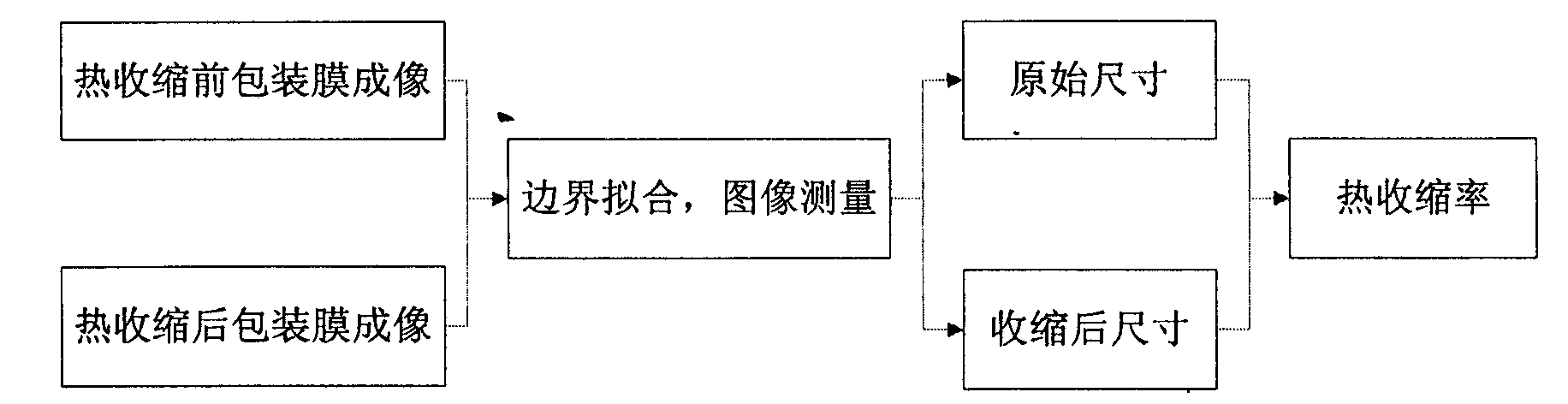

Measuring method of thermal shrinkage rate of cigarette packaging film

A technology of thermal shrinkage rate and measurement method, applied in the direction of material thermal expansion coefficient, etc., can solve the problems that the center size cannot represent the overall size, affect the thermal shrinkage rate test results, and affect the film shrinkage degree, etc., to achieve fast testing speed and improve accuracy. performance and measurement accuracy, the effect of eliminating human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

