Patents

Literature

55results about How to "Speed up the loading process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-language supporting webpage processing method, webpage loading method and systems

ActiveCN102693322AReduce storage capacitySpeed up the loading processNatural language translationCode conversionMulti languageNetwork application

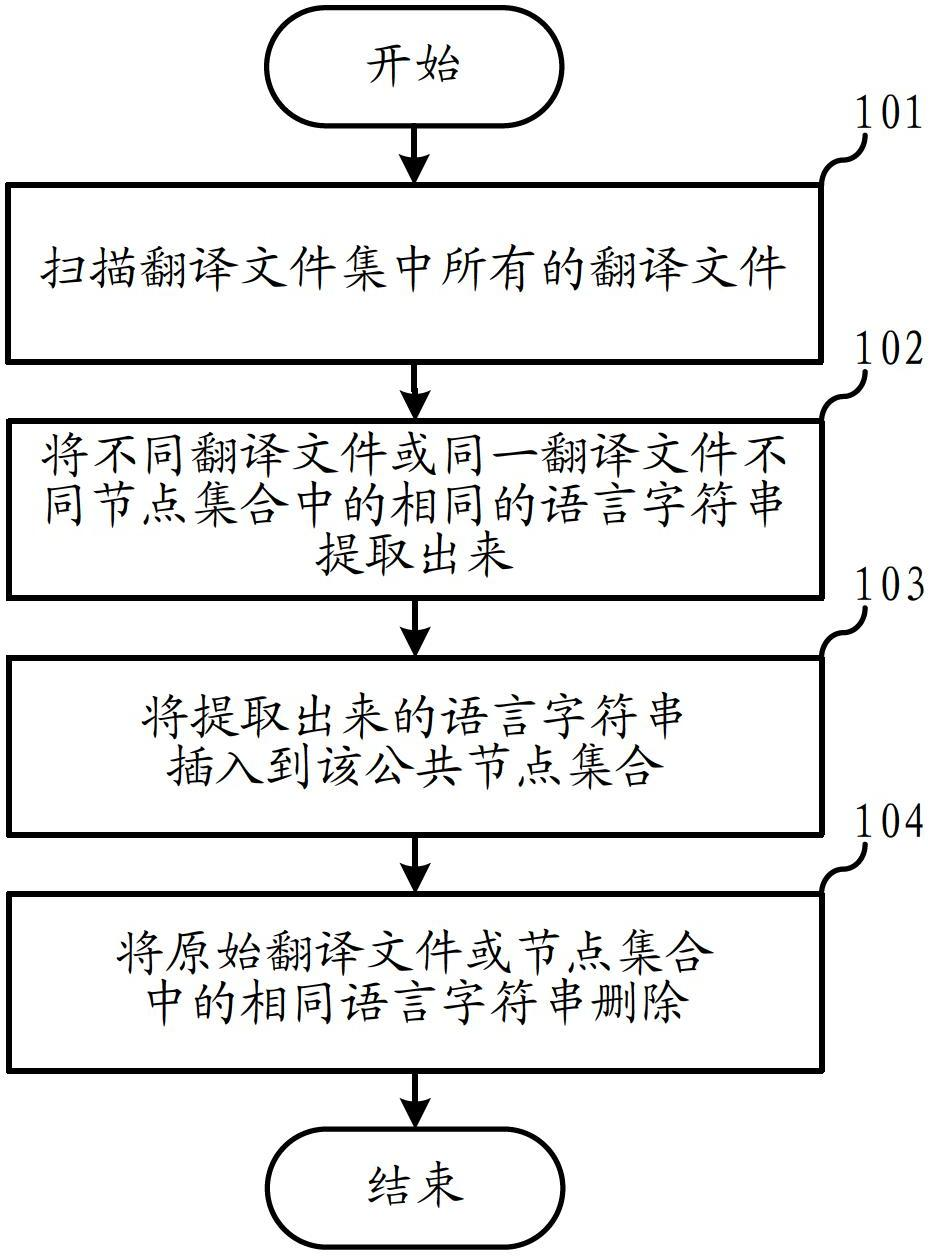

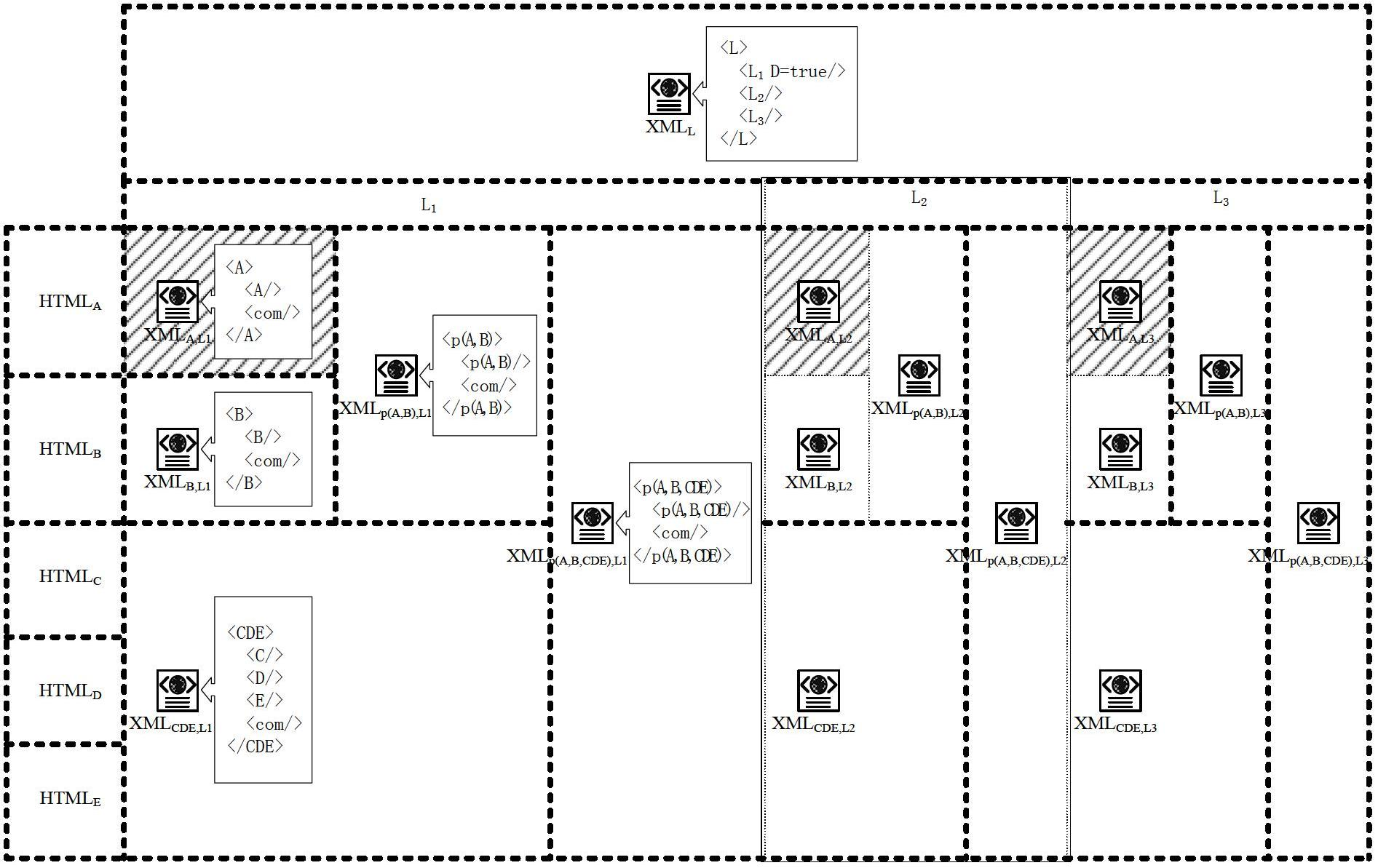

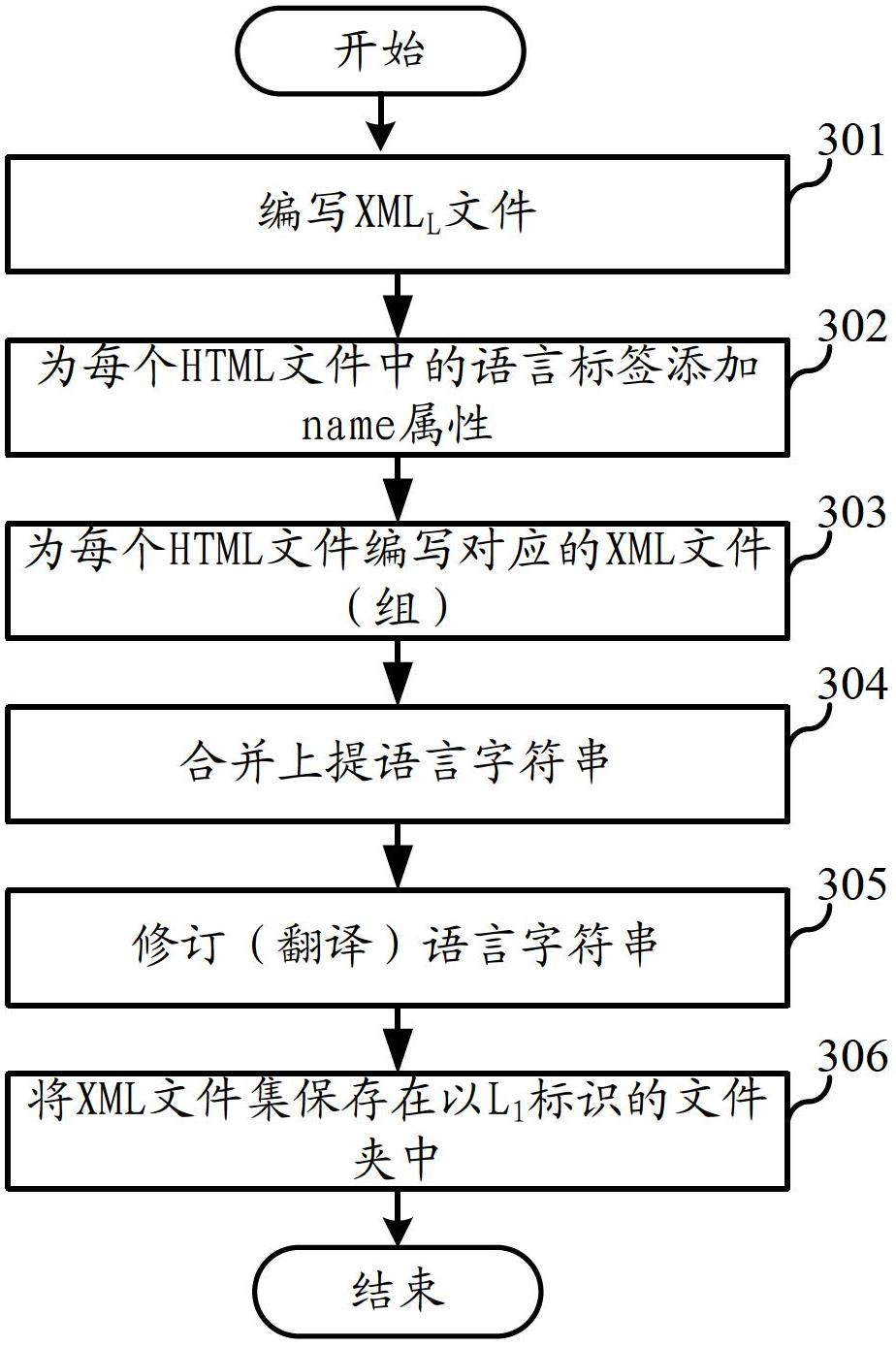

The invention relates to the field of computer network application, and discloses a multi-language supporting webpage processing method, a multi-language supporting webpage loading method, a multi-language supporting webpage processing system and a multi-language supporting webpage loading system. When a certain language is added or modified, labor time and labor cost are reduced, the storage capacity of a webpage server is saved, webpage loading speed and translation rendering speed are increased, and the redundancy of a translated file set is reduced. The multi-language supporting webpage processing method is based on a translated file set with a tree structure, wherein each hyper text markup language (HTML) file corresponds to a translated file. The multi-language supporting webpage processing method comprises the following steps of: scanning all translated files in the translated file set; extracting the same language character string in different node sets of different translated files or the same translated file, and inserting the same language character string into a least common ancestor translated file of the different translated files or a common node set of the same translated file; and deleting the same language character string from the original translated files or the node sets.

Owner:HANGZHOU HIKVISION DIGITAL TECH

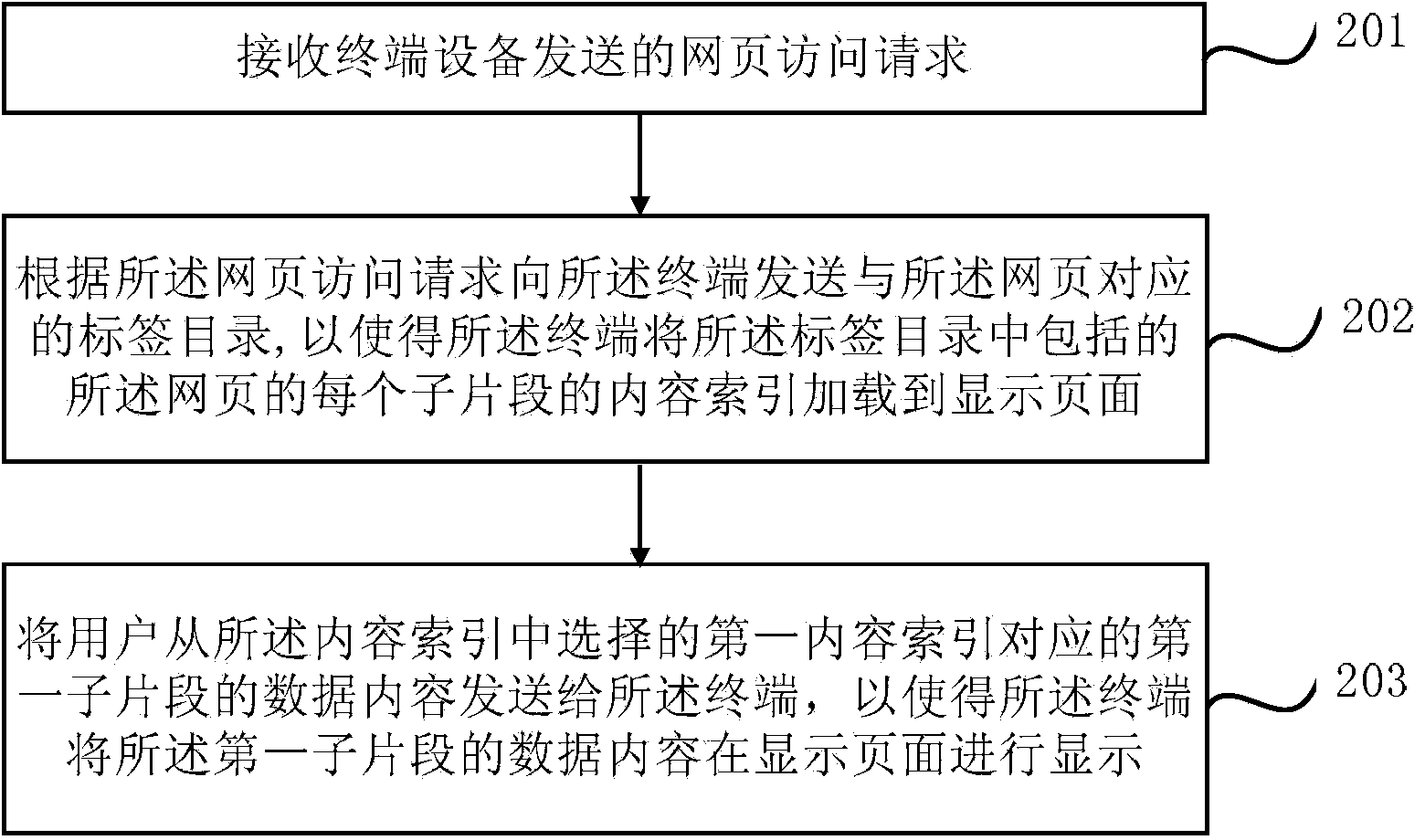

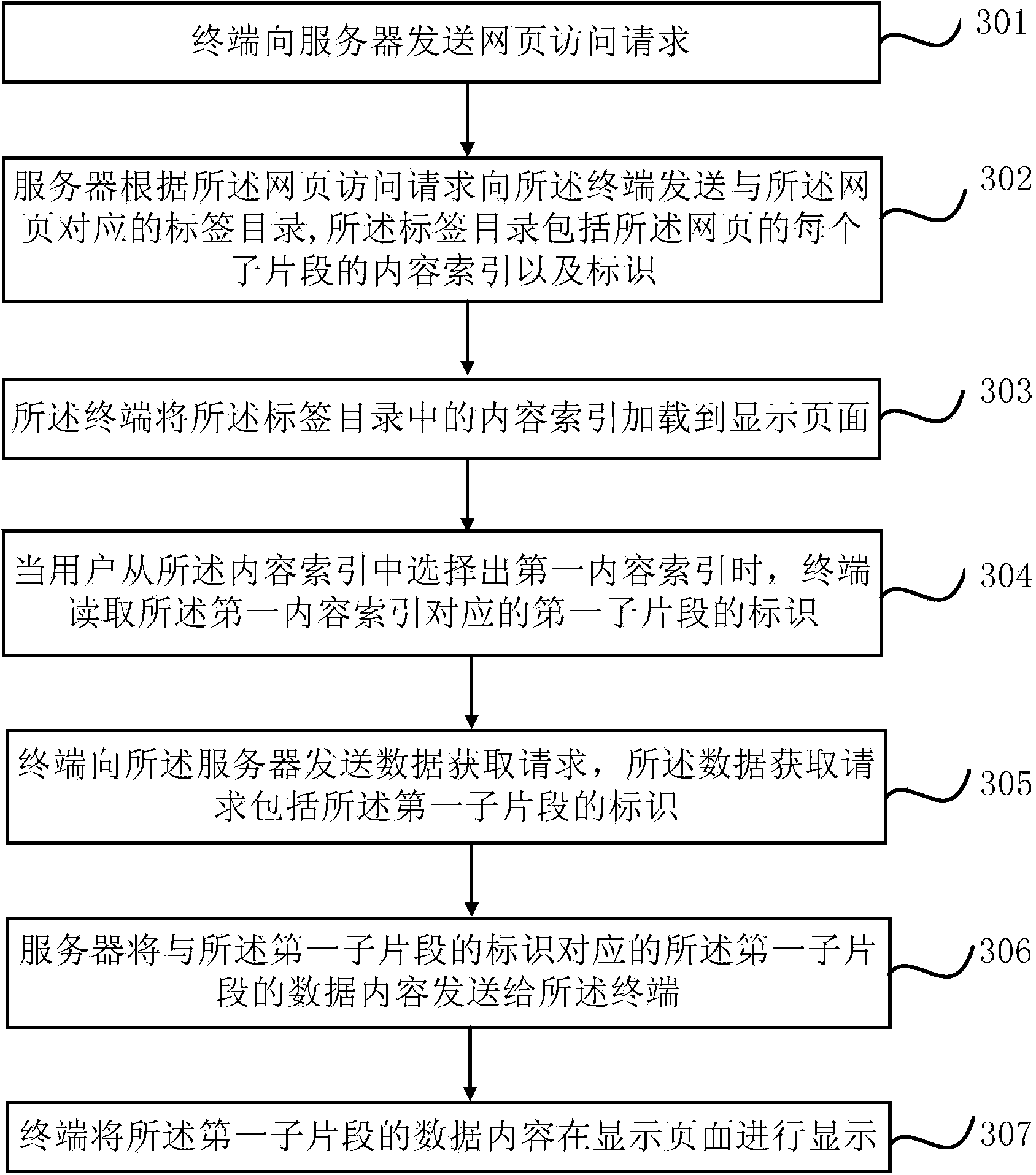

Webpage display method and device

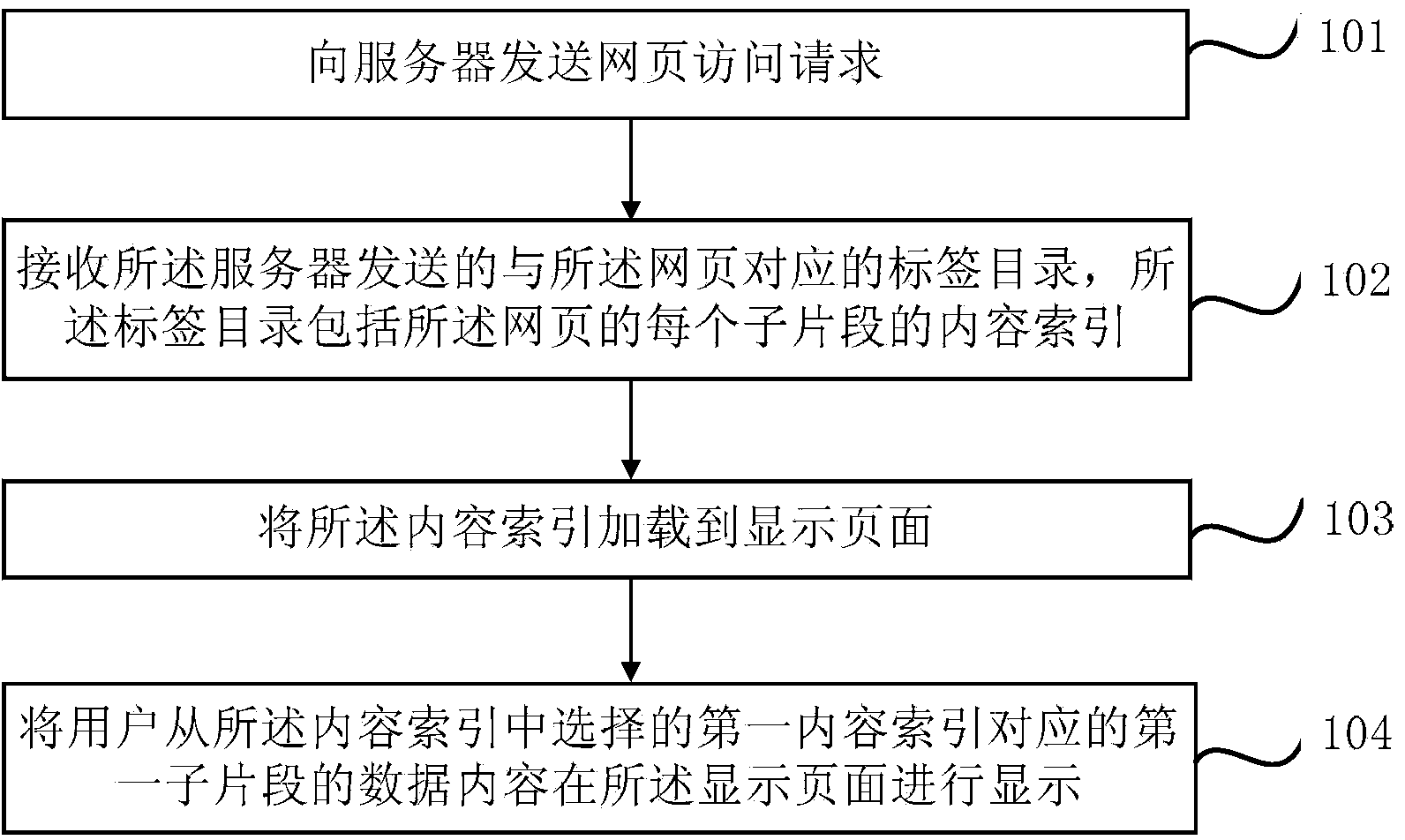

InactiveCN104021155ASpeed up the loading processImprove reading experienceTransmissionSpecial data processing applicationsData contentFile comparison

The invention discloses a webpage display method and device. The webpage display method comprises the steps that a webpage access request is sent to a server; a label catalogue corresponding to the webpage and sent by the server is received, and the label catalogue comprises content indexes of each sub-fragment of the webpage; the content indexes are loaded to the display webpage; data content of a first sub-fragment corresponding to the first content index selected by a user from all the content indexes is displayed on the display webpage. The webpage display method and device can accelerate the webpage loading progress when the webpage data are large and the network environment is not good, thereby improving reading experience of the user.

