Online type automatic weighing device and method thereof

An automatic weighing device and automatic weighing technology, applied in the field of weighing, can solve the problems of low weighing efficiency, achieve high weighing efficiency, reduce production costs, and simple weighing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

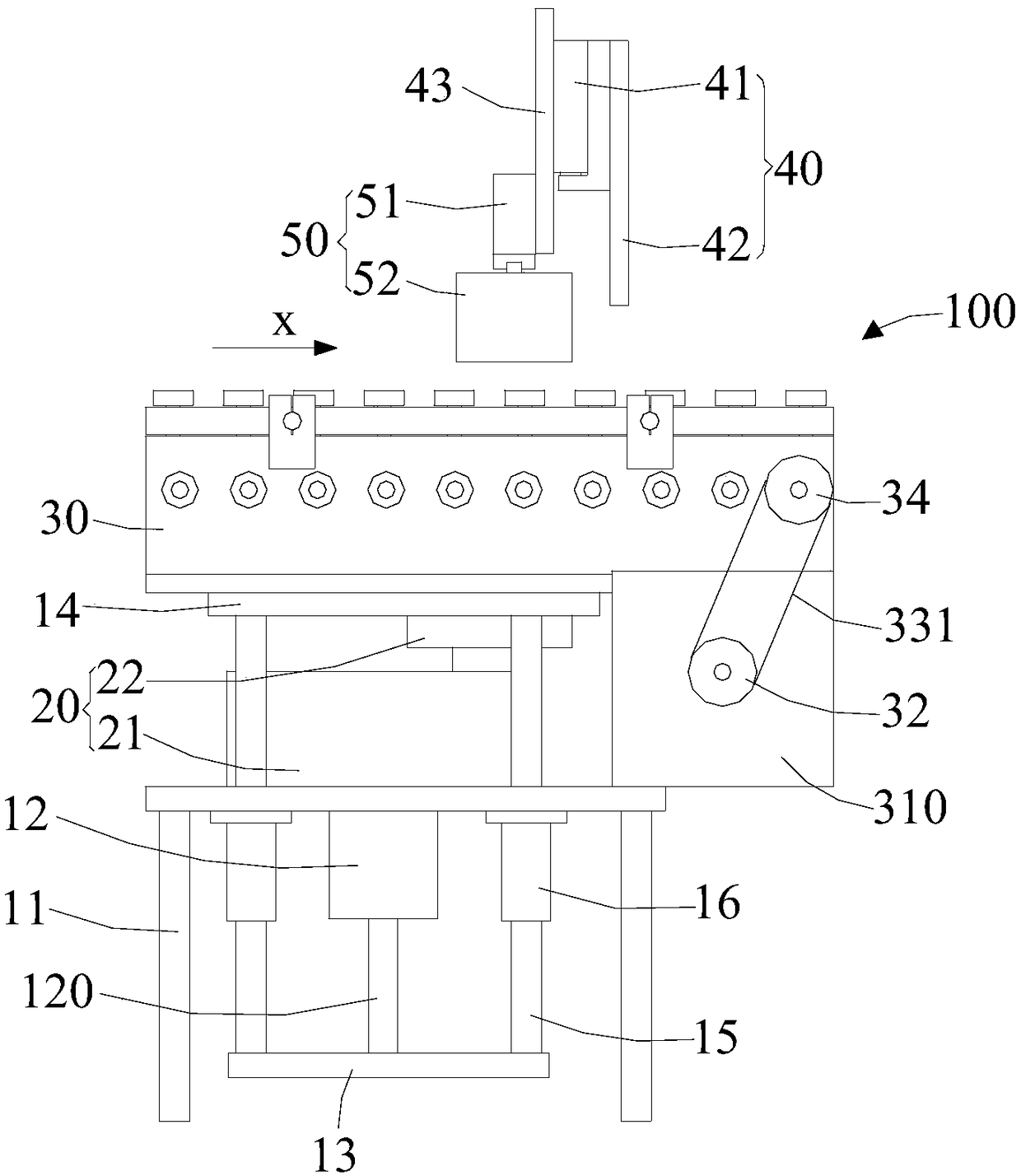

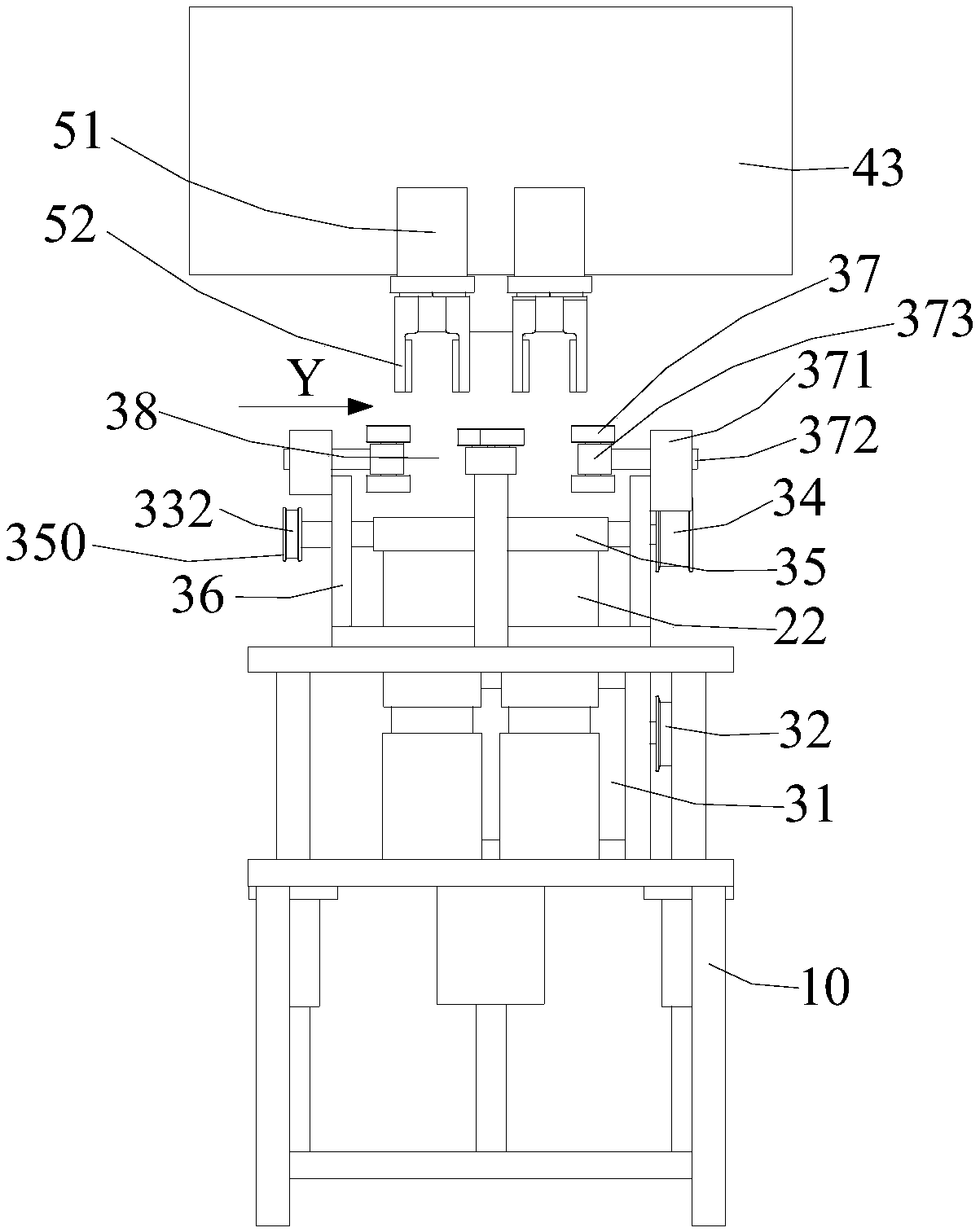

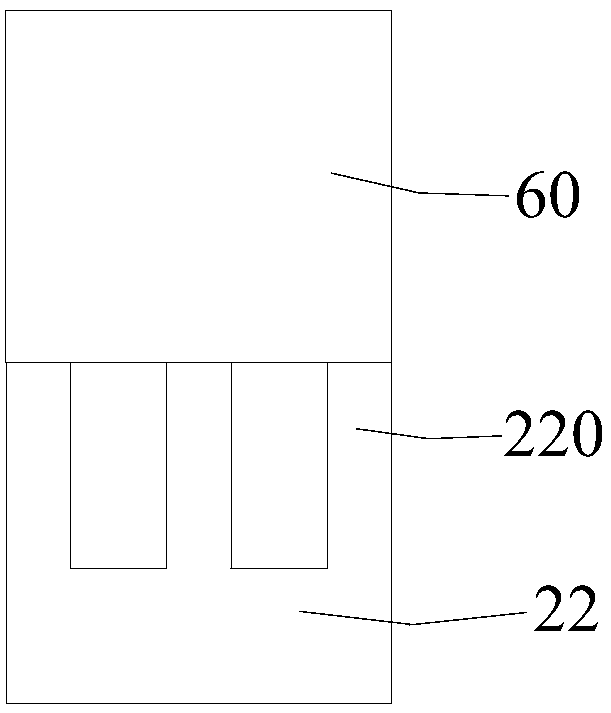

[0024] Please refer to Figure 1 to Figure 3 As shown, an embodiment of the present invention discloses an online automatic weighing device 100, which is used to realize automatic weighing during the conveying process of the product 60, improve weighing efficiency, and reduce production costs. In this embodiment, The product 60 is a battery cell, and the online automatic weighing device includes a lifting mechanism 10 , a weighing mechanism 20 , a roller conveying line 30 , a stopping mechanism 40 and a deviation-correcting mechanism 50 .

[0025] The lifting mechanism 10 includes a fixing base 11 , a lifting driving member 12 , a driving plate 13 , a lifting platform 14 , a guide post 15 and a guide sleeve 16 .

[0026] The lifting driving part 12 is a lifting cylinder, which is fixedly arranged on the bottom of the fixing seat 11, and is used to drive the lifting platform 14 to perform lifting motion. The lifting driving member 12 is provided with a driving end 120 connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com