High-voltage lithium cobaltate based composite cathode material of lithium ion battery and preparation method of high-voltage lithium cobaltate based composite cathode material

A composite positive electrode material and lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unstudied electrochemical properties of positive electrode materials, inability to ensure uniform distribution of trace elements, and inability to synchronize surface coating production processes, etc. problems, to achieve excellent electrochemical performance, improve cycle performance, and good morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

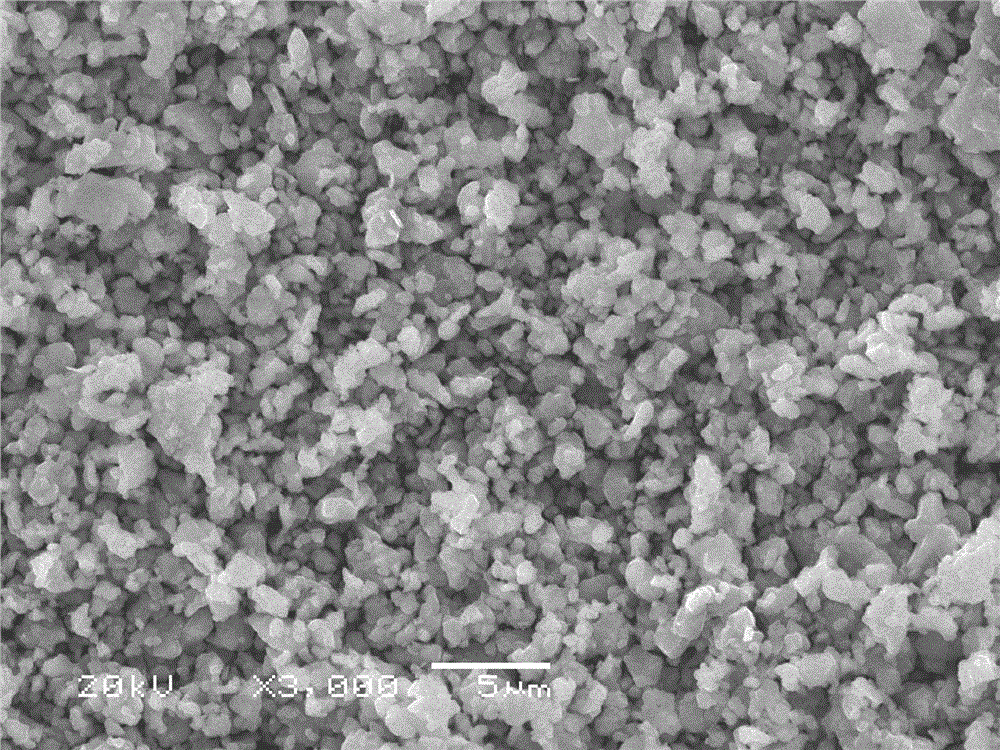

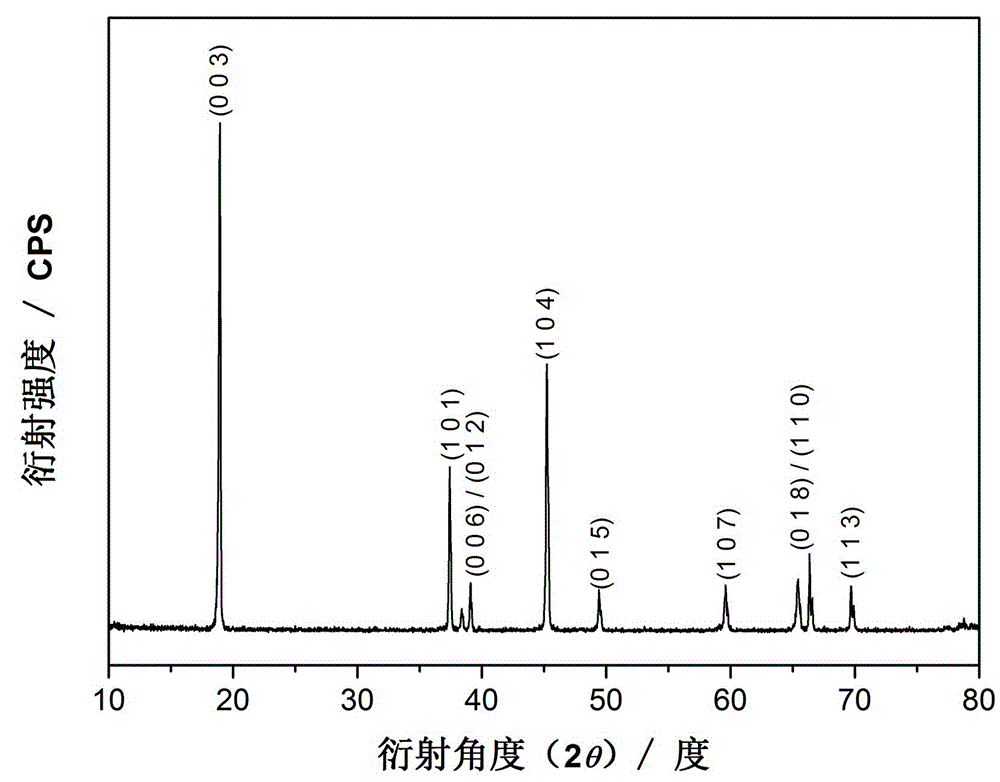

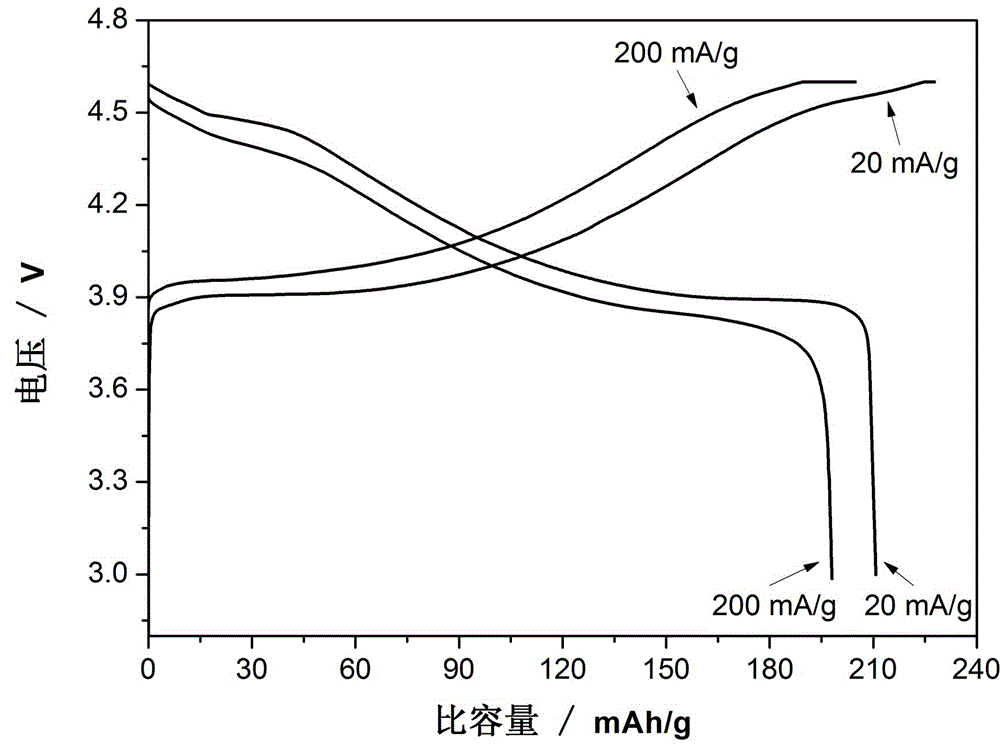

[0031] A high-voltage lithium cobalt oxide-based composite cathode material for lithium ion batteries of the present invention, the molecular formula is 0.05Li 2 MnO 3 ·0.95LiCo 0.98 Mg 0.02 O 2 .

[0032]The preparation method of the above-mentioned composite positive electrode material, the specific steps are: taking lithium acetate, cobalt acetate, manganese acetate and magnesium acetate as raw materials, and weighing the raw materials according to the molar ratio of Li, Co, Mn and Mg as 1.10:0.931:0.05:0.019 and mixing them , adding deionized water and stirring to prepare a solution with a total metal concentration of 0.5mol / L; spray drying the solution, the air inlet temperature is 110°C, the outlet air temperature is 110°C, and the feed rate is 300mL / L during spray drying. h, after drying, a composite cathode material precursor is obtained; the precursor is pre-fired at 400 °C for 5 hours in an air atmosphere, ground after cooling, and then calcined at 900 °C for 10 ...

Embodiment 2

[0038] A high-voltage lithium cobalt oxide-based composite positive electrode material for lithium ion batteries of the present invention, the molecular formula is 0.01Li 2 MnO 3 ·0.99LiCo 0.995 Al 0.005 O 2 .

