Technology device for magnetic permanent electromotor stator/rotor installation

A technology of process equipment and permanent magnet motors, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of time-consuming, labor-intensive, low labor efficiency, high risk, etc., and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

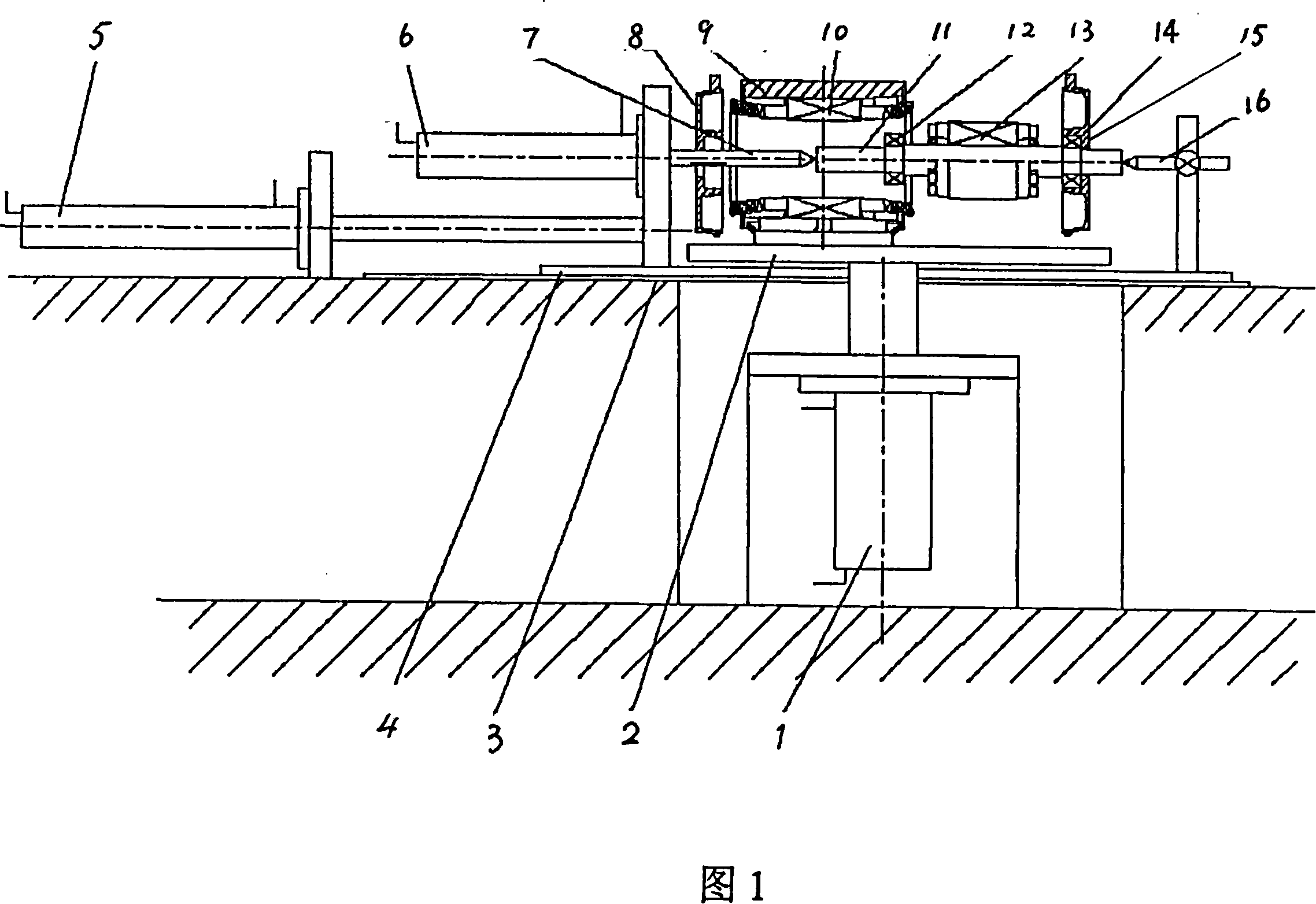

[0015] With reference to Fig. 1, this is the structural representation of the technical equipment used for assembling the stator and rotor of the large-scale permanent magnet motor of the present invention.

[0016] As shown in the figure, the process equipment includes three sets of relatively independent hydraulic systems (hydraulic cylinders) and auxiliary fixtures, guide rails, and trolleys.

[0017] The hydraulic system refers to the working platform lifting hydraulic system 1, the hydraulic cylinder 5, and the clamping hydraulic cylinder 6. The auxiliary tooling fixture includes the front thimble 7, the rear thimble 16, etc.; the relative positions of the parts of the process equipment Yes: hydraulic cylinder 5 and clamping hydraulic cylinder 6 are located on the left side of the process equipment, the front thimble 7 and rear thimble 16 of the auxiliary fixture are located on the right, the working platform 2 and the working platform lifting hydraulic system 1 are locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com