Professional mortar production system for aerated bricks

A production system and technology of aerated bricks, applied in liquid ingredient supply devices, clay preparation devices, mixing operation control devices, etc., can solve the problems of long mortar production time and low efficiency, avoid dust spreading, speed up production efficiency, The effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

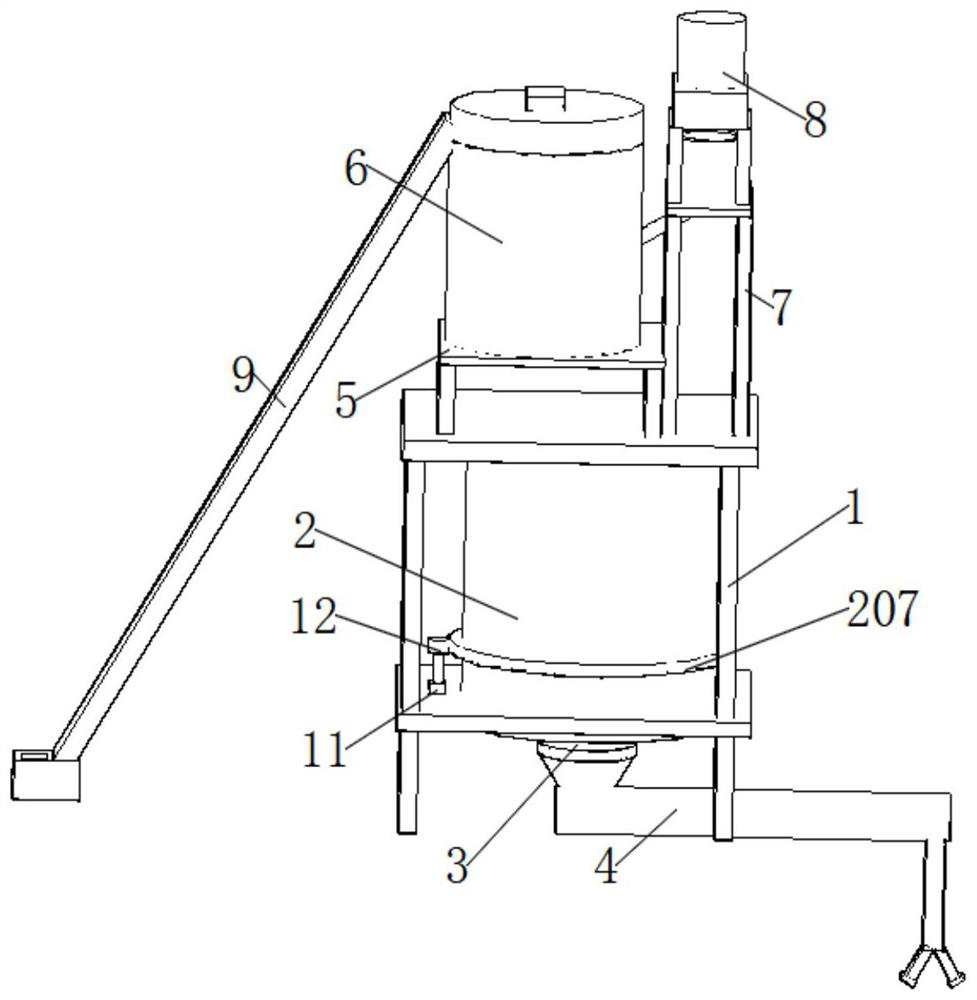

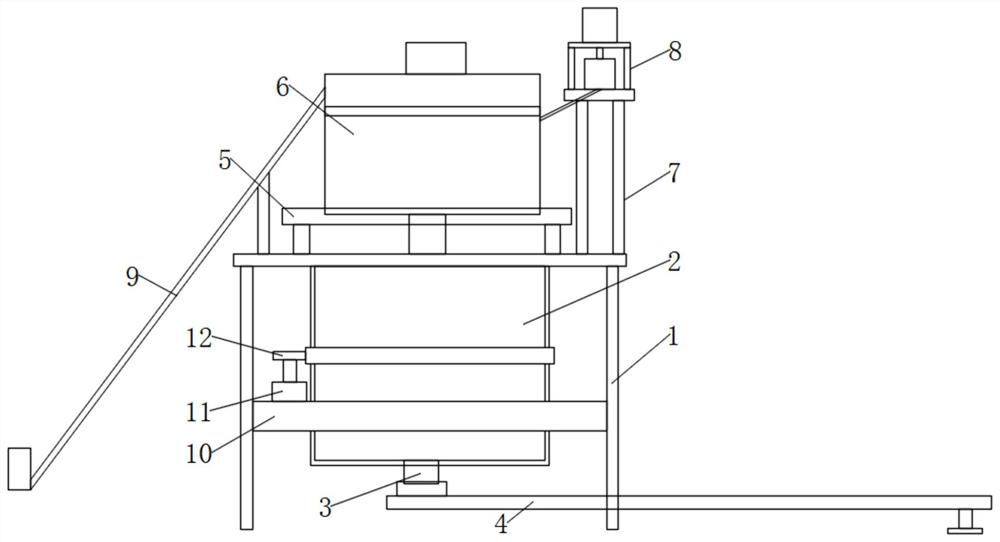

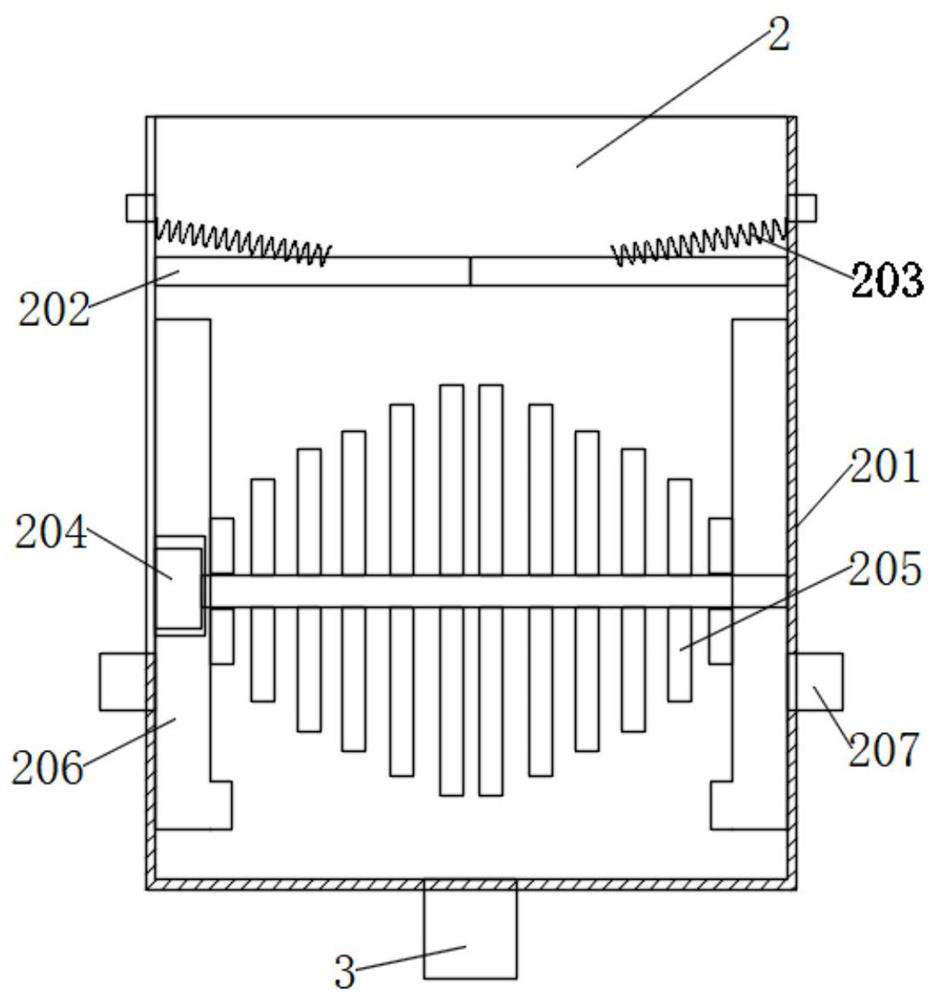

[0034] Such as Figure 1-8 As shown, the embodiment of the present invention provides a professional mortar production system for aerated bricks, including a support frame 1 and a support device. A stirring device 2 is provided inside the support frame 1 to stir the mortar. The stirring device 2 includes a mixing drum 201, The inside of the mixing drum 201 is provided with a baffle 202, which prevents the internal dust from flying out when a large number of materials are fed. The upper surface of the baffle 202 is fixedly connected with a spring 203 to close the baffle 202. The spring 203 is far away from the end of the baffle 202. Fixedly connected with the inner wall of the mixing drum 201, the inside of the mixing drum 201 and below the baffle plate 202 are provided with a stirring motor 204 to provide stirring power, and the output end of the stirring motor 204 is fixedly connected with a stirring blade 205 through a rotating shaft for stirring , the inner wall of the mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com