Liquid reservoir automatic calibration device and calibration method

A technology for verification devices and liquid storage tanks, applied in measuring devices, test/calibration devices, liquid/fluid solid measurements, etc., can solve the problems of low verification efficiency, insufficient accuracy, long verification time, etc., and shorten the calibration work The effects of saving time, improving work efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

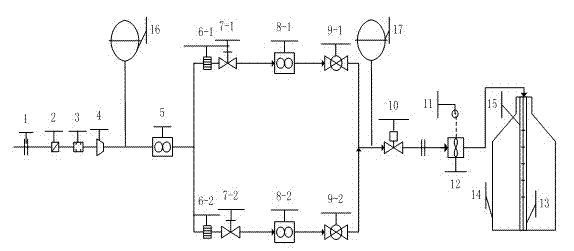

[0022] Such as figure 1 As shown, the external pipeline is connected to the standard measurement pipeline through a flexible hose or a variable diameter flange 1, and the measurement medium passes through the filter 2 to filter impurities, and then exhausts the air in the pipeline through the exhaust valve 3 to obtain a medium with a full pipe and less impurities. Then the outlet pressure of the valve is stabilized through the pressure reducing and stabilizing valve 4 to obtain a stabilizing medium. According to the flow rate of the measurement pipeline, the switches of the upper and lower solenoid valves 9-1 and 9-2 are controlled by PLC to select the upper branch (small pipe diameter), the lower branch (large pipe diameter) or use two branches at the same time, the small The upper rectifying plate 6-1, the upper manual valve 7-1 and the upper standard table 8-1 are also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com