Owner:XIAOMI INC

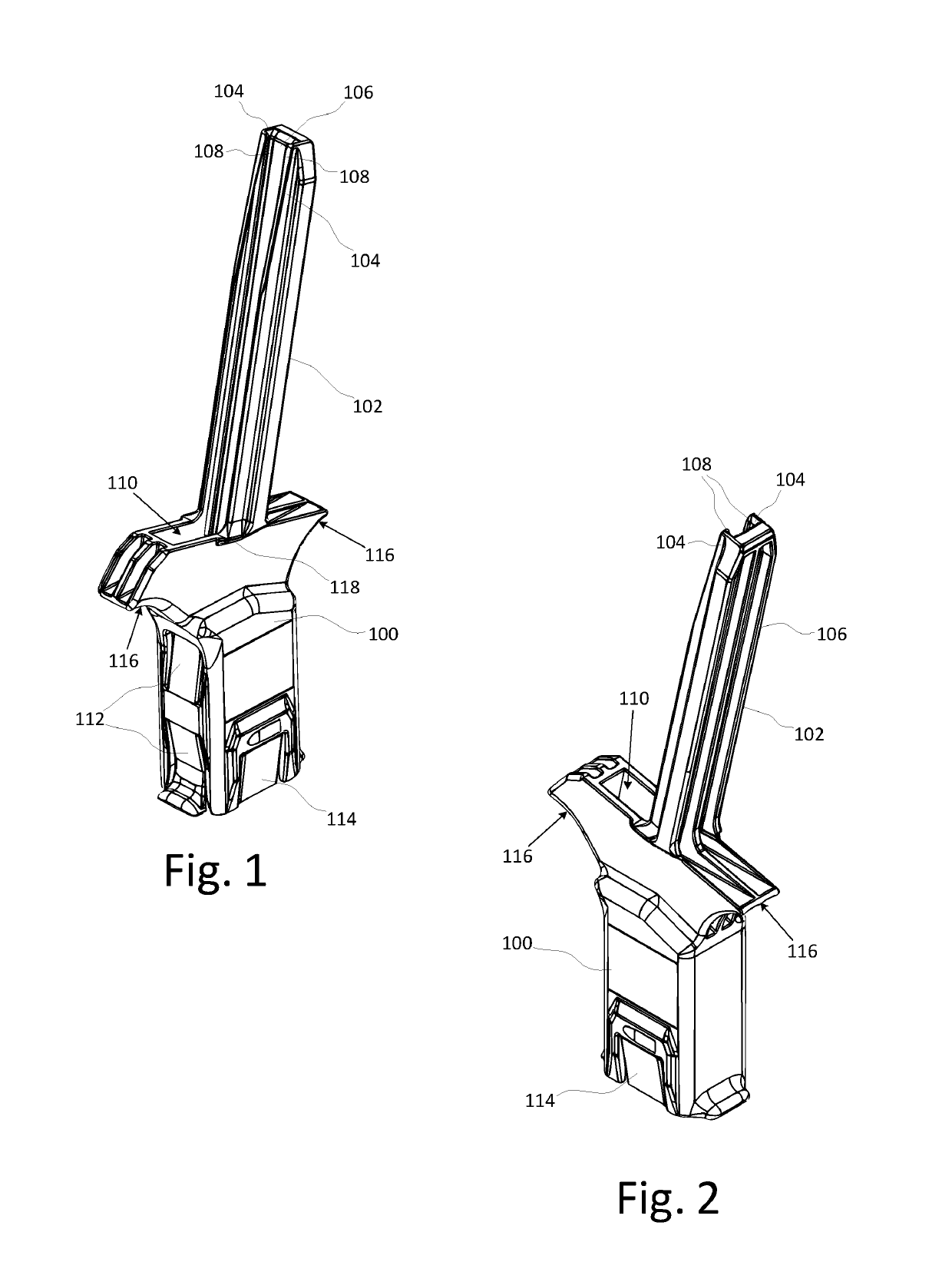

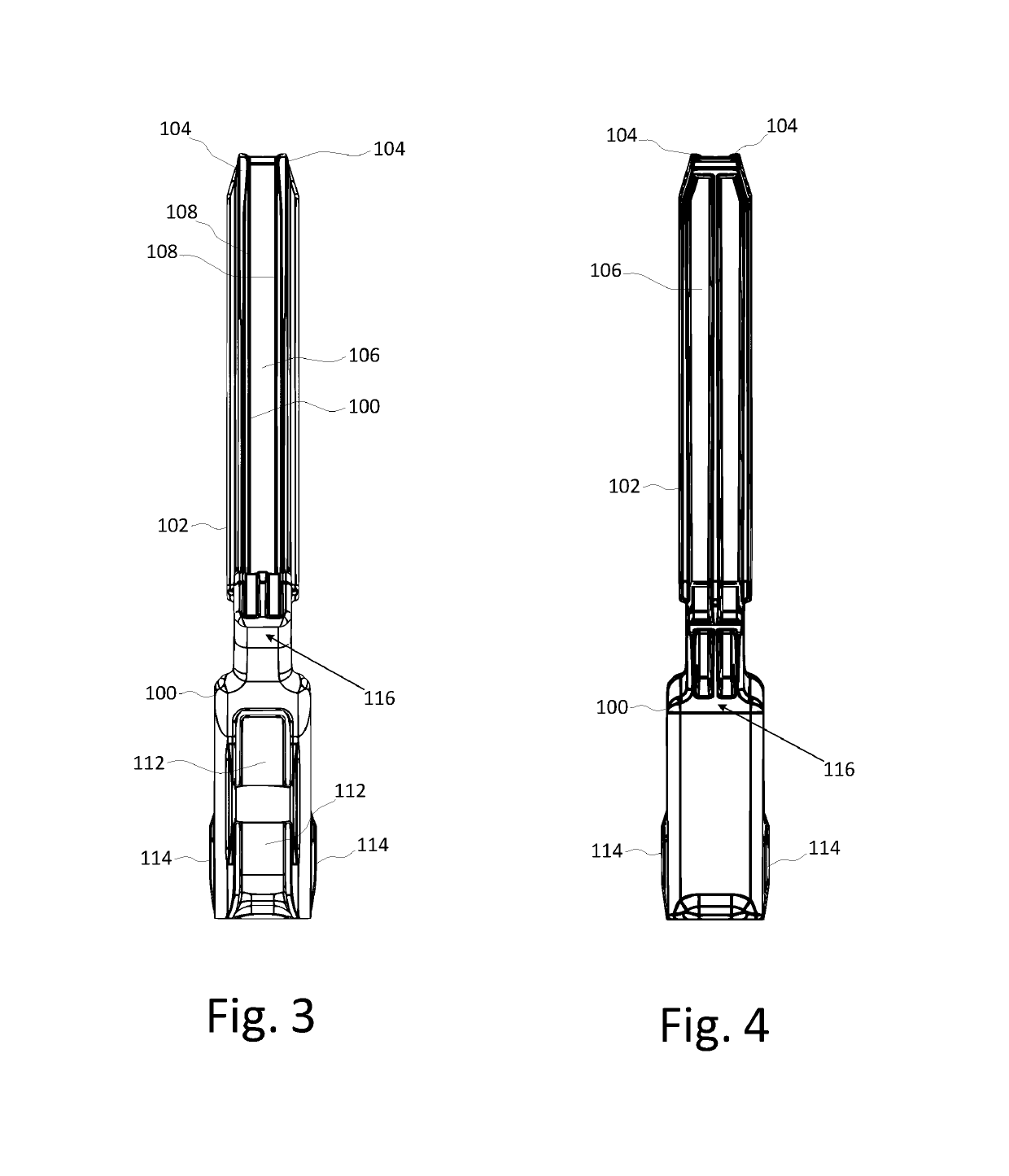

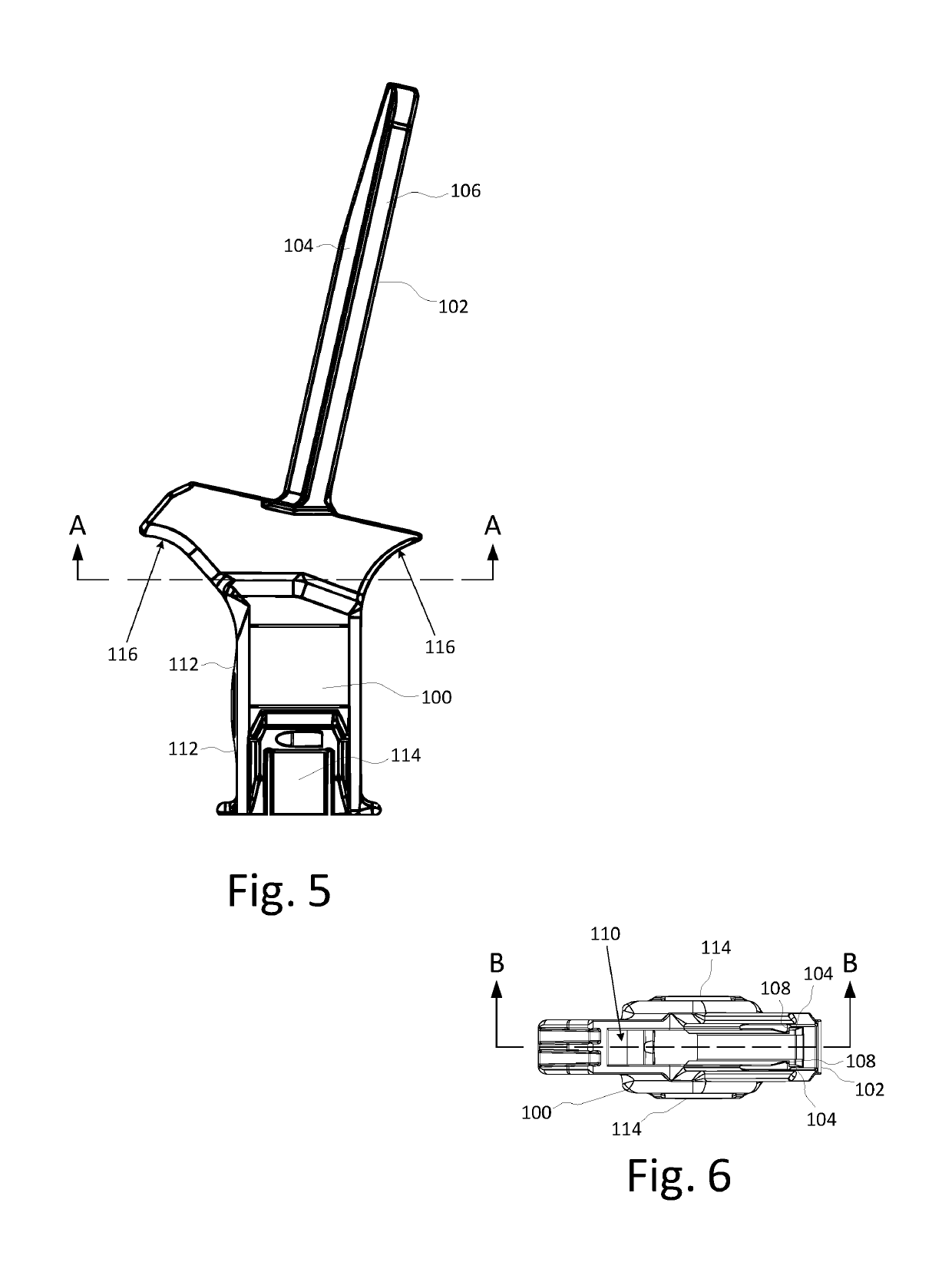

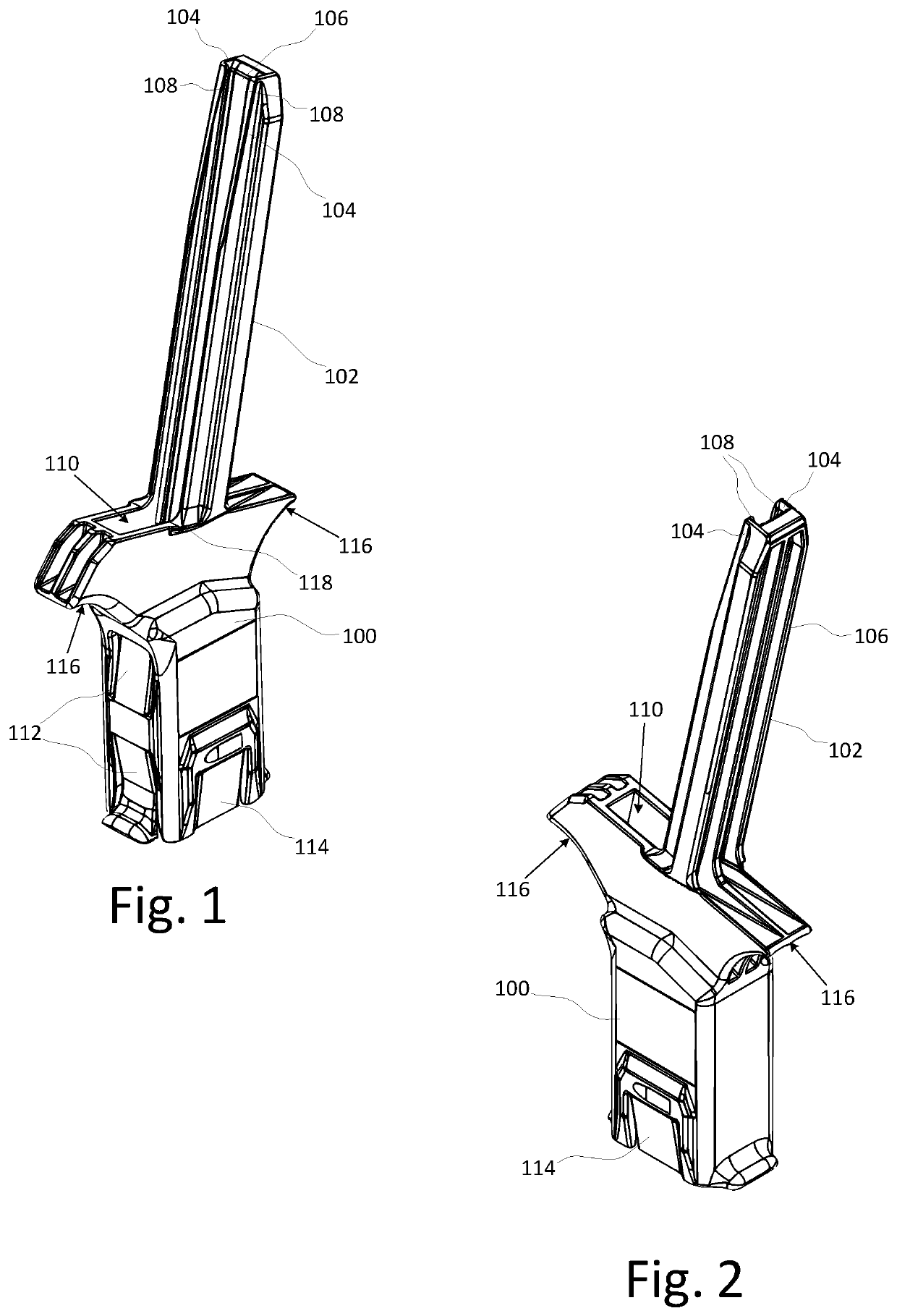

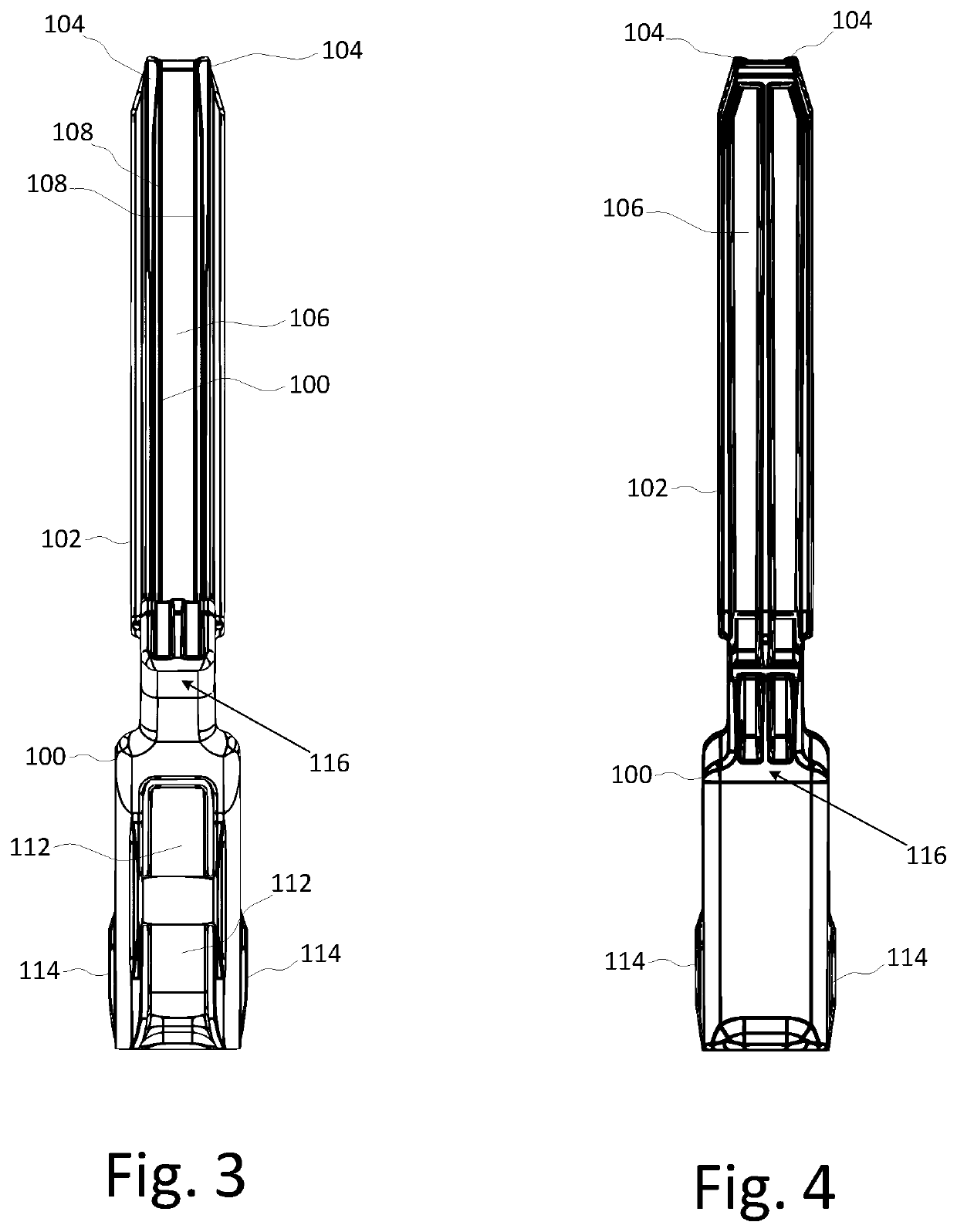

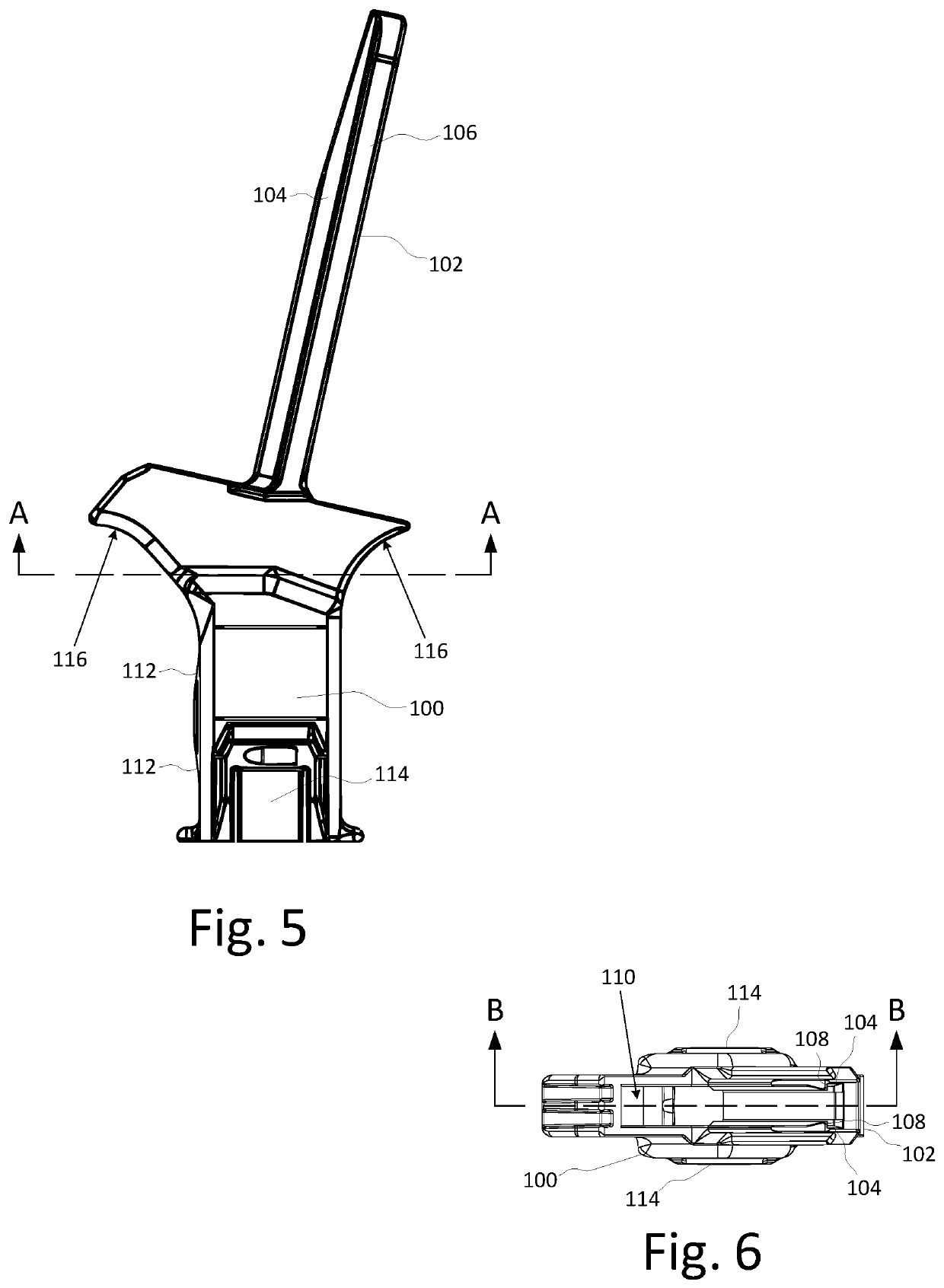

Firearm magazine loader

A firearm magazine loader. The loader includes a body having a linear projection extending from the top of the loader for holding rounds of ammunition and an optional plunger for pushing the rounds into a magazine. The loader accommodates and centers a wide variety of magazines due to a self-centering mechanism incorporated into the body. An angled feed channel pivots the rounds into position to slide under the feed lips of a magazine to significantly reduce the insertion force required and allow a double stack magazine to be quickly filled to capacity with minimal effort.

Owner:ELITE TACTICAL SYST GRP LLC

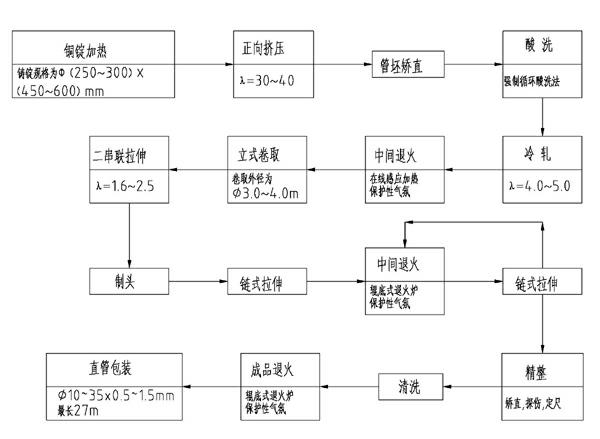

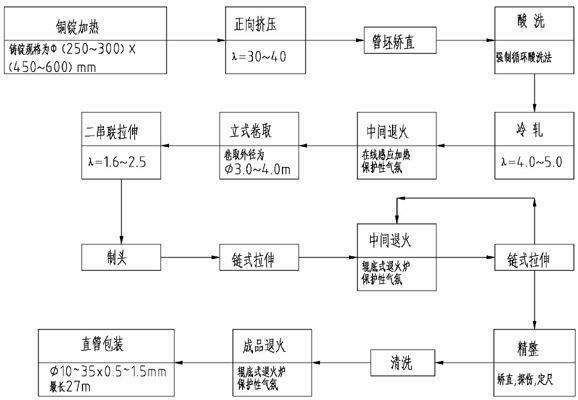

Production process of super long brass condenser pipe

The invention relates to a production process of a super long brass condenser pipe, comprising the following steps of: preheating a cast ingot, peeling and extruding, scale sawing, straightening, forced circulation acid washing, cold rolling, induction continuous annealing, vertical rolling, secondary series stretching, scale sawing, intermediate annealing with protective atmosphere, multi-pass chain type stretching, finishing, cleaning, finished product annealing with protective atmosphere and packaging. According to the production process disclosed by the invention, a large-cast-ingot high-extrusion-ratio is adopted, thus extrusion finished product ratio is improved; a forced circulation acid washing method is adopted, thus environmental protection is enhanced and production operational safety is guaranteed; induction cast ingot heating and online induction intermediate annealing are adopted, thus energy consumption is reduced; a vertical rolling process after online induction is adopted, thus floor area of the process in a workshop is reduced; higher cold rolling elongation is adopted, thus flow of the production process is shortened and production efficiency is improved; longer intermediate product production is adopted, thus number of stretching manufacturing heads is reduced, and finished product ratio is improved; and a super long straight bar condenser pipe is produced, thus application range of the product is expanded.

Owner:CHINA NERIN ENG

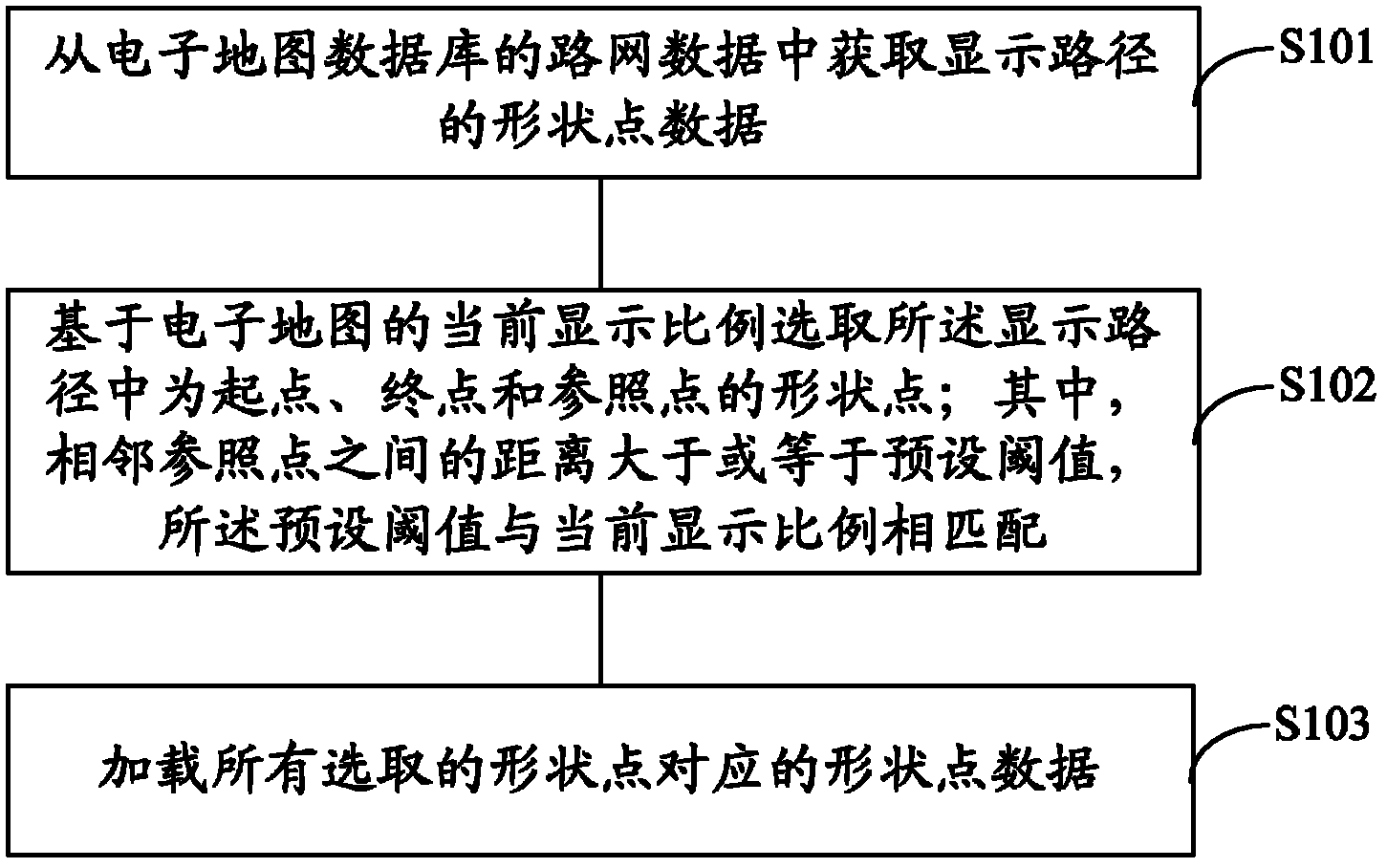

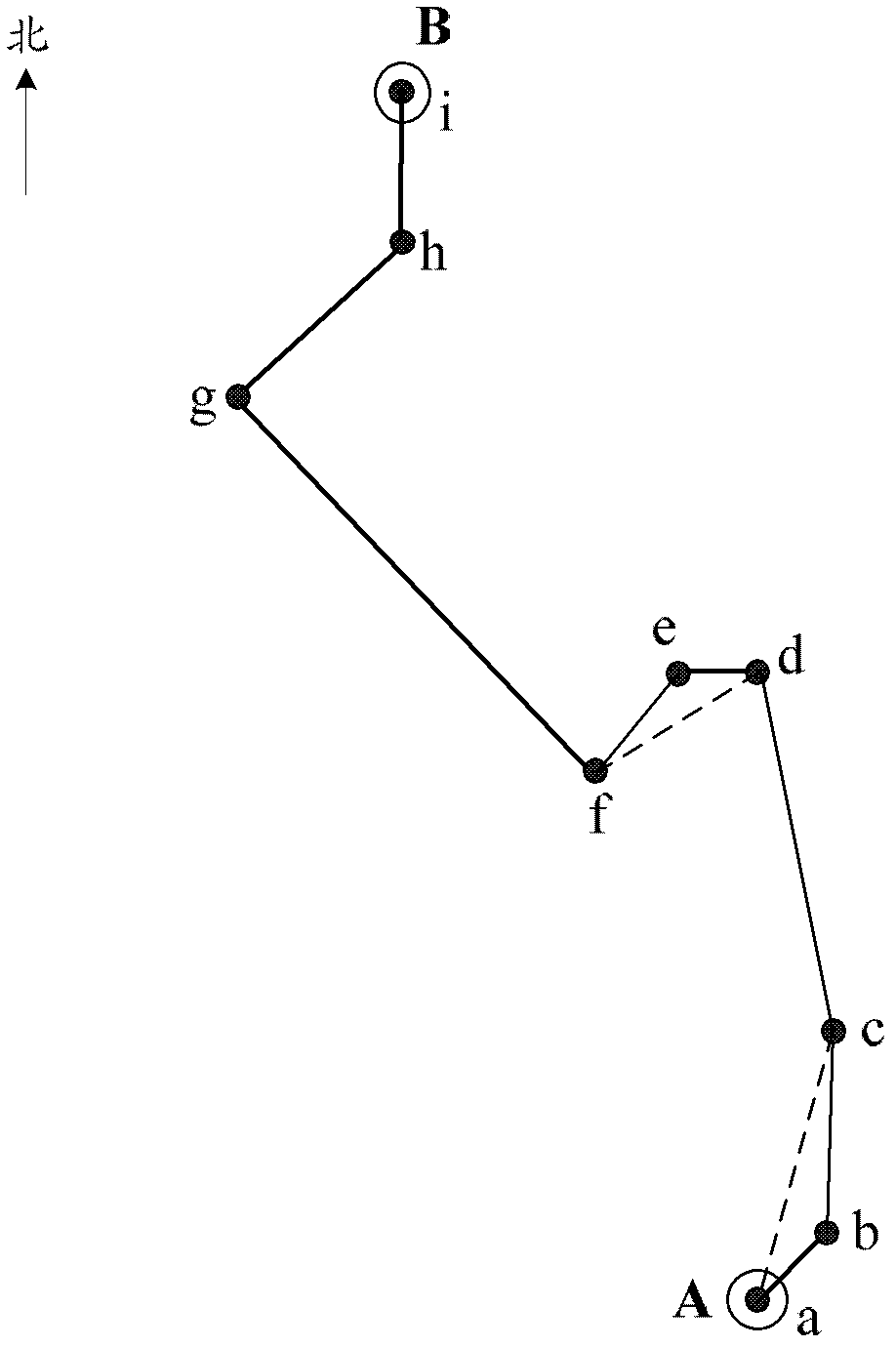

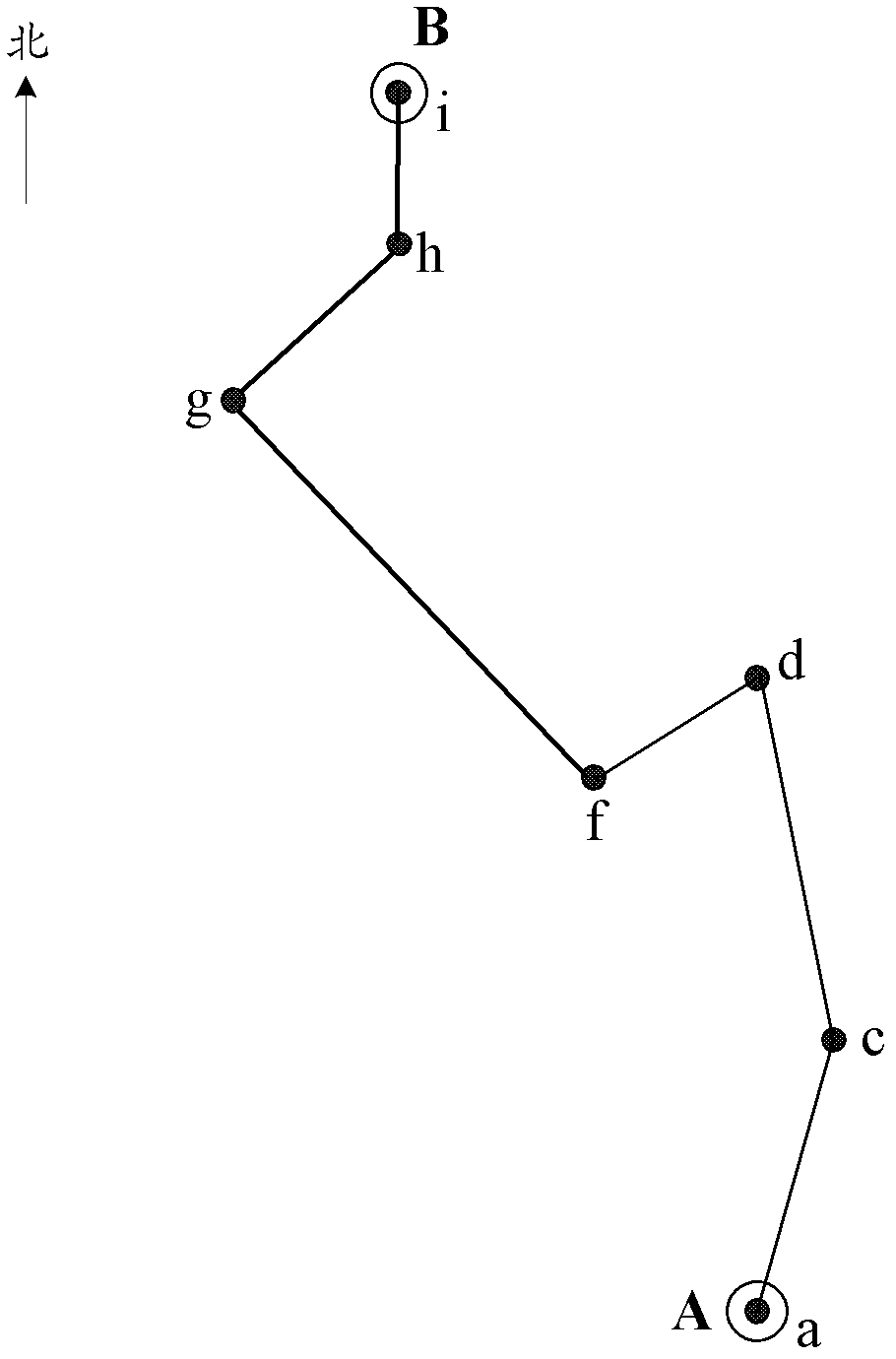

Road network shape point data loading method and device, and navigation method and device

ActiveCN103185582AImproved loading and usage performanceImprove loading speedInstruments for road network navigationMaps/plans/chartsElectronic mapPoint data

The invention provides a road network shape point data loading method and device, and a navigation method and device. The road network shape point data loading method comprises: obtaining shape point data of display road from road network data in an electronic map database; and selecting shape points of a start point, an end point and a reference point in the display path based on a current display proportion of an electronic map. Wherein, distance between adjacent reference points is larger than or equal to a preset threshold, and the preset threshold is matched to the current display proportion; shape points relative to all selected shape points are loaded. The technical scheme of the invention, based on the different display proportion of the electronic map, abstracts the relative road network shape point data, to raise the loading and using performances of the shape point data.

