Ceramic high-temperature insulation material

A thermal insulation material and high-temperature technology, which is applied in the field of ceramic high-temperature thermal insulation materials with a multi-metal oxide modified perovskite structure, can solve the problem that cannot meet the design and use requirements of high-performance, low-emission gas turbines, and the thermal conductivity of coatings. Rate and elastic modulus increase, damage to the structural integrity of the coating, etc., to achieve low thermal conductivity, reduce thermal conductivity, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of ceramic high-temperature insulation material Sr(Zr 0.8 Ta 0.1 Yb 0.1 )O 3 , which includes the following steps:

[0027] (1) Ingredients: SrCO 3 , ZrO 2 、 Ta 2 o 5 oxides and Yb 2 o 3 The oxide powder is mixed in a molar ratio of 1:0.8:0.05:0.05;

[0028] (2) Ball milling: add 2 times the total powder mass of deionized water and ball mill for 24 hours to make a slurry;

[0029] (3) Drying: Pour the ball-milled slurry into a container, put it in a drying oven, and dry it at 100°C for 12 hours;

[0030] (4) Heat treatment: pour the dried powder into a corundum crucible and heat at 1500°C for 24 hours;

[0031] (5) Repeat steps (1)-(4) until the synthesis of single-phase Sr (Zr 0.8 Ta 0.1 Yb 0.1 )O 3 Powder, usually one to three times.

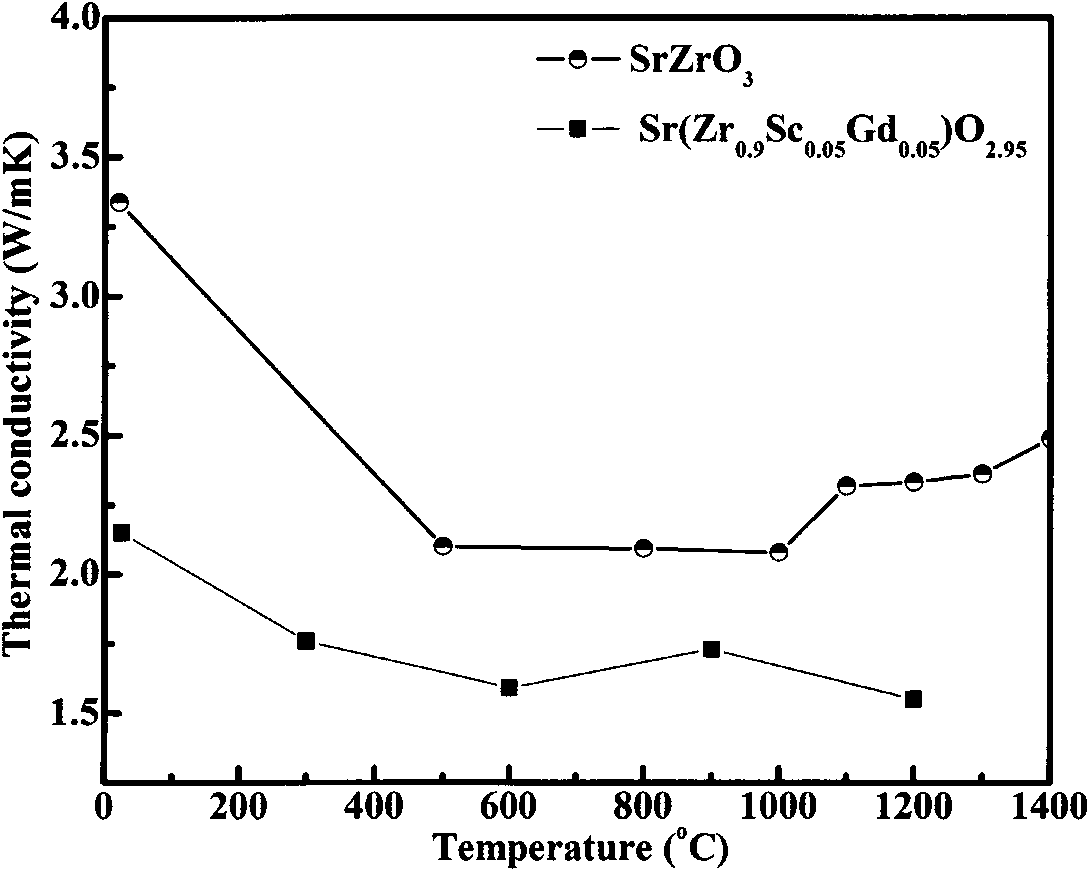

[0032] The material has good phase stability under long-term heat treatment conditions from room temperature to 1400°C and 1450°C, and the thermal conductivity at 1000°C is 1.70Wm -1 K -1 , and u...

Embodiment 2

[0033] Embodiment 2: Adopt the method of embodiment 1 to prepare ceramic high-temperature insulation material Sr (Zr 0.9 sc 0.05 Gd 0.05 )O 2.95 .

[0034] The material has good phase stability under long-term heat treatment conditions from room temperature to 1400°C and 1450°C, and the thermal conductivity at 1000°C is 1.75Wm -1 K -1 , and under the same temperature conditions SrZrO 3 thermal conductivity (~2.10Wm -1 K -1 ) compared to 16.7% lower. The resulting powder is spray granulated to produce a high flowability powder. Prepare a layer of PtAl metal bonding layer 3 with a thickness of about 80 μm on the surface of the nickel-based superalloy substrate 4 by electroplating Pt infiltration with Al, and then apply atmospheric plasma spraying technology to deposit a layer of YSZ with a thickness of about 150 μm on the surface of the PtAl metal bonding layer 3 Ceramic layer 2, and then deposit a layer of Sr (Zr 0.9 sc 0.05 Gd 0.05 )O 2.95 The ceramic layer 1 fina...

Embodiment 3

[0035] Embodiment 3: adopt embodiment 1 method to prepare ceramic high-temperature heat-insulating material Sr (Hf 0.8 Nb 0.1 Dy 0.1 )O 3 . The material has good phase stability under long-term heat treatment conditions from room temperature to 1400°C and 1450°C, and its thermal conductivity at 1000°C is 2.2Wm -1 K -1 , and under the same temperature conditions SrHfO 3 thermal conductivity (~2.70Wm -1 K -1 ) compared to 22.7% lower. The obtained powder was cold-pressed under the condition of 60MPa, and the green body was put into a muffle furnace, and the temperature was raised to 400°C at a heating rate of 3°C / min for 2 hours, and then the heating rate was raised to 1200°C for 4 hours at a heating rate of 2°C / min. , and then cooled to room temperature with the furnace to obtain a target suitable for electron beam physical vapor deposition. Electron beam physical vapor deposition technology is used to deposit a NiCrAlY metal bonding layer 2 with a thickness of about 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com