Feed automatic overturning mechanism of remote controller detection equipment

A detection equipment and automatic turning technology, applied in the field of machinery, can solve the problems of increasing production costs, not satisfying automatic production, wasting manpower, etc., and achieving the effect of improving accuracy, ensuring positioning, and reducing beats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

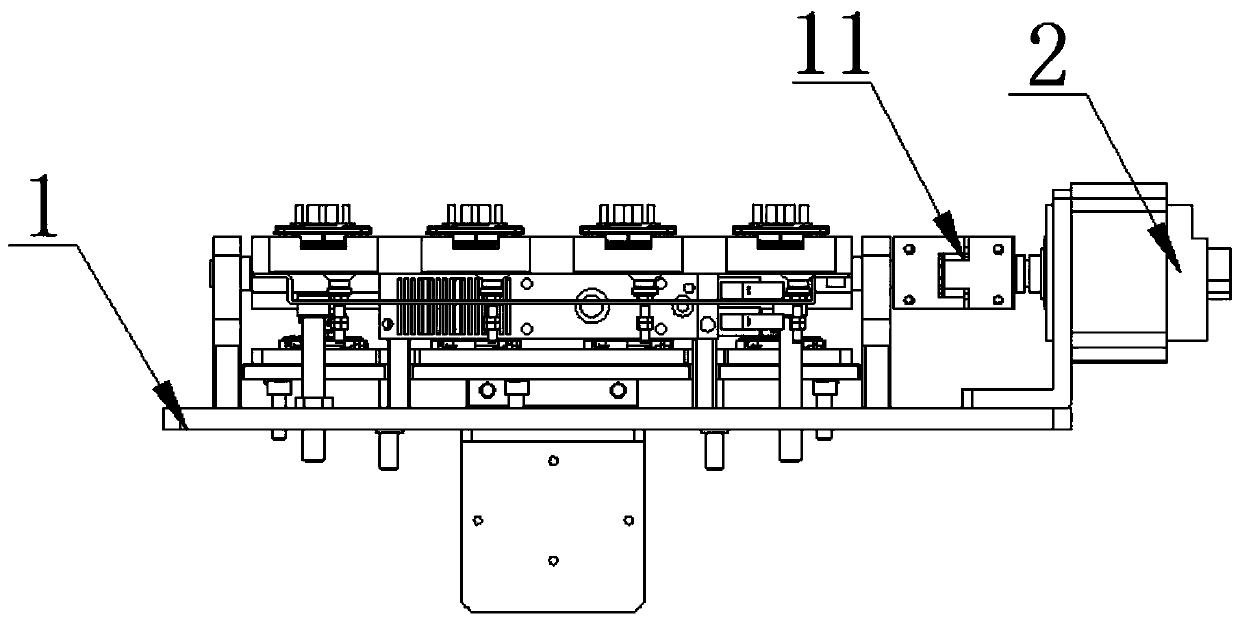

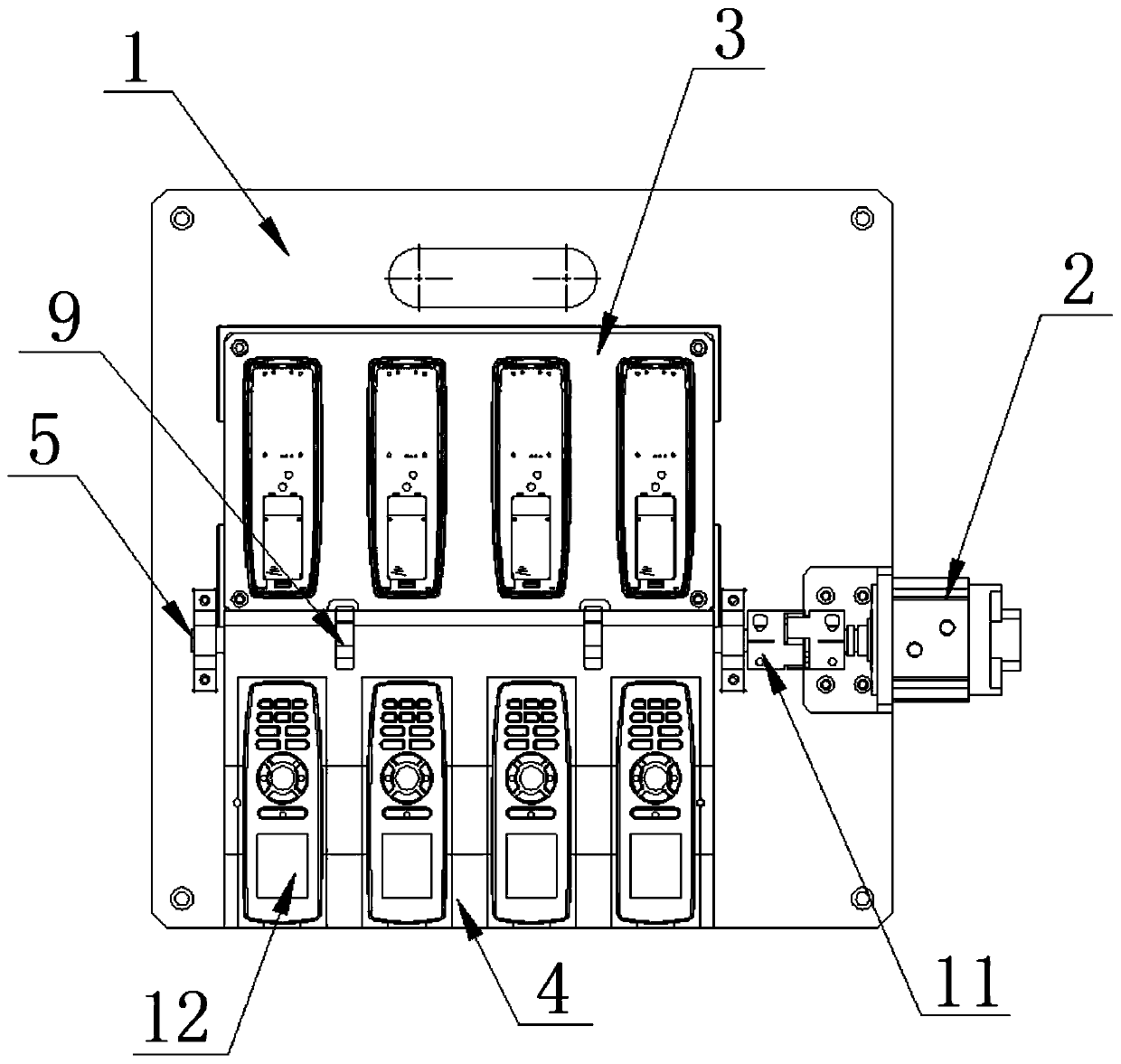

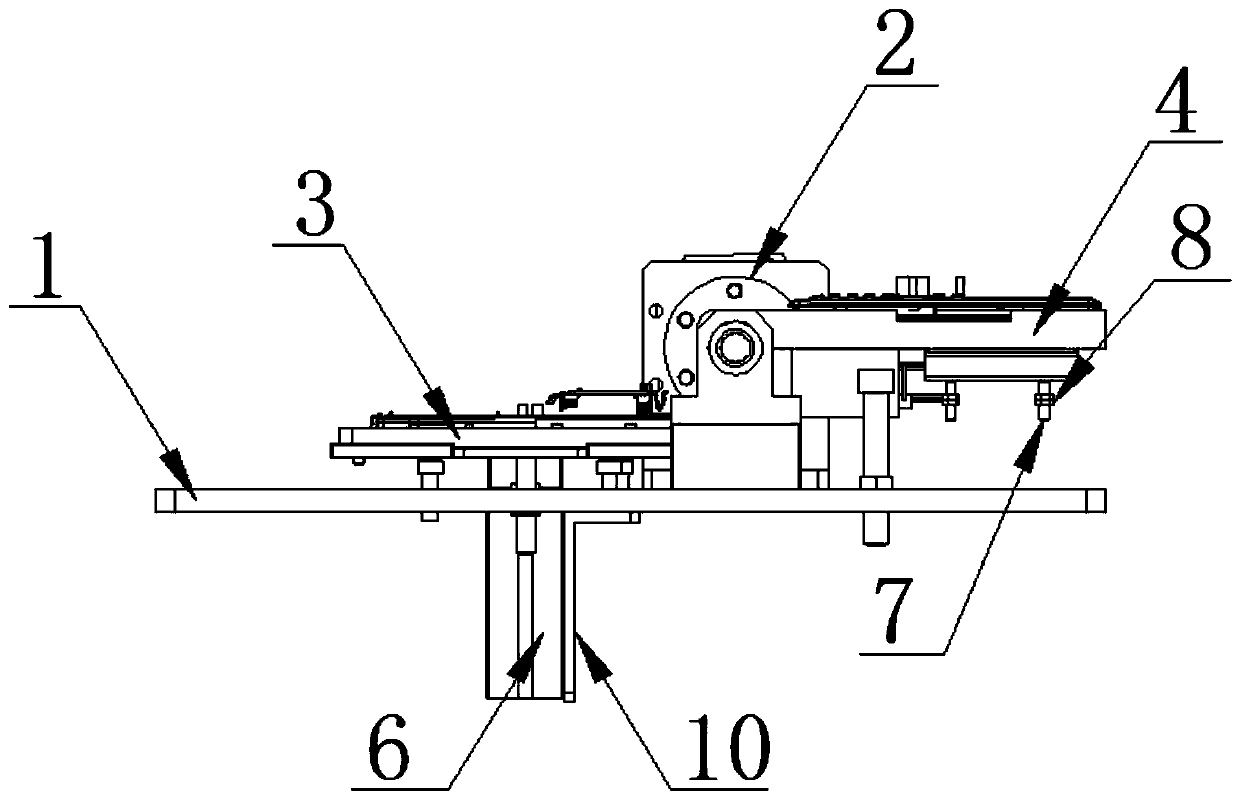

[0026] In order to better understand the purpose, structure and function of the present invention, below in conjunction with appendix Figure 1-5 , understanding of the present invention.

[0027] Such as Figure 1-4 , designed a remote control detection equipment feeding automatic turning mechanism, including a bracket installed on the bottom plate 1, and the bracket is connected to the rotating shaft 5, one side of the rotating shaft 5 is provided with the first station 3 that can carry the workpiece 12 The rotating shaft 5 is also fixedly connected with the second station 4 for carrying the workpiece 12; the second station 4 is equipped with a vacuum chuck 7 for absorbing the workpiece 12 to transfer, and the workpiece 12 is sucked by the vacuum chuck 7 to remove the workpiece 12 from The first station 3 is transferred into the second station 4 .

[0028] The rotating shaft 5 is connected with a driving mechanism that drives the rotating shaft 5 to rotate. The driving mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com