Assembly tooling for double assembly and main drive of head side plate on staircase and assembly method

An assembly tooling and main drive technology, which is applied in the direction of assembly machines, auxiliary devices, manufacturing tools, etc., can solve the problems of poor positioning accuracy of side panels and main drives, poor assembly accuracy of double assembly, long tooling adjustment time, etc., to achieve work Rhythm, improve efficiency, reduce the effect of placing the venue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. The accompanying drawings and embodiments should not be regarded as limiting the protection scope of the present invention, and any expansion and addition on the basis of the technical solution of the present invention shall be regarded as the protection scope of the present invention.

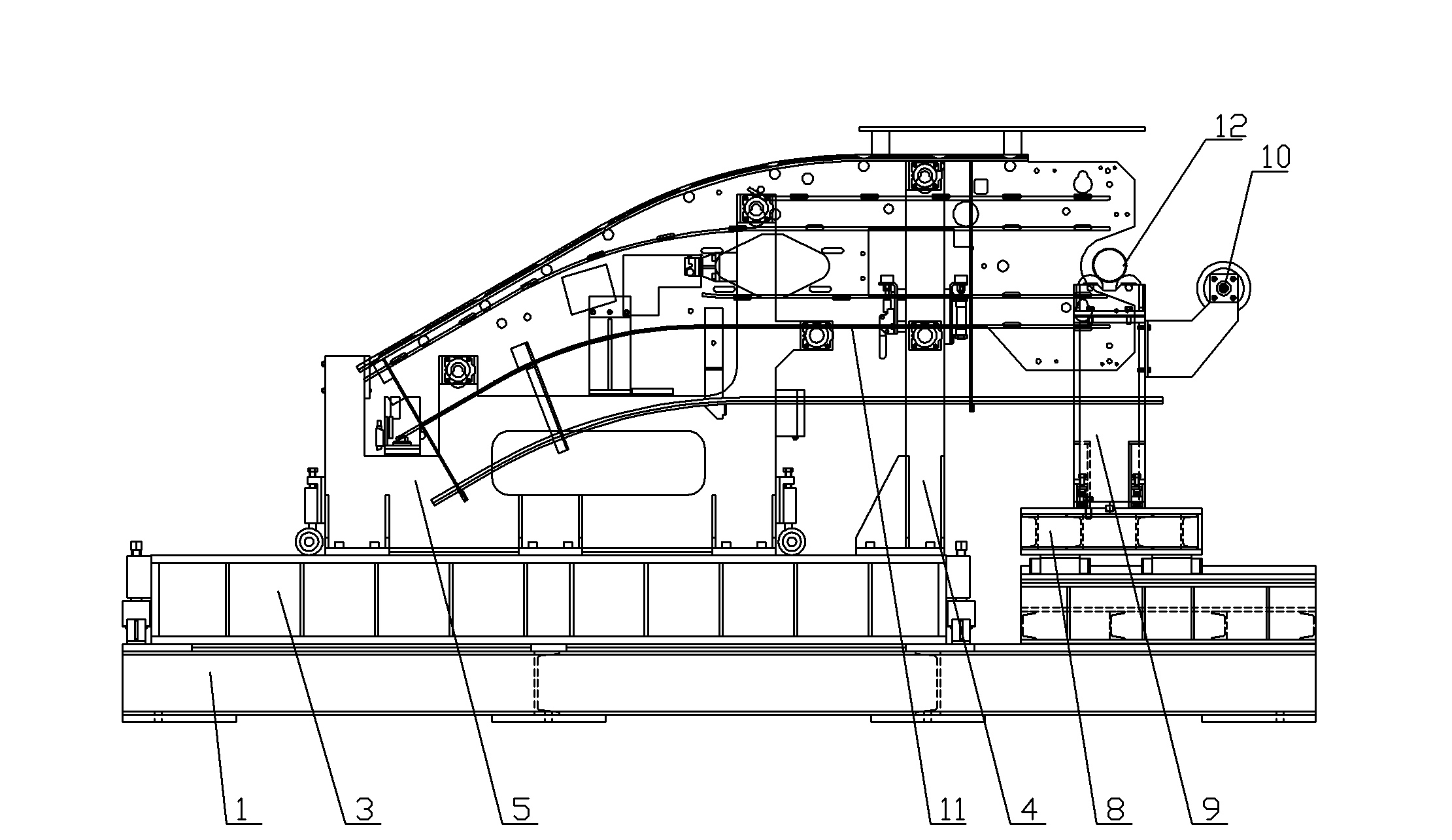

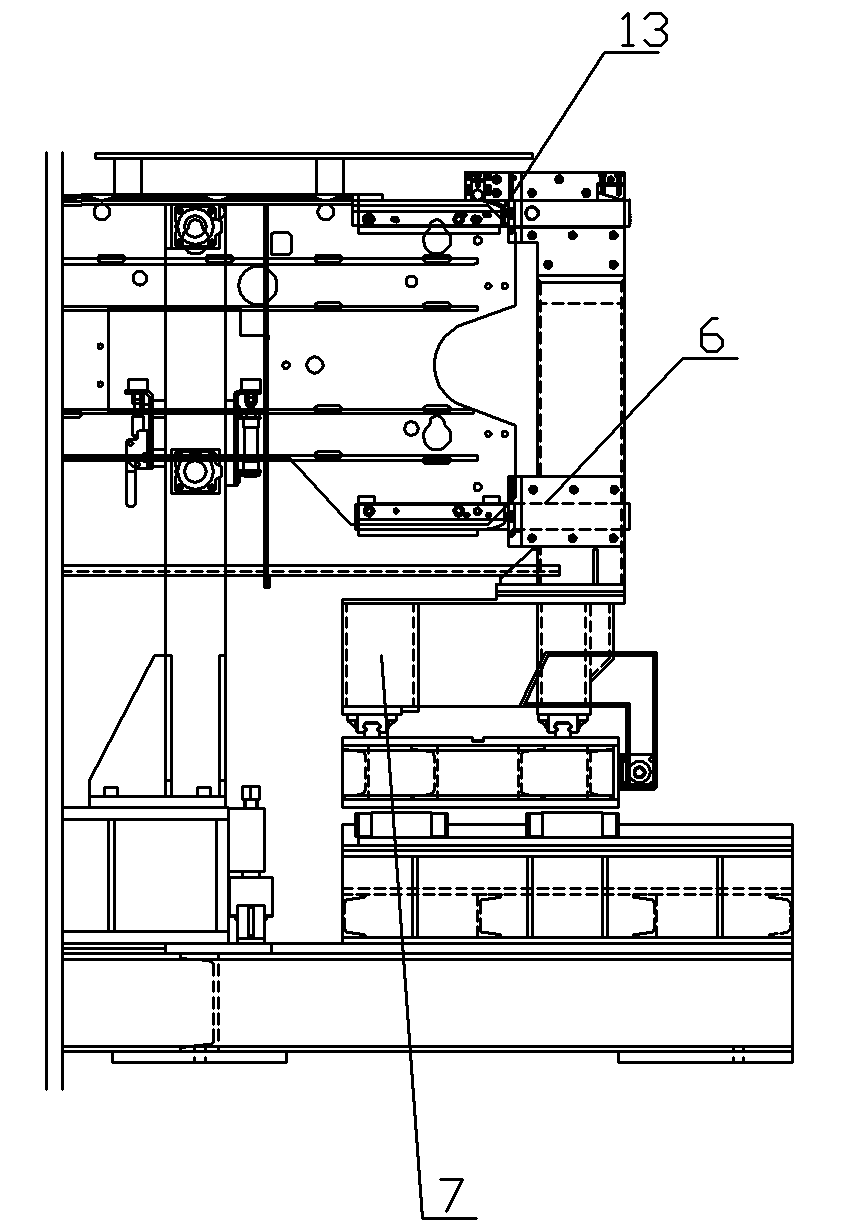

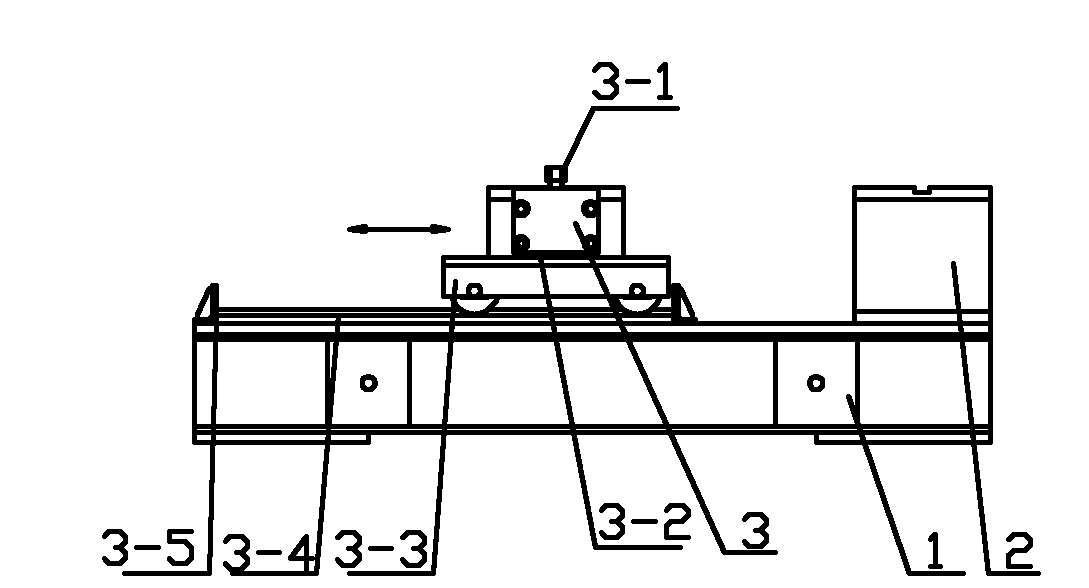

[0049] refer to figure 1 , 2 , the escalator upper head side plate double assembly and the main drive integrated assembly tooling, including: working platform 1, fixed reference beam 2, laterally movable beam 3, positioning column for fixing the escalator side plate 4, vertically movable escalator side Panel positioning wall panel 5, tangential guide rail automatic docking device 6, tangential guide rail mounting seat transverse moving trolley 7, main drive longitudinal moving trolley 8, main drive height positioning device 9, main drive axial centering device 10, specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com