Accurate-weighing food processing machine and weighing method

A food processing machine and weighing technology, applied in the direction of weighing equipment, weighing, and measuring devices using elastically deformable parts, can solve the problem of being easily affected by temperature and humidity, affecting food processing and production, pressure sensor interference, etc. problem, to achieve the effect of reducing the quantity, ensuring the accuracy of weighing, and ensuring the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

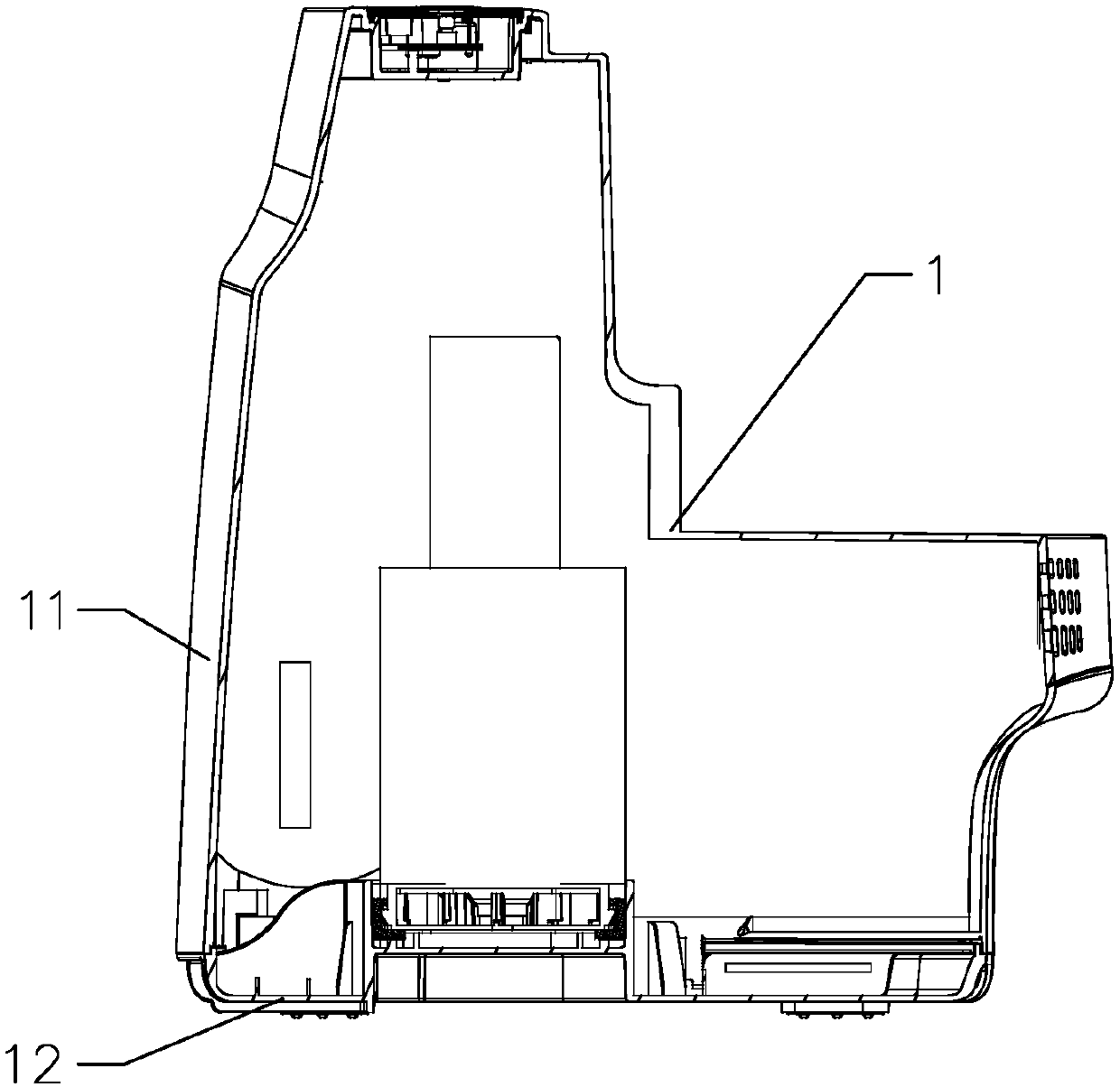

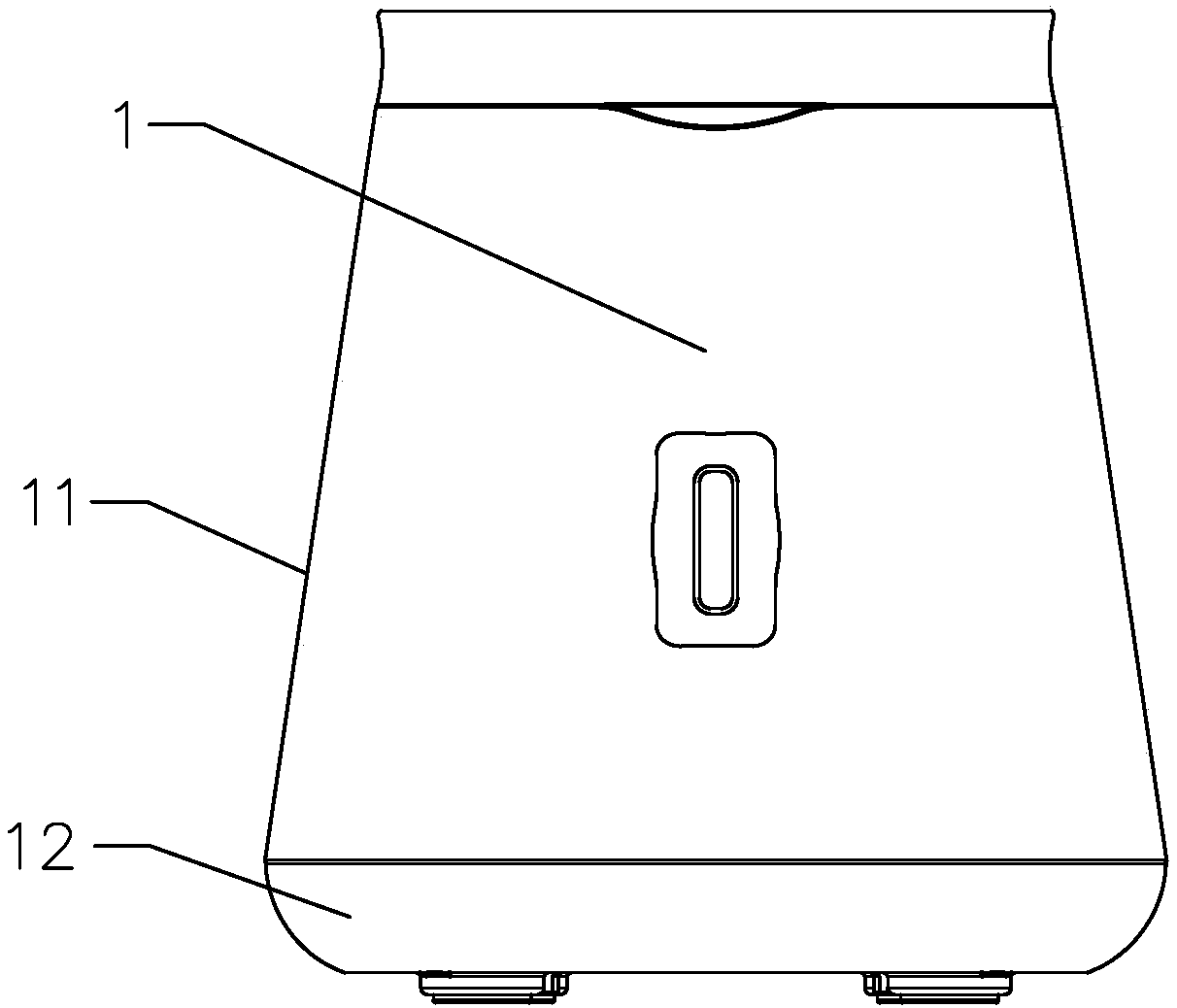

[0037] Such as Figures 1 to 4 As shown, the present invention provides a food processing machine with accurate weighing, which includes a machine base 1, a weighing unit and a main control board. The machine base 1 includes a casing 11 and a bottom cover 12 arranged below the casing. The weighing control board electrically connected to the main control board and the pressure sensor 2 electrically connected to the weighing control board, the pressure sensor 2 is arranged on the bottom cover 12, refer to figure 1 The frame structure shown can be used for noodle machines and juice extractors, refer to figure 2 The base structure shown can be used for food processors, soybean milk makers, and of course, the structure of some ovens, frying machines, air fryers, etc. is also different. Anyway, the structure of the base is based on the specific application. Depending on the situation, the base here generally refers to the base of all types of food processing machines. Since there ...

Embodiment 2

[0069] The difference between this embodiment and Embodiment 1 is that the number of pressure sensors is different.

