Patents

Literature

119 results about "Free feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

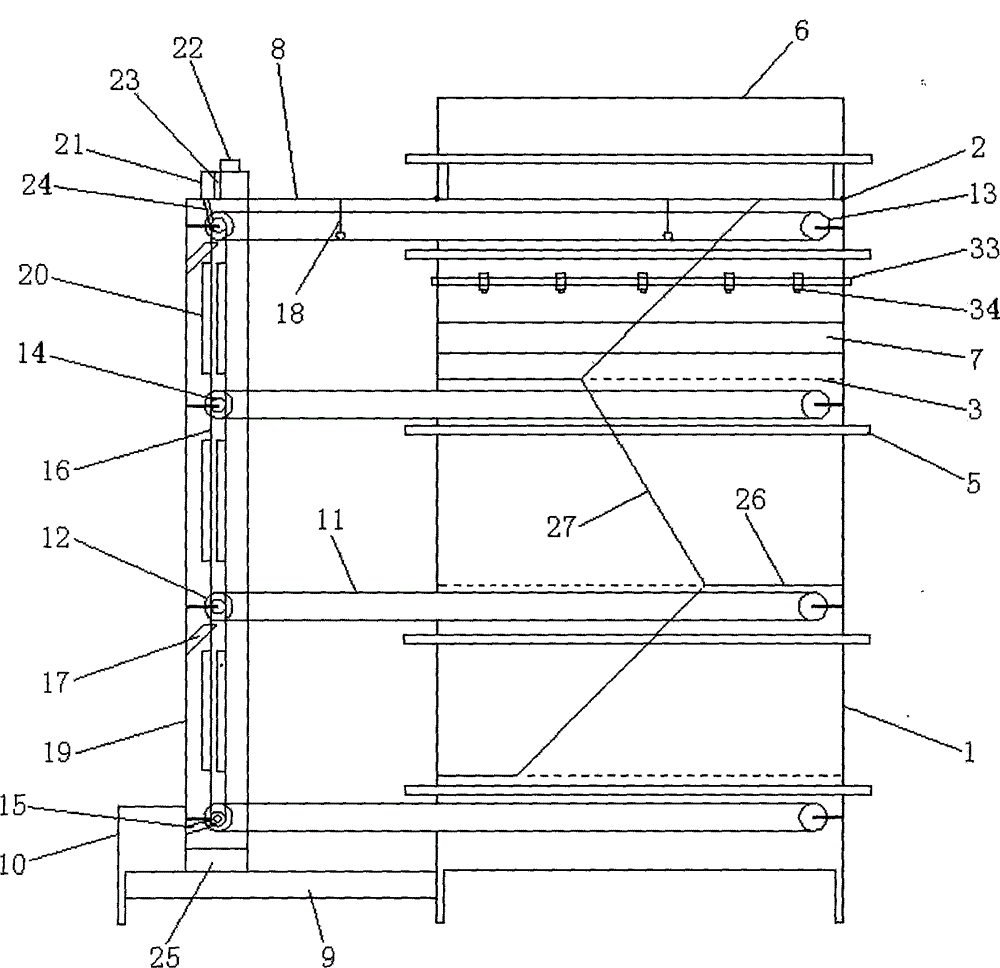

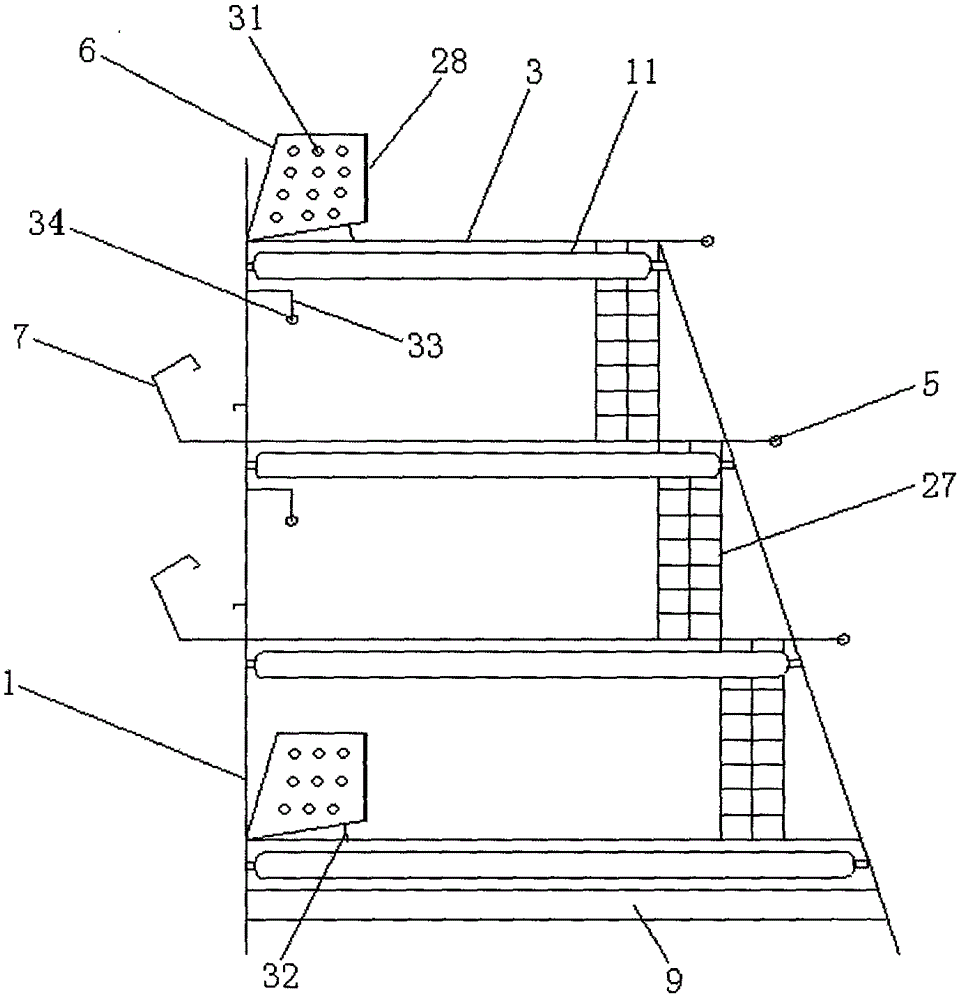

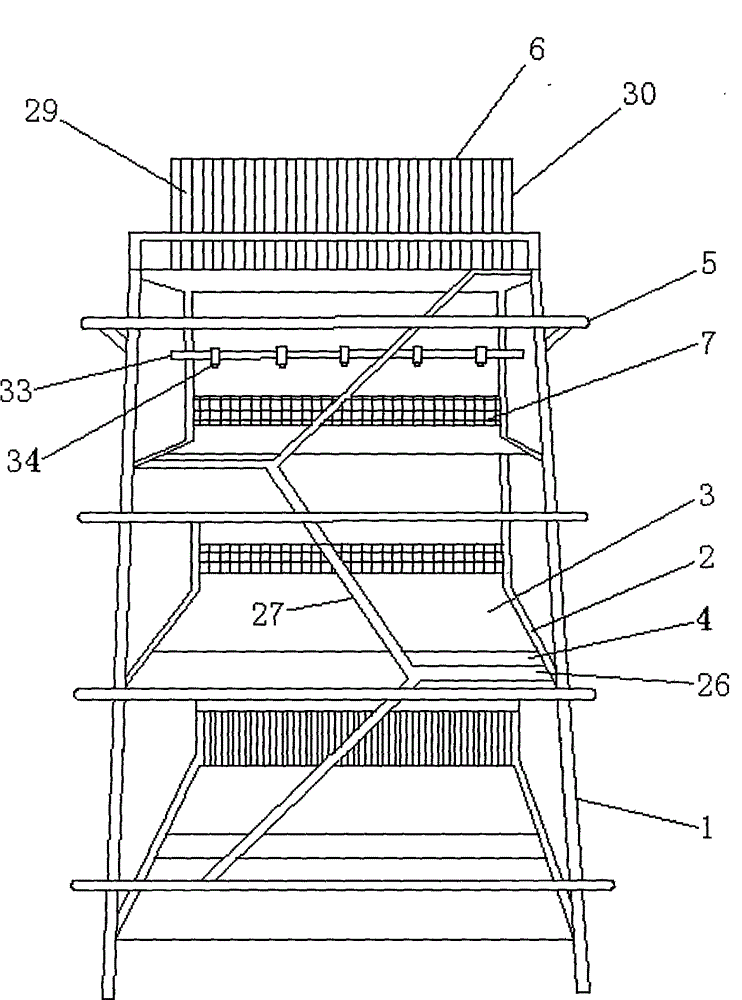

Stacked coop for drylot feeding and cage-free feeding of laying hens

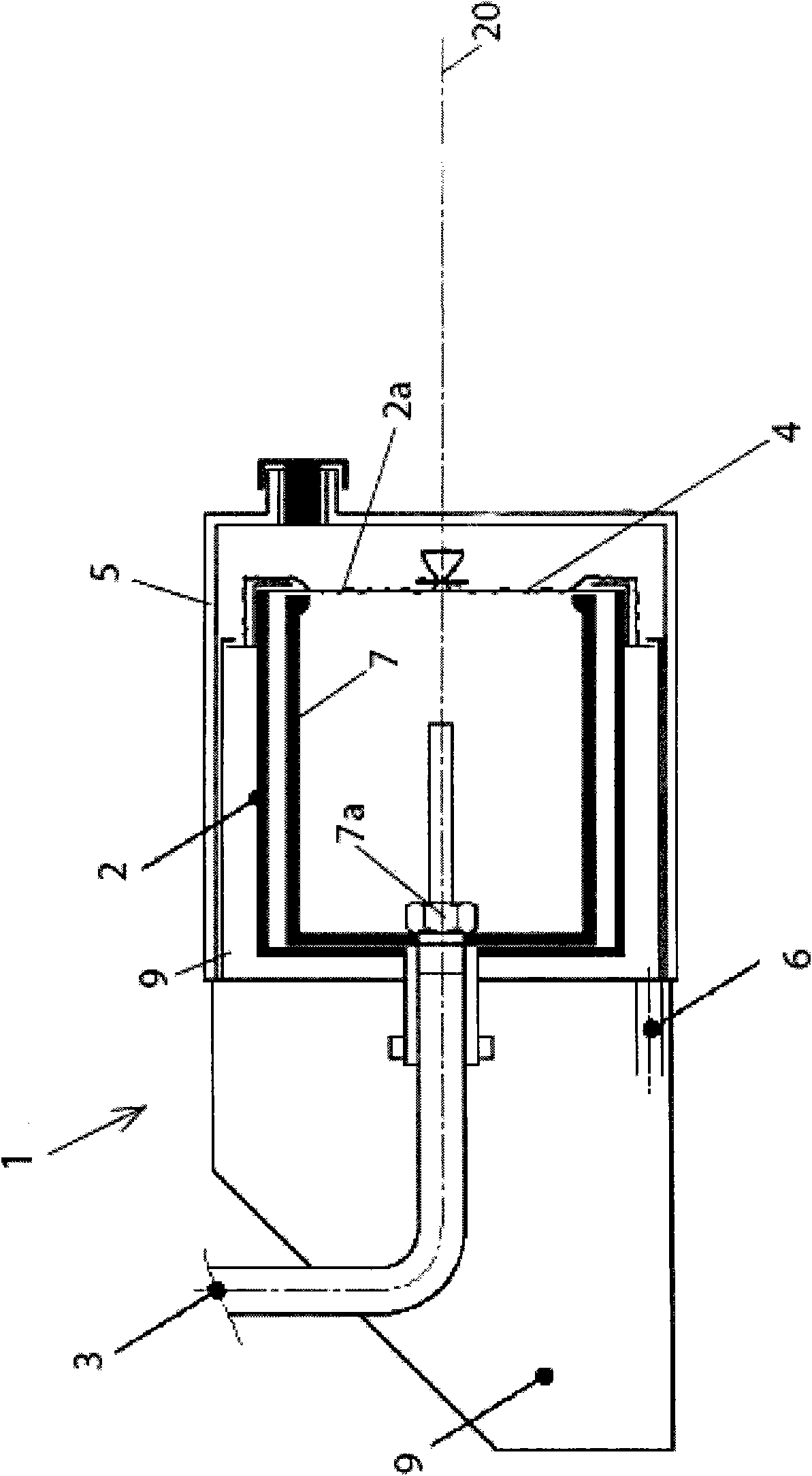

The invention belongs to a stacked coop for drylot feeding and cage-free feeding of laying hens, wherein the stacked coop is capable of improving the welfare state of the laying hens. The stacked coop comprises a trapezoid coop frame, wherein the trapezoid coop frame is laterally provided with an automatic excrement removing mechanism; the middle of the trapezoid coop frame is provided with a transverse brace; the middle of the transverse brace is provided with bottom nets which are parallelly arranged in the vertical direction; the front of a space between two adjacent bottom nets is provided with a net-shaped step; leakage slots are formed between the net-shaped step and the bottom nets; two ends of the net-shaped step are connected with the transverse brace; the front end of the transverse brace is provided with perch; the upper left end of each bottom net is provided with a laying nest; the trapezoid coop frame below the bottom nets is provided with a drinking trough; a material trough is arranged at the lower rear side of the drinking trough. The laying hen movement space is enlarged, so that the laying hens can take food and drink water on the bottom nets and lay eggs in the laying nests; the laying hens can move conveniently in the stacked coop due to the net-shaped step and the perch, so that the living welfare of the laying hens is improved; the automatic excrement removing mechanism is capable of removing excrement of the laying hens in time, so that the laying hen feeding environment is effectively improved and the eggs are prevented from being polluted by the excrement.

Owner:HENAN UNIV OF ANIMAL HUSBANDRY & ECONOMY

Fine and rough feed composition for latter fattening period of high-quality beef cattle and feeding method of fine and rough feed composition

InactiveCN103704481AGet rid of dependenceEnsure ad libitum feedingFood processingAnimal feeding stuffFiberHydrogen phosphate

The invention relates to a fine and rough feed composition for a latter fattening period of high-quality beef cattle and a feeding method of the fine and rough feed composition. A fine feed is prepared by taking corns and corn germ cakes as main materials, and adding brans, cottonseed cakes, soybean cakes, calcium hydrogen phosphate, table salt, baking soda, microelements, vitamin AD3 powder and the like. A rough feed is prepared from 50% of ensiling corn straws and 50% of fresh brewer's grain. The feed resources including the ensiling corn straws, the fresh brewer's grain, the cottonseed cakes and the like are sufficiently utilized so that the cost of the feed is greatly reduced and a feeding method of free feeding of the fine feed for the latter fattening period of the high-quality beef, quantity-limiting and fixed-time feeding, and first-rough feed and second-fine feed feeding is realized; nutrition needed by muscle growth of the beef cattle and deposition of fat between muscle fibers is sufficiently met; the synchronization of the muscle growth and the rapid deposition of the fat between the muscle fibers is realized; the beef color and the fat color and luster meet the standard requirements. The dependence on barley and straws by the latter fattening period of the high-quality beef cattle is completely removed; the beef performance indexes including daily gain of the beef cattle, the slaughter performance, the high-quality beef block yield and the like are improved.

Owner:QINGDAO AGRI UNIV

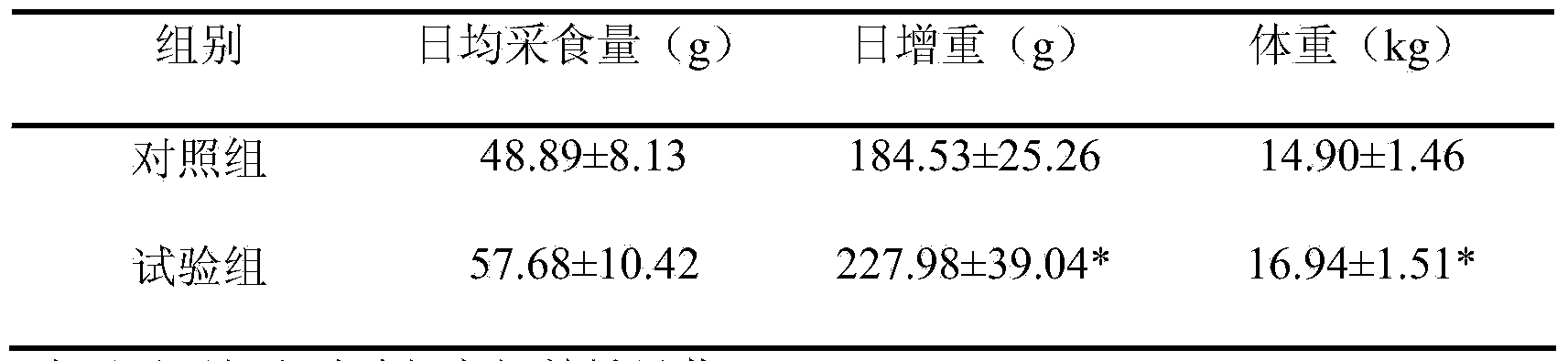

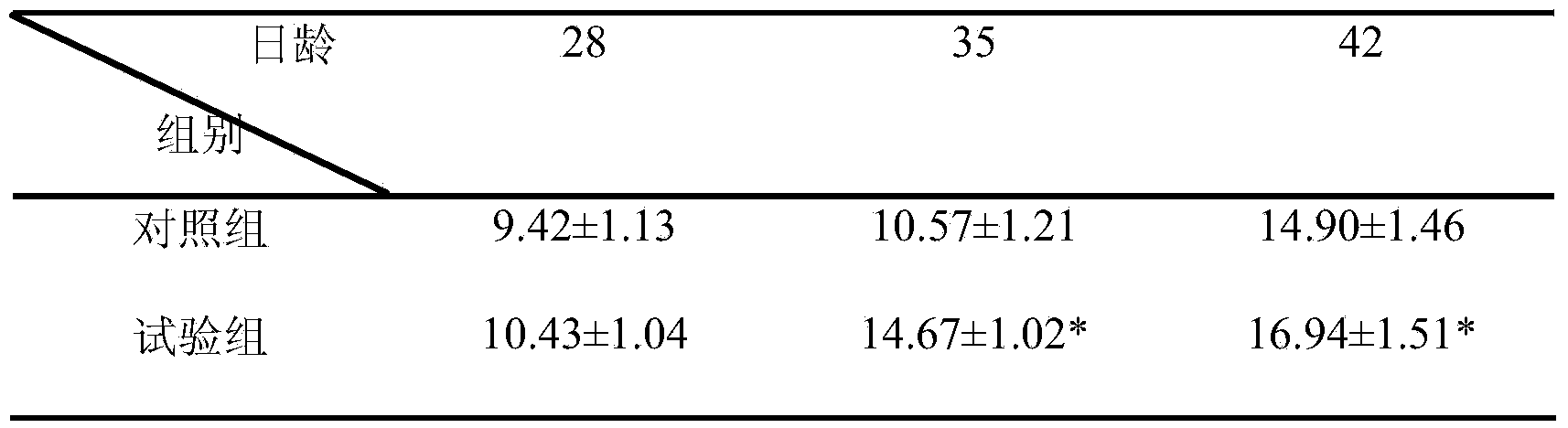

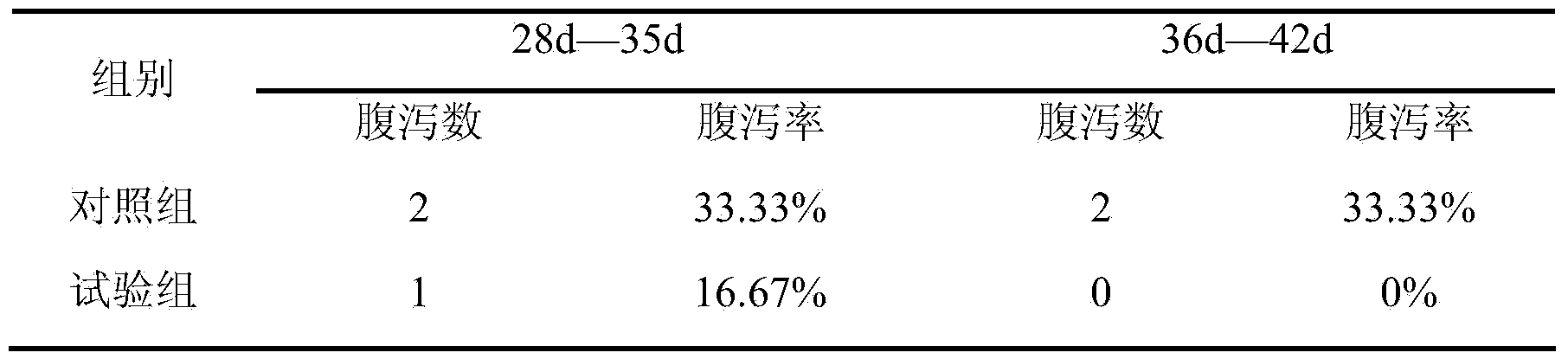

Traditional Chinese medicine feed additive capable of improving growth and function development of animal gastrointestinal tract, preparing method thereof and application thereof

ActiveCN103445001AEasy to preparePromote growth and developmentFood processingAnimal feeding stuffSide effectAnimal product

The invention discloses a traditional Chinese medicine feed additive capable of improving growth and function development of the animal gastrointestinal tract, a preparing method of the traditional Chinese medicine feed additive and application of the traditional Chinese medicine feed additive. The traditional Chinese medicine feed additive mainly comprises astragalus membranaceus, medicated leaven, poria cocos, hawthorn fruits, rhizoma atractylodis macrocephalae, honeysuckle, Chinese pulsatilla roots, liquorice and the like. The raw materials are dried, smashed, screened and prepared in an evenly-blended mode through a traditional Chinese medicine production device, a prepared traditional Chinese medicine preparation is added to basic ration of piglets of 3 yearlings to 6 yearlings according to the weight ratio of 0.5% to 2%, the preparation and the ration are stirred evenly and fed to the piglets, and free feeding and water drinking are conducted. Tests prove that the traditional Chinese medicine feed additive can increase the weight and the stomach weight of the piglets, promote the activity of stomach protease and stomach proton pumps, improve the growth and the function development of the animal stomach, and reduce the diarrhea rate of the piglets. According to the traditional Chinese medicine feed additive capable of improving the growth and the function development of the animal gastrointestinal tract, multiple shortages of various chemical drugs and antibiotic feed additives are overcome, toxic and side effects and medicine residue do not exist, the growth and the function development of the animal stomach are facilitated, and meanwhile production of green high-quality animal products is guaranteed.

