Patents

Literature

98results about How to "Save the beat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

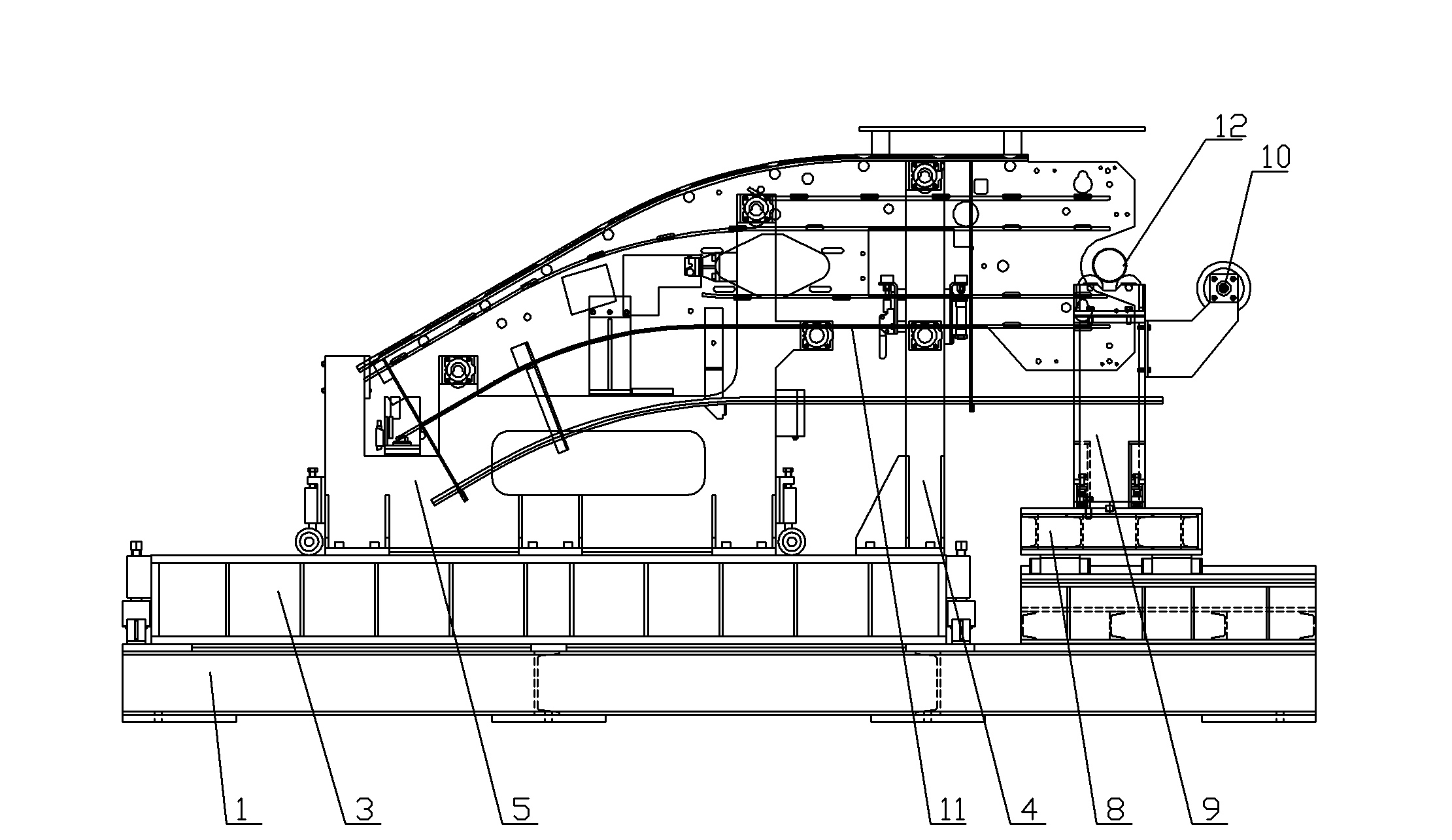

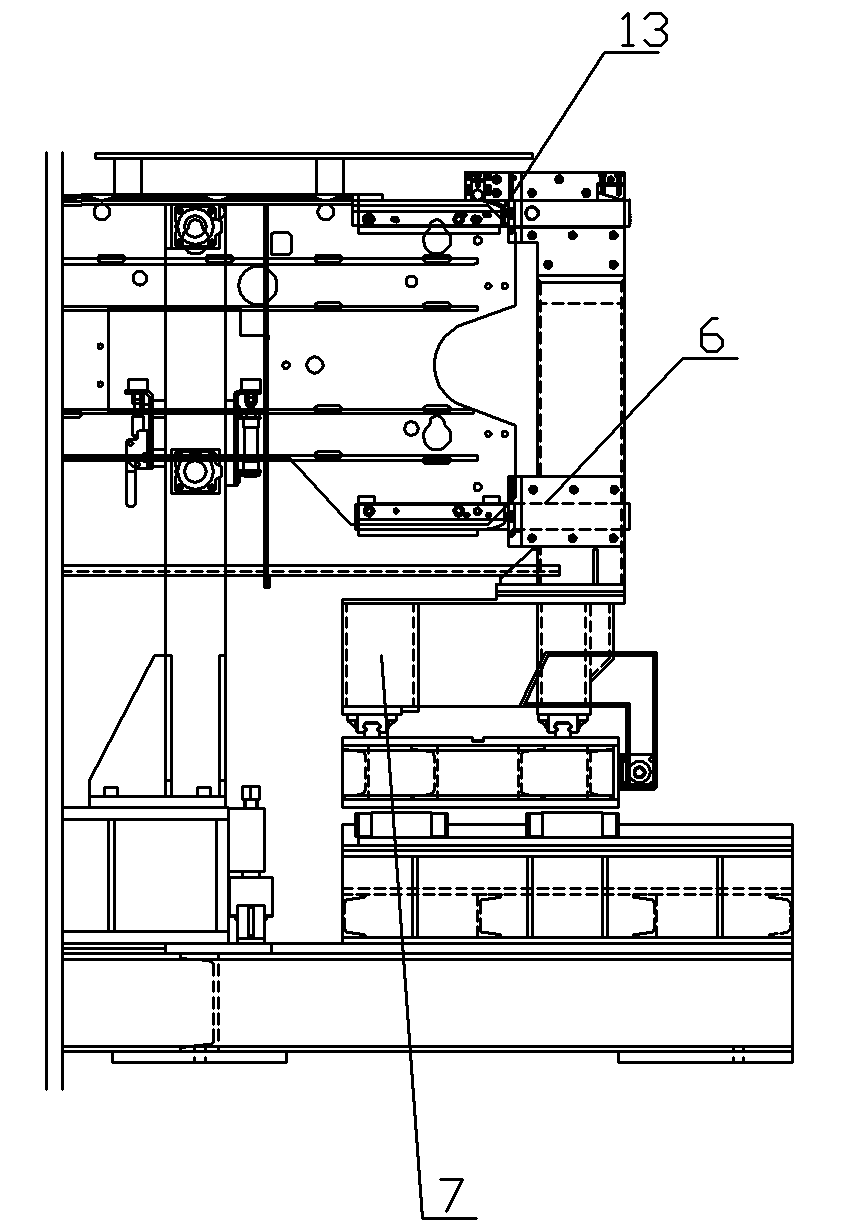

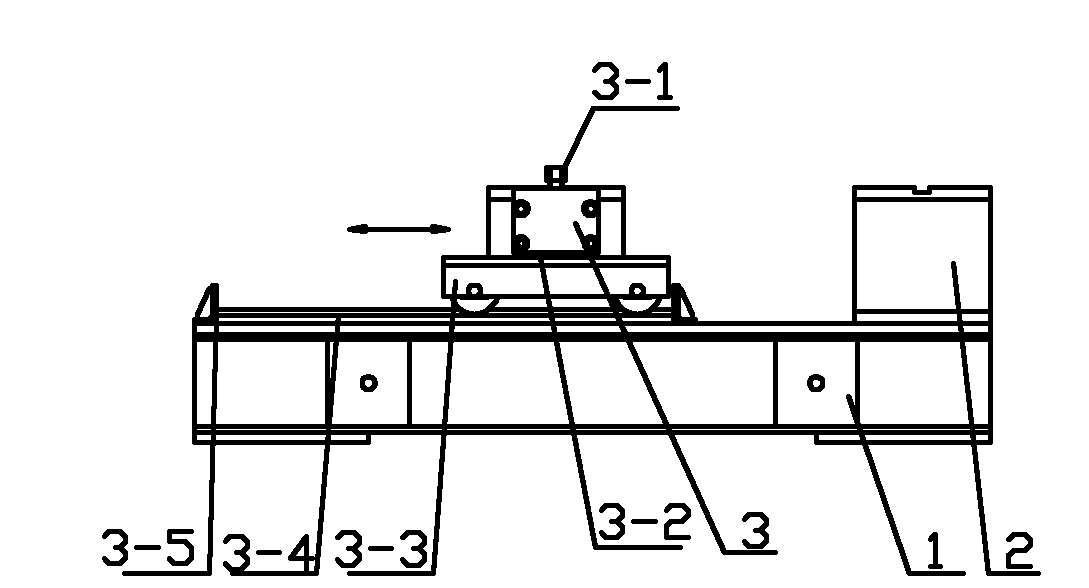

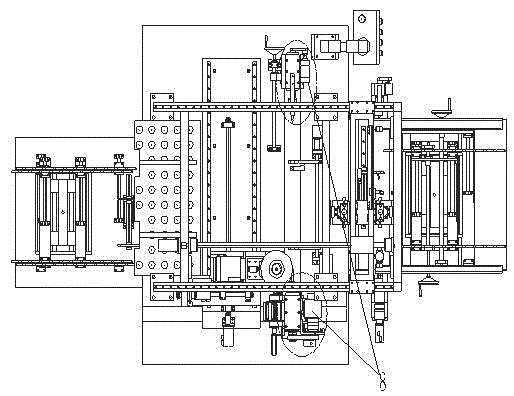

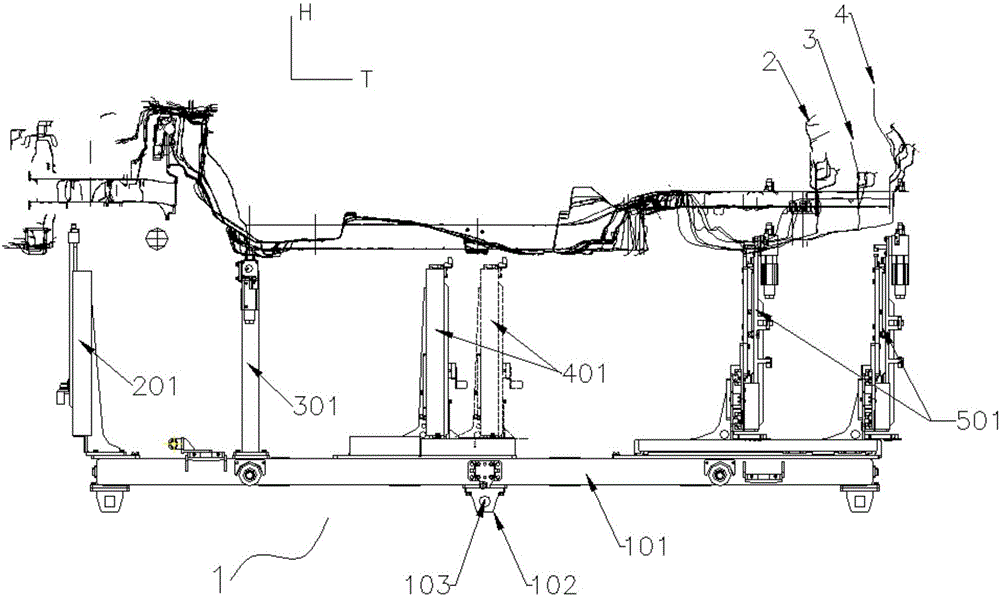

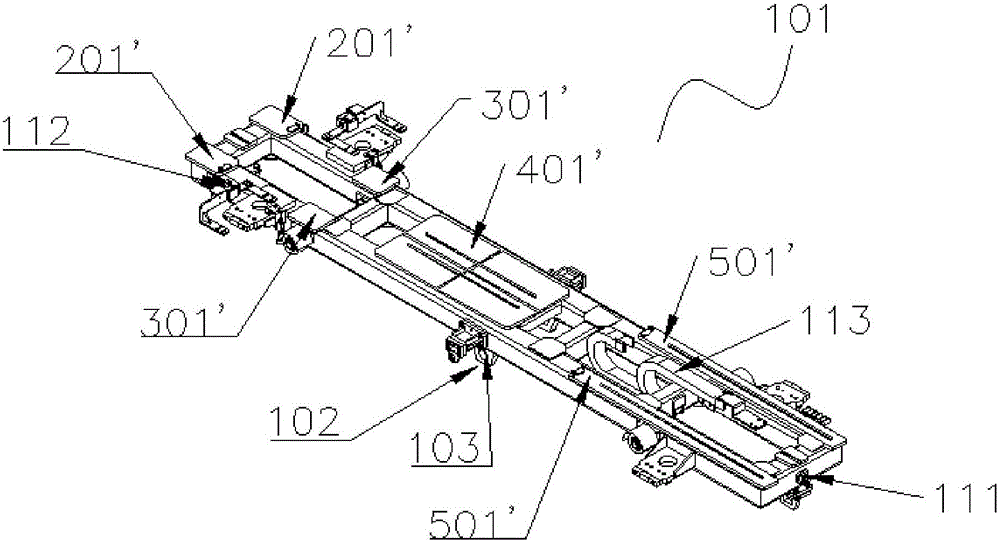

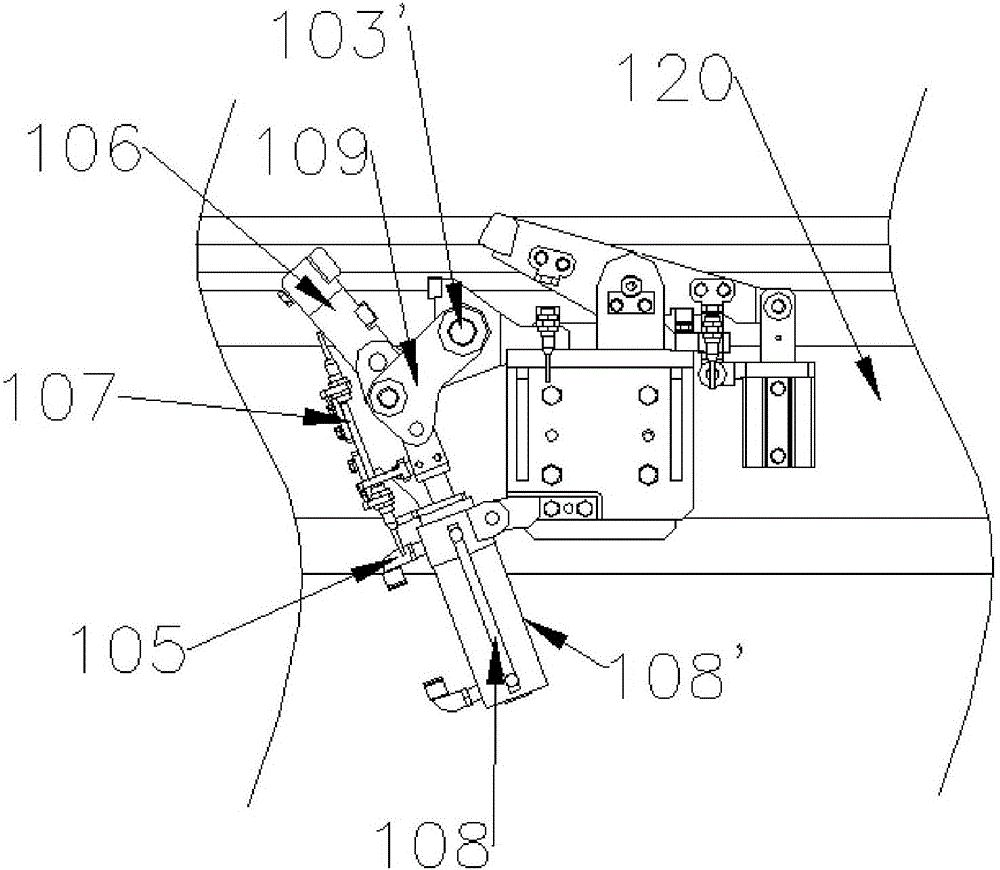

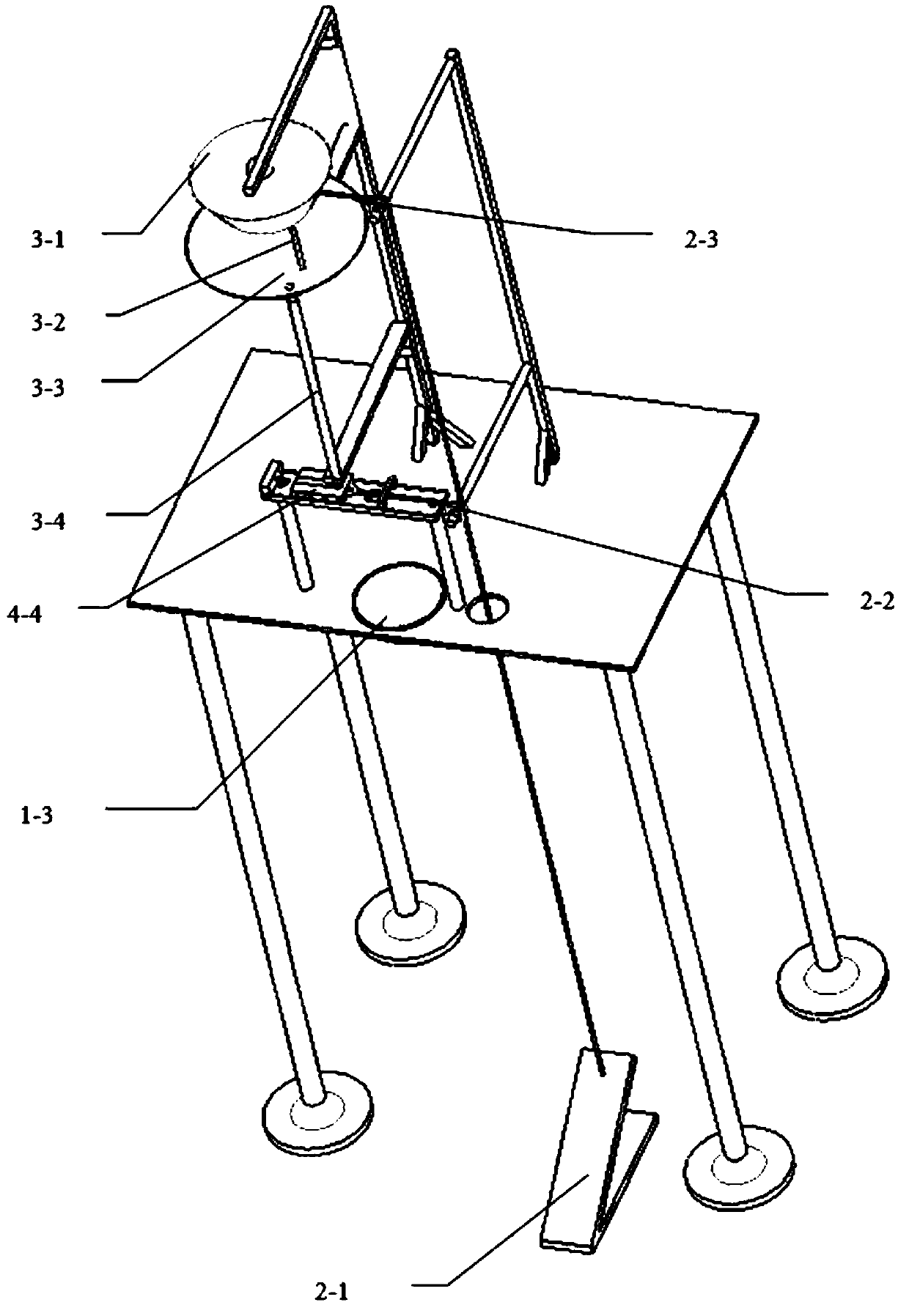

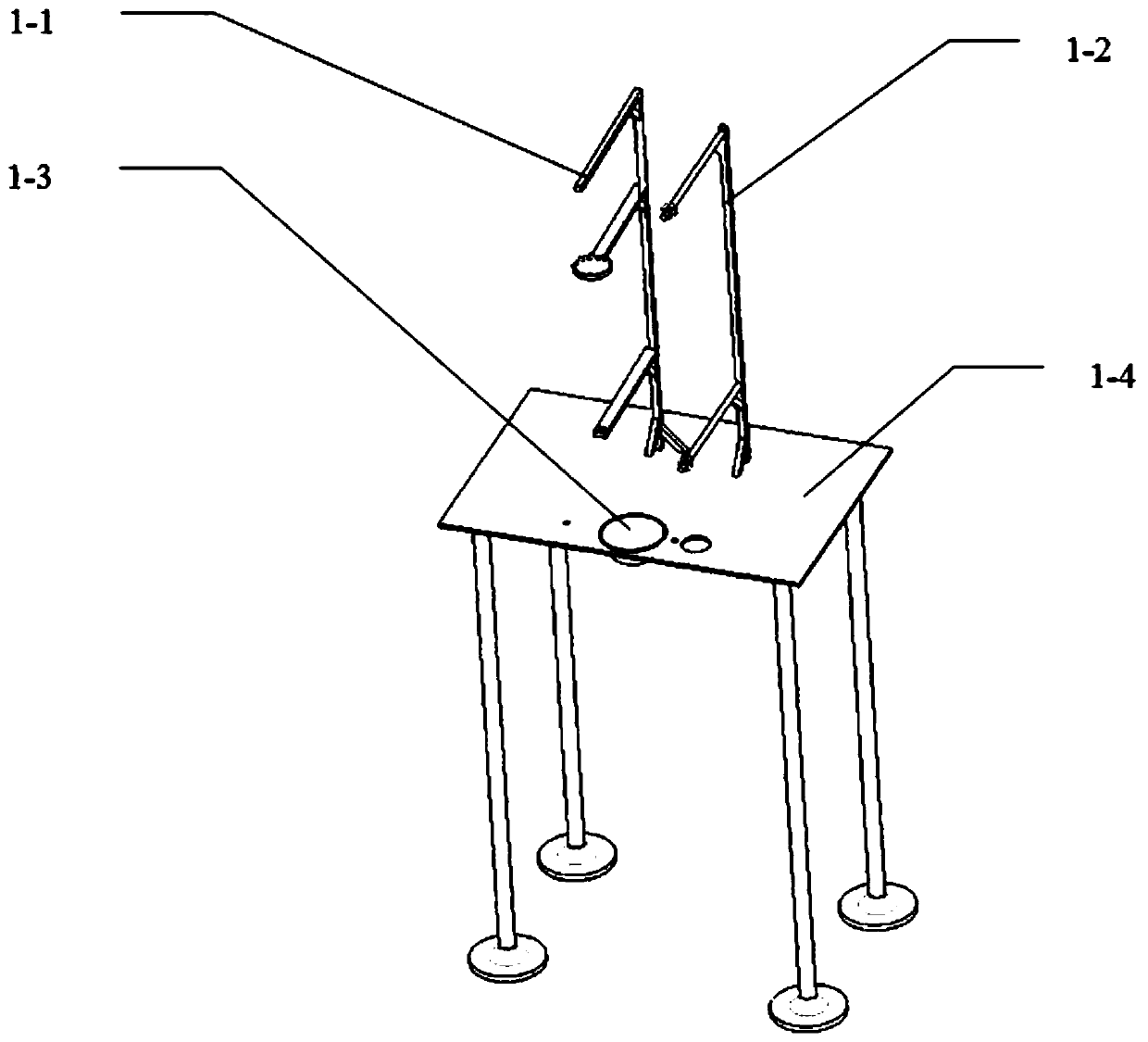

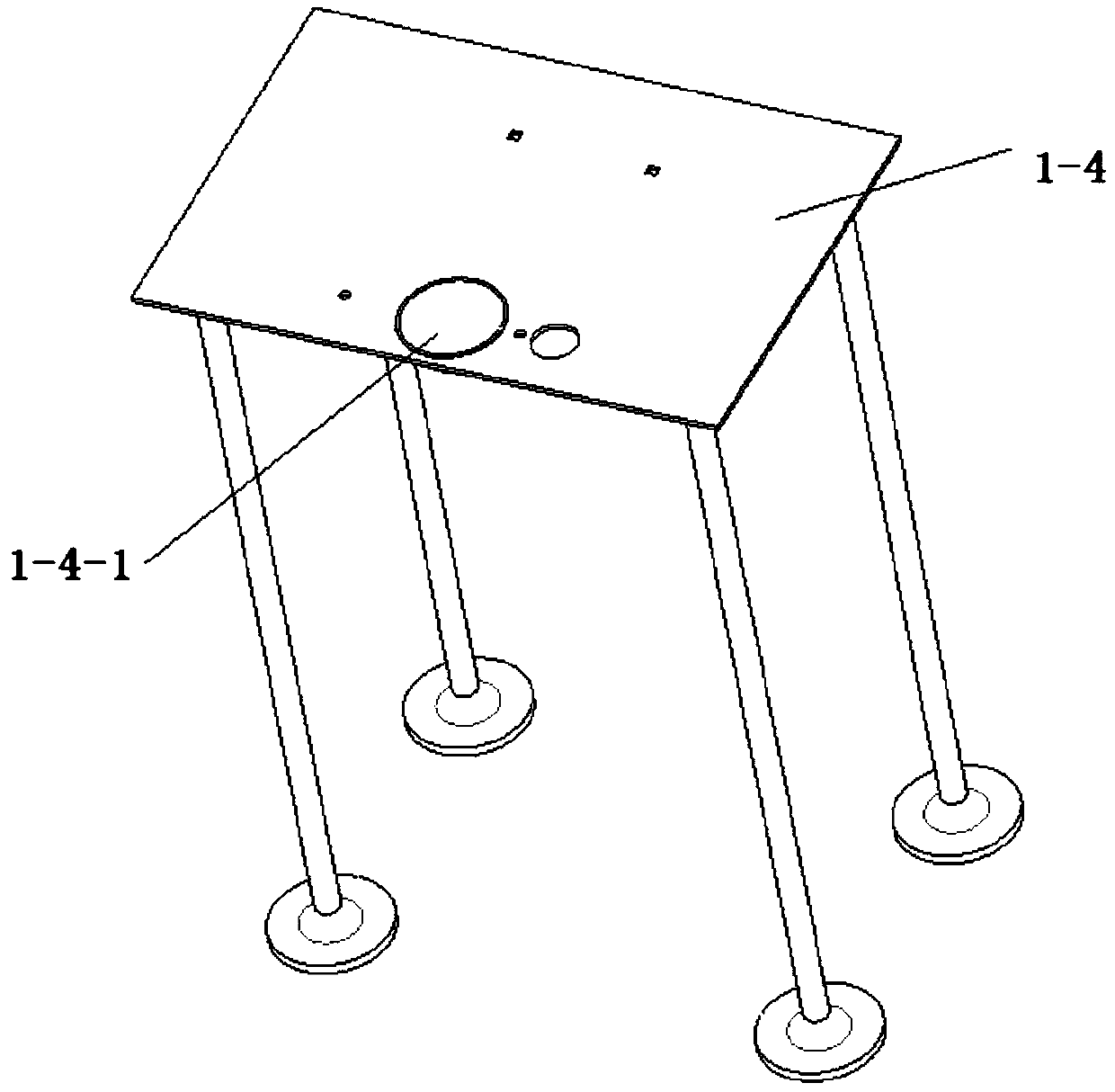

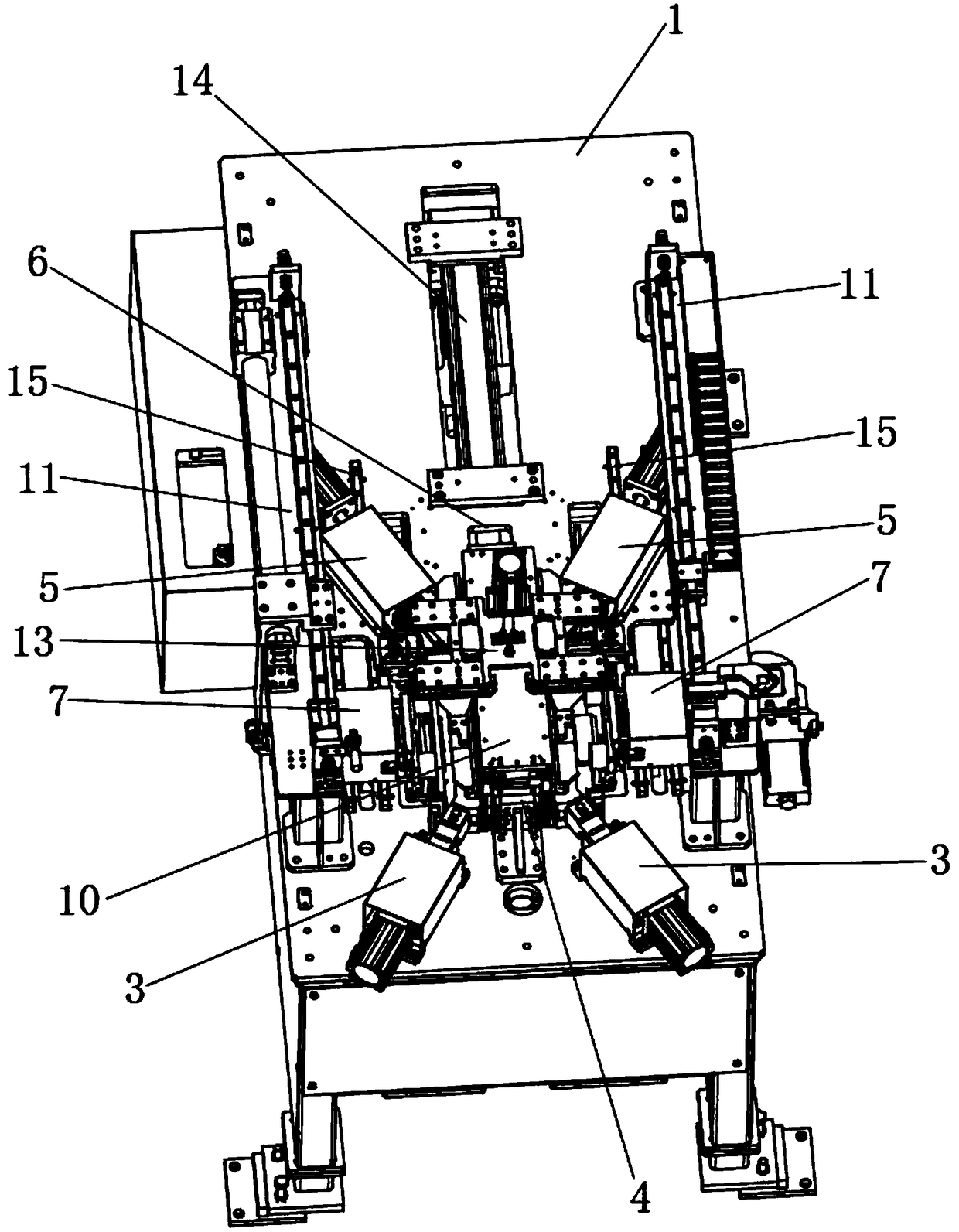

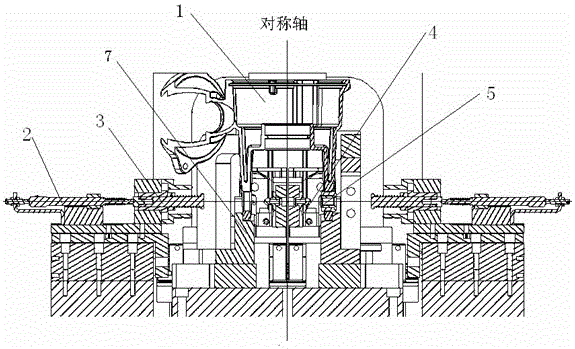

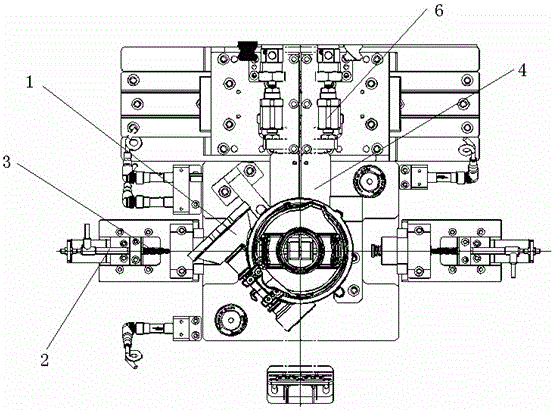

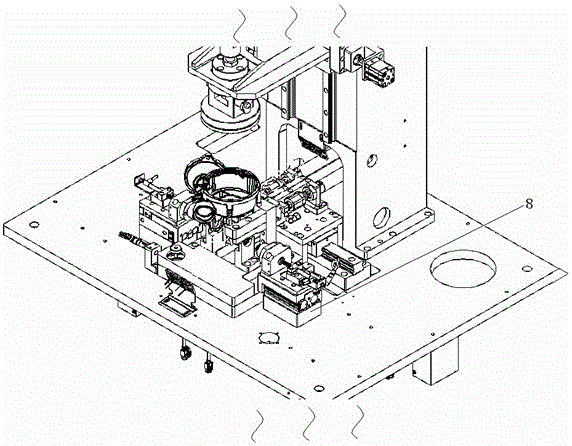

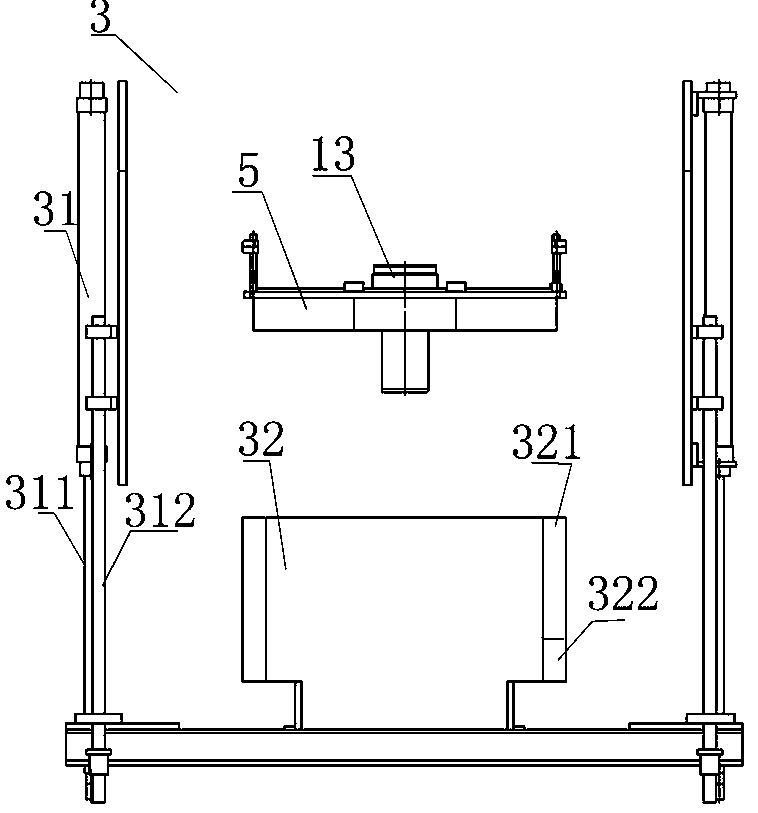

Assembly tooling for double assembly and main drive of head side plate on staircase and assembly method

ActiveCN102632382AReduce spacingLow costWelding/cutting auxillary devicesAssembly machinesAssembly lineEngineering

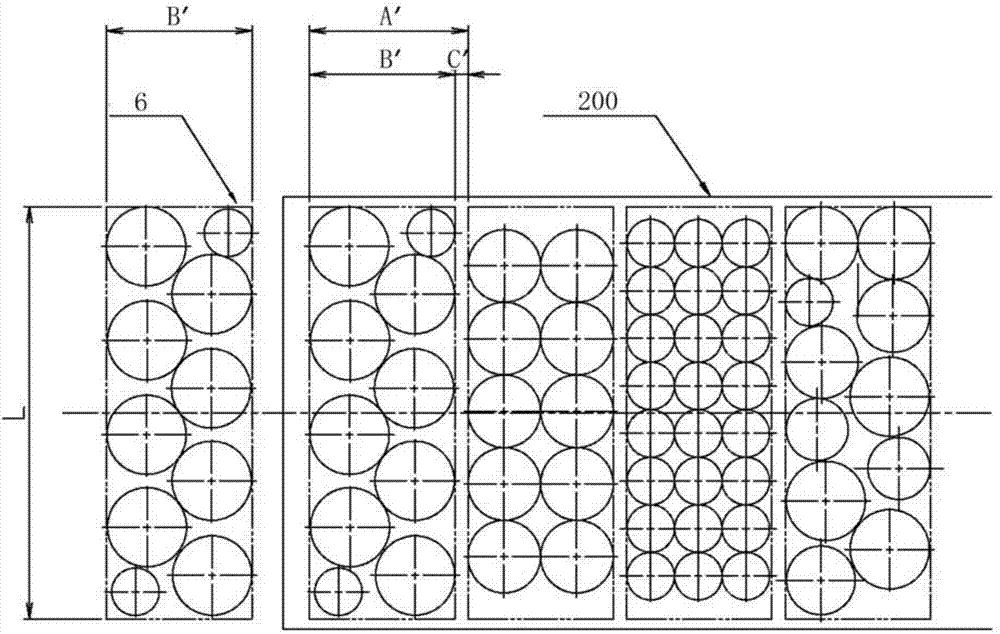

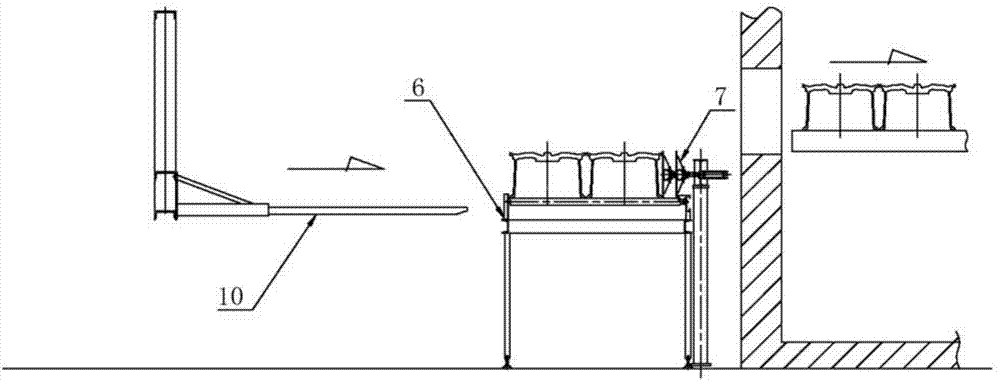

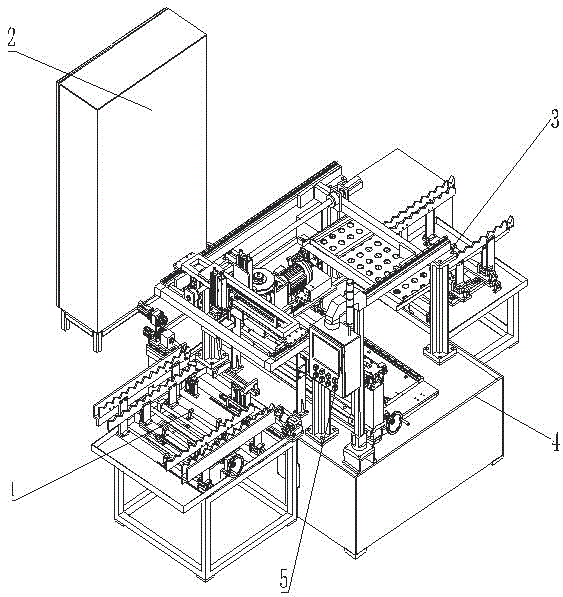

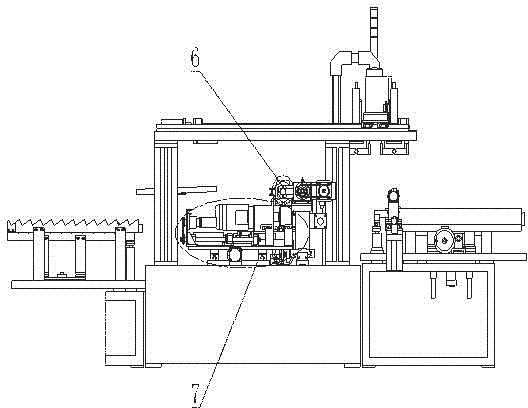

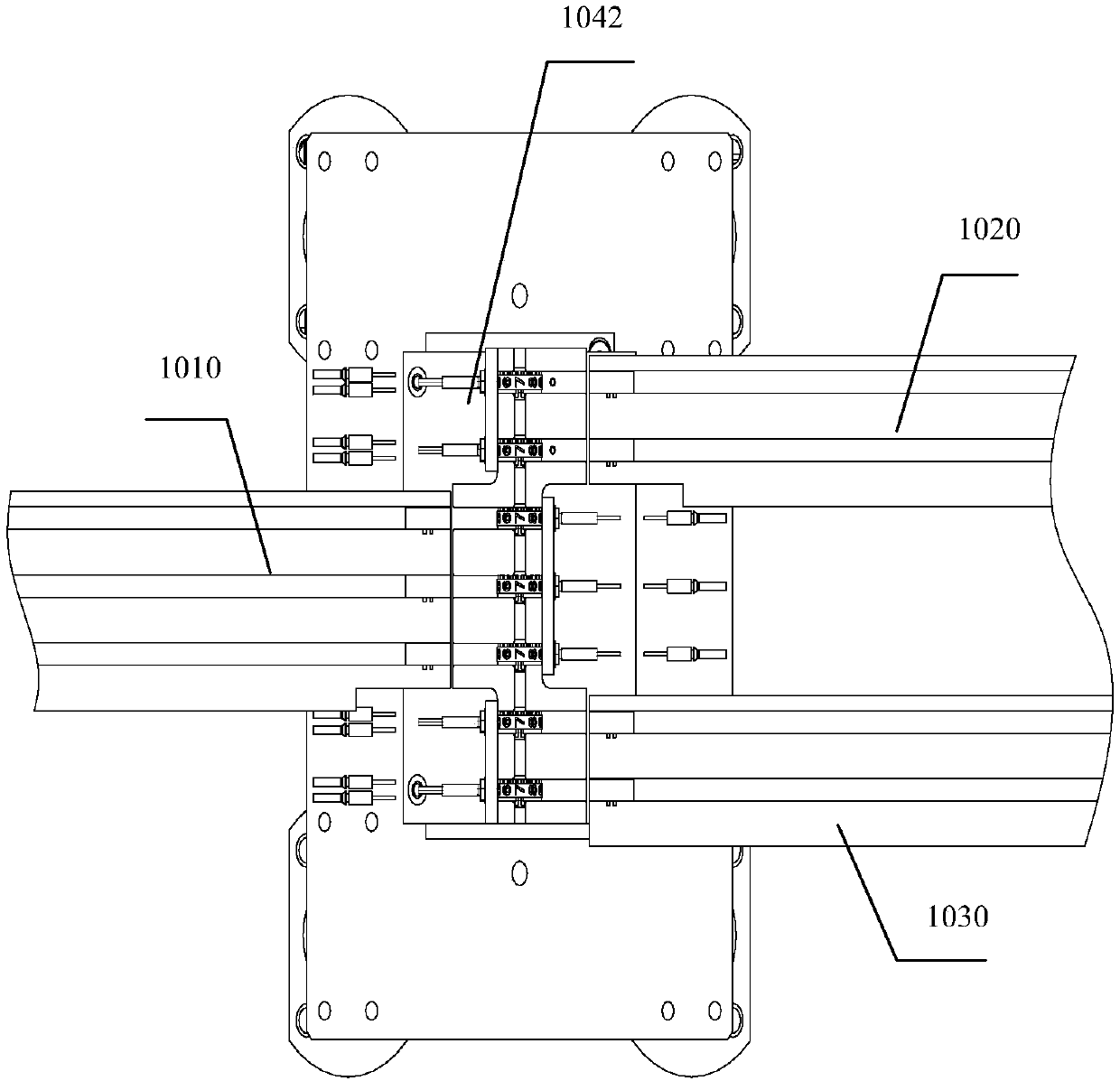

The invention discloses an assembly tooling for the double assembly and the main drive of a head side plate on a staircase and an assembly method. The tooling comprises a work platform, wherein a fixed reference beam, a beam capable of transversely moving, a main drive lengthways moving dolly are arranged on the work platform, and the two beams are in parallel with each other by moving the beam capable of transversely moving; and a positioning stand column and a positioning wall plate capable of lengthways moving the side plate of the staircase are respectively arranged on the two beams, gaps are remained between the corresponding positioning stand columns and positioning wall plates, and the corresponding positioning wall plates can respectively move along the beams, so that the distances between the corresponding positioning wall plates and the corresponding positioning stand columns are changed; a pair of tangential guide rail arranging