Intermission-free automatic feeding and discharging mechanism for panel materials

An automatic loading and unloading, non-intermittent technology, used in conveyor objects, furnaces, lighting and heating equipment, etc., can solve the problems of longer processing time and lower work efficiency, and achieve a small footprint, improved efficiency, and improved structure. Simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

