Quantitative package scale and weighing method

A quantitative packaging and weighing technology, which is applied in the field of quantitative packaging and weighing of granular materials, can solve the problems that the actual weight is greater than the rated weight, reducing the efficiency of material weighing and packaging, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

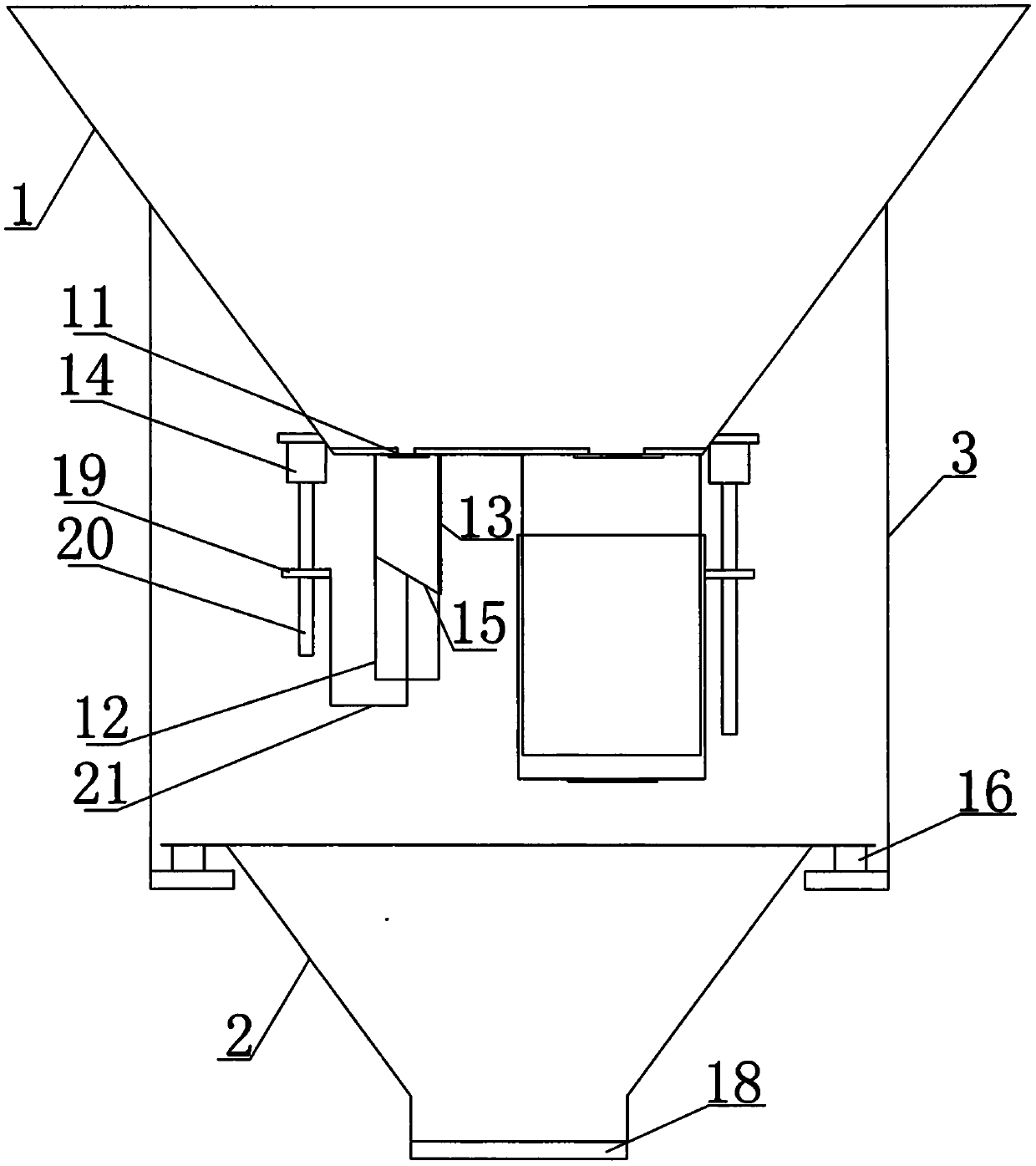

Embodiment 1

[0071] A weighing method for a quantitative packaging scale, comprising the steps of:

[0072] Step 1: Determine the minimum volume V1 of the variable quantitative discharge bin unit, the maximum volume V2 of the variable quantitative discharge bin unit, and the unit volume V3 of the variable quantitative discharge bin unit when the amount changes;