seat transverse moving trolleys are distributed on the main drive lengthways moving dolly, and the tangential guide rail is transported to the installing position of the tangential guide rail on the side plate by the dolly; a left / right main drive height positioning device is further arranged on the main drive lengthways moving dolly, and the device is used for positioning the double assembly height position of the center and the side plate of the main drive axis; and a pair of driving axial centering devices is arranged on the main drive height positioning device.

Owner:HANGZHOU XO ELEVATOR

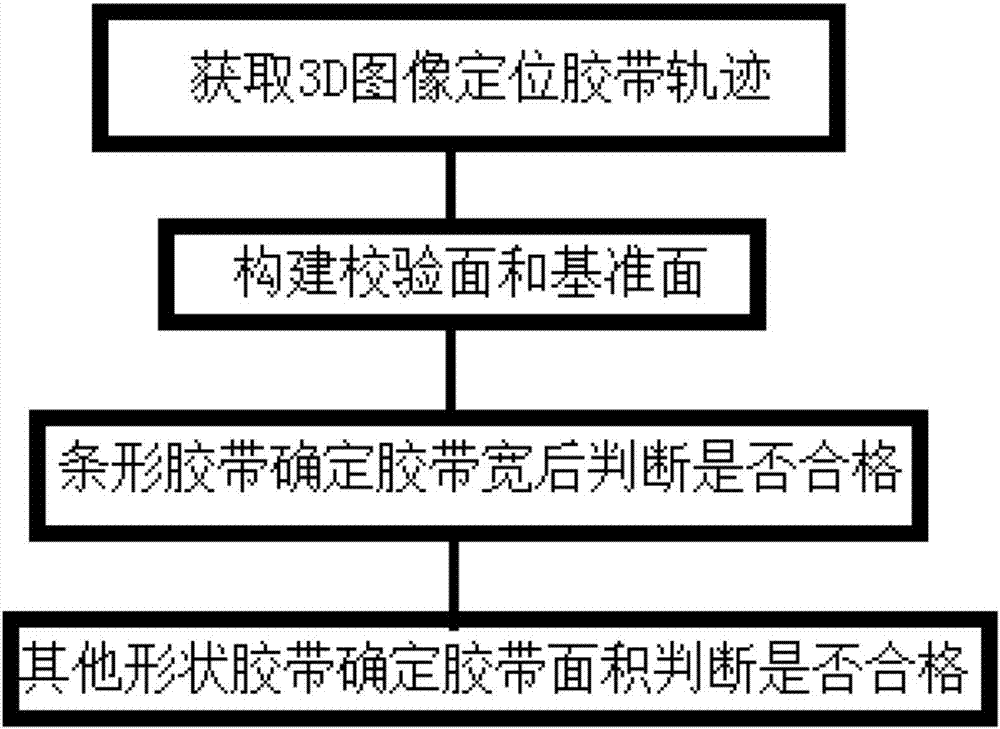

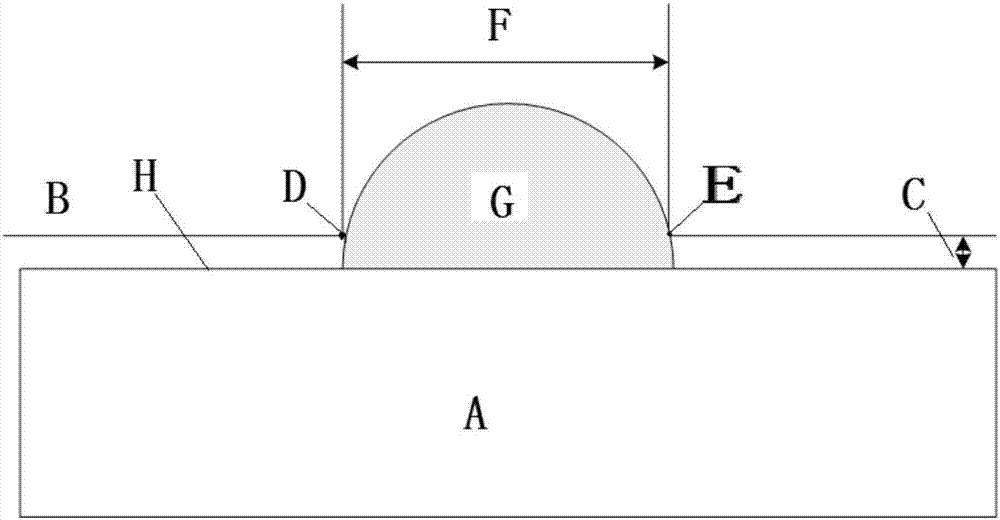

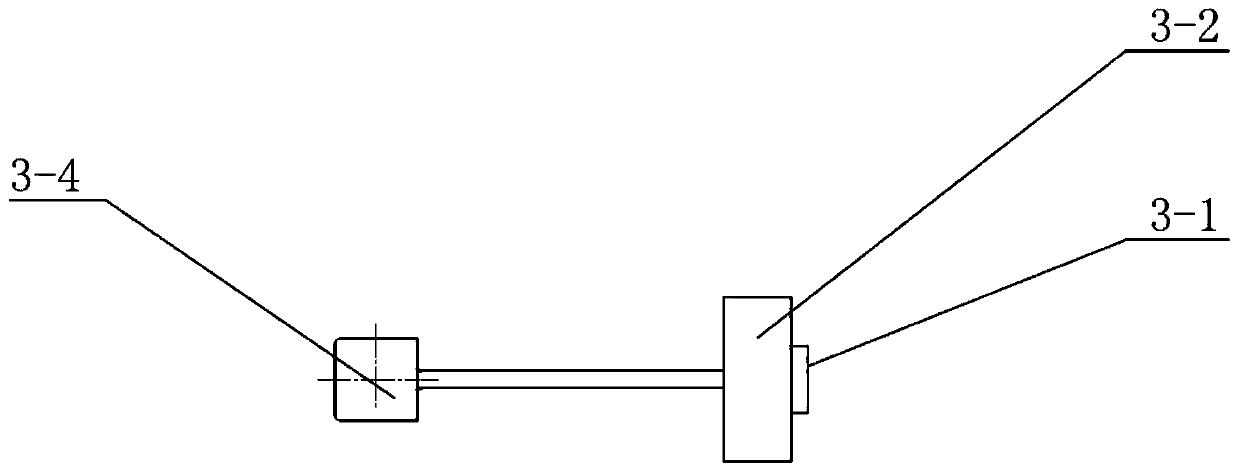

3D visual inspection system and inspection method of gluing quality

InactiveCN107883879AExtend the scan rangeMeet sizeUsing optical meansImaging processingVisual inspection

The invention discloses a 3D visual inspection system of gluing quality. The system comprises a 3D contour scanner, an image processing unit, an encoder, and a computer. The 3D contour scanner consists of an area array CCD and a straight linear laser generator. The image processing unit transmits an adhesive tape 3D image signal shot by the 3D contour scanner to the computer. The encoder fixed with the 3D contour scanner together generates a pulse and triggers the 3D contour scanner to collect an image. The computer with image processing software arranged inside the computer is able to locatean adhesive tape track, calculate the width and area of the adhesive tape, and compare the width and area of the adhesive tape with respective preset threshold values to determine whether the gluing is qualified. In addition, the invention also discloses a 3D visual inspection method of gluing quality. Compared with the prior art, the 3D visual inspection system and method have the following beneficial effects: the continuity and location of glue can be detected accurately and stably; the detection efficiency is improved; and the detection reliability is enhanced.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