Owner:SHANGHAI PATEO ELECTRONIC EQUIPMENT MANUFACTURING CO LTD

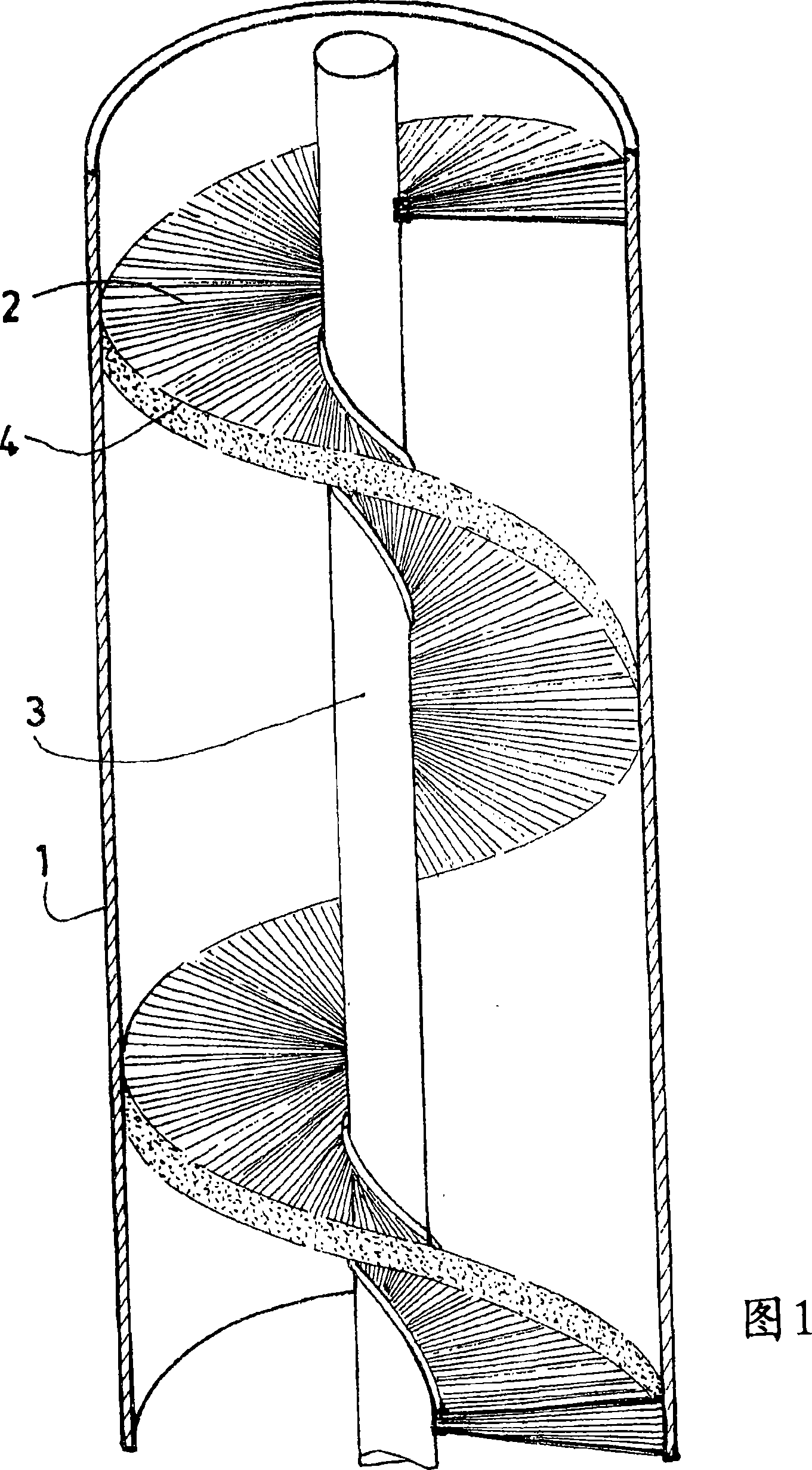

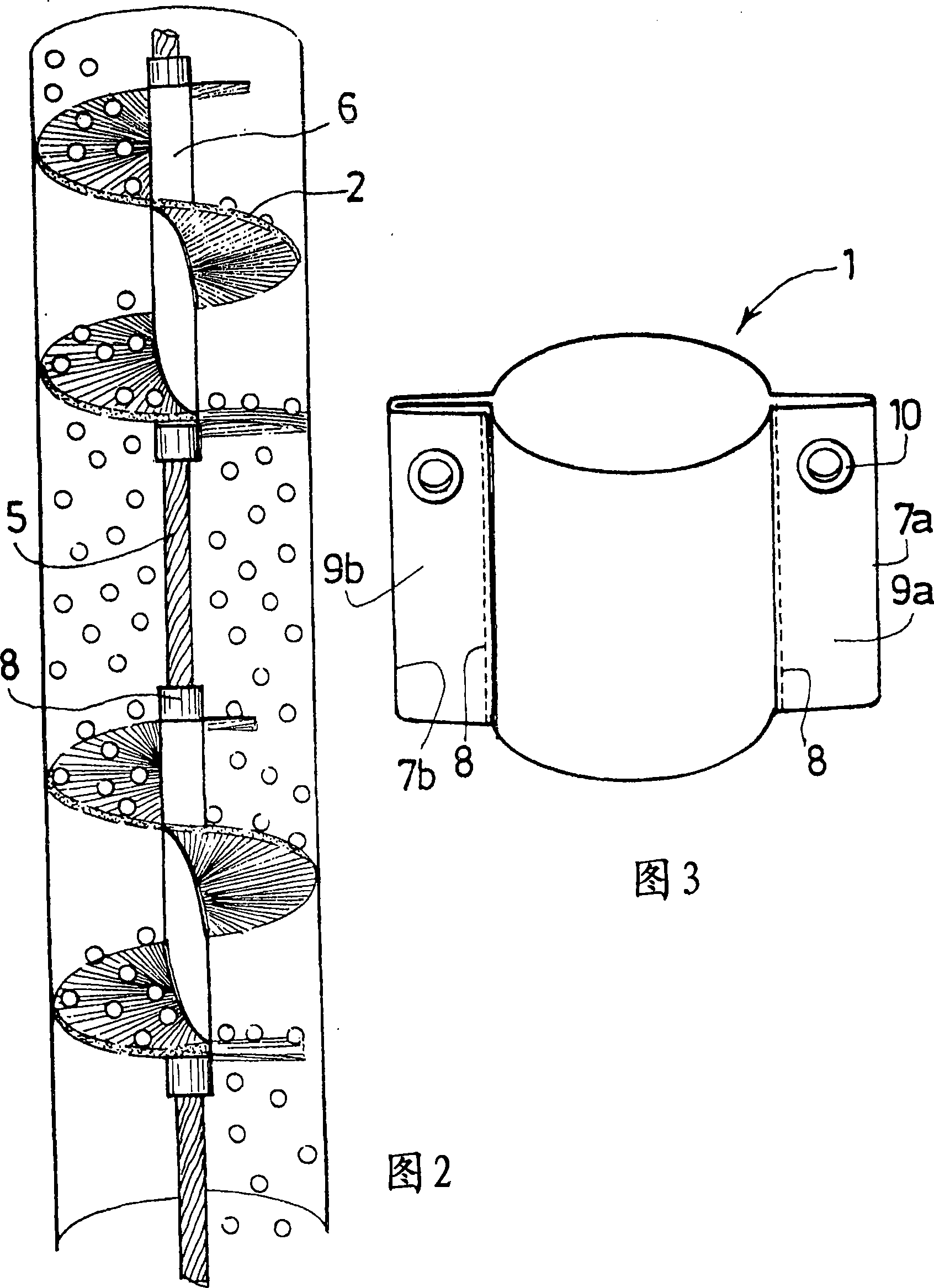

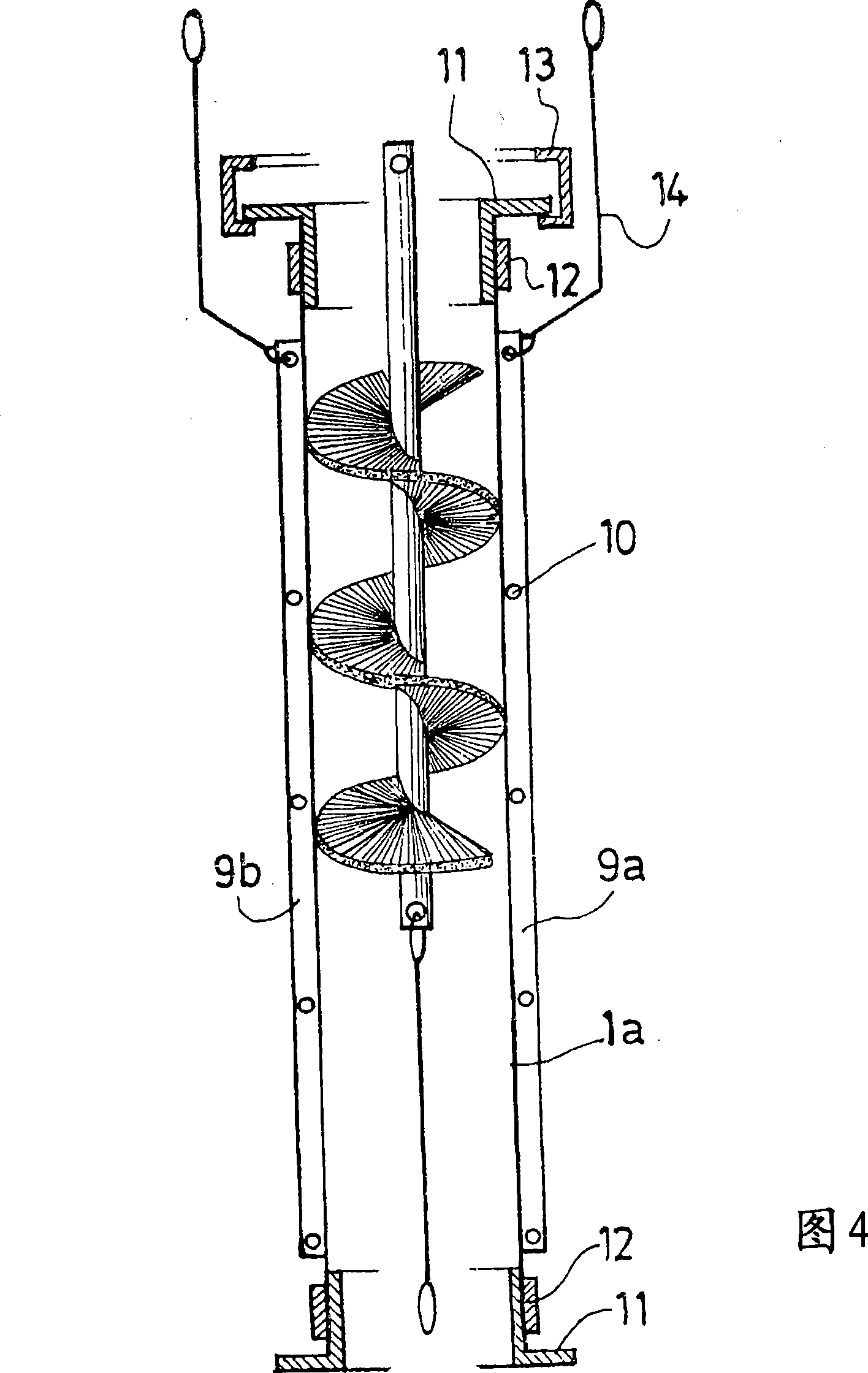

Device for loading a vessel with solid particles and method using said device

InactiveCN101006000AReduce tearingReduce riskLoading/unloadingChemical/physical processesParticle flowChemical reactor

The invention relates to a device for introducing solid particles into a vessel, in particular into a chemical reactor which comprises a pipe, preferably flexible and cylindrical, through which said particles flow from the top downward and is characterised in that it also comprises at least one helicoidal ramp (2) which is placed inside the pipe, wound around a central axis (2) and whose width issuch that a distance between the external edge (4) of the ramp (2) and the pipe (1) is less than the size of introducible solid particles. A method using the inventive device is also disclosed.

Owner:TOTAL RAFFINAGE MARKETING

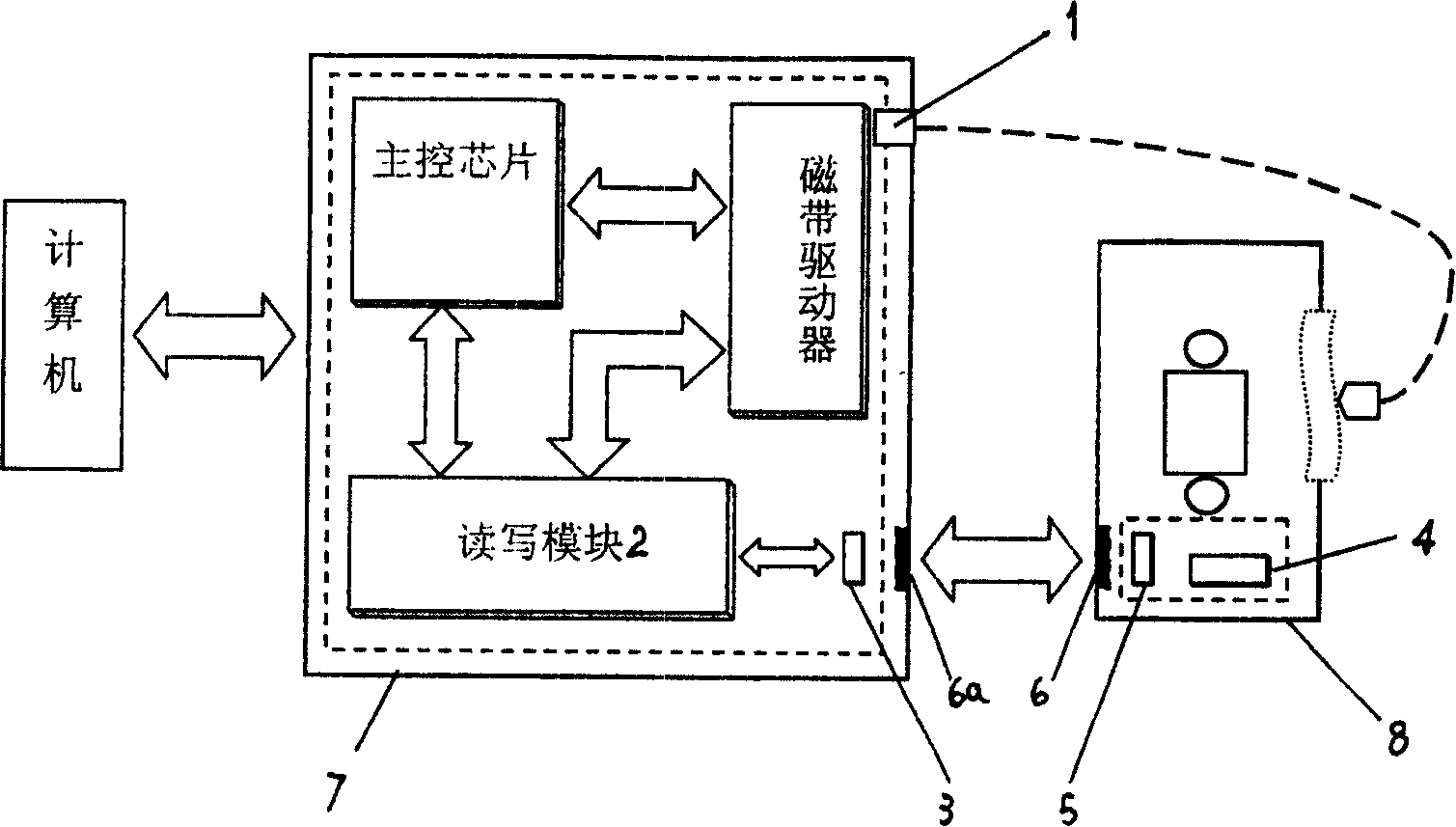

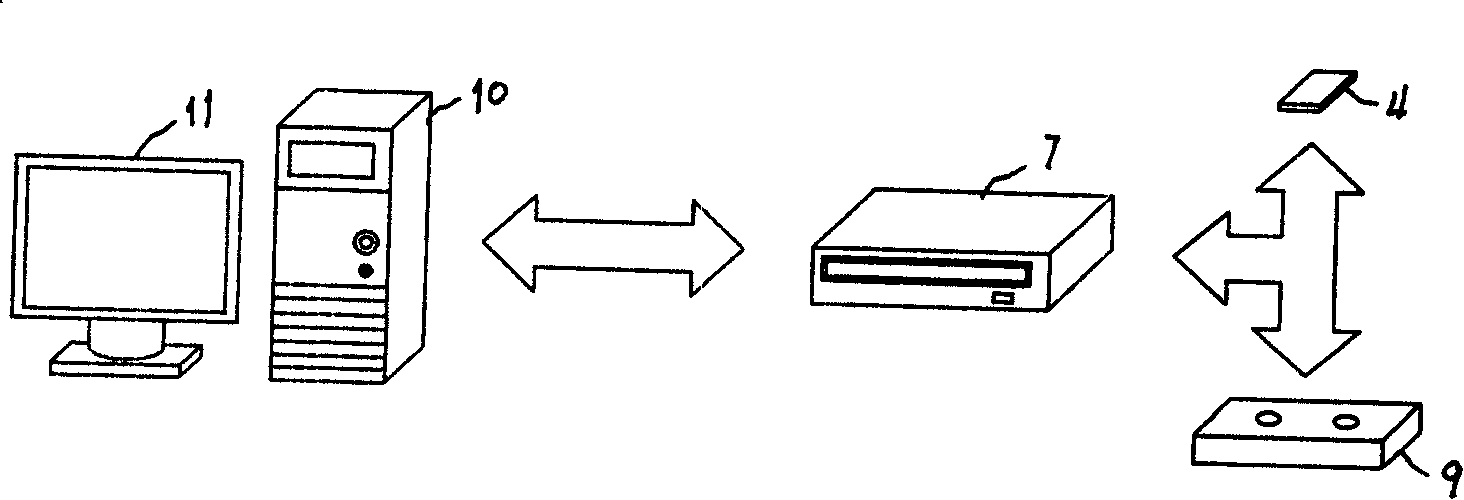

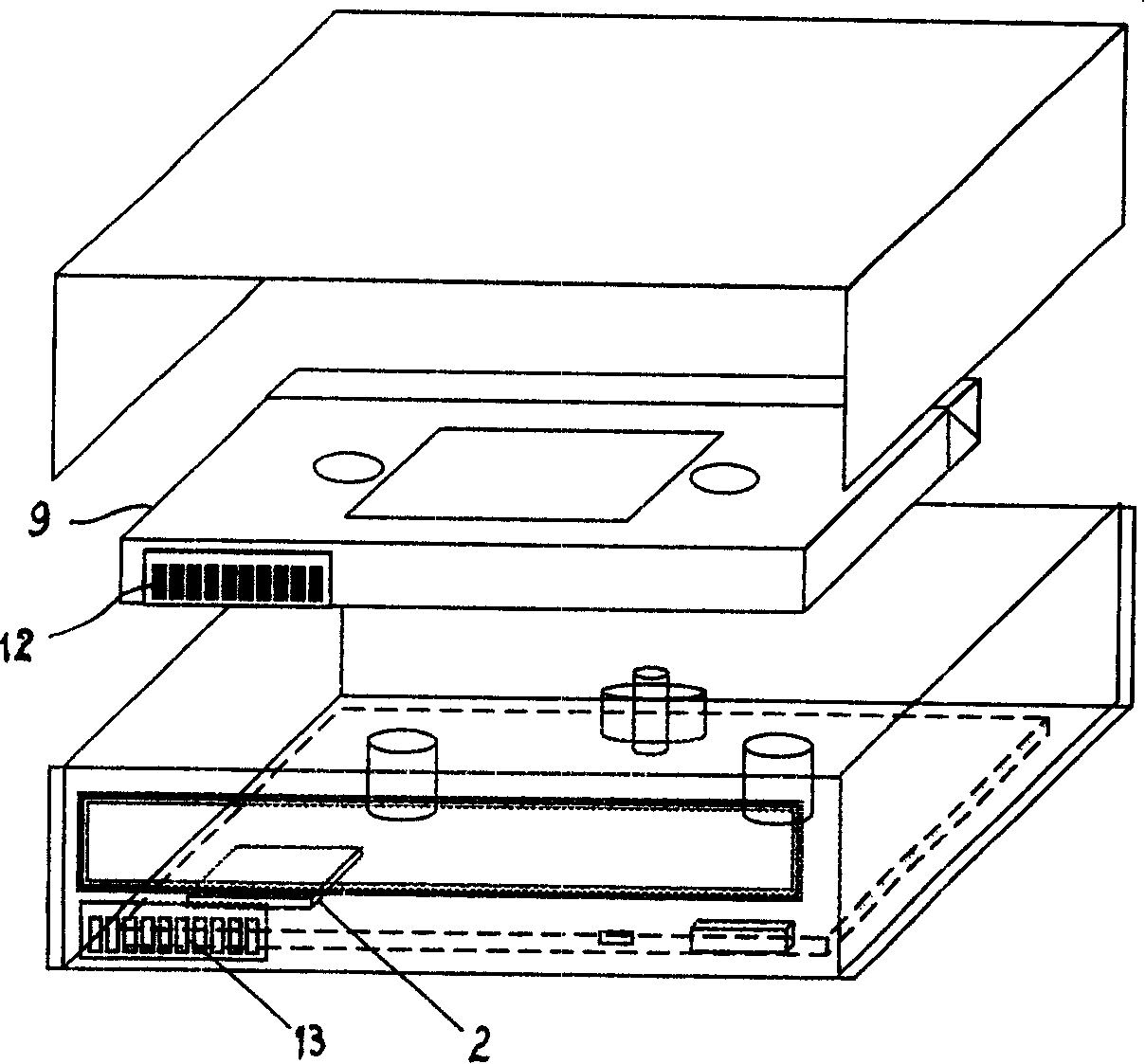

Novel intelligent tape unit and data processing method

InactiveCN101197177AReduce seek timeIncreased durabilityRecord information storageDigital storageMemory chipElectricity

The invention discloses a novel intelligent tape driver and a data processing method thereof, belonging to a chip-tape storage device and a data processing method thereof, which comprises a memory chip arranged inside a tape cassette and an interface circuit thereof, and a memory chip read-write module arranged on the tape driver and an interface circuit thereof, wherein, the two interface circuits are electrically connected by a pair of metal contacts. The tape driver processor is connected with the memory chip through an interface circuit after being connected with the memory chip read-write module. Only a data area is arranged on the tape. The memory chip is divided into an index mark section, a writing cache, a read cache and other data section, wherein, both reading and writing requests of data are performed in the reading and writing caches, other than in the tape driver. The combination of the sequential memory of the tape and the random memory of the chip reduces the frequent mechanical motion of the tape driver, thereby improving the retrieval speed and the memory efficiency and prolonging the service life of the tape driver.