Owner:北京中农华正兽药有限责任公司

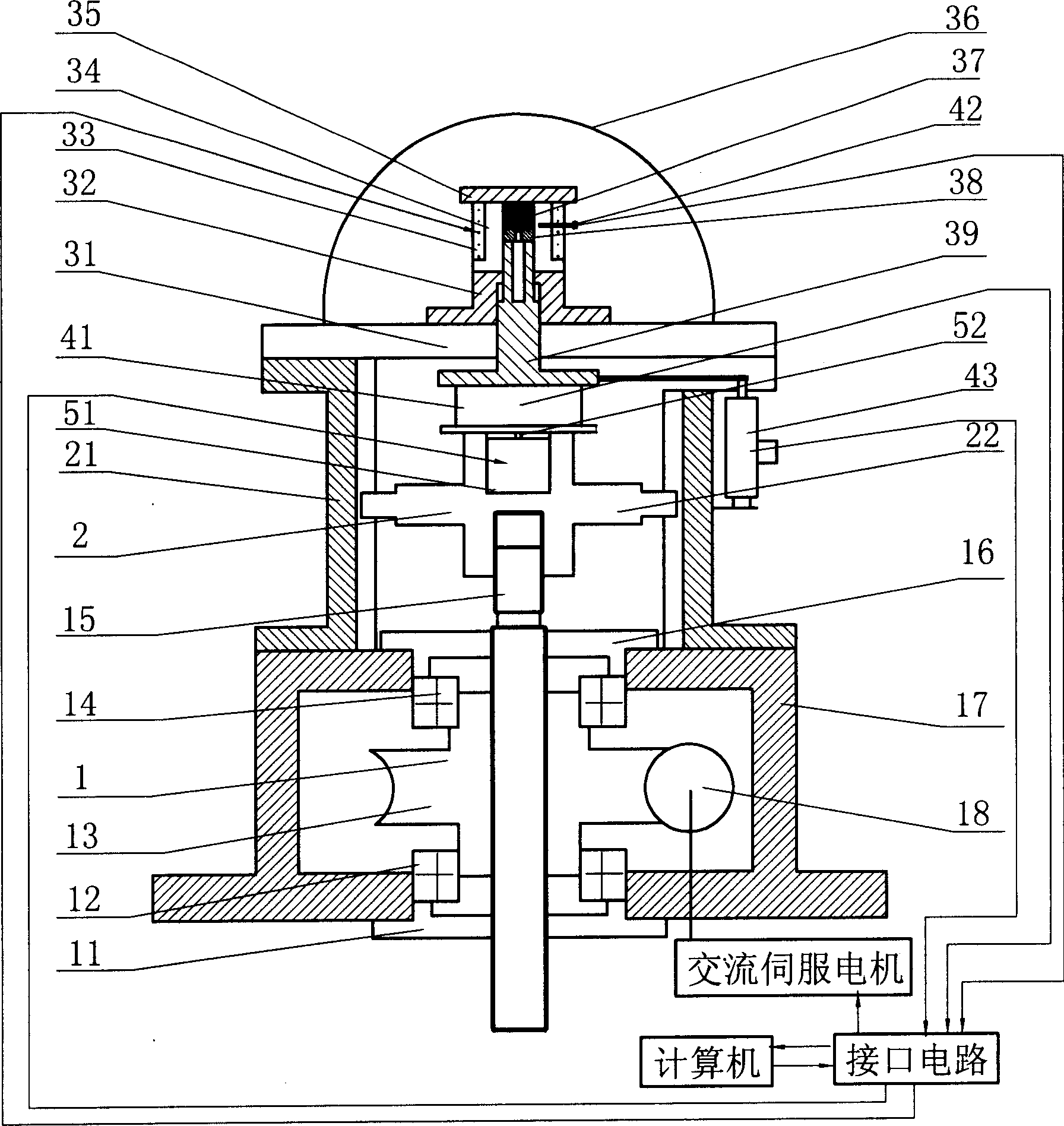

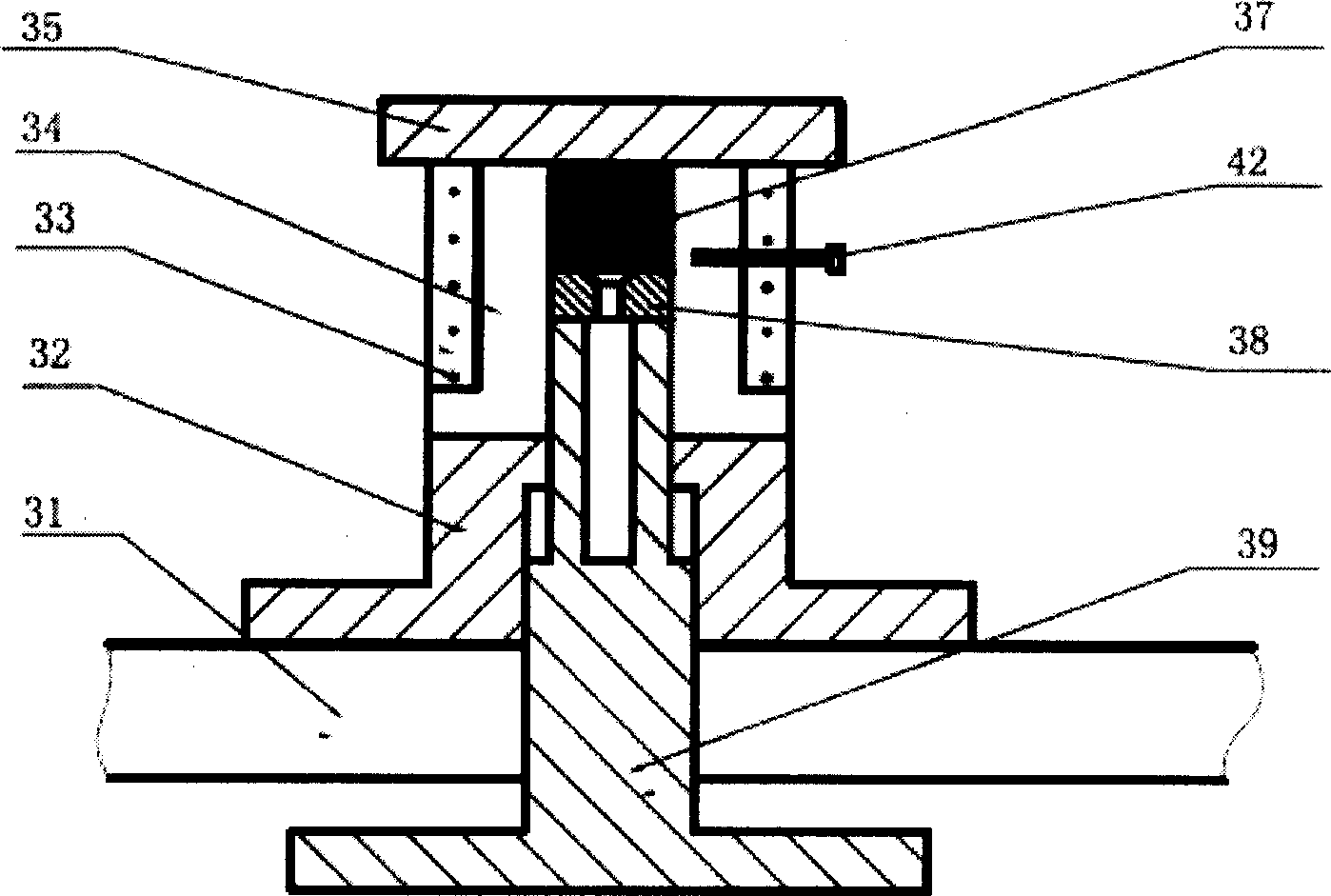

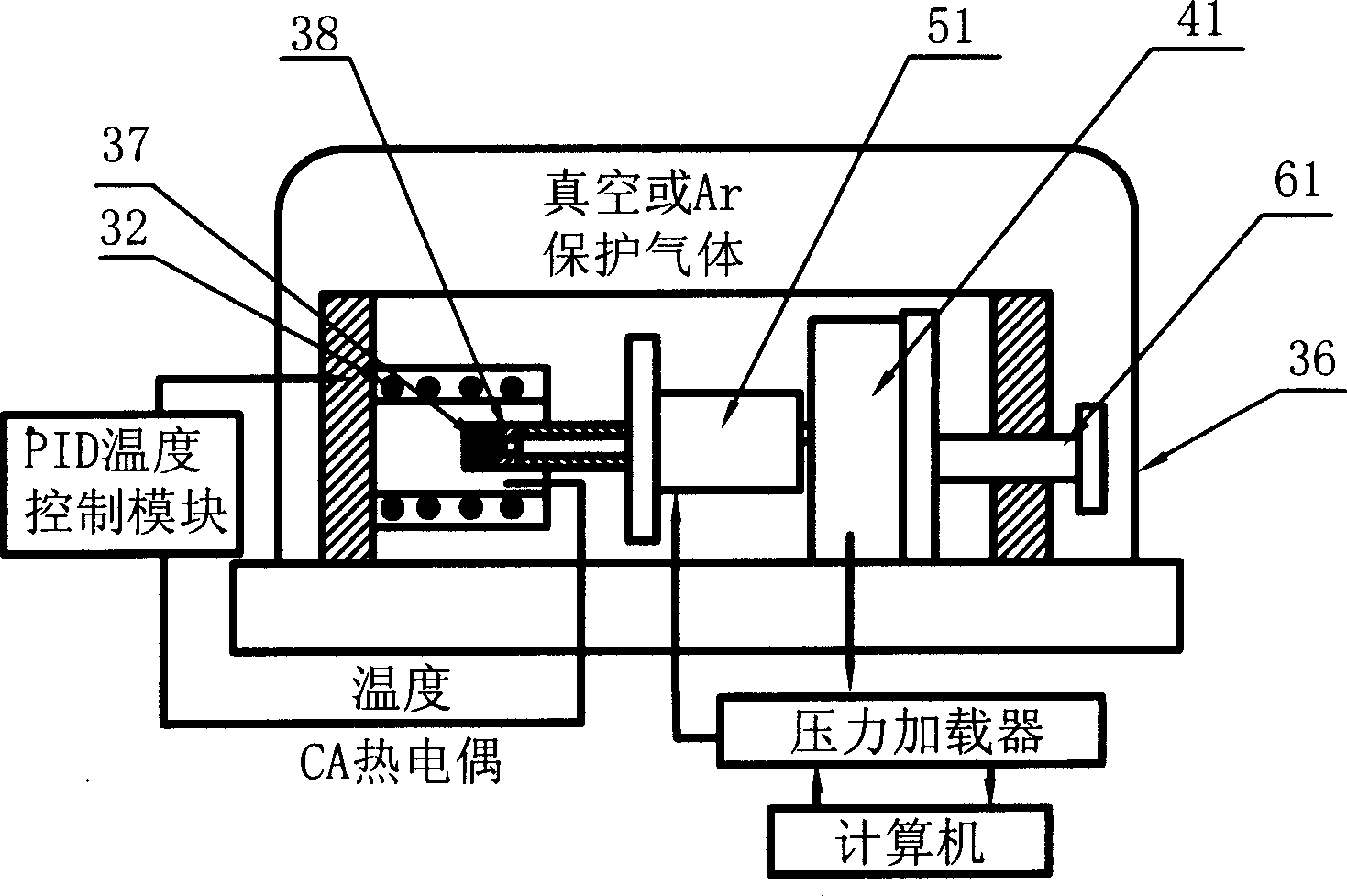

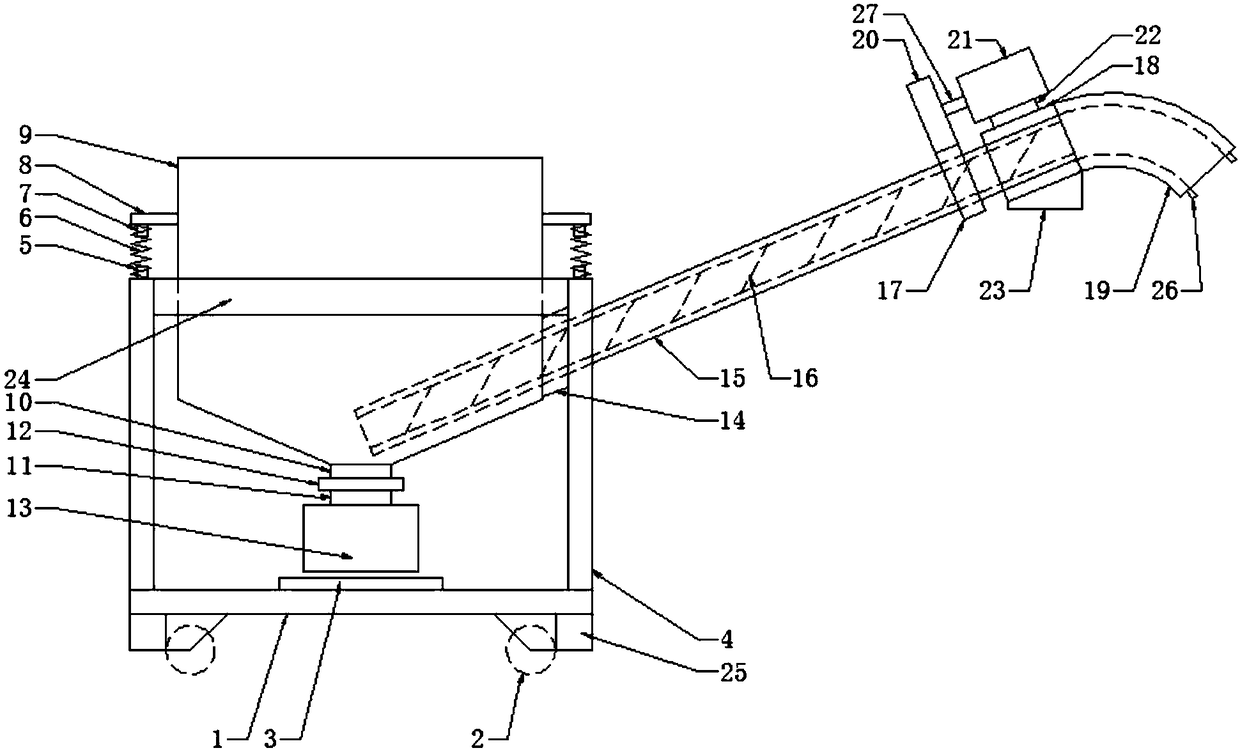

Super plasticity extruding and forming device for micro parts

InactiveCN1820933AExtrusion stroke increasedPrecise control of extrusion precisionPress ramMechanical engineeringFree feeding

The super plasticity extruding formation apparatus for miniature parts includes a reduction mechanism, a guide mechanism, a forming mechanism, a piezoelectric ceramic driver, an AC servo motor, a sensor assembly and a computer. Worm gear and differential nut are used to produce force driving the mold, so that the extruding formation apparatus has increased stroke and free feeding in millimeter level. The piezoelectric ceramic driver is used in trimming the extruding stroke just before finishing the extrusion, so as to reach the aim of precise extrusion in micron level.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Egg chicken feed capable of reducing cholesterol in eggs and production method of low-cholesterol eggs

ActiveCN104642811ALower cholesterol levelsAvoid absorptionFood processingAnimal feeding stuffAnimal scienceBran

The invention relates to an egg chicken feed capable of reducing cholesterol in eggs and a production method of low-cholesterol eggs. The egg chicken feed is prepared from corn, bran, soybean meal, mountain flour, calcium hydrogen phosphate, corn protein powder, soybean oil, methionine, egg chicken microelements, egg chicken vitamins, choline chloride, and additive for reducing the cholesterol, wherein the additive for reducing the cholesterol is prepared from polygonum multiflorum, hawthorn, cassia occidentalis, Bacillus subtillis premix and lactobacillus premix in any ratio; the low-cholesterol egg is produced as follows: the additive for reducing the cholesterol is added into base feed for egg chicken, the egg chicken are subjected to free feeding and can lay the low-cholesterol egg after ten days, wherein the additive is prepared from polygonum multiflorum, hawthorn, cassia occidentalis, Bacillus subtillis premix and lactobacillus premix; and the content of the cholesterol in the egg fed by the feed is lower 27% than that of the common eggs, and the low-cholesterol egg is more suitable for the aged.

Owner:西安格润牧业股份有限公司

Full-automatic PCB ultraviolet laser cutting machine

ActiveCN109175680ARealize fully automated operationImprove work efficiencyPrinted circuitsLaser beam welding apparatusUltravioletLaser cutting