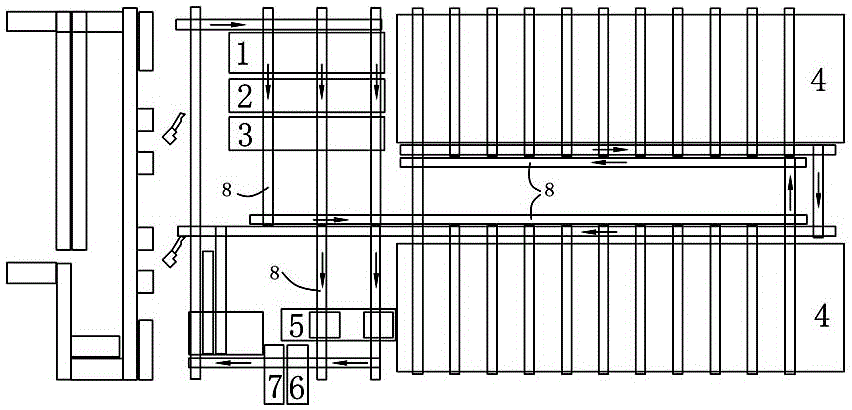

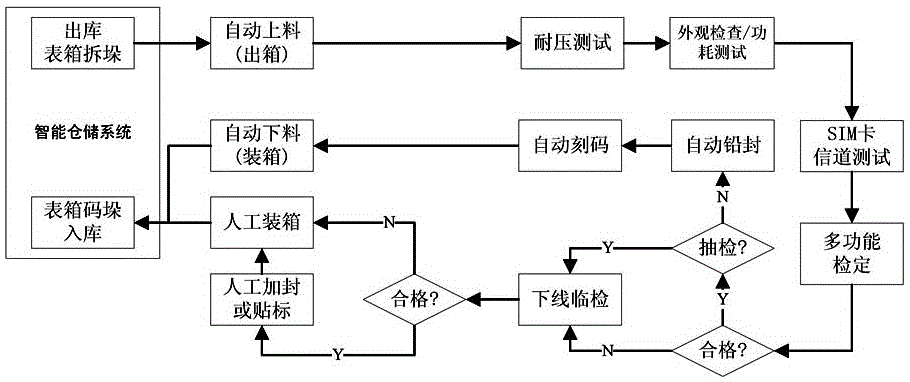

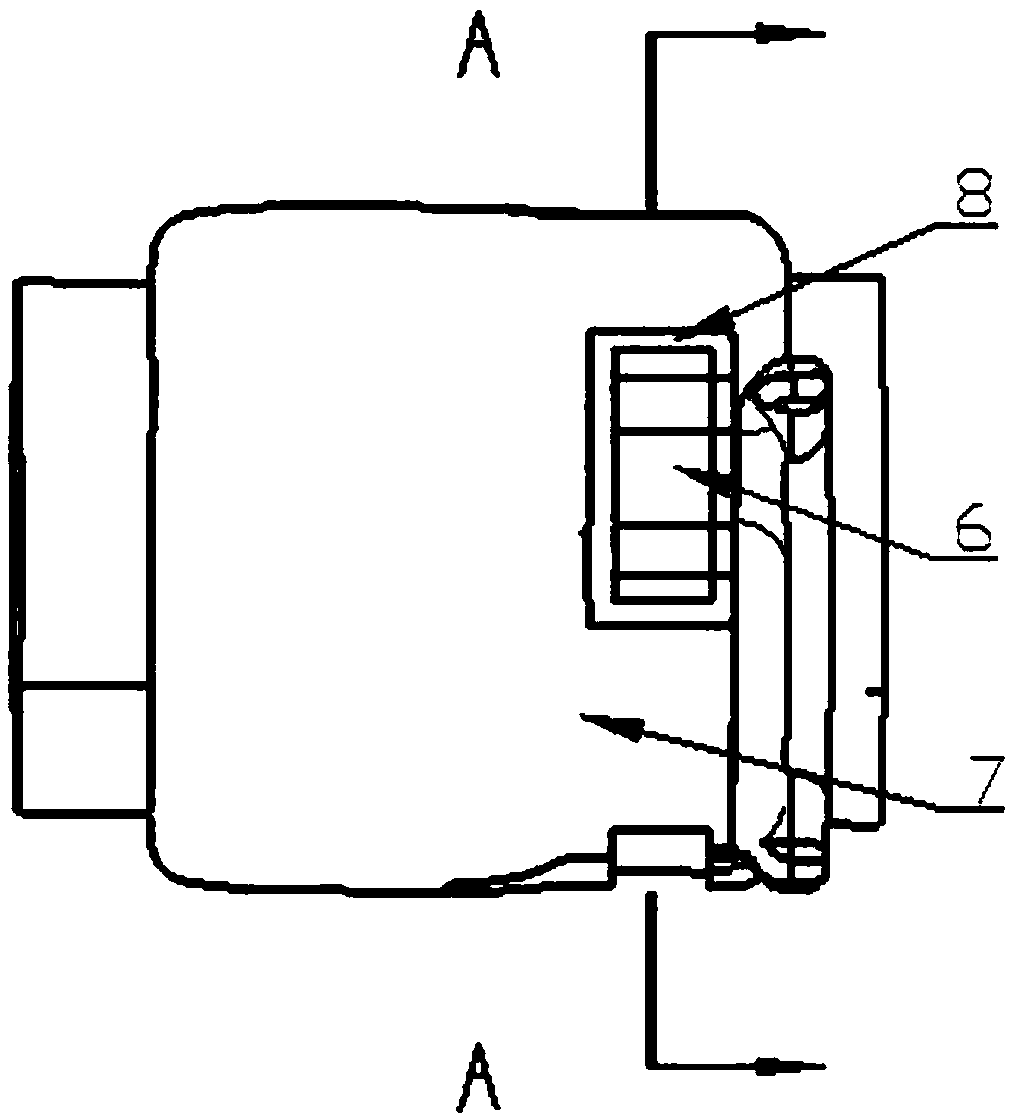

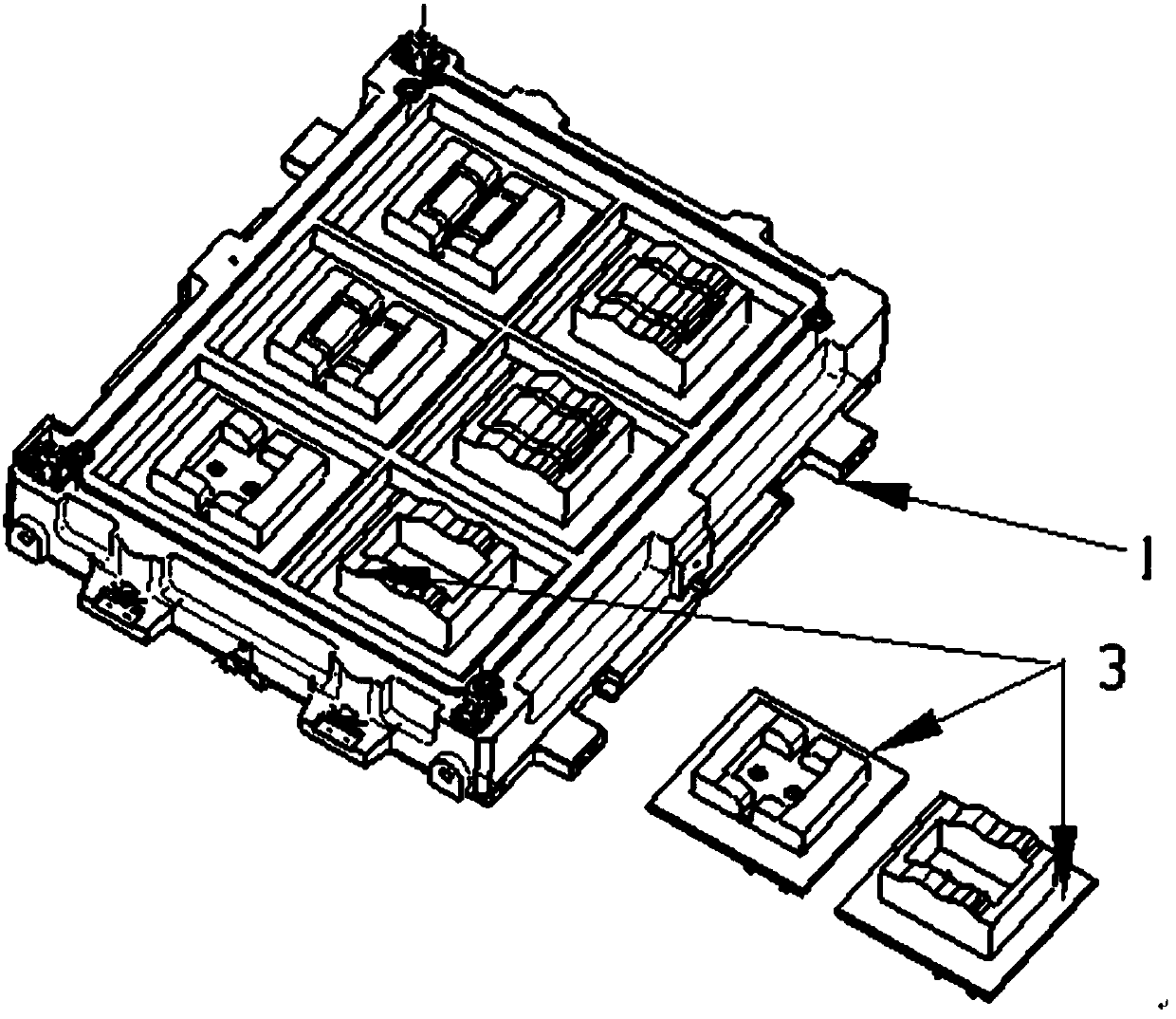

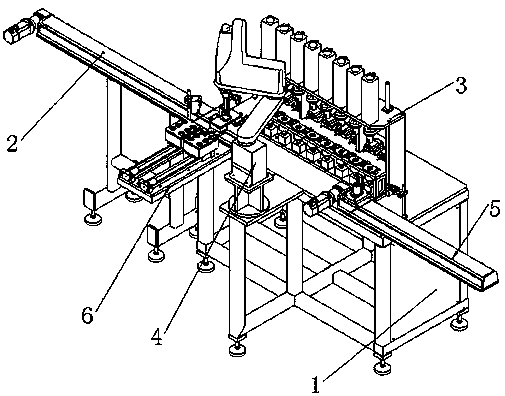

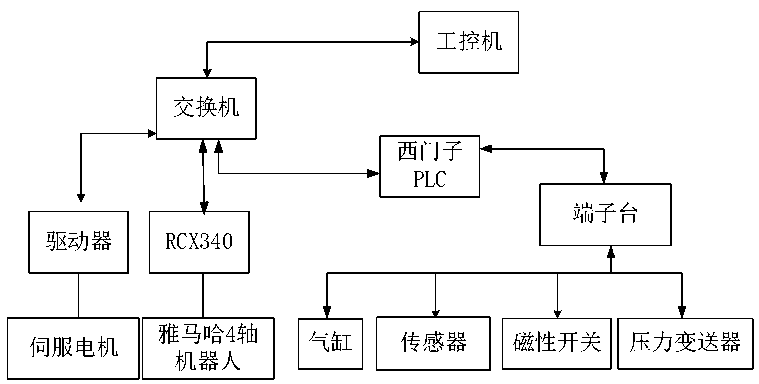

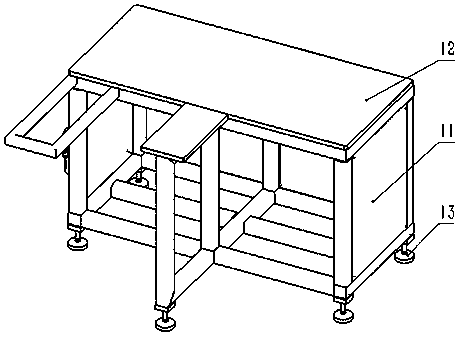

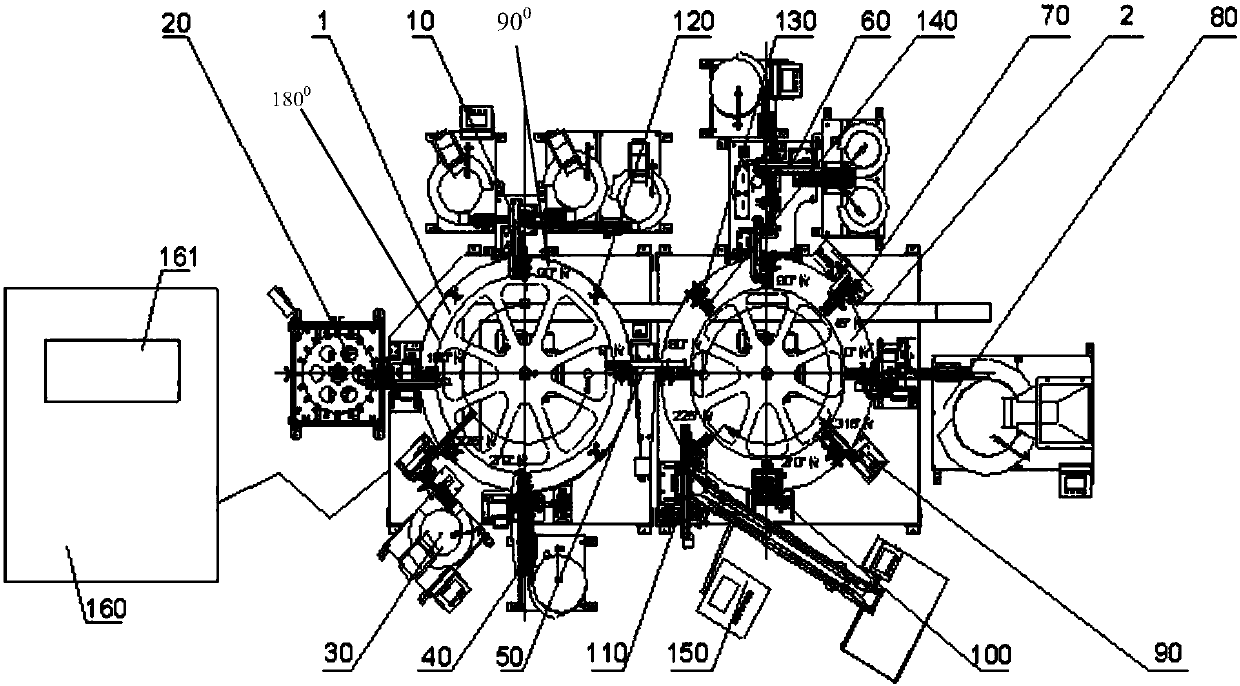

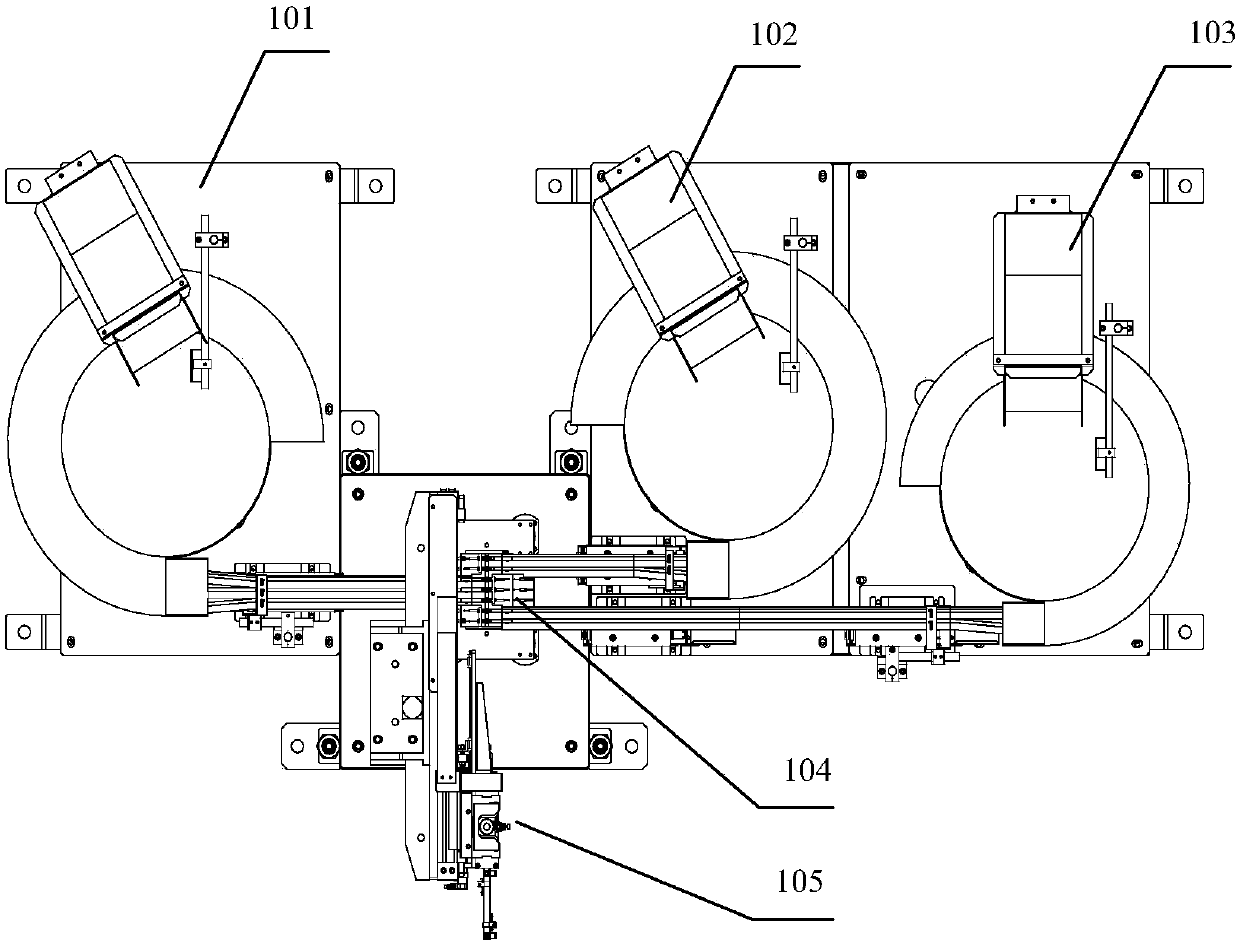

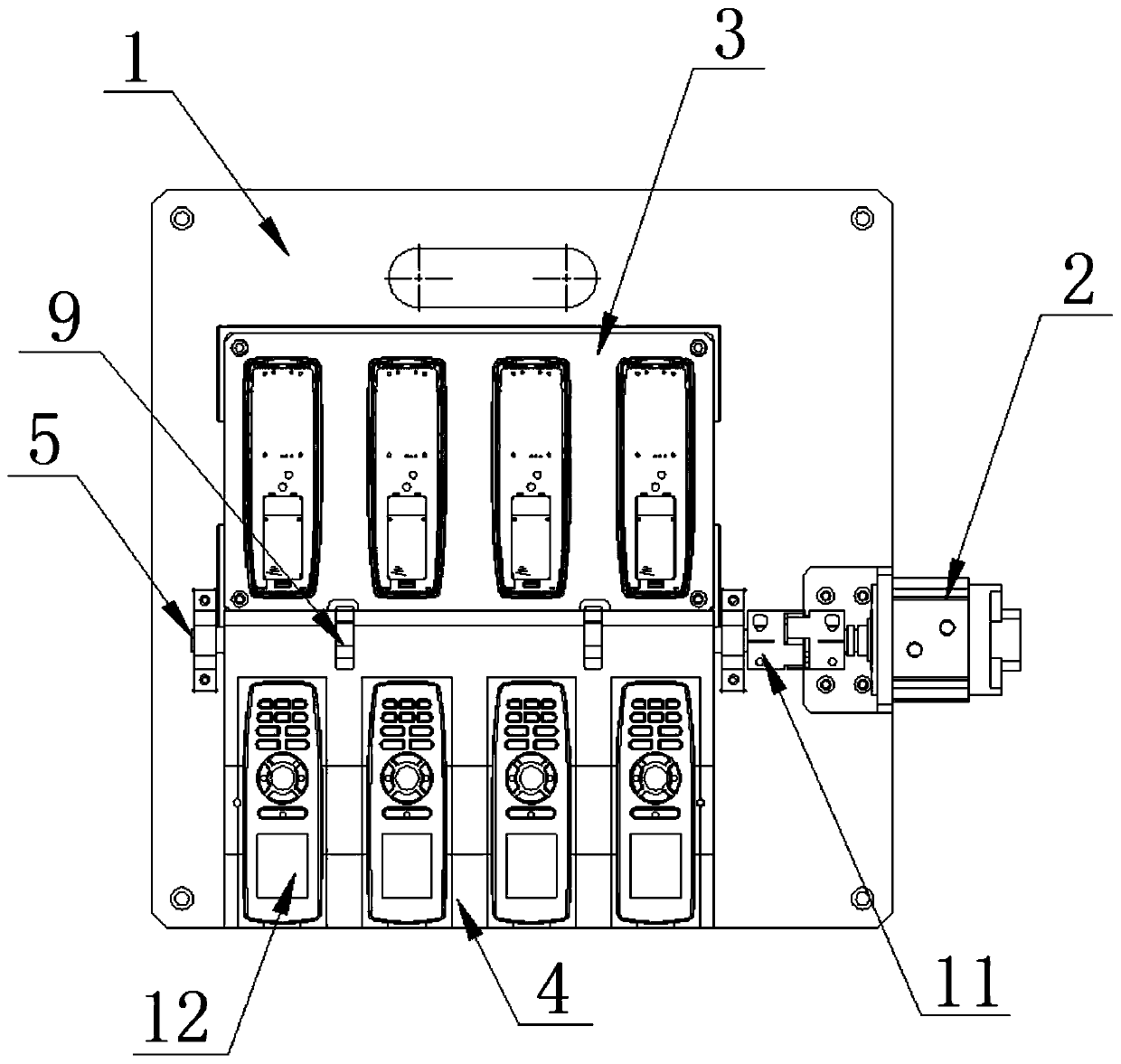

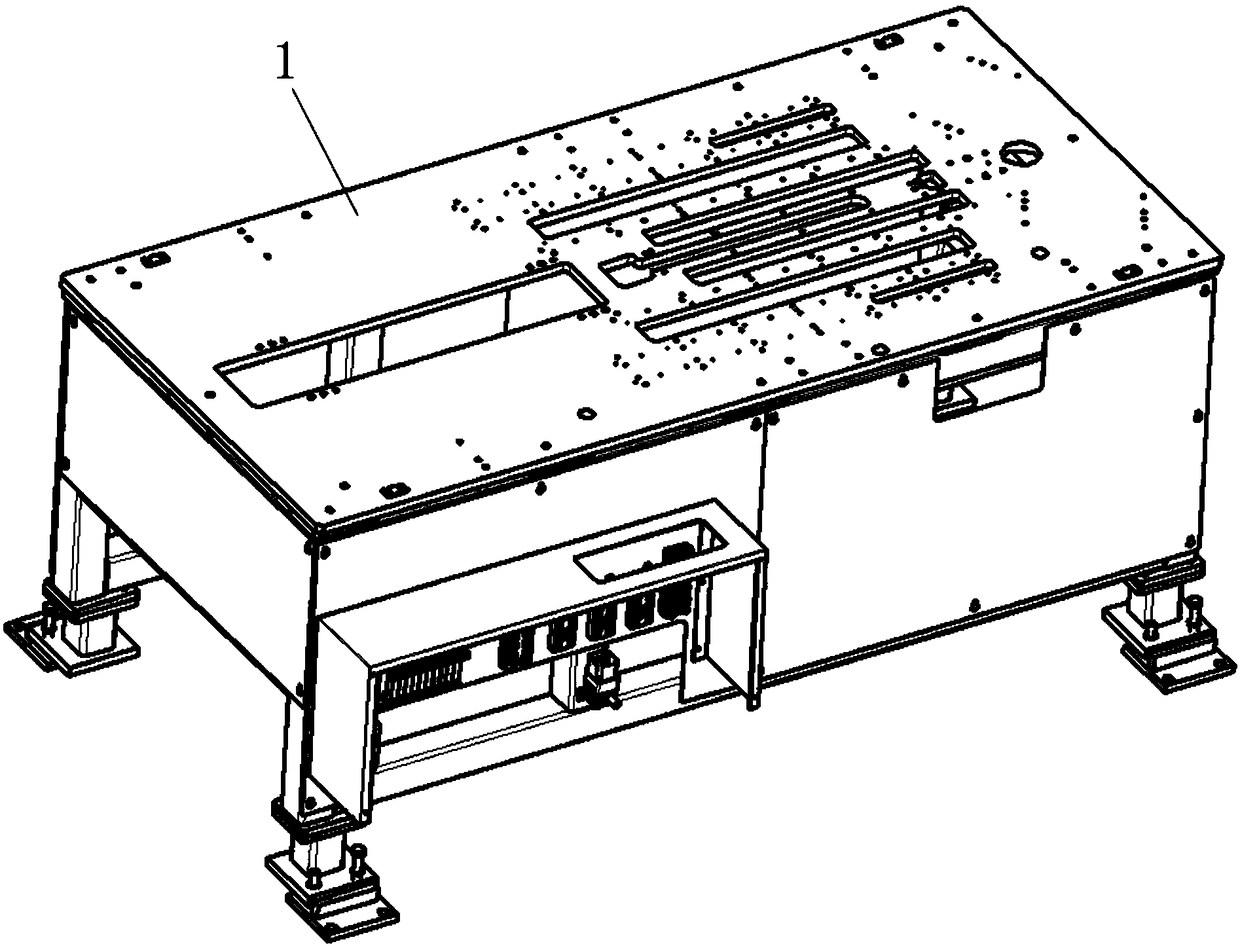

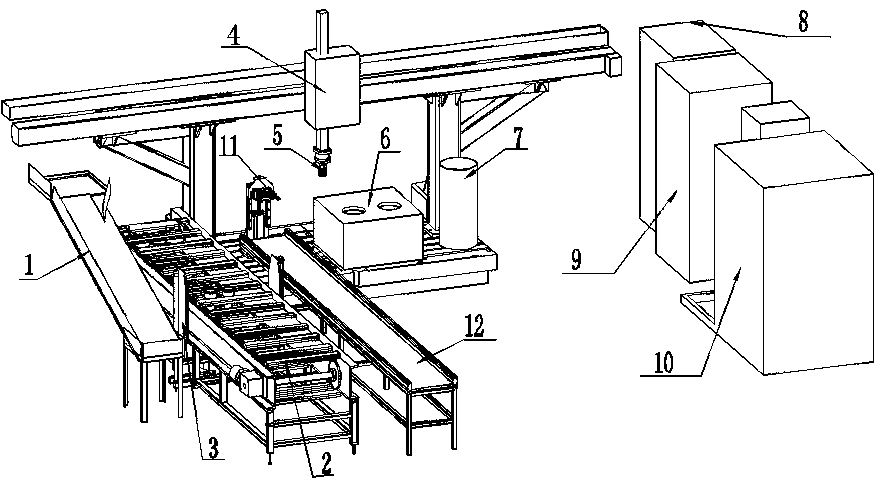

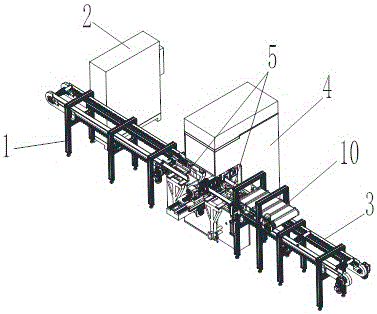

Automatic calibration assembly line for measuring instruments

ActiveCN105783971AImprove test efficiencyImprove the transfer linkElectrical measurementsLabelling machinesMeasuring instrumentProcess engineering

The invention discloses an automatic calibration assembly line for measuring instruments. The automatic calibration assembly line comprises a conveying track, a pressure resistance testing station, an appearance testing station, a power consumption testing station, a multifunctional calibration station, an automatic lead sealing station, an automatic code engraving station and an automatic labeling station, wherein the appearance testing station, the power consumption testing station, the multifunctional calibration station, the automatic lead sealing station, the automatic code engraving station and the automatic labeling station are mounted in the conveying track. The automatic lead sealing station, the automatic code engraving station and the automatic labeling station are successively arranged in the conveying direction of the conveying track. The pressure resistance testing station, the appearance testing station, the power consumption testing station and the multifunctional calibration station are mounted in front of the automatic lead sealing station. The numbers of detecting positions on the pressure resistance testing station, the appearance testing station, the power consumption testing station, the multifunctional calibration station, the automatic lead sealing station, the automatic code engraving station and the automatic labeling stations are 3N, 3N, 3N, 22N, 2N, 1N and 1N, wherein the N is a natural number. The automatic calibration assembly line for the measuring instruments has advantages of reasonable layout, small occupation area, high calibration efficiency, etc.

Owner:STATE GRID CORP OF CHINA +2

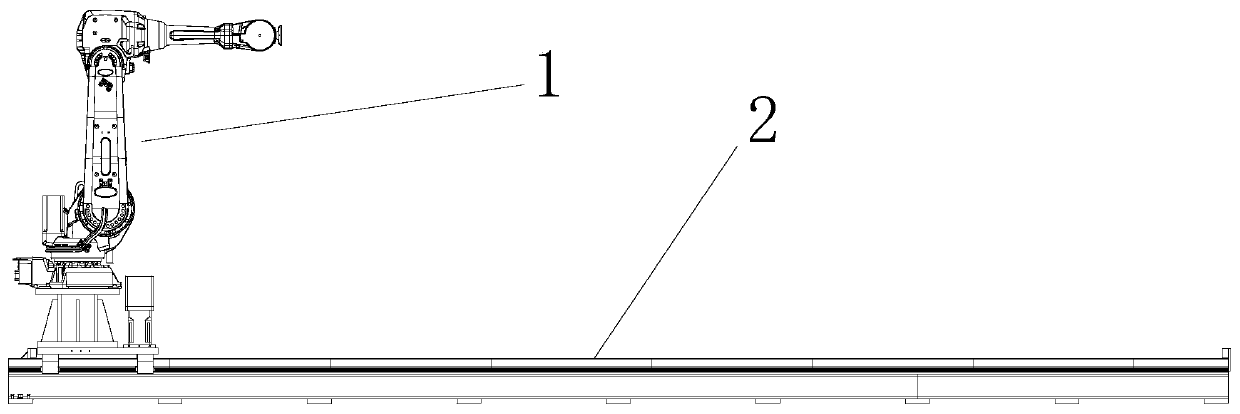

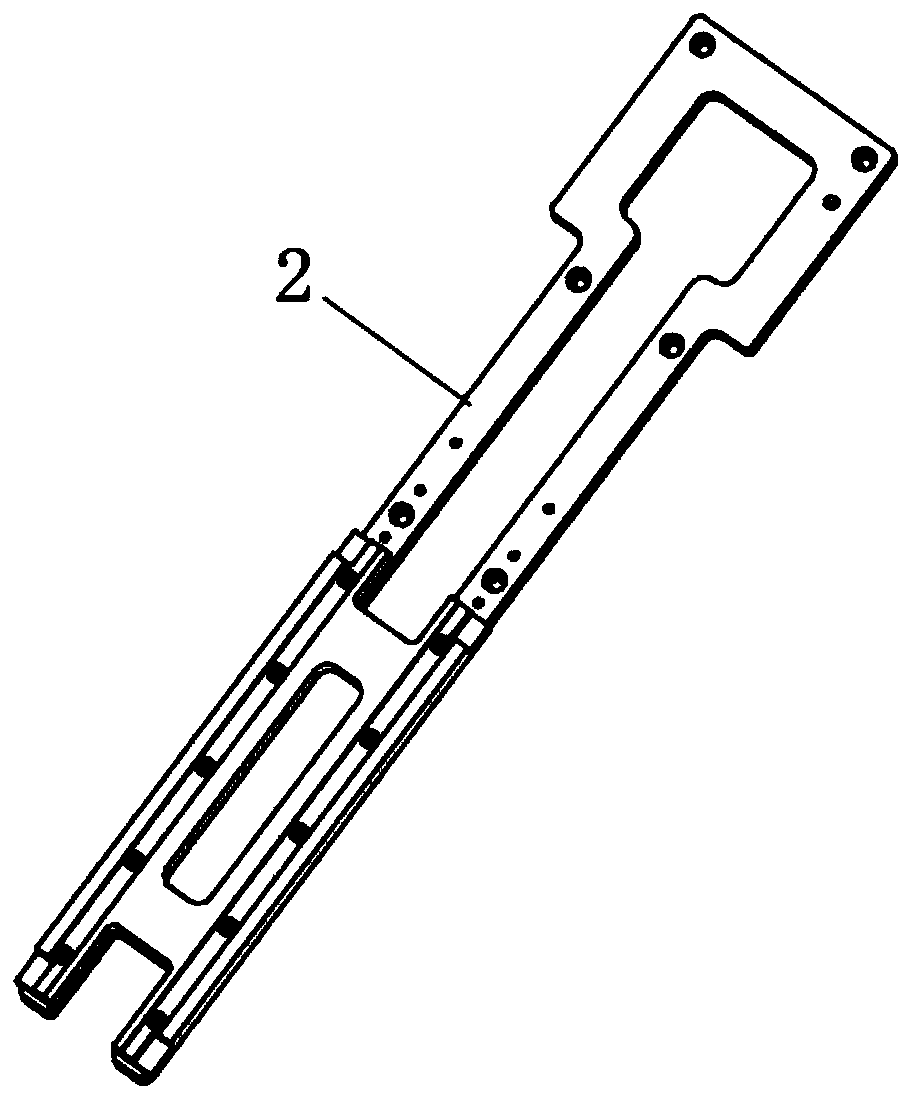

Automatic production line of planetary gears and method

InactiveCN110757171AGuaranteed machining accuracyGuarantee processing qualityOther manufacturing equipments/toolsMetal working apparatusNumerical controlProduction line

The invention discloses an automatic production line of planetary gears and a method. The automatic production line comprises a numerically-controlled lathe, a gear hobbing machine, a chamfering machine, a temporary storage platform, a cleaning machine and a robot. The robot is arranged on one guide rail and can move along the arranged guide rail; one side of the robot is provided with the numerically-controlled lathe, the temporary storage platform and the gear hobbing machine; the numerically-controlled lathe conducts rough turning and finish turning on blanks; the temporary storage platformis used for putting the blanks machined by the numerically-controlled lathe, and the gear hobbing machine conducts gear hobbing on the blanks to obtain semi-finished products; the end of the robot isprovided with the chamfering machine, and the chamfering machine conducts chamfering on the semi-finished products; the other side of the robot is provided with a detection platform, a cleaning device and a first feeding line; the detection platform is used for detecting the quality of finished products, the cleaning device cleans the qualified planetary gears, and the first feeding line is usedfor conveying the blanks.