Owner:WISESOFT CO LTD +1

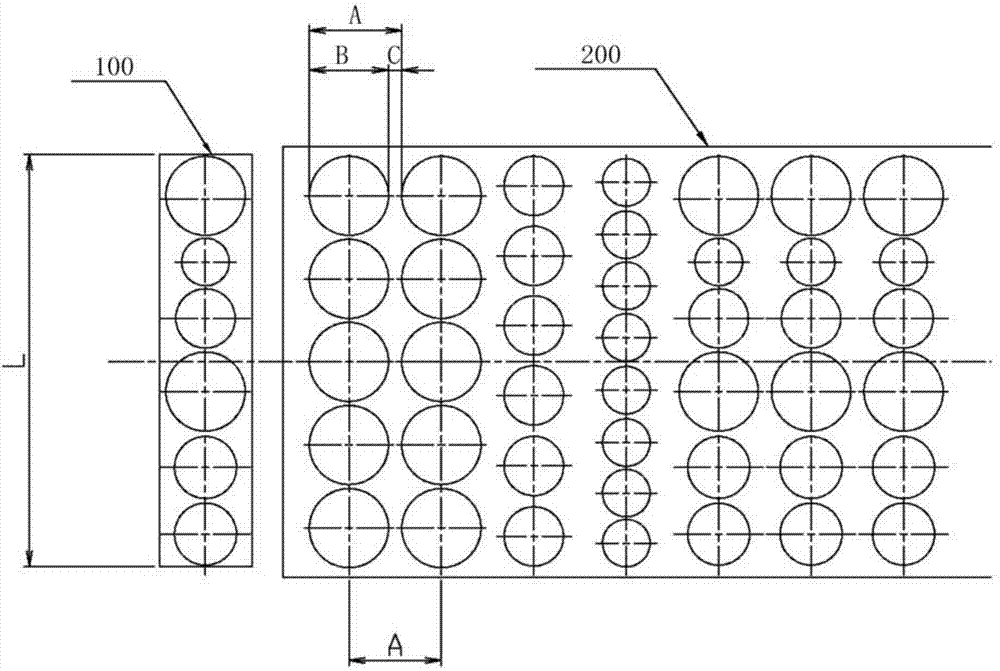

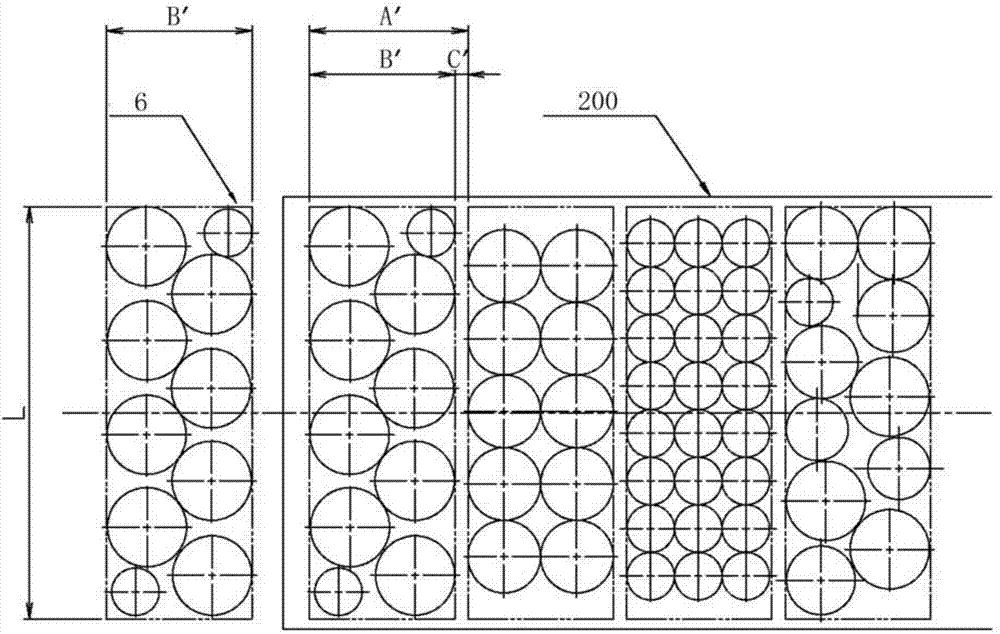

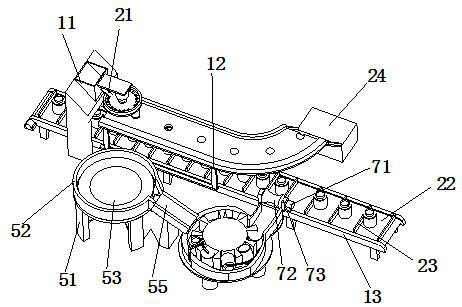

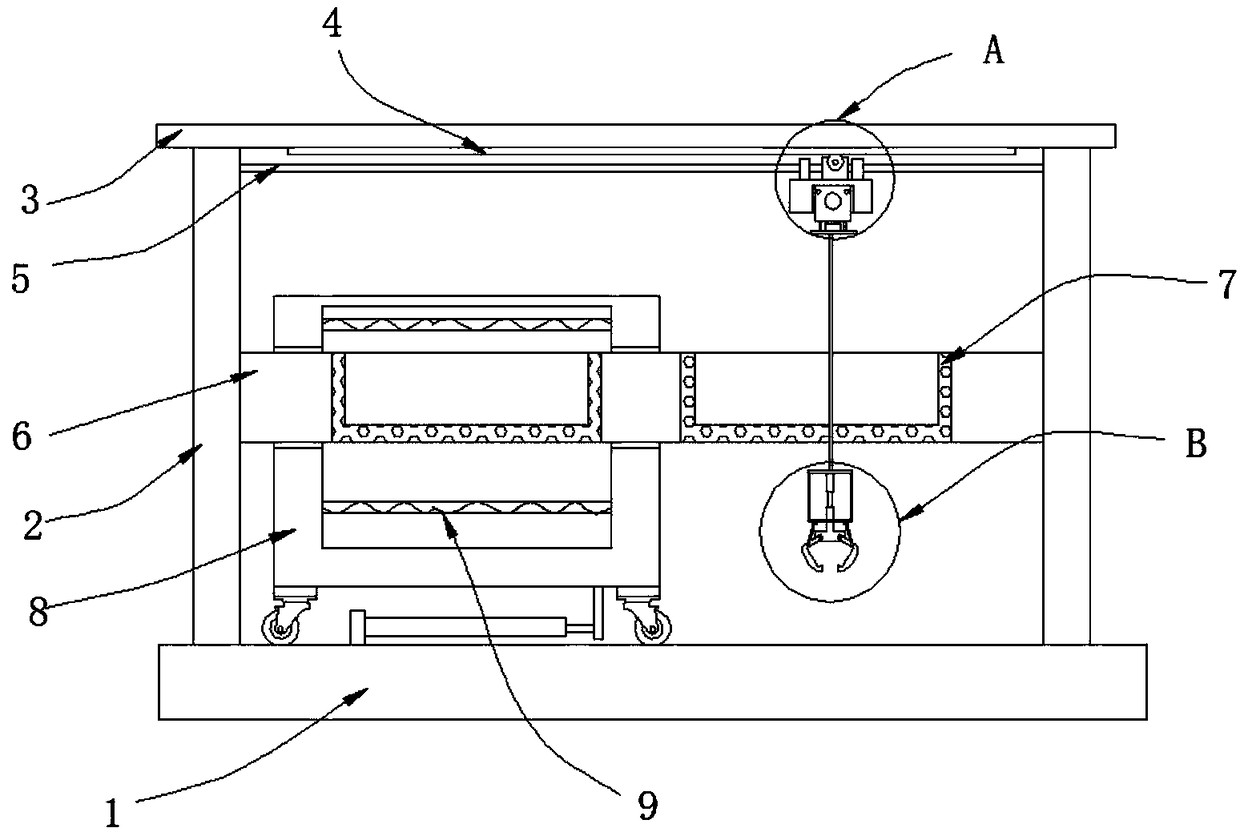

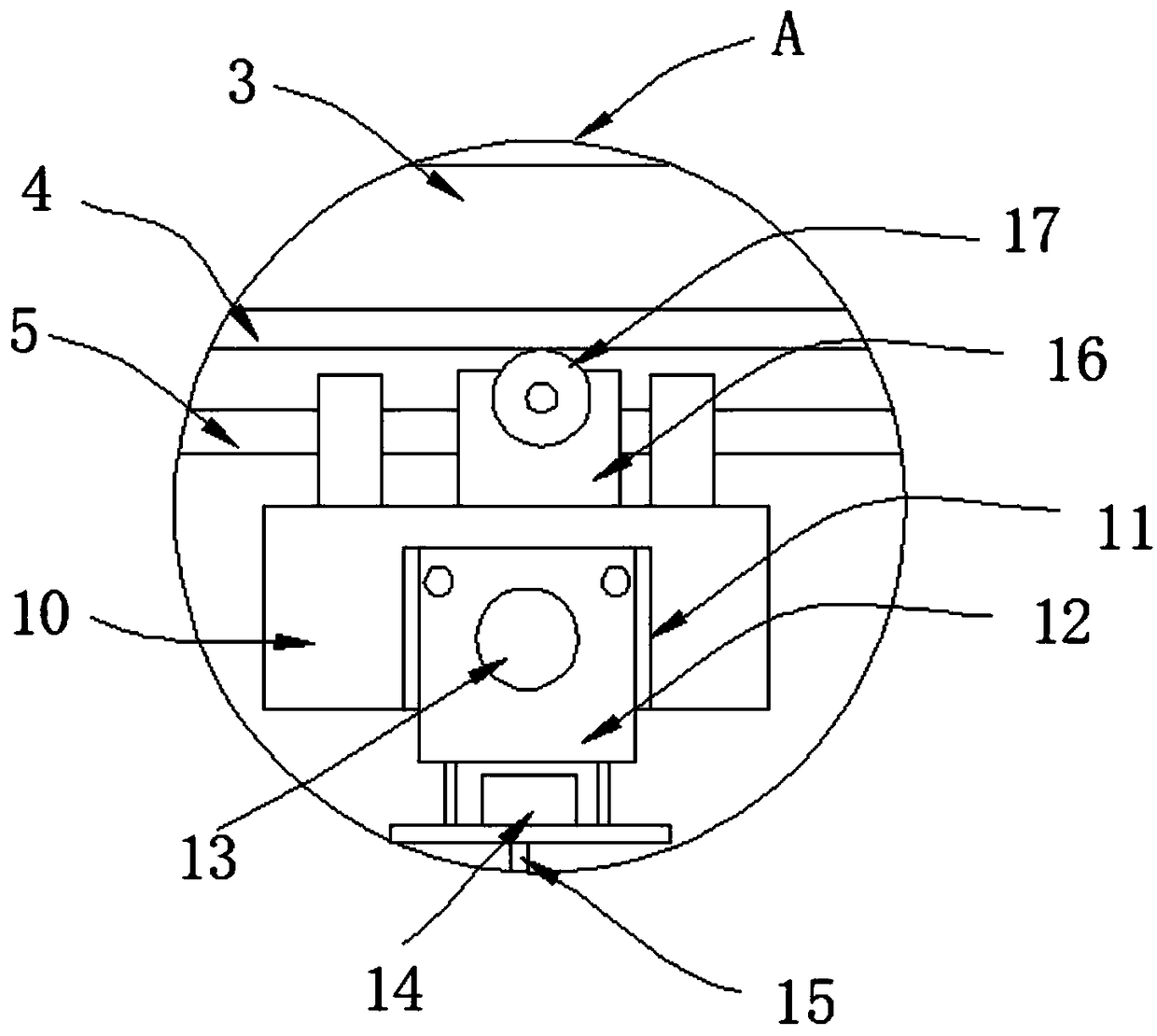

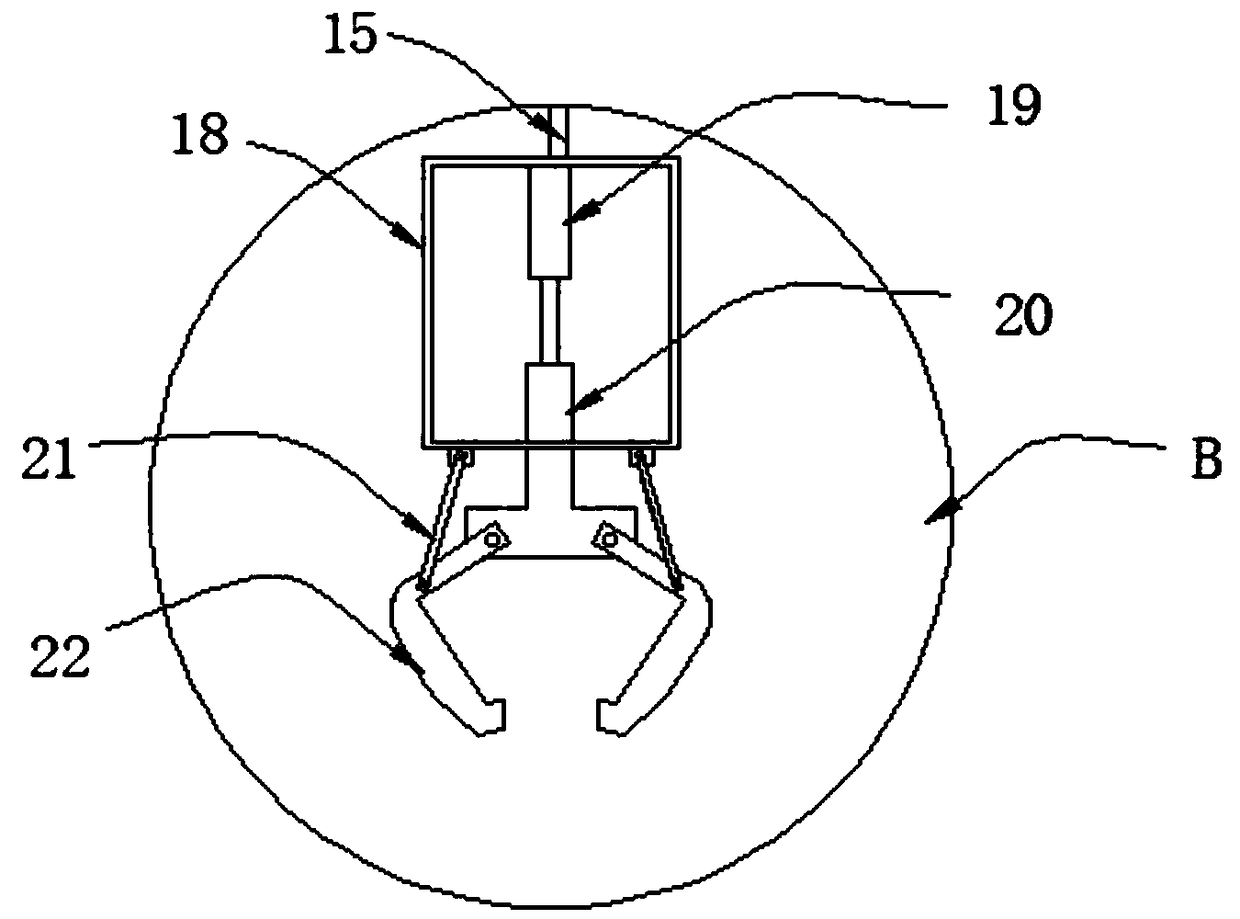

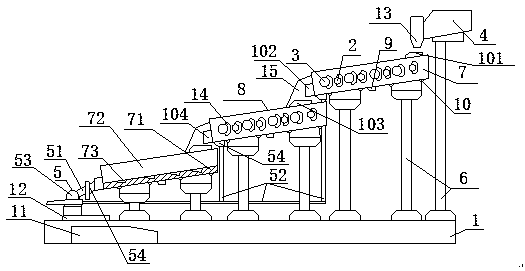

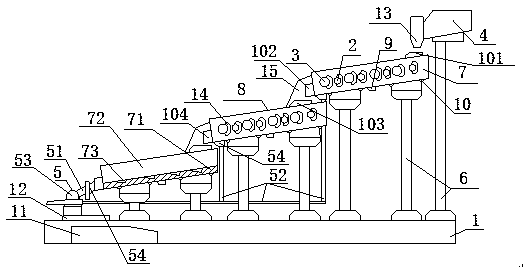

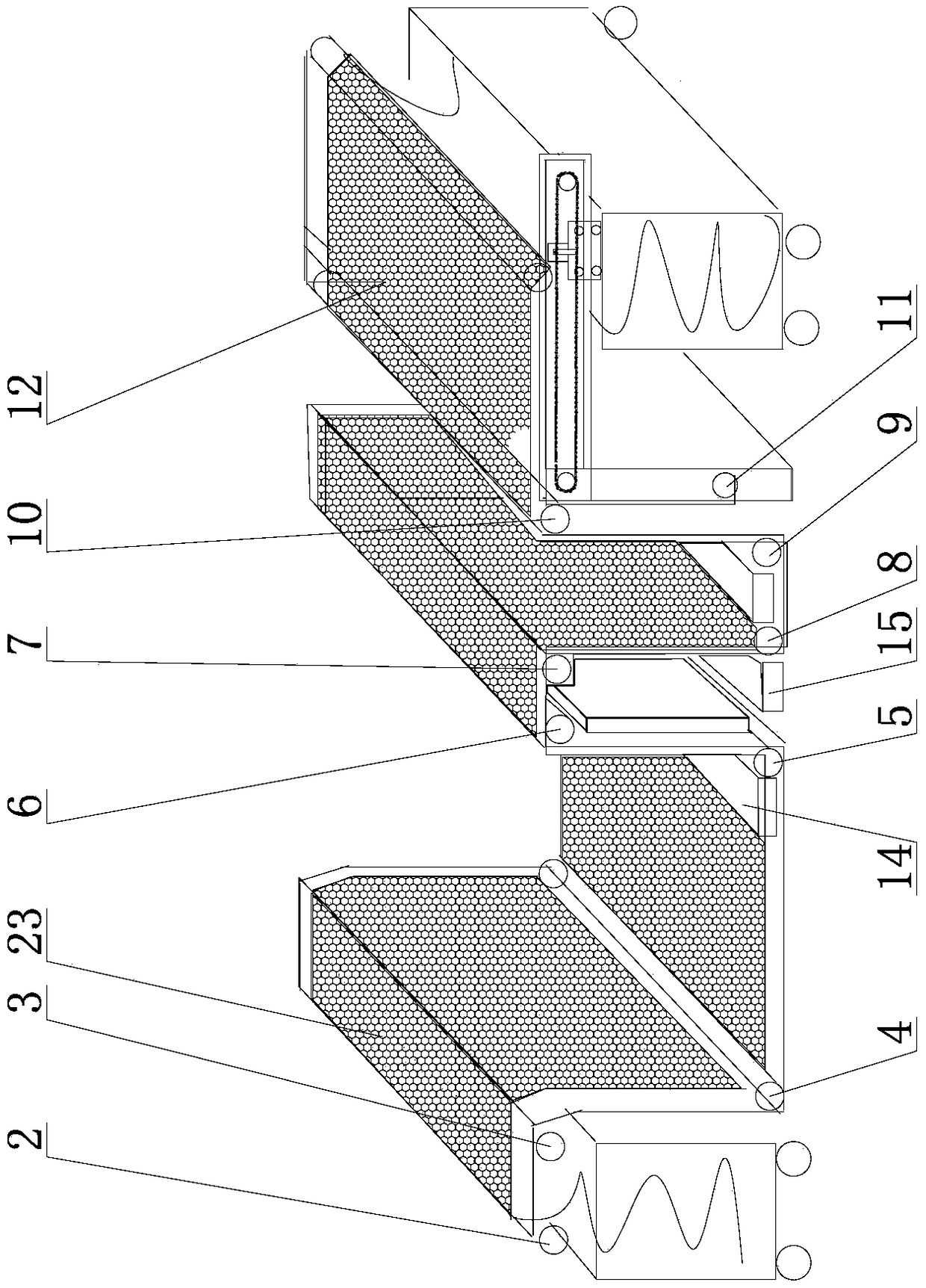

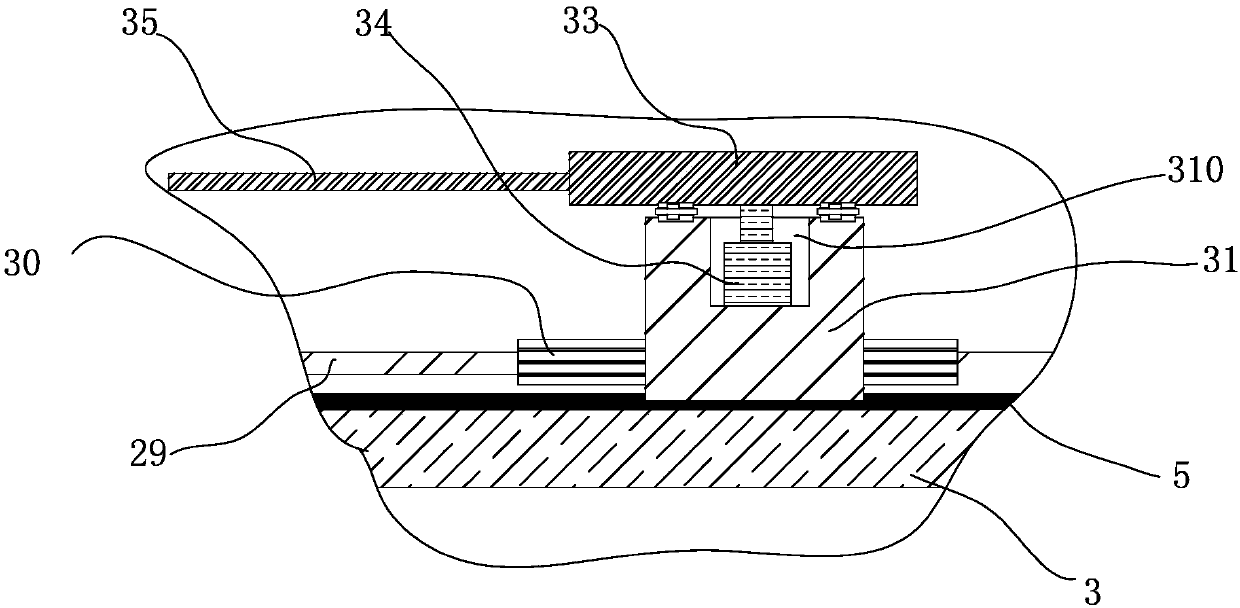

Power-and-free material-loading and transporting apparatus used for material-basket-free thermal-treatment furnace of aluminum alloy product

ActiveCN104328263ASpeed up the loading processIncrease delivery speedFurnace typesHeat treatment process controlUtilization rateHeat treating

A power-and-free material-loading and transporting apparatus used for a material-basket-free thermal-treatment furnace of an aluminum alloy product belongs to the technical filed of thermal treatment devices of the aluminum alloy product. By means of parts, including a transporting roller track, a pre-assembling roller track, a material pushing machine, a material-feeding detection photoelectric tube, a material-full detection photoelectric tube, a power-and-free roller track, a removing roller cylinder, a removing motor, a material-loading fork and the like, the power-and-free material-loading and transporting apparatus enables workpieces arranged in a material-loading zone on the power-and-free roller track to be changed from one row into two or more rows, wherein the workpieces are pre-arranged by a material baffle. Redundant workpieces are removed from the roller cylinder and from the material-loading zone. The pieces in the material-loading zone are sent to the thermal-treatment furnace by the material-loading fork in one step for thermal treatment. By means of the power-and-free material-loading and transporting apparatus, automatic level of the device is improved and time period during material loading is effectively prolonged. In addition, the power-and-free material-loading and transporting apparatus can increase effective space in the thermal-treatment furnace by 20%, can reduce a production cost and can increase energy resource utilization rate.

Owner:SHENYANG NEU-SANKEN IND FURNACE MFG CO LTD

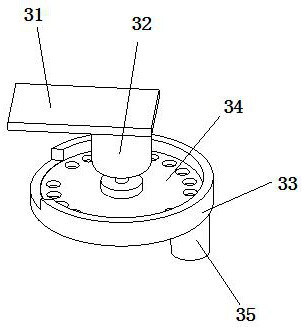

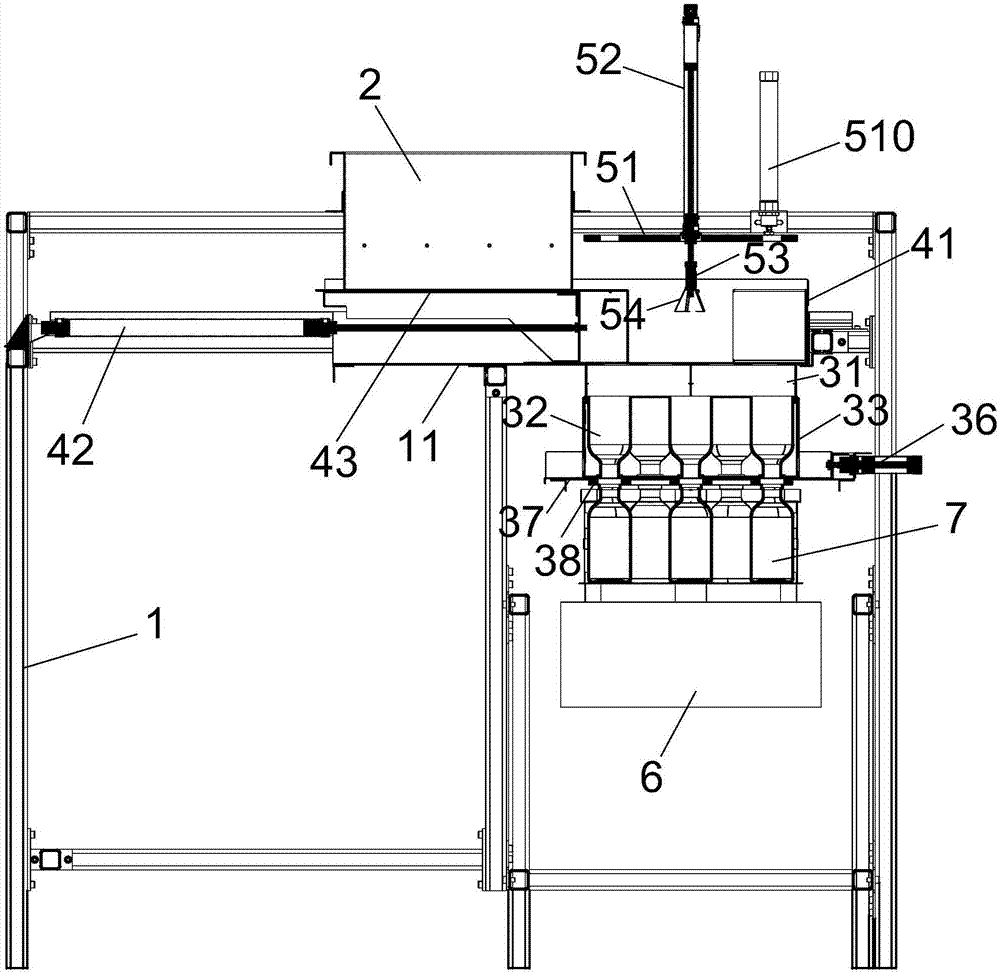

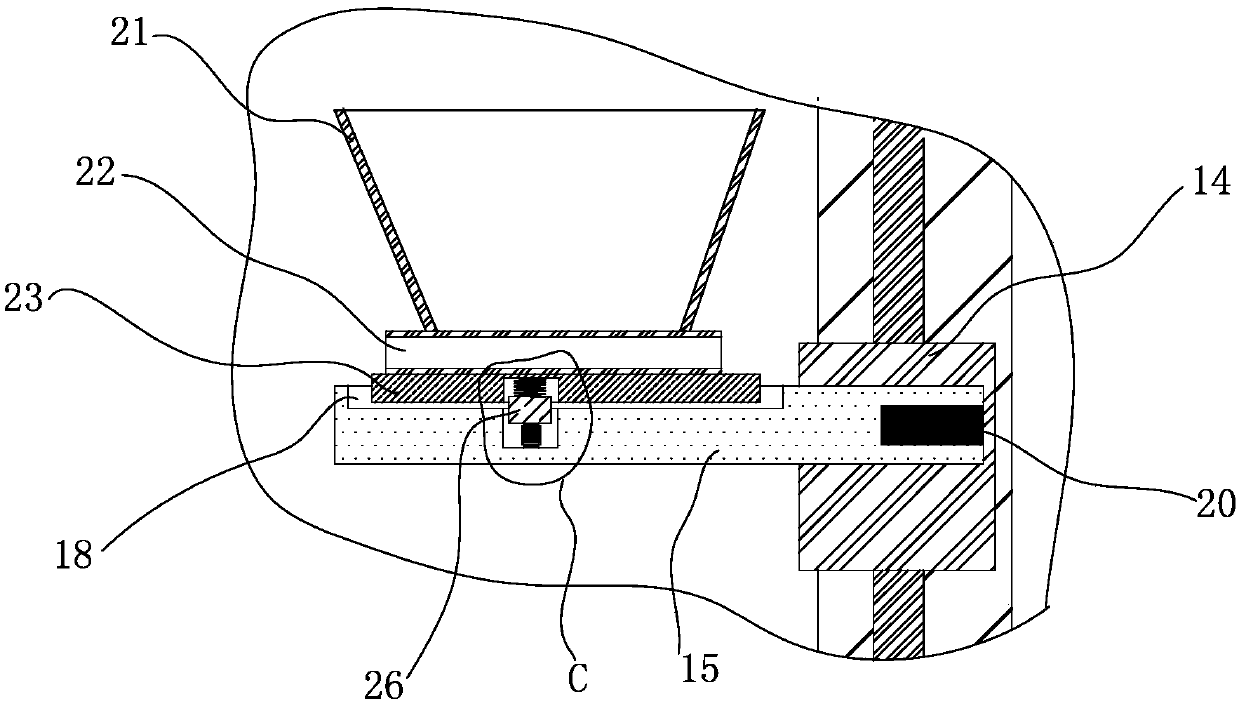

Two-way loading device for chelated calcium

ActiveCN111977065AImprove feeding effectThe same amountIndividual articlesChelated calciumPhysical chemistry

The invention discloses a two-way loading device for chelated calcium, and belongs to the technical field of loading devices. The two-way loading device for the chelated calcium comprises a feeding frame, a feeding tank, a component loading device, a conveying frame, a closing device, a conveying seat, a bottle loading device, a limiting device and a turnover device. The feeding tank is arranged on the top part of the feeding frame; the component loading device is arranged on the feeding tank; the conveying frame is arranged on the conveying seat; an opening is formed in the conveying frame; the closing device is arranged on the conveying frame; the bottle loading device is arranged beside the conveying seat; the limiting device is arranged beside the bottle loading device; and the turnover device is arranged on the conveying seat. According to the two-way loading device for the chelated calcium provided by the invention, the chelated calcium and bottles can be loaded at the same time,the chelated calcium is quantified and the bottles can be ranked and turned over in the two-way loading process, then one batch of chelated calcium is filled into the bottles, and the other batch ofchelated calcium is conveyed to other operation devices.

Owner:SHANDONG BUSINESS INST

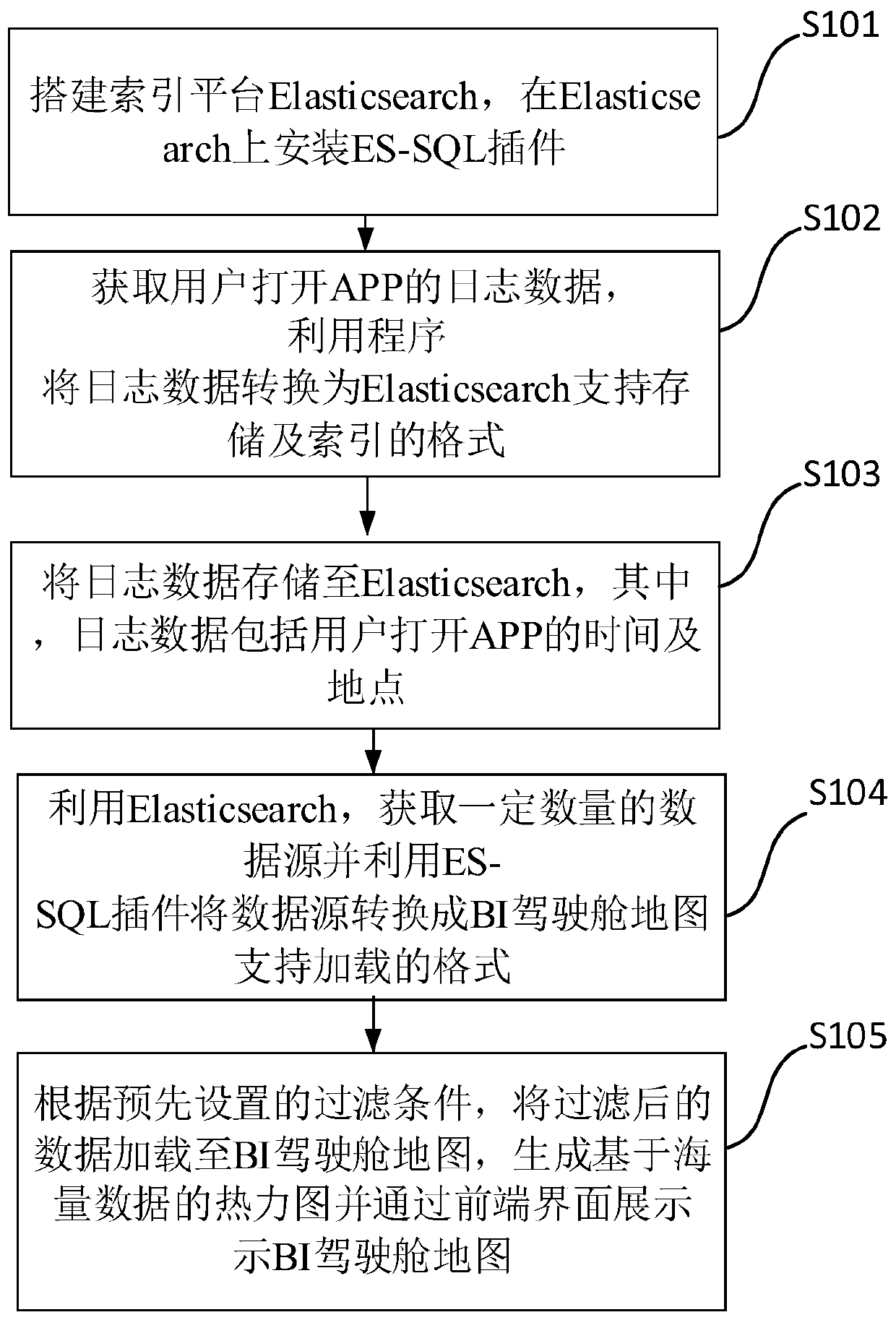

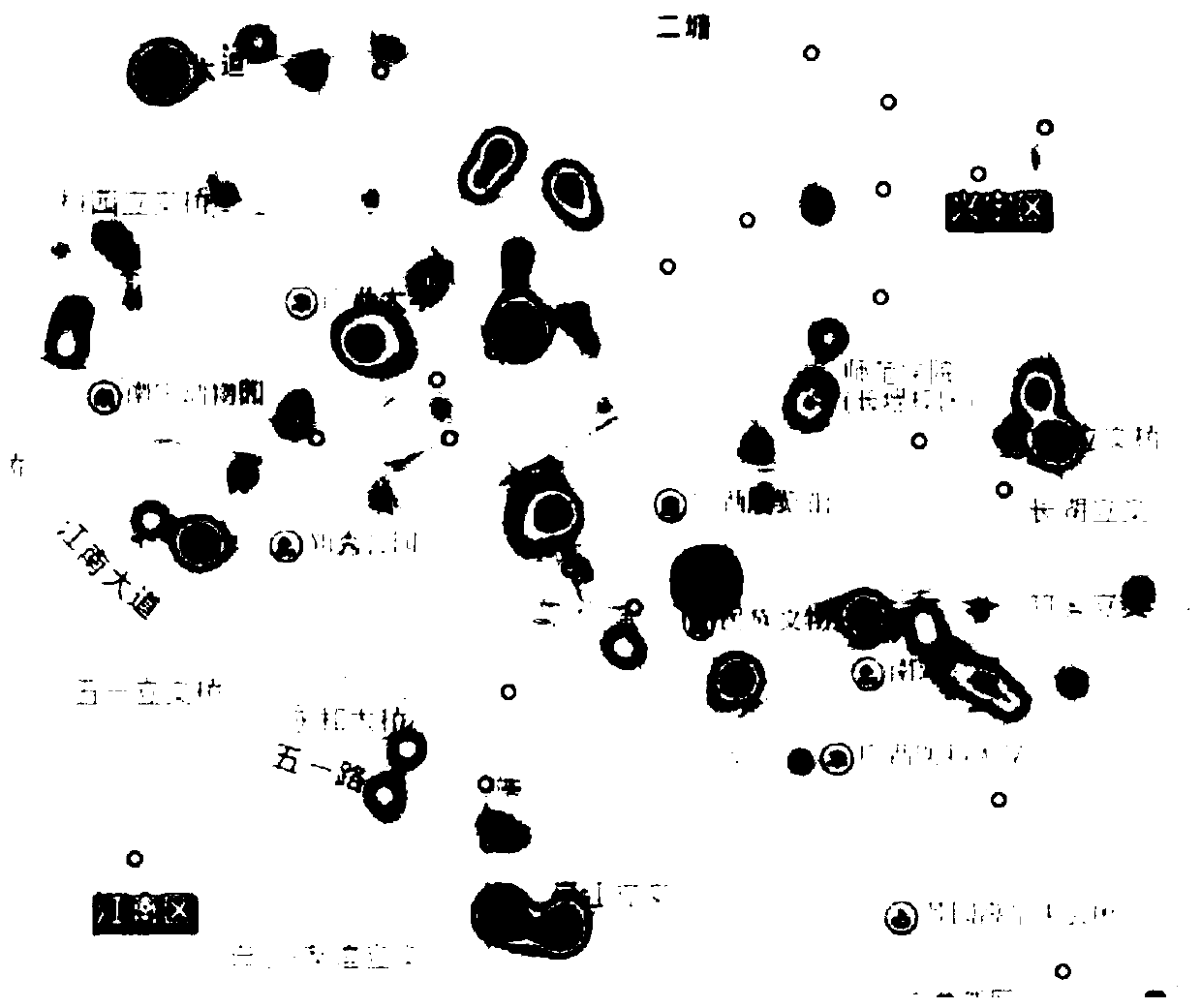

Thermodynamic diagram loading and displaying method based on mass data

InactiveCN110276025AImprove efficiencySpeed up the loading processDigital data information retrievalSpecial data processing applicationsLongitudeData source

Owner:北京首汽智行科技有限公司

Drying device for refractory material production

InactiveCN108444228AImplement rotationShorten the timeDrying chambers/containersDrying solid materialsRefractoryEngineering

The invention discloses a drying device for refractory material production. The drying device for refractory material production comprises a base plate, wherein two symmetrically arranged side platesare welded to the top of the base plate; a top plate is welded to the tops of the side plates; a rack is fixedly connected to the bottom of the top plate; a slide bar is fixedly mounted between the two side plates; the slide bar is located below the rack; a rail plate is slidably mounted on the slide bar; a first motor is fixedly mounted on the top of the rail plate; a first motor is fixedly mounted on the top of the rail plate; a gear is fixedly mounted on the output shaft of the first motor; the gear is engaged to a rack; a rail groove is formed in the bottom of the rail plate; a movable block is slidably mounted on the rail groove; a threaded rod is rotatably mounted in the rail groove; and the threaded rod is in threaded connection to the movable block. The drying device disclosed by the invention achieves automatic loading and unloading, reduces the manpower and improves the efficiency and lowers the cost, and meanwhile, two drying boxes dry the material alternately; the loading and unloading work is finished within the drying waiting time, so that the a lot of time is saved, and the drying efficiency is improved.

Owner:浙江康斯迪冶金科技有限公司

Firearm magazine loader

A firearm magazine loader. The loader includes a body having a linear projection extending from the top of the loader for holding rounds of ammunition and an optional plunger for pushing the rounds into a magazine. The loader accommodates and centers a wide variety of magazines due to a self-centering mechanism incorporated into the body. An angled feed channel pivots the rounds into position to slide under the feed lips of a magazine to significantly reduce the insertion force required and allow a double stack magazine to be quickly filled to capacity with minimal effort.

