Construction method of tunnel two-lining concrete pouring system

A construction method and concrete technology, which are applied in tunnel lining, tunnel, earthwork drilling and other directions, can solve the problems of inability to accurately judge whether the concrete of the secondary lining vault is full, the concrete construction is invisible, the vibration radius is small, etc. The effect of voiding and non-compacting of the second lining of the vault, realizing visual operation and ensuring the quality of the entity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

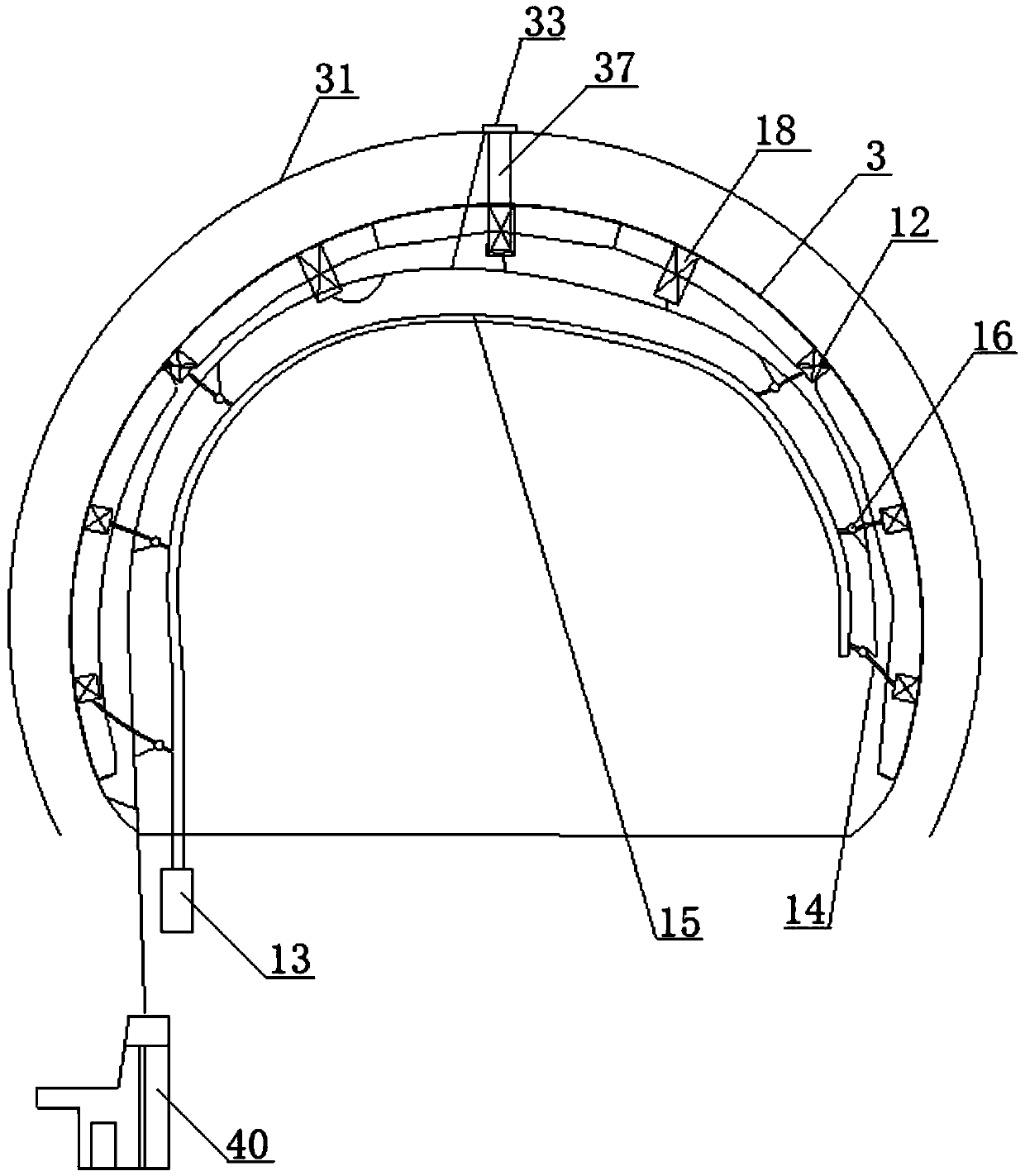

[0046] see figure 1 , the construction method of the concrete pouring system for the second lining of the tunnel, wherein the pouring system includes a flow monitoring device, a mold entry temperature monitoring device, a pressure visualization soft lap device, a plurality of high-frequency pneumatic vibrators 12, and a plurality of automatic plug-in vibrating devices 18. Vault endoscopic anti-vacation device, pressure sensing sheet 32, strip pressure sensing gasket 33, vault exhaust overflow grouting device, gas compressor 13 and electric control box 40.