Owner:青岛默森智能科技有限公司

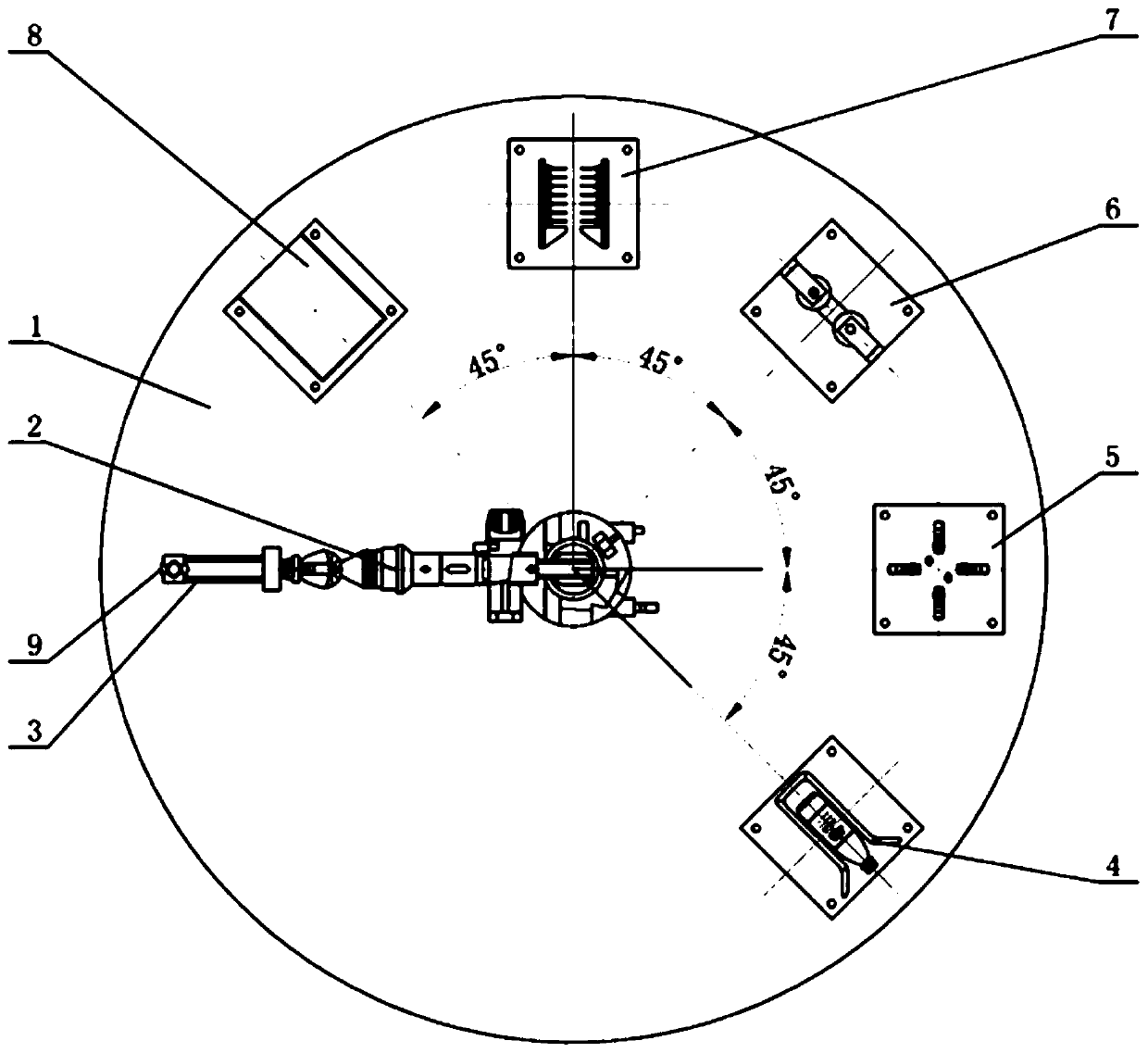

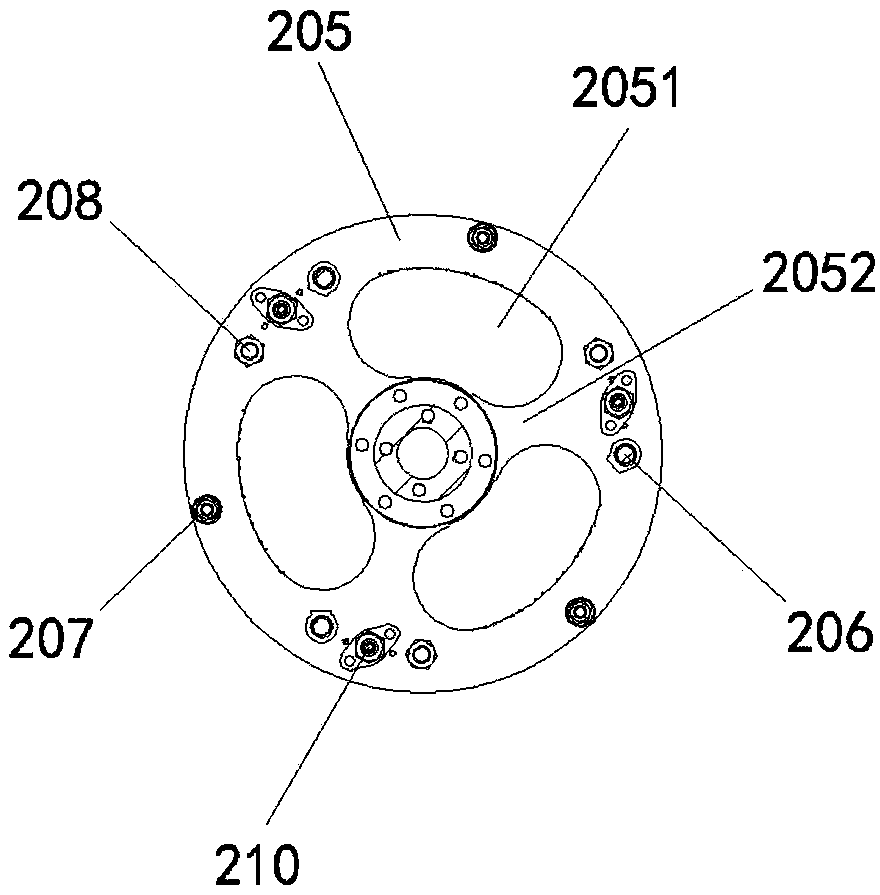

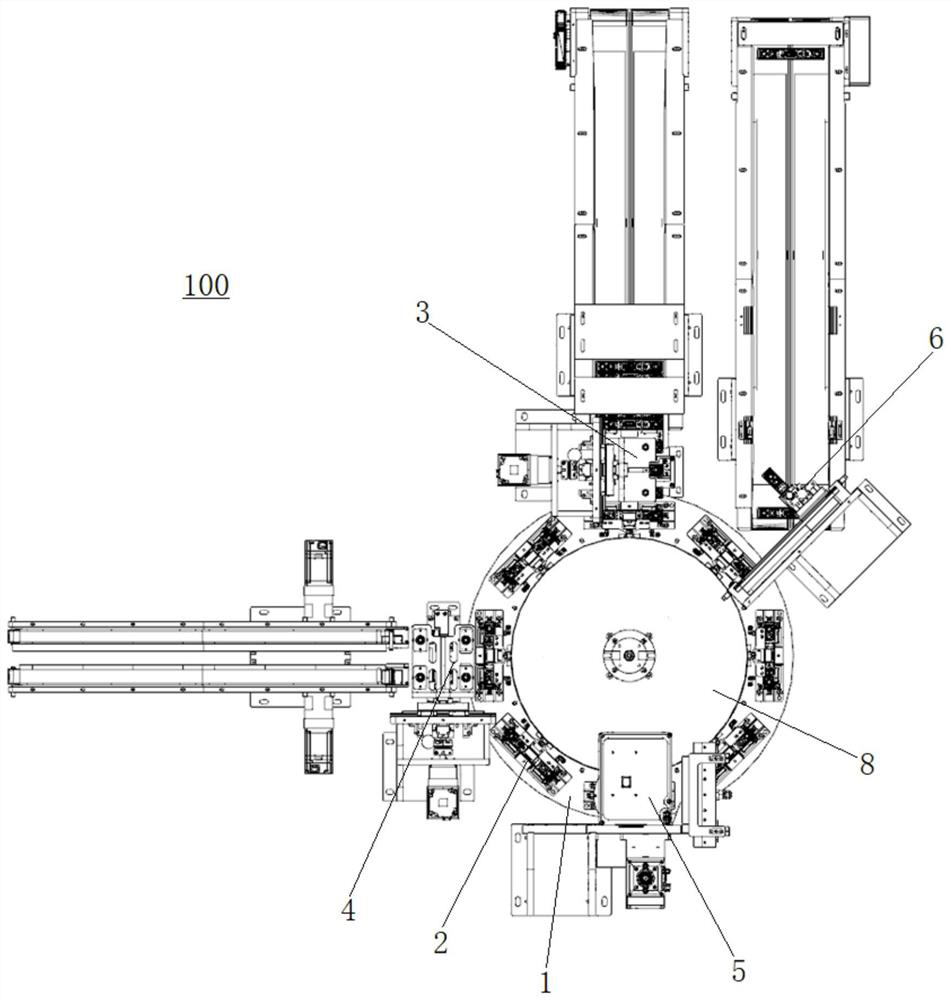

Intelligent flexible automatic assembly system for drill bit assembly

The invention discloses an intelligent flexible automatic assembly system for a drill bit assembly. The intelligent flexible automatic assembly system for the drill bit assembly comprises a rotating disc mechanism, a plurality of fitting assemblies, a robot system and a controller, wherein the rotating disc mechanism is arranged to rotate at the action of rotating at a preset angle for each time,a preset time is stopped between every two adjacent rotating actions, the sum of the angles of all the rotating actions is 360 degrees, a plurality of jig assemblies are arranged on the rotating discmechanism, and a preset angle is formed between every two adjacent jig assemblies; every two adjacent fitting assemblies are arranged at a position close to the circumferential direction of the rotating disc mechanism at a preset angle, and the fitting assemblies are aligned with the jig assemblies after the rotary disc mechanism completes one rotation action; the robot system is one of the multiple fitting assemblies, and a feeding mechanism and a discharging mechanism are arranged on the two sides of the robot system respectively; and the controller is electrically connected with the rotating disc mechanism, the robot system and the multiple fitting assemblies respectively. The intelligent flexible automatic assembly system for the drill bit assembly is suitable for various assembling processes, can improve the assembling efficiency of the parts and can expand the application range of assembling parts of equipment.

Owner:INST OF INTELLIGENT MFG TECH JITRI

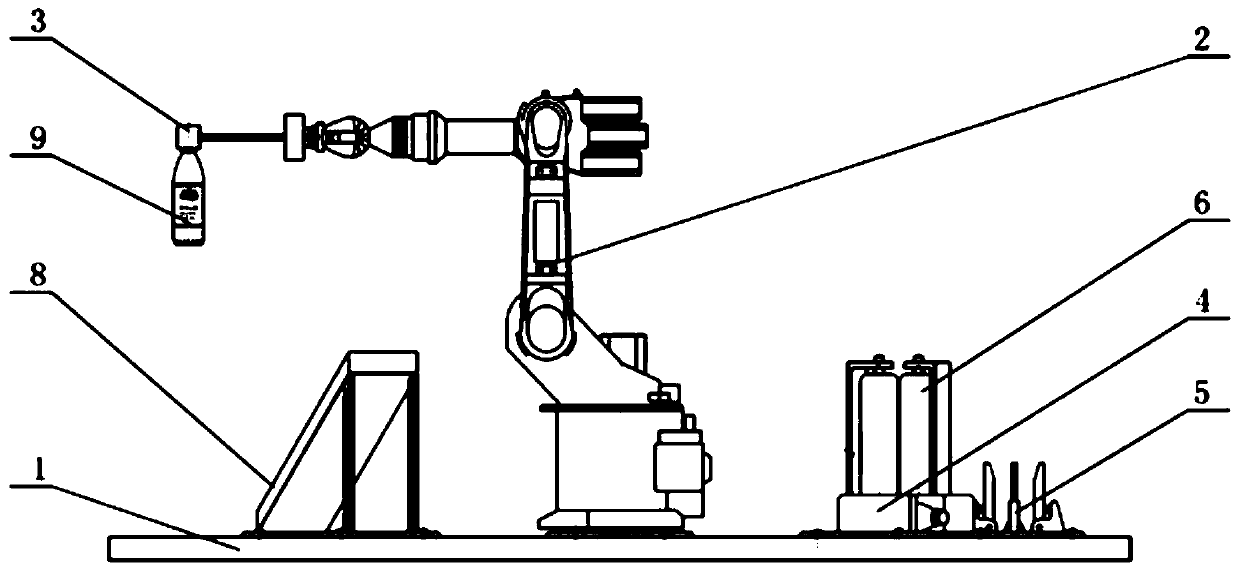

Intelligent industrial robot device for recycling waste plastic bottle

InactiveCN110355901AAccurate removalUnmanned operationPlastic recyclingHollow article cleaningBottle capSix degrees of freedom

The invention discloses an intelligent industrial robot device for recycling a waste plastic bottle. A machine arm is arranged on a base and fixed on the base; a plastic bottle clamping jaw is arranged at the front end of the upper part of the machine arm; a plastic bottle is arranged between two clamping jaw bodies of the plastic bottle clamping jaw; a waiting station clamp is arranged on the upper right part of the base; a bottle cap removing station clamp is arranged on the right part of the base; a flattening station clamp is arranged on the upper right part of the base; a trademark removing station clamp is arranged on the upper part of the base; and a blanking station clamp is arranged on the upper left part of the base. According to the intelligent industrial robot device for recycling the waste plastic bottle, by adopting the mechanical arm and the special clamps, the full-automatic grabbing, overturning, unscrewing of a bottle cap, discharging of residual liquid in the bottle,scraping of a trademark and other actions of the waste plastic bottle can be realized, the recycling efficiency is obviously improved, the labor intensity is reduced, and the flexibility and adaptability of the plastic bottle recycling device are improved by using the six-degree-of-freedom mechanical arm.

Owner:刘亦晴

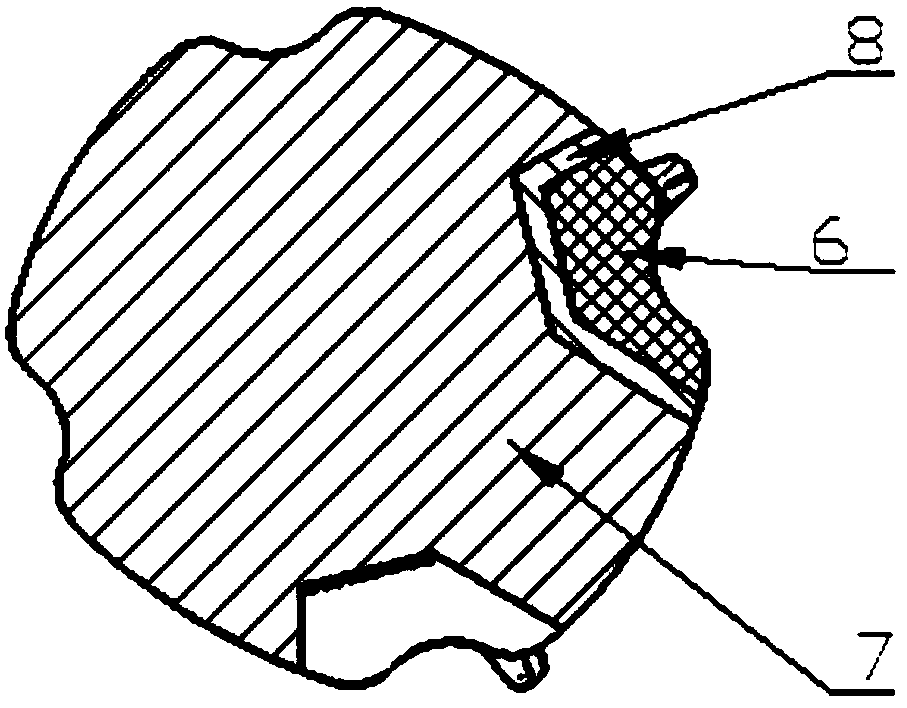

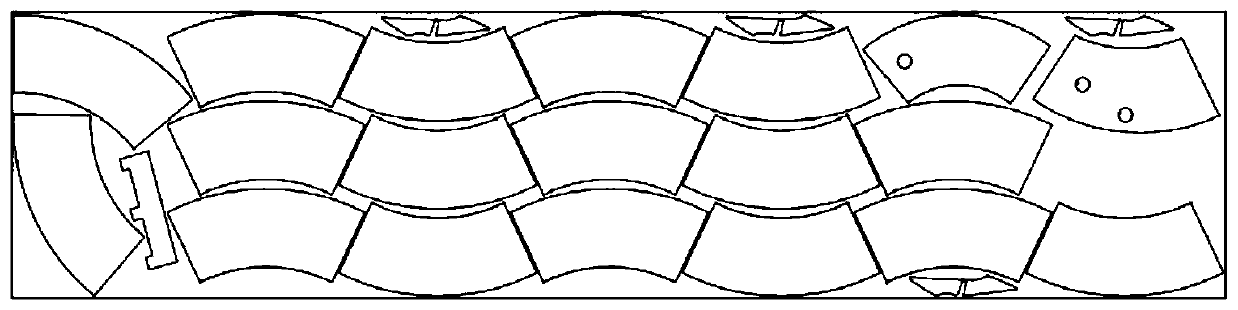

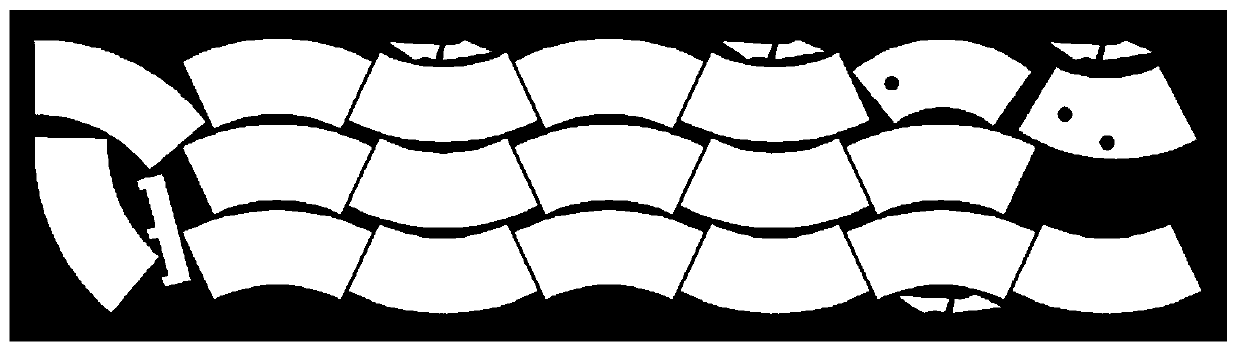

Sand core and core shooting universal mold for cold box and manufacturing method thereof

ActiveCN107745087ASolve productivitySolve efficiency problemsAdditive manufacturing apparatusFoundry mouldsMaterials scienceProcess engineering

Owner:四川共享铸造有限公司

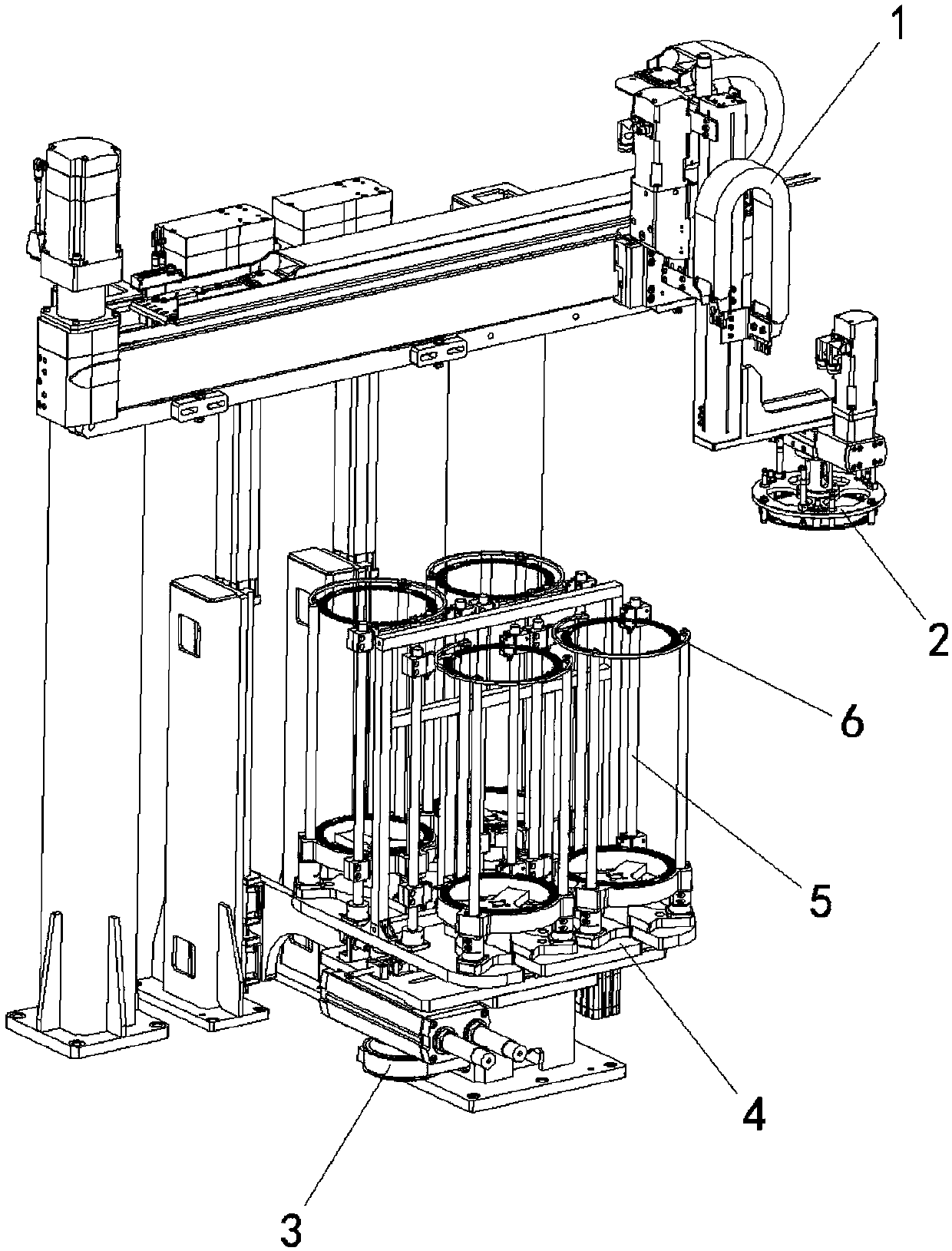

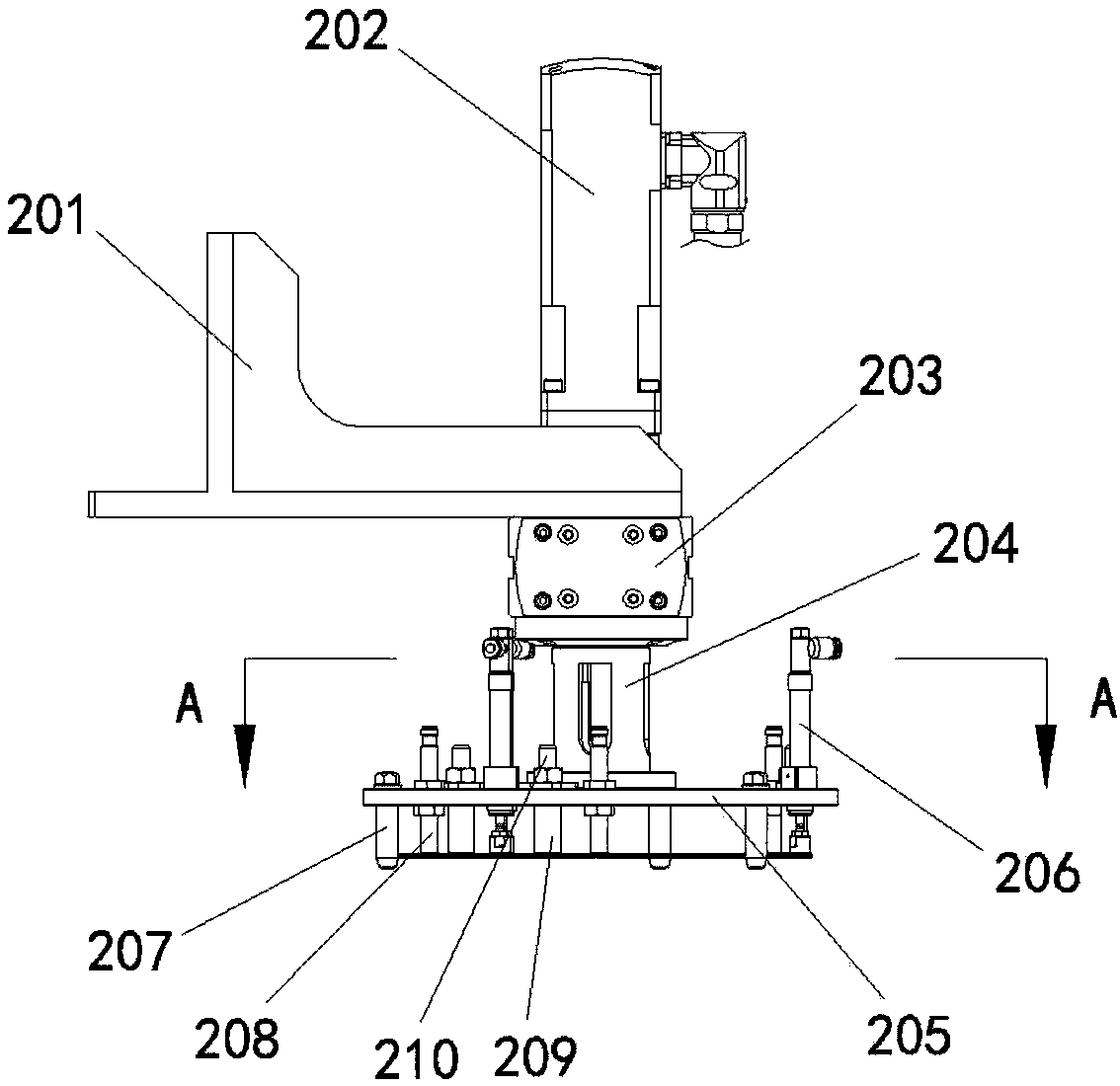

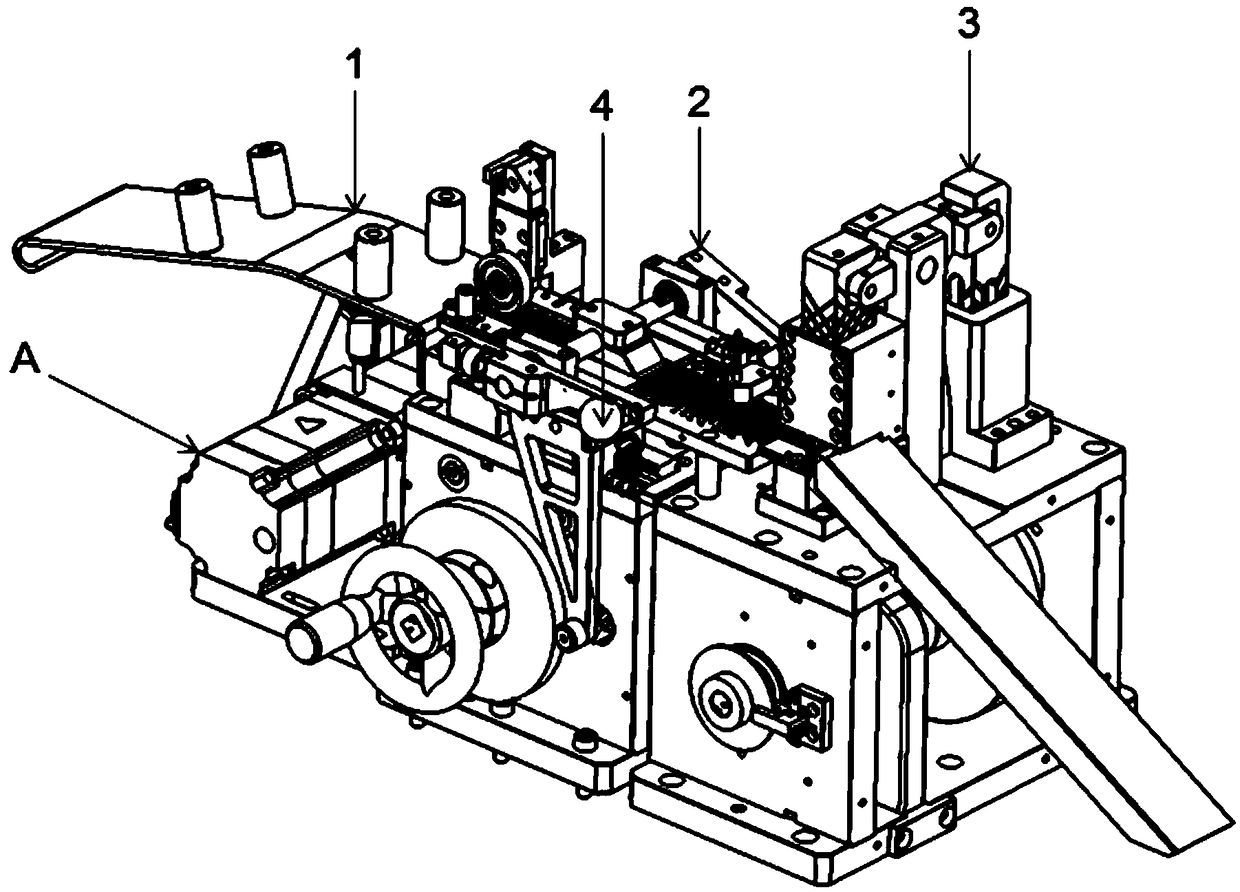

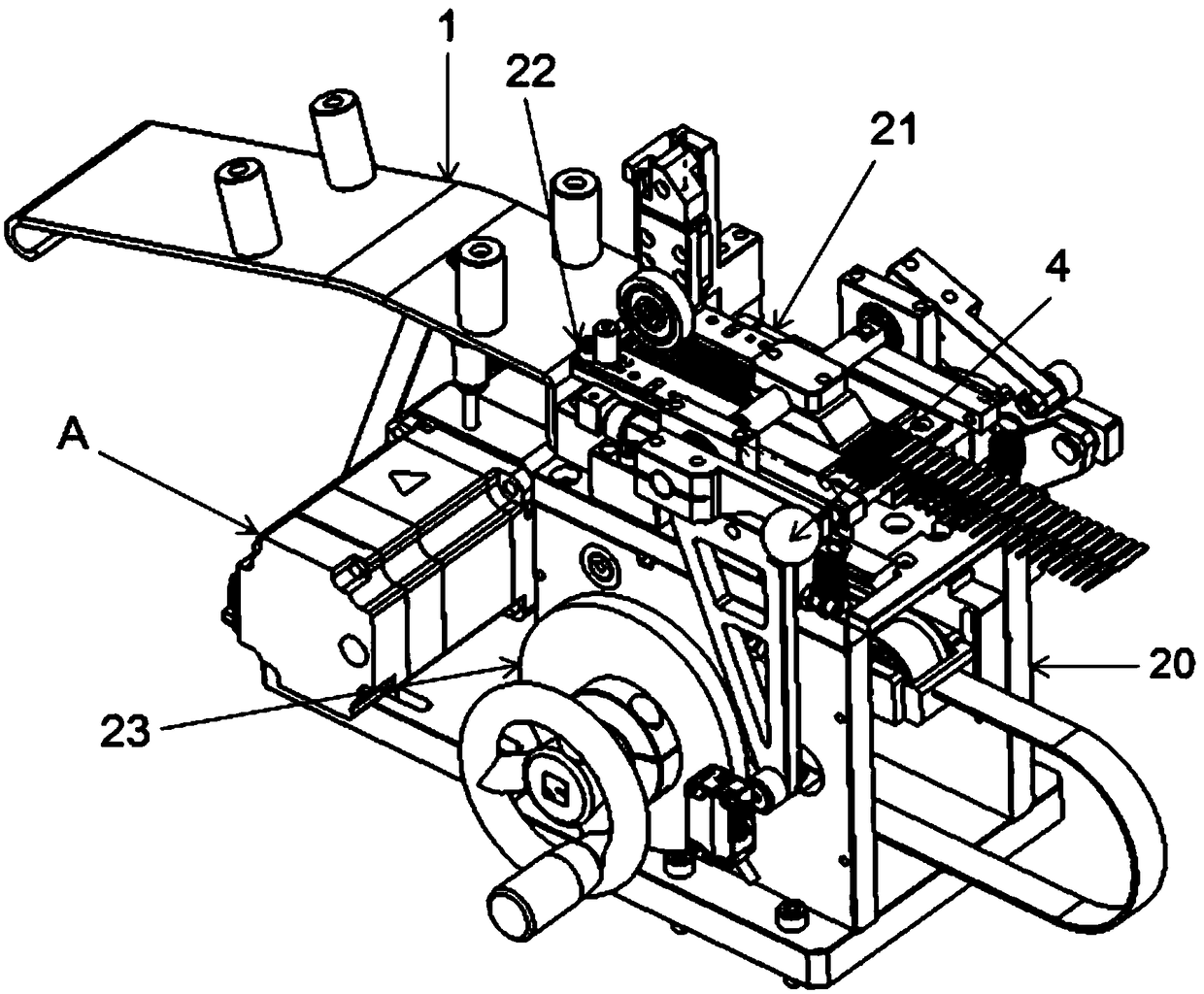

Automatic feeding and grabbing device for sheet-type parts with rough surfaces

ActiveCN107803833AAchieve adsorptionRealize handlingProgramme-controlled manipulatorGripping headsRough surfaceRotary stage

