High-specific-creep-strength nickel base single crystal high-temperature alloy and preparation method and application thereof

A creep strength, nickel-based single crystal technology, applied in the preparation of aeroengine turbine blades, high specific creep strength nickel-based single crystal superalloy and its preparation field, can solve the problems of high density and high cost, Achieve the effect of low density, high temperature bearing capacity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

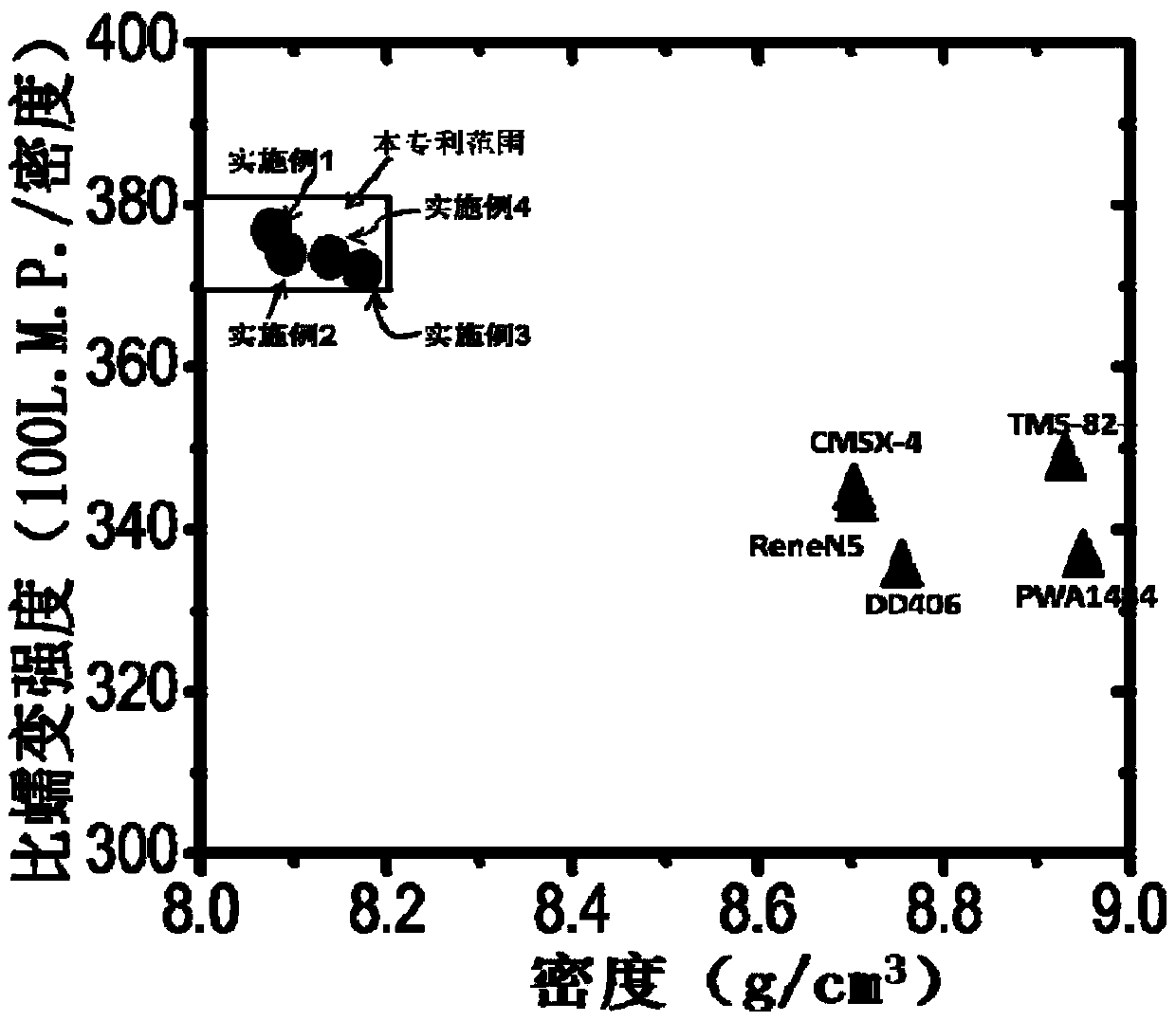

[0041] Embodiment 1~4 and comparative example

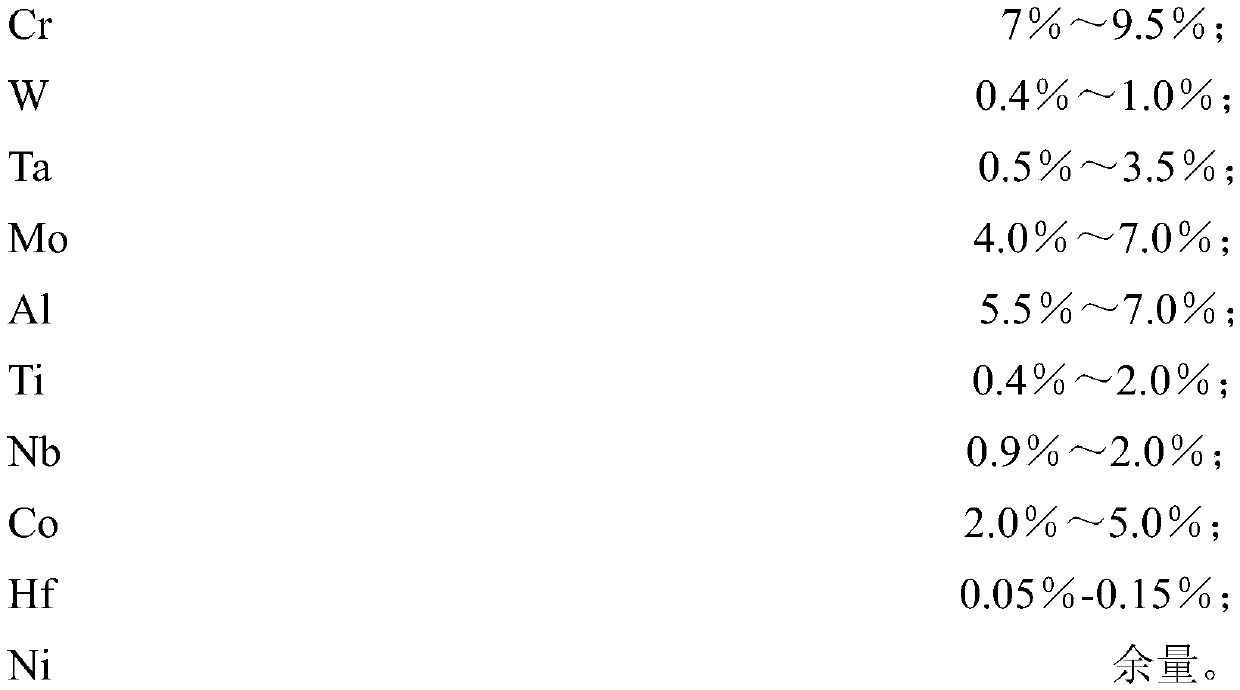

[0042] See Table 1 for the chemical composition of the examples of the present invention and the comparative examples of known Ni-based single crystal superalloys.

[0043] Specific preparation method:

[0044] The first step: the alloy is smelted in a vacuum induction furnace, first cast into various Ni-based superalloy master alloys whose chemical composition meets the requirements, and cast to prepare master alloy rods;

[0045] Step 2: Remelt the master alloy bar through directional solidification equipment, and then use the seed crystal method to pass through the Brizmann (Bridgeman) directional solidification technology, at a temperature gradient of 100°C / cm and a pulling rate of 3mm / min Preparation of single crystal test rod;

[0046] The third step: the single crystal test rod prepared in Examples 1 to 4 was subjected to solid solution treatment for 4 hours in the range of 1310-1330° C., followed by air cooling; then ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com