Power-and-free material-loading and transporting apparatus used for material-basket-free thermal-treatment furnace of aluminum alloy product

A technology of conveying device and heat treatment furnace, applied in heat treatment furnace, heat treatment equipment, heat treatment process control and other directions, can solve the problems of increasing failure rate of conveying device action frequency, failing to meet the requirements of heat treatment process, shortening interval time period, etc. The effect of increased speed, expanded feeding range and longer time period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

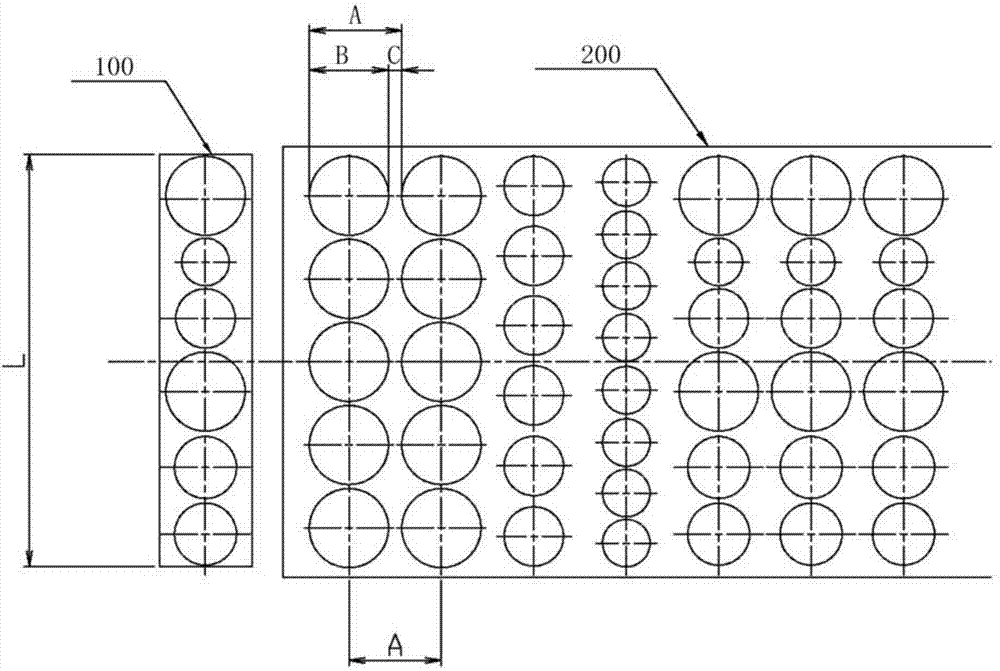

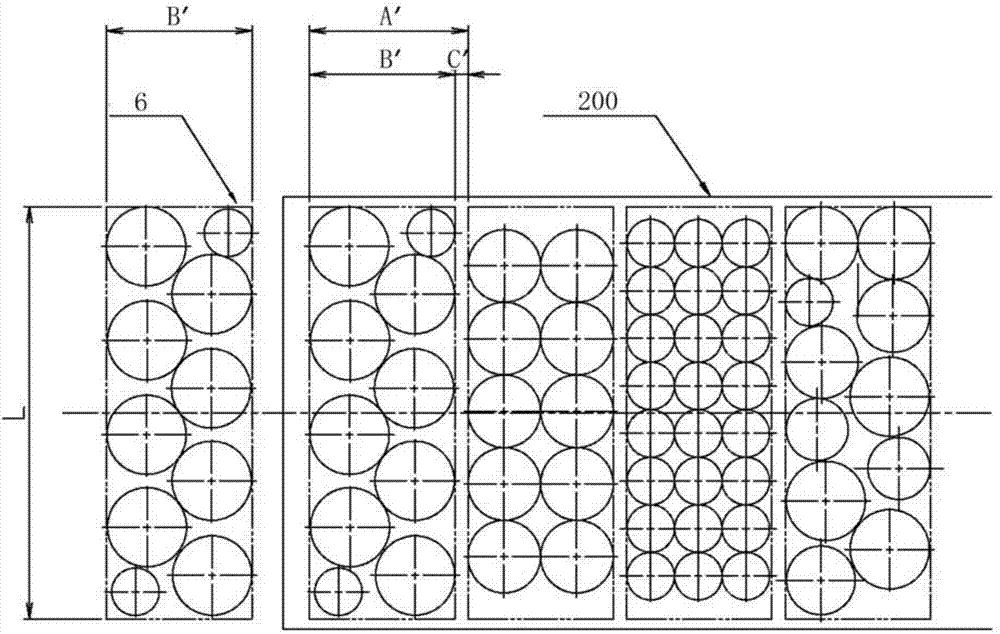

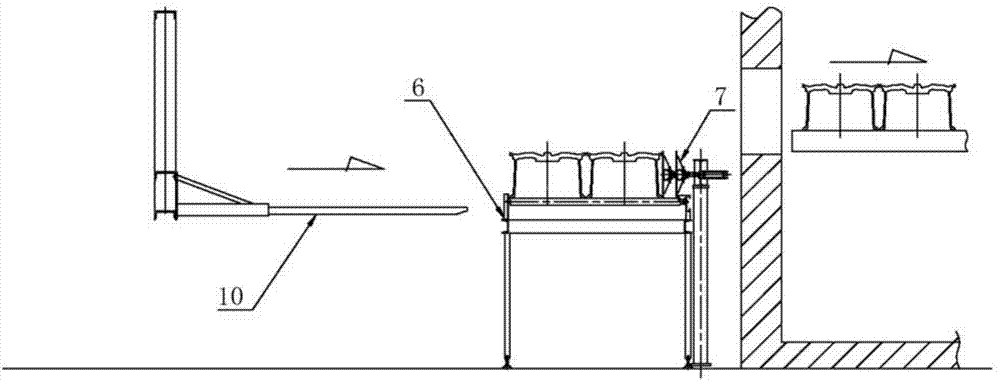

[0024] The invention discloses a flexible and rapid accumulative and free feeding and conveying device. The specific structure is as follows: Figure 2 to Figure 4 As shown, the width of each feeding area of the accumulation type feeding conveying device is figure 2In the dimension B' shown, the number of workpiece rows in each area increases from the previous one row to two or more rows according to the size of the workpiece specification. Using the conveying roller table 1, the workpieces conveyed from the previous process are automatically filled in the pre-set loading area regardless of size, without identification, and without manual intervention. The workpieces in this loading area Free combination regardless of the number of rows or columns, until the loading area is filled, such as figure 2 As shown, the conveying distance A' in the furnace should also be moderately lengthened, so the single conveying amount is more than doubled, and the time interval period of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com