Owner:ELITE TACTICAL SYST GRP LLC

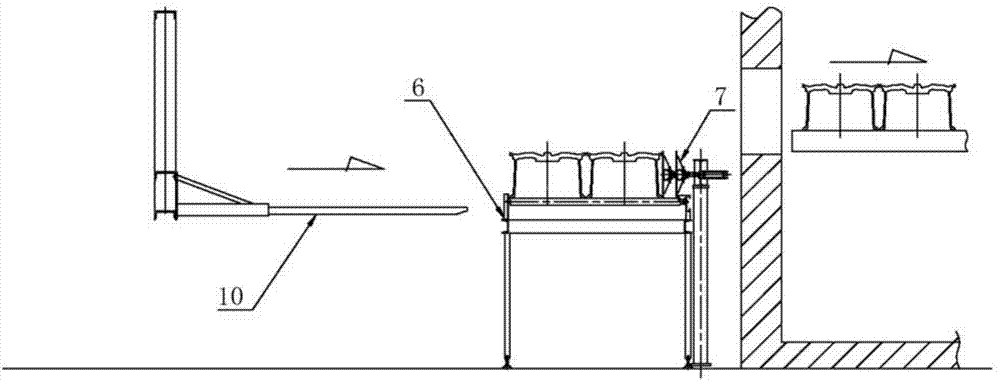

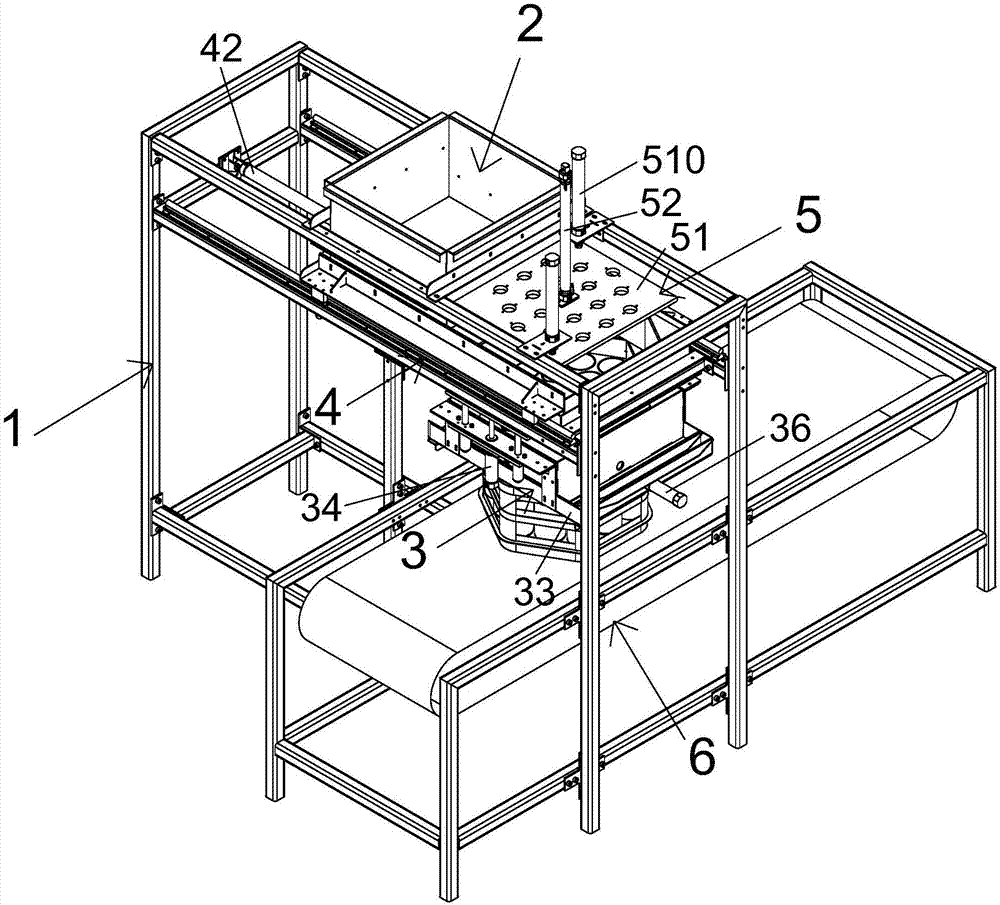

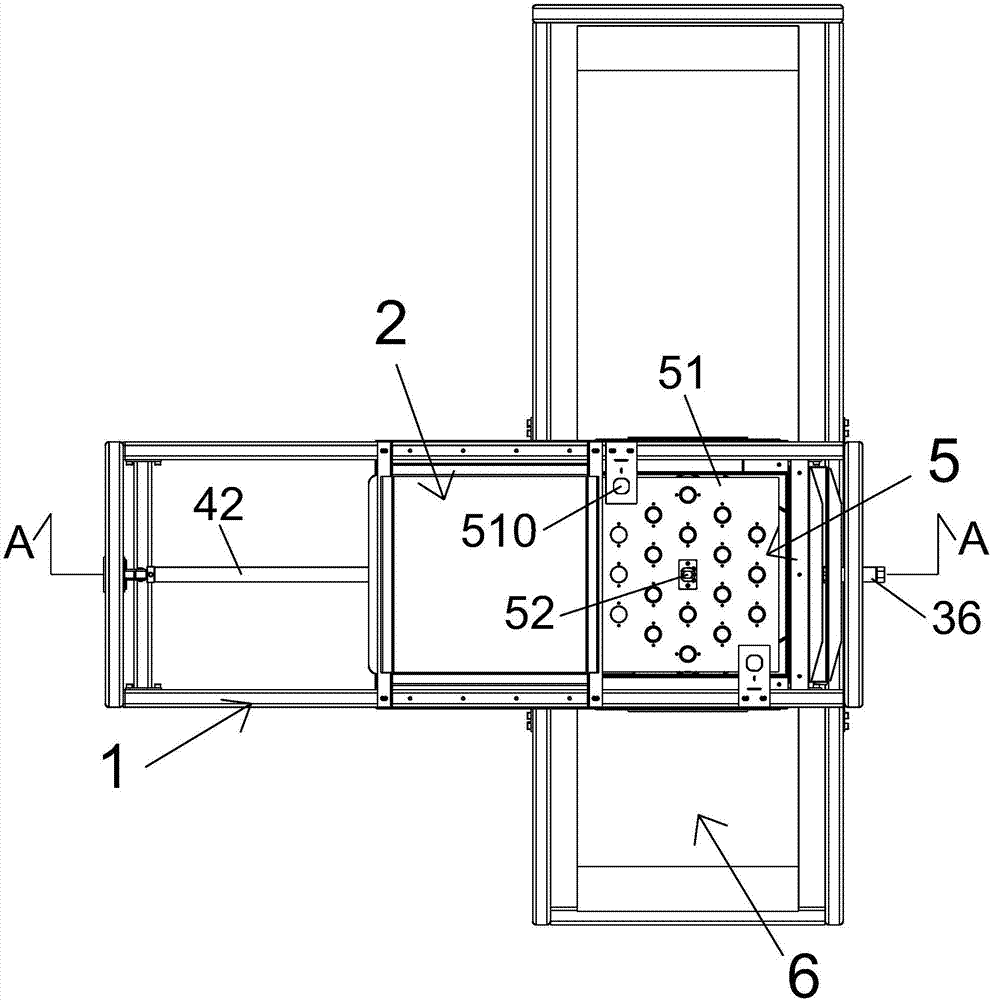

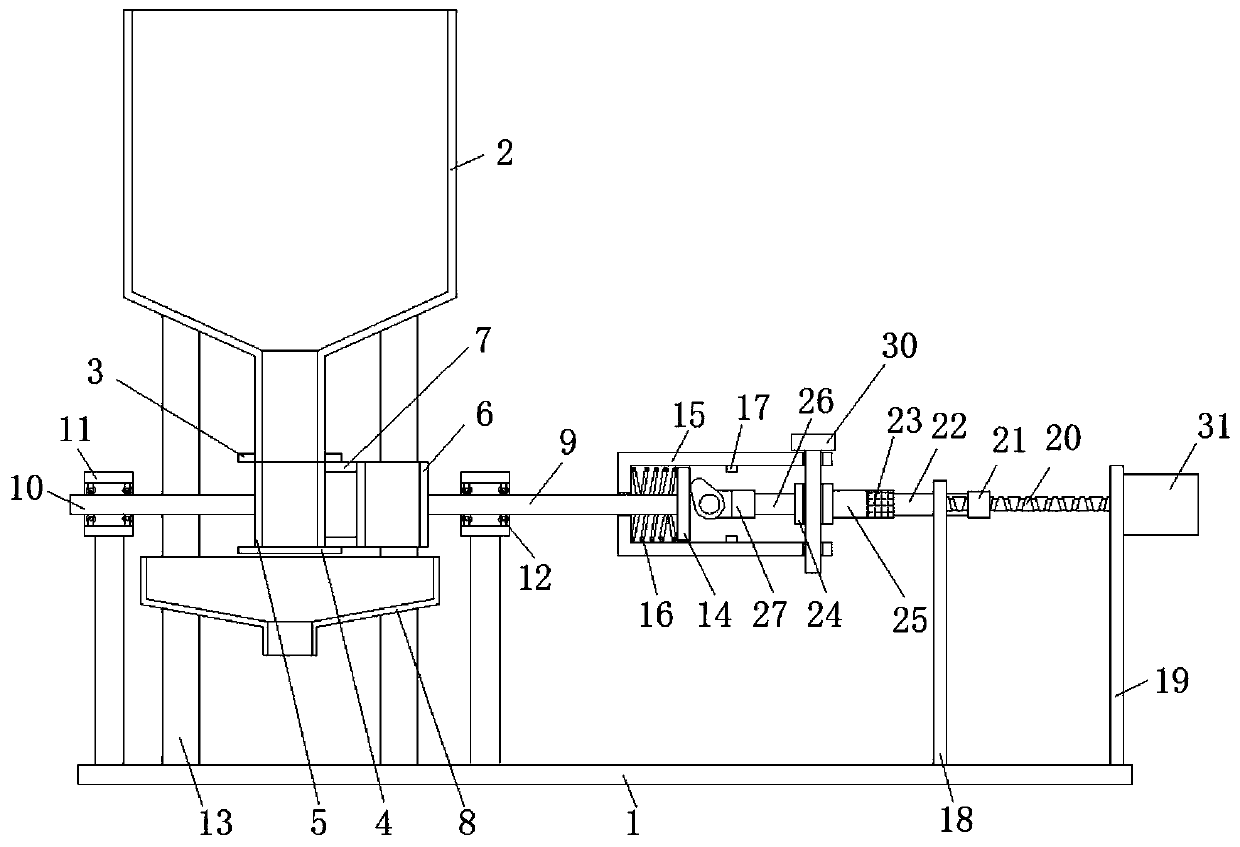

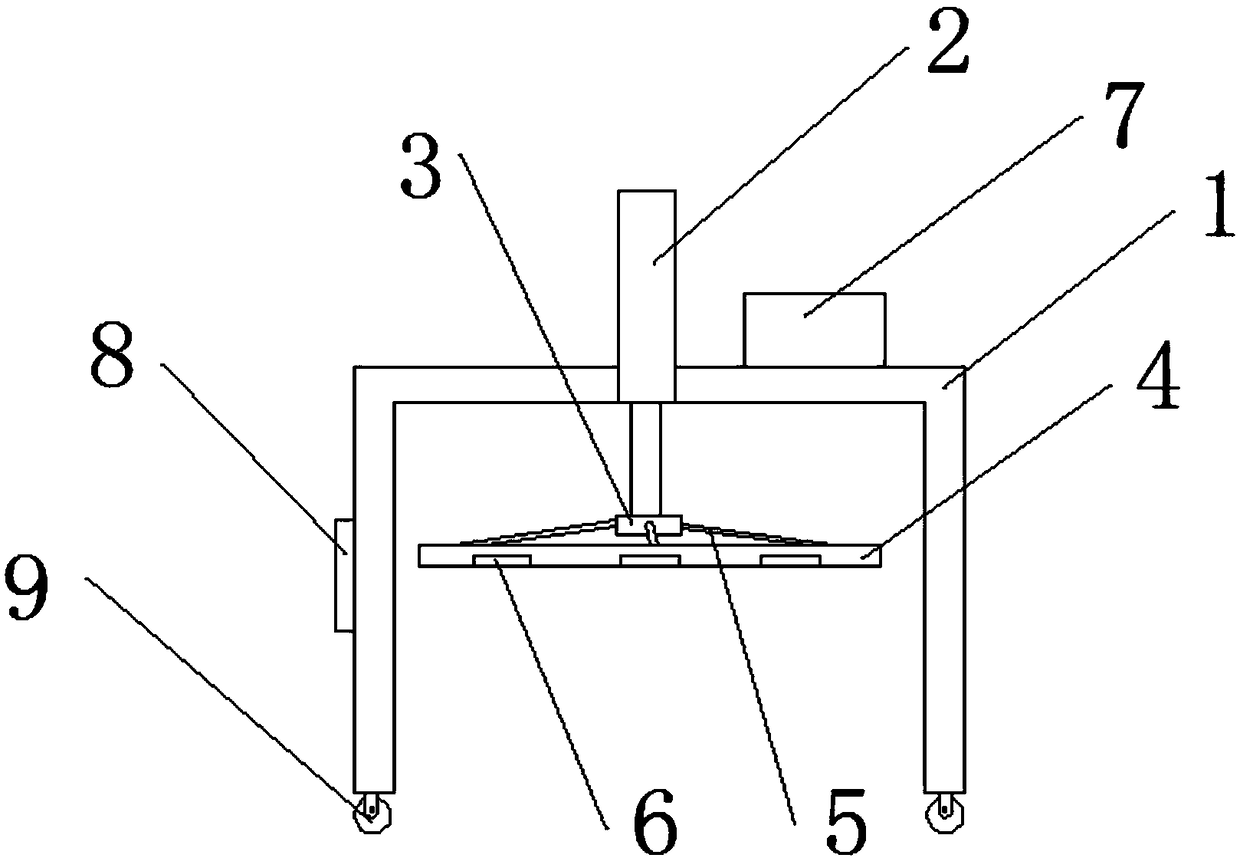

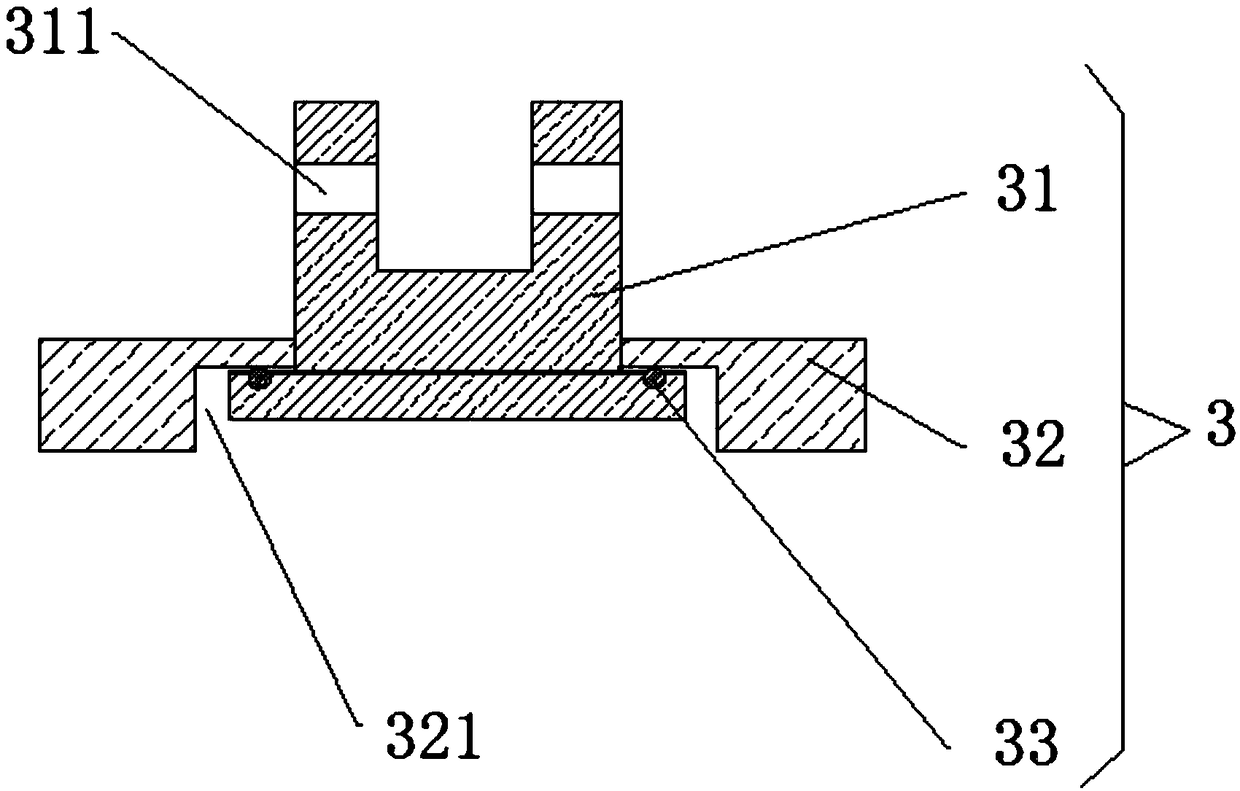

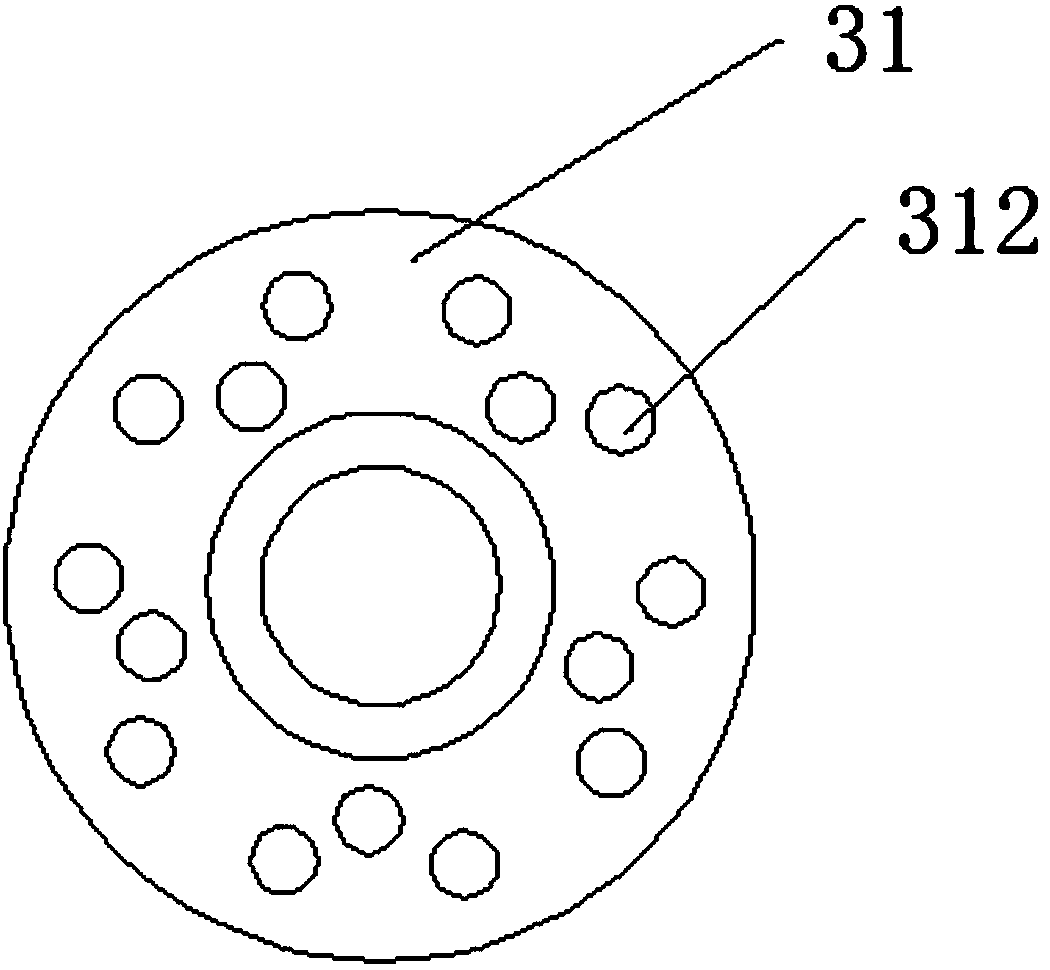

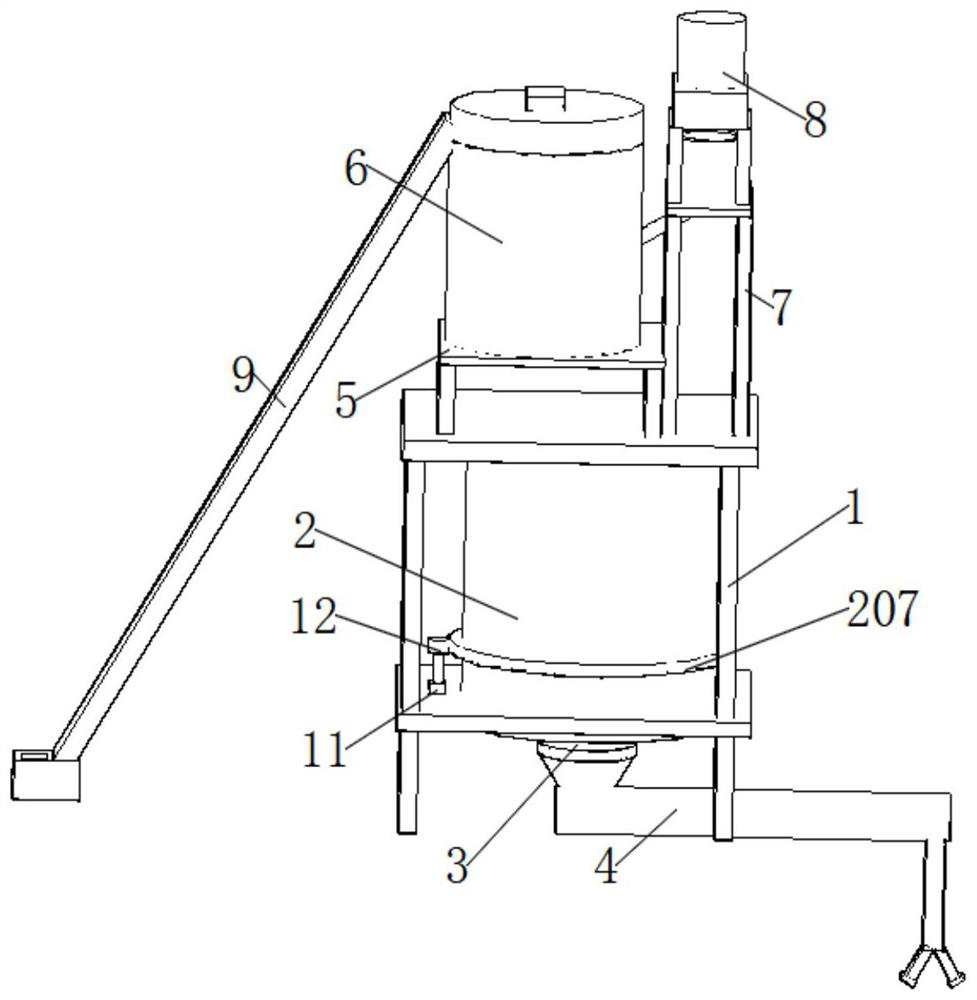

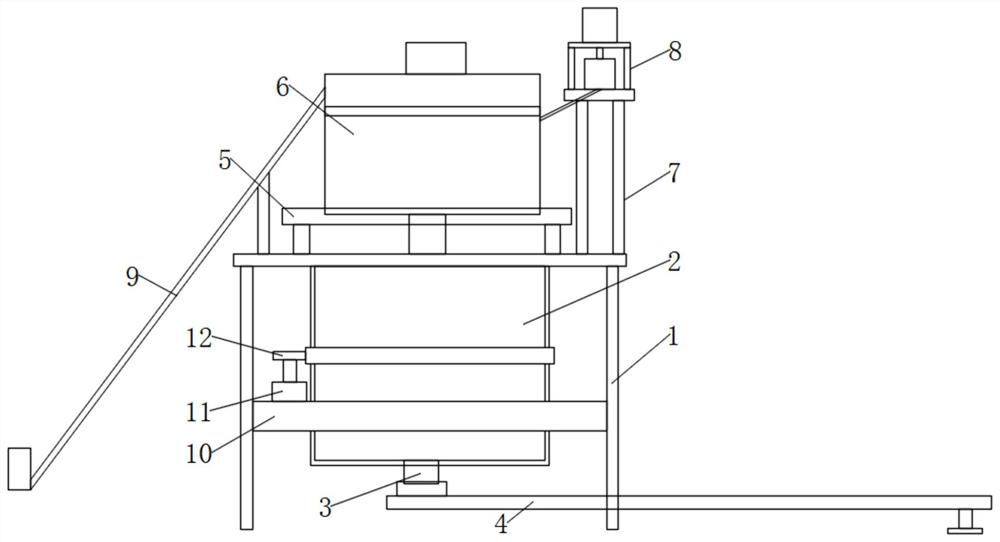

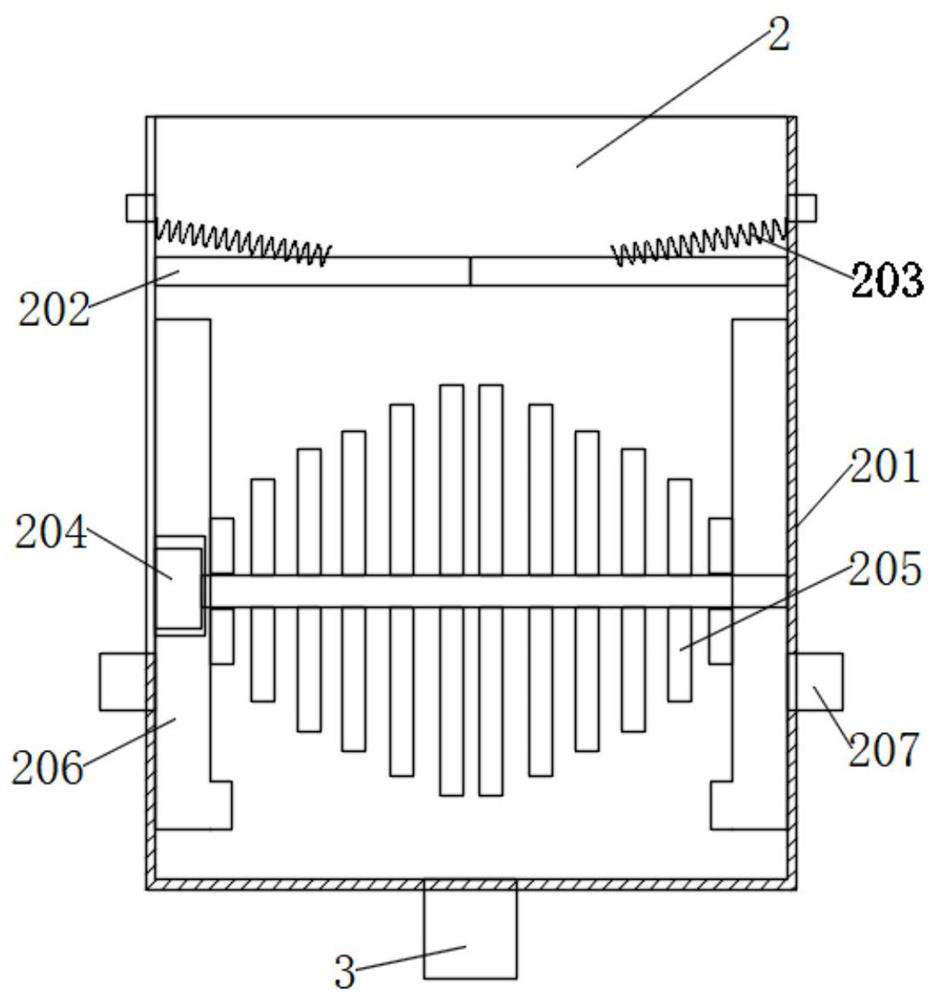

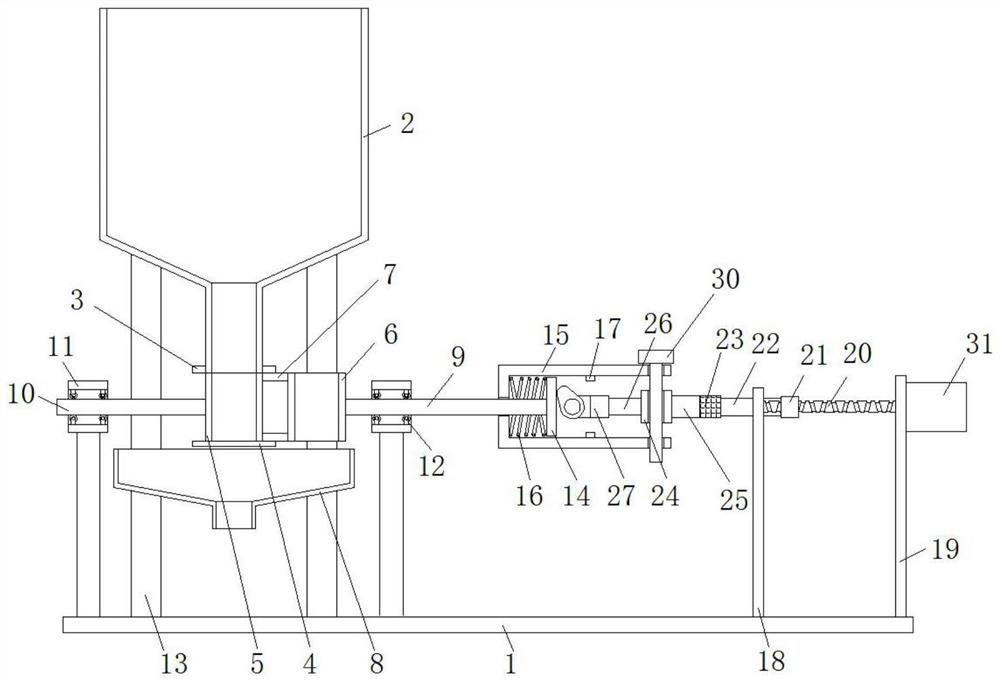

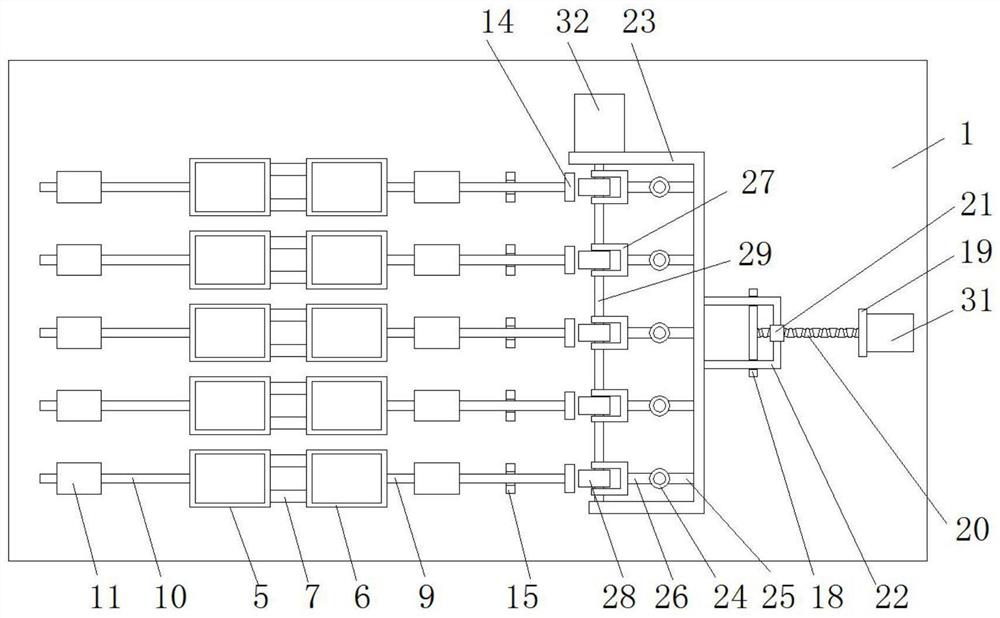

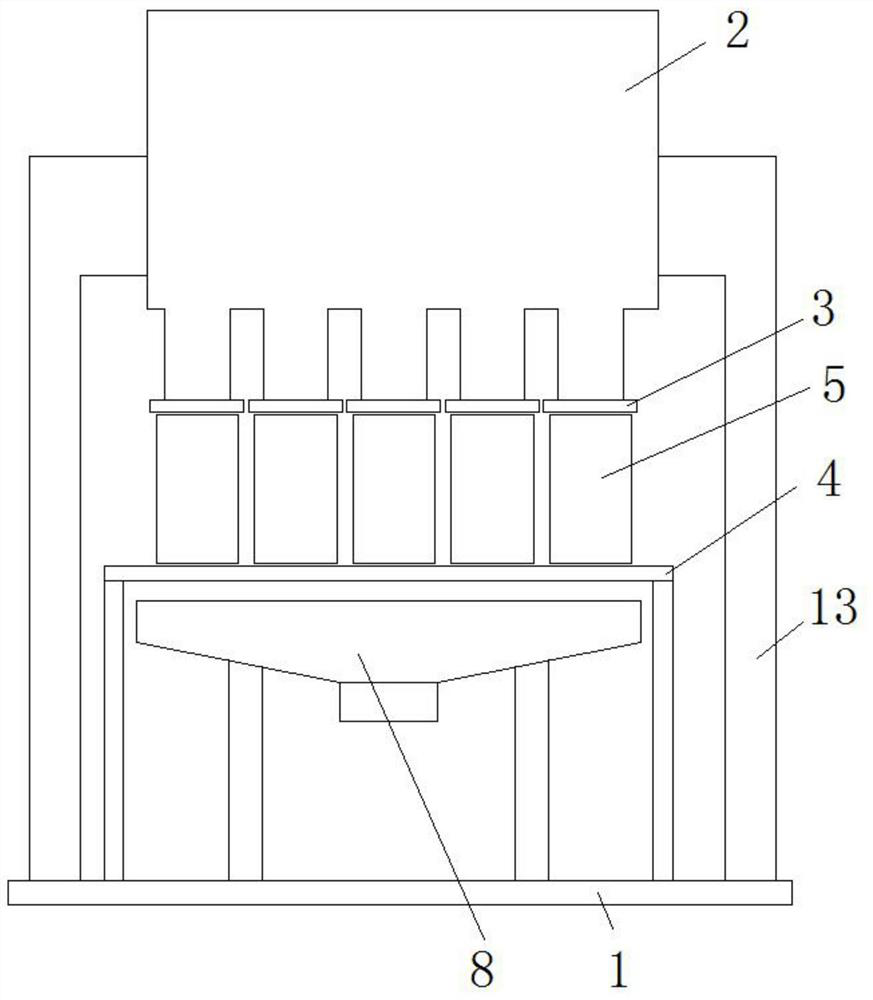

Automatic bacterium bottle quantitative feeding device

InactiveCN107360860AEfficient automatic quantitative chargingSpeed up the loading processCultivating equipmentsMushroom cultivationEngineeringBottle

The invention relates to an automatic bacterium bottle quantitative feeding device which comprises a rack, a feeding hopper, a quantitative discharge mechanism and a moving mechanism, wherein the feeding hopper is arranged on the rear side of the rack; the quantitative discharge mechanism is arranged on the front side of the rack; the moving mechanism makes reciprocation movement between a lower outlet of the feeding hopper and an upper inlet of the quantitative discharge mechanism; the quantitative discharge mechanism comprises a discharge frame and a plurality of quantifying cups which are distributed on the bottom surface of a discharge frame in an array manner; the quantifying cups are communicated with the discharge frame; the mouths of the quantifying cups face downwards; and a pressing mechanism for pressing a bacterium material inside the discharge frame into a bottle to be filled with bacteria is arranged on the quantitative discharge mechanism. The invention aims at providing the automatic bacterium bottle quantitative feeding device with high feeding efficiency. The automatic bacterium bottle quantitative feeding device comprises the feeding hopper, the quantitative discharge mechanism and the moving mechanism which makes reciprocation movement between the feeding hopper and the quantitative discharge mechanism, so that bacteria inside the feeding hopper can be automatically conveyed into the discharge frame and are equally allocated into the bottles through the quantifying cups, and thus efficient and automatic qualitative material feeding is achieved.

