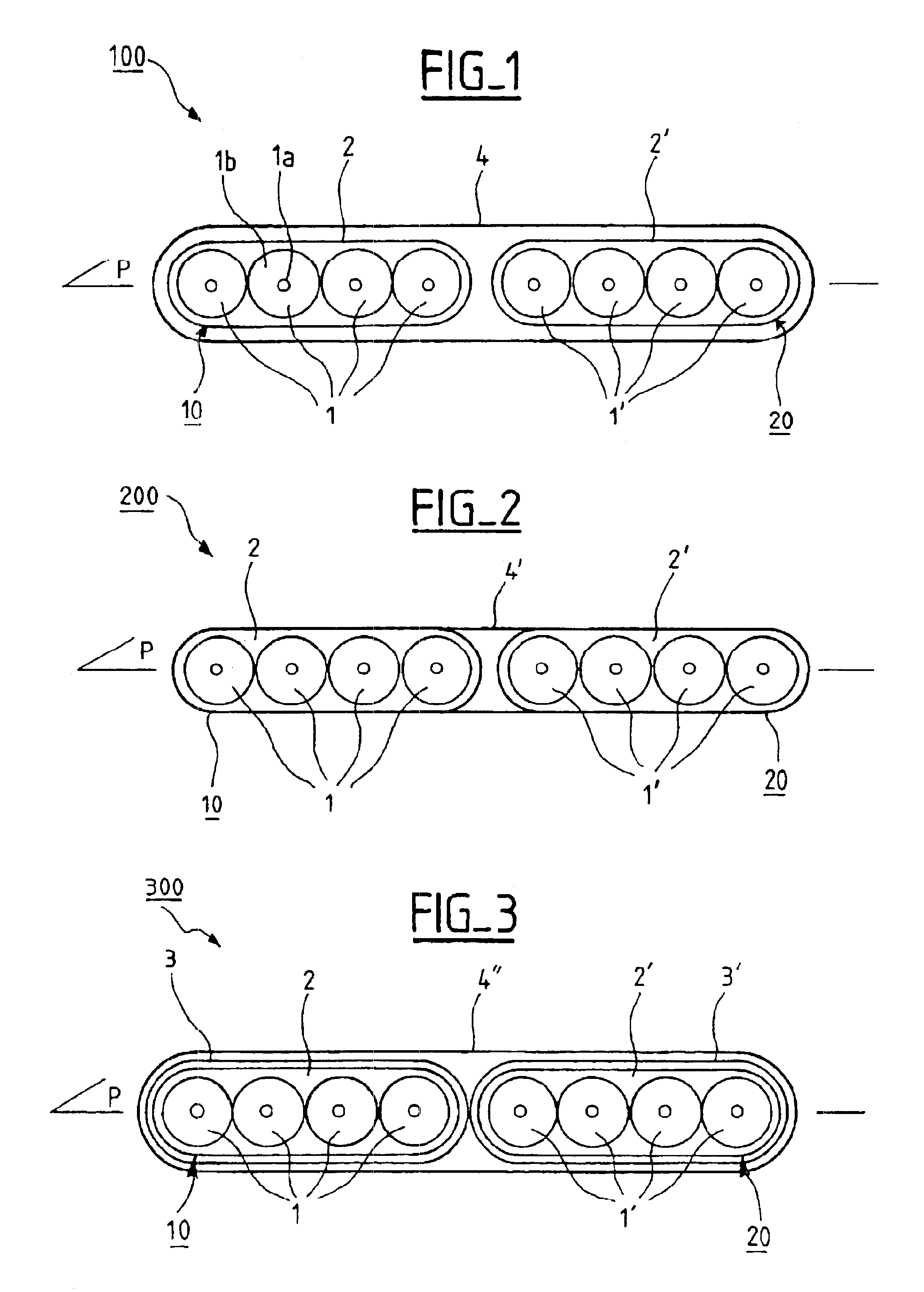

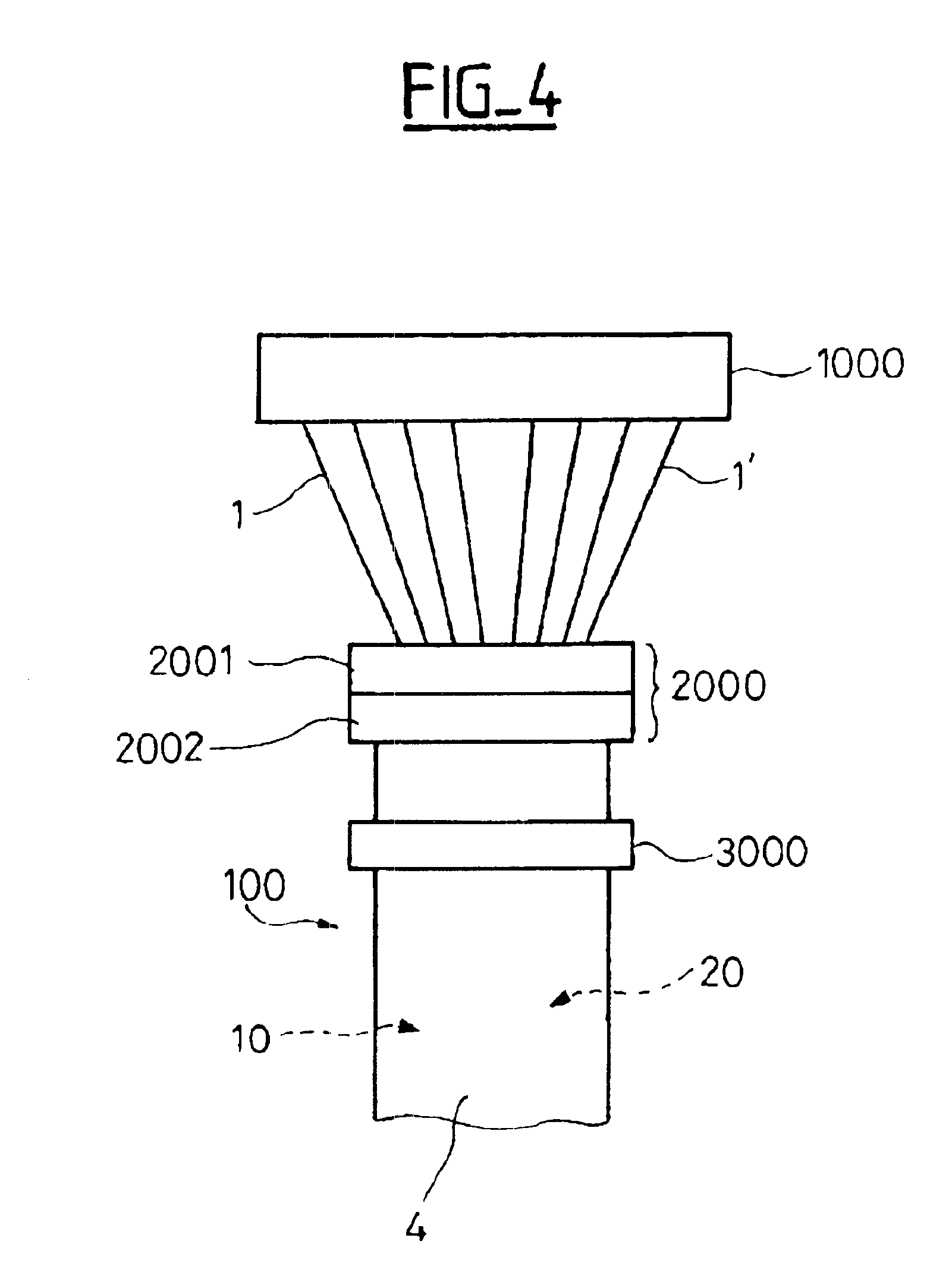

Method of manufacturing an optical fiber ribbon, and an optical ribbon

InactiveUS6859593B2Reducing time and costSatisfactory productivityCommunication cablesFibre mechanical structuresFiberEngineering

The present invention relates to a method of manufacturing an optical fiber ribbon comprising the following steps: arranging N groups of optical fibers so that the fibers in any one group are disposed in the same plane, applying a first layer of a first liquid resin settable under the action of UV type radiation onto each group of optical fibers to form first casings, applying a second layer of a second liquid resin settable under the action of UV type radiation disposed to link together the adjacent first casings, and applying a single irradiation step to the second layer and the first layers using UV type radiation in order to form the first matrices and to form the “link” second matrix.

