Feeding device for alkyd resin ship paint production

A technology of alkyd resin and marine paint, applied in the direction of measuring device, loading/unloading, transportation and packaging, etc., can solve the problems of low efficiency and labor consumption, achieve convenient use, improve production efficiency, improve weighing efficiency and The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

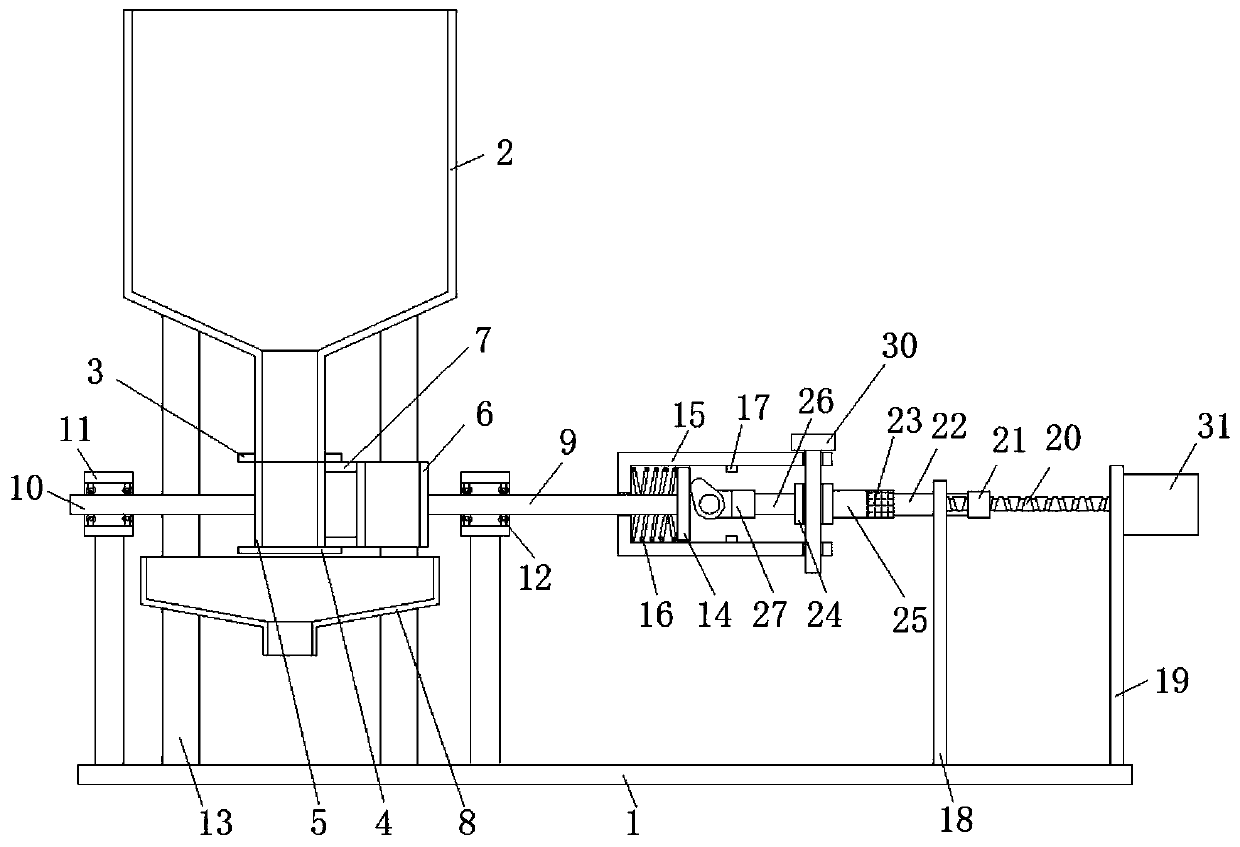

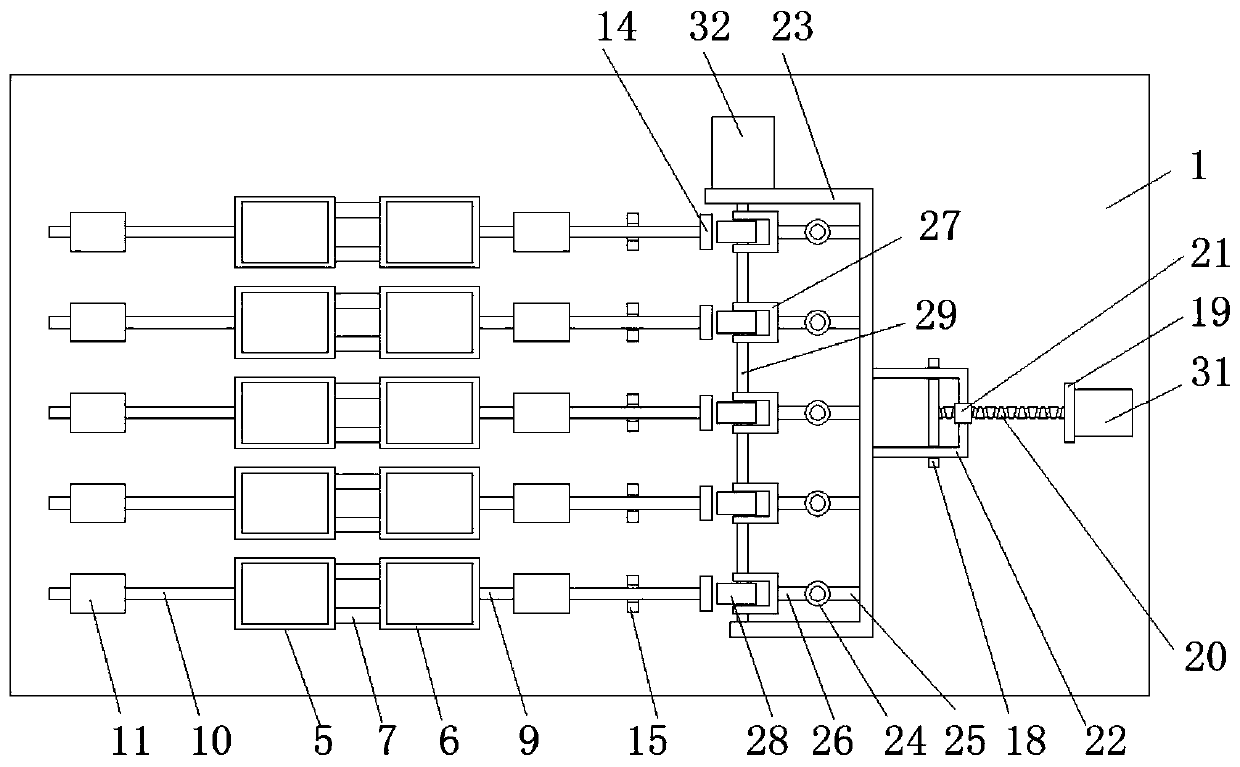

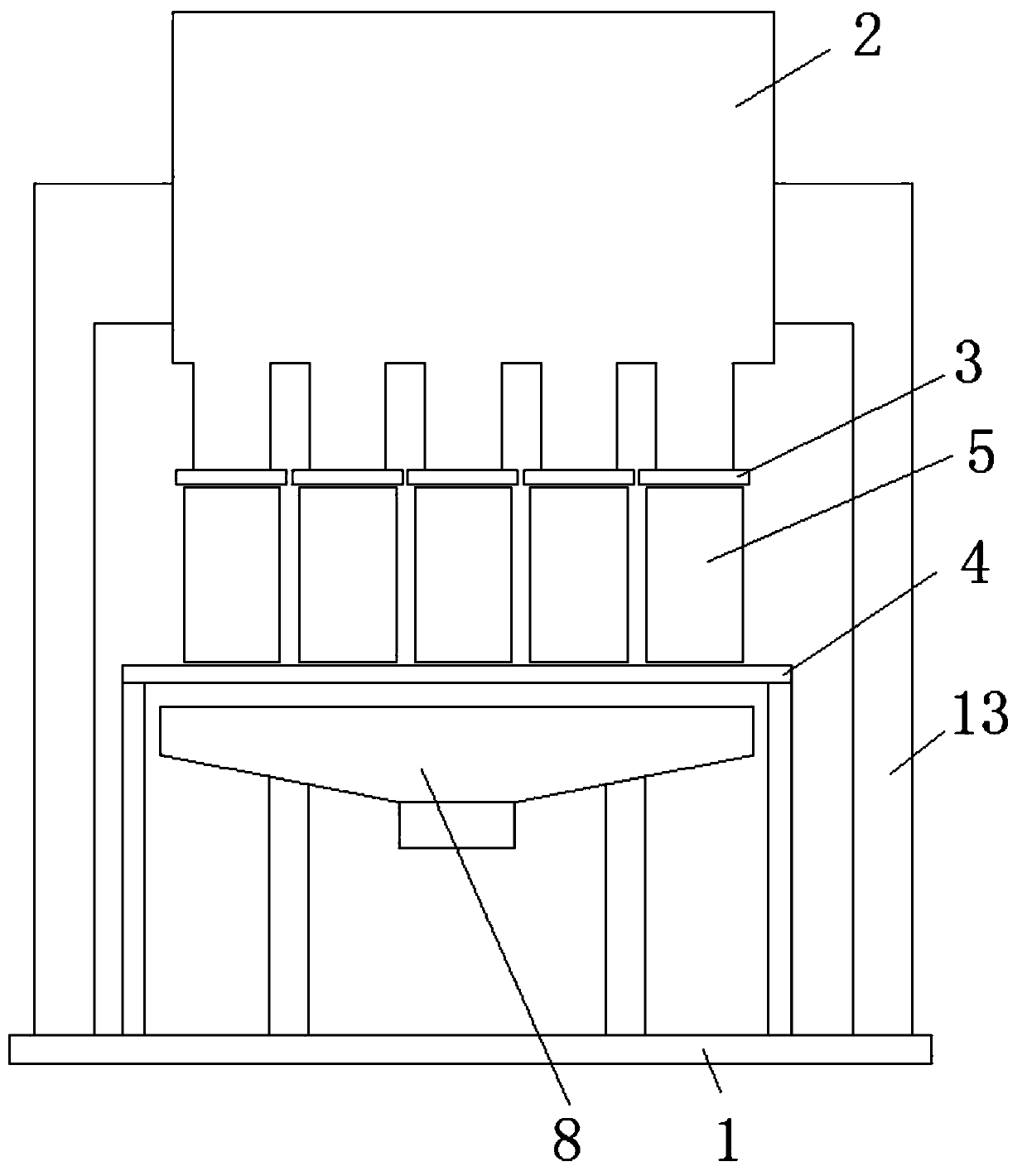

[0022] refer to Figure 1-3 , a feeding device for the production of alkyd resin marine paint, comprising a device base plate 1, a storage bin 2 is arranged vertically above the device base plate 1, and several discharge ports are arranged at the bottom of the storage bin 2, and The edge of the bottom end of the discharge port is fixedly connected with the edge plate 3 respectively, and