Isolator automatic online detecting system

A detection system, one-way device technology, applied in the direction of grinding feed motion, grinding drive device, workpiece feed motion control, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

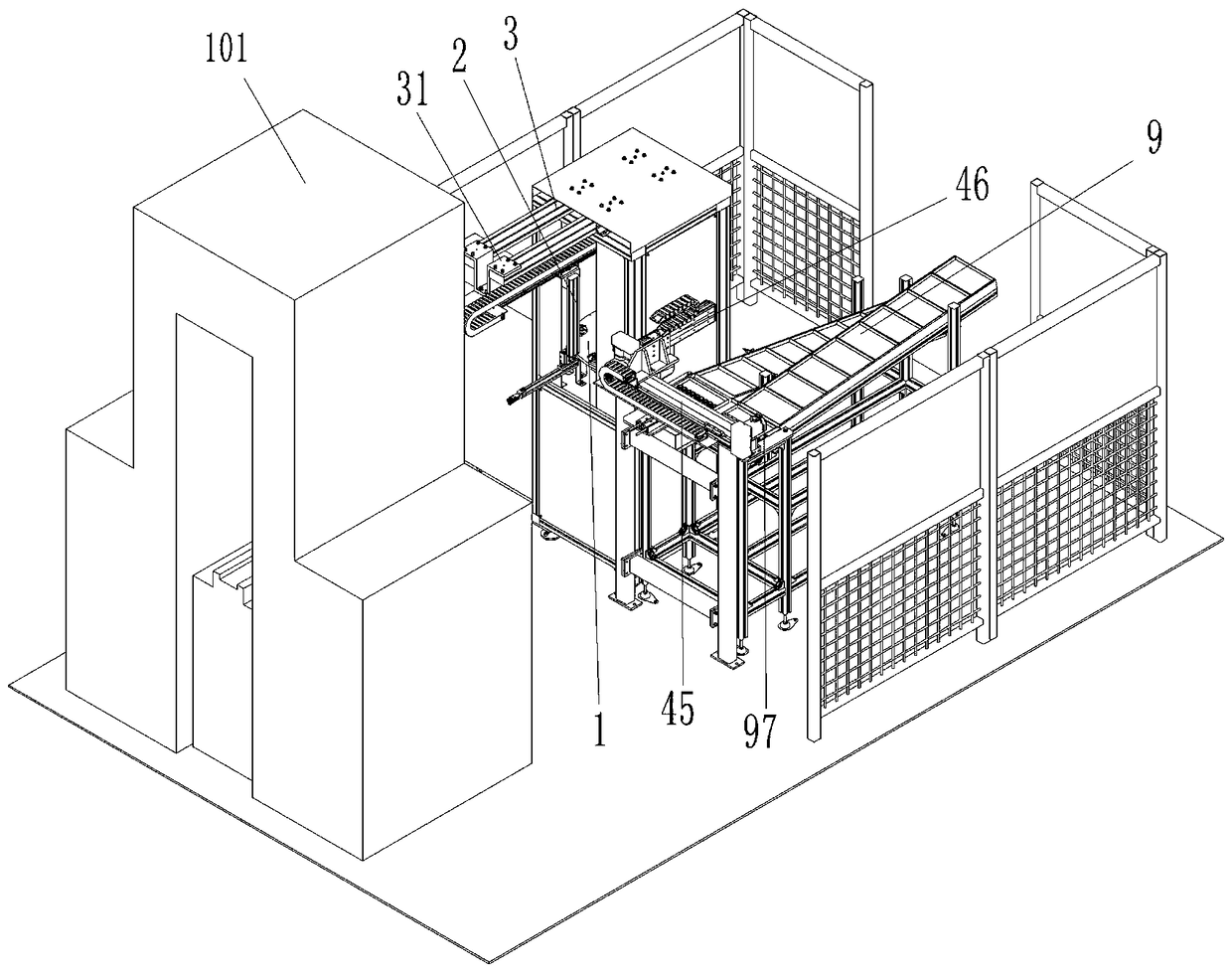

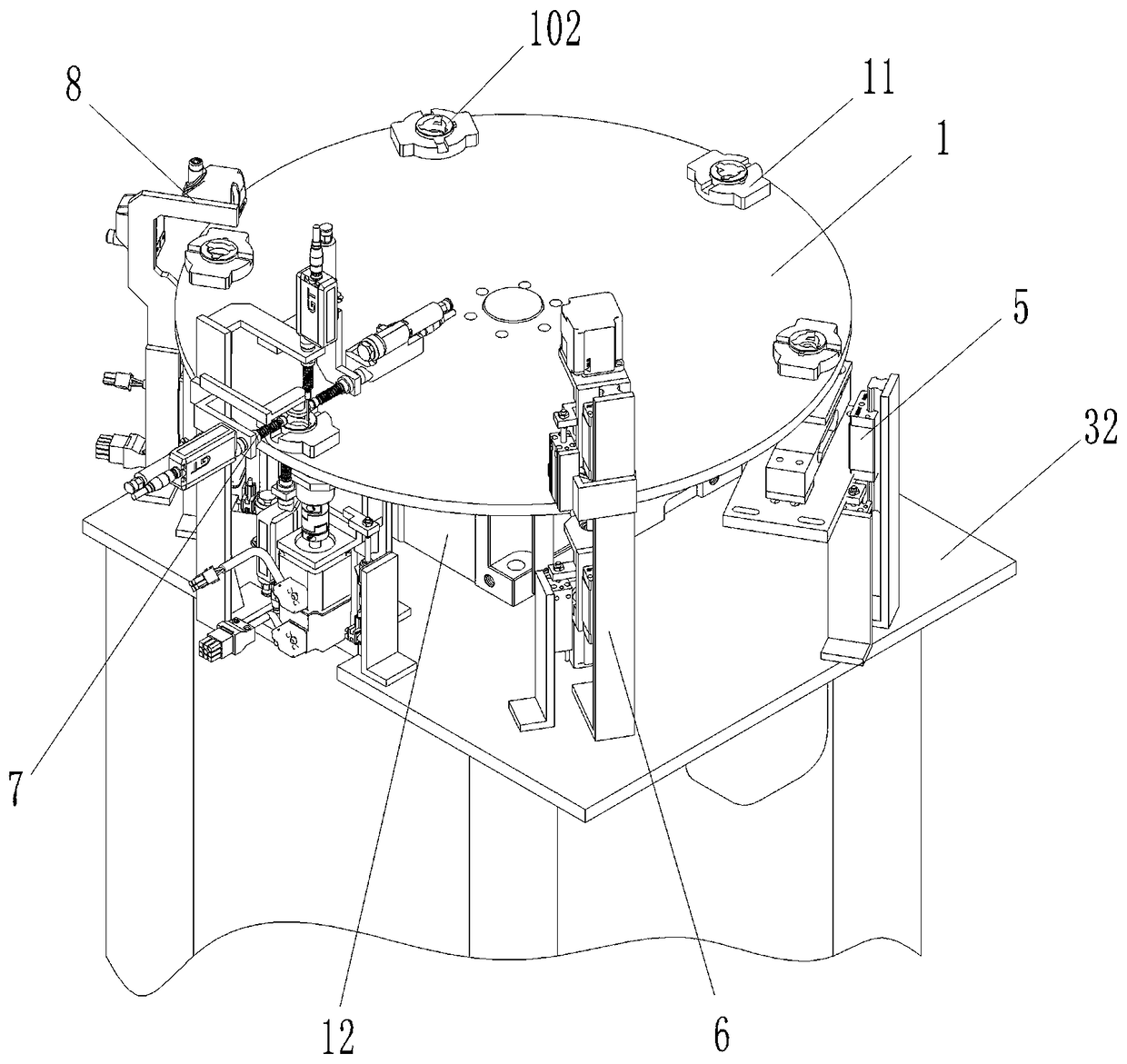

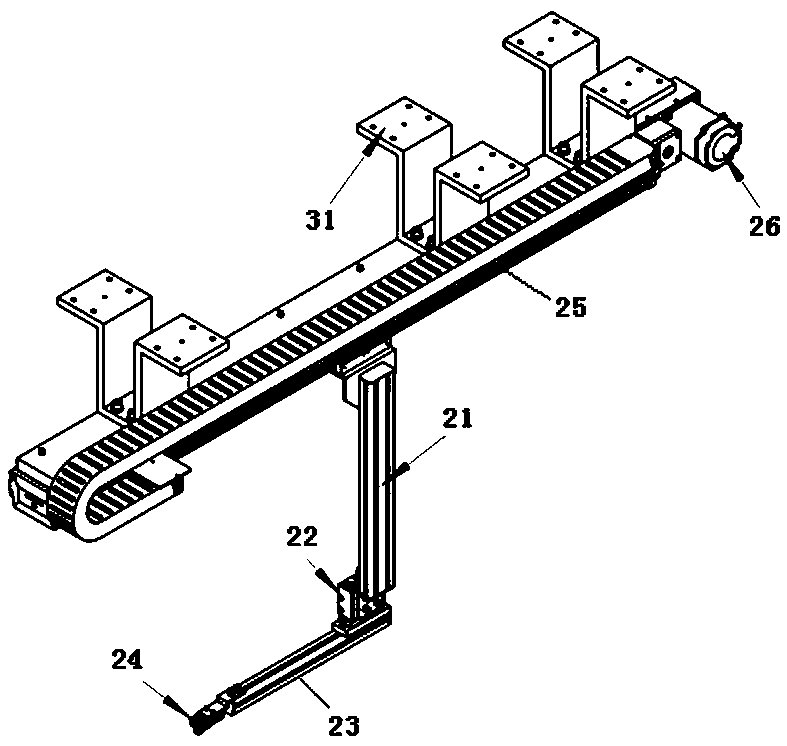

[0032]Referring to the accompanying drawings, an automatic online detection system for a one-way device, the frame 3 is installed on the side of the reclaiming port of the press 101 . The cam divider 12 is fixed on the rack mounting plate 32, and the intermittent indexing turntable 1 is installed on the cam divider 12. The cam divider 12 is connected with the motor and the matching reducer, and can drive the turntable 1 to rotate according to the indexing interval, Stop intermittent operation. Positioning fixtures 11 are distributed on the turntable 1 , and the interval of each positioning fixture 11 corresponds to the rotation interval of the cam divider 12 , and the number matches the number of stations. According to a general inspection process, a weighing unit 5 , a deburring unit 6 , a dimension measuring unit 7 and an appearance inspection unit 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com