Integrated machine for in-situ hole digging, material mixing and backfilling and working method thereof

An all-in-one machine and mixing technology, applied in planting methods, fertilizer distributors, excavation/covering trenches, etc., can solve the problems of lack of mixing, backfilling function, low degree of mechanization, and uneven mixing, etc. Low cost, high mixing uniformity and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

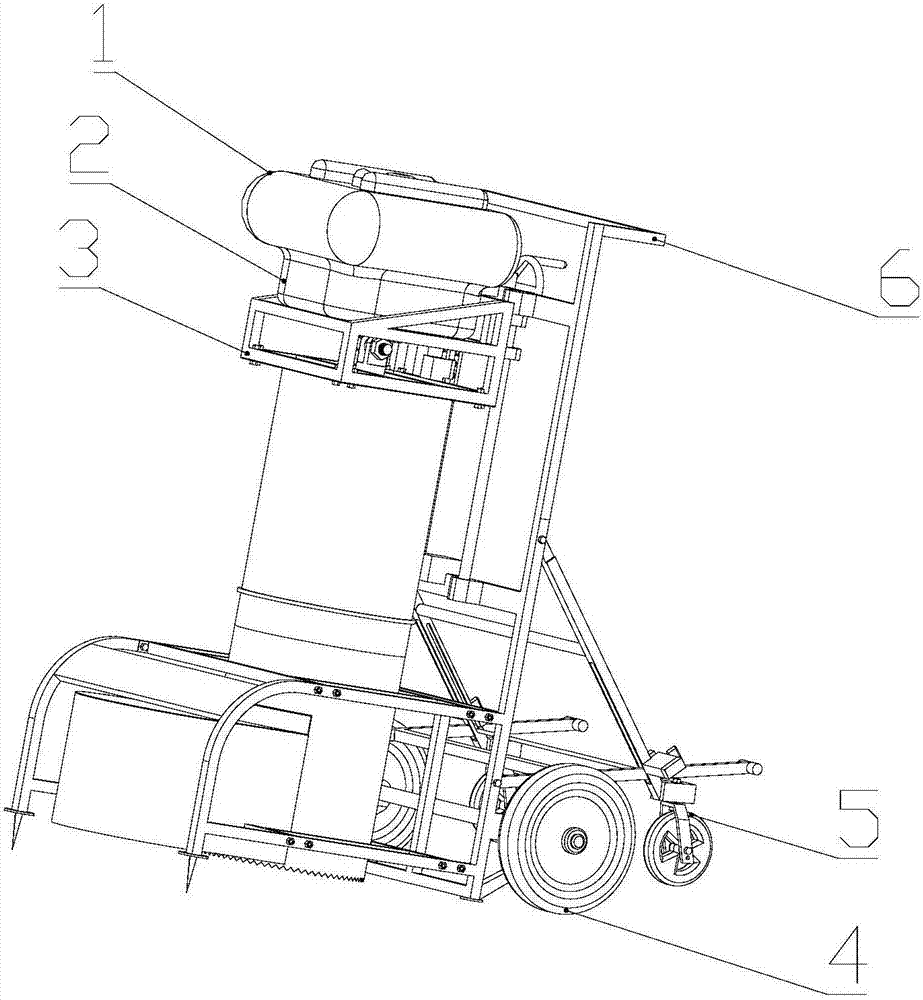

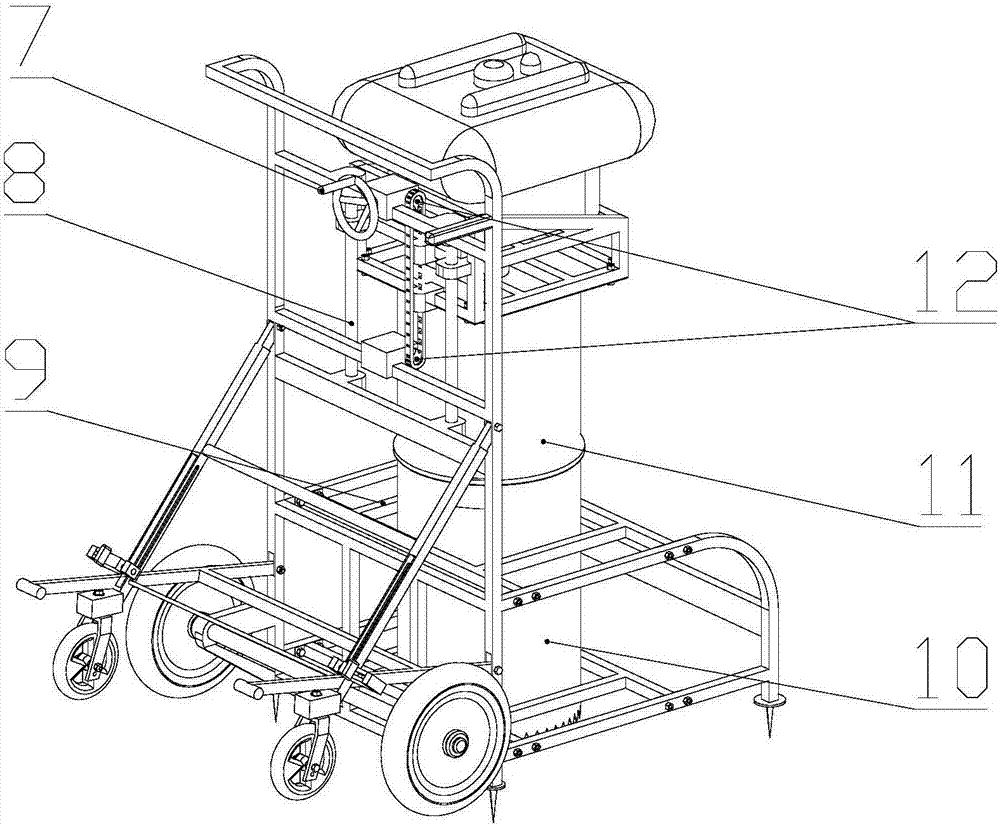

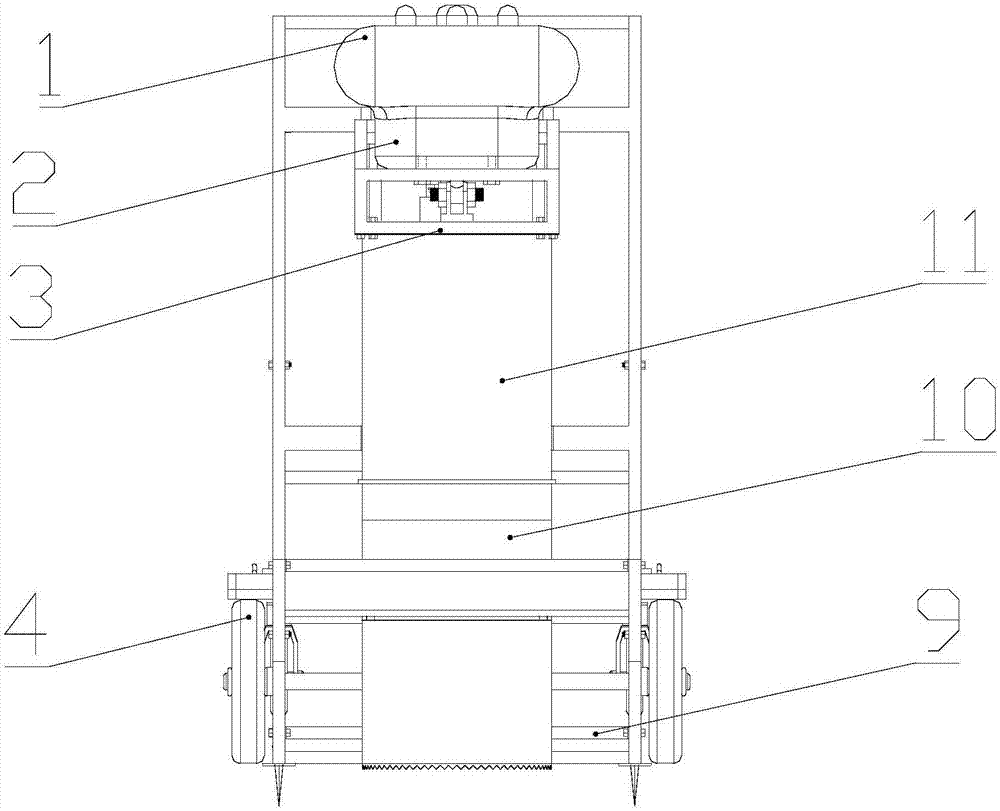

[0036] Below in conjunction with accompanying drawing this patent is further described. The present invention is an in-situ pit digging, mixing and backfilling integrated machine, such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10. A technical solution adopted by an in-situ digging, mixing and backfilling integrated machine: including a power system, a drill bit lifting device, a traveling device and an operating device.

[0037] The power system includes an engine 1 and a speed reducer 2 . The input shaft of the reducer 2 is connected with the power output shaft of the engine 1, and the power output of the engine 1 is decelerated and increased to provide power for the working device.

[0038]Described bit lifting device comprises lifting hand wheel 7, lifting reducer 18, linear guide rail 8, lifting frame 3, sprocket wheel and chain 16. The lifting reducer 18 is fixed in the middle of the beam on the top of the frame 6. The lifting reducer 18 adopts a corner reducer. Above; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com