the vertical bottom of the storage bin 2 is provided with a material retaining horizontal plate 4, and the bottom side of the edge plate 3 and the material retaining horizontal plate 4 are respectively provided with Metering barrel one 5 and metering barrel two 6, metering barrel one 5 and metering barrel two 6 are arranged side by side, and between metering barrel one 5 and metering barrel two 6, a stopper slide plate 7 is arranged respectively, the top side of the stopper slide plate 7 and The top edge of metering barrel 1 5 and metering barrel 2 6 are flush, the top side and bottom side of m...

Embodiment 2

[0025] Such as Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the second vertical plate 19 is located on the side of the first vertical plate 18 away from the first horizontal bar 9 .

[0026]In this embodiment, the reciprocating lead screw 20 is driven to rotate by the servo motor-31, and the lead screw nut 21 reciprocates accordingly. The metering barrel-5 passes through the bottom of the storage bin 2, and the material in the storage bin 2 falls to the metering position. barrel one 5, and vibrate under the drive of servo motor two 32, so that the material in the metering barrel one 5 is more uniform, after finishing the blanking, move to the vertical top of the opening of the concentrated lower hopper 8, and vibrate The material is unloaded in the center, and the loading and unloading speed is fast.

Embodiment 3

[0028] Such as Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the bottom end of the concentrated discharge hopper 8 is provided with a discharge port.

[0029] In this embodiment, the weighed materials are collected through the lower hopper 8 and then loaded, which speeds up the feeding process and improves production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com