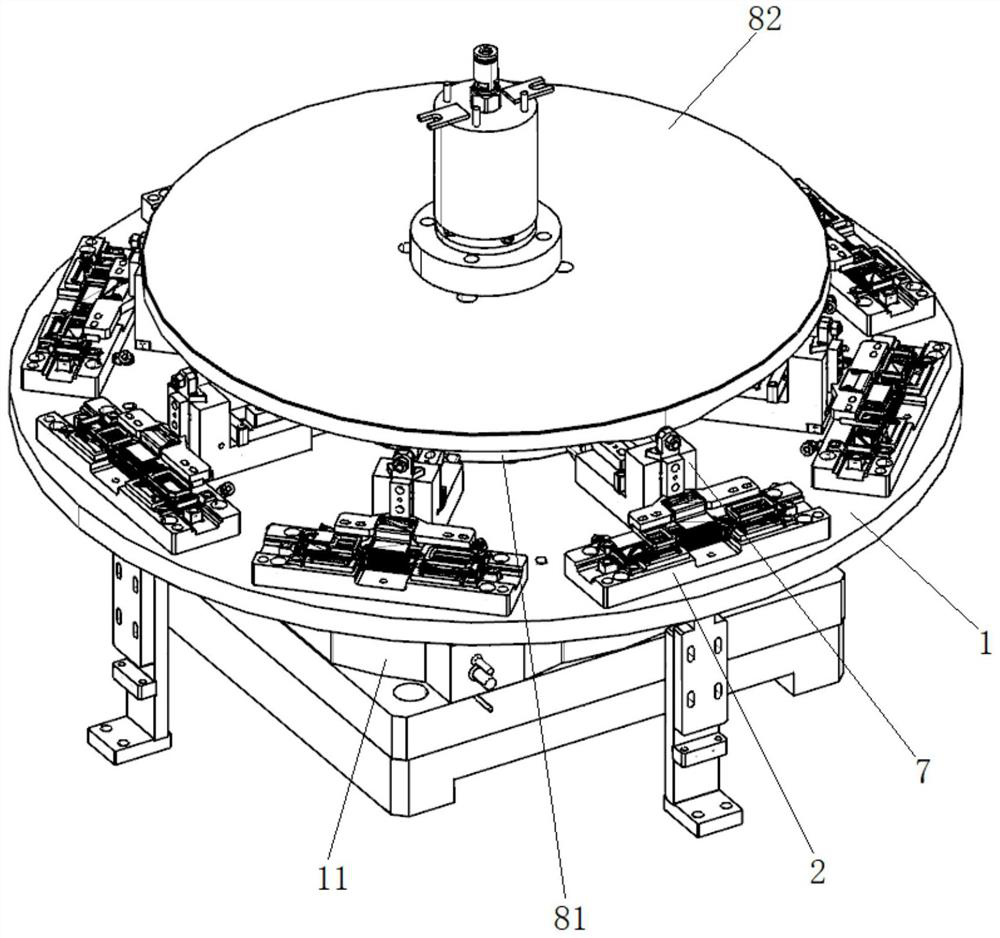

The invention discloses an automatic feeding and grabbing device for sheet-type parts with rough surfaces and relates to the technical field of feeding and grabbing devices. The automatic feeding andgrabbing device comprises a grabbing mechanism for grabbing the sheet-type parts with the rough surfaces, a manipulator for driving the grabbing mechanism to move, material barrel mechanisms for storing the sheet-type parts with the rough surfaces, a rotary table mechanism for being connected with the material barrel mechanisms and driving the material barrel mechanisms to rotate, and a stepping mechanism for pushing the sheet-type parts with the rough surfaces in a stepping mode. According to the automatic feeding and grabbing device for the sheet-type parts with the rough surfaces, automaticstepping feeding and grabbing of the sheet-type parts with the rough surfaces are integrated, alternate stacking work of double-clutch friction pieces and steel pieces can be achieved only through combined work of the multiple sets of devices, beats are saved, and the work efficiency is high; and through the manipulator and a swing driver, X-and-Y direction moving and Z-direction rotating are achieved, the position of the grabbing mechanism is adjusted at three degrees of freedom, the positioning accuracy is high, adsorbing, grabbing and carrying of the sheet-type parts with the rough surfaces can be achieved, and grabbing is firm and reliable.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

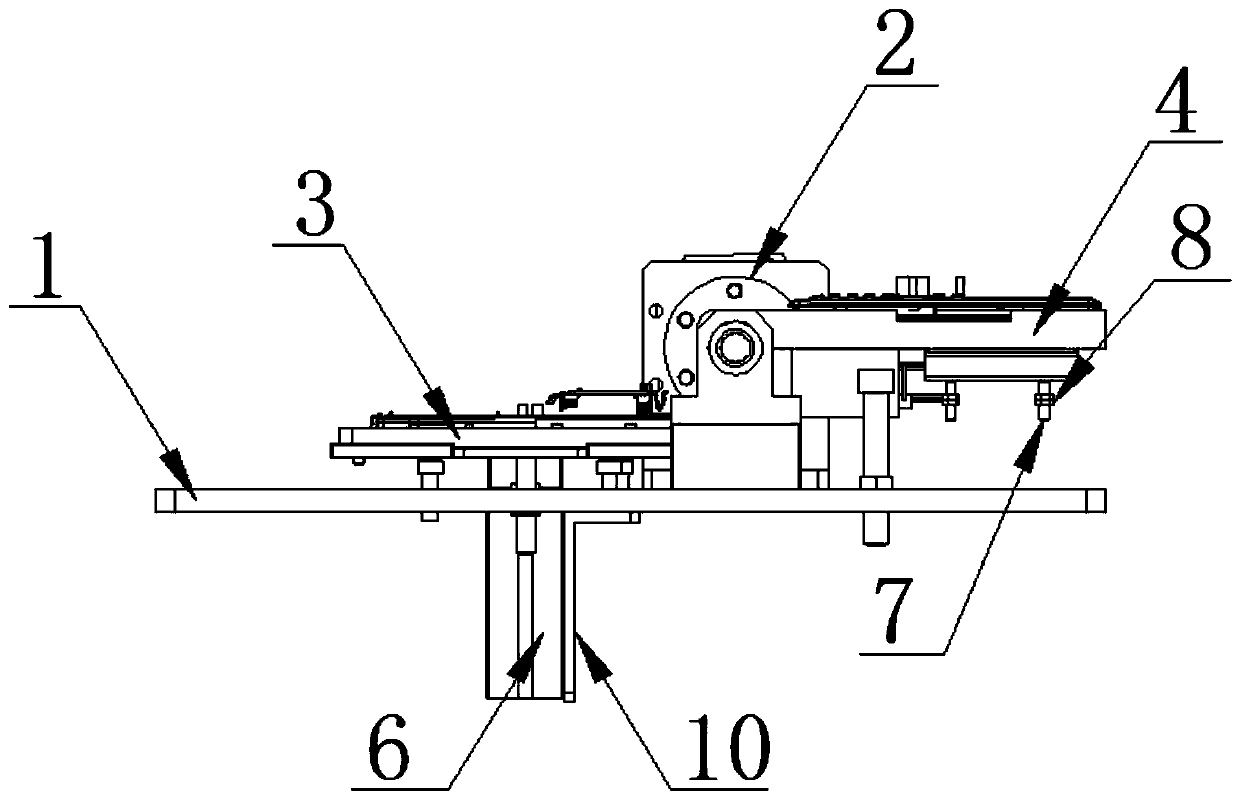

Manual folding method and folding device for air bag

ActiveCN101973241ASimple structureEasy to operatePedestrian/occupant safety arrangementEngineeringOperational maintenance

The invention discloses a manual folding method for an air bag, which comprises the following steps of: longitudinally folding the horizontal spread air bag at one time; overlapping the left air bag twice along the central line for folding, overlapping the right air bag for folding, and dividing the air bag folded into an oblong into an upper piece and a lower piece along the longitudinal direction, wherein the longitudinal length of the upper piece is lower than that of the lower piece; winding the air bag upper piece folded in the third step for two circles to form a first air bag reel, andplacing the first air bag reel beside a gas generator in a shell; winding the air bag lower piece folded in the third step for two circles to form a second air bag reel; and placing the second air bag reel above the first air bag reel and the gas generator in the shell. A manual folding device for the air bag comprises a frame body, a guide rail, a main folding mechanism, a left folding mechanism, a right folding mechanism, a locking block, a positioning piece and a folding ruler; the main folding mechanism can move linearly front and back along the guide rail; and the left folding mechanism and the right folding mechanism can move linearly left and right along the guide rail. The move linearly has the advantages of simple structure, small floor area, light weight and convenience for operation and maintenance.

Owner:FAWER AUTOMOTIVE PARTS +1

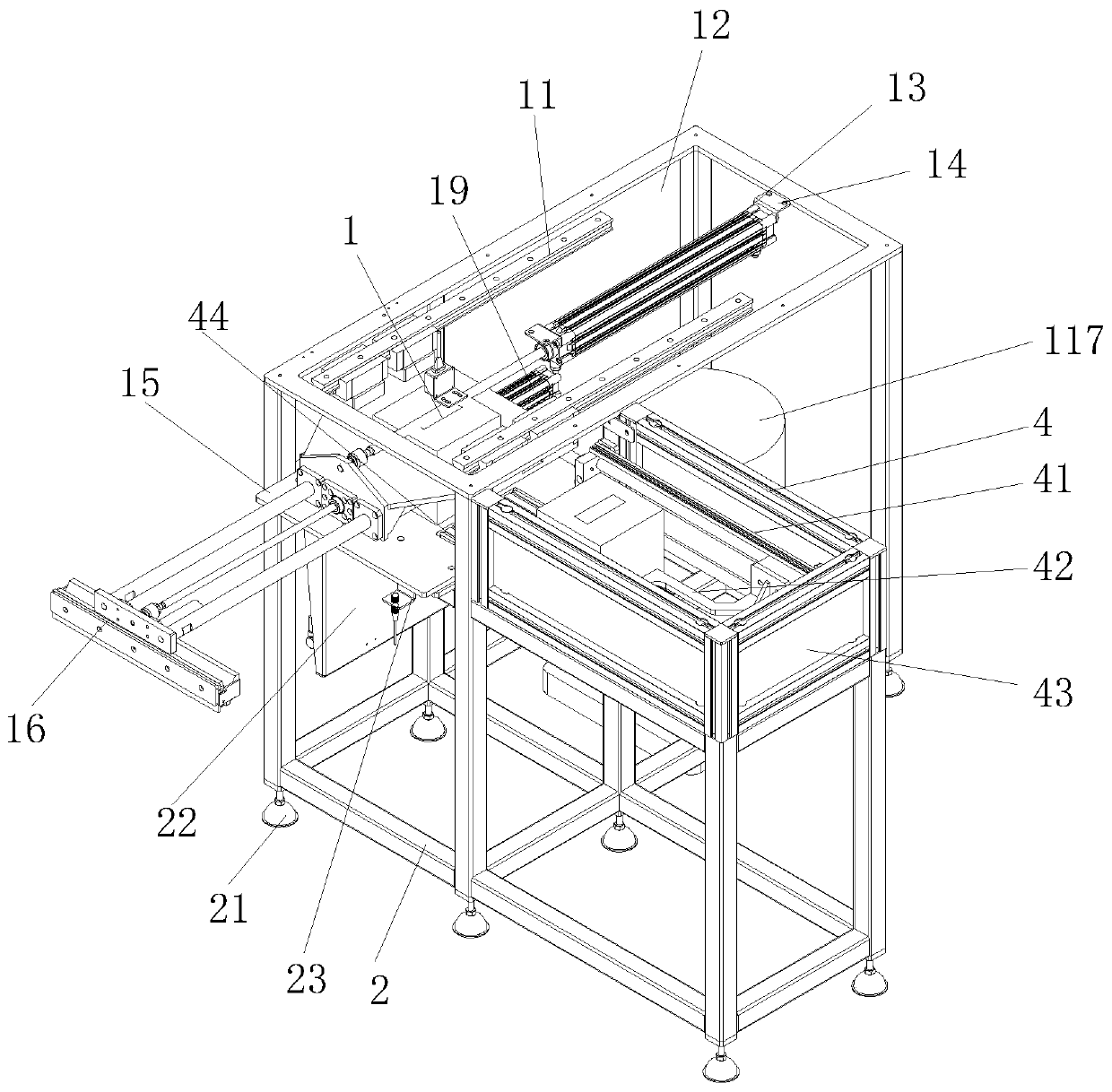

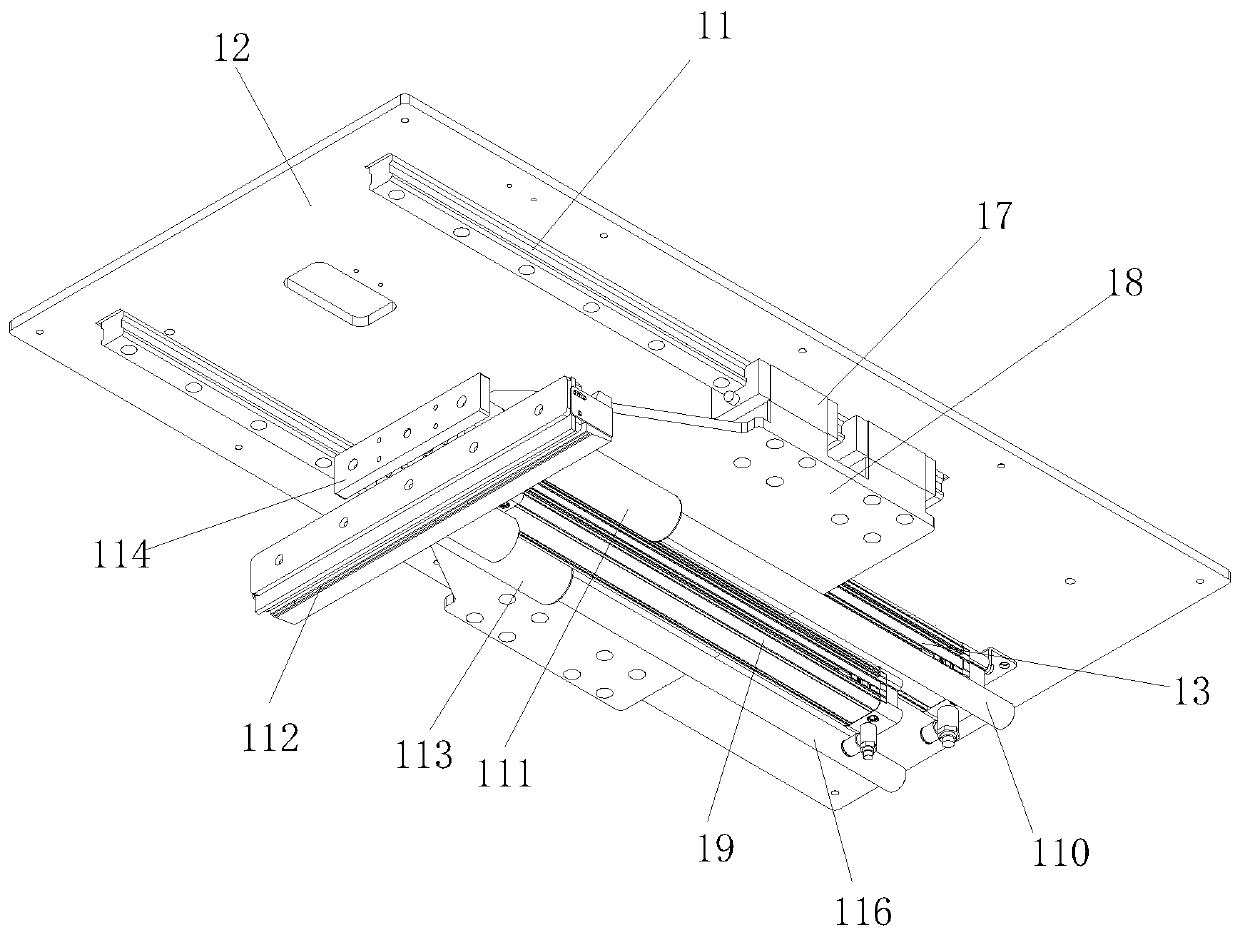

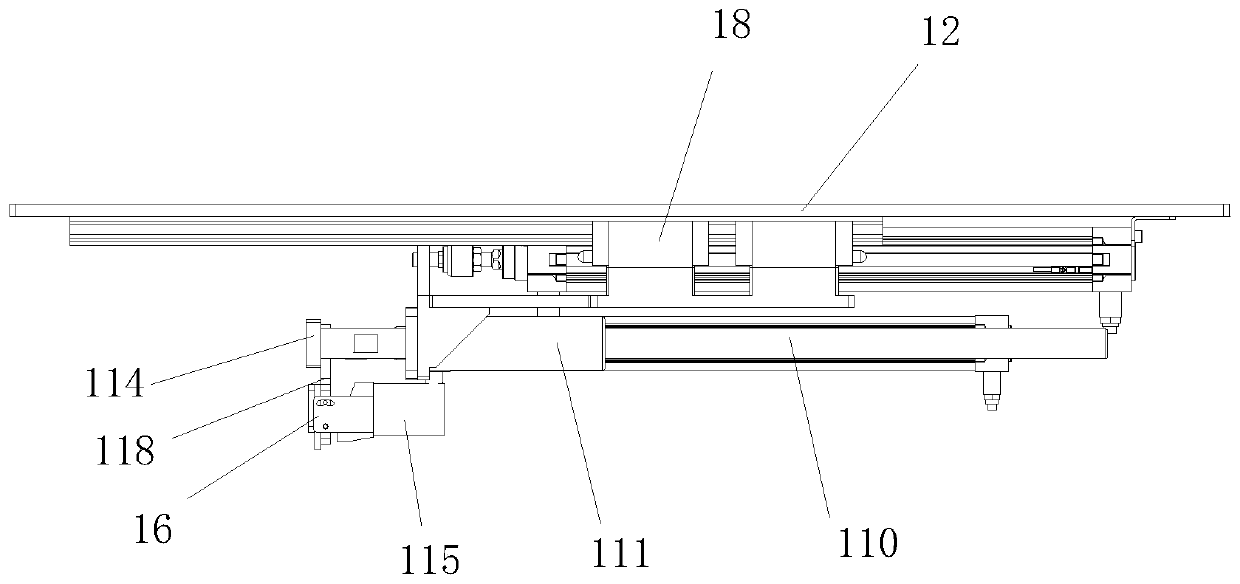

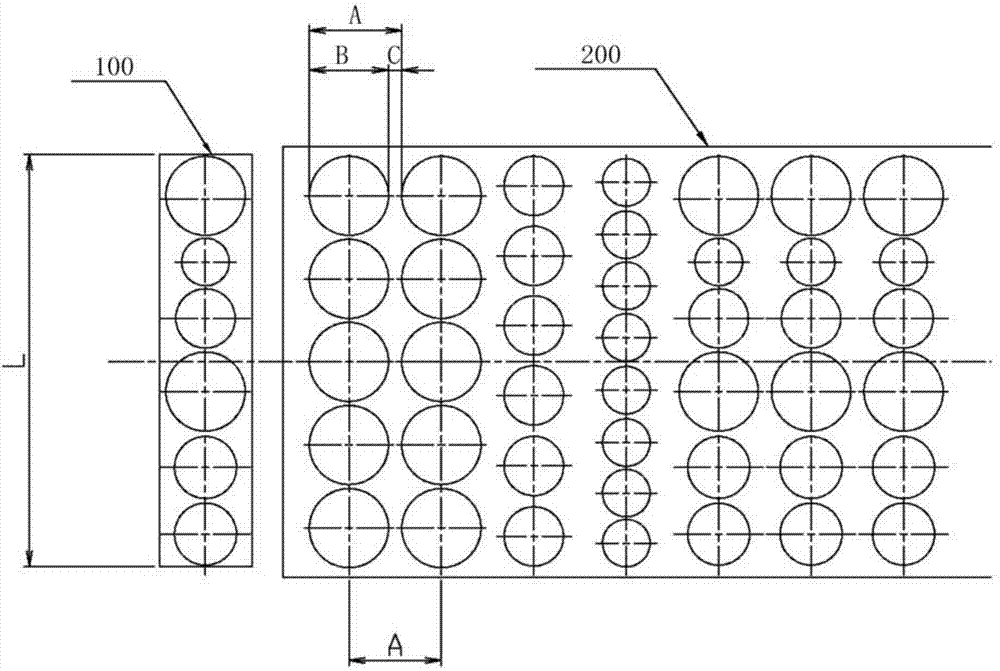

Feeding and discharging device for full-automatic concrete compression experiment test block

PendingCN110654850AMechanizationRealize mechanized feeding and dischargingConveyor partsRobot handClassical mechanics

The invention discloses a feeding and discharging device for a full-automatic concrete compression experiment test block. The device comprises a feeding and discharging manipulator, a frame, a feedingmanipulator, a sweeping stacking and slag discharging dust removing mechanism, the feeding and discharging manipulator is arranged on one side of the frame, the feeding manipulator is arranged on theother side of the frame, the feeding and discharging manipulator device comprises a top plate, a first air cylinder, a sliding plate, a second air cylinder and a second material pushing plate, the top plate is fixedly mounted at the top of the frame, linear guide rails are arranged on two sides of the bottom of the top plate in parallel correspondingly, the feeding manipulator comprises a third air cylinder and a first material pushing plate, a protective plate is fixedly mounted on the side surface of the frame where the feeding manipulator is located, the third air cylinder is fixedly mounted on the inner side of the protective plate, the first material pushing plate is slidably mounted on the third air cylinder, and a material receiving platform is arranged below the first material pushing plate. According to the device, the mechanized feeding of the concrete experiment block can be realized, the experiment cost is saved, and the working efficiency is improved.

Owner:南京研华智能科技有限公司

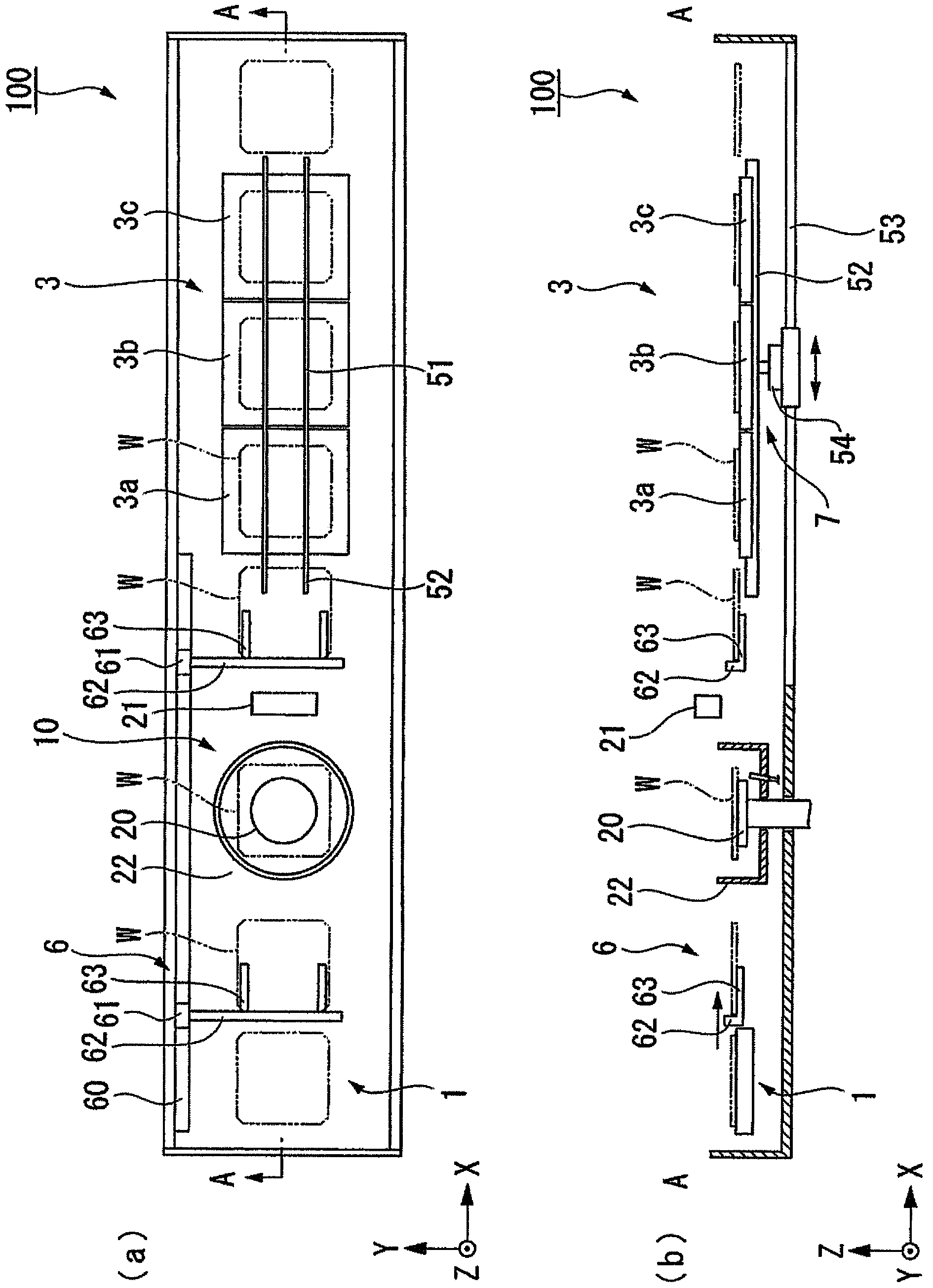

Power-and-free material-loading and transporting apparatus used for material-basket-free thermal-treatment furnace of aluminum alloy product

ActiveCN104328263ASpeed up the loading processIncrease delivery speedFurnace typesHeat treatment process controlUtilization rateHeat treating

A power-and-free material-loading and transporting apparatus used for a material-basket-free thermal-treatment furnace of an aluminum alloy product belongs to the technical filed of thermal treatment devices of the aluminum alloy product. By means of parts, including a transporting roller track, a pre-assembling roller track, a material pushing machine, a material-feeding detection photoelectric tube, a material-full detection photoelectric tube, a power-and-free roller track, a removing roller cylinder, a removing motor, a material-loading fork and the like, the power-and-free material-loading and transporting apparatus enables workpieces arranged in a material-loading zone on the power-and-free roller track to be changed from one row into two or more rows, wherein the workpieces are pre-arranged by a material baffle. Redundant workpieces are removed from the roller cylinder and from the material-loading zone. The pieces in the material-loading zone are sent to the thermal-treatment furnace by the material-loading fork in one step for thermal treatment. By means of the power-and-free material-loading and transporting apparatus, automatic level of the device is improved and time period during material loading is effectively prolonged. In addition, the power-and-free material-loading and transporting apparatus can increase effective space in the thermal-treatment furnace by 20%, can reduce a production cost and can increase energy resource utilization rate.

Owner:SHENYANG NEU-SANKEN IND FURNACE MFG CO LTD

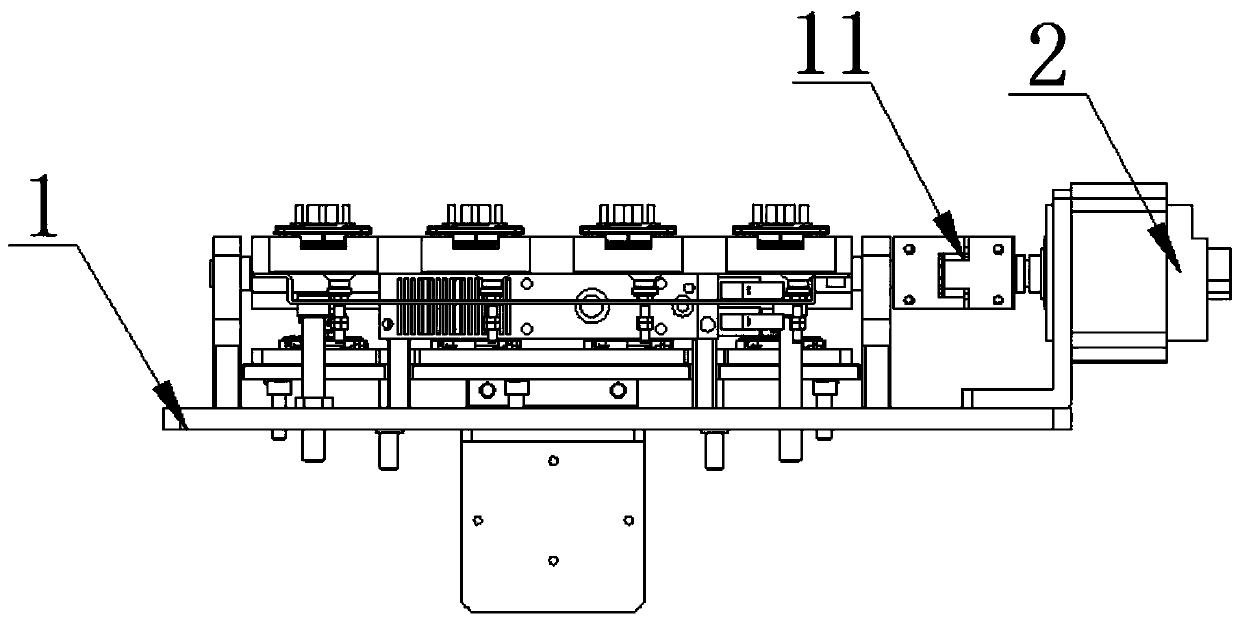

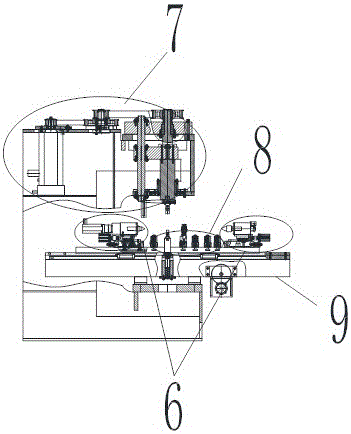

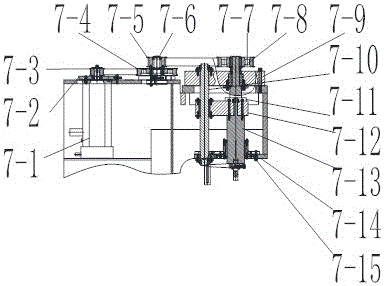

Longitudinal rack polishing machine

ActiveCN105983896AMeet polishing requirementsGuaranteed reflowPolishing machinesGrinding drivesMotor driveProgrammable logic controller

The invention belongs to the field of ultra-precision machining equipment and relates to a longitudinal rack polishing machine. The longitudinal rack polishing machine comprises an automatic discharging mechanism, a PLC (programmable logic controller) electrical control box, an automatic feeding mechanism, a frame, a touch screen control board, an automatic shape modifying mechanism, a polishing mechanism and a centre driving mechanism. A nylon resin polishing wheel is adopted for longitudinal polishing of a tooth back portion and a shaft portion of a rack. The polishing wheel in high-speed rotation has a certain floating quantity and can completely fit the rack, and the polishing wheel has a certain precompression force on the rack by the aid of a servo motor and a pressure sensor. Angular rotation of the rack is also realized under action of the servo motor, and full coverage of the tooth back portion can be realized. The servo motor drives the polishing wheel to move longitudinally to meet requirements of workpieces in different lengths. In electrical control, A PLC and a touch screen are adopted for controlling, and the servo motor and an air cylinder serve as power sources to be responsible for all operation instructions of equipment and implementation.