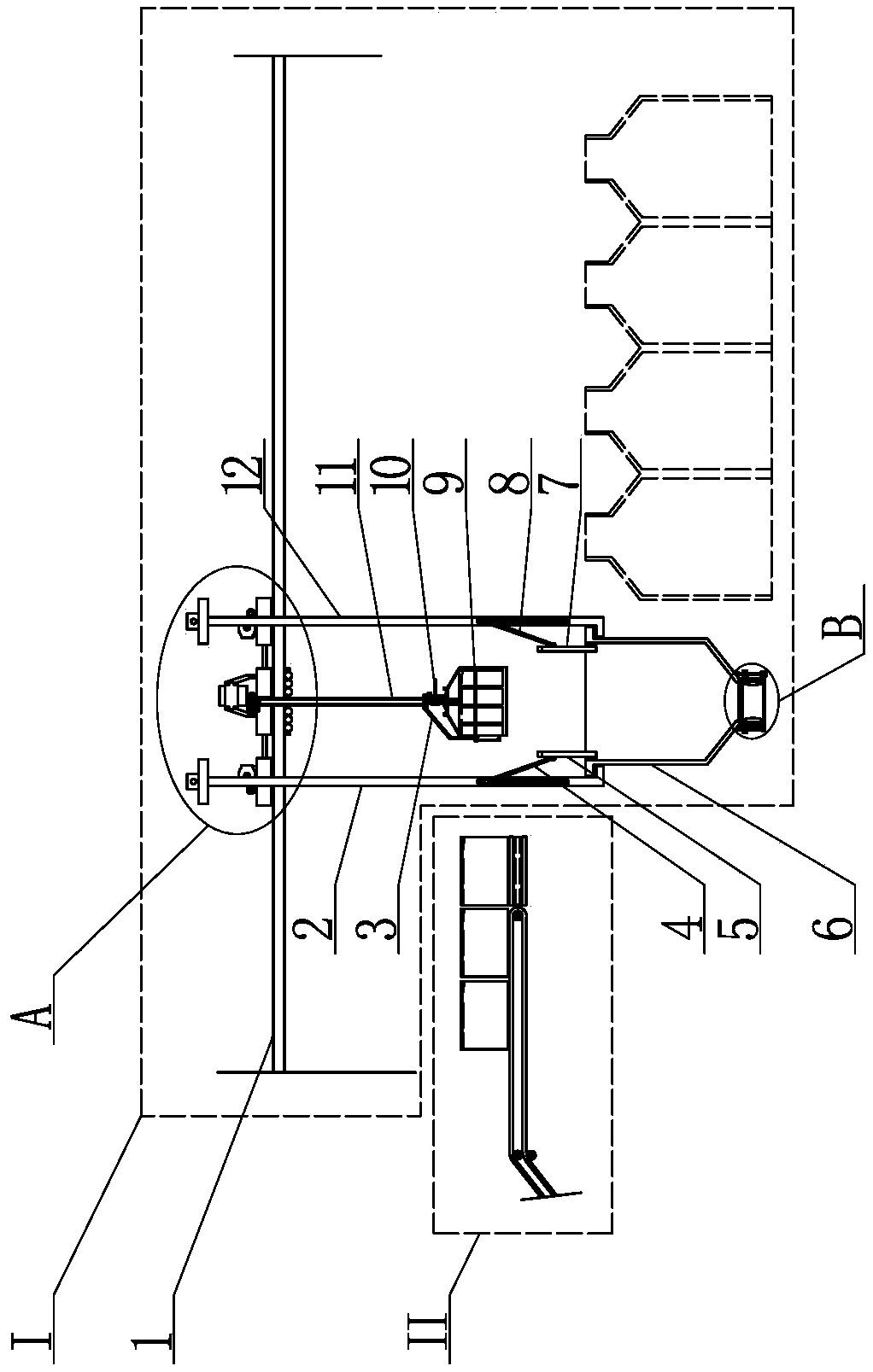

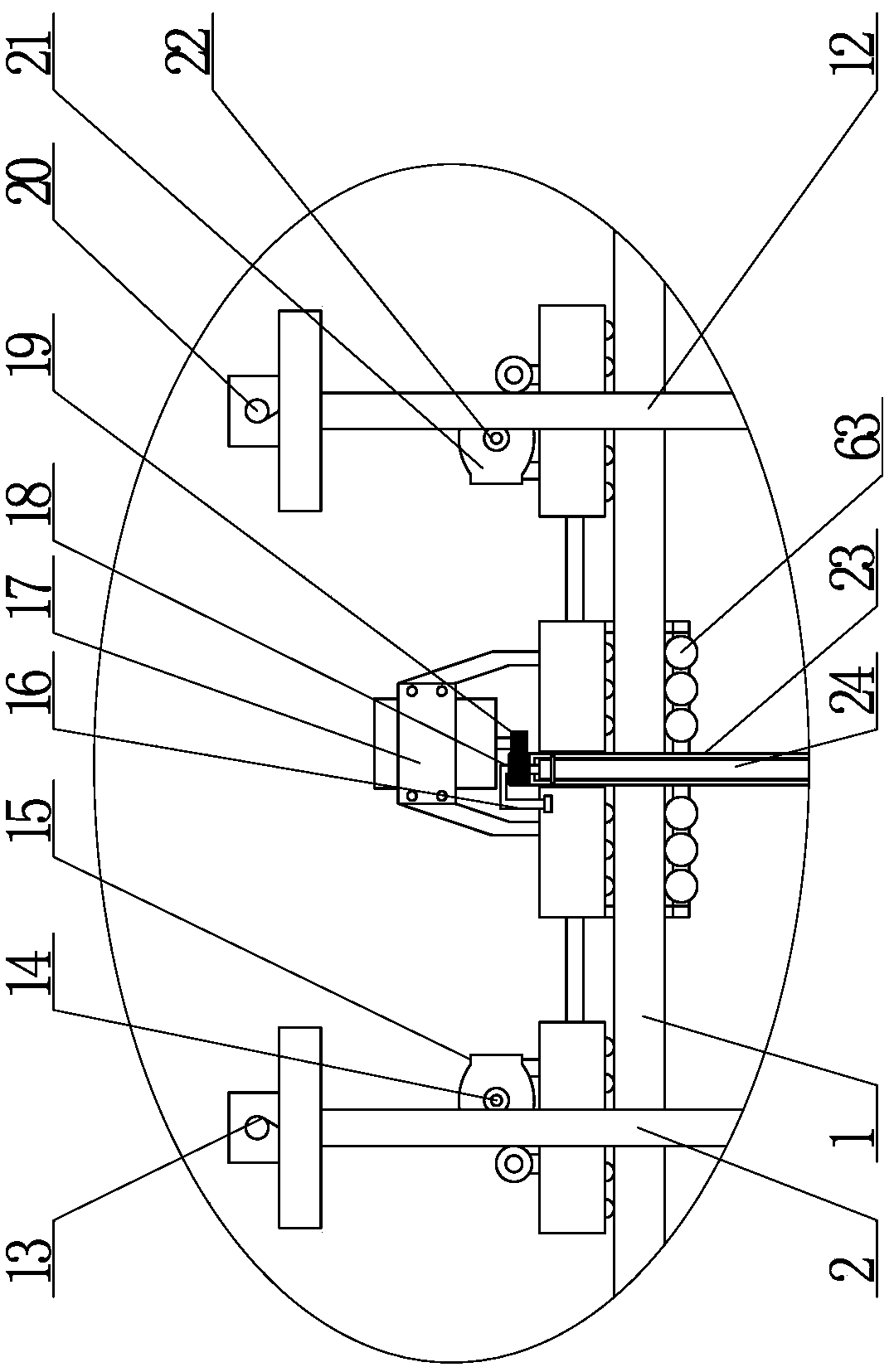

The invention discloses a full-automatic PCB ultraviolet laser cutting machine. The full-automatic PCB ultraviolet laser cutting machine comprises a feeding mechanism, a cutting mechanism and a discharging mechanism, wherein the feeding mechanism comprises a feeding manipulator, a first jig transferring platform, a first tray transferring device, a first tray storage area and a first empty tray storage area; the cutting mechanism is arranged on one side of the feeding mechanism and comprises a ultraviolet laser, a cutting head assembly, an X-axis movement unit, a Y-axis movement platform and aZ-axis movement unit; and the discharging mechanism is arranged on the other side of the cutting mechanism and comprises a discharging manipulator, a second jig transferring platform, a second tray transferring device, a second tray storage area and a second empty tray storage area. According to the full-automatic PCB ultraviolet laser cutting machine, manual-intervention-free feeding, cutting, discharging and quality detection are achieved through full-automatic operation, the work efficiency is effectively improved, the labor investment is reduced, the machining precision is improved, and automatic and intelligent production requirements are met.

Owner:SHENZHEN GDLASER TECH CO LTD

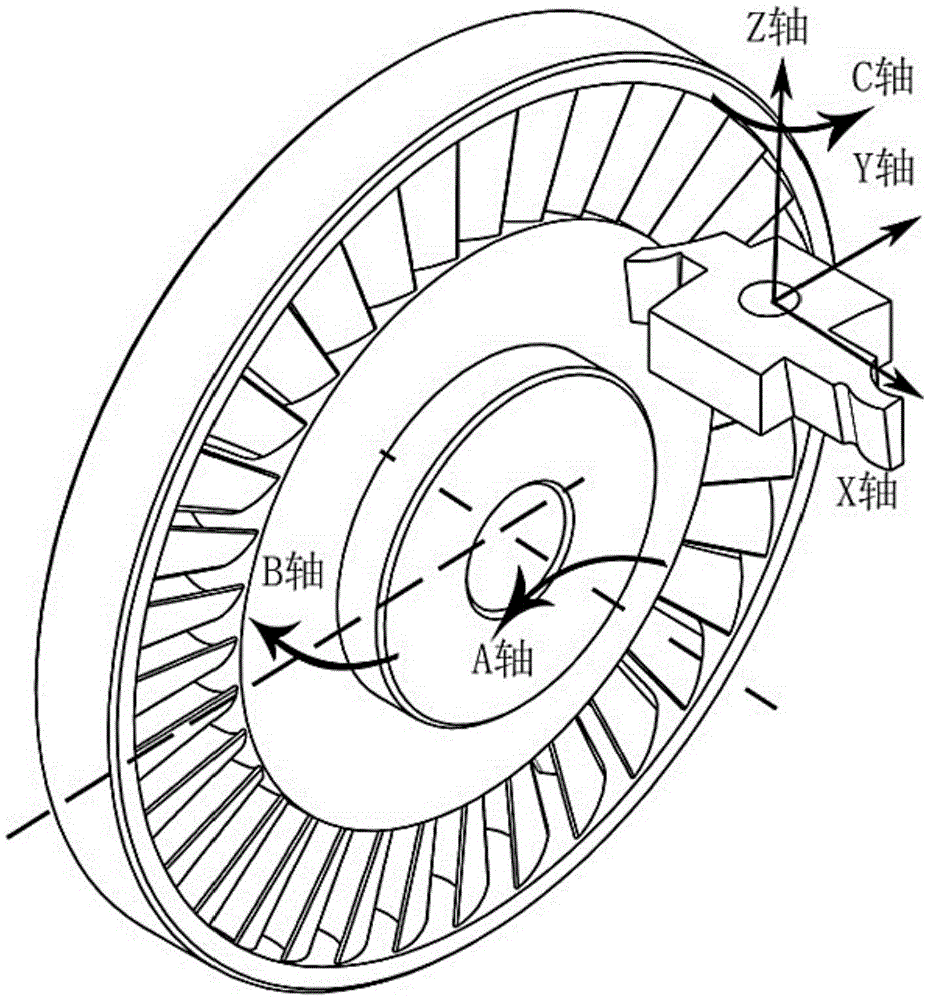

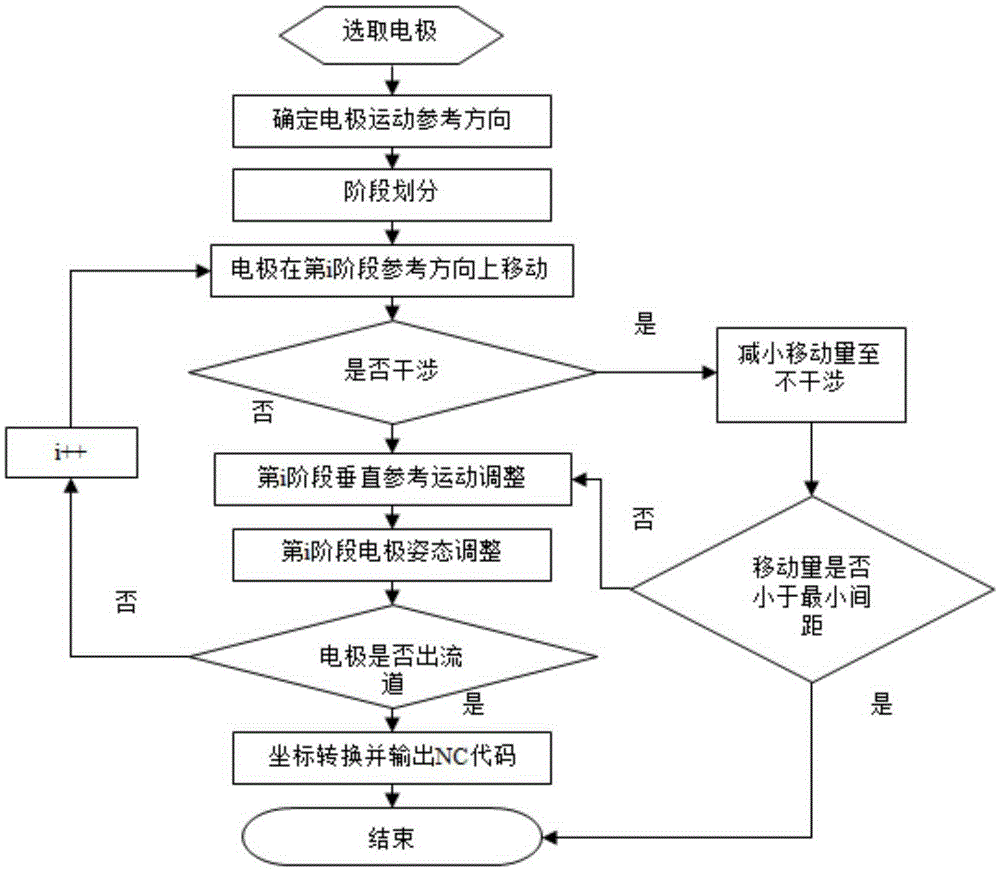

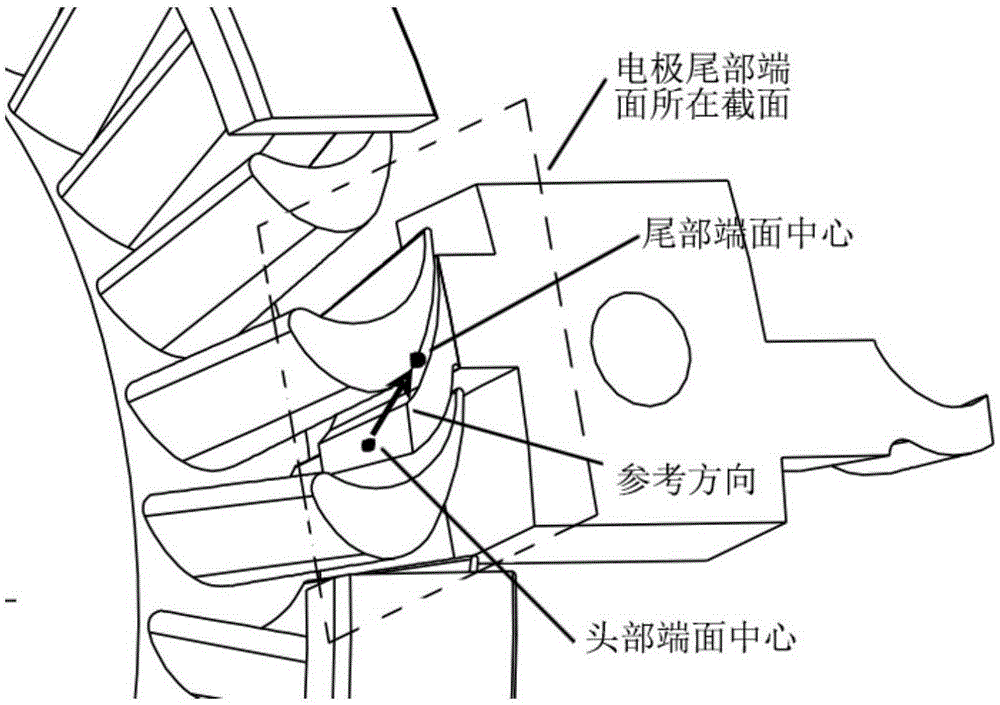

Method for searching maximum free movement stroke track of electrode in electrosparking of closed blisk

ActiveCN105345187AHigh success rate of trajectory searchImprove versatilityElectrical-based machining electrodesEngineeringElectrical discharge machining

A method for searching a maximum free movement stroke track of an electrode in electrosparking of a closed blisk is characterized in that an electrode feeding stopping position is treated as an optimal track starting point, a position where the whole electrode moves out of a flow channel is treated as an optimal track end point, a vector direction that the center of the end surface of a head part of the electrode points to the center of the end surface of a tail part of the electrode is treated as a reference direction of the electrode movement, and on that basis, the process that the electrode moves from the optimal track starting point to the optimal track end point is divided into a plurality of stages; the electrode translates from one movement node of each stage along the reference direction without interference to obtain the next movement node of the same stage, and meanwhile, the posture of a rotating shaft of the electrode is adjusted in each movement node; all movement nodes can be obtained after the electrode moves out of the flow channel without interference, and all nodes can be smoothly connected to form a complete optimal track; the optimal track is subjected to coordinate transformation to obtain an interference-free feeding track. The method is applicable to flow channel structures of various shapes, is high in success rate of searching the optimal track, can achieve multi-shaft linking, and is high in processing efficiency.

Owner:SHANGHAI JIAO TONG UNIV

Pollution-free feeding method for young laying hens

InactiveCN105165715AScientific norms of feeding methodsPhysical healthAnimal husbandryAnimal scienceEconomic benefits

The present invention discloses a pollution-free feeding method for young laying hens, and relates to the technical field of laying hen feeding. The method comprises the following steps: brooding pre-preparation, chick rearing, and chick management. The pollution-free feeding method for young laying hens provided by the present invention has the benefits that: the feeding method for young laying hens implemented by the present invention is scientific and standardized, and convenient and simple; reasonable raising is strictly performed according to growth demand of young laying hens, so that the survival rate is high, and raised young laying hens are physically healthy, thereby creating favorable conditions for later stage laying hens, ensuring the economic benefits of farmers and stimulating raising interest of farmers.

Owner:蚌埠经济开发区燕山养殖场

Dust-free feeding mechanism for mixing machine

InactiveCN104118731APromote absorptionAvoid flyingDispersed particle filtrationMixer accessoriesAir springWorking environment

The invention discloses a dust-free feeding mechanism for a mixing machine. The dust-free feeding mechanism comprises a feeding chamber, wherein a discharging port connected with a feeding port of a mixing cylinder is formed in the bottom end of the feeding chamber, a chamber cover is arranged on one side of the feeding chamber and connected with an air spring, and a dust removal port is formed in the top end of the feeding chamber and connected with a dust removal device. By means of the dust-free feeding mechanism for the mixing machine, dust flying is avoided, impurities mixed in powder are removed, work environments are improved greatly, and dust-free feeding is achieved.