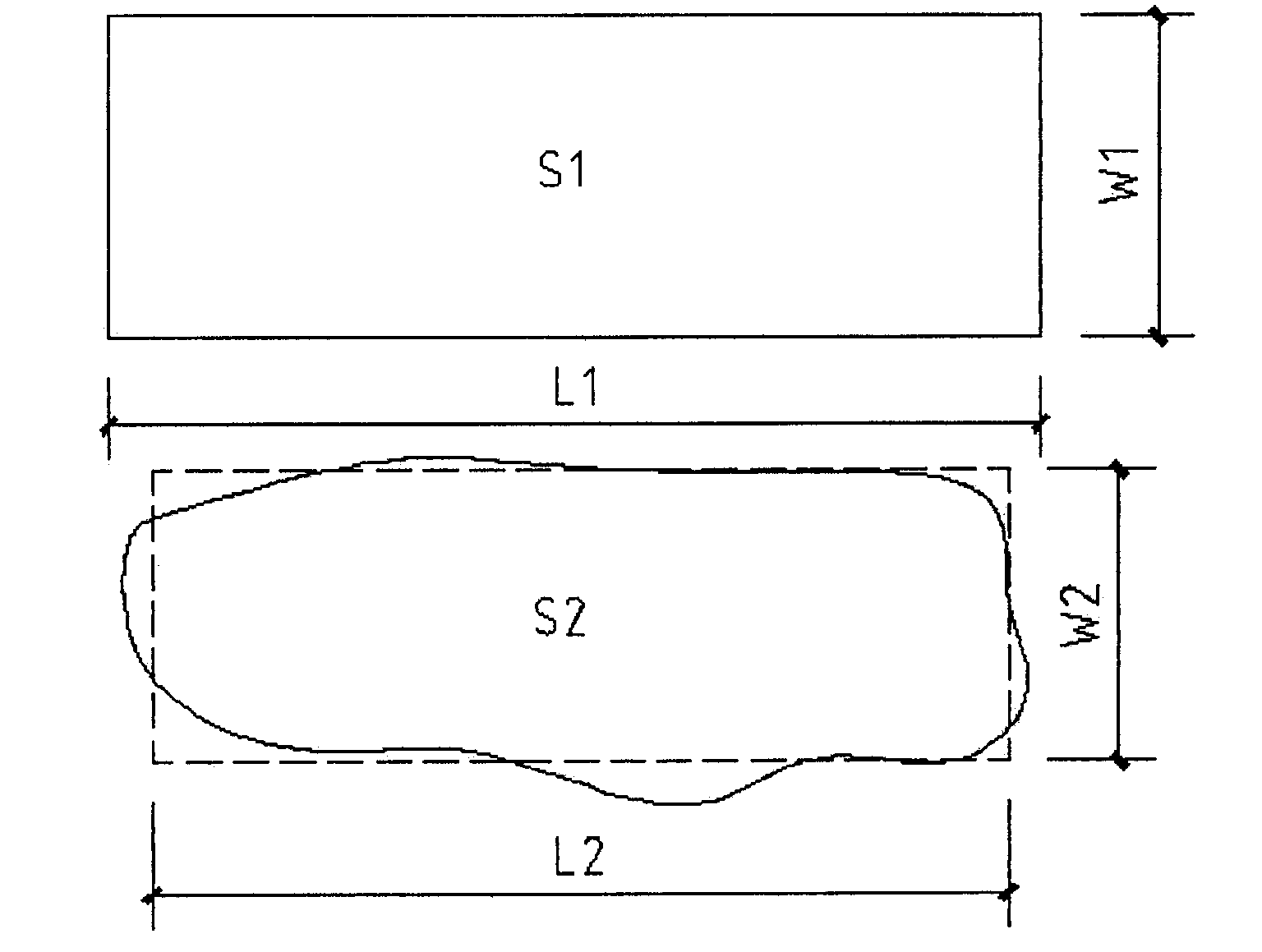

[0043] 1. Cut the cigarette packaging film into a square with a side length of 50mm;

[0044] 2. Put the packaging film under the sample pressing device to keep the film flat;

[0045] 3. Collect the cigarette packaging film image through the calibrated CCD imaging device, use the Motic2.0 image analysis software to fit the packaging film boundary, and use the Motic2.0 image measurement software to measure the vertical length of 50.1mm, the horizontal length of 50.0mm, and the area of 2505mm 2 ;

[0046] 4. Place the packaging film in a blast drying oven and heat it at 120°C for 5 minutes;

[0047] 5. Take out the packaging film for cigarettes from the blast drying oven, place it under the sample pressing device after cooling, and keep it flat;

[0048] 6. Use the calibrated CCD imaging device to collect the image of the shrinking packaging film, use the Motic2.0 image analysis software to fit the packaging film boundary, and use the Motic2.0 image measurement software to ...

Embodiment 2

[0051] 1. Cut the cigarette packaging film into a square with a side length of 50 mm;

[0052] 2. Put the packaging film under the sample pressing device to keep the film flat;

[0053] 3. Collect the image of cigarette packaging film with a digital camera, use Motic2.0 image analysis software to shield the image of the sample pressing device, and then use the software to fit the boundary of the packaging film, and use Motic2.0 image measurement software to measure the vertical length of 510 pixels and the horizontal length 500 pixels long, 510 pixels x 500 pixels in area;

[0054] 4. Place the packaging film in a blast drying oven and heat it at 120°C for 5 minutes;

[0055] 5. Take out the packaging film for cigarettes from the blast drying oven, place it under the sample pressing device after cooling, and keep it flat;

[0056]6. Use a digital camera to collect the image of the shrinked packaging film, use Motic2.0 image analysis software to shield the image of the sample...

Embodiment 3

[0059] 1. Cut the cigarette packaging film into a square with a side length of 50 mm;

[0060] 2. Put the packaging film under the sample pressing device to keep the film flat;

[0061] 3. Collect the image of cigarette packaging film through the calibrated CCD imaging device, use the image analysis function of MATLAB 8.0 to fit the boundary of the packaging film, and use the image measurement function of MATLAB 8.0 to measure the vertical length of 50.1mm, the horizontal length of 50.0mm, and the area of 2505mm 2 ;

[0062] 4. Place the packaging film in silicone oil at 120°C for 20 s;

[0063] 5. Take out the packaging film for cigarettes from the silicone oil, place it under the sample pressing device after cooling, and keep it flat;

[0064] 6. Use the calibrated CCD imaging device to collect the image of the shrinking packaging film, use the image analysis function of MATLAB 8.0 to fit the boundary of the packaging film, and use the image measurement function of MATLA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com