Full-automatic carpet inspecting device

An inspection device and fully automatic technology, which is applied in the inspection, transportation and packaging of textile materials, textiles and papermaking, etc., can solve the problems of time-consuming, labor-intensive, large floor space, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

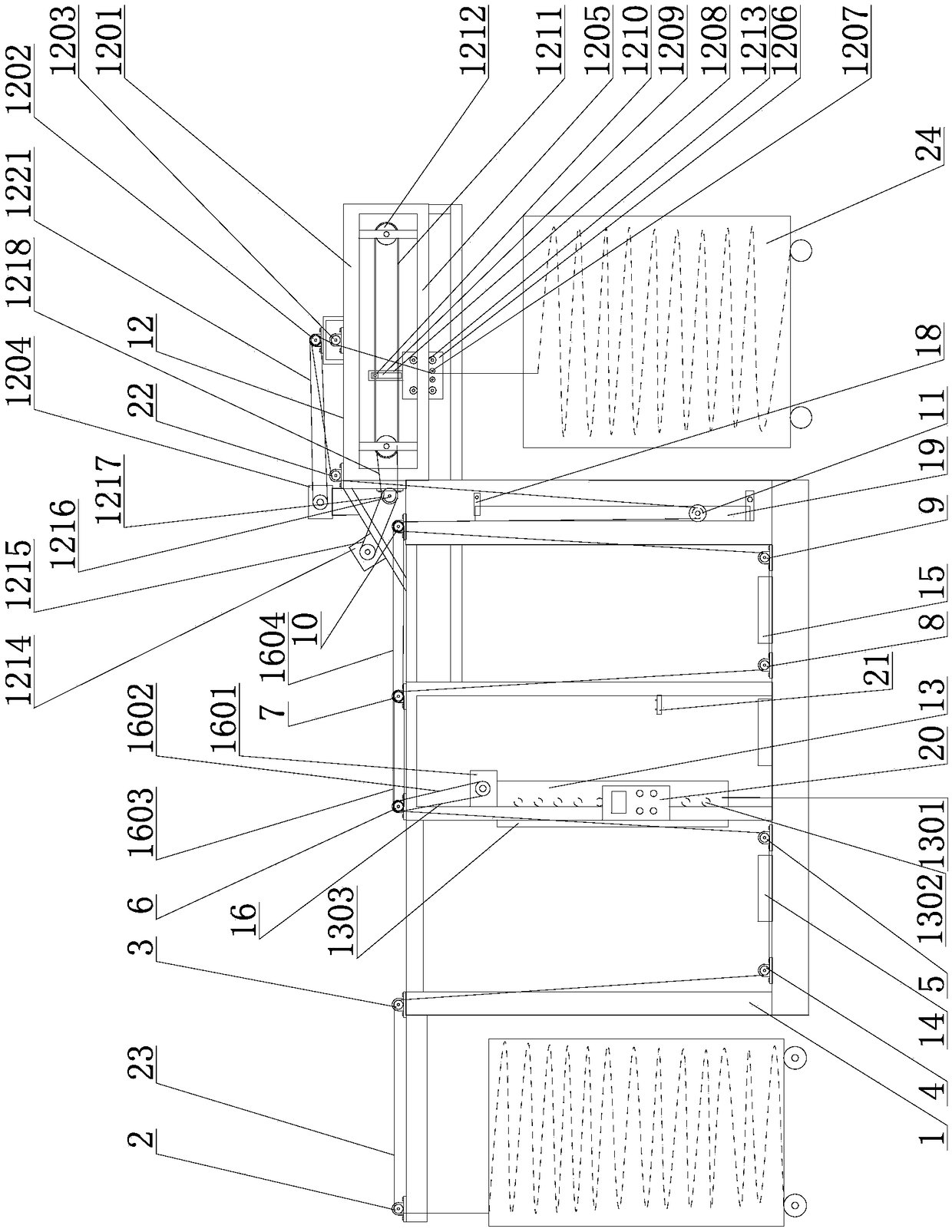

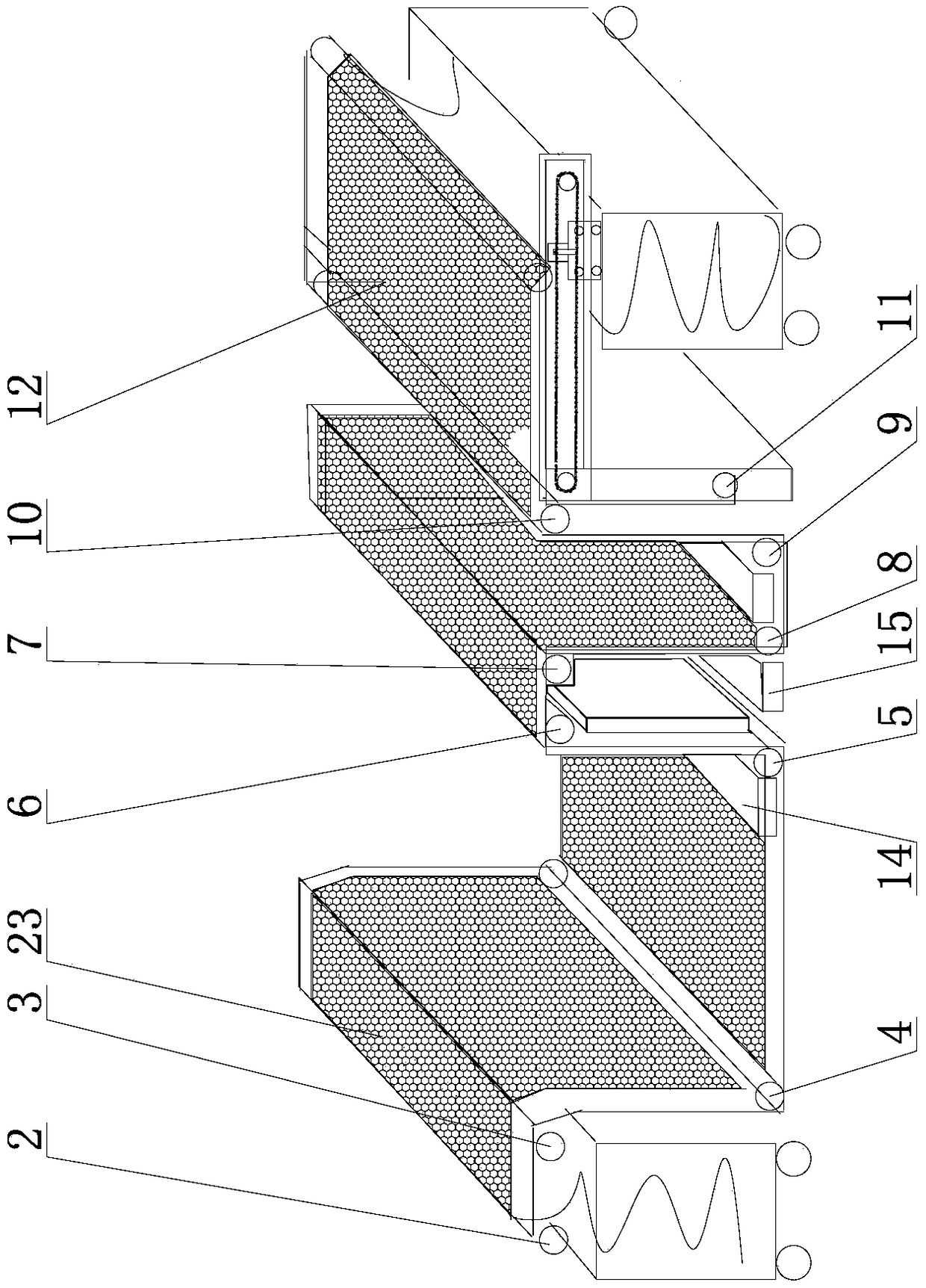