Owner:GUANGDONG LIANSU MACHINERY MFG

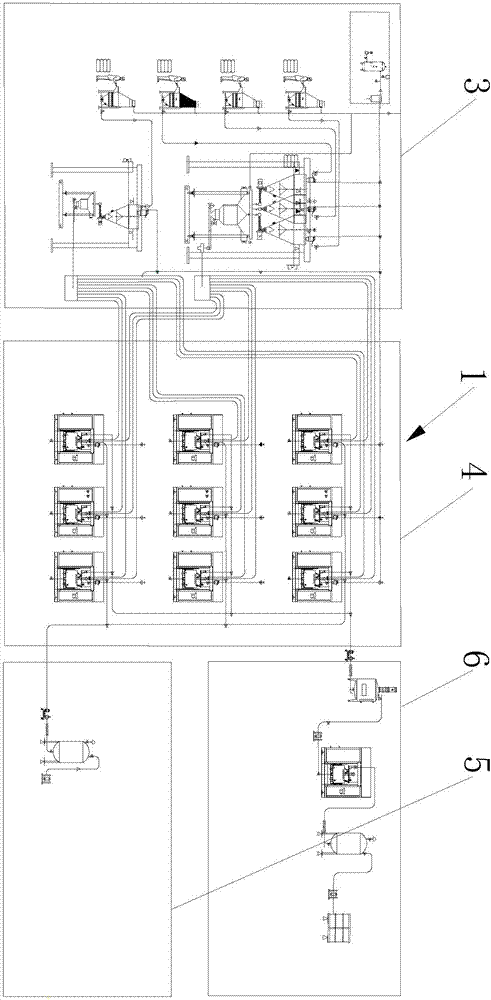

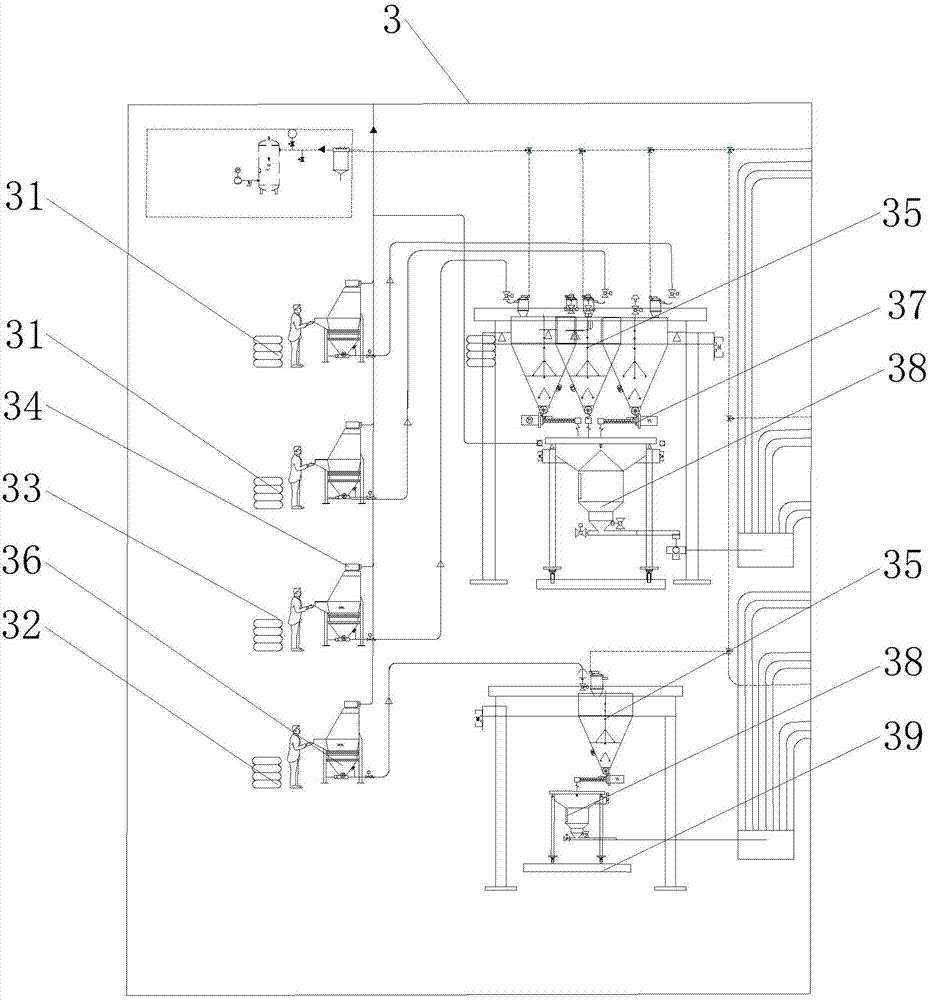

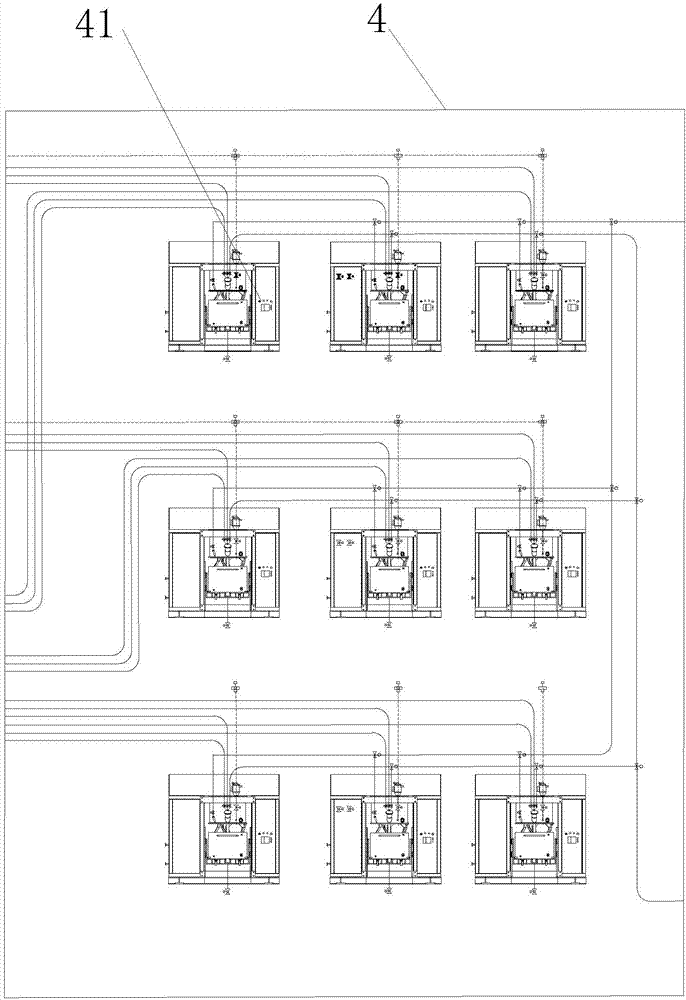

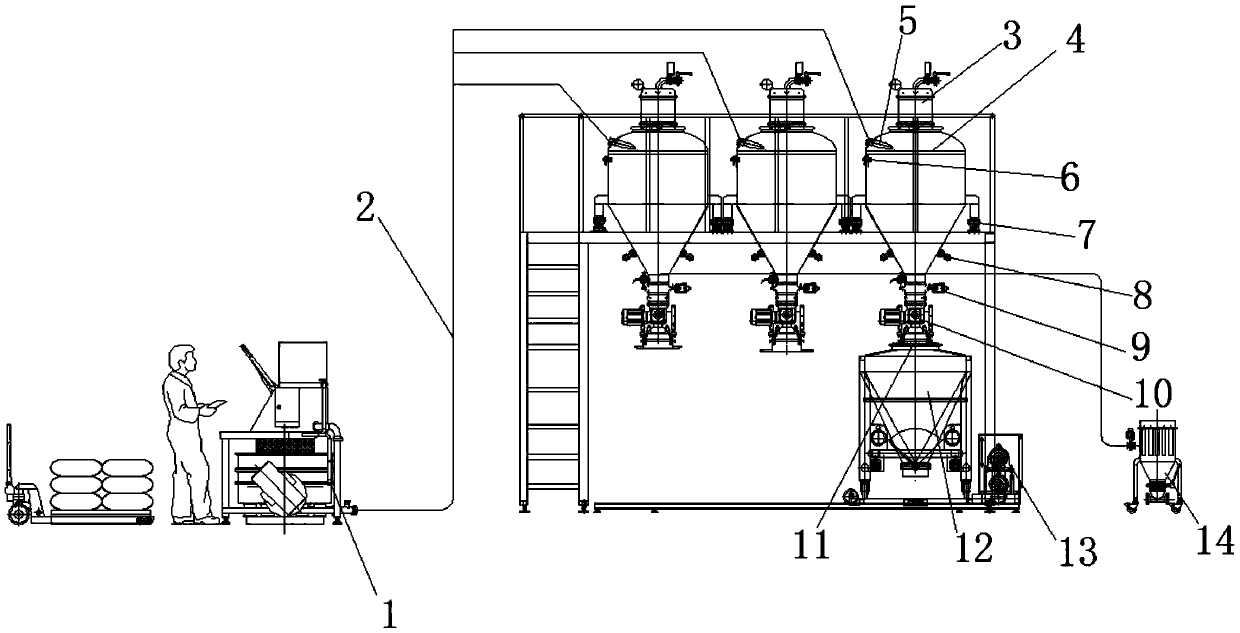

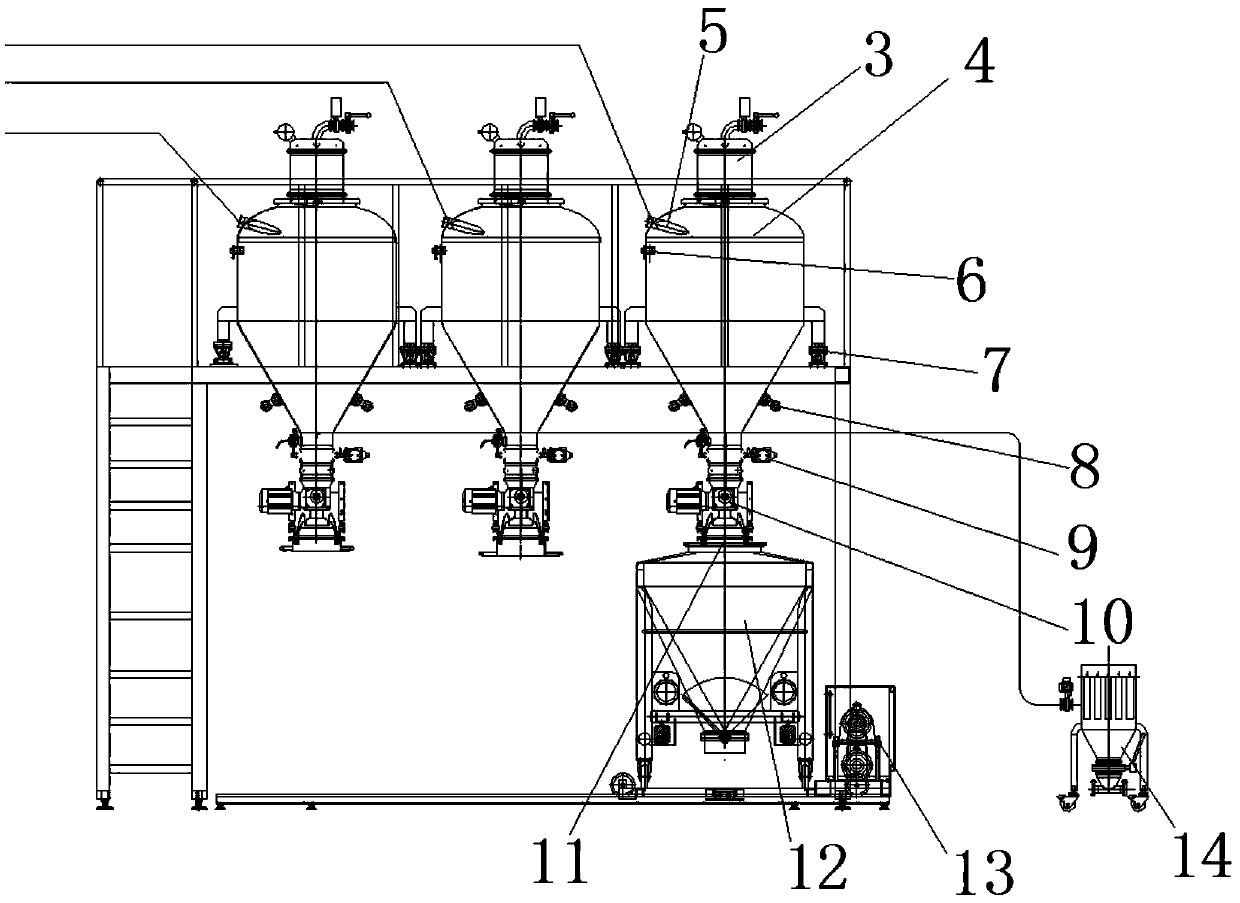

Automatic pulp equalizing system

InactiveCN106943942AHigh precisionIncrease productivityElectrode manufacturing processesTransportation and packagingLoop controlAutomatic control

The invention discloses an automatic pulp equalizing system. The automatic pulp equalizing system comprises an anode automatic pulp equalizing system and a cathode automatic pulp equalizing system, wherein the anode automatic pulp equalizing system comprises an automatic powder charging system, a high-viscosity stirring system, an automatic solvent injection system and an automatic CNT (carbon nanotube) charging system; the cathode automatic pulp equalizing system comprises an automatic powder charging system, a high-viscosity stirring system, an automatic solvent injection system and an automatic SBR (styrene butadiene rubber) charging system; the gel powder can be selectively dissolved or not dissolved in advance; the gel powder is conveyed to a metering tank by a dust-free feeding station and a vacuum conveyor, and the metering tank is connected with a screw conveyor; the gel powder is precisely conveyed to a fermenting tank by the precise metering of the screw conveyor and the real-time closed-loop control of a weighing scale; when a material feeding signal is received, the system is started, and the powder in the conveying tank is completely conveyed into a stirrer or a gel dissolving machine. The automatic pulp equalizing system has the advantages that the full automatic control type of one for multiple machines is realized, the production efficiency and production quality of a lithium battery are effectively improved, and the production environment is improved.