Owner:NEXANS

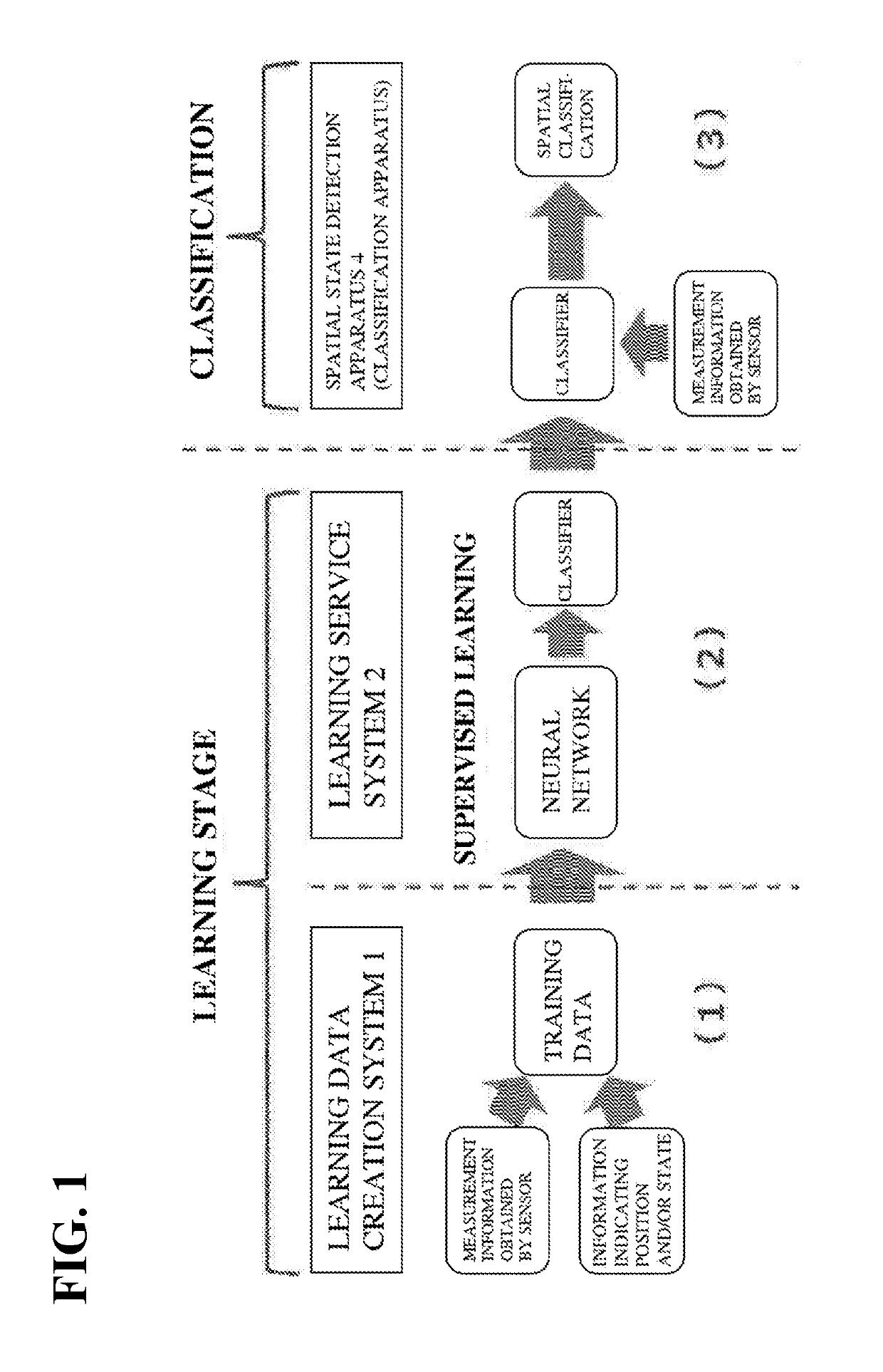

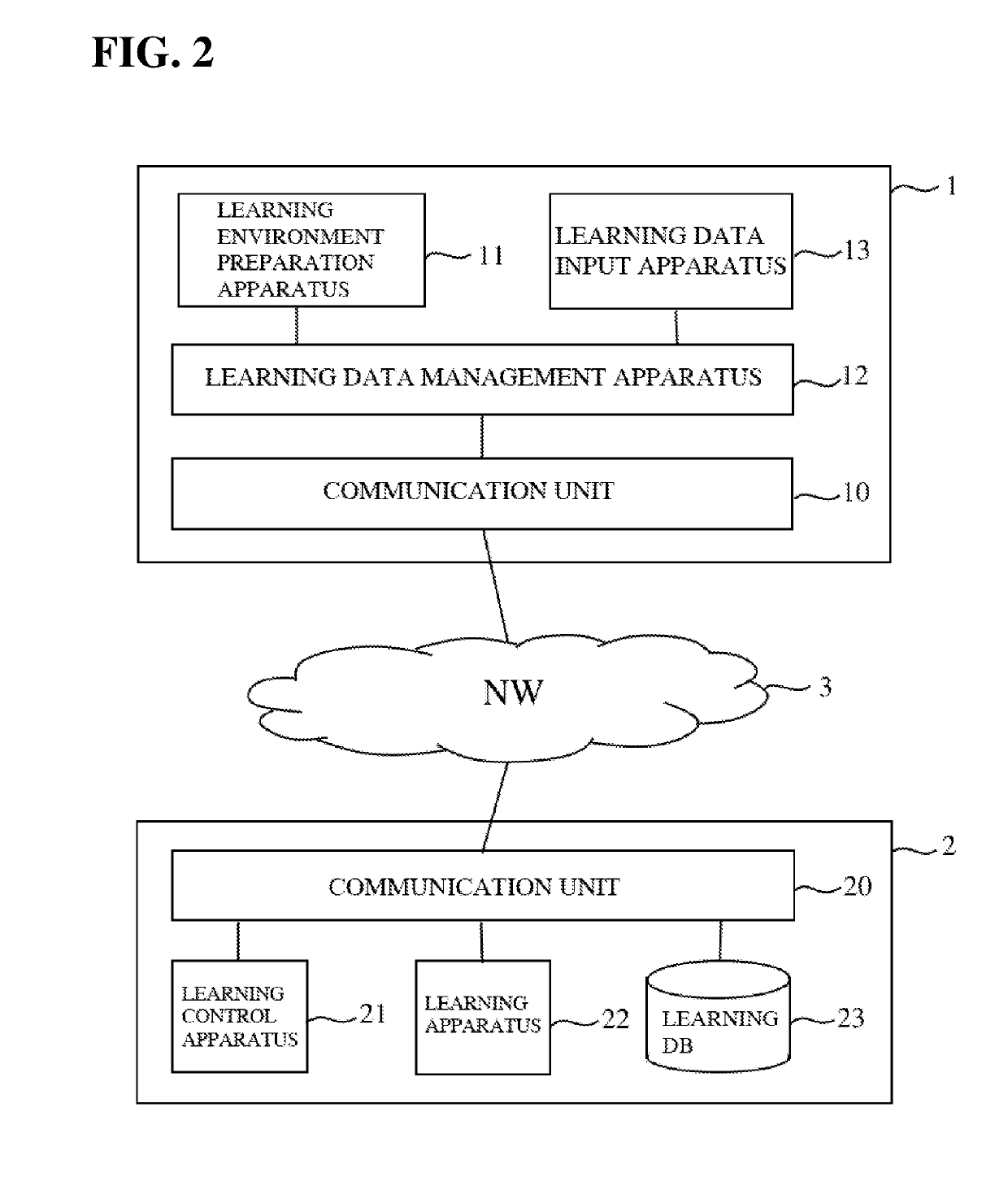

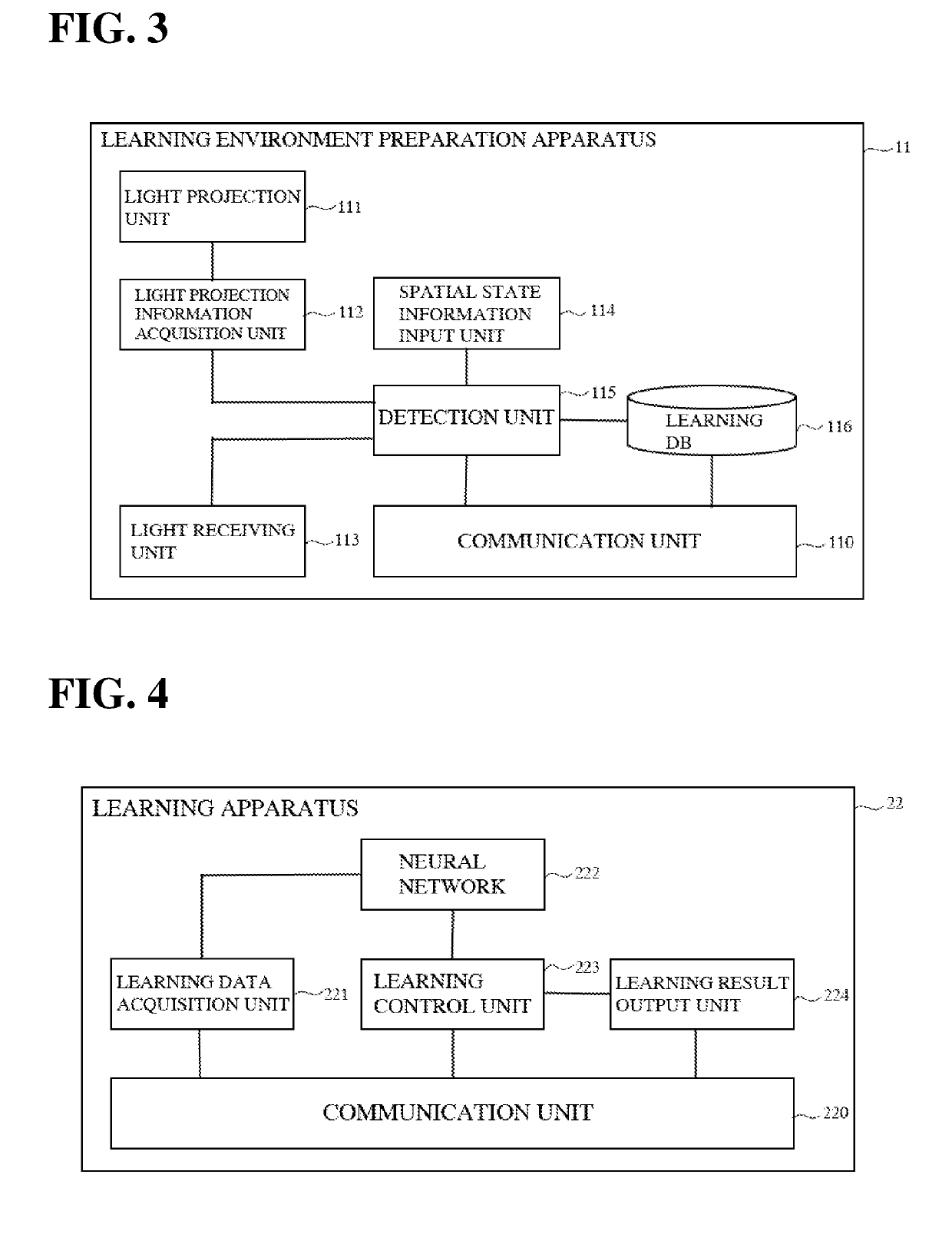

Classification apparatus, classification method, and program

ActiveUS20190244101A1Reducing time and costImage analysisKernel methodsClassification methodsComputer science

A classification apparatus includes: a specifying unit integrated with a neural network that has been trained to classify a state of a space using information indicating a light projection pattern and information indicating a light reception pattern; a light projection information acquisition unit configured to acquire information indicating a light projection pattern of light projected into a predetermined space, and output the acquired information to the specifying unit; and a light receiving unit configured to acquire information indicating a light reception pattern of light received from the predetermined space, and output the acquired information to the specifying unit, wherein the specifying unit outputs a classification result of classifying a state of the predetermined space, based on the information indicating the light projection pattern acquired by the light projection information acquisition unit and on the information indicating the light reception pattern of the light received by the light receiving unit.

Owner:ORMON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com