Owner:吉林瑞铭机电设备有限公司

Workpiece grabbing method and device based on vision system

ActiveCN111251302AIncrease productivityIncrease productionProgramme-controlled manipulatorImage enhancementInformation controlProduction line

The invention provides a workpiece grabbing method and device based on a vision system and relates to the technical field of workpiece grabbing. The method comprises the steps that actual image information of a workpiece collected by the vision system is received and subjected to fitting comparison with preset image information of the workpiece, correction data of the actual image information andthe preset image information of the workpiece is obtained, and an actual movement path of an execution mechanism when grabbing the workpiece is analyzed according to the correction data; and the execution mechanism is controlled to move to the grabbing position along the actual movement path, and according to preset grabbing action information of the execution mechanism when grabbing the workpiece, the execution mechanism is controlled to move to grab the workpiece. By adopting a pre-processing technology in background, the data analysis volume is low, and the response and operation time of the system is greatly shortened, which helps to shorten the takt of automation production. Therefore, the production efficiency and yield of a production line are improved.

Owner:三一机器人科技有限公司

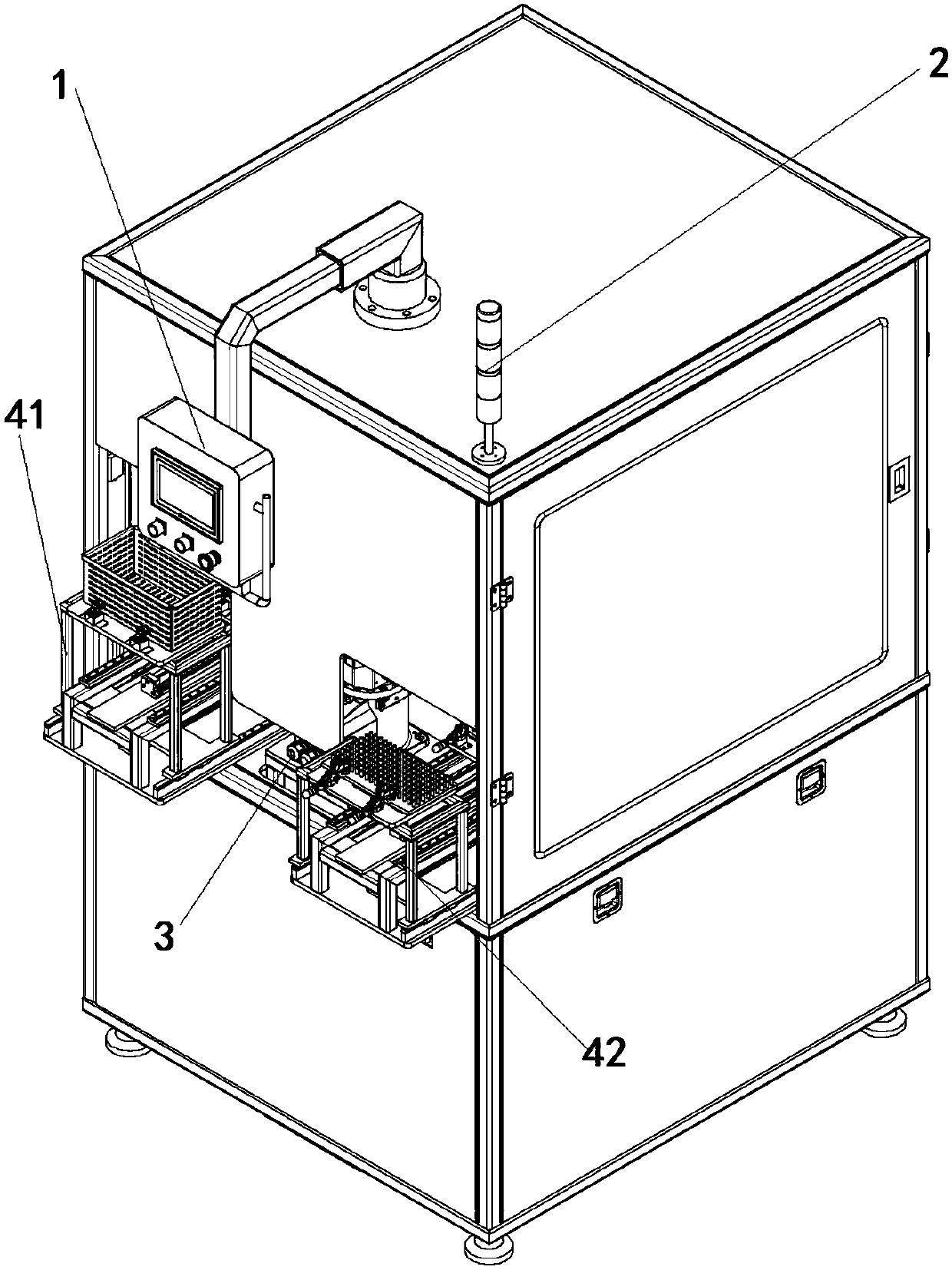

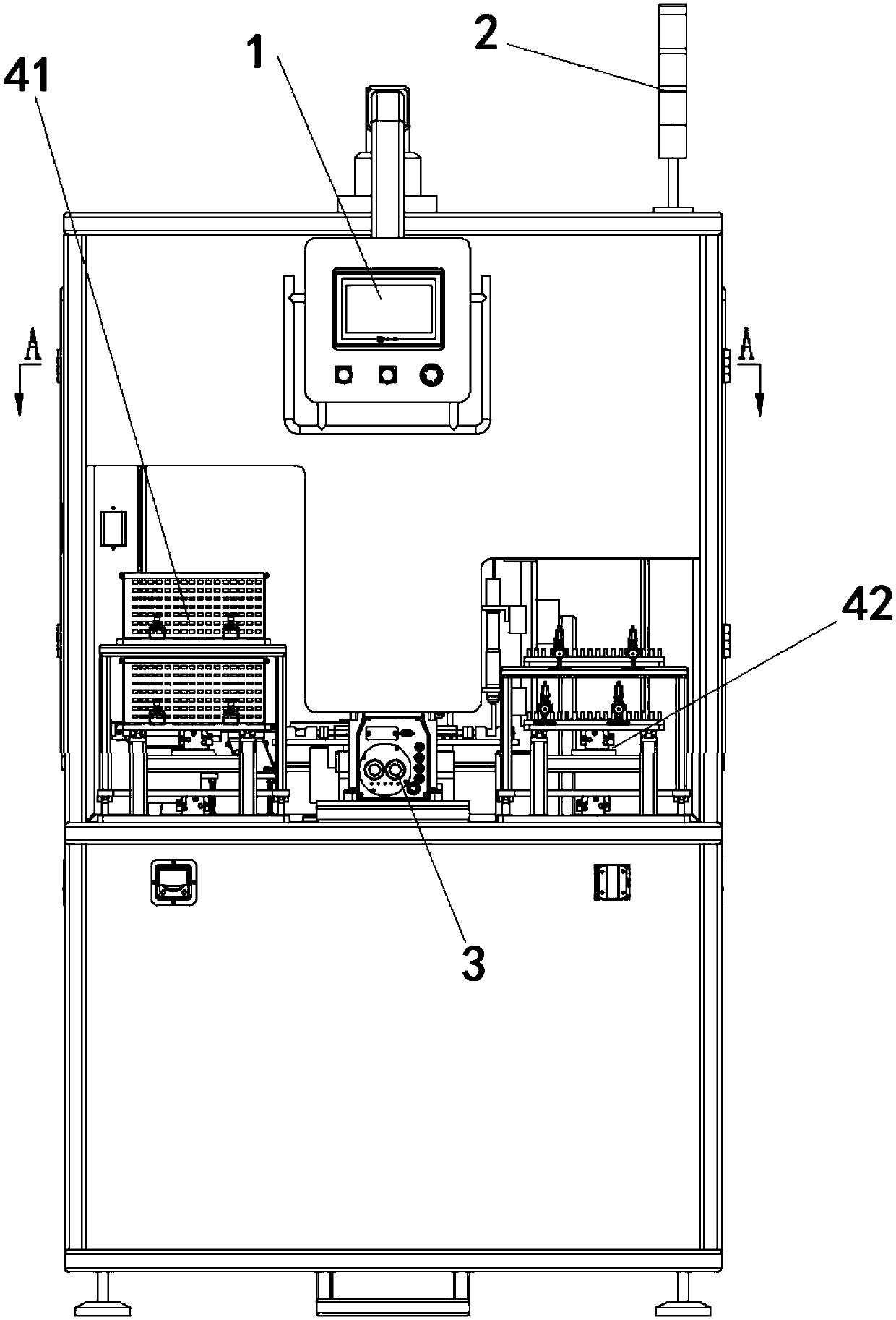

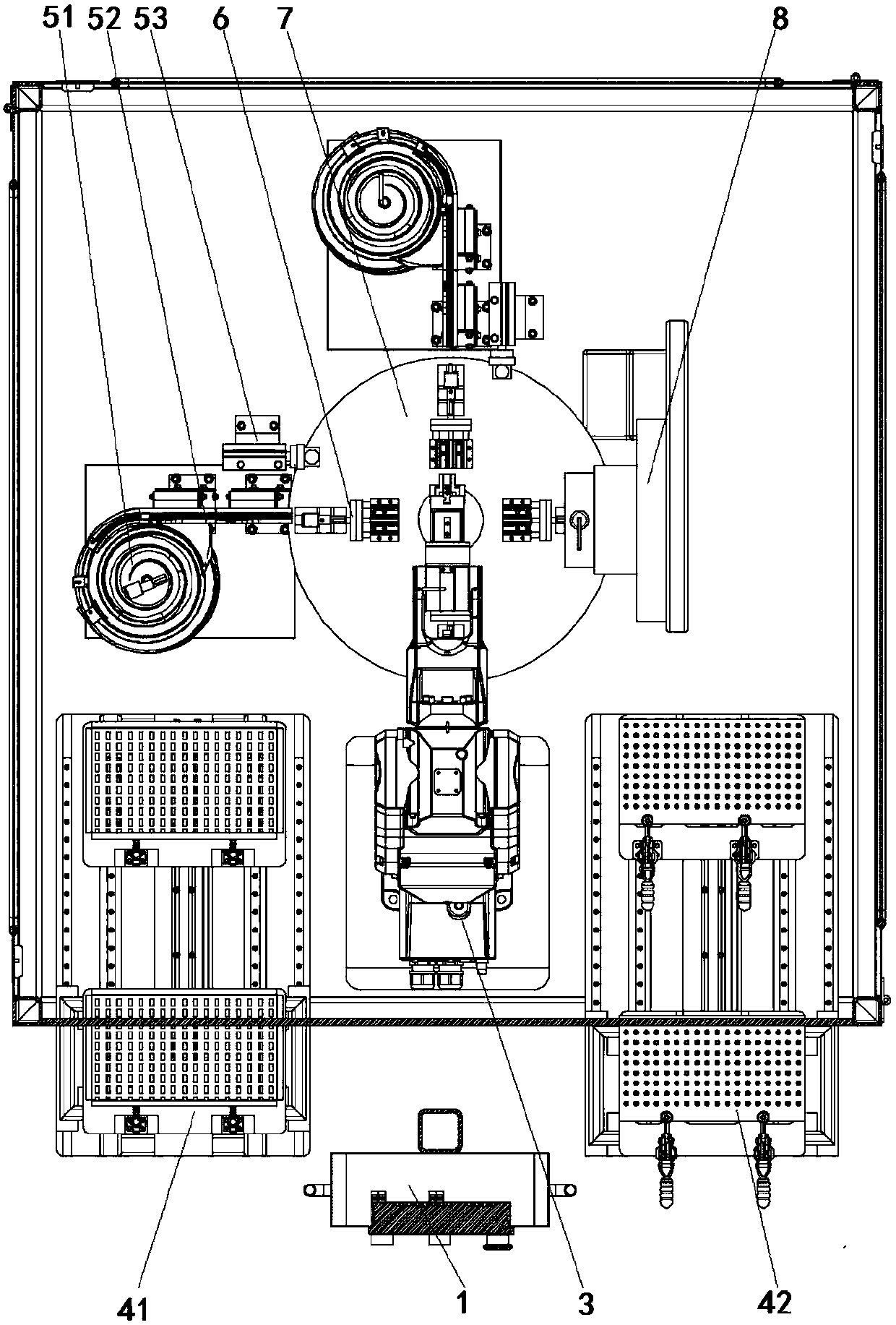

Full-automatic detection device of performance of electric control valve

The invention provides a full-automatic detection device of performance of an electric control valve. The device structurally comprises a device support, a loading module, a detection module, a robotmodule, a discharging module and an unaccepted product discharging module. The loading module is arranged on the left end of the front side of the upper surface of the top of the device support, the discharging module is arranged on the right end of the front side of the upper surface of the top of the device support, the detection module is arranged between the loading module and the dischargingmodule, the robot module is arranged on the protruding part of the front side of the device support, and the unaccepted product discharging module is arranged on the side, close to the loading module,of the edge of the top of the device support. A robot and a linear module are used for achieving device automation, through multi-station detection, production efficiency is improved, a loading codescanning gun is used for achieving one-to-one data recording of products, tracing is achieved, and through design of a loading clamping claw and a discharging clamping claw of the robot module, loading and discharging efficiency of the device can be improved.

Owner:苏州新智机电科技有限公司

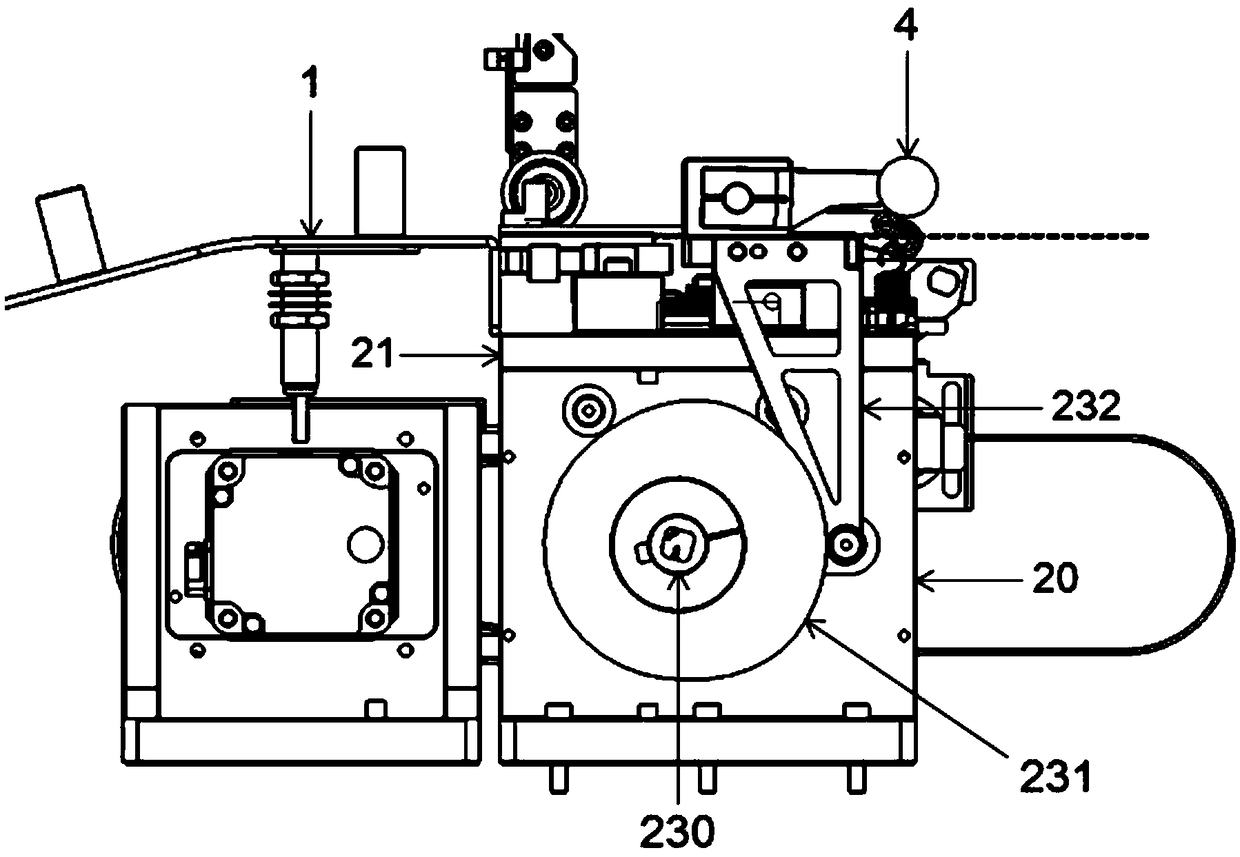

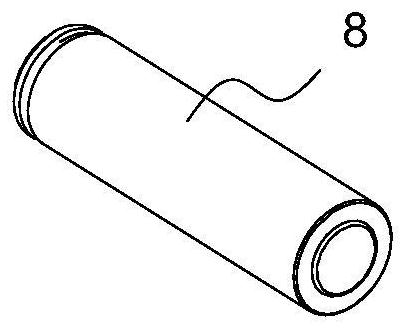

Gas meter counter magnetic steel wheel automatic feeding device

InactiveCN107813122ASave the beatImprove feeding efficiencyMetal working apparatusTransfer mechanismCam

The invention discloses a gas meter counter magnetic steel wheel automatic feeding device. The gas meter counter magnetic steel wheel automatic feeding device comprises a second rack, an indexing material disc mechanism, a dragging lifting mechanism and a second transferring mechanism; the indexing material disc mechanism is mounted on the second rack, and comprises a cam divider, an indexing discis arranged on the cam divider, multiple material cylinders used for containing magnetic steel wheels are evenly distributed on the peripheral side of the indexing disc, and groove openings are formed in the outer sides of the material cylinders; the dragging lifting mechanism is arranged on one side of one material cylinder and comprises a servo lifting electric cylinder and a lifting bracket connected with the lower part of the servo lifting electric cylinder, one end of a lifting bracket is provided with a push plate inserted in the groove openings, and the second transferring mechanism isarranged above the dragging lifting mechanism and is used for clamping and transferring the magnetic steel wheels in the material cylinders. Automatic feeding of the magnetic steel wheels can be achieved, and the magnetic steel wheels can be effectively separated.

Owner:CSIC PRIDENANJINGINTELLIGENT EQUIP SYST CO LTD

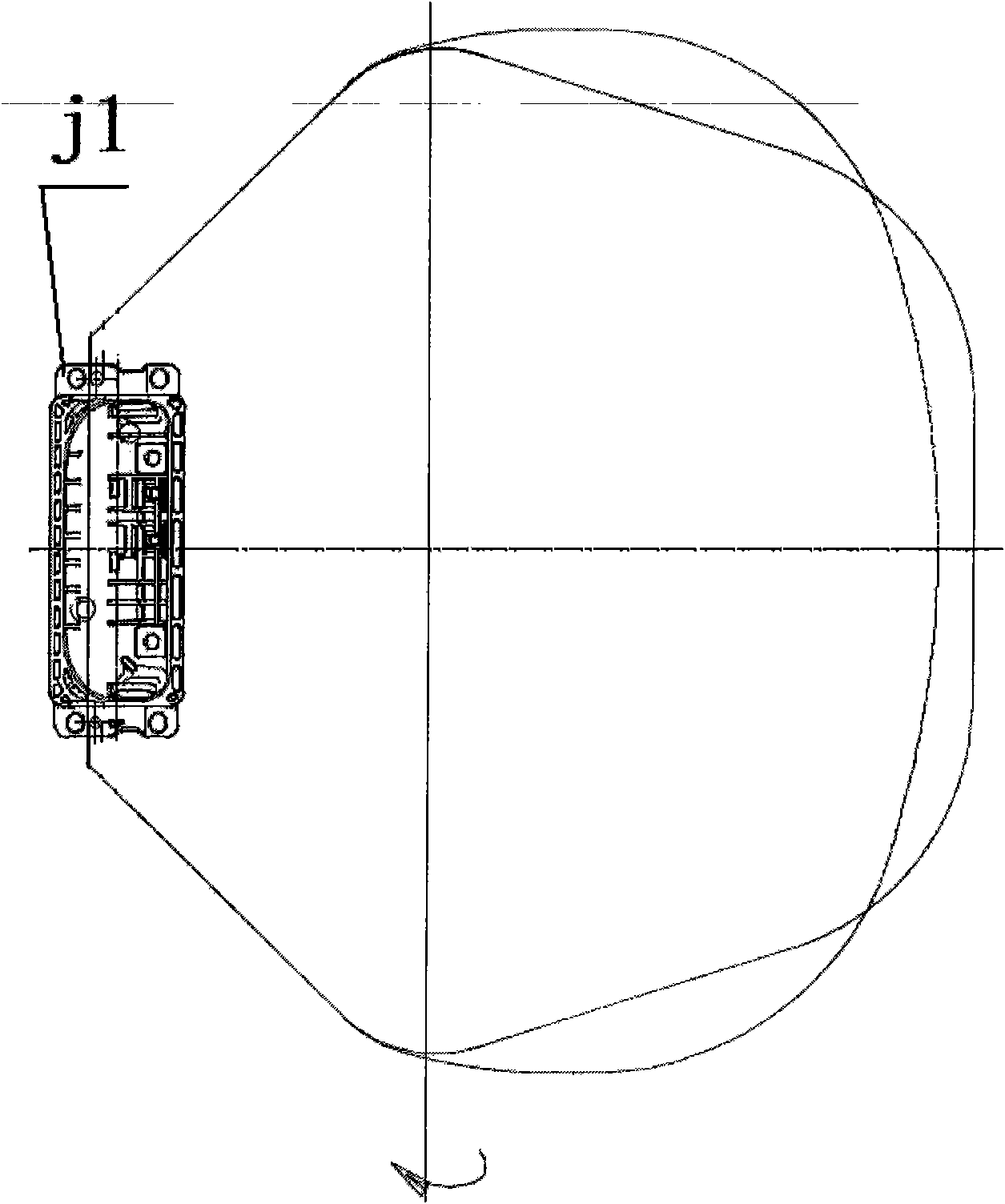

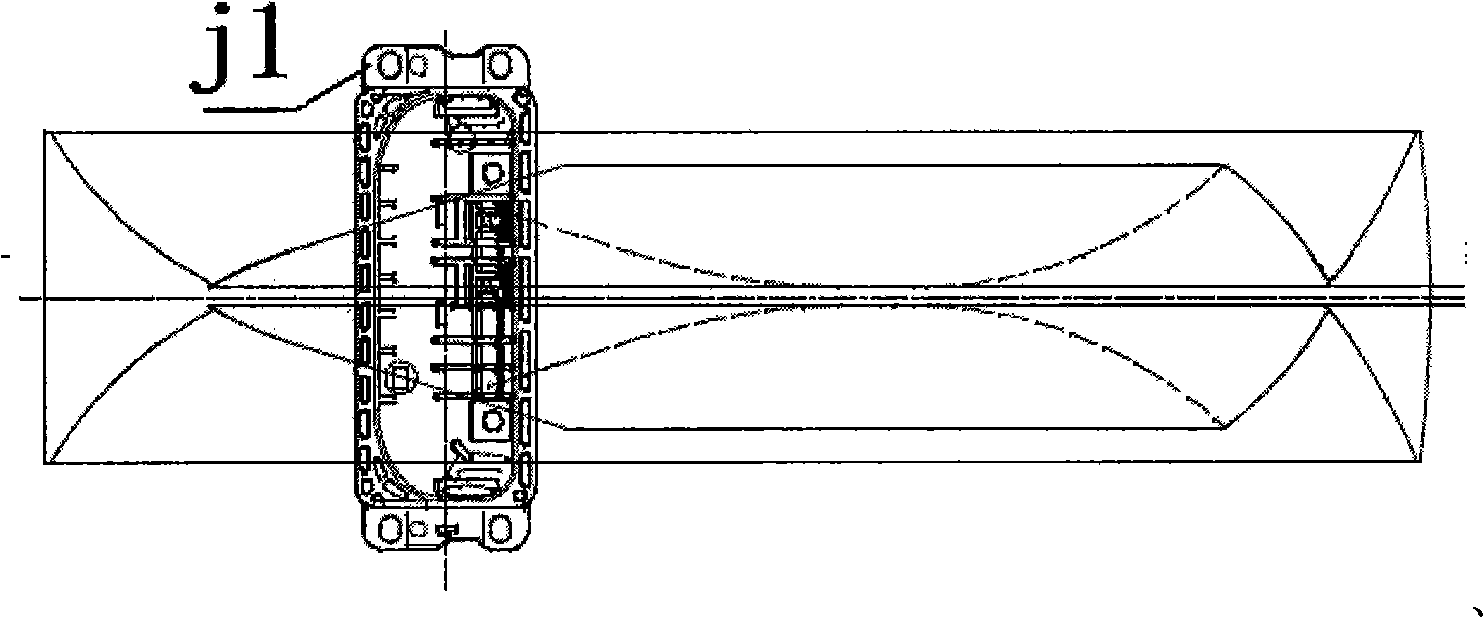

Full-automatic welding equipment for battery cover plate guide sheets

PendingCN113351993AImprove efficiencyImprove welding qualityLaser beam welding apparatusElectrical batteryElectric machinery

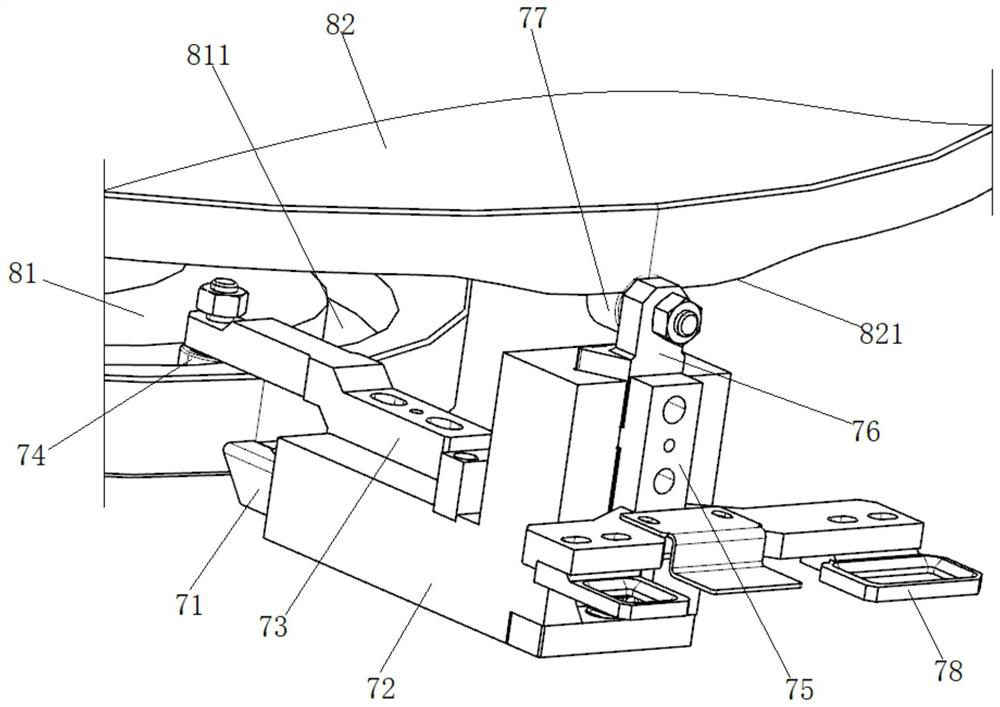

The invention discloses full-automatic welding equipment for battery cover plate guide sheets. The full-automatic welding equipment comprises a rotating disc, a plurality of jigs, a cover plate feeding unit, a positive and negative electrode guide sheet feeding unit, a laser welding module and a finished product discharging and conveying unit, wherein the rotating disc rotates, the jigs are annularly distributed on the rotating disc at equal angles, and the cover plate feeding unit, the positive and negative electrode guide sheet feeding unit, the laser welding module and the finished product discharging and conveying unit are arranged around the rotating disc. The rotating disc is provided with cover plate guide sheet pressing units in one-to-one correspondence with the jigs, and a cam unit for driving the cover plate guide sheet pressing units on set stations to move forwards and downwards to press the cover plates and the guide sheets on the jigs is fixedly arranged above the rotating disc. The assembling and welding efficiency of the battery cover plate and the guide sheets is greatly improved, the welding quality is improved, and the quality of the battery cover plate is guaranteed; and the driving effect of a driving source is fully utilized, so that the configuration of a driving motor is greatly reduced, the manufacturing cost is reduced, and the energy consumption is saved.