[0020] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

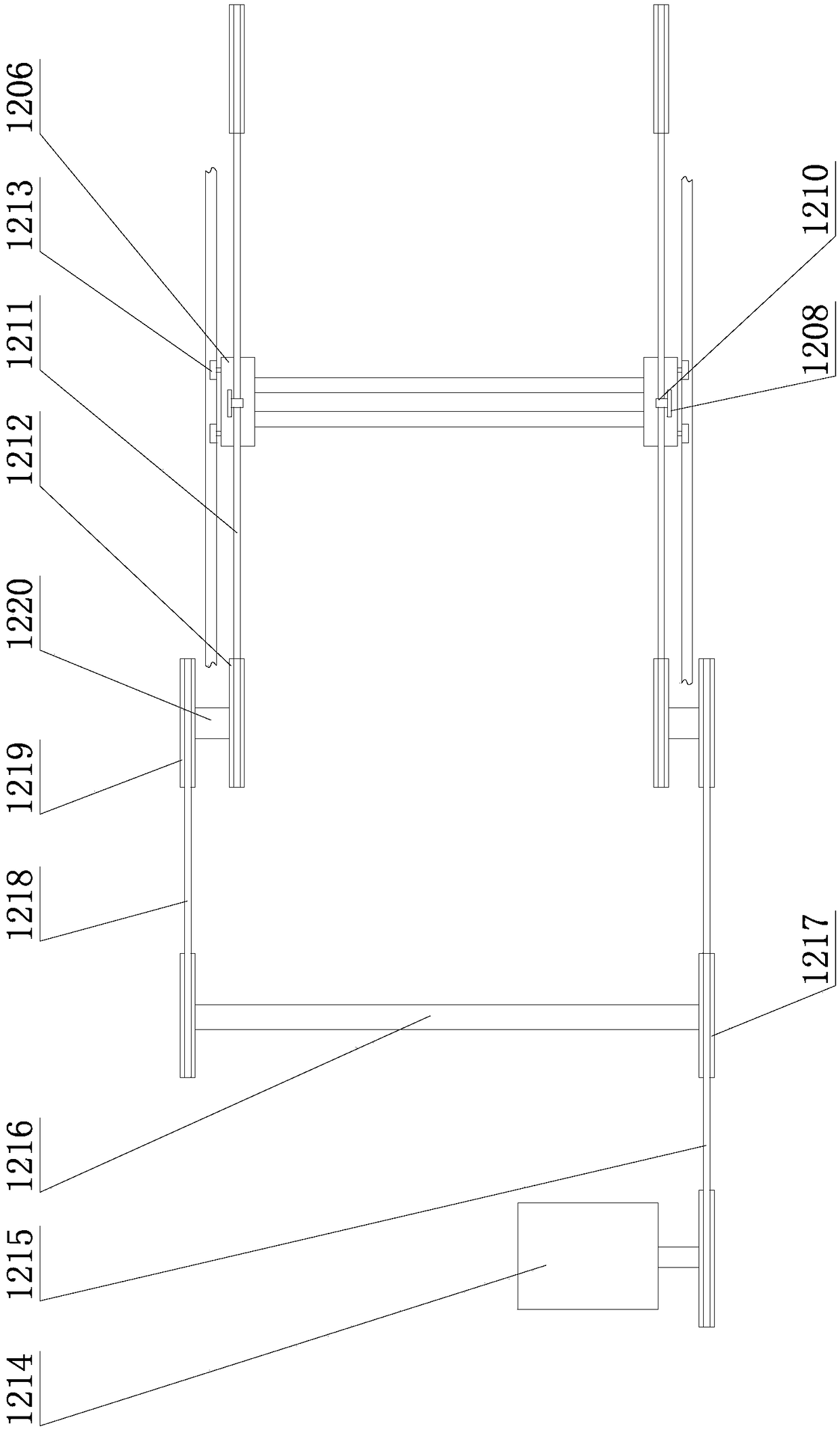

[0021] Such as Figure 1-3As shown, a fully automatic inspection device for carpets includes a frame 1, and the frame 1 is sequentially provided with a feeding roller A2, a feeding roller B3, a reversing roller A4, an inspection roller A5, and an inspection roller along the carpet 23 inspection feeding direction. Roller B6, repairing roller A7, repairing roller B8, repairing roller C9, repairing roller D10, upper and lower floating rollers 11, reversing roller B22 and swing blanking mechanism 12, feeding roller A2, feeding roller B3, inspection roller B6, repairing Roller A7, repair roller D10 and reversing roller B22 are arranged on the upper end of frame 1 respectively, reversing roller A4, inspection roller A5, repairing roller B8 and repairing roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com