Owner:福建省闽武机械有限公司

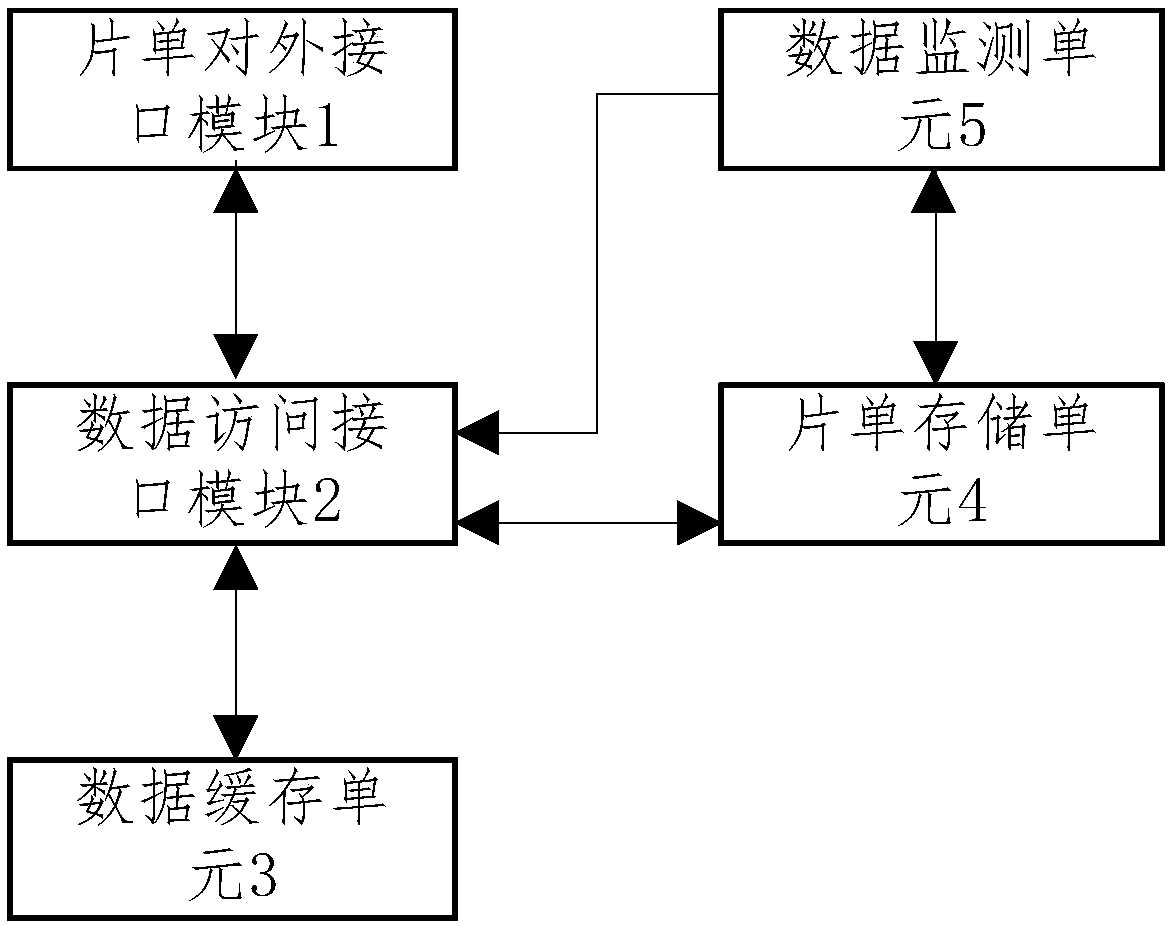

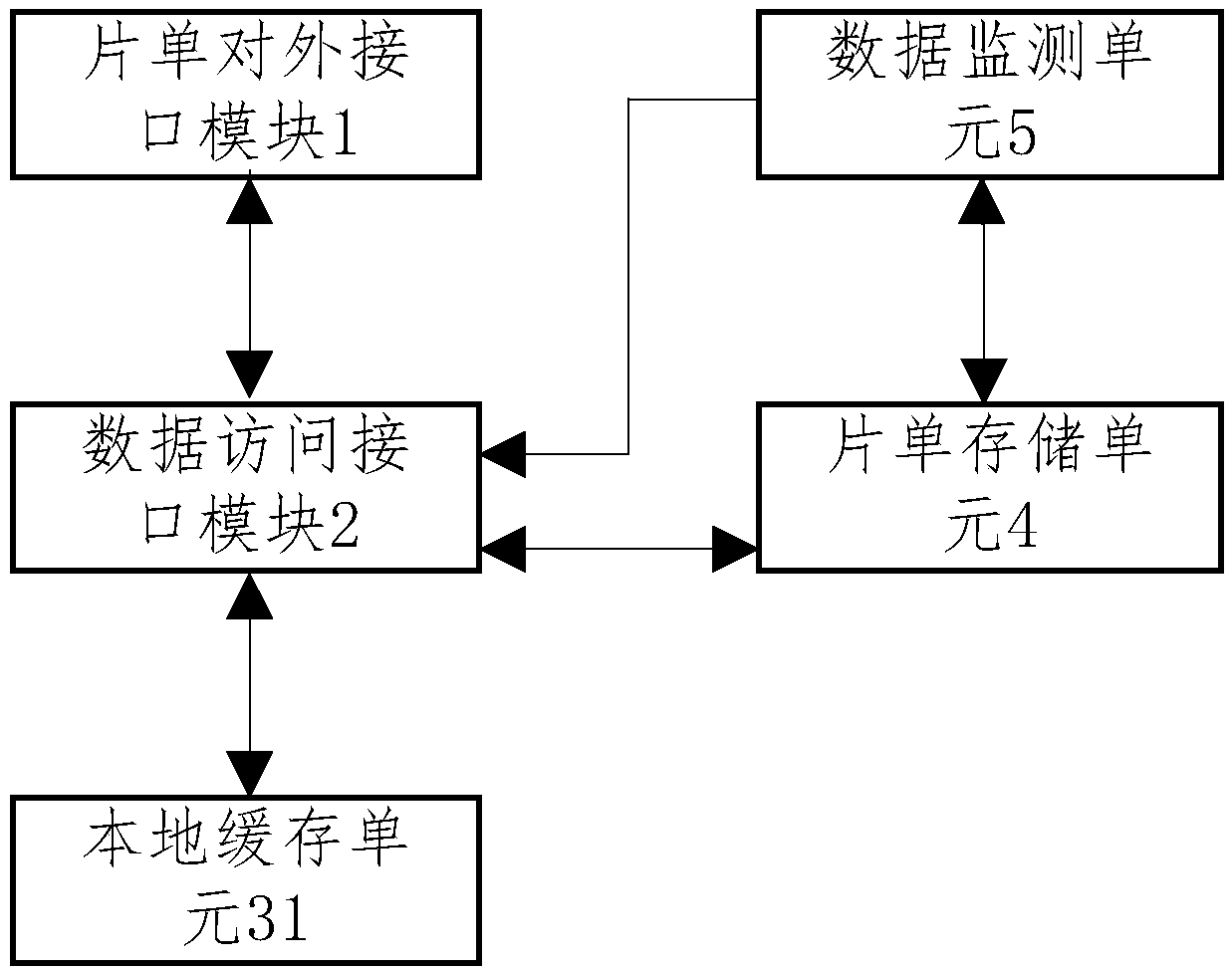

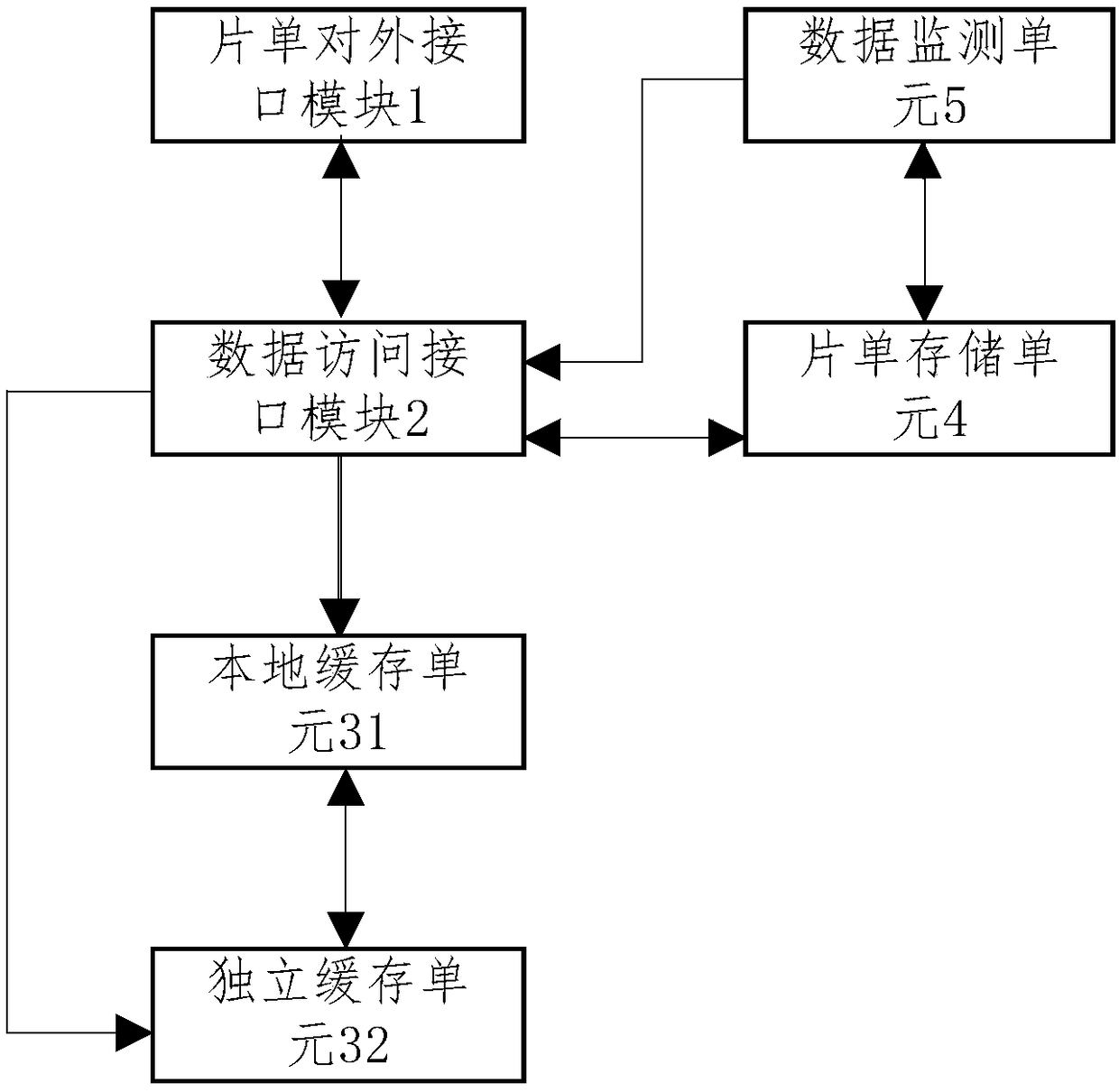

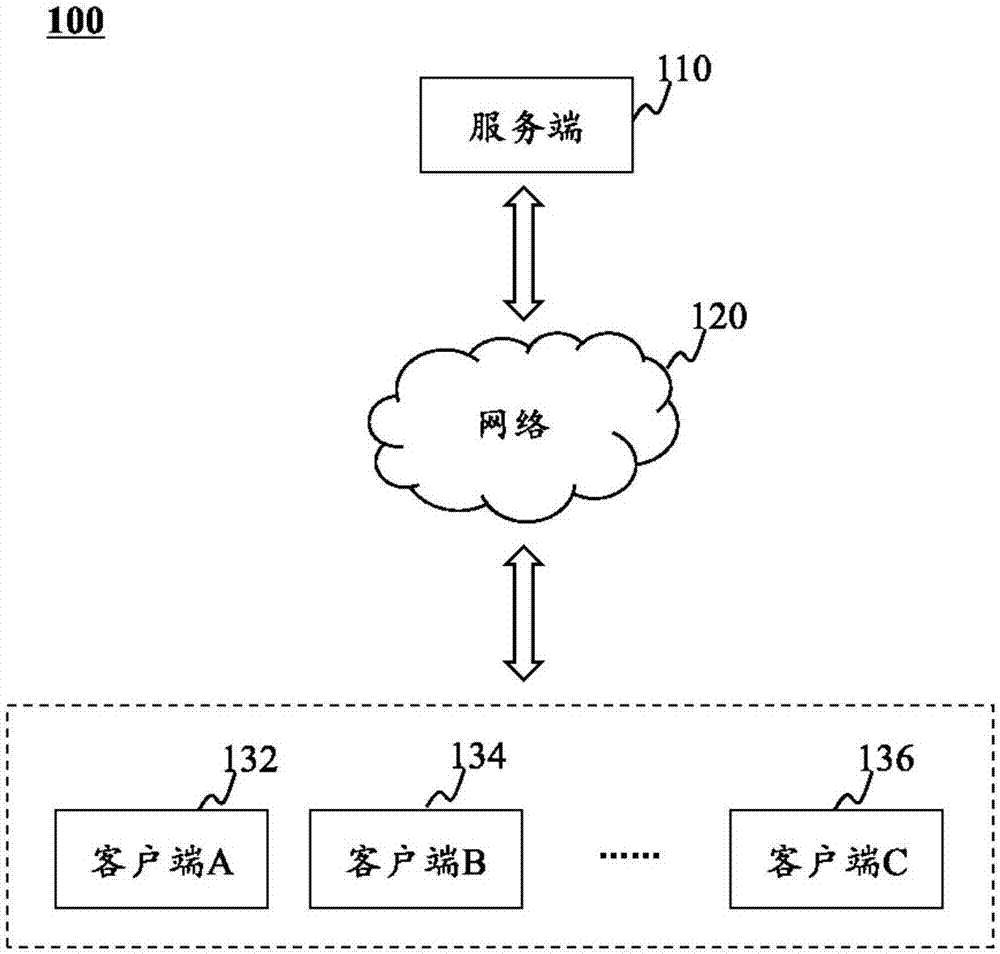

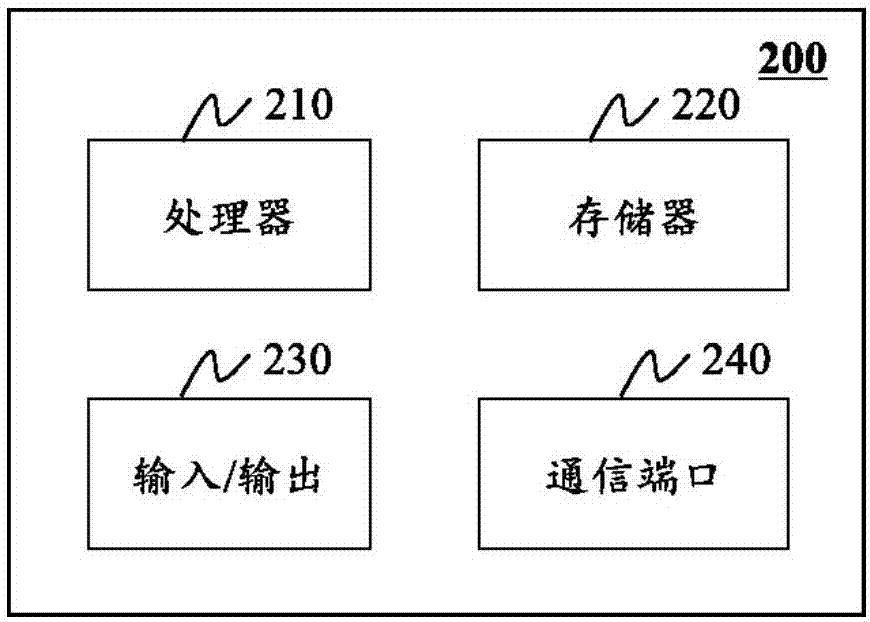

Data acquiring and updating method, sheet service system and sheet system

InactiveCN108228624ASpeed up the loading processHigh speedDatabase distribution/replicationSpecial data processing applicationsData sourceData access

The invention discloses a data acquiring and updating method, a sheet service system and a sheet system, and belongs to the technical field of media asset management. The sheet service system comprises a sheet external interface module, a data access interface module and a data monitoring unit, wherein the sheet external interface module is used for sending an access request to a data access interface, the data access interface module is used for acquiring target sheet data from a data caching unit based on the access request and returning the target sheet data, and / or updating sheet data in the data caching unit based on a received sheet data updating message, and the data monitoring unit is used for sending the sheet data updating message to the data access interface module when monitoring that sheet data in a sheet storage unit is updated, wherein the sheet data updating message comprises unique attribute identifiers of the updated sheet data in the sheet storage unit. By adopting amulti-level caching scheme, data sources are increased, the burden of media asset databases is relieved, the data throughput is increased, and the data loading and presenting speed is increased.

Owner:深圳市优朋普乐传媒发展有限公司

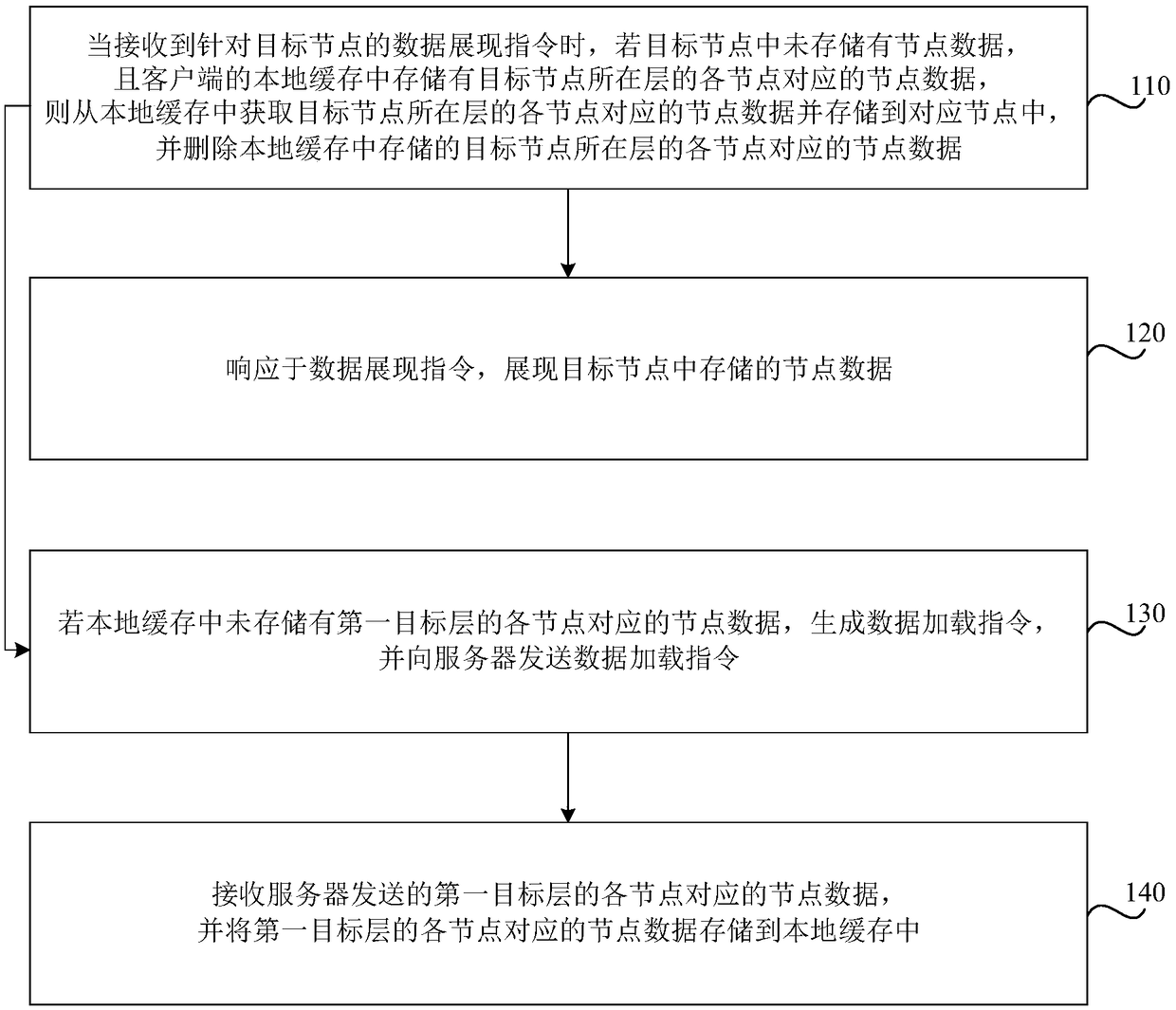

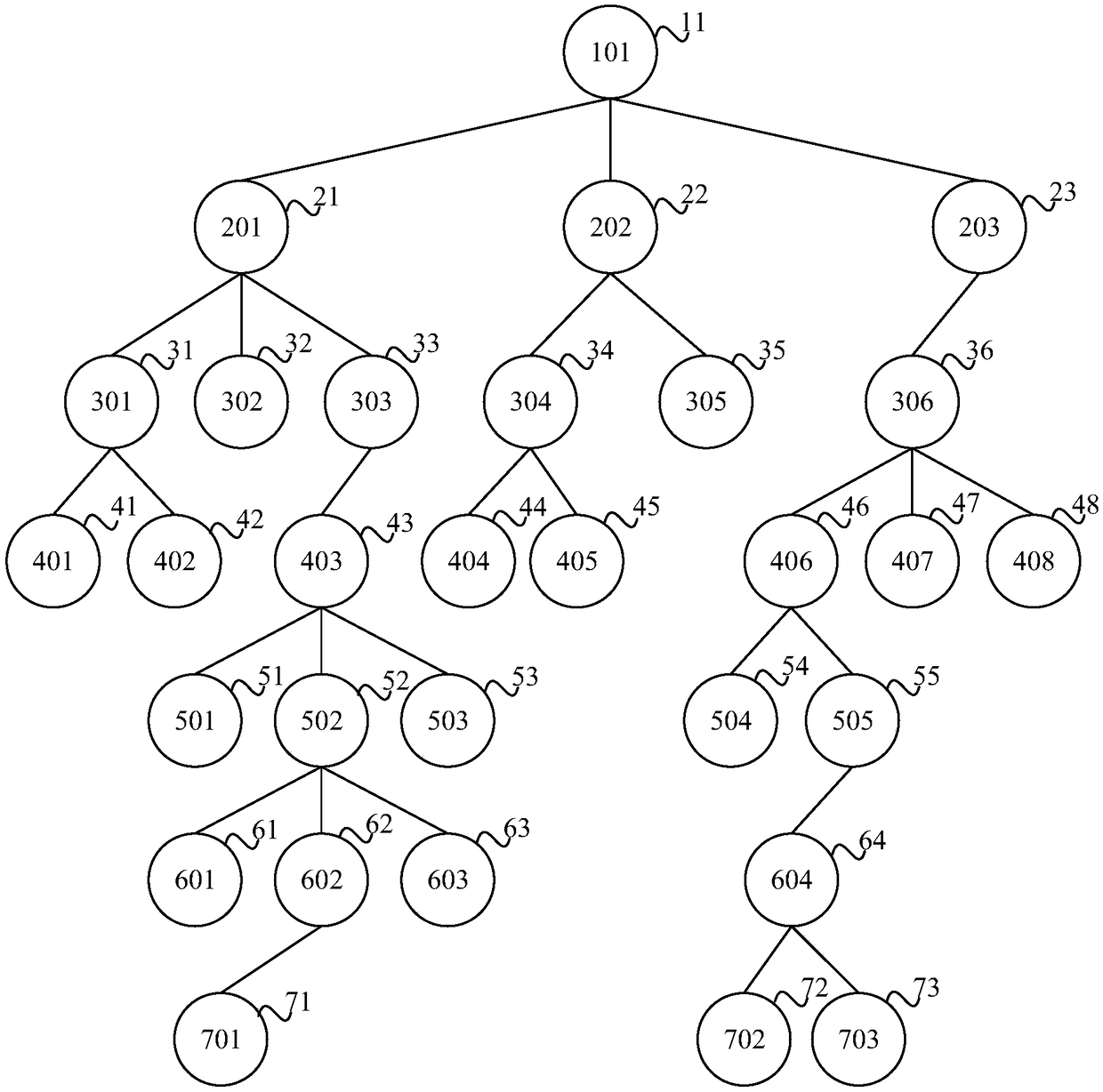

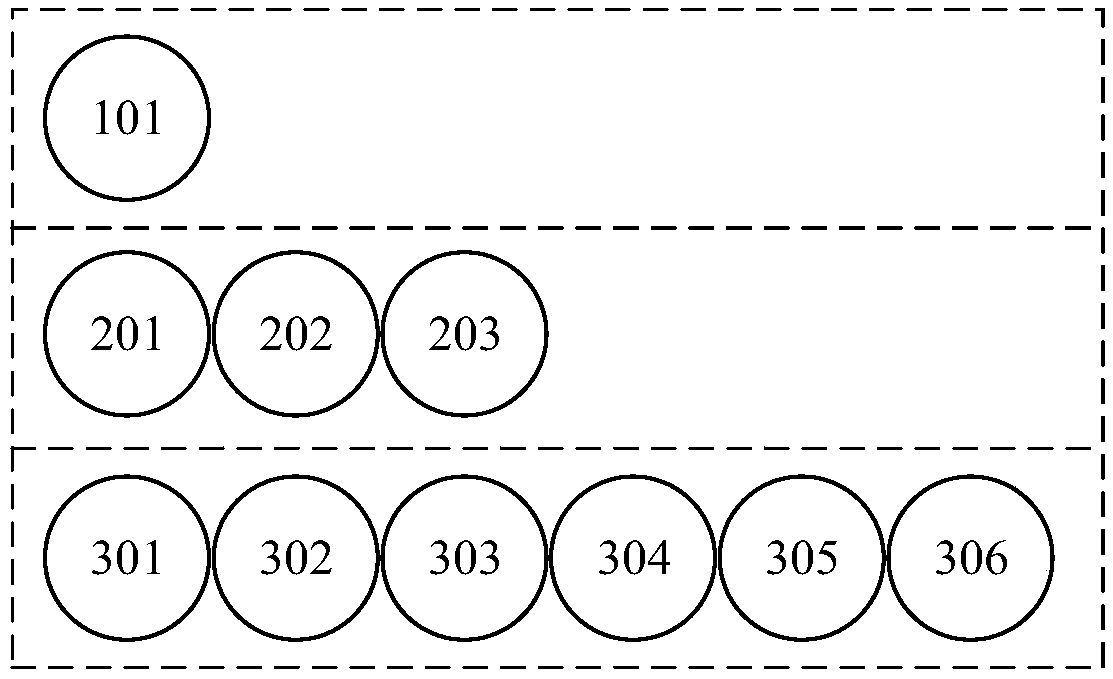

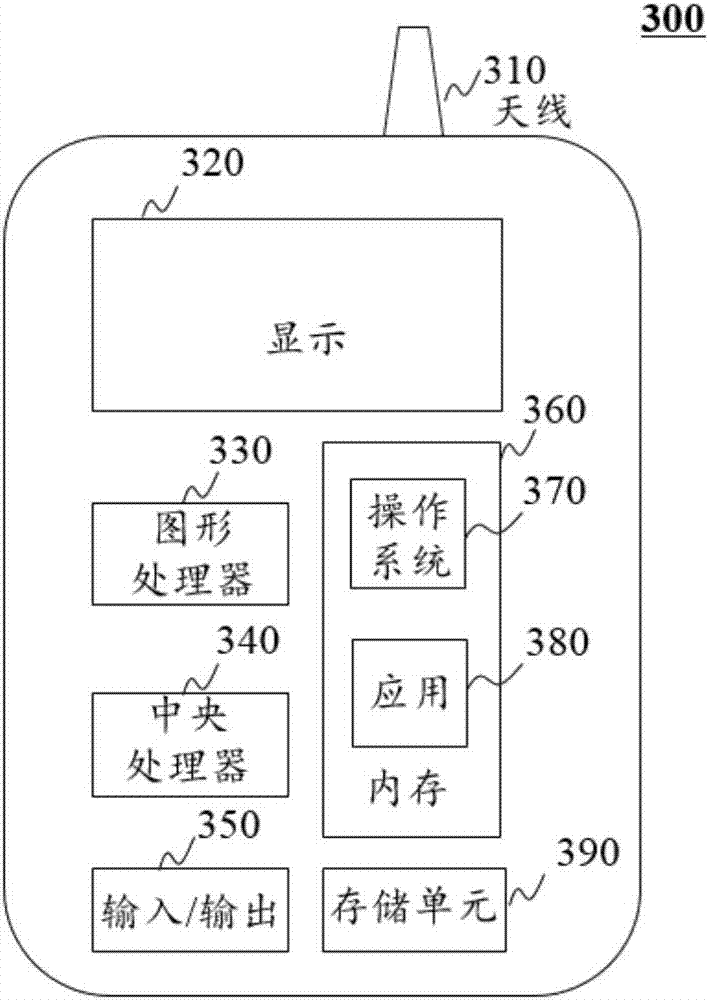

Node data presentation method, device, storage medium and electronic device

ActiveCN109144998ASpeed up the loading processImprove efficiencyDatabase updatingSpecial data processing applicationsComputer networkStructure of Management Information

The present disclosure relates to a method, an apparatus, a storage medium and an electronic device for presenting node data. A plurality of nodes form a tree structure, and the methods include: whena data presentation instruction for a target node is received, if the node data is not stored in the target node, and the client local cache stores node data corresponding to each node of the layer where the target node is located, obtaining the node data from the local cache and storing the node data to the corresponding node, deleting the node data in the local cache, and in the initial state, pre-storing the node data of each node in the first N layers of the tree structure in the local cache, wherein N is a positive integer greater than 1 and smaller than the largest layer of the tree structure; displaying the node data in the target node; if the node data of each node of the first target layer is not stored in the local cache, a data loading instruction being generated and sent to theserver; the node data sent by the server being stored in the local cache, which improves data loading and presentation efficiency and reduces data presentation latency.

Owner:NEUSOFT CORP

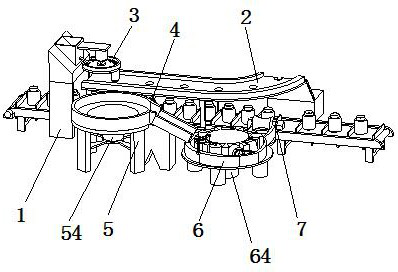

Multistage diamond micro-powder selecting machine

PendingCN110026338AEfficient conveying and transmissionMeet the screening requirementsSievingGas current separationModel selectionUltrasonic vibration

The invention relates to a multistage diamond micro-powder selecting machine. The machine comprises a bearing base, electromagnetic vibration devices, ultrasonic vibration devices, electric telescopiclegs, a main sorting disc, secondary sorting discs, inclination angle sensors and vibration sensors, the upper end surface of the bearing base is connected with the main sorting disc and the lower end surfaces of the secondary sorting discs through the electric telescopic legs, the main sorting disc and each secondary sorting disc are uniformly distributed on the upper end surface of the bearingbase in a stepped mode, and the distance between each sorting disc and the upper end surface of the bearing base is not less than 10 cm, electromagnetic vibration devices and ultrasonic vibration devices are uniformly distributed on the side surfaces of the main sorting disc and the secondary sorting discs, the inclination angle sensors are connected with the centre-of-gravity position of the lower end surfaces of the main sorting disc and the secondary sorting discs, and the vibration sensors are arranged on the lower end surfaces of the main sorting disc and the secondary sorting discs in arectangular array structure correspondingly. The multistage diamond micro-powder selecting machine is flexible and convenient in use, good in universality, high in integration and automation degree, high in model selection precision and operation efficiency, high in the degree of automation of feeding and discharging, and the production operation and the daily maintenance cost are low.

Owner:焦作天宝桓祥机械科技有限公司

Data sharing equipment and method

ActiveCN107205034ABalancing communication pressureReduce operating pressureTransmissionResource informationClient-side

The invention discloses a data sharing method which mainly comprises the following steps: receiving a request of acquiring sequence information from a first client; acquiring a sequence information table; according to the request, checking the sequence information in the sequence information table, and generating a checking result; according to the checking result, processing the request. By adopting the method, the communication burden of a whole network is balanced, and the operation burden of a server is alleviated. By adopting the method, the client can relatively rapidly acquire the sequence information, and meanwhile processing information that the sequence information is processed by other clients can be acquired, so that the sequence information loading process is accelerated.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

Full-automatic carpet inspecting device

PendingCN108729183AMechanizationRealize left and right swing blanking collectionMarking textilesInspecting textilesSmall footprintControl switch

A full-automatic carpet inspecting device comprises a machine frame, wherein along the carpet inspecting feeding direction, a feeding roll A, a feeding roll B, a reversing roll A, an inspecting roll A, an inspecting roll B, a repairing roll A, a repairing roll B, a repairing roll C, a repairing roll D, an up-and-down floating roll, a reversing roll B and a swinging discharging mechanism are sequentially arranged on the machine frame; a vertical light-emitting device is arranged between the inspecting roll A and the inspecting roll B; an inspecting bench is arranged on one side of the inspecting roll A; repairing benches are arranged on the two sides of the repairing roll B respectively; a carpet advance driving mechanism is arranged on the machine frame; an upper sensor is arranged at theupper end of a vertical guide rail; a lower sensor is arranged at the lower end of the vertical guide rail; the upper sensor and the lower sensor are connected with a controller through conductive wires respectively; the controller is connected with the carpet advance driving mechanism, the swinging discharging mechanism and a control switch through the conductive wires respectively. The full-automatic carpet inspecting device has the advantages of reasonable structural design, relatively high mechanization degree, high feeding and collecting automation degree, low labor intensity, small occupied floor area, high inspecting efficiency and the like.

