Passive trolley applicable to multiple vehicles

A passive trolley, multi-model technology, applied in vehicle parts, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of high manufacturing cost and maintenance cost, inability to realize multi-model switching, complex trolley structure, etc. Lightweight, save control beats, and improve the effect of switching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

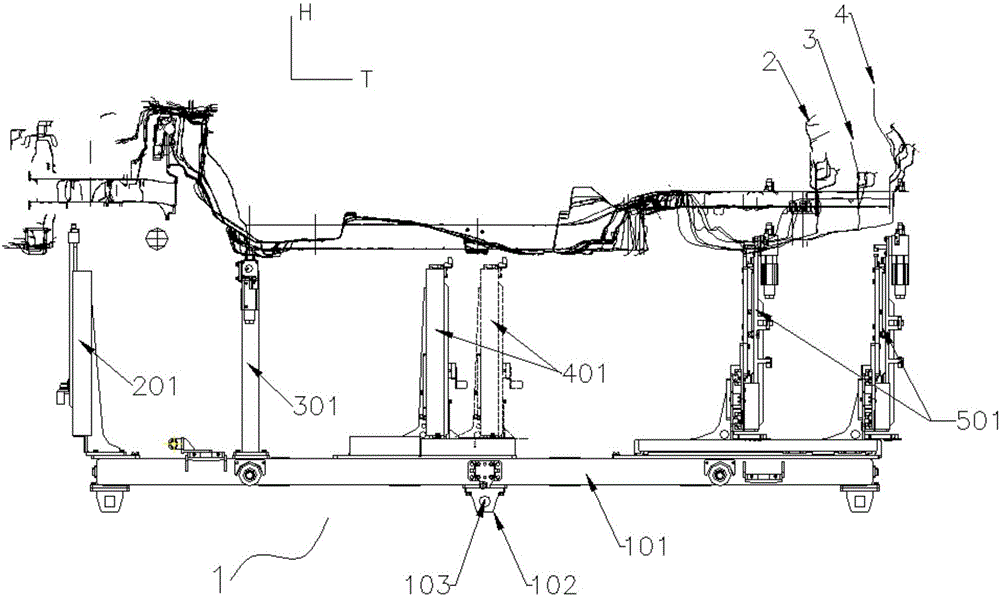

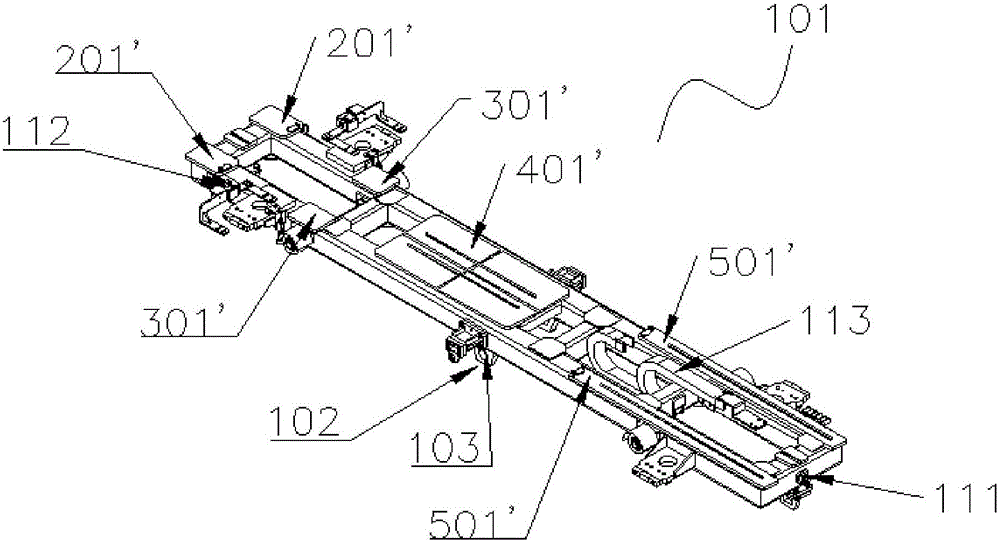

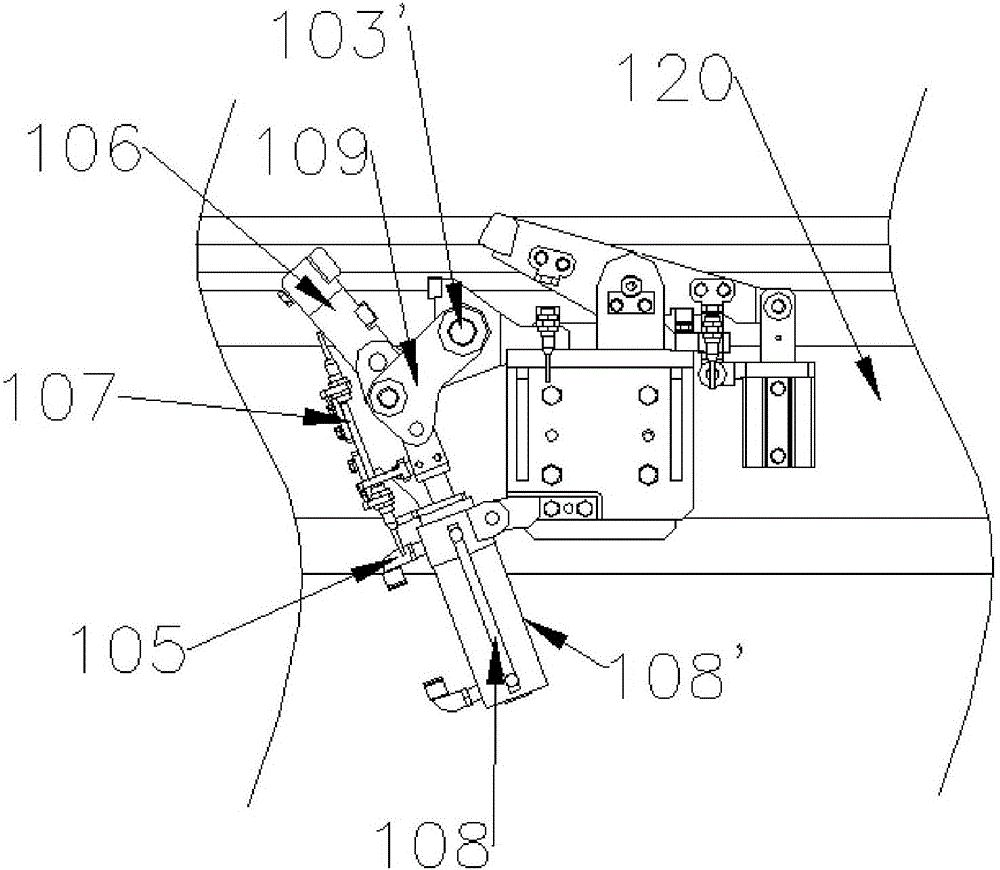

[0031] Such as figure 1 , a passive trolley 1 suitable for multiple vehicle types, referred to as passive trolley, including a multi-vehicle passive trolley platform 101 with front and rear parts that can walk along the track, referred to as passive trolley platform, and The fixed main reference structure 301 of the vehicle model workpiece installed on the multi-model passive trolley platform 101, the multi-model passive trolley platform 101 is provided with a height position at the front, with two positions of height and length in the middle, and two positions at the rear. There are three positions of length, width and height used to determine the vehicle width direction and vehicle height direction of the passive trolley 1. There are two left and right positions in the middle to determine the vehicle length direction of the passive trolley 1. The trolley platform 101 is also provided with an interface that cooperates with a device that provides external power, so that the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com