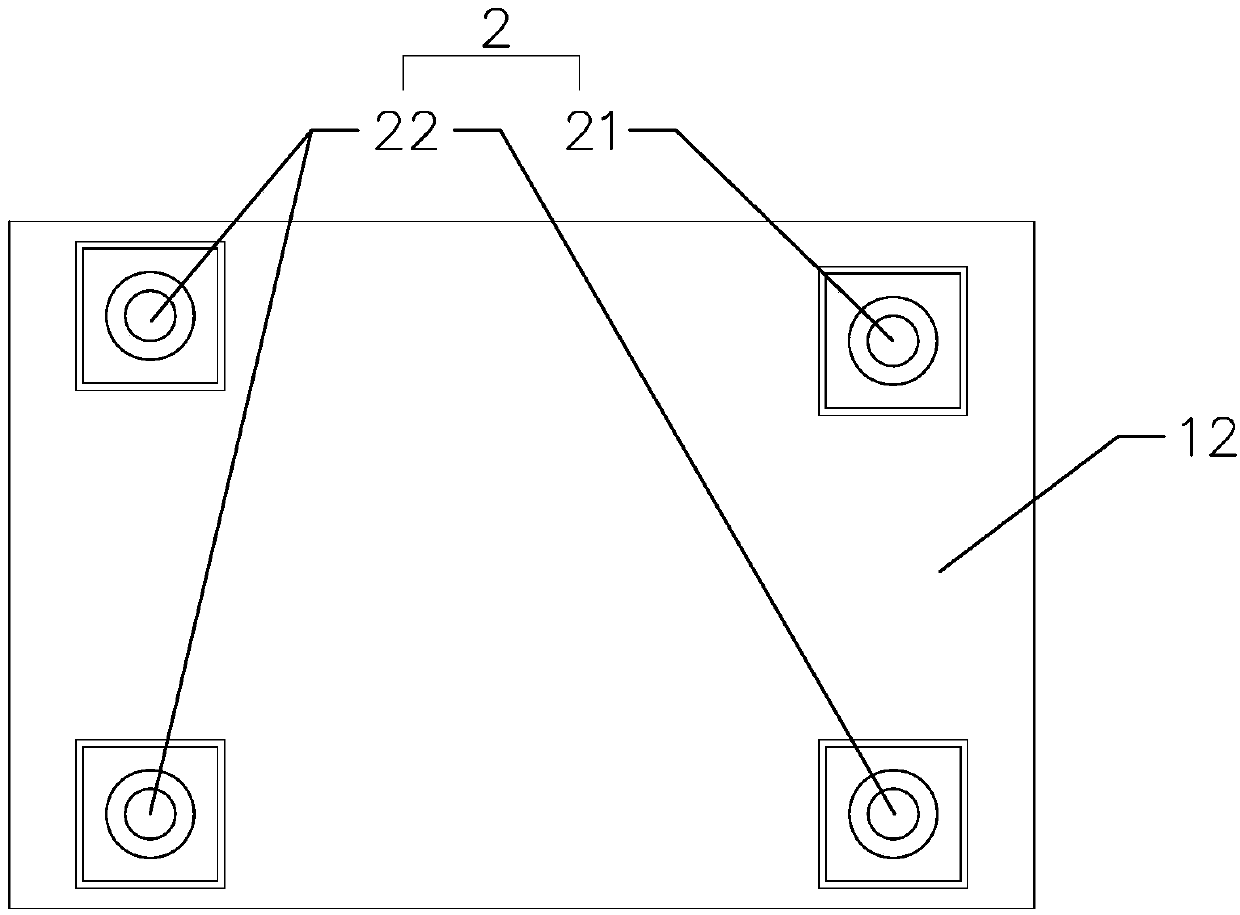

[0070] In this example, if Figure 5 As shown, the pressure sensor includes a calibration sensor 21 and a load-bearing sensor 22, that is, there are two pressure sensors, and the load-bearing sensor 22 is located at the center of gravity of the bottom cover 12, that is, the center of gravity of the food processor, and is weighed by a single point support. There is no problem of inaccurate weighing caused by multi-point support and no force on the same plane. Only one calibration sensor and one load-bearing sensor are used to detect the weight, which not only ensures the accuracy of the detection, but also reduces the number of pressure sensors and food. The manufacturing cost of the processing machine.

[0071] The structures and beneficial effects of other parts not described are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0073] The difference between this embodiment and Embodiment 1 is that the number of pressure sensors is different.

[0074] In this example, if Figure 6 As shown, the pressure sensor is provided with three and includes a calibration sensor 21 and two load-bearing sensors 22. It is weighed by two-point support, and the two-point support is easy to be stressed on the same plane to ensure the accuracy of weighing, and the two load-bearing The sensors 22 are distributed diagonally, and the calibration sensor 21 is distributed on any one of the other two corners of the bottom cover 12, which can better ensure that the two load-bearing sensors are simultaneously stressed on the same plane, and better ensure the accuracy of weighing .

[0075] The structures and beneficial effects of other parts not described are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com