Owner:S Z JUHONG COMP TELECOMM TECH CO LTD

Passive trolley applicable to multiple vehicles

ActiveCN106312404ALight structureSimple structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringElectrical and Electronics engineering

Owner:GUANGZHOU RISONG HOKUTO AUTOMOTIVE EQUIP CO LTD

Feed automatic overturning mechanism of remote controller detection equipment

PendingCN110540038AIncrease the number of testsSave the beatConveyor partsTotal factory controlAbsolute accuracyEngineering

The invention discloses a feed automatic overturning mechanism of remote controller detection equipment. The feed automatic overturning mechanism comprises a support installed on a bottom plate, and arotary shaft is rotationally connected to the support. A first station capable of bearing a workpiece is arranged on one side of the rotary shaft. A second station used for bearing the workpiece is further fixedly connected to the rotary shaft. A driving mechanism driving the rotary shaft to rotate is connected to the rotary shaft. The driving mechanism drives the second station on the rotary shaft to rotate to be above the first station. The workpiece on the first station is picked up and transferred onto the second station and is then overturned. A vacuum sucker is used, locating guiding isadded, thus a remote controller can be sucked stably during equipment overturning, absolute accuracy of locating is ensured while overturning is conducted, stable reliability of the equipment is relatively enhanced, and reliability and precision of the feed automatic overturning mechanism can be ensured through the whole structural design.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

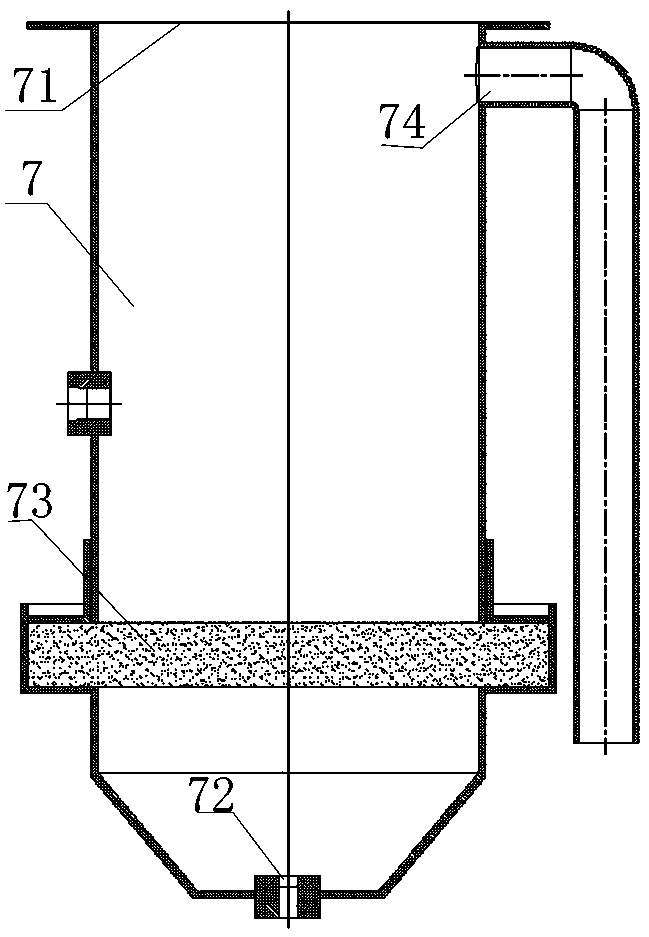

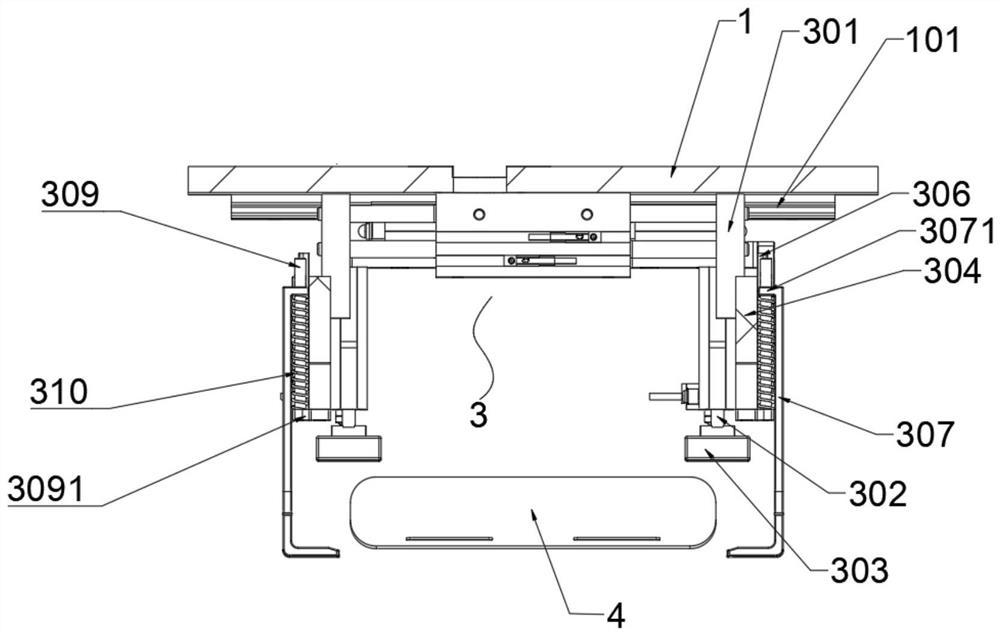

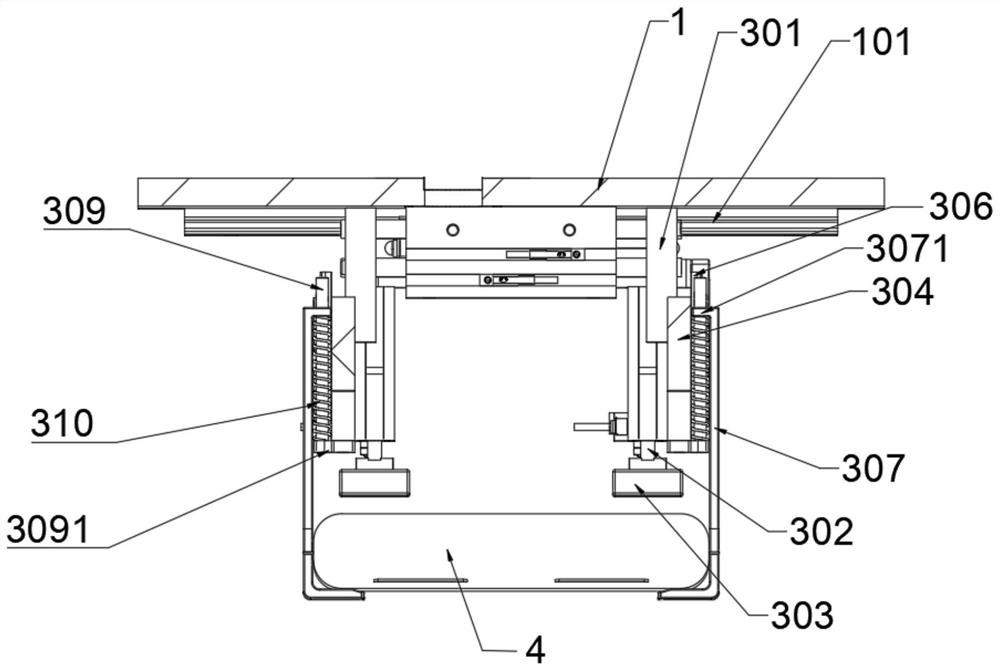

Positioning pin positioned taking mechanism

ActiveCN109648508AAvoid repeated fetchingReduce labor intensityMetal-working hand toolsEngineeringDistributor

The invention discloses a positioning pin positioned taking mechanism. The mechanism comprises a machine frame, a driver, a material distributor and a feeder; the machine frame comprises a left support, a right support, a material receiving box and a machine frame body, wherein the lower ends of the left support and the right support are positioned and connected to the machine frame body; the driver comprises a pedal, a first rope and a second rope, and the lower ends of the first rope and the second rope are connected with the pedal respectively; the feeder comprises a balancer, a stirring rod, a funnel and a pipe body, the balancer is arranged on a first supporting part, a cone pulley inner steel rope of the balancer is connected with the upper end of the first rope, the stirring rod isconnected to a cone pulley of the balancer, the funnel is arranged on a second supporting part, the tube body is arranged on a third supporting part, and the upper end of the tube body is connected with the outlet of the funnel; and the material distributor comprises a sliding groove and a sliding block, the sliding groove is horizontally arranged on the machine frame body, and the sliding block is located in the sliding groove and can move back and forth along the sliding groove between a first position and a second position. According to the mechanism, an operator can be prevented from repeatedly taking and placing positioning pins.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Square shell battery module laser welding clamp

ActiveCN108127317AAchieve clampingGuaranteed positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesMobile endEngineering

The invention relates to a square shell battery module laser welding clamp. A fixed end module positioning mechanism is fixedly mounted on a base; fixed end side plate compressing mechanisms are positioned on two sides of the fixed end module positioning mechanism; a moving end module positioning mechanism and the fixed end module positioning mechanism are arranged oppositely and are driven and positioned through a moving end driving mechanism; two groups of moving end side plate compressing mechanisms are symmetrically mounted on a first sliding rail on two sides of the moving end module positioning mechanism; two groups of side plate positioning mechanisms are symmetrically mounted on the first sliding rail on two sides; two groups of side plate jacking mechanisms are symmetrically mounted on two second sliding rails; the side plate positioning mechanisms and the side plate jacking mechanisms are driven by a side plate positioning switching mechanism to move synchronously along the sliding rail; a sliding table mechanism is mounted on the base; a pressure arm mechanism is mounted on the sliding table mechanism in a slidable manner; and a module centring mechanism and a module compressing mechanism are mounted on the pressure arm mechanism in a lifting manner. The square shell battery module laser welding clamp is suitable for automatic and fast reloading of battery modules ofdifferent types and ensures the assembling precision.

Owner:SHANGHAI JUNYI IND AUTOMATION CO LTD

Rubber bushing automatic oil coating pressing and closed-loop pressing compensation system and method

ActiveCN106002176AReduce the number of pressingSave the beatMetal working apparatusClosed loopPosition sensor

The invention discloses a rubber bushing automatic oil coating pressing and closed-loop pressing compensation system. The system comprises a shell, a position sensor for detecting a pressing depth and a position, a floating spring mechanism, a rubber bushing pressing head and a rubber bushing; the rubber bushing is positioned on the rubber bushing pressing head; the position sensor is connected with the floating spring mechanism; the rubber bushing pressing head and the rubber bushing are in control connection; and the shell is positioned at the tops of the rubber bushing pressing head and the rubber bushing. Through the mode, the rubber bushing automatic oil coating pressing and closed-loop pressing compensation system, provided by the invention, realizes an automatic procedural learning function, and can reduce the pressing times to save the equipment beat.

Owner:NEXTEER AUTOMOTIVE SYST SUZHOU

Aluminum-piece nylon coating machine and coating method

PendingCN109395982AUniform temperatureReduced strength damagePretreated surfacesCoatingsNumerical controlMedium frequency

The invention discloses an aluminum-piece nylon coating machine and coating method. Undercoat painting mechanisms are arranged on the two sides of a feeding conveying machine, a truss and a mechanicalarm are arranged at the tail end of the feeding conveying machine, and a medium-frequency heating furnace and a nylon powder box are arranged below the truss; a numerical-control and electronic-control operating table and a water cooling tower are arranged outside the truss, wherein the numerical-control and electronic-control operating table provides an electric wire to be connected to the feeding conveying machine, the undercoat painting mechanisms, the nylon powder box, the truss and the mechanical arm; the medium-frequency heating furnace is connected with a medium-frequency heating cabinet, and cooling is carried out through the water cooling tower. For achieving the aims that the strength loss of an aluminum piece is lowest, and melting of nylon powder is considered, the temperatureof the aluminum piece is controlled to be 250 DEG C to 255 DEG C in the medium-frequency heating furnace, two times of powder dipping are carried out, the aluminum piece enters the nylon powder box for the first time and is soaked into the nylon powder, and then time stays for 2 seconds to 3 seconds; powder dipping is carried out for the second time after the aluminum piece is separated from thenylon powder box and stays for 1.5 seconds, the aluminum piece enters the nylon powder box for the second time and is soaked into the nylon powder to also stay 2 seconds to 3 seconds, and it can be achieved that the coating thickness is controlled to be 0.5 mm to 0.6 mm.

Owner:东风汽车传动轴有限公司

Terminal cutting device

PendingCN109500862AIncrease productivitySave the beatContact member manufacturingMetal working apparatusEngineeringMechanical engineering

The invention relates to the field of terminal production, and discloses a terminal cutting device. The terminal cutting device comprises a feeding way, a conveying mechanism and a cutting mechanism;and the conveying mechanism comprises a main body, a sliding block seat, a conveying rail and a pushing structure, wherein the sliding block seat is arranged on the main body, the conveying rail is slidably arranged on the sliding block seat, and the pushing structure is used for pushing the conveying rail to slide on the sliding block seat. The terminal cutting device comprises the conveying railarranged on the sliding block seat, the conveying rail is pushed through the pushing structure to slide on the sliding block seat, a first pressure spring is connected between the conveying rail andthe sliding block seat, after conveying is conducted in place, the pushing structure can pull the conveying rail back to the original point to conduct conveying of the next time, through the design, the takt time of conveying is slowed greatly, and thus the production efficiency of terminal cutting is improved.

Owner:天泽精密技术(上海)有限公司

A C-type mechanical shaft automatic straightening machine

ActiveCN106607476APrevent crushingMeet straightening needsMetal-working feeding devicesMetal working apparatusElectric machineryElectrical control

The invention relates to a C-type straightening machine and belongs to the field of ultra-precision machining apparatuses. The C-type mechanical shaft automatic straightening machine comprises an automatic feeding mechanism, a touch screen and operation control panel and PLC electrical control box; an automatic discharging mechanism, a rack, a material pouring mechanism, a work piece clamping mechanism, a straightening mechanism, a measuring mechanism, a straightening moving mechanism and an automatic NG processing mechanism. With the automatic straightening and automatic feeding and discharging mechanisms and with the function of automatic angle rotation, repeated clamping is not needed in measurement and correction and procedures are saved. A displacement sensor can perform high speed data collection on work pieces and perform timely feedback. A servo motor is used as a power source for moving straightening points, so that rapid and accurate location to the straightening points is achieved and the straightening requirements of work pieces with different lengths are met. A PLC and a touch screen are used for control in the aspect of electrical control and the servo motor and an air cylinder are used as power sources; the parts are responsible for all operation commands and implementation of the apparatus.

Owner:吉林瑞铭机电设备有限公司

Wet process forming machine

ActiveCN111516130AHigh surface finishSave the beatDischarging arrangementCeramic shaping plantsMolding machineEngineering

The invention provides a wet process forming machine and belongs to the technical field of concrete product production. The wet process forming machine comprises a main frame, a rotating disc and a fixed chassis. The rotating disc is provided with six working stations uniformly in the circumferential direction, the six working stations successively comprise a main pressure forming station, a demolding station, a fabric distributing station, a fabric pressing station, a cleaning station and a backing material distributing station. The six working stations are provided with lifting devices for lifting a lower die and vibrating tables for auxiliary forming. The six vibrating tables are connected to the rotating disc and rotate a station along with rotation of the rotating disc. According to the wet process forming machine, the six working stations are uniformly arranged on the rotating disc, and backing material and fabric distributing, demolding and high pressure forming are carried outsimultaneously in different stations, so that the wet process forming machine is compact in structure, shortens the production takt of products and improves the production efficiency. Raw materials for wet process forming contain fewer air bubbles compared with those of dry and hard concrete. Formed by a high pressure, the strength and compactness of the product are improved.

Owner:LANGFANG HESS BUILDING MATERIALS MACHINERY CO LTD

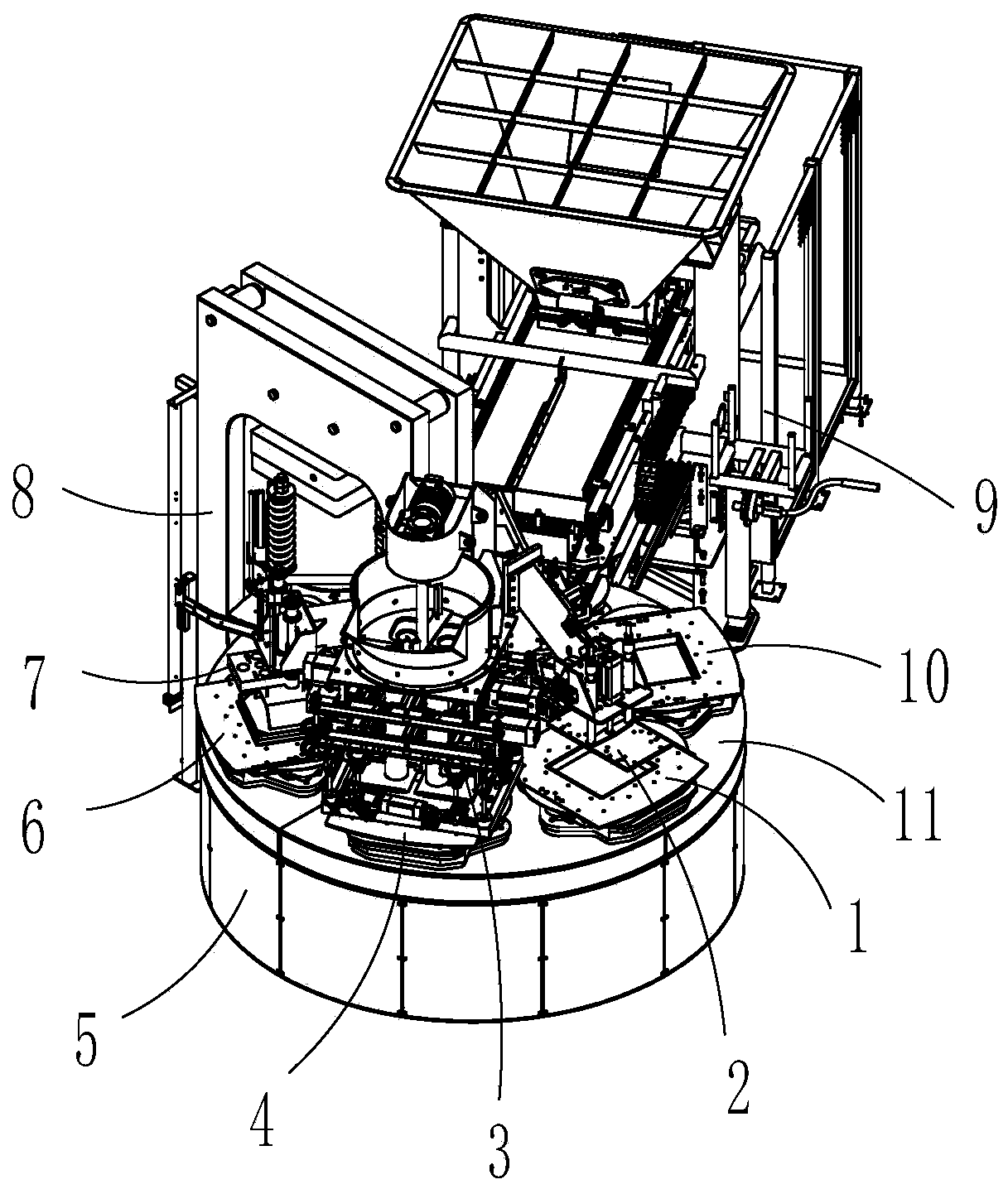

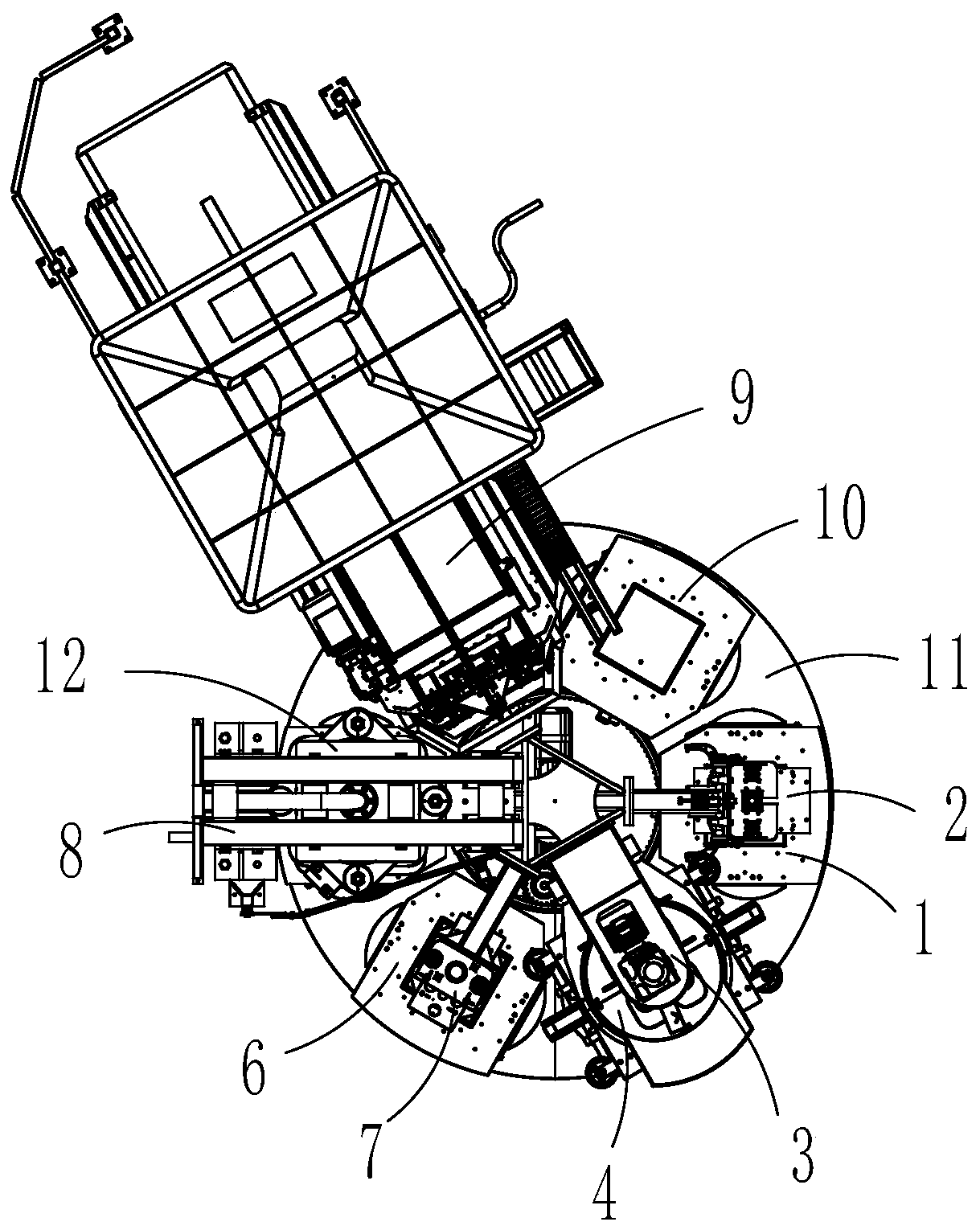

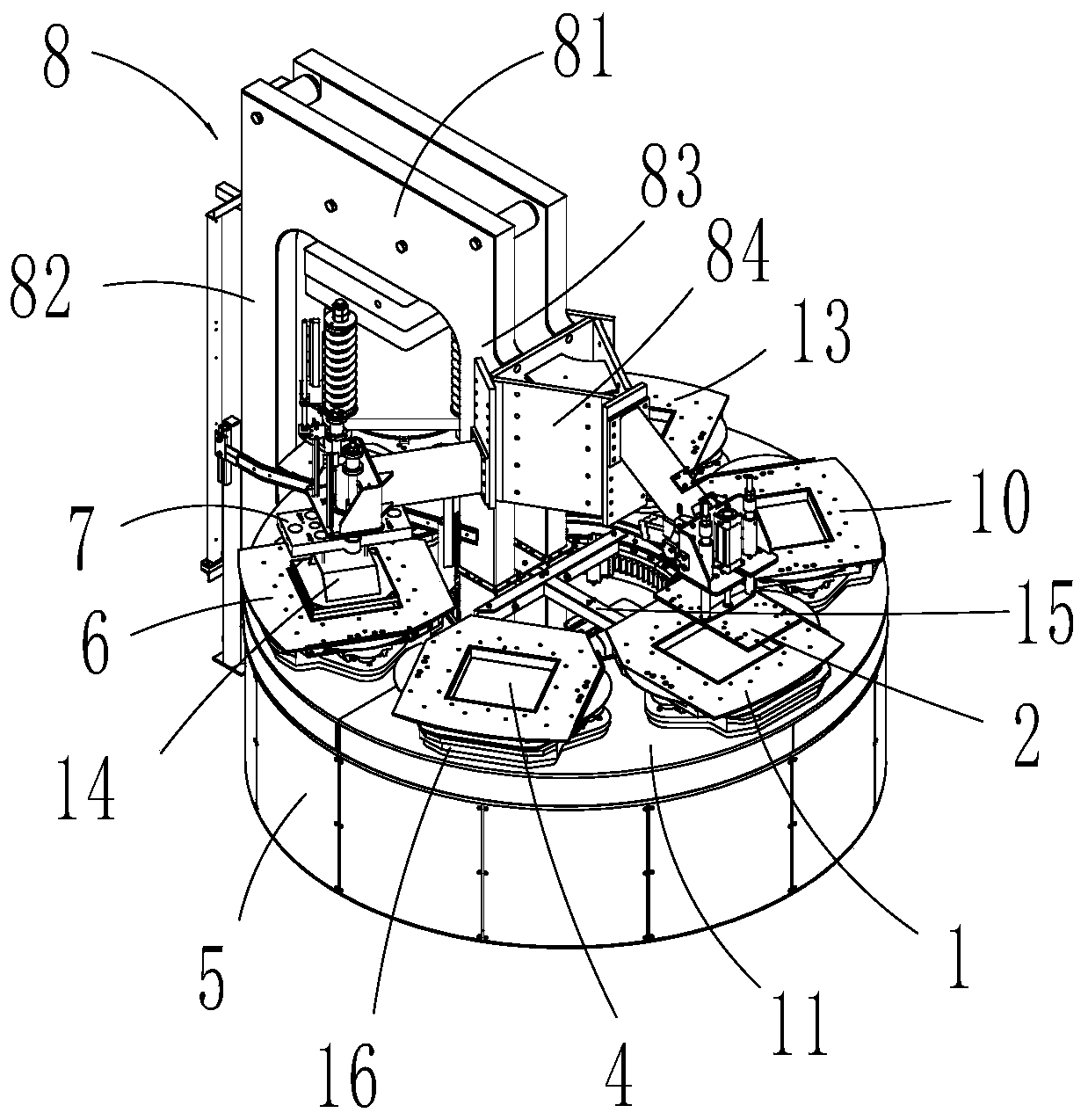

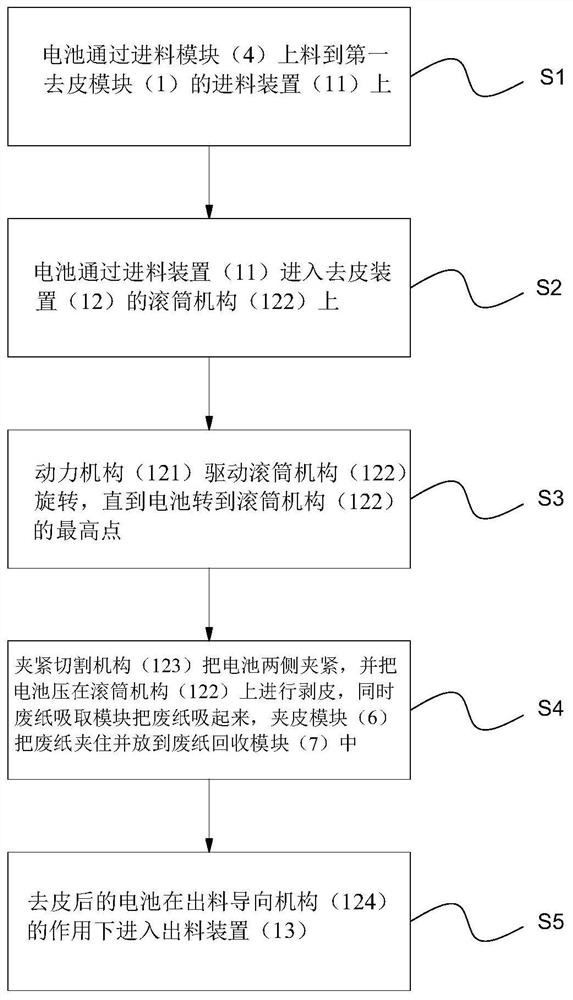

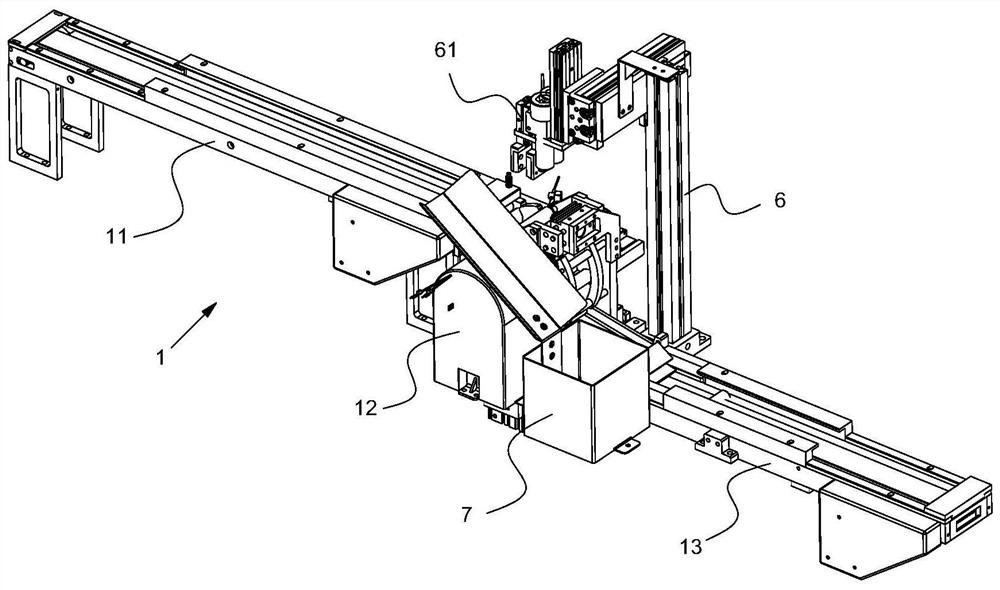

Cylindrical lithium battery peeling method and equipment

InactiveCN111934022ASave the beatGuaranteed sharpnessAssembling battery machinesFinal product manufactureCell fabricationStructural engineering

The invention relates to the field of battery manufacturing, in particular to a cylindrical lithium battery peeling method and equipment. A peeling device comprises a power mechanism, a roller mechanism, a clamping and cutting mechanism and a discharging guide mechanism; a plurality of notches for positioning are formed in the circumference of the roller mechanism; a battery is transversely placedon the notches, the power mechanism drives the roller mechanism to rotate on the vertical plane, when the battery is conveyed to the highest point of the roller mechanism, the clamping and cutting mechanism clamps the two sides of the battery and presses the battery on the roller mechanism, the battery is peeled, and the peeled battery is discharged under the action of the discharging guide mechanism. The method and equipment have the technical effects that a plurality of limiting grooves are formed in a left baffle and a right baffle, when the previous battery is peeled, the latter battery is positioned, and when the previous battery is peeled, a shell rotates to enable the latter battery to enter a peeling station, so that the beat of the mechanism is reduced, and the peeling efficiencyis improved.

Owner:张俊

Battery cell feeding and discharging clamping jaw mechanism and battery cell assembly production line

PendingCN114193432AMaintain grip stabilityAvoid damageProgramme-controlled manipulatorGripping headsStructural engineeringMechanical engineering

The invention discloses a battery cell feeding and discharging clamping jaw mechanism and a battery cell assembly production line. A mounting plate is connected with a Z-axis servo driving module, and a mounting plate guide rail is arranged below the mounting plate; the clamping jaw mechanisms are arranged in pairs, and each pair of clamping jaw mechanisms comprises two sets of clamping jaw assemblies which are oppositely arranged in a mirror image mode; the clamping jaw assembly comprises a clamping jaw sliding block, one end of the clamping jaw sliding block is slidably connected with the mounting plate guide rail, and the other end is connected with a cell pressing driving mechanism; the battery cell pressing driving mechanism is connected with the battery cell longitudinal pressing plate; the outer side of the clamping jaw sliding block is connected with a clamping jaw sliding block guide rail; the clamping jaw sliding block guide rail is in sliding connection with a battery cell clamping jaw; a jaw elastic member; and the battery cell clamping jaw is connected with the clamping jaw elastic component, so that the movement mode of the battery cell clamping jaw is a combination of elastic movement and sliding movement. And the clamping jaw sliding block is connected with a clamping jaw clamping driving mechanism. On one hand, the grabbing stability of the battery cell in the up-down and left-right directions can be kept, the downward-pressing grabbing force is kept within the elastic range, and the situation that the battery cell is damaged or has potential safety hazards due to the fact that the battery cell is excessively stressed is avoided.