Owner:东莞市科锐机电设备有限公司

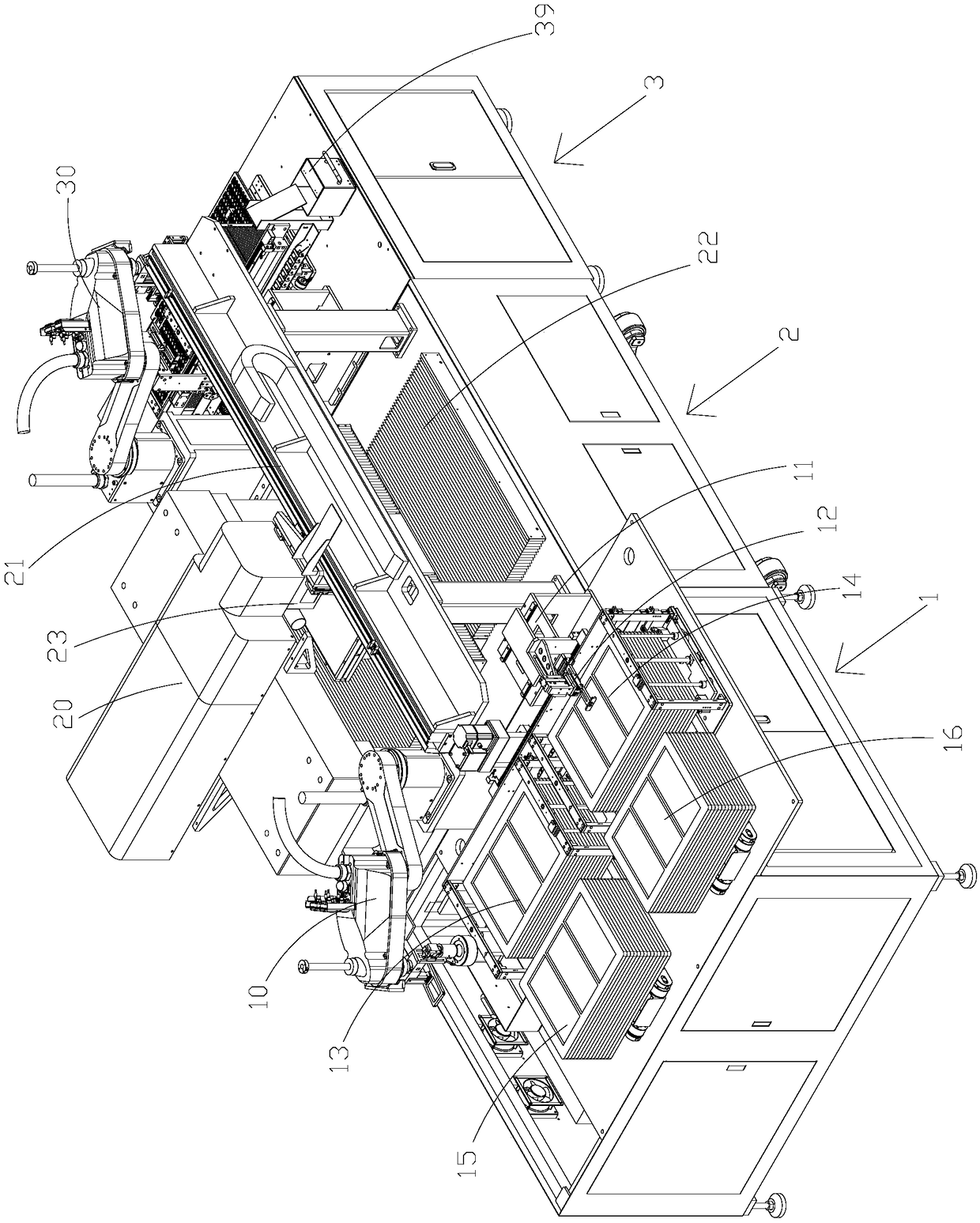

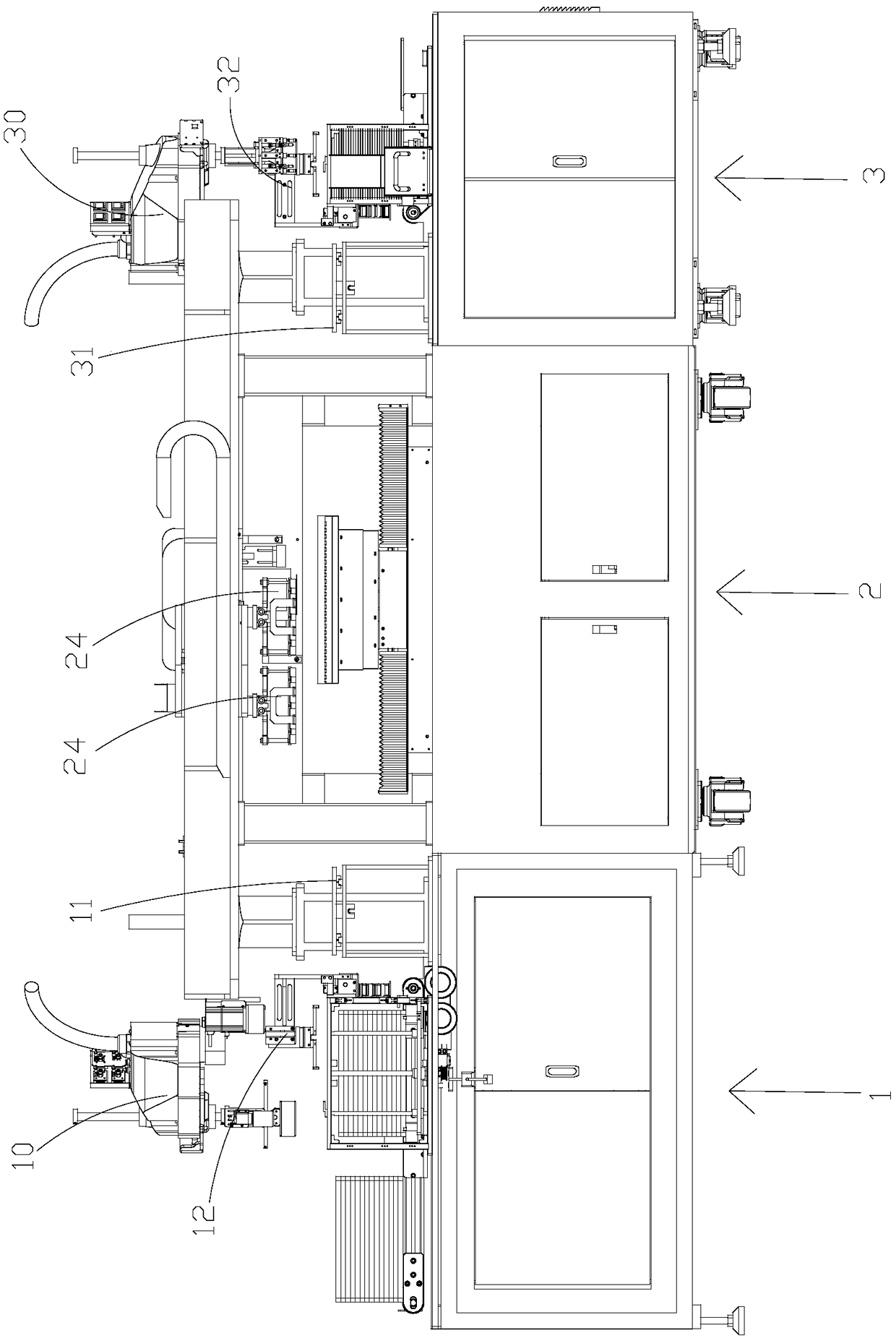

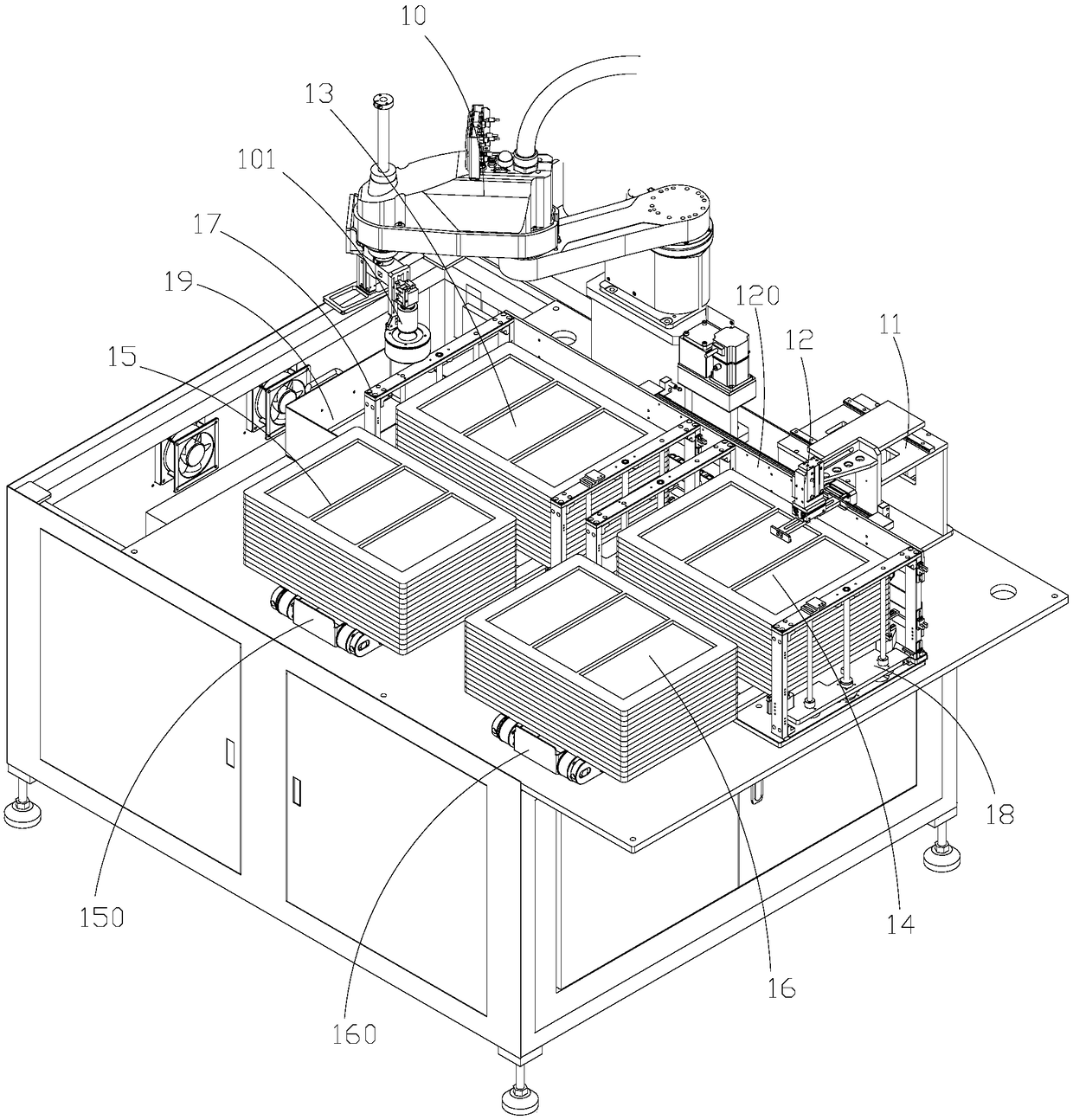

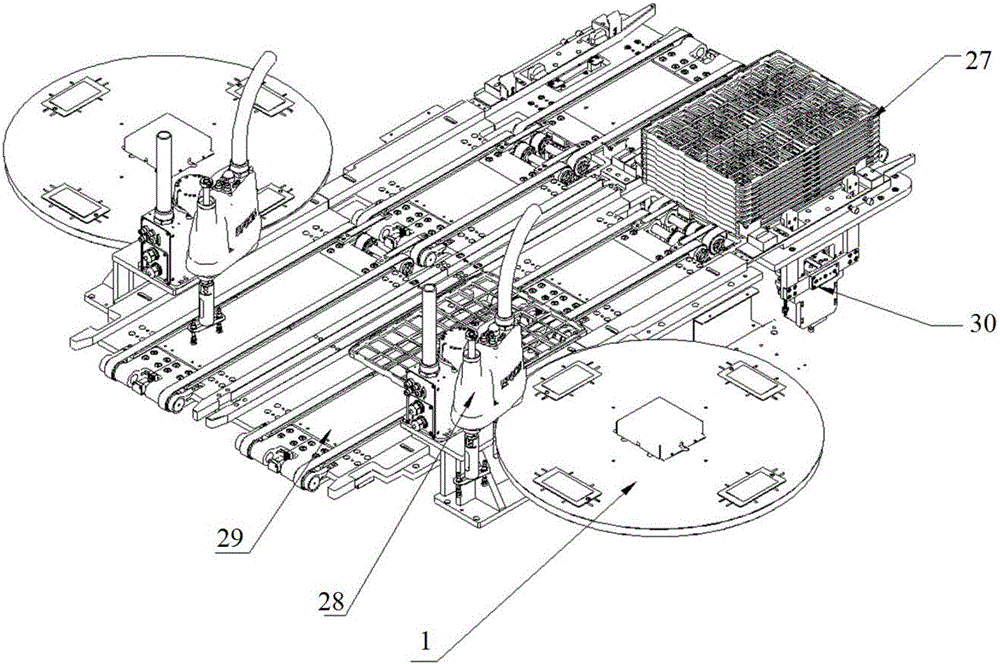

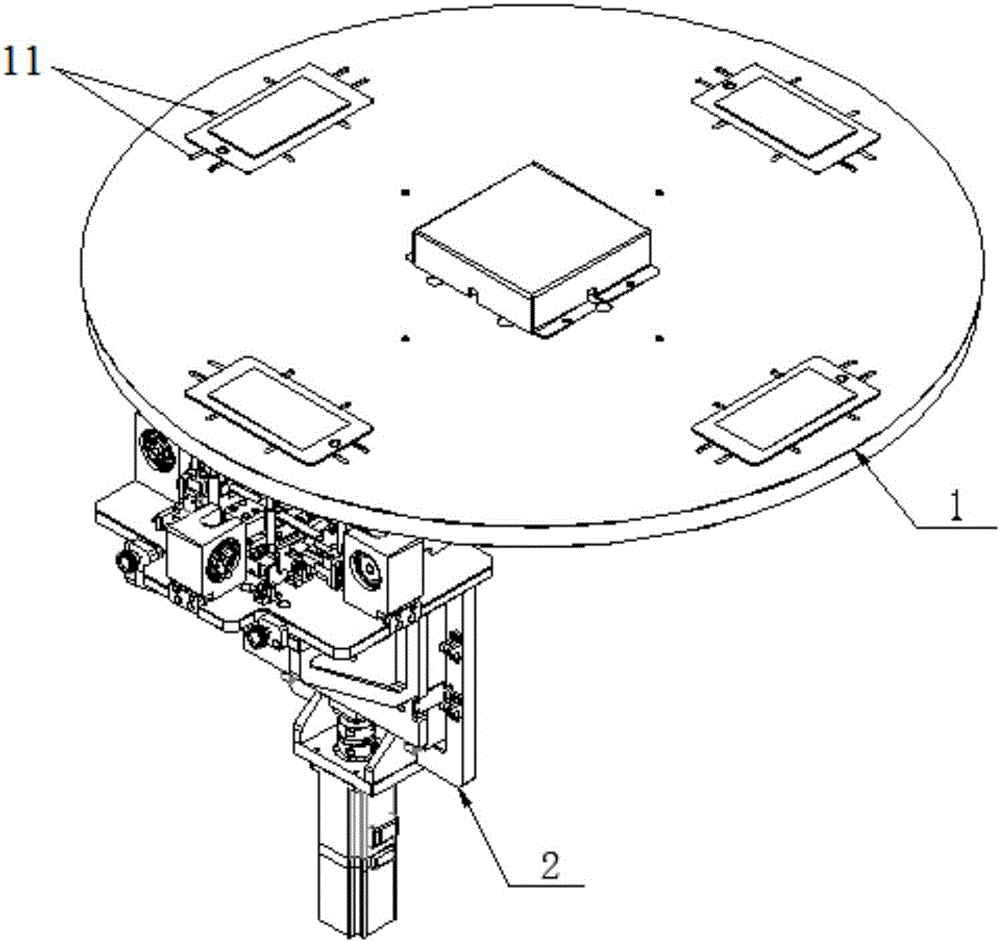

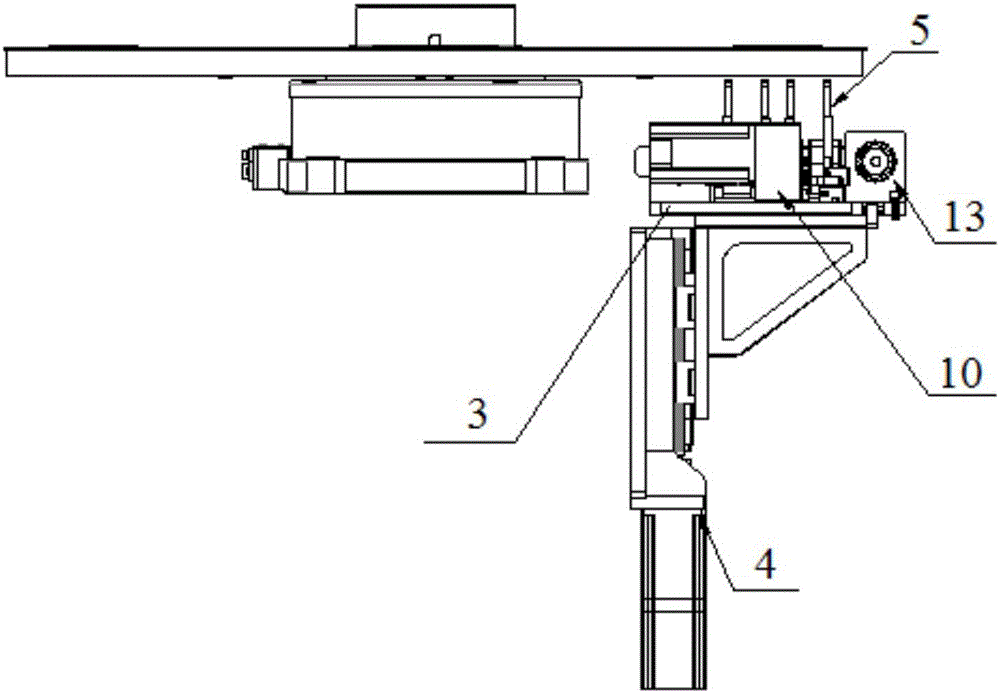

Intermission-free automatic feeding and discharging mechanism for panel materials

ActiveCN106044228ACompact structureImprove efficiencyCharge manipulationConveyor partsEngineeringManipulator

The invention discloses an intermission-free automatic feeding and discharging mechanism for panel materials. The intermission-free automatic feeding and discharging mechanism for the panel materials comprises a Tray conveying device, a rotating disk platform and a manipulator; the rotating disk platform is arranged on one side of the Tray conveying device; and the manipulator is arranged on the same side as the rotating disk platform and serves as an intermediate carrier for conveying the panel materials between the Tray conveying device and the rotating disk platform. The intermission-free automatic feeding and discharging mechanism for the panel materials has the technical effects that by arranging the three-segment type conveying parts, the function of receiving incoming materials, the function of fast transition and the function of conveying the materials to a machining station are included; compared with an existing conveying device, interval-free feeding and discharging can be achieved, and that is to say, when the panel materials are machined, the conveying action of conveying a next Tray to the machining station immediately after a previous Tray is achieved through cooperation of the three segments of conveying parts; and meanwhile, high-speed and high-precision station conversion can be provided by a rotating disk, seamless connection of the whole procedure is achieved through the rotating disk and a positioning device, and the purposes of a simple and compact structure, the improvement of efficiency, continuous production and small floor space are achieved.

Owner:湖南三兴精密工业股份有限公司

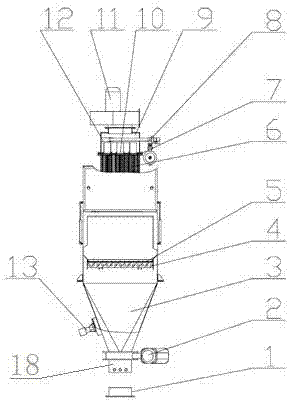

Automatic feeding equipment

InactiveCN108609404AStable feeding environmentReduce noiseLarge containersLoading/unloadingAutomatic test equipmentArchitectural engineering

The invention discloses automatic feeding equipment. The automatic feeding equipment comprises a support plate. Multiple universal wheels are symmetrically arranged at the bottom of the support plate.A buffer plate and a support frame are arranged at the top of the support plate. The buffer plate is positioned at the inner side of the support frame. Multiple first positioning rods are arranged atthe top end of the support frame. The first positioning rods are correspondingly sleeved with damping springs. Second positioning rods are correspondingly inserted into the top ends of the damping springs. The second positioning rods are arranged at the bottoms of support plates. The support plates are correspondingly arranged on the outer side of the upper part of a hopper. The hopper is positioned on the top of the support frame. The bottom of the hopper extends to the middle of the inner side of the support frame. The lower part of the hopper is of a taper structure. A bottom platform is arranged at the bottom of the hopper. A vibrating platform is arranged at the bottom of the bottom platform. The bottom platform is fixedly connected with the vibrating platform through a connecting disc. The automatic feeding equipment has the beneficial effects of realizing a stable, efficient and noise-free feeding environment.

Owner:HEFEI SHENGERWEI IND EQUIP CO LTD

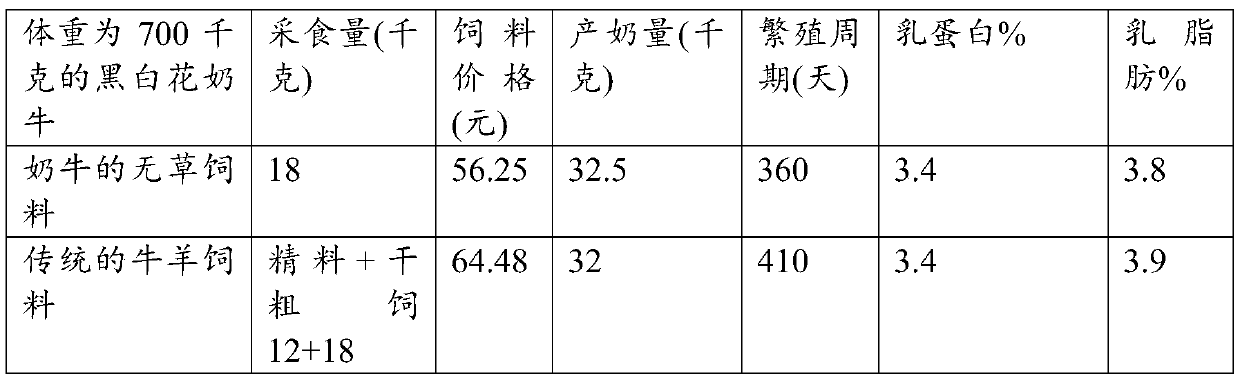

Full-ration compound feed for grass-free feeding of dairy cows and preparation method of full-ration compound feed

The invention discloses a full-ration compound feed for grass-free feeding of dairy cows. The full-ration compound feed comprises the following raw materials in parts by weight: 500-600 parts of corn,260-290 parts of soybean meal, 50-80 parts of DDGS, 12-15 parts of salt, 4-8 parts of calcium hydrophosphate, 1.5-2 parts of rumen bypass methionine, 2-2.5 parts of rumen bypass lysine, 2-3 parts ofrumen bypass choline, 10-20 parts of cane sugar molasses, 30-40 parts of palm oil, 1-2 parts of saccharomyces cerevisiae, 1-2 parts of bacillus subtilis, 0.05-0.1 parts of VE, 1-2 parts of dairy cow compound trace elements, 0.15-0.2 parts of dairy cow compound vitamins, 3-6 parts of fructus aurantii, 8-10 parts of hawthorn fruits and 0.05-0.06 parts of hexanol. The invention further provides a preparation method of the full-ration compound feed for grass-free feeding of dairy cows. The full-ration compound feed is convenient to transport and store, milk output of dairy cows is large, feeding management is facilitated, the labor cost of feeding is reduced, and the quality of dairy products is improved.

Owner:肖鹏宏

Baby pig forced supplementary feeding method

InactiveCN101331865AAlleviate Early Weaning SyndromeReduce disease rateAnimal husbandryTraining periodAnimal science

The invention discloses a grice forcing supplementary feeding method and relates to the technical field of scientific cultivation. The grice forcing supplementary feeding method is a wholly new supplementary feeding method which is designed for the purposes of accurately controlling the quantity and time of grice supplementary feeding, achieving the ideal supplementary feeding effect and reducing the harm caused by the 'early ablactation syndrome' of grice. The technical points are that the grice supplementary feeding period is 8-21 age in days, in the supplementary feeding period, 'free feeding and forcing supplementary feeding' are carried out, the 'teaching feedstuff' with high quality is selected as the supplementary feedstuff, the times of supplementary feeding is 4 times every day, and the total amount of supplementary feeding is 290g. The supplementary feeding course is divided into three stages: 8-11 age in days is the training period, the dosage is increased from less to more and is 10g per day averagely; 12-16 age in days is the middle period, and the dosage is 20g per day averagely; 17-21 age in days is the anaphase, the dosage is 30g per day averagely. By adopting the method provided by the invention, the 'early ablactation syndrome' can be alleviated obviously, disease rate and death rate of the grice can be reduced, and the growth state of the grice can be improved.