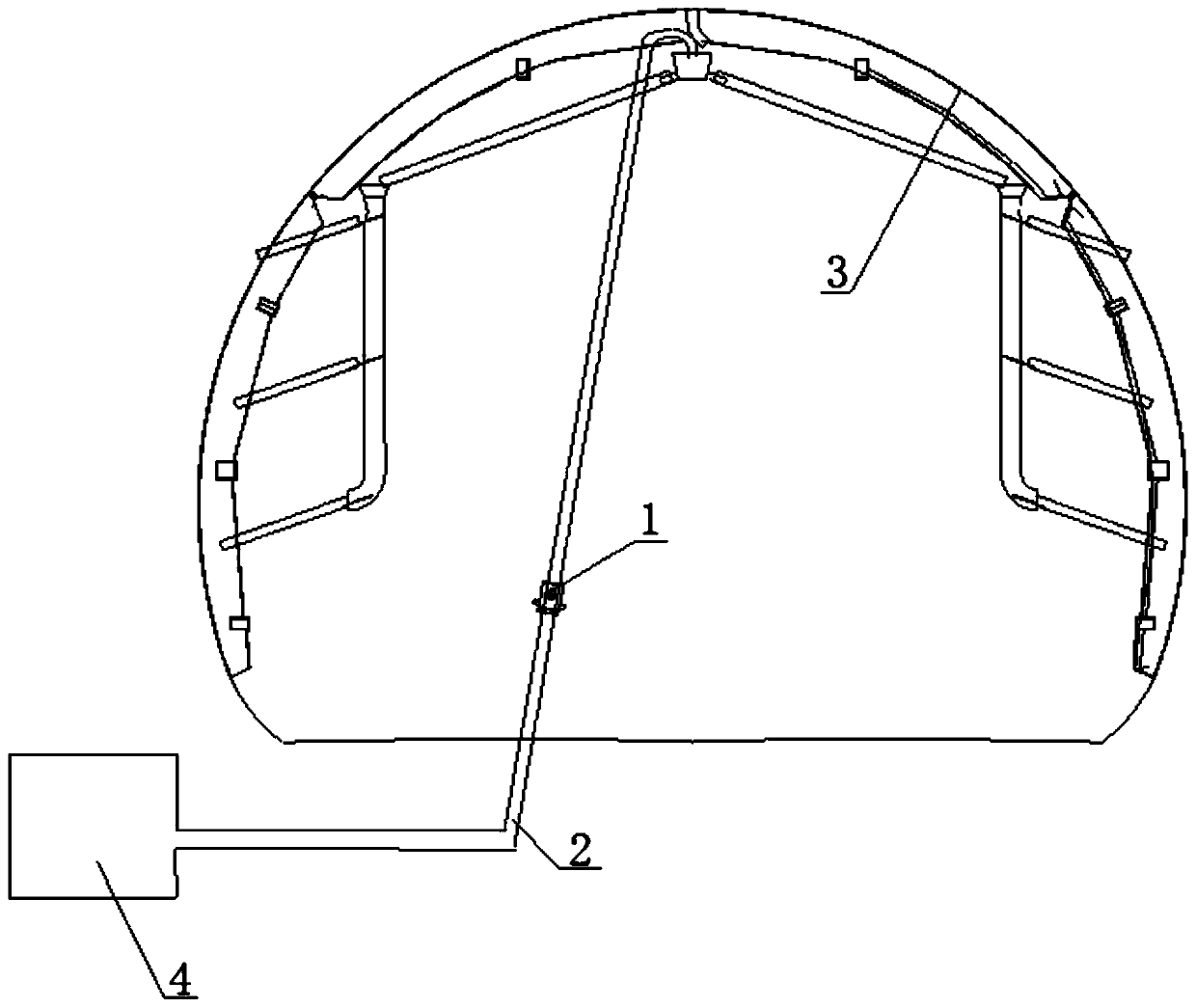

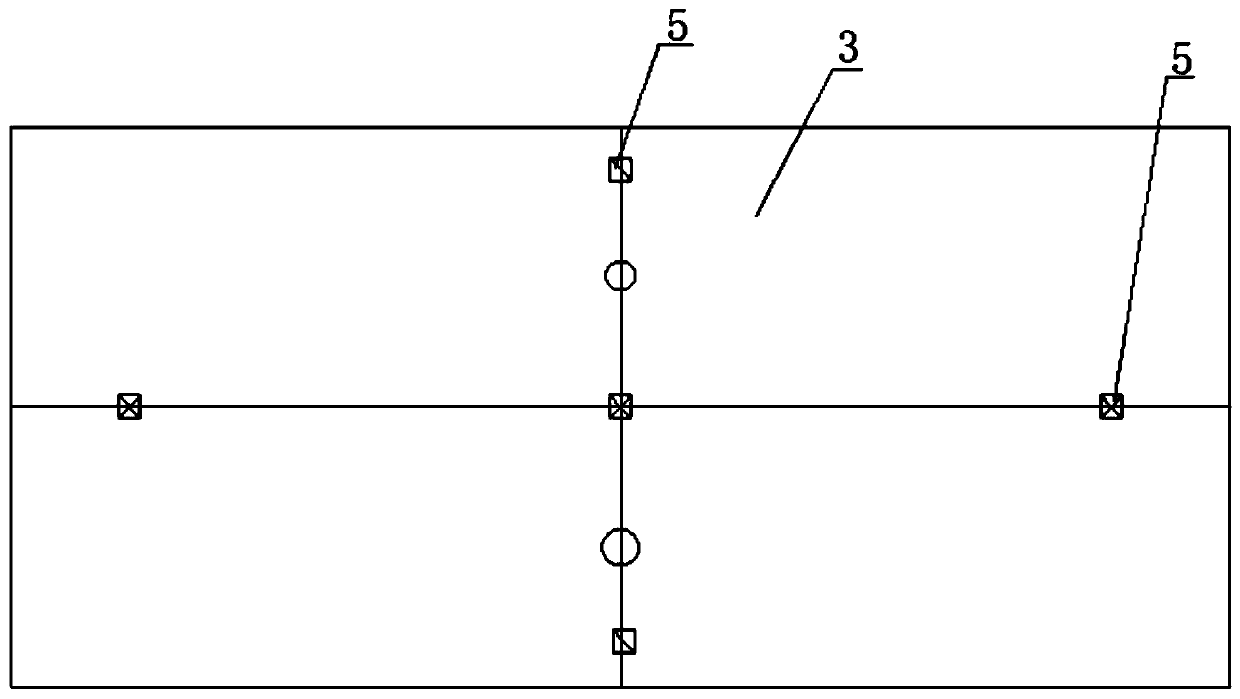

[0047] see figure 2 , the flow monitoring device includes a three-dimensional laser scanner and a flow sensor 1, and the flow sensor 1 is installed on the concrete main delivery pump pipe 2; all the concrete entering the second lining is transported through the concrete main deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com