Owner:YANGXIN NUORUI TEXTILE PROD CO LTD

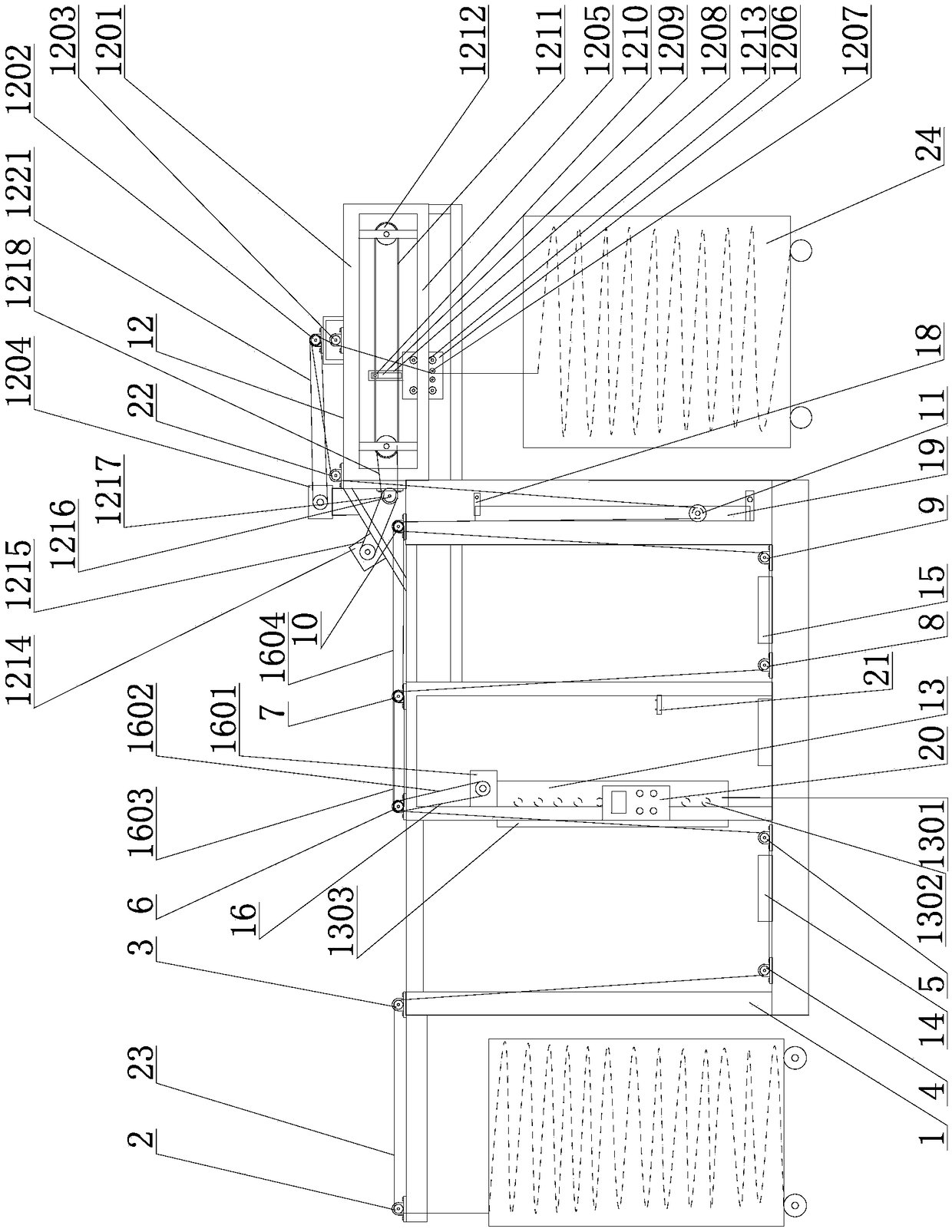

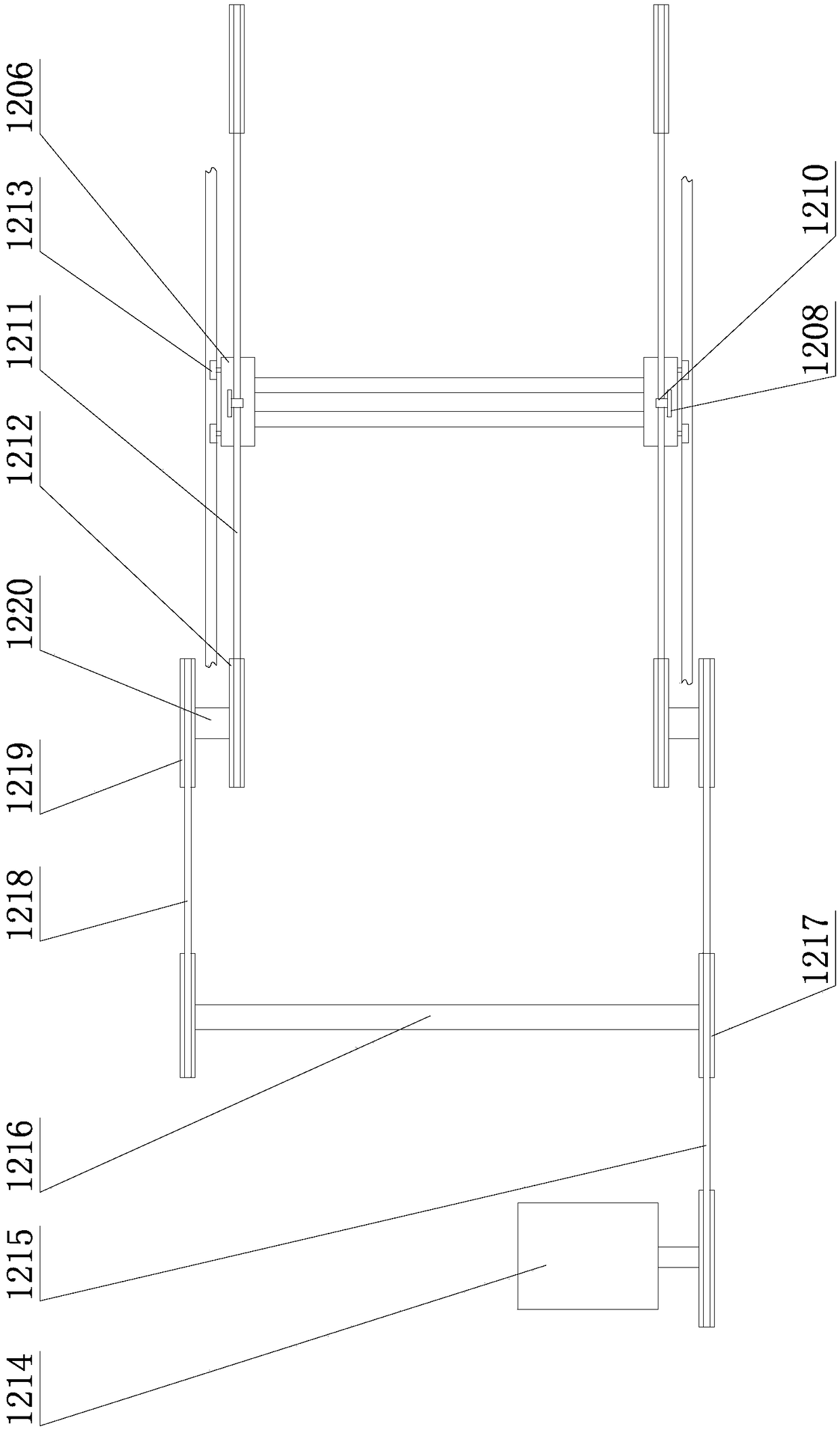

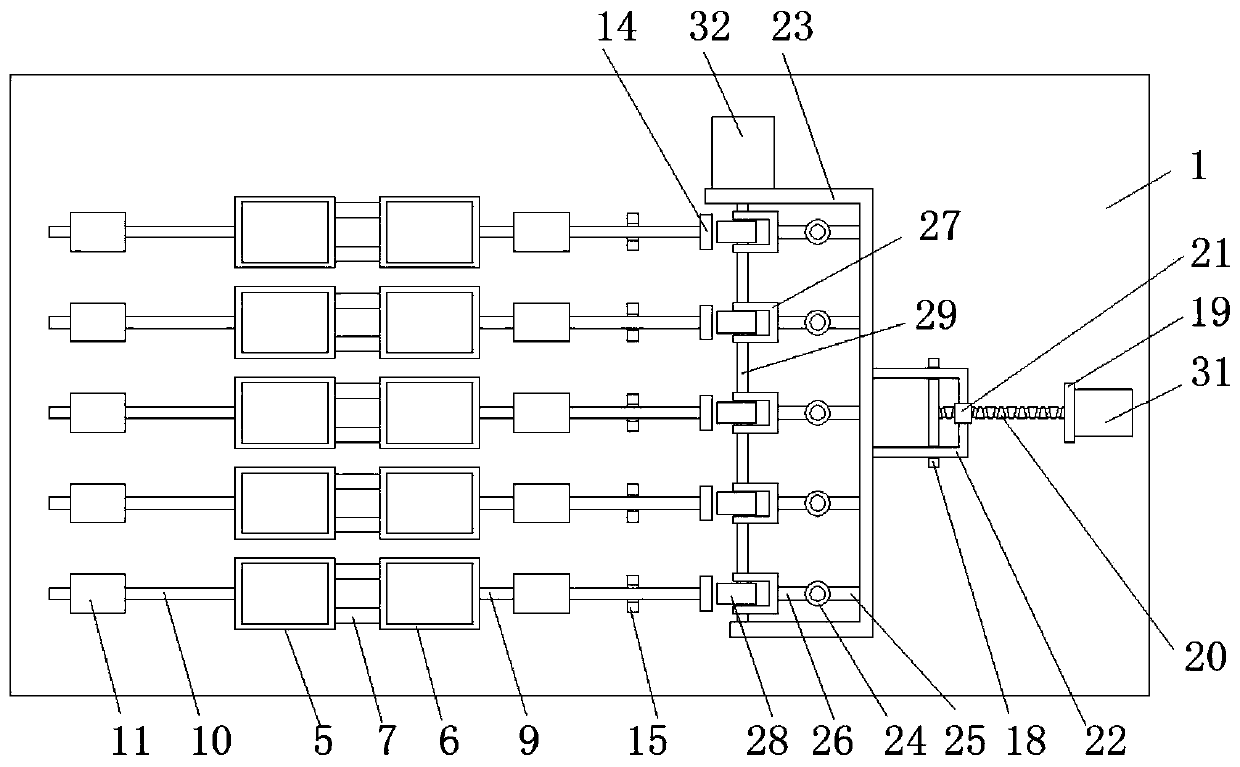

Wall building machine with automatic feeding function

ActiveCN107700858ASave human effortSpeed up the loading processBuilding material handlingBrickControl system

The invention aims to provide a wall building machine with an automatic feeding function. The technical problems of automatic feeding and wall building in the wall building process are solved. The wall building machine with the automatic feeding function comprises a rack, a vertical feeding system, a transverse material conveying system, a wall building machine body system, a material box system,a wall building delivering system, a wall building execution system and a control system. The wall building machine with the automatic feeding function has the beneficial effects that materials (bricks) can be automatically conveyed from the lower part to the upper part, and transferring and transverse moving can be achieved, thus the materials are transferred to the designated wall building position, manpower is greatly saved, and the feeding efficiency and the wall building efficiency are improved. The wall building machine with the automatic feeding function can realize intelligent wall building, has the high efficiency and the high reliability, and saves time and labor.

Owner:THE ELEVENTH METALLURGICAL CONSTR GRP

Feeding device for alkyd resin ship paint production

ActiveCN110861934AImprove weighing efficiencyImprove accuracyWeighing apparatus detailsWeighing apparatus for materials with special property/formMechanical engineeringAlkyd

The invention discloses a feeding device for alkyd resin ship paint production. The feeding device comprises a device bottom plate, wherein a storage bin is arranged vertically above the device bottomplate; a plurality of discharging ports are formed in the bottom end of the storage bin; edge plates are fixedly connected to the edge ports of the bottom ends of the discharging ports correspondingly; a material blocking transverse plate is arranged vertically below the storage bin; a first metering barrel and a second metering barrel are arranged between the bottom sides of the edge plates andthe material blocking transverse plate correspondingly and are arranged side by side; a material blocking sliding plate is arranged between the first metering barrel and the second metering barrel; and the top side of the material blocking sliding plate is flush with the edge ports of the top ends of the first metering barrel and the second metering barrel. According to the feeding device, the weighing efficiency and accuracy are improved, use by people is greatly facilitated, the feeding process of alkyd resin ship paint production is accelerated, the production efficiency is improved, and the use requirements of people in production and life are met.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

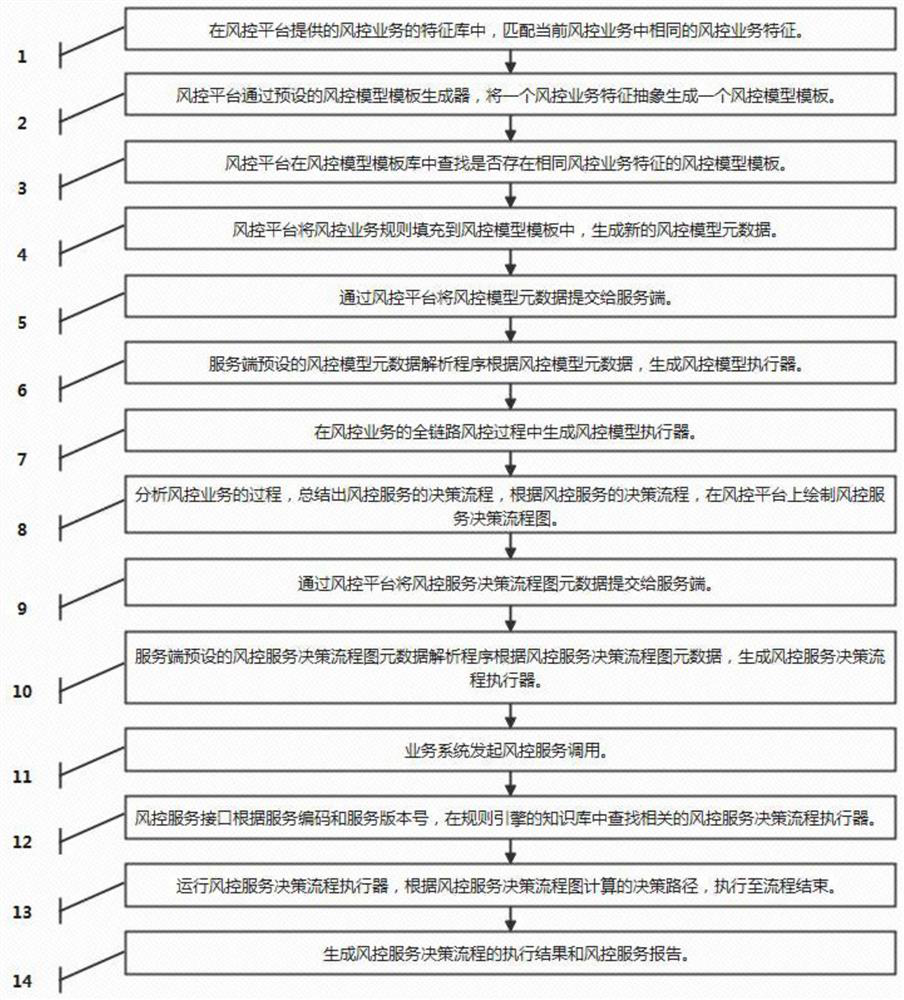

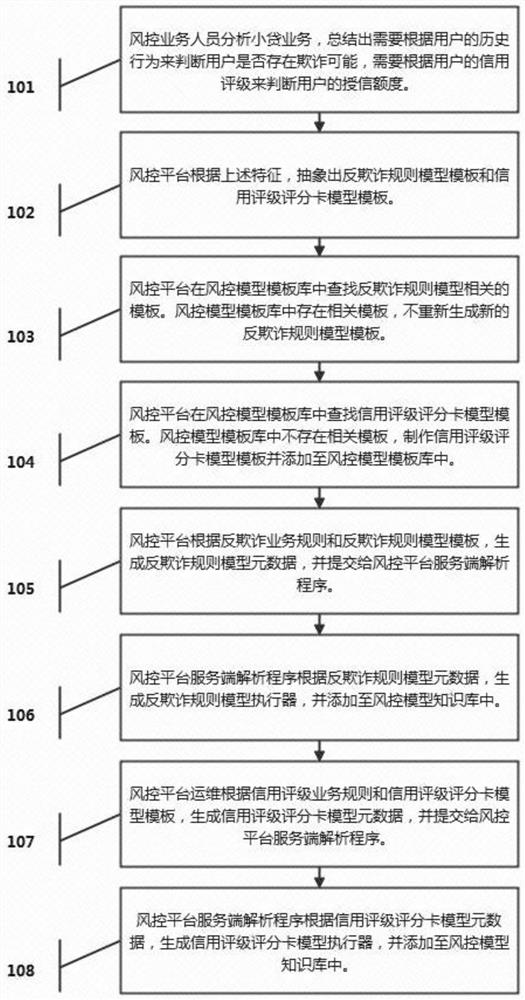

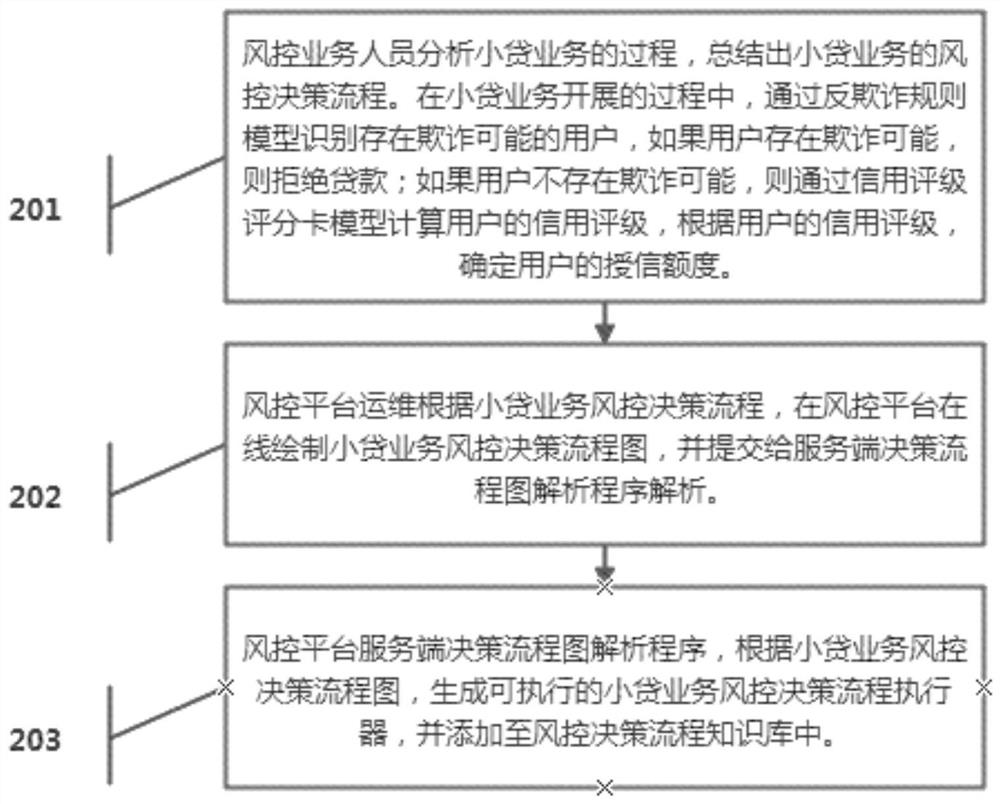

Method for realizing risk control rule configuration based on rule engine

PendingCN113888050AImprove accuracy and efficiencyReduce complexityFinanceResourcesBusiness ruleMetadata

The invention discloses a method for realizing risk control rule configuration based on a rule engine, and the method is characterized in that the method comprises the steps: matching risk control business features in a risk control platform; generating a risk control model template; filling the risk control business rule into a risk control model template, generating new risk control model metadata, and submitting the new risk control model metadata to a server; enabling the analysis program to generate a risk control model actuator in a full-link risk control process of the risk control business according to the risk control model metadata; analyzing a risk control business process, and drawing a risk control service decision flow chart; generating a risk control service decision flow executor; enabling a business system to initiate risk control service calling; operating the risk control service decision flow executor; and generating an execution result of the risk control service decision process and a risk control service report. The efficiency and accuracy of risk control service definition are improved; a user is prevented from manually compiling rule execution logic, the complexity of defining the model is reduced, and the efficiency of defining the model is improved; the system flexibility is improved; and the maintenance difficulty is reduced.

Owner:FOCUS TECH

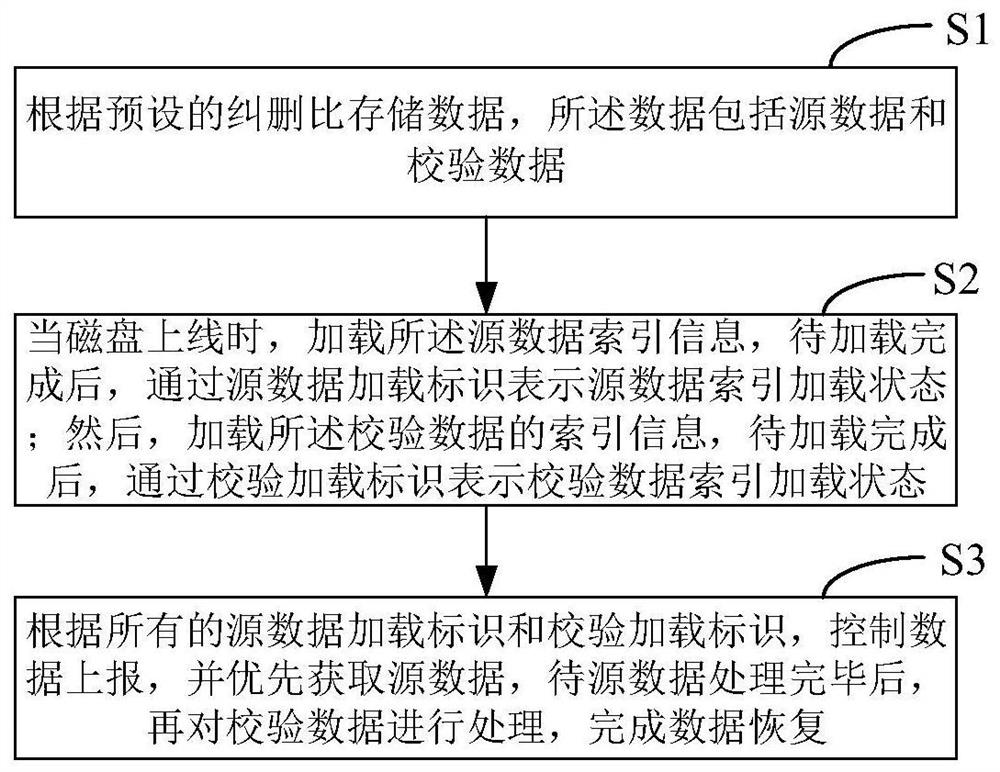

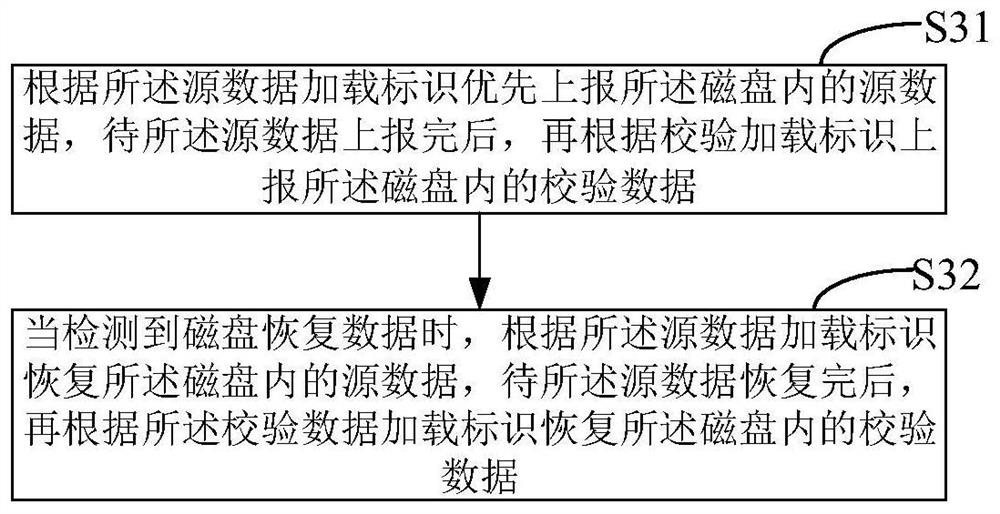

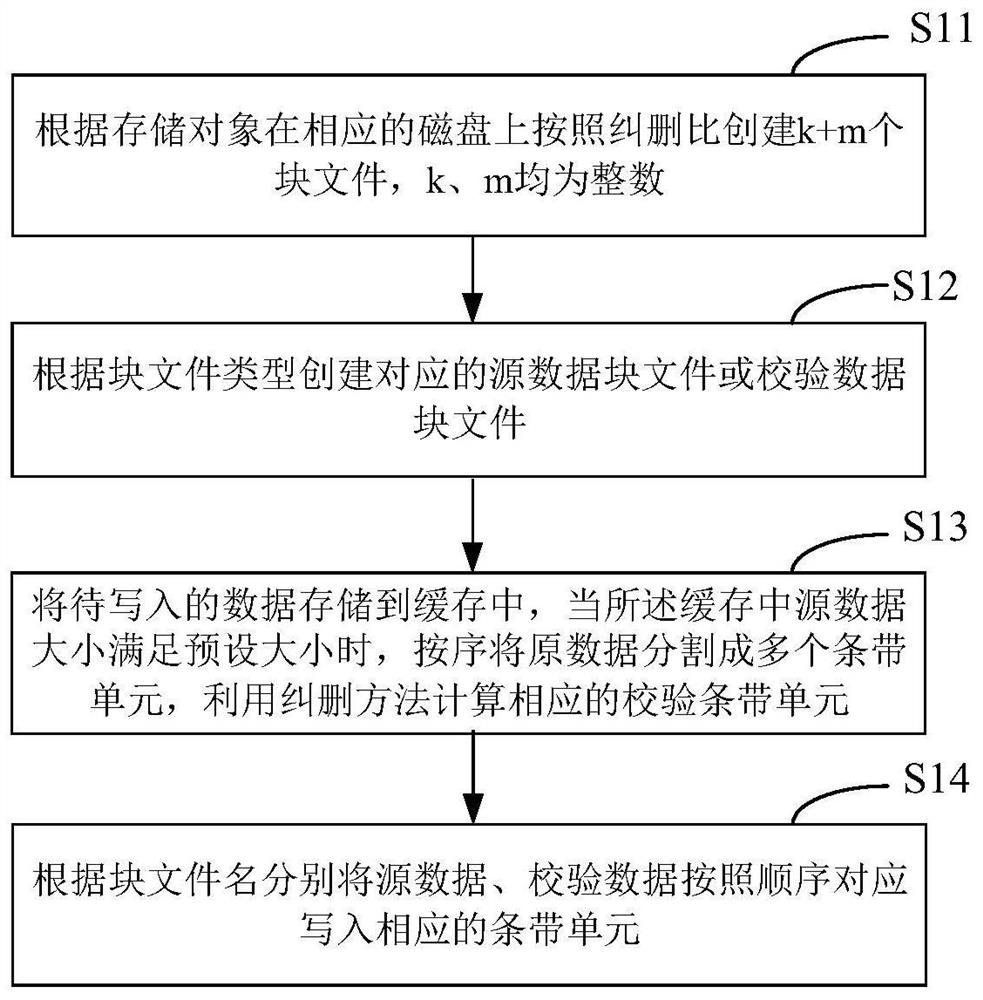

Data recovery control method and device based on erasure codes, equipment and medium

ActiveCN113190384AShorten the timeReduce readRedundant operation error correctionData packStart time

The invention provides a data recovery control method and device based on erasure codes, equipment and a medium, and the method comprises the steps: storing data according to a preset erasure ratio, the data comprising source data and verification data; when the disk is online, loading source data index information, and after loading is completed, representing a source data index loading state through a source data loading identifier; then, loading index information of the verification data, and after loading is completed, representing a verification data index loading state through a verification data loading identifier; and according to all the source data loading identifiers and the verification data loading identifiers, controlling data reporting, preferentially acquiring the source data, and after the source data is processed, processing the verification data to complete data recovery. According to the method, the source data and the verification data are distinguished through the identifier, and the mode of loading the source data first and then loading the verification data is adopted, so that the loading process of the file system and the starting process of the service node are accelerated, the starting time of the service node under the abnormal condition is shortened, and the response efficiency is improved.

Owner:重庆紫光华山智安科技有限公司

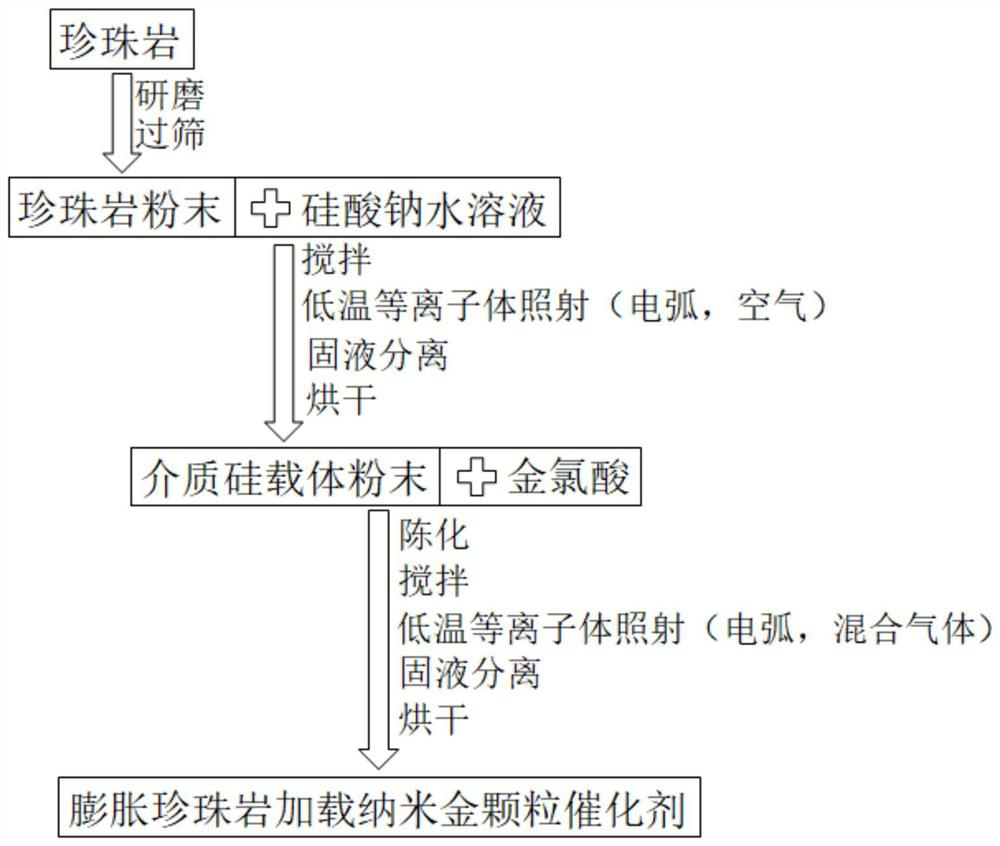

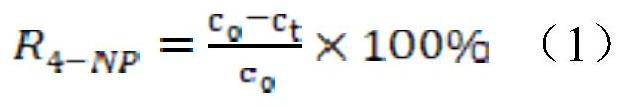

Preparation method and application of expanded perlite loaded gold nanoparticle catalyst

ActiveCN111672507ASpeed up the loading processGood dispersionMaterial nanotechnologyWater contaminantsPtru catalystGold particles

The invention discloses a preparation method and application of an expanded perlite loaded gold nanoparticle catalyst, wherein the preparation method comprises the following steps: mixing expanded perlite powder into a sodium silicate aqueous solution, stirring, carrying out low-temperature plasma irradiation, carrying out solid-liquid separation, and drying to obtain medium silicon carrier powder; and mixing the medium silicon carrier powder into gold chlorate, aging for 12-24 hours, stirring, carrying out low-temperature plasma irradiation, carrying out solid-liquid separation, and drying toobtain the expanded perlite loaded nano-gold particle catalyst. The preparation process is simple, and no reducing reagent needs to be added in the preparation process of the gold nanoparticles. Silicate is converted into polysilicagel by applying a low-temperature plasma technology, so that loading and dispersion of the gold nanoparticles on the surface of the expanded perlite are enhanced. Thegold nano catalytic material prepared by the method can catalyze and remove 99% of 4-nitrophenol to the maximum extent.

Owner:KANFORT JIANGMEN ENVIRONMENTAL TECH CO LTD

Industry raw material feeding and discharging device

InactiveCN108408624ARealize transportationReasonable designPortable liftingRotational axisSheet steel

The invention discloses an industry raw material feeding and discharging device. The industry raw material feeding and discharging device comprises a portal frame, a hydraulic lifting rod, a loading and unloading frame and electromagnets. The hydraulic lifting rod is fixedly arranged on a top plate at the upper top end of the portal frame and is vertically downwards arranged. A rotation shaft is fixedly arranged at the front end of the hydraulic lifting rod. The loading and unloading frame is horizontally arranged below the rotation shaft, and a steel cable is connected between the loading andunloading frame and the outer side wall of the rotation shaft. The multiple electromagnets are arranged and embedded in the lower bottom face of the loading and unloading frame. A hydraulic assemblyis fixedly arranged on the top plate of the portal frame, and a plurality of universal wheels are arranged at the bottom of the portal frame. The industry raw material feeding and discharging device is reasonable in design, ingenious in concept, capable of conducting elevating feeding or discharging on steel plates or iron plates with the large mass and the large superficial area, convenient to use, practical, high in flexibility and capable of achieving object transportation between short-distance machining devices, and the work efficiency is greatly improved.