Owner:张明海

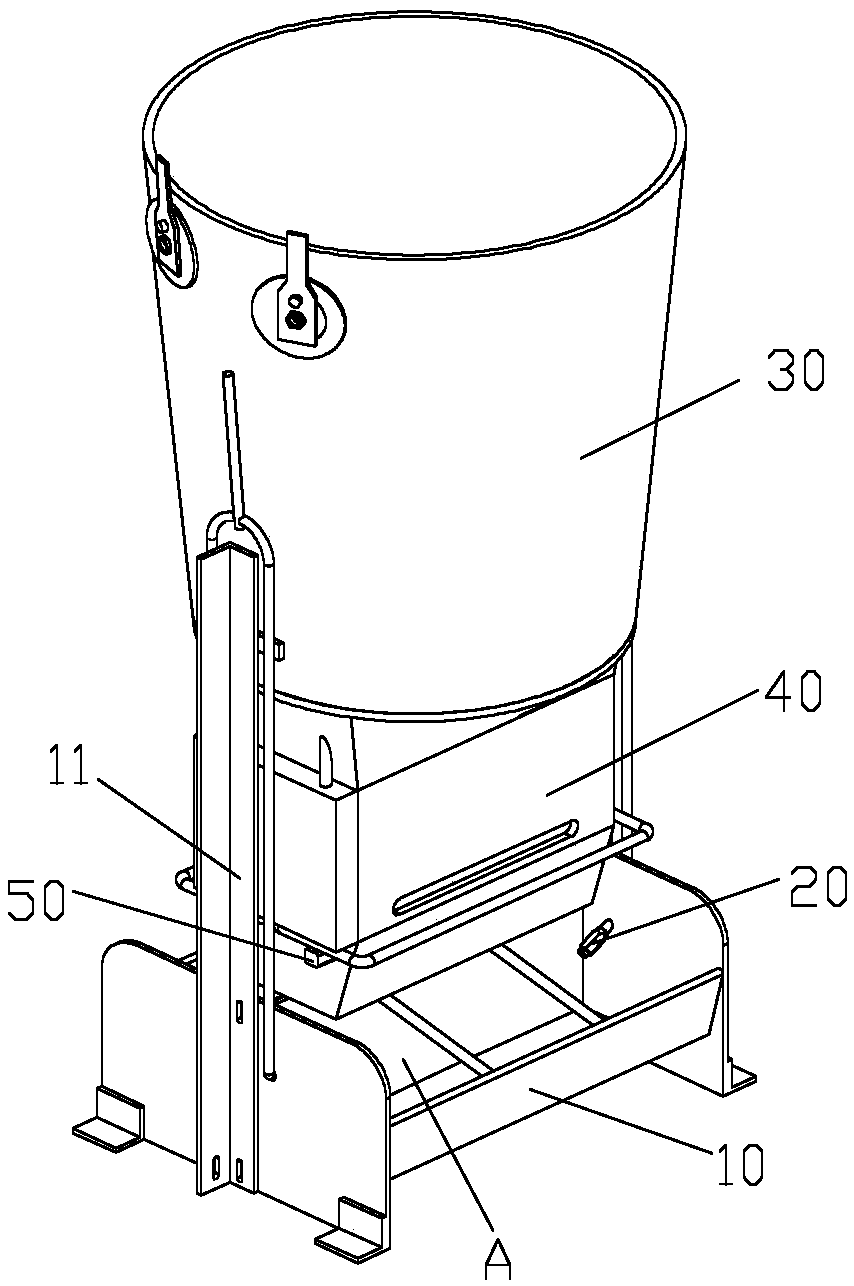

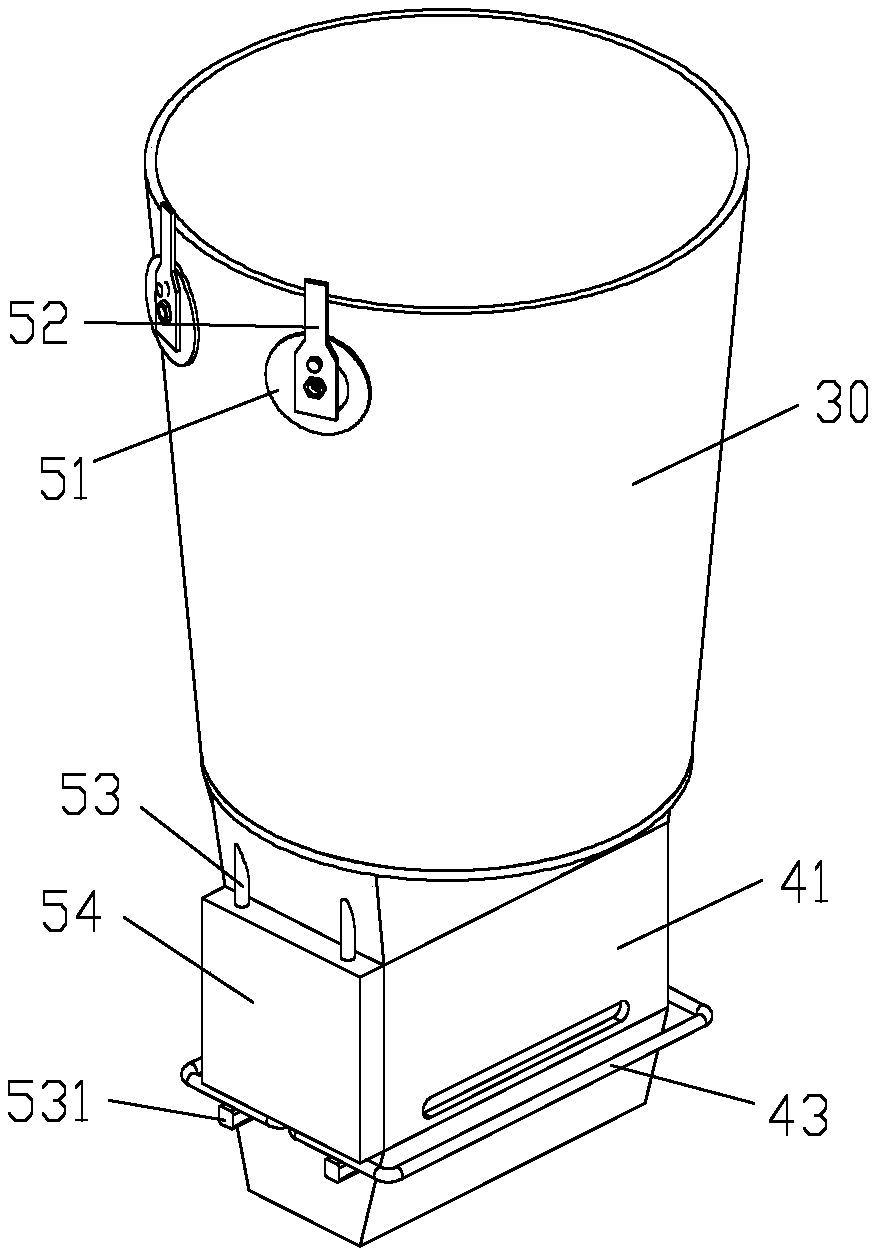

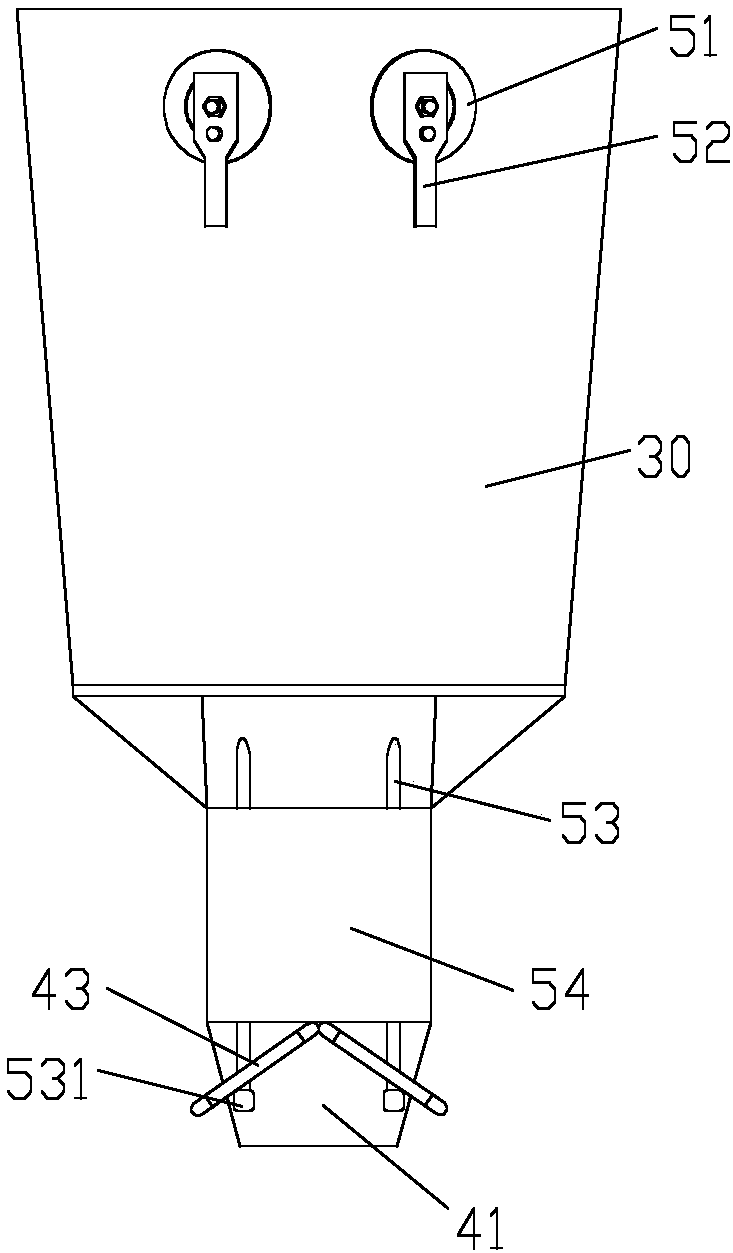

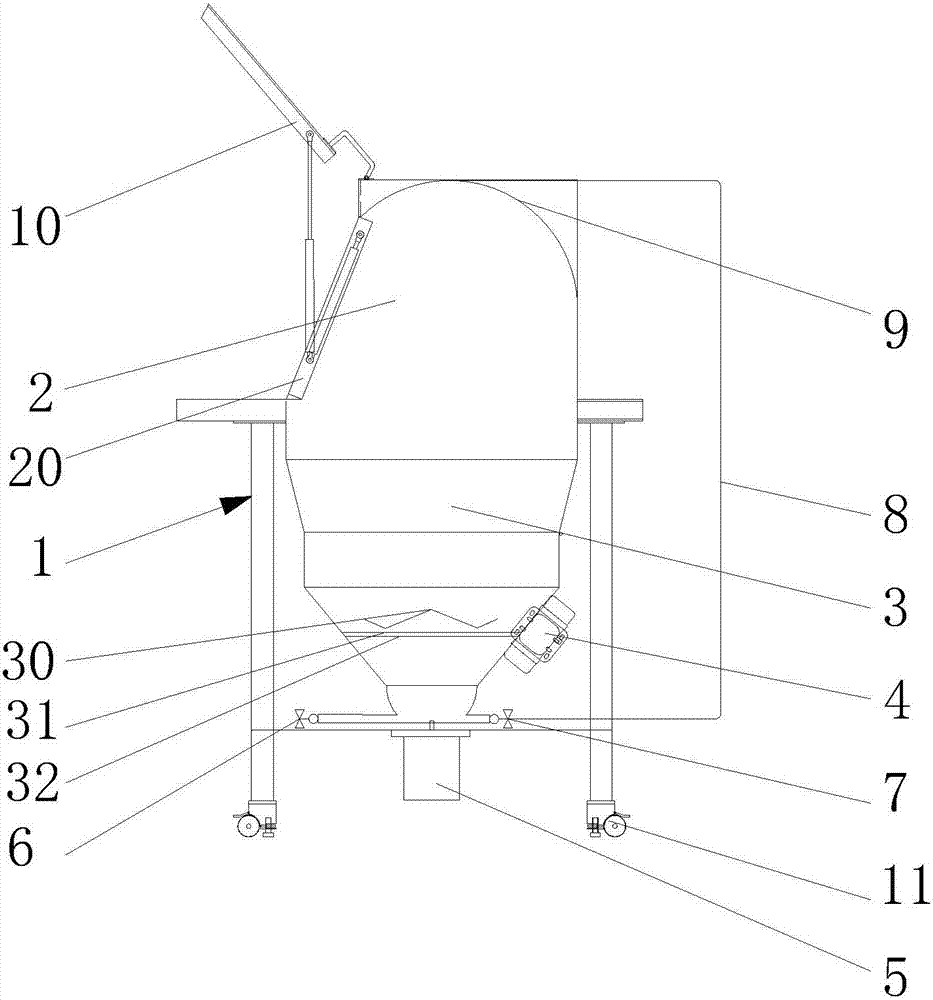

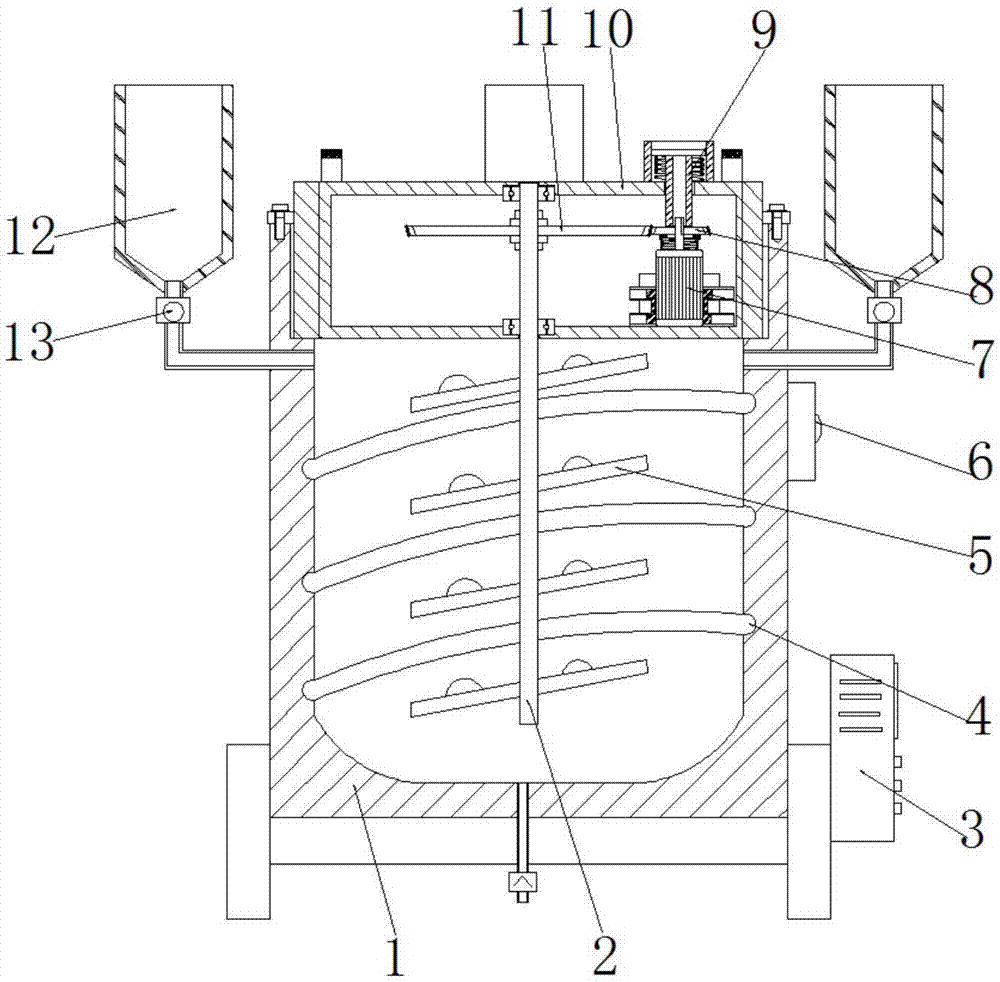

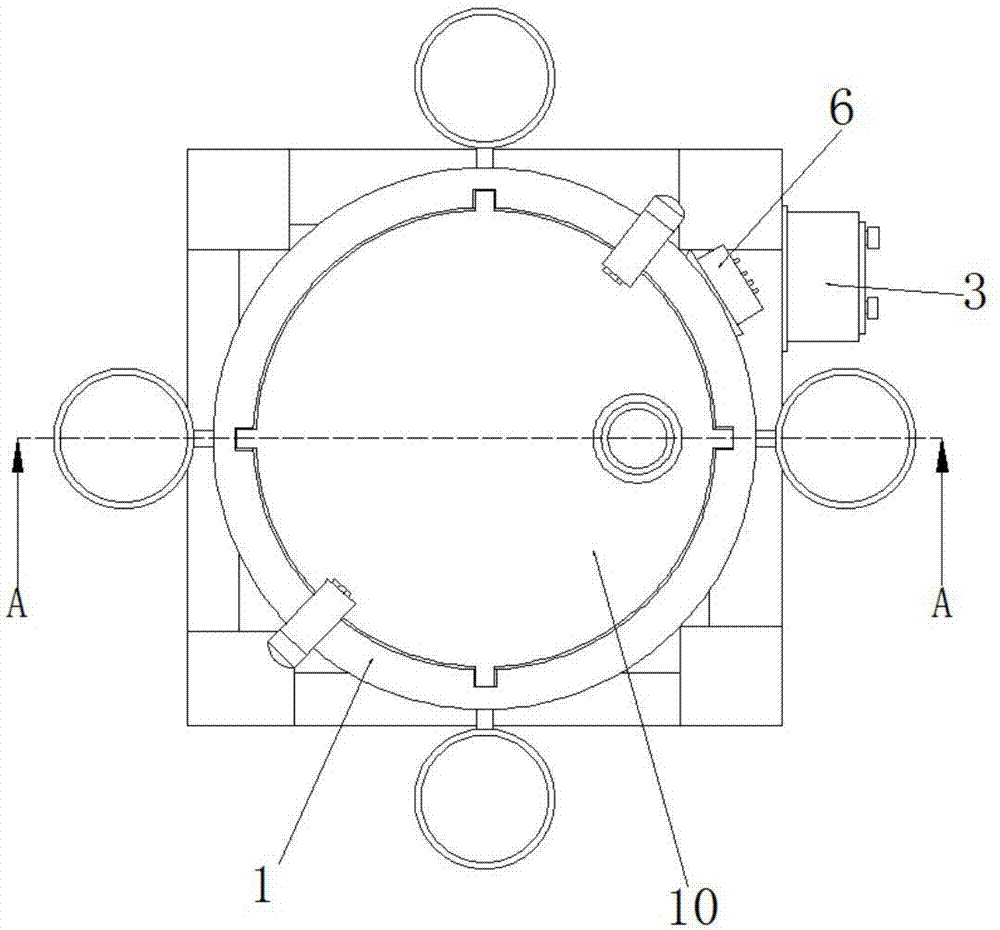

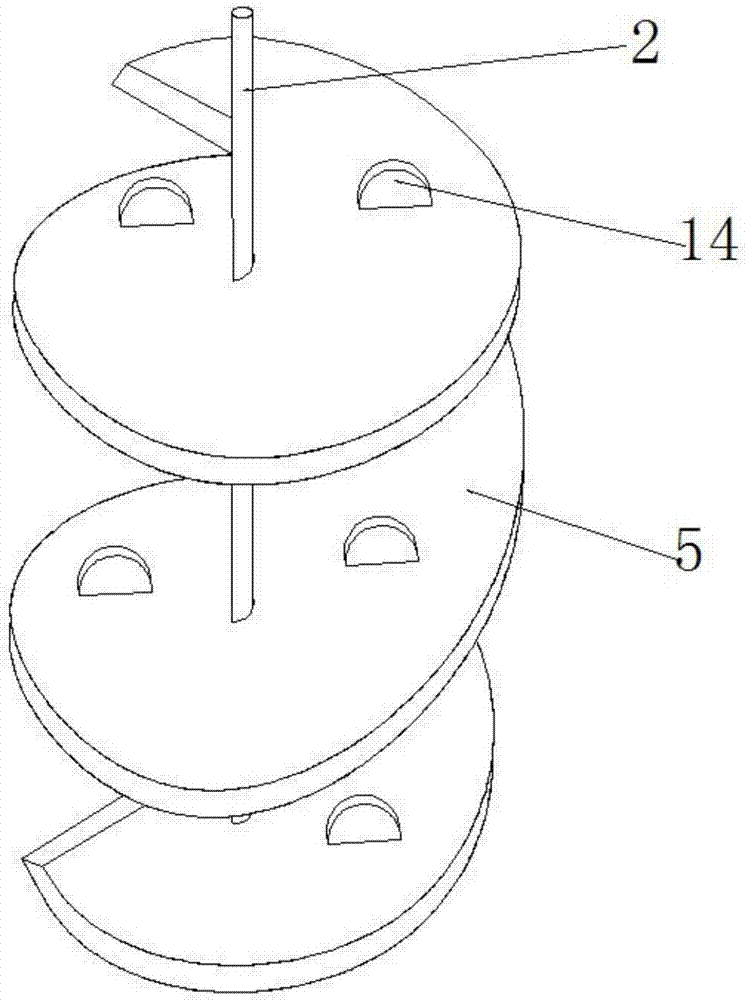

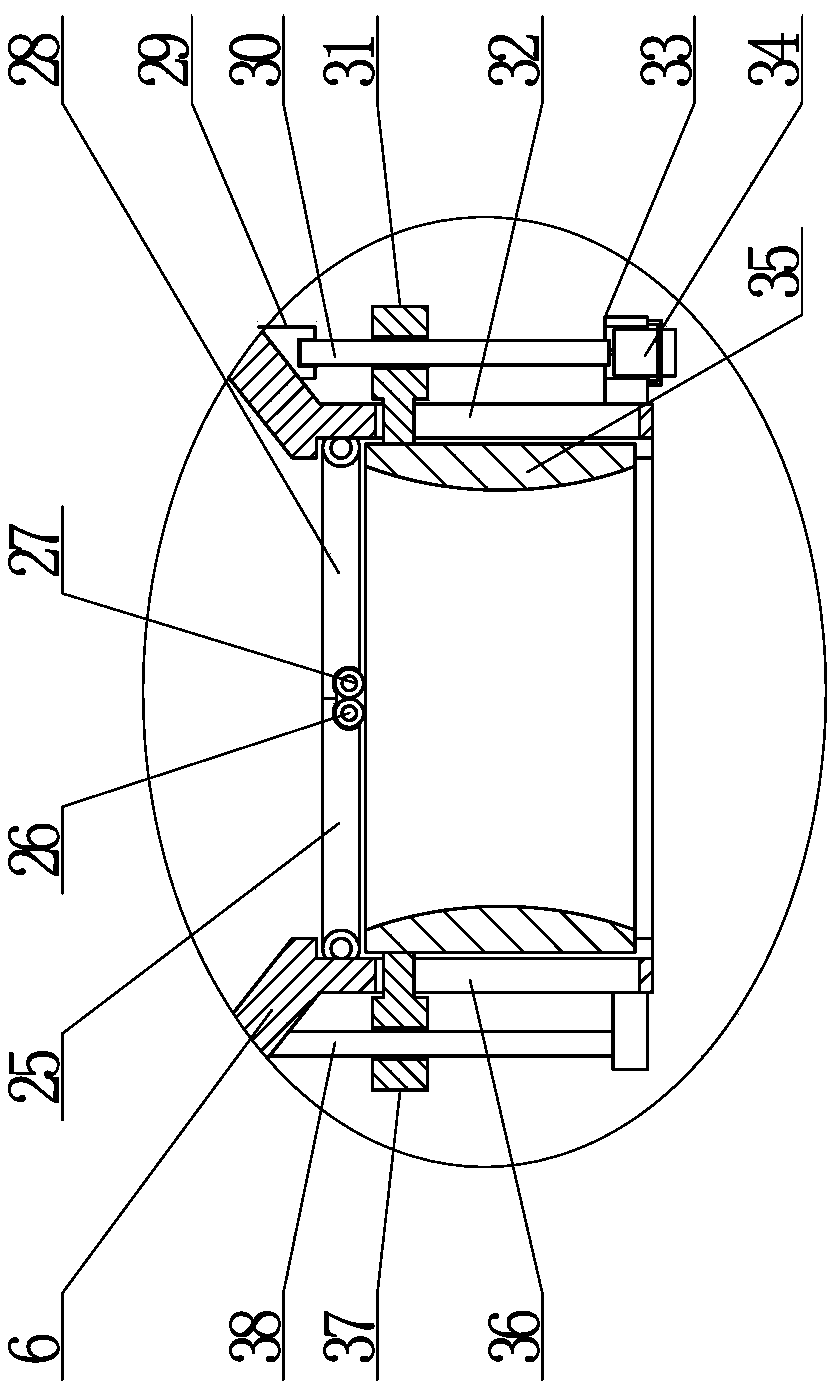

Free feeding dry and wet material groove for pigs

InactiveCN108012944AGreat tasteAdd funAnimal watering devicesAnimal feeding devicesPig breedingEating time

The invention relates to the technical field of pig breeding equipment, in particular to a free feeding dry-and-wet material groove for pigs. The free feeding dry-and-wet material groove for the pigsincludes a feeding groove, a drinking mechanism, a storage cylinder, a feeding mechanism and a control mechanism; the feeding mechanism includes a feeding device, a bottom plate and hogging rods, andbaffles are arranged on the hogging rods; the control mechanism is used for controlling the widths of gaps between the baffles and the bottom plate to control the feeding quantity of feed in the storage cylinder. According to the free feeding dry-and-wet material groove for the pigs, the storage cylinder is adopted to store the feed, and the pigs freely eat the feed; through the structural cooperation of the feeding mechanism and the control mechanism, the widths of the gaps between the baffles and the bottom plate can be controlled, and therefore the feeding quantity is controlled. When a feeder finishes feeding, the pigs can hog the hogging rods by themselves and then freely eat the feed. By arranging the drinking mechanism, the pigs can drink water when eating the feed, functions of a dry-and-wet material groove are achieved, the mouthfeel of the feed and eating enjoyment of the pigs are improved, and eating time is saved.

Owner:广州荷德曼农业科技有限公司

Production technology of waterborne damping slurry

ActiveCN105733386ASimple structureEasy to operateAnti-corrosive paintsBulk conveyorsLiquid stateIntegrated design

The invention provides a production technology of waterborne damping slurry. The production technology includes the concrete steps that a liquid-state raw material is conveyed to a mixing machine through liquid conveying equipment, a solid raw material is weighed and put into a dust-free feeding station and conveyed to the mixing machine through a pneumatic conveying system to be mixed with the liquid-state raw material, and the materials are mixed uniformly, then weighed, subpackaged and output through a belt. Integrated design and a control mode of combining with on-site conventional operation are adopted in the production process to form a complete collecting, control and management system. By means of program setting and received in-place signals, feeding, mixing and discharging actions are completed continuously and stably, dust flying is avoided in the production process of feeding, conveying and stirring the powder material, and the production environment is improved.

Owner:QINGDAO AIR NEW MATERIALS

Breeding method of antibiotics and hormones-free selenium-enriched chicken

InactiveCN105941304ANo side effectsImprove absorption rateFood processingAnimal feeding stuffAnimal scienceSide effect

The invention discloses a breeding method of antibiotics and hormones-free selenium-enriched chicken. The method comprises following steps: (1) selenium-enriched forage grass selecting: diluting water-soluble protein selenium to obtain water-soluble protein selenium solution and spreading the solution on forage grass inside a farm once a week, and collecting and storing the selenium-enriched forage grass after four months for free feeding of chicken; (2) fodder selecting: natural grain and the selenium-enriched forage grass collected in step (1) are used as breeding fodder; (3) drinking water preparing: water-soluble protein selenium is added to drinking water for chicken according to prescribed ratio; (4) breeding environment: free-ranging covers the whole breeding process and no antibiotic and medicinal component is used. The bred chicken has no side effect and is non-toxic; the chicken has high selenium content, good taste, and meets the dual requirement of health and delicacy.