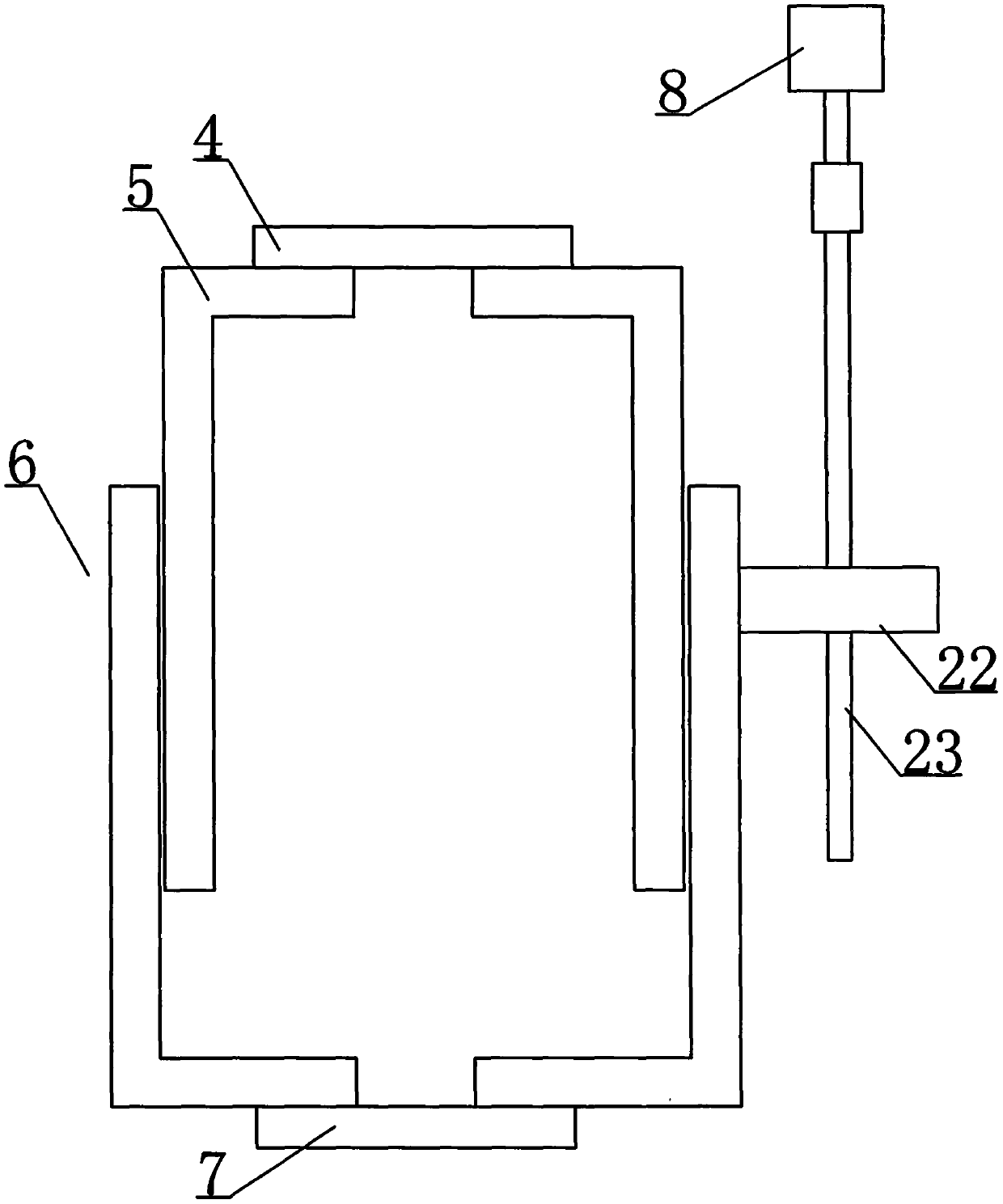

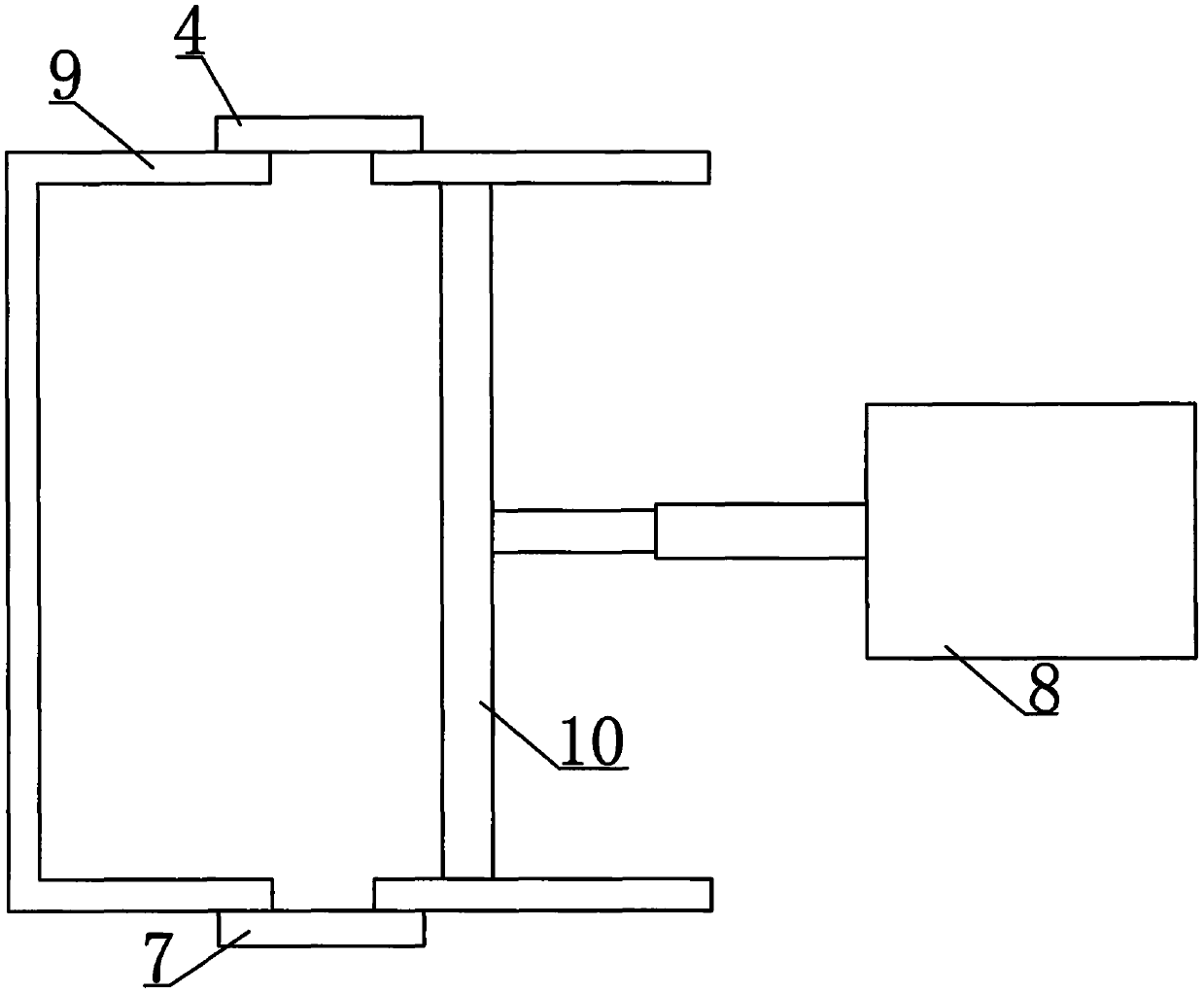

[0073] When using the upper and lower volume adjustment quantitative discharge bin, the volume of the upper and lower volume adjustment quantitative discharge bin is the minimum volume when the second slider 22 is in the uppermost position, and the upper and lower volume adjustment quantitative discharge when the second slider 22 is in the lowermost position The volume of the bin is the maximum volume, and the rotation of the second screw rod 23 causes the displacement of the second slider 22. Before the displacement occurs and after the displacement occurs, the volume difference between the upper and lower volume adjustments and t...

Embodiment 2

[0091] A weighing method for a quantitative packaging scale, comprising the steps of:

[0092] Step 1: Determine the minimum volume V1 of the variable quantitative discharge bin unit, the maximum volume V2 of the variable quantitative discharge bin unit, and the unit volume V3 of the variable quantitative discharge bin unit when the amount changes;

[0093] When using the upper and lower volume adjustment quantitative discharge bin, the volume of the upper and lower volume adjustment quantitative discharge bin is the minimum volume when the second slider 22 is in the uppermost position, and the upper and lower volume adjustment quantitative discharge when the second slider 22 is in the lowermost position The volume of the bin is the maximum volume, and the rotation of the second screw rod 23 causes the displacement of the second slider 22. Before the displacement occurs and after the displacement occurs, the volume difference between the upper and lower volume adjustments and t...

Embodiment 3

[0111] A weighing method for a quantitative packaging scale, comprising the steps of:

[0112] Step 1: Determine the minimum volume V1 of the variable quantitative discharge bin unit, the maximum volume V2 of the variable quantitative discharge bin unit, and the unit volume V3 of the variable quantitative discharge bin unit when the amount changes;

[0113]When using the upper and lower volume adjustment quantitative discharge bin, the volume of the upper and lower volume adjustment quantitative discharge bin is the minimum volume when the second slider 22 is in the uppermost position, and the upper and lower volume adjustment quantitative discharge when the second slider 22 is in the lowermost position The volume of the bin is the maximum volume, and the rotation of the second screw rod 23 causes the displacement of the second slider 22. Before the displacement occurs and after the displacement occurs, the volume difference between the upper and lower volume adjustments and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com