[0039] The preparation method of the above-mentioned composite positive electrode material includes the following steps: taking lithium nitrate, cobalt nitrate, manganese nitrate, and aluminum nitrate as raw materials, and weighing and mixing the raw materials according to the molar ratio of Li, Co, Mn, and Al of 1.01:0.98505:0.01:0.00495 , deionized water was added and stirred to prepare a solution with a total metal concentration of 0.1 mol / L; the solution was spray-dried, the air inlet temperature was 150 °C, the air outlet temperature was 110 °C, and the feed rate was 600 mL / h. After drying, the composite cathode material precursor is obtained; the precursor is pre-fired at 300 ° C for 1 hour in an air atmosphere, ground after cooling, and then calcined at 500 ...

Embodiment 3

[0042] A high-voltage lithium cobalt oxide-based composite positive electrode material for lithium ion batteries of the present invention, the molecular formula is 0.01Li 2 MnO 3 ·0.99LiCo 0.9 Zn 0.1 O 2 .

[0043] The preparation method of the above-mentioned composite positive electrode material, the specific steps are: using lithium chloride, cobalt chloride, manganese chloride, zinc chloride as raw materials, according to Li, Co, Mn, Zn molar ratio is 1.11:0.891:0.01:0.099 weighed Take the raw materials and mix them, add deionized water and stir to prepare a solution with a total metal concentration of 1 mol / L; the solution is spray-dried, and the air inlet temperature is 180°C during spraying, the air outlet temperature is 100°C, and the feeding speed is 100mL / h, dried to obtain a composite cathode material precursor; the precursor was pre-fired at 500 ° C for 8 hours in an air atmosphere, ground after cooling, and then calcined at 1000 ° C for 2 hours, after the mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com