Owner:OMEGA BIOTECH LUAN CO LTD

Pure straw stackretting-free feeding methane fermentation method

ActiveCN101591677AReduce consumptionEasy to put inWaste based fuelFermentationMethane fermentationFree feeding

The invention relates to a methane fermentation method, in particular to a pure straw stackretting-free feeding methane fermentation method. The pure straw stackretting-free feeding methane fermentation method comprises the following steps: starting according to the conventional fermentation process, preferably selecting biogas residue by strains to inoculate straw, feeding a material, adding water according to the ratio of the water to the material being 9:1, stopping feeding the material when the added water and the material account for 10 percent of the whole fermentation volume of a biogas pool, and waiting for generating gas; after the gas is generated normally, feeding chopped or silage stalk in a multipoint feeding mode, feeding the material from one feed inlet each day, and feeding the material from another feed inlet for next day so as to feed the material circularly day by day and inlet by inlet; arranging a plurality of spray-heads on the top in the biogas pool, arranging a scum pump on the bottom of the pool, transporting biogas liquid on the lower part of the biogas pool through a liquid conveying pipe to the spray heads by the scum pump, spraying fermenting raw materials which enter the biogas pool and float on the upper part of the biogas liquid to acidize and neutralize the raw materials; and according to the feed amount of the current day, discharging certain amount of waste biogas residue which is fermented from the lower part of the biogas pool every day. Compared with the conventional fermentation method, the method can improve the gas production by 30 to 40 percent.

Owner:唐山明仁生物能开发有限公司

Circular breeding method for laying hens

InactiveCN109275622AEnhance anti-disturbanceImprove developmentAccessory food factorsDiseaseAnimal science

The invention relates to a circular breeding method for laying hens. The method adopts a breeding circulation mode of stocking in a brooding period, training to raise in a nurturing period, and captivity in an egg producing period, and specifically includes the following steps: 1) selection and construction of breeding sites; 2) a method of stocking in the brooding period; 3) the method of training to raise in the nurturing period; and 4) captivity in the egg producing period. The method is based on ecological breeding, adopts zoned circular breeding, and is high in utilization rate of the sites. According to growth and development stages of the laying hens, self-help feeding is adopted in the brooding period, drinking water with vitamin C or erythromycin is added, and so, the probabilityof catching a disease of chicks is reduced. In the nurturing period, a mode that artificial feeding is a main method supplemented by free feeding is adopted, and vitamin E is added to promote development of gonads and sexual organs; and at the same time, dogs for training the laying hens are reasonably introduced, not only avoid over-fatness of hen bodies in nurturing period, but also the anti-disturbance capability of the laying hens is enhanced. In the egg producing period, pure artificial high calcium feed is used for feeding the laying hens, and so, the egg production is increased, and theegg producing period is prolonged. The method of the invention not only achieves the ecological breeding, but also is simple in operation and is high in economic benefit and can be promoted as a large-scale and standardized breeding mode.

Owner:龚海华

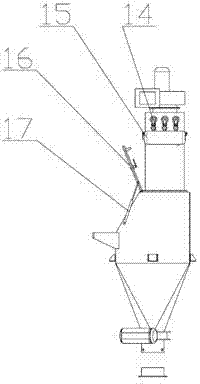

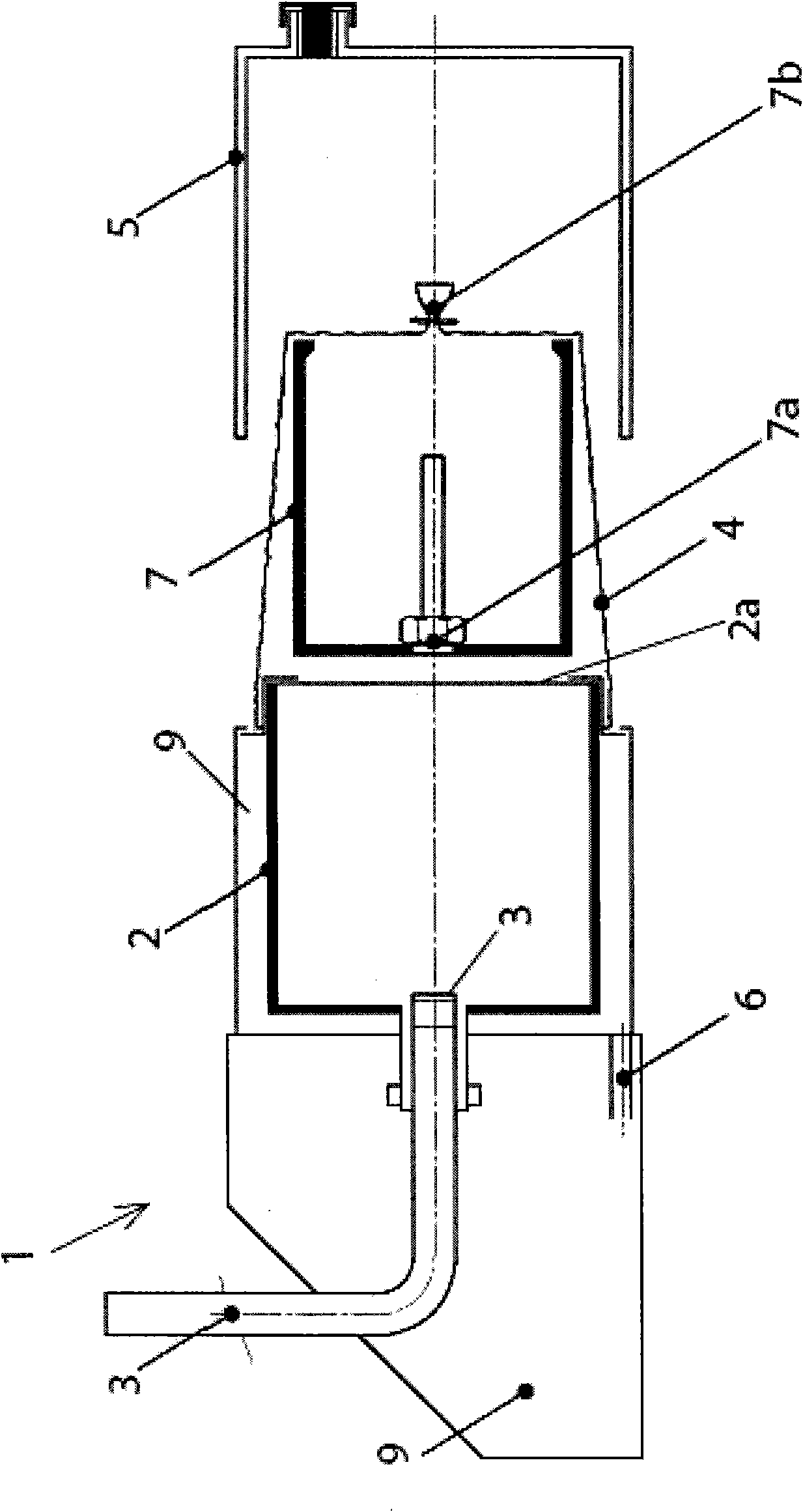

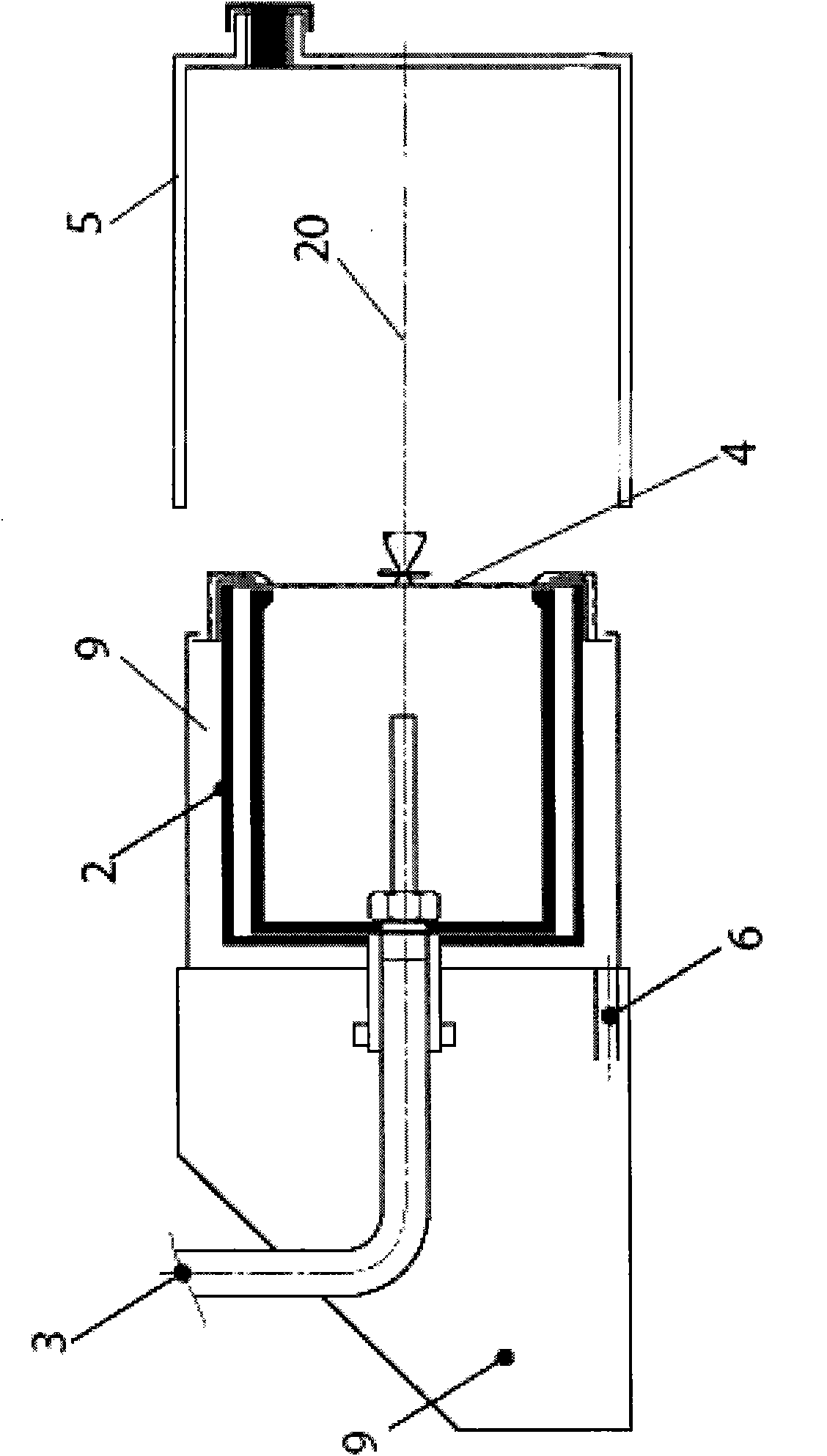

Dust-free feeding station

InactiveCN106946064AIncrease profitSimple structureLoading/unloadingEngineeringMechanical engineering

The invention discloses a dust-free feeding station which comprises a feeding platform. A feeding cavity is arranged on the feeding platform, a feeding opening is formed in the outer wall of the feeding cavity, a bin opening capable of being opened and closed vertically is installed on the feeding platform, the feeding cavity extends into the feeding platform, the lower end of the feeding cavity is communicated with a material bin, and a breaking and scattering device is arranged inside the hopper-shaped lower end of the material bin; the breaking and scattering device is arranged above a material removing device, a filtering screen is arranged below the material removing device in parallel, the material removing device and the filtering screen penetrate the outer wall of the material bin to be connected with a vibrating device, and the vibrating device is fixedly installed on the outer surface of the hopper-shaped lower end of the material bin; a discharging opening in the lower end of the material bin is connected with a breaking motor, a powder valve and an air supplementing valve are arranged at the positions, on the two sides of the discharging opening, of the lower end of the material bin, and the air supplementing valve is connected with a dust removal cover through a dust removal loop. The dust-free feeding station is simple in structure and convenient to use, the dust removal effect can be effectively improved, and the powder using rate is promoted.

Owner:东莞市科锐机电设备有限公司

1-monopropionine compound and its isomer 3-monopropionine as preserving agents for animal feed, grains and animal-origin meals

InactiveUS20110038996A1Improve scalabilityReduce pollutionMilk preservationEdible seed preservationIngested foodContamination

“1-MONOPROPIONINE COMPOUND AND ITS ISOMER 3-MONOPROPIONINE AS PRESERVING AGENTS FOR ANIMAL FEED, GRAINS AND ANIMAL-ORIGIN MEALS” refers to the technical field of animal feed products, more specifically a 1-monopropionine compound and its isomer 3-monopropionine as preserving agents for animal feed, grains and animal-origin meals, with the object to reduce the contamination by deleterious fungi, yeasts and bacteriae (especially Salmonella spp and Coli spp) in animal feed, grains and animal-origin meals, and consequently enhance the growth of the animal by means of practically contaminant-free feeding.

Owner:AUSTER NUTRICAO ANIMAL

Bucket opening-free feeding device for bean pulp fermentation

InactiveCN107495450AGuaranteed temperatureGuarantee the environmentFeeding-stuffSpiral bladeEngineering

The invention discloses a tank-free feeding device for soybean meal fermentation, which comprises a fermentation tank with a fixed frame welded at the bottom, four equidistant rectangular chutes arranged on the inner wall of the top of the fermentation tank, and four rectangular The chute is slidingly connected with the same barrel cover with a cavity in the form of a disc structure. The top inner wall and the bottom inner wall of the barrel cover are provided with counterbore holes near the middle, and tapered rollers are welded in the two counterbore holes. Bearings, the inner rings of the two tapered roller bearings are plugged with the same transmission rod, and the outer wall of the end of the transmission rod away from the tapered roller bearings is welded with a spiral blade, and the top of the barrel cover is on the side close to the counterbore A metal pipe is welded on the surface, and the inner wall of the metal pipe is slidably connected with a top pipe, and the inner wall of the bottom of the barrel cover is welded with a motor fixing frame. The invention can mix and inoculate the composite bacterial liquid obtained after the reasonable proportioning of various bacterial liquids, shorten the fermentation time and reduce the production cost through the synergistic effect of multiple strains.

Owner:湖北大中生物科技有限公司

Pure straw stackretting-free feeding methane fermentation method

ActiveCN101591677BReduce consumptionEasy to put inWaste based fuelFermentationMethane fermentationFree feeding

The invention relates to a methane fermentation method, in particular to a pure straw stackretting-free feeding methane fermentation method. The pure straw stackretting-free feeding methane fermentation method comprises the following steps: starting according to the conventional fermentation process, preferably selecting biogas residue by strains to inoculate straw, feeding a material, adding water according to the ratio of the water to the material being 9:1, stopping feeding the material when the added water and the material account for 10 percent of the whole fermentation volume of a biogas pool, and waiting for generating gas; after the gas is generated normally, feeding chopped or silage stalk in a multipoint feeding mode, feeding the material from one feed inlet each day, and feeding the material from another feed inlet for next day so as to feed the material circularly day by day and inlet by inlet; arranging a plurality of spray-heads on the top in the biogas pool, arranging ascum pump on the bottom of the pool, transporting biogas liquid on the lower part of the biogas pool through a liquid conveying pipe to the spray heads by the scum pump, spraying fermenting raw materials which enter the biogas pool and float on the upper part of the biogas liquid to acidize and neutralize the raw materials; and according to the feed amount of the current day, discharging certain amount of waste biogas residue which is fermented from the lower part of the biogas pool every day. Compared with the conventional fermentation method, the method can improve the gas production by 30 to 40 percent.

Owner:唐山明仁生物能开发有限公司

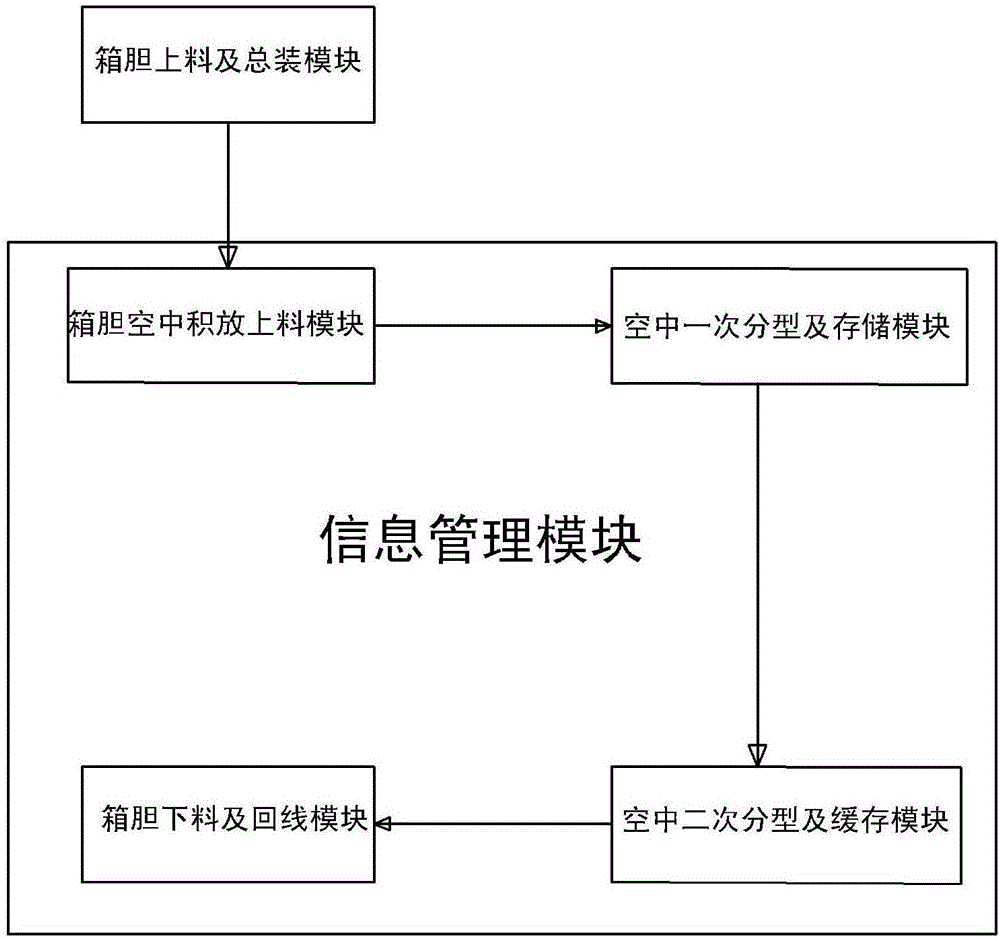

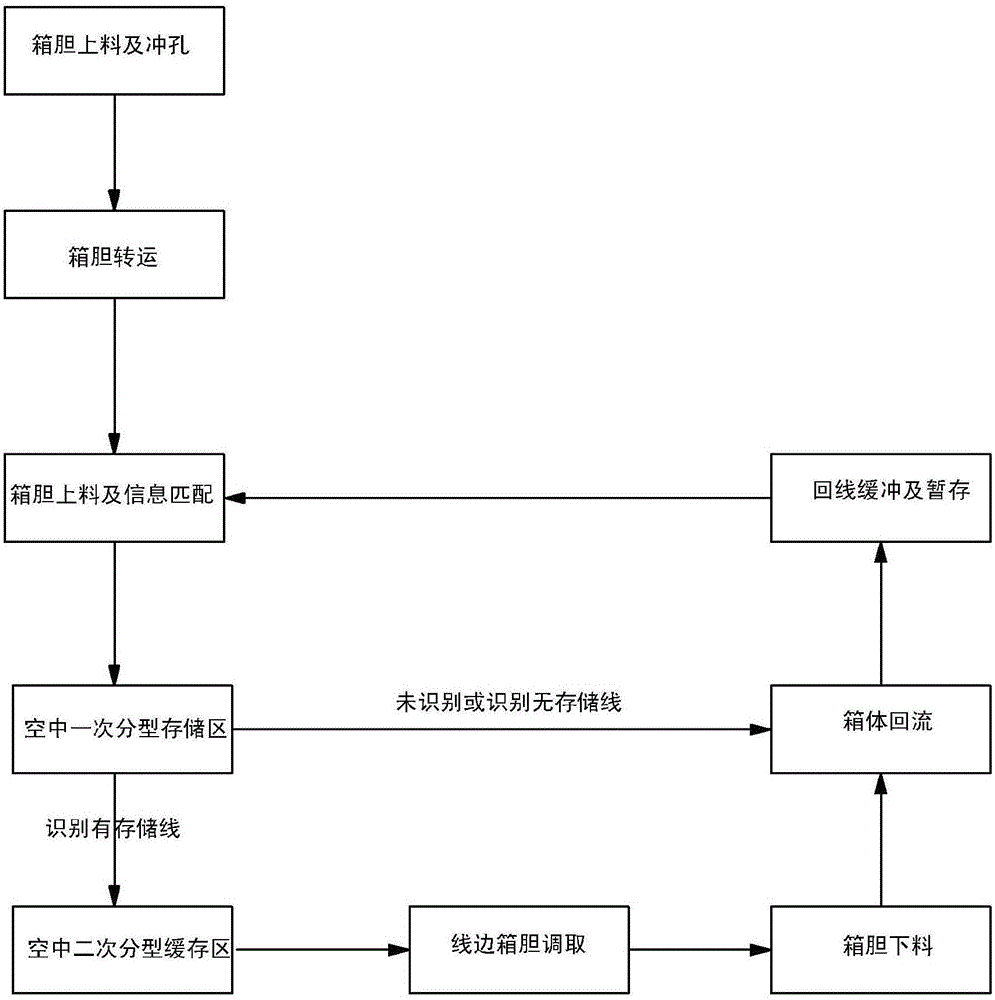

Automatic production and distribution system and method for refrigerator liner

ActiveCN106503931ASolve the problem of efficiency loss such as production stoppageSolve the problem of high abnormal rate of delivery errorsResourcesManufacturing computing systemsRefrigerator carDistribution system

The invention discloses an automatic production and distribution system and method for a refrigerator liner. The automatic production and distribution system for a refrigerator liner includes a liner feeding and punching module, a liner aerial power and free feeding module, an aerial primary parting buffer module, an aerial secondary parting buffer module, a refrigerator liner blanking and loop module, and an information management module. The automatic production and distribution system and method for a refrigerator liner can realize automatic production and distribution of plastic refrigerator liners being taken to refrigerator body pre-assembling stations beside a streamline in the mixed routing manufacturing state of the refrigerator industry, thus greatly improving the situation that a refrigerator liner is high in breakage rate and labor cost; the exterior quality of the refrigerator liner is hard to improve; the inventory of refrigerator liners is high; and the visual effect of refrigerator liners is low.