Owner:WUXI JIAN AUTOMATION TECH CO LTD

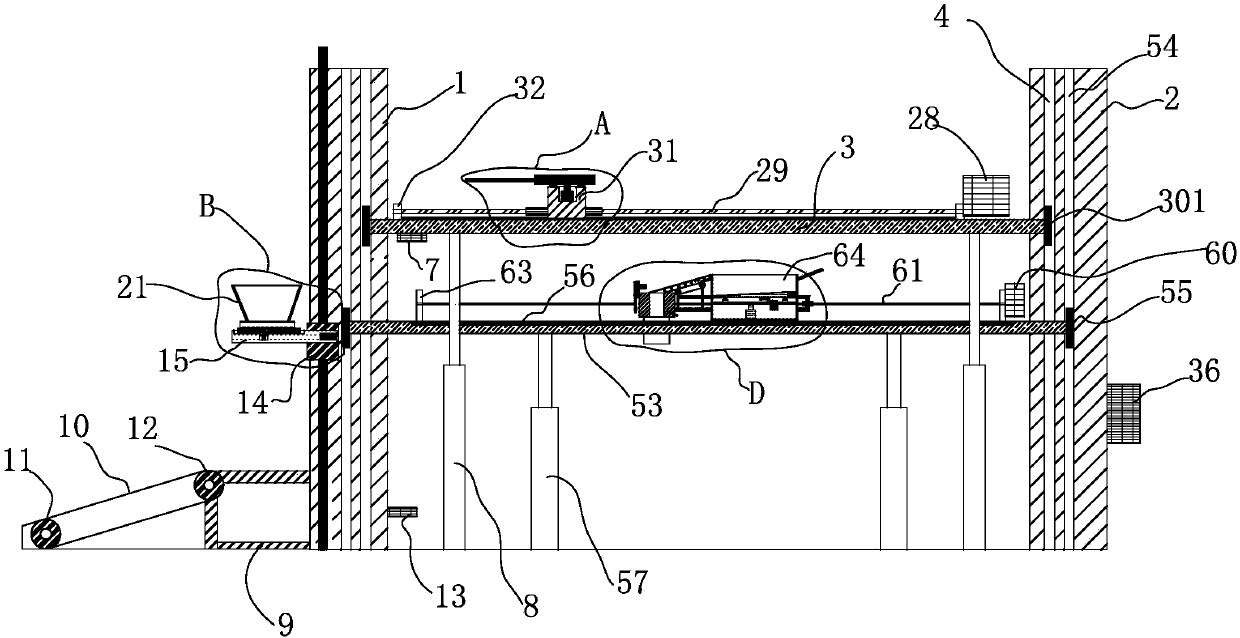

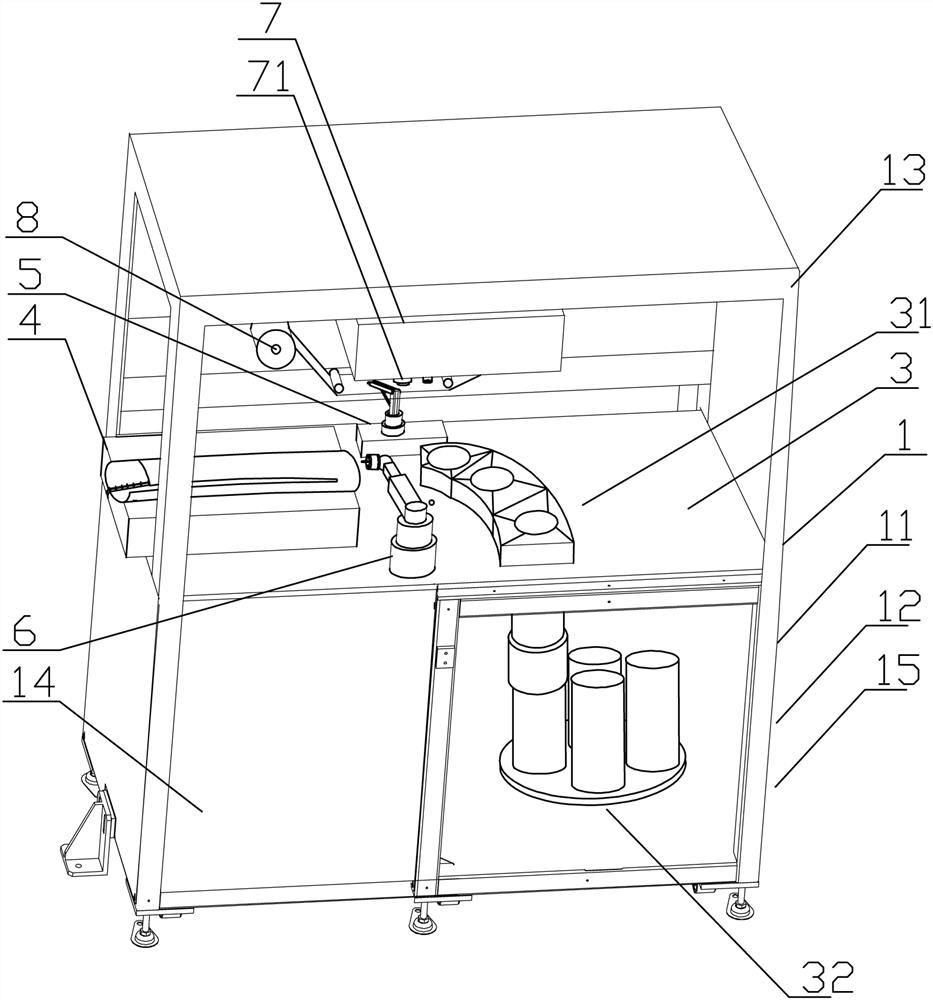

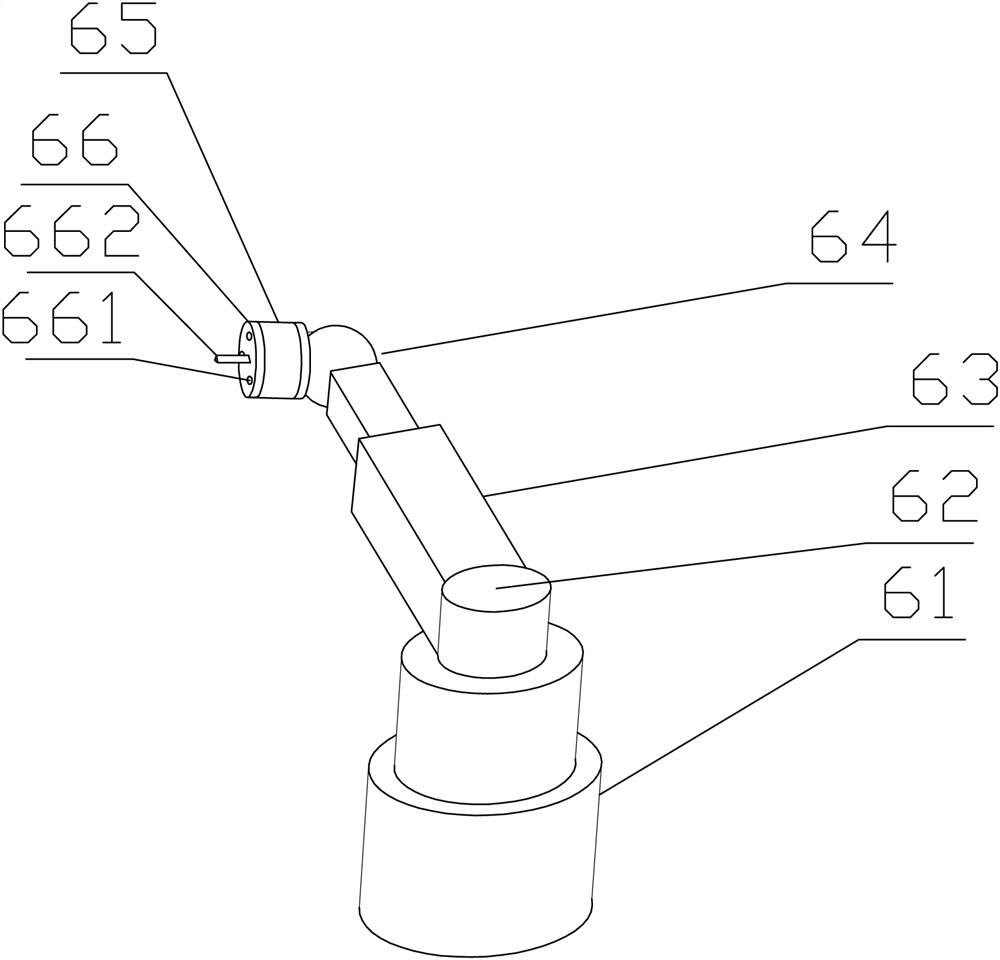

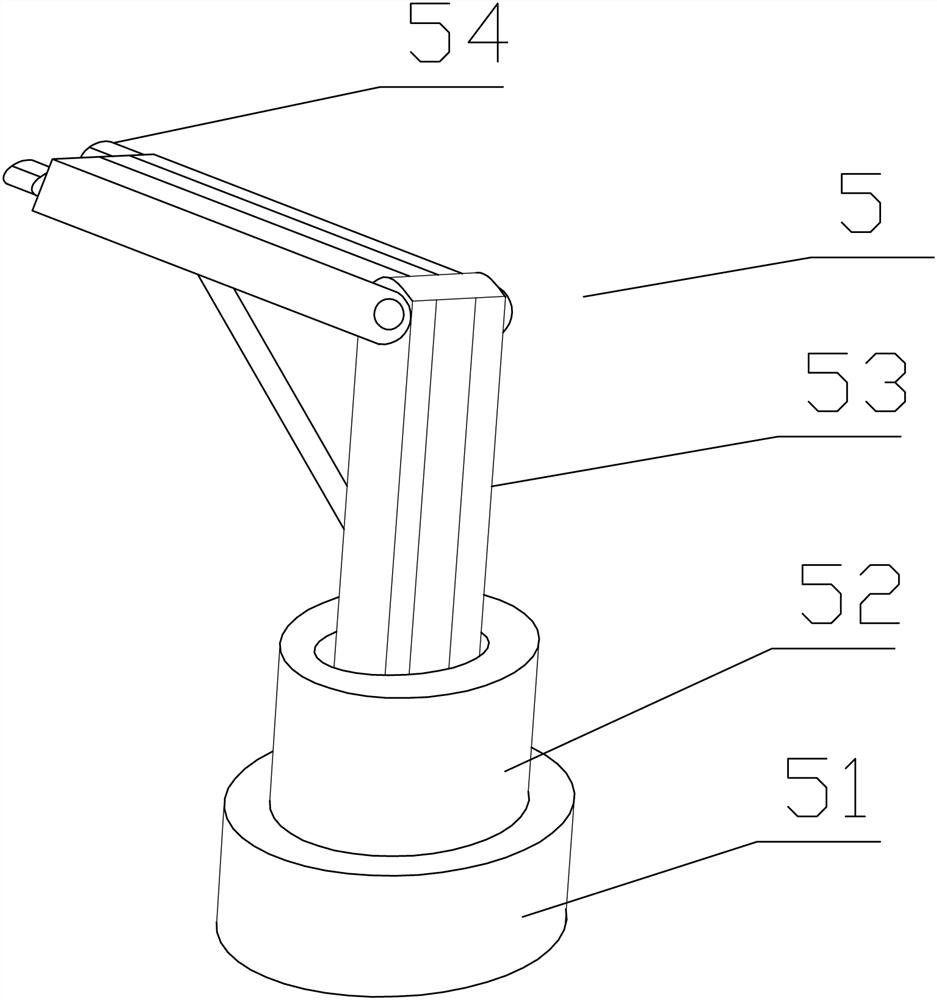

A labeling system with automatic calibration function

ActiveCN111153008BHigh precisionGood labeling stabilityLabelling machinesControl engineeringProcess engineering

The invention discloses a labeling system with an automatic calibration function, which includes a base arranged at the lower part of the machine frame, and an operating table arranged on the base, and the operating table is provided with a material-feeding operation mechanism and a driving connection with a control cabinet. Labeling mechanism; the two sides of the reclaiming operation mechanism are respectively provided with a feeding mechanism and a receiving device, and the feeding mechanism includes a transfer table; the frame is provided with a posture detection mechanism facing the reclaiming operation mechanism. Mechanism; the reclaiming operation mechanism includes a swing arm that is oscillatingly arranged on the operating table, and a reclaiming device that is movably arranged at the end of the swing arm. The invention provides a labeling system with an automatic calibration function, which has good labeling stability, improves labeling accuracy, and facilitates loading and receiving materials.

Owner:SUZHOU DELTA LOGISTICS

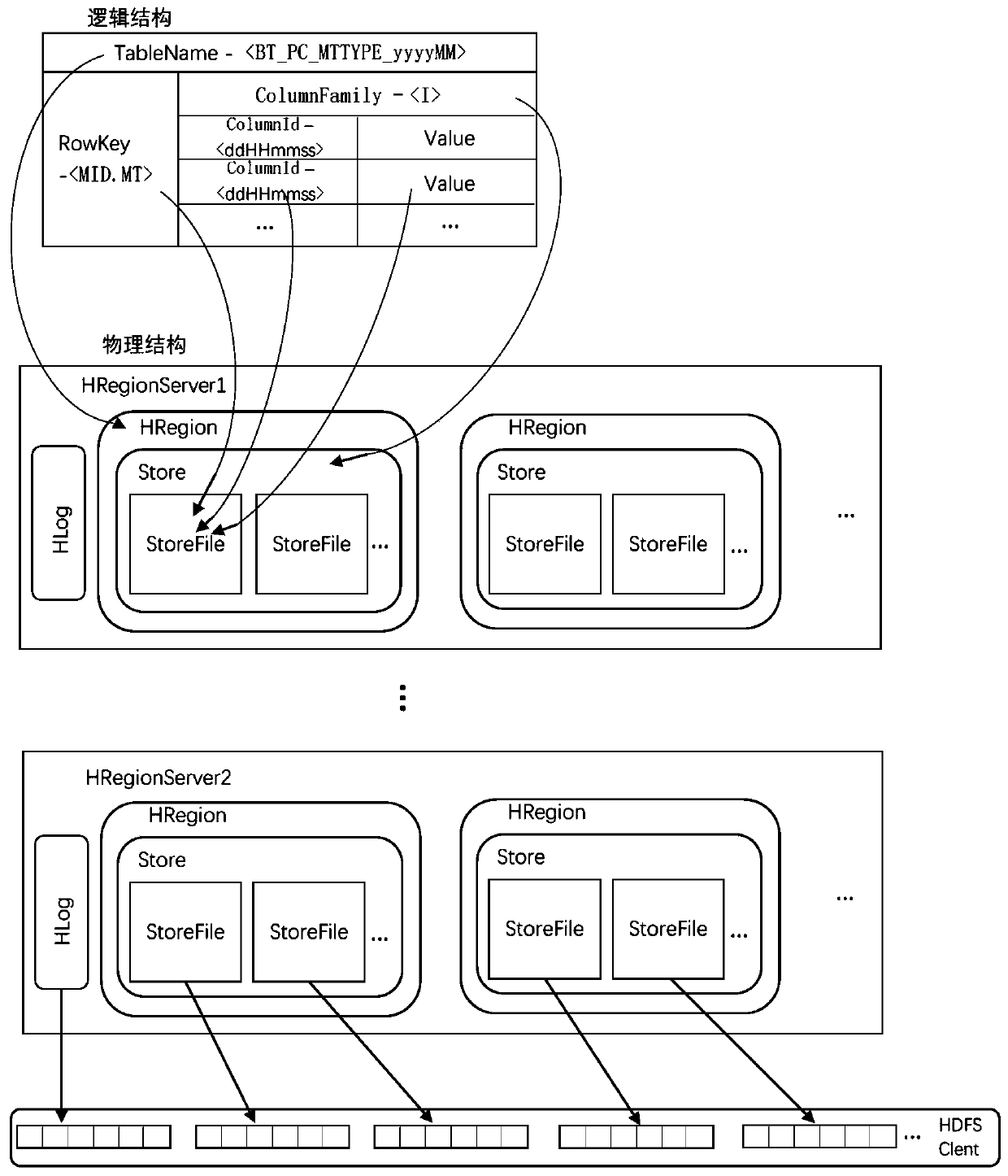

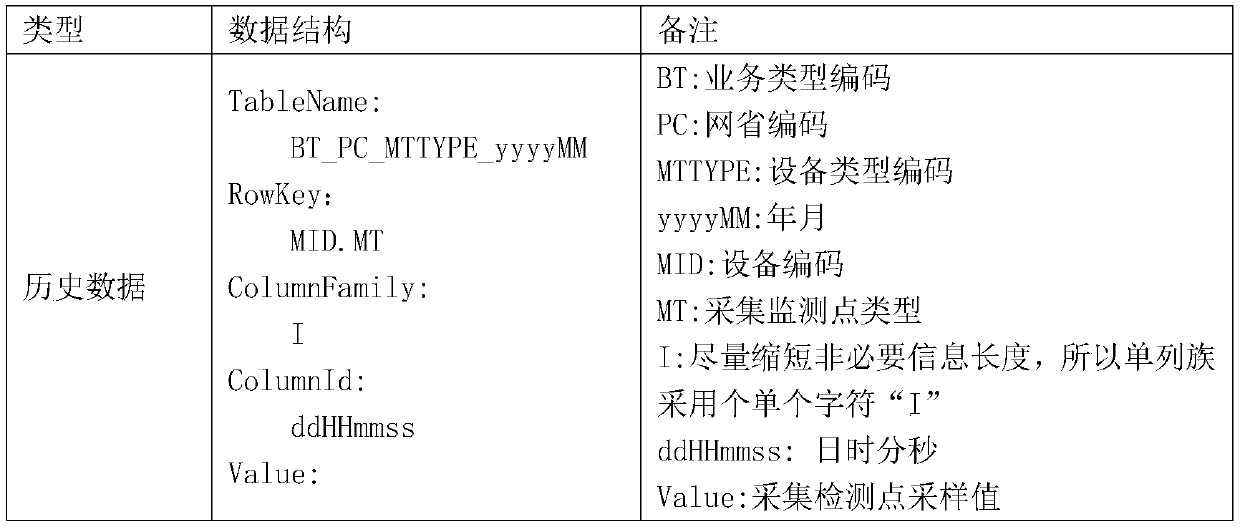

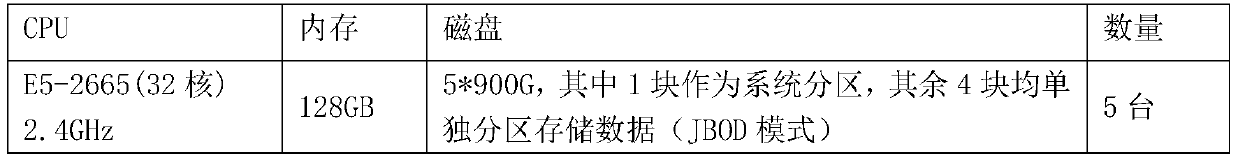

HBase-based intelligent power grid acquisition and monitoring data storage system and storage method

PendingCN110807032AIncrease loading capacityImprove access performanceData processing applicationsDatabase distribution/replicationMonitoring sitePower grid

The invention provides an HBase-based intelligent power grid collection monitoring data storage system and storage method, and the system is provided with a plurality of storage units, and the data format of data stored in each storage unit comprises a table name, a row key, a column family, a column name, and a collection detection point sampling value; wherein the row key is composed of an equipment code and acquired monitoring point type data; wherein the single-column family is composed of single characters ' I '; wherein the column name is composed of day-hour-minute-second data. Partialinformation of the row key and the column family is transferred and stored, the length of the row key and the column family is shortened, unnecessary information is simplified, redundancy is reduced,the space utilization rate is increased, and the loading and access performance of collected monitoring data is improved. And meanwhile, the distribution of RowKey is reasonably and fully considered,and a pre-partitioning mode is adopted, so that the loading performance of the acquired monitoring data is improved.

Owner:CHINA REALTIME DATABASE +1

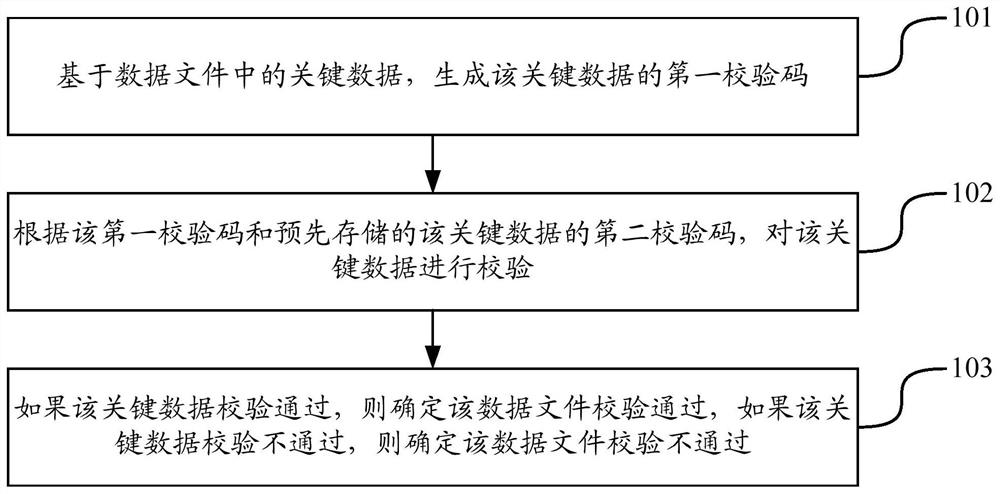

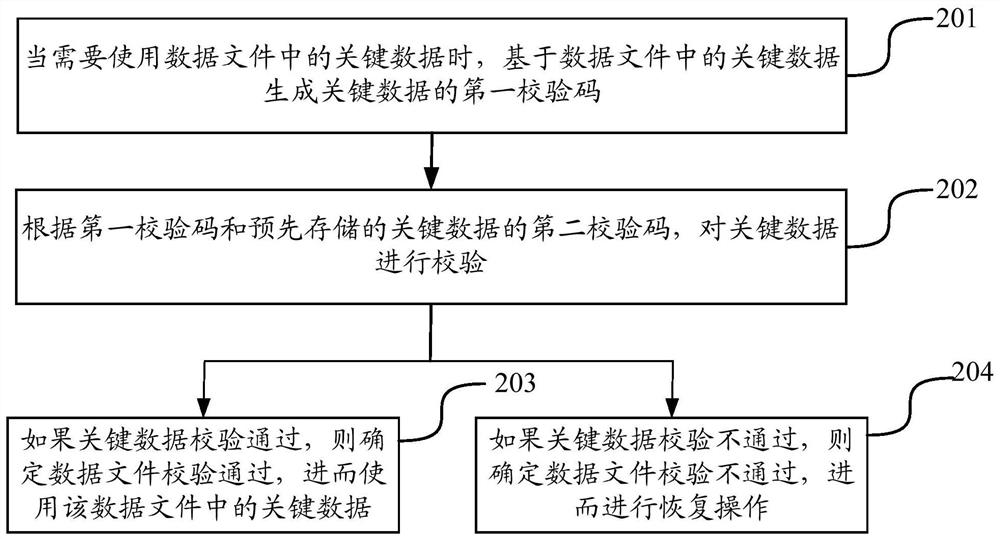

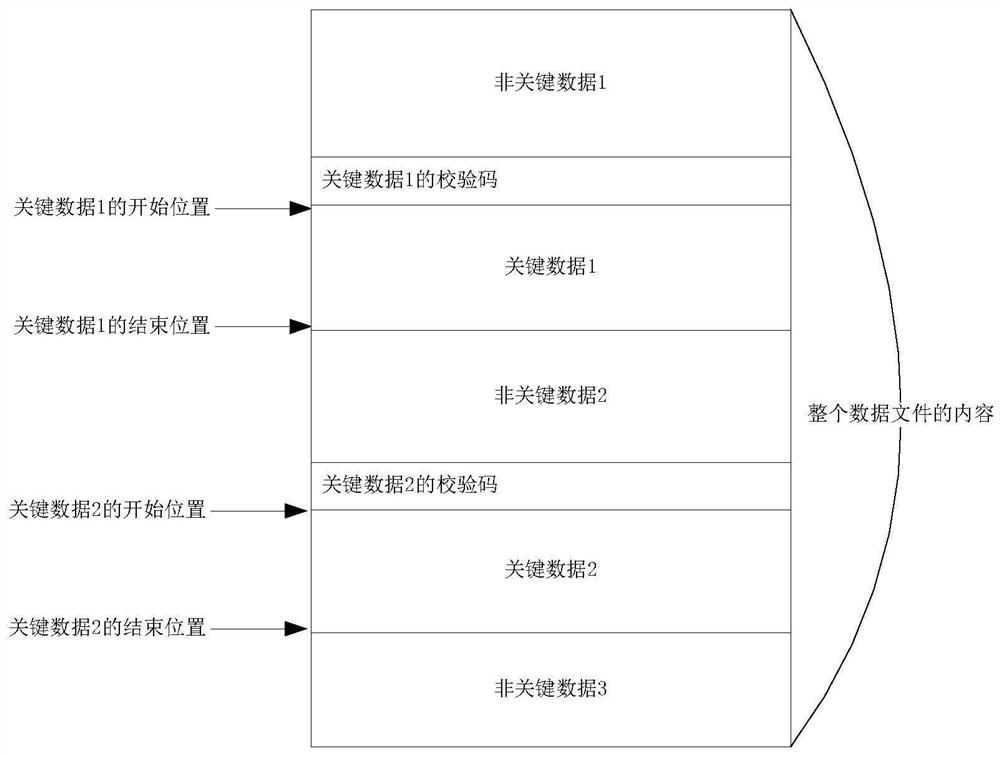

Data file verification method and device

ActiveCN107220141BImprove fault toleranceAvoid recoveryRedundant data error correctionData fileCheck digit

The invention discloses a data file verification method and device, belonging to the technical field of data processing. The method includes: generating a first check code of the key data based on the key data in the data file; and verifying the key data according to the first check code and the pre-stored second check code of the key data ; If the verification of the key data is passed, it is determined that the verification of the data file is passed; if the verification of the key data is not passed, it is determined that the verification of the data file is not passed. The invention realizes the verification of the data file by verifying the key data in the data file, avoids the system-level recovery operation of the electronic device caused by the error of the non-key data in the data file, and improves the electronic device verification. The fault tolerance rate is high, and the calculation resources consumed by the electronic equipment to generate the verification code based on the key data are small, which improves the efficiency of the electronic equipment system to load and verify data files.

Owner:VIDAA(荷兰)国际控股有限公司

Professional mortar production system for aerated bricks

InactiveCN112659374AAchieve hybridReduce mixMixing operation control apparatusCement mixing apparatusBrickProcess engineering

The invention provides a professional mortar production system for aerated bricks, and relates to the field of building auxiliary equipment. The professional mortar production system for the aerated bricks comprises a supporting frame, a stirring device is arranged in the supporting frame, a discharging pipe is arranged on the lower surface of the stirring device, a conveying device is arranged below the discharging pipe, and a first weighing device is arranged on the upper surface of the supporting frame; and a raw material mixing device is arranged on the upper surface of the first weighing device, a second weighing device is arranged on the upper surface of the supporting frame and located on the right side of the first weighing device, and an auxiliary material storage device is arranged on the upper surface of the second weighing device. The raw material mixing device is arranged above the stirring device, mixing of raw materials can be achieved in one step, so that the mixing process of the raw materials is reduced, the production efficiency of mortar is improved, meanwhile, the first weighing device and the second weighing device are arranged, the proportion of raw materials can be accurately measured, and the quality of mortar is better.

Owner:福建奇胜环保建材科技有限公司

A feeding device for the production of alkyd resin marine paint

ActiveCN110861934BImprove weighing efficiencyImprove accuracyWeighing apparatus detailsWeighing apparatus for materials with special property/formFisheryMechanical engineering

The invention discloses a feeding device for alkyd resin ship paint production. The feeding device comprises a device bottom plate, wherein a storage bin is arranged vertically above the device bottomplate; a plurality of discharging ports are formed in the bottom end of the storage bin; edge plates are fixedly connected to the edge ports of the bottom ends of the discharging ports correspondingly; a material blocking transverse plate is arranged vertically below the storage bin; a first metering barrel and a second metering barrel are arranged between the bottom sides of the edge plates andthe material blocking transverse plate correspondingly and are arranged side by side; a material blocking sliding plate is arranged between the first metering barrel and the second metering barrel; and the top side of the material blocking sliding plate is flush with the edge ports of the top ends of the first metering barrel and the second metering barrel. According to the feeding device, the weighing efficiency and accuracy are improved, use by people is greatly facilitated, the feeding process of alkyd resin ship paint production is accelerated, the production efficiency is improved, and the use requirements of people in production and life are met.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

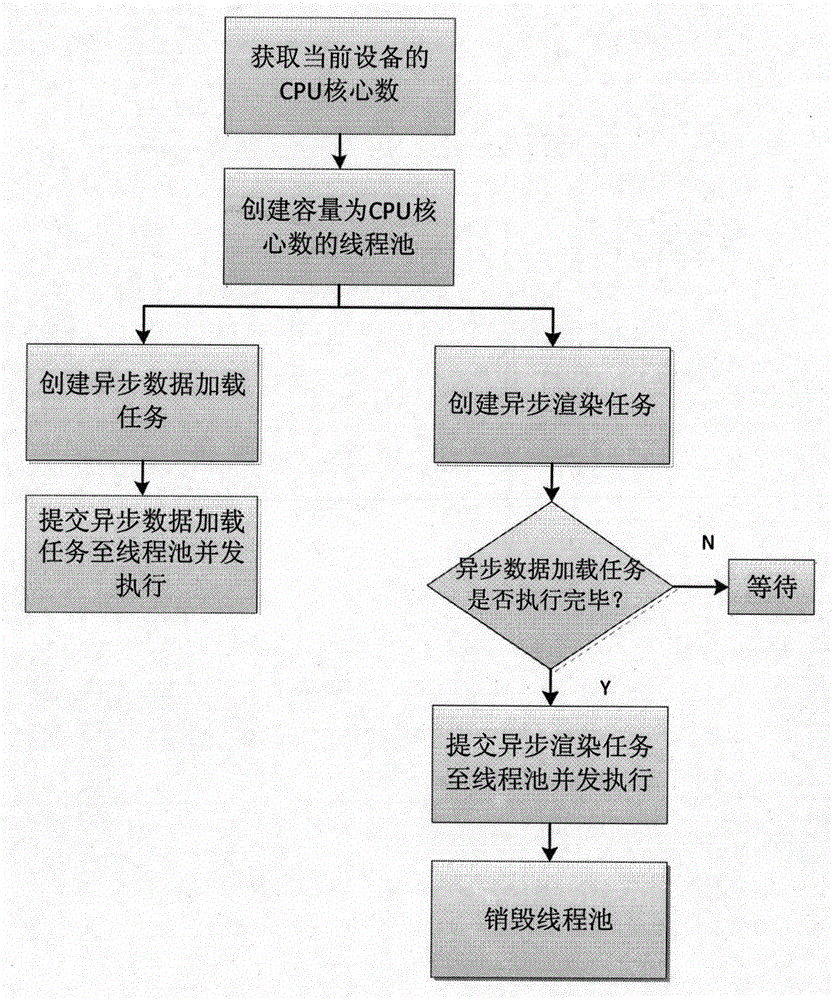

Method for concurrent loading and rendering of 3D models on multi-core mobile devices

InactiveCN103455356BGive full play to handlingSpeed up the loading processResource allocationProgram loading/initiatingComputer graphics (images)Mobile device

The invention relates to a concurrence loading and rendering method of 3D (three-dimensional) models on a multi-core mobile device, comprising the following steps of taking a CPU (Central Processing Unit) core number of the current device as the capacity of a thread pool to create the thread pool; respectively creating 3D model data loading tasks for each 3D model file stored on a secondary storage device; respectively creating a rendering task for each 3D model; submitting all data loading tasks to a buffering queue of the thread pool, and carrying out concurrent execution on the data loading tasks by the thread pool; after the data loading tasks are all executed, submitting the rendering tasks into the buffering queue of the thread pool and carrying out concurrent execution on the rendering tasks by the thread pool; finally, after all rendering tasks are completed, destroying the thread pool and releasing system resources.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com