Owner:无锡骄成智能科技有限公司

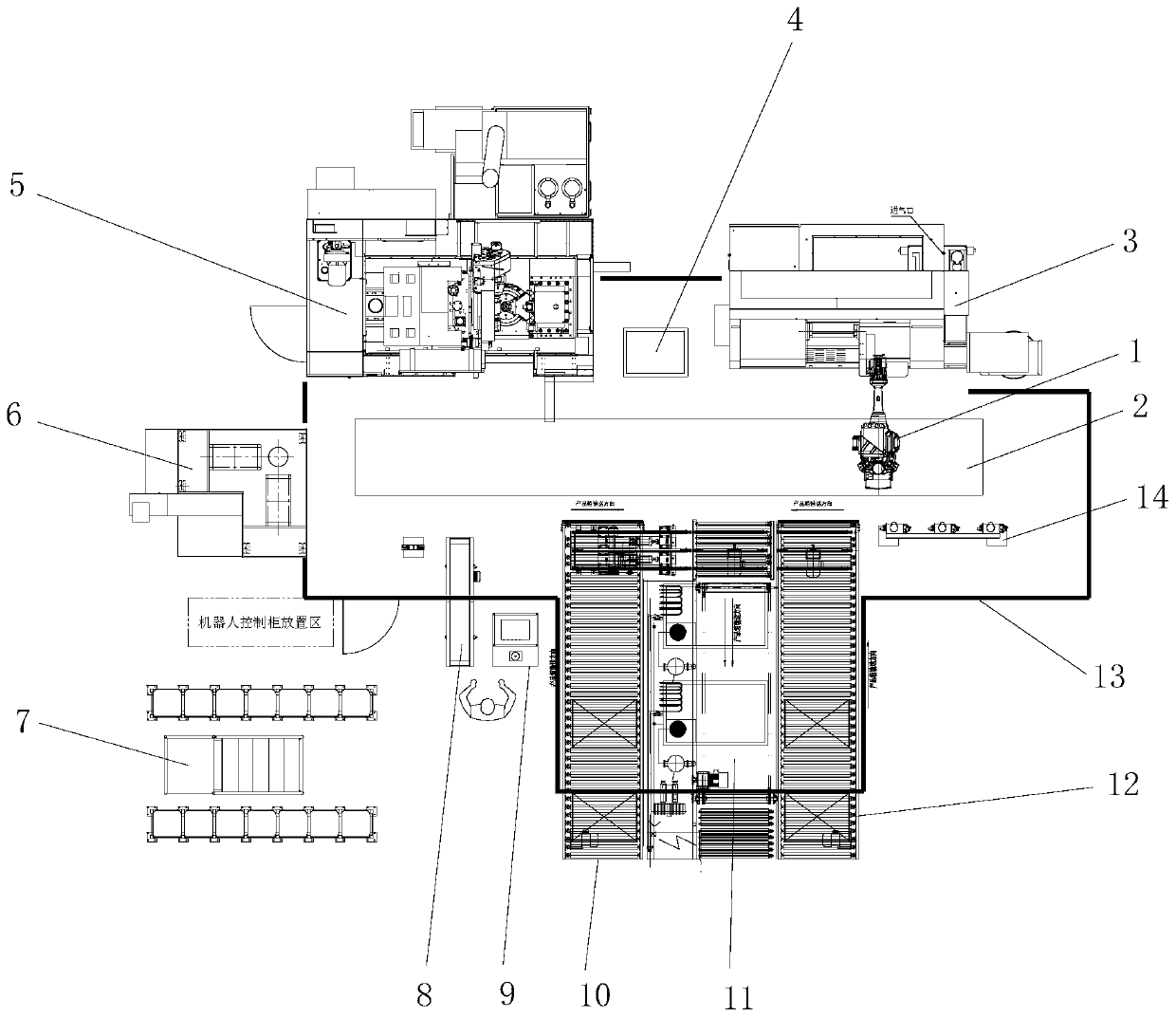

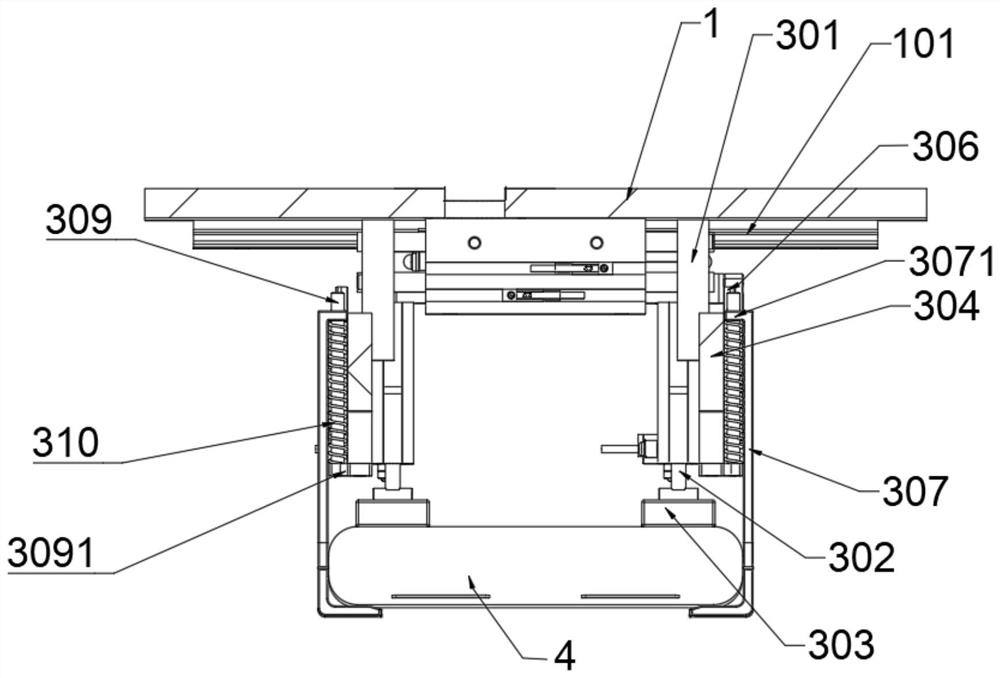

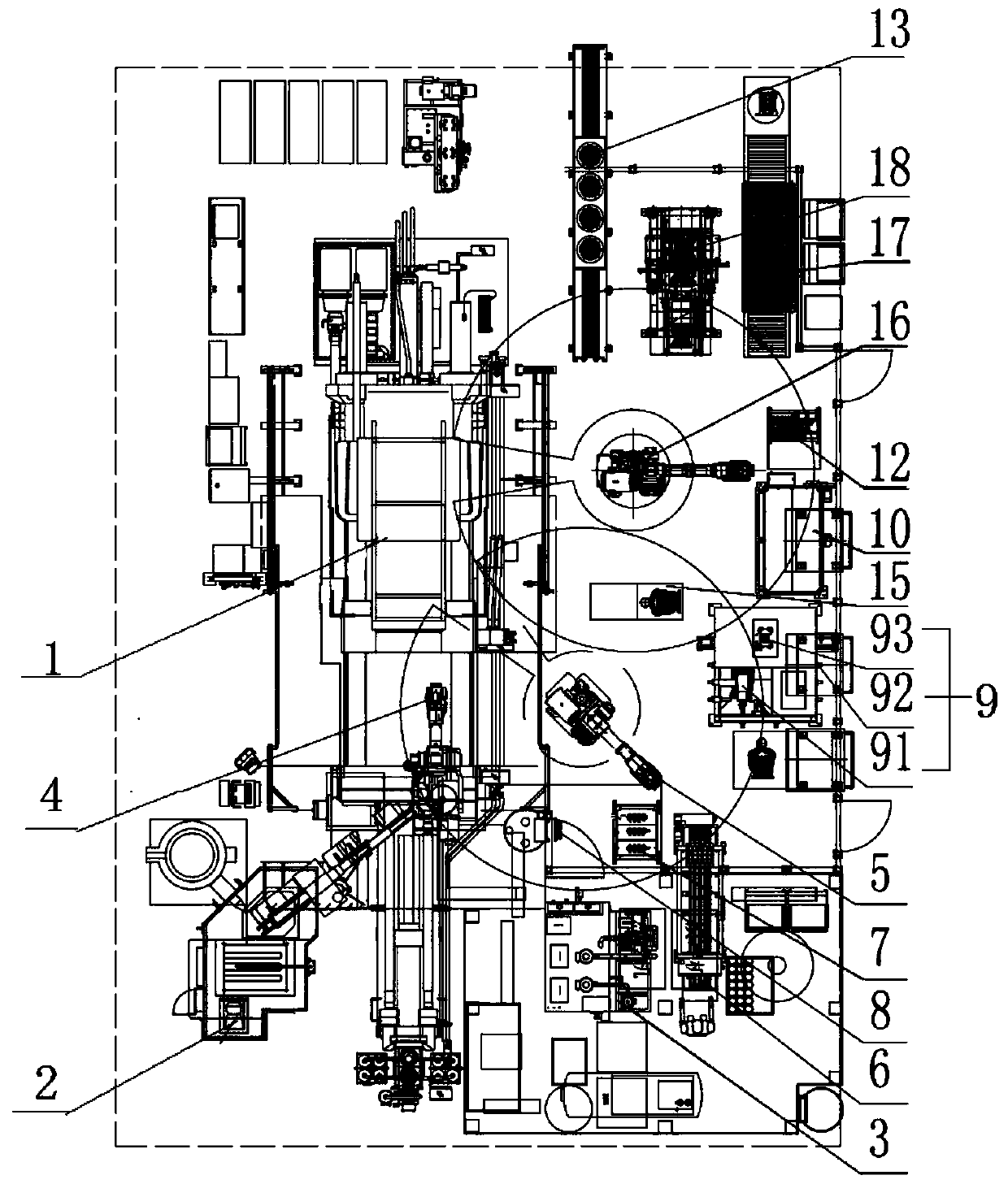

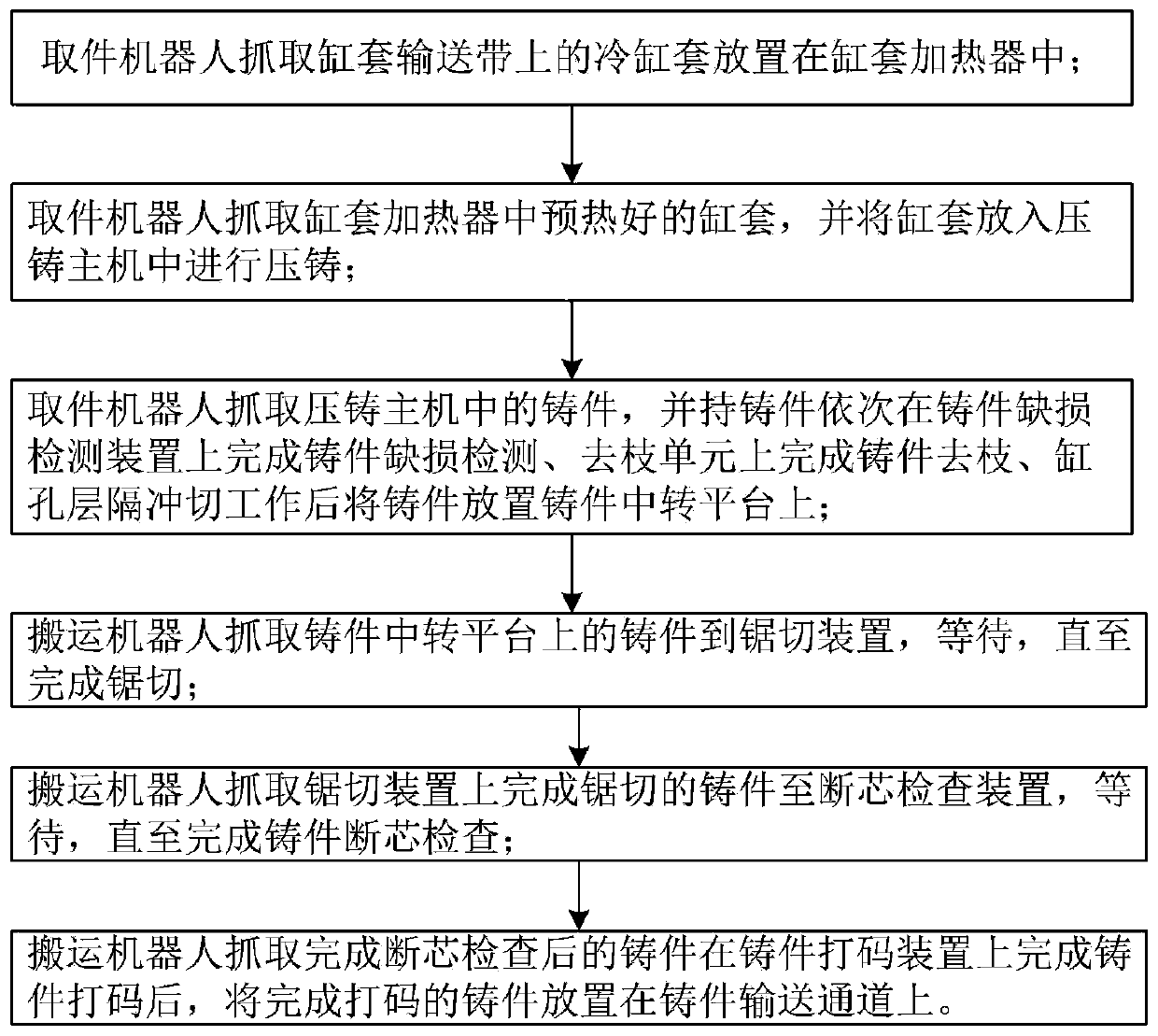

Aluminum alloy crankcase high-pressure casting method and integrated system

The invention discloses an aluminum alloy crankcase high-pressure casting integrated system. The aluminum alloy crankcase high-pressure casting integrated system comprises a die-casting main machine,a part taking robot, a cylinder sleeve conveying belt, a cylinder sleeve heater, a casting defect detection device, a branch removing unit, a saw cutting device, a casting code printing device, a casting conveying channel, a casting transfer table, a carrying robot and a broken core inspection device, wherein the part taking robot and the carrying robot are arranged on the two sides of the castingtransfer table correspondingly and positioned in a public area where the part taking robot and the carrying robot can grab; the die-casting main machine, the cylinder sleeve heater, the cylinder sleeve conveying belt, the casting defect detection device and the branch removing unit are positioned on one side of the casting transfer table and arranged in the grabbing range of the part taking robotin a surrounding manner; and the saw cutting device, the casting code printing device, the casting conveying channel and the broken core inspection device are positioned on the other side of the casting transfer table and arranged in the grabbing range of the carrying robot in a surrounding manner. The invention further discloses a crankcase die-casting method. By means of the system and method,full automation is achieved, and 100% full inspection of products is achieved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

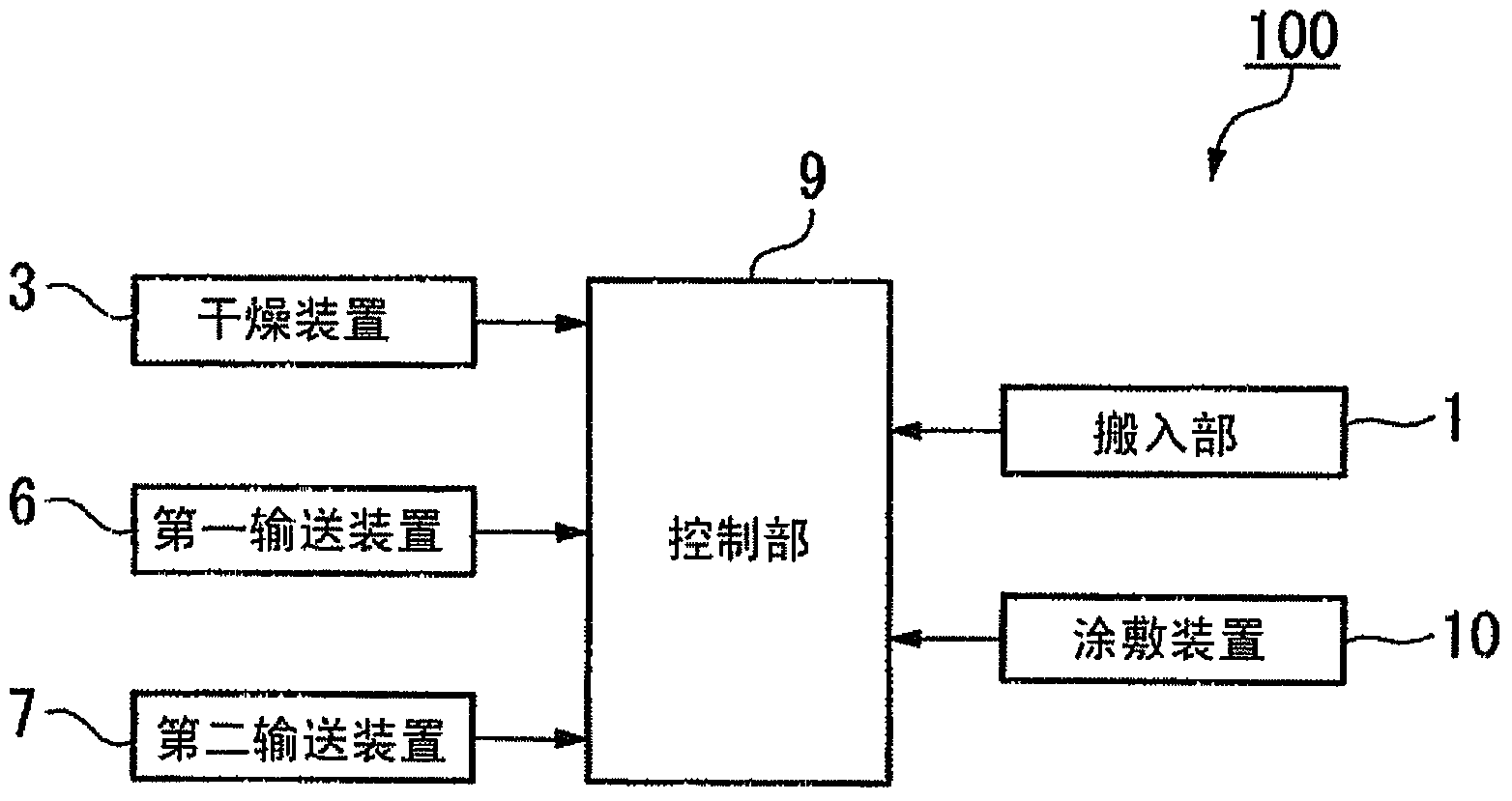

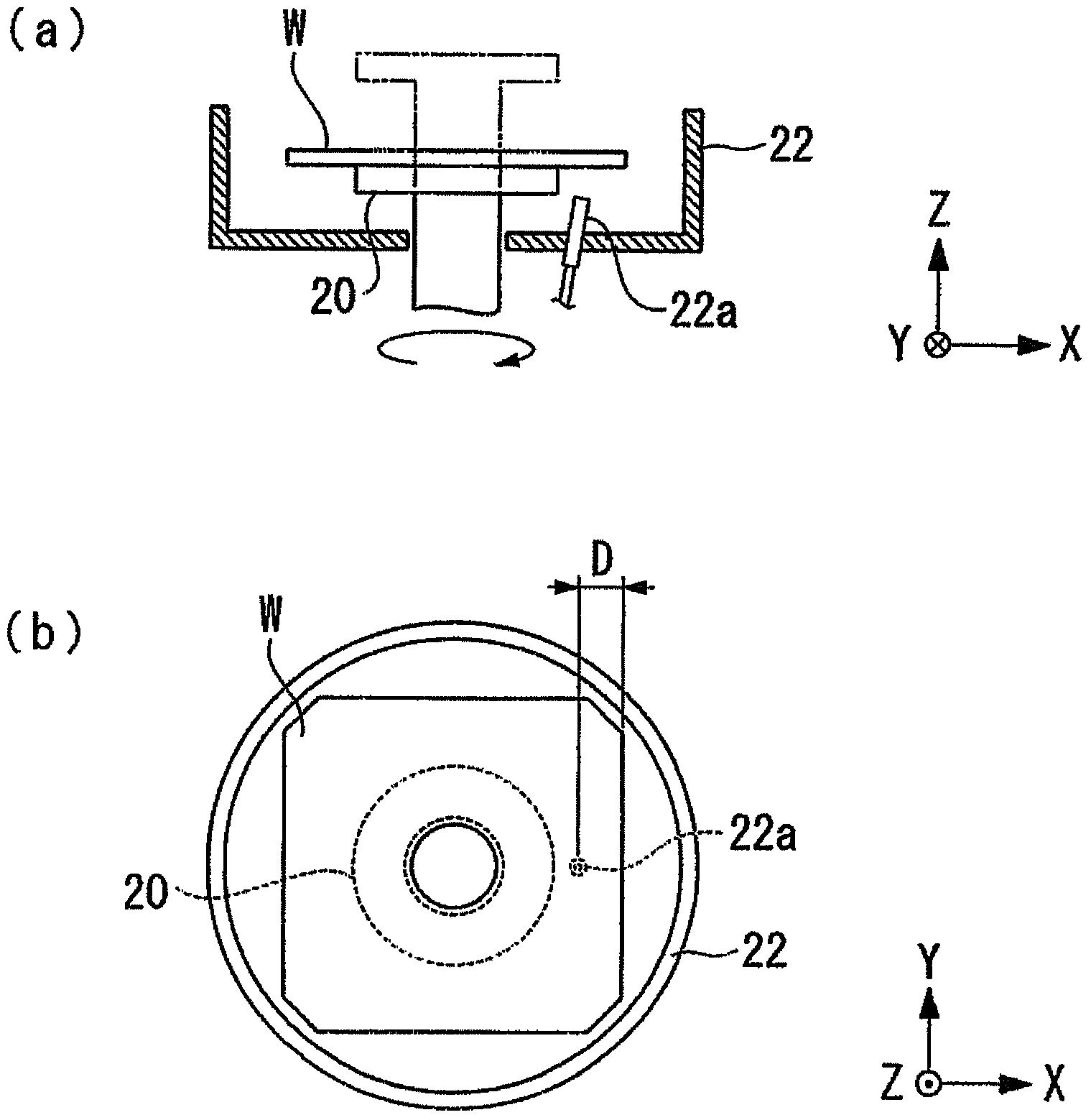

Coating method and coating device

InactiveCN103721913AEconomical and stable coatingSave the beatPretreated surfacesCoatingsMaterials scienceCoating

Owner:TOKYO OHKA KOGYO CO LTD

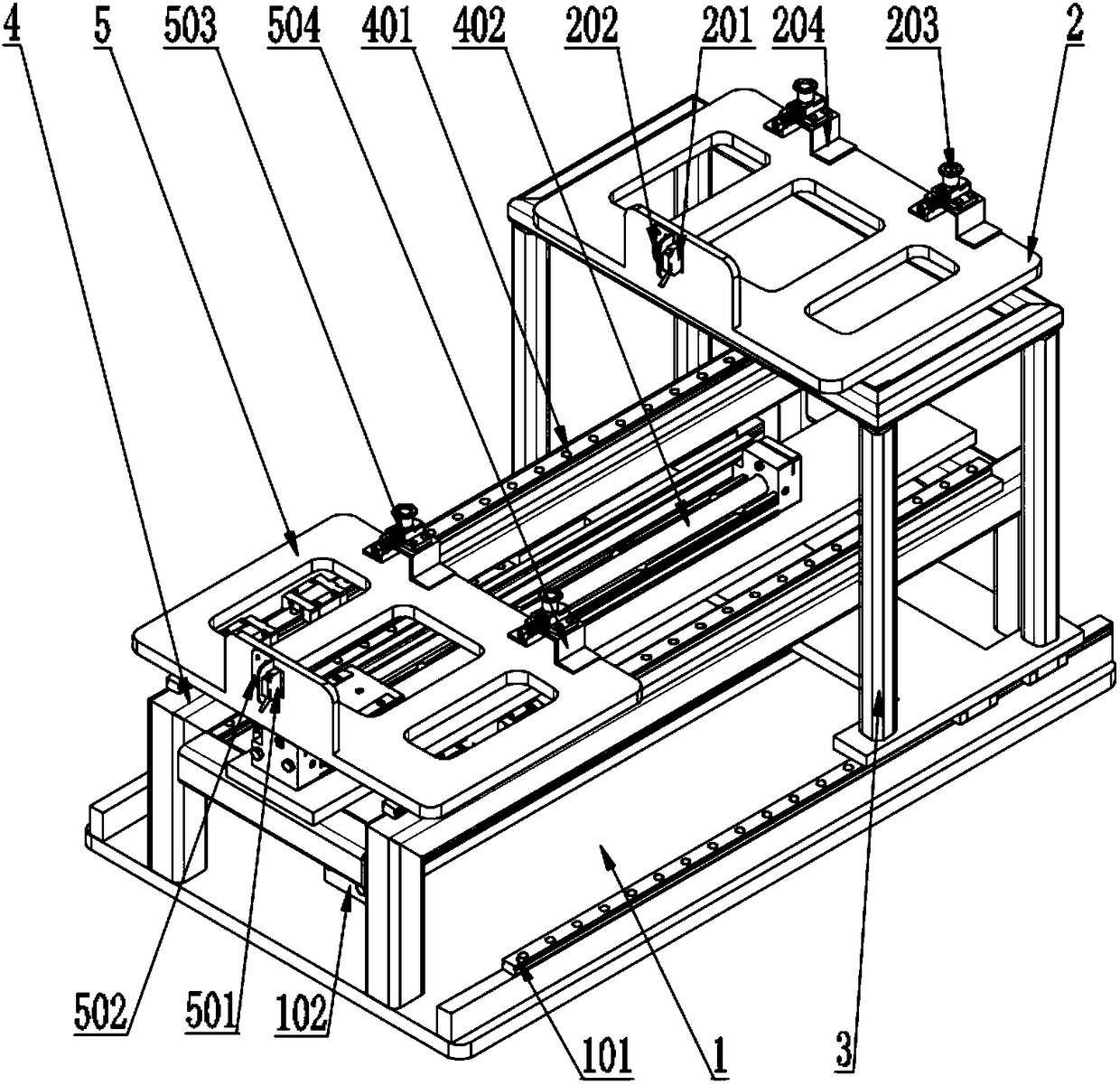

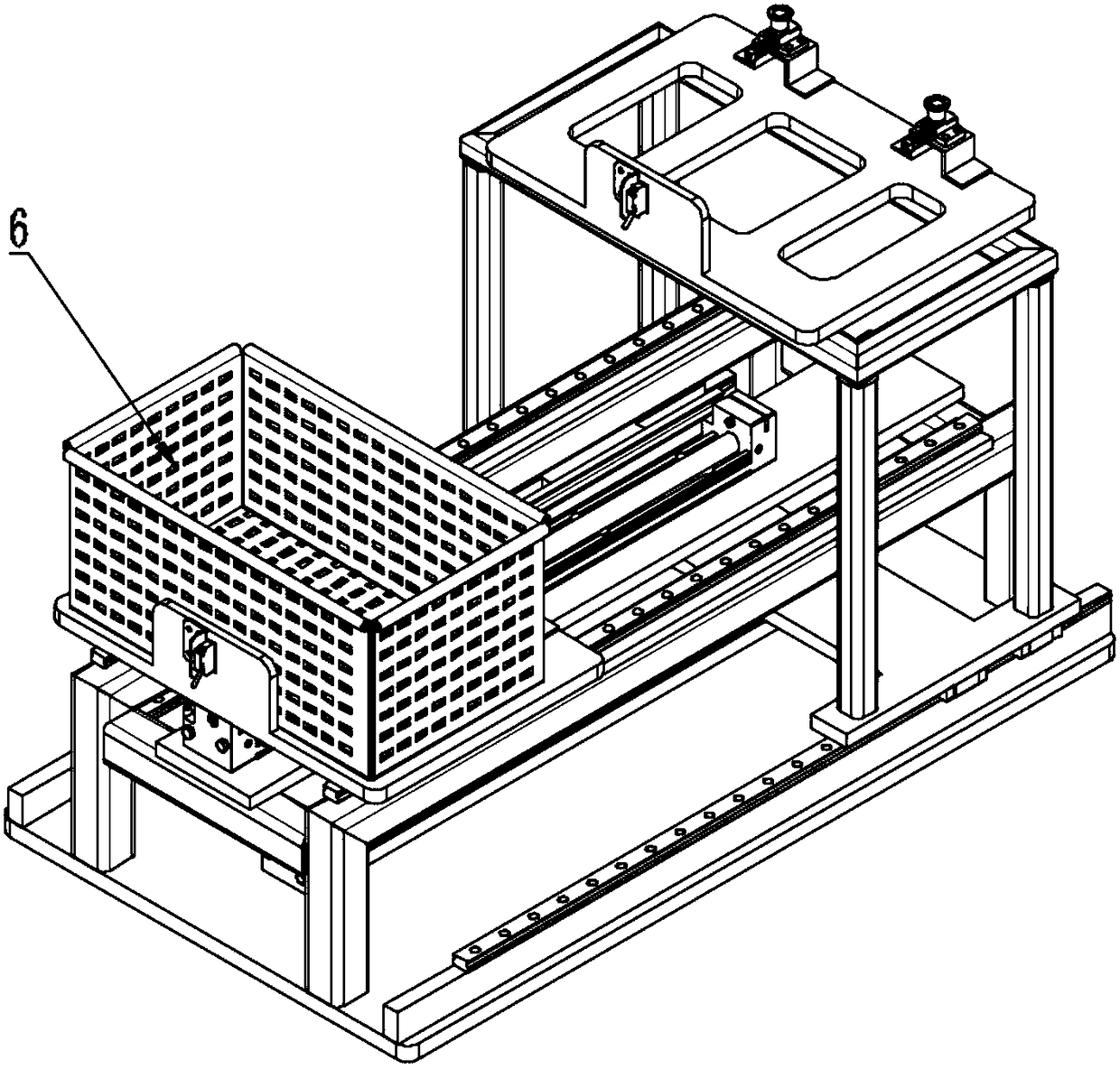

Double-layer feeding and discharging mechanism with continuity

PendingCN108080919AReproducibleWide versatilityMetal working apparatusEngineeringMechanical engineering

Owner:INST OF INTELLIGENT MFG TECH JITRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com