Owner:CHANGHONG MEILING CO LTD

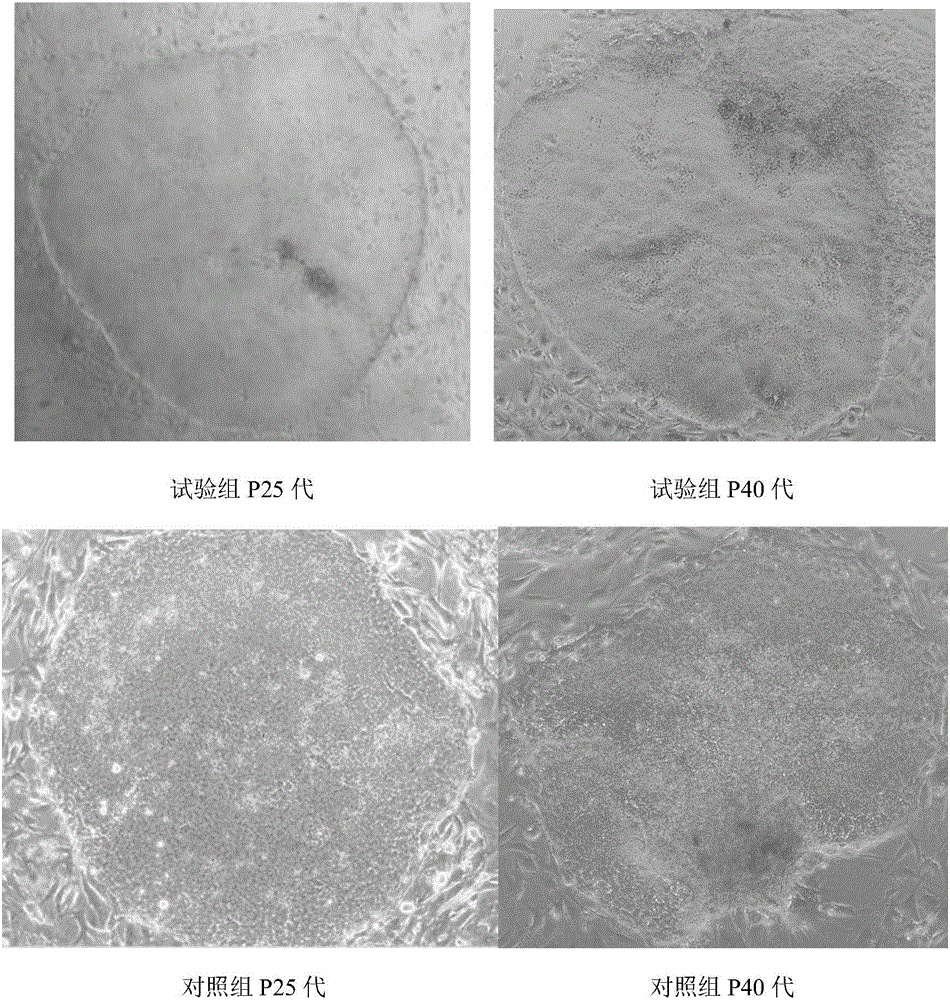

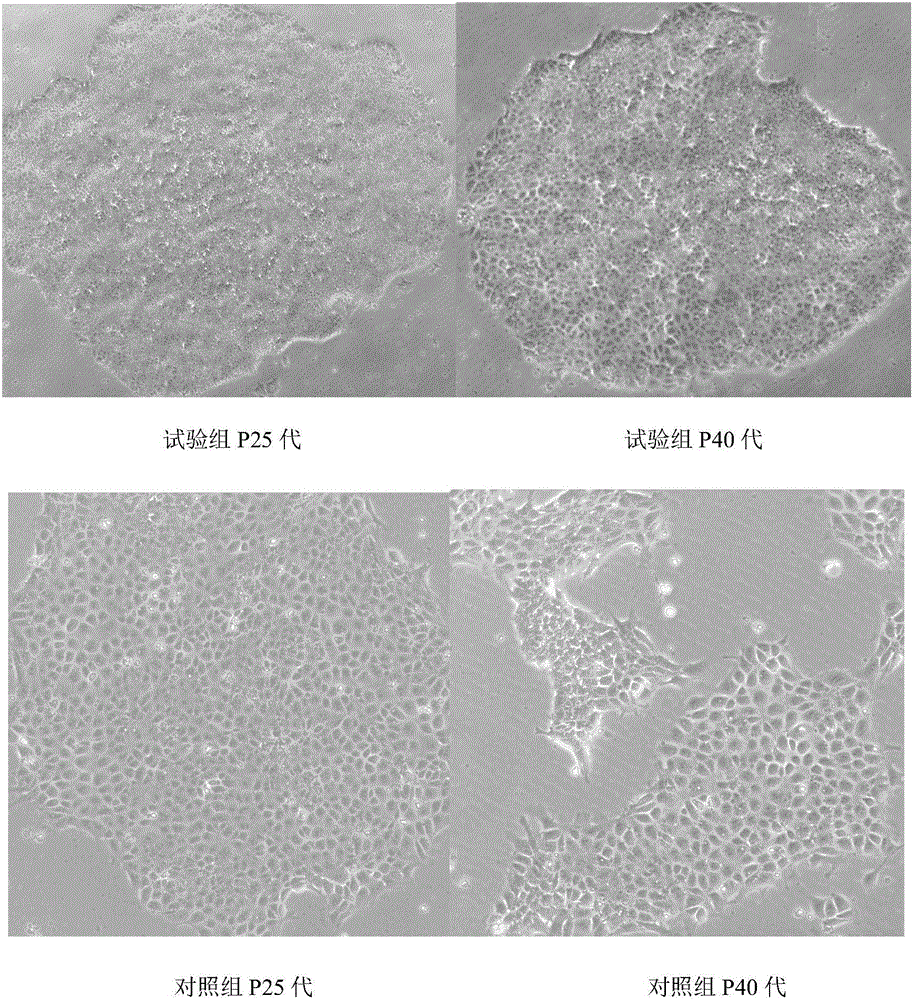

Serum-free medium for monkey embryonic stem cell

ActiveCN106754657AMaintain self-renewalMaintain normal stateCulture processCell culture active agentsInsulin activitySerum free media

The invention discloses a serum-free medium for a monkey embryonic stem cell. The serum-free medium comprises a basic medium and additives, wherein the additives are dissolved in the basic medium; the basic medium comprises a DMEM-F12 medium; and the additive comprises L-glutamine, non-essential amino acid, L-ascorbic acid, sodium selenite, beta-mercaptoethanol, human serum albumin, heparin sodium, human transferring, insulin human, a basic fibroblast growth factor, a transforming growth factor beta 1 and an epidermal growth factor. The serum-free medium is capable of maintaining an undifferentiation state and totipotency of the monkey embryonic stem cell within a relatively long time, and is applicable to culture of the monkey embryonic stem cell in both a free-feeding layer system and a feeding layer system.

Owner:北京赛斯达生物技术有限公司

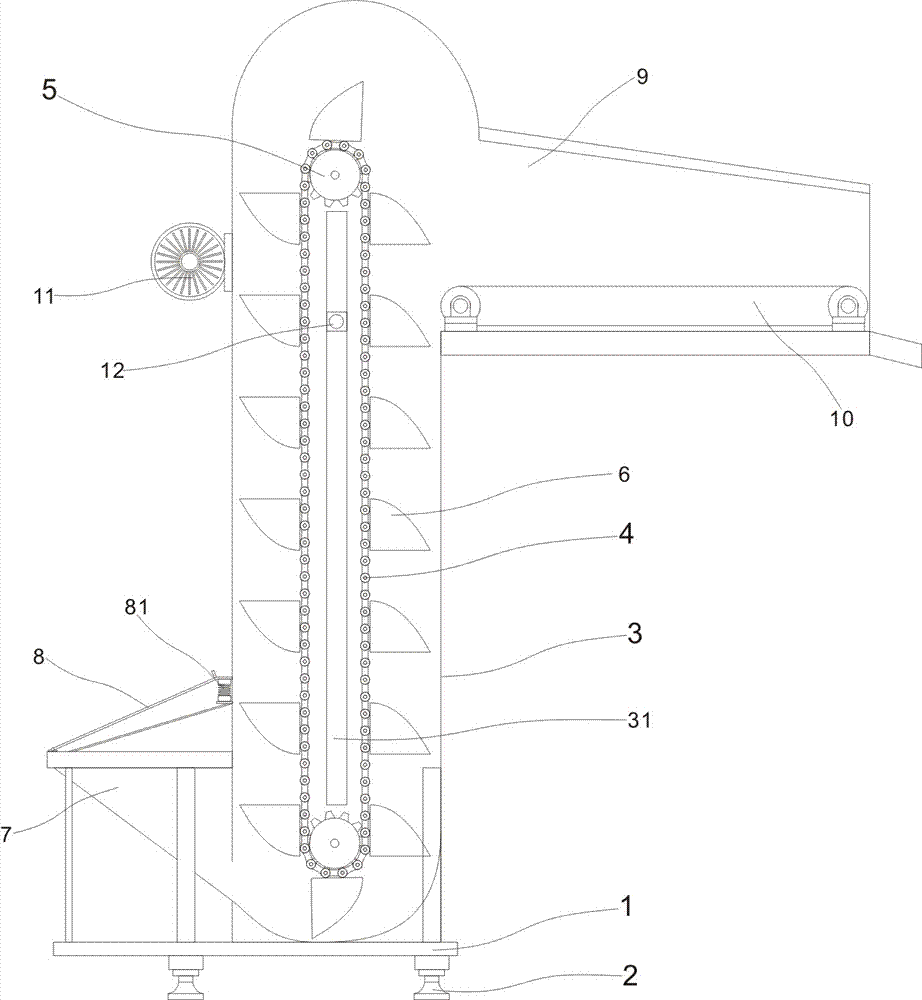

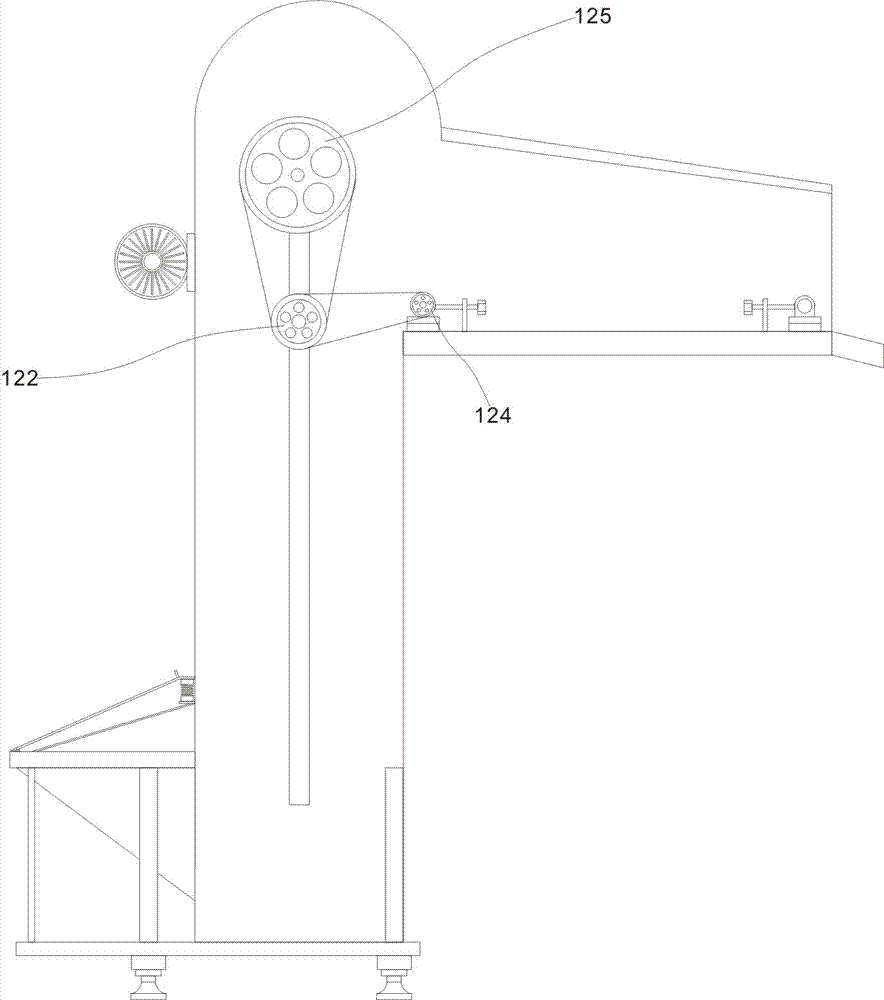

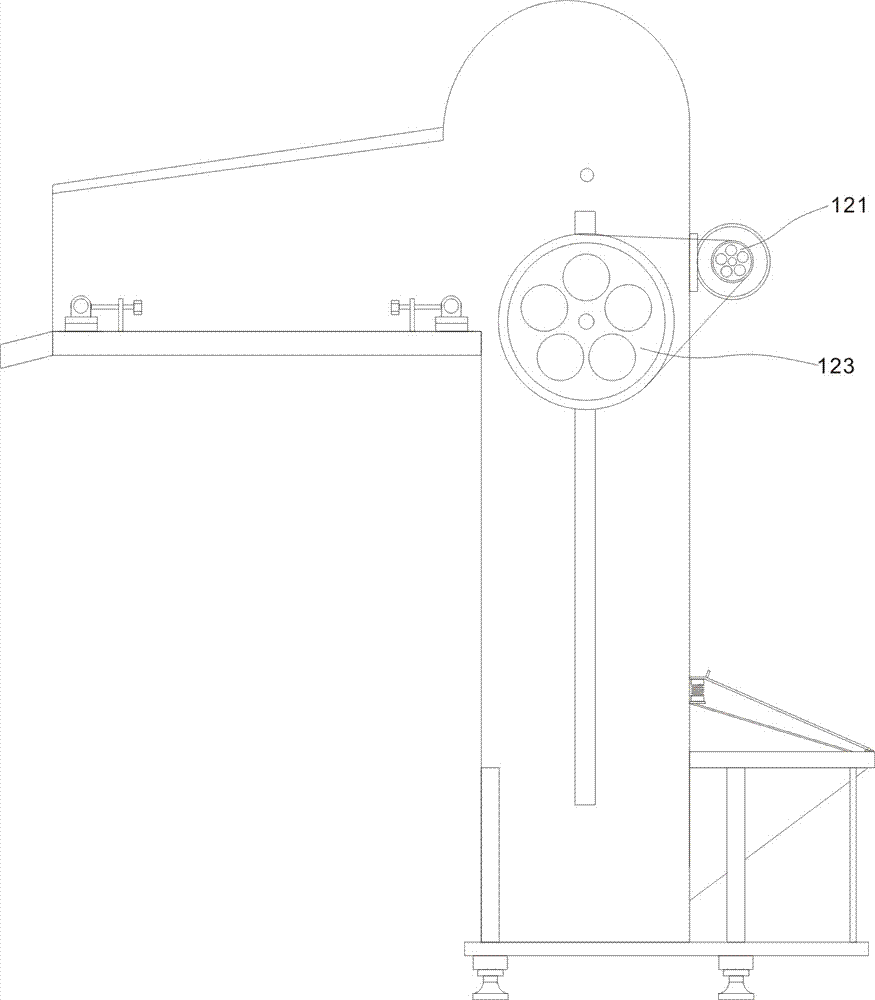

Full-closed dust-free feeding device

InactiveCN104495226AImprove filtering effectAchieve improvemeConveyorsWorking environmentFree feeding

The invention relates to a full-closed dust-free feeding device capable of effectively reducing the amount of dust. The full-closed dust-free feeding device comprises a rack, a support, an enclosure, a chain, chain wheels, feeding hoppers, a blanking hopper, a filter sieve, a side extending supporting arm, a conveying belt and an electric motor. The full-closed dust-free feeding device adopts a closed feeding mechanism; the structure is a vertical structure; the full-closed dust-free feeding device occupies a small space; operation can be implemented in the narrow working environment. The full-closed dust-free feeding device has the simple integral structure and has high feeding stability in the using process; by adoption of the closed feeding mode, excessive dust cannot be generated in the using process, so that environment pollution is effectively controlled; the vertical structure occupies the small space, and thus, the application range of the full-closed dust-free feeding device is greatly increased.

Owner:平顶山鸿顺源工贸有限公司

Ecological breeding method for improving disease resistance of black-bone chickens

The invention relates to an ecological breeding method for improving the disease resistance of black-bone chickens. The breeding method mainly comprises the steps of selection of a breeding site, chick breeding, young chicken breeding, adult chicken breeding and daily management. By means of the ecological breeding method, the growth cycle of the black-bone chickens is controlled within 6-7 months, movable stocking in the field dominates in the feeding process, and free feeding is conducted, so that not only are natural properties of the black-bone chickens kept, but also the movement range ofthe black-bone chickens is widened. In the feeding process, the chickens in different growth stages are fed with different kinds of feed, the nutritional needs of the chickens are met, the immunity of the chickens is improved, the disease resistance is greatly increased, the input cost of the feed is saved, and the quality of chicken is improved. By means of the method, the bred black-bone chickens are good in meat taste, lower in disease incidence, strong in muscle and especially suitable for large-scale breeding.

Owner:赵文江

Batching system of solid preparation and working method of batching system

The invention relates to a batching system for a solid preparation. The batching system comprises a feeding screening station, wherein a dust-free feeding screening station is connected to material inlets of a plurality of material temporary storage bins through a plurality of vacuum pipelines, and quick-opening manholes are formed in the tops of the material temporary storage bins; vacuum feedingmachine are installed on the manholes, and material level sensors are installed on the inner walls of the material temporary storage bins; pneumatic butterfly valves, screw conveyors and butting devices are further arranged at the bottom of the material temporary storage bins, a moving trolley is arranged below the material temporary storage bins, and a platform scale is arranged on the moving trolley; and a material mixing bin is fixed to the top of the moving trolley, the top of the material mixing bin is open and the material mixing bin can be accurately butted with any material temporarystorage bin through the butting devices. The batching system of the solid preparation is solid preparation equipment which automatically operates in dust-free environment from feeding to batching, thewhole dispensing process is dust-free and can be double-checked and traced, cross-contamination, confusion and other risks during material transportation are reduced to the utmost extent.

Owner:JIANGYIN GUIBAO TECH CO LTD

Dust-free feeding and charging equipment for high-strength abrasion-resistant castables

ActiveCN109335614ARealize the whole process of dust-free operationProperly connect the shipmentBags openingWinding mechanismsRefractoryEngineering

The invention provides dust-free feeding and charging equipment for high-strength abrasion-resistant castables, and belongs to the field of refractory material construction equipment. The dust-free feeding and charging equipment is characterized in that the dust-free feeding and charging equipment comprises a feeding device and an unpacking charging device; the feeding device comprises a transverse conveying belt and a longitudinal conveying belt which are perpendicularly arranged on the same horizontal plane, and the tail end of the transverse conveying belt and the starting end of the longitudinal conveying belt are mutually connected; an automatic telescopic plate is arranged at the tail end of the longitudinal conveying belt; and the automatic telescopic plate is located on the lower part of the longitudinal conveying belt in a retracting state, and can extend towards the rear part of the tail end of the longitudinal conveying belt in an extending state.

Owner:SHANDONG YAOHUA REFRACTORY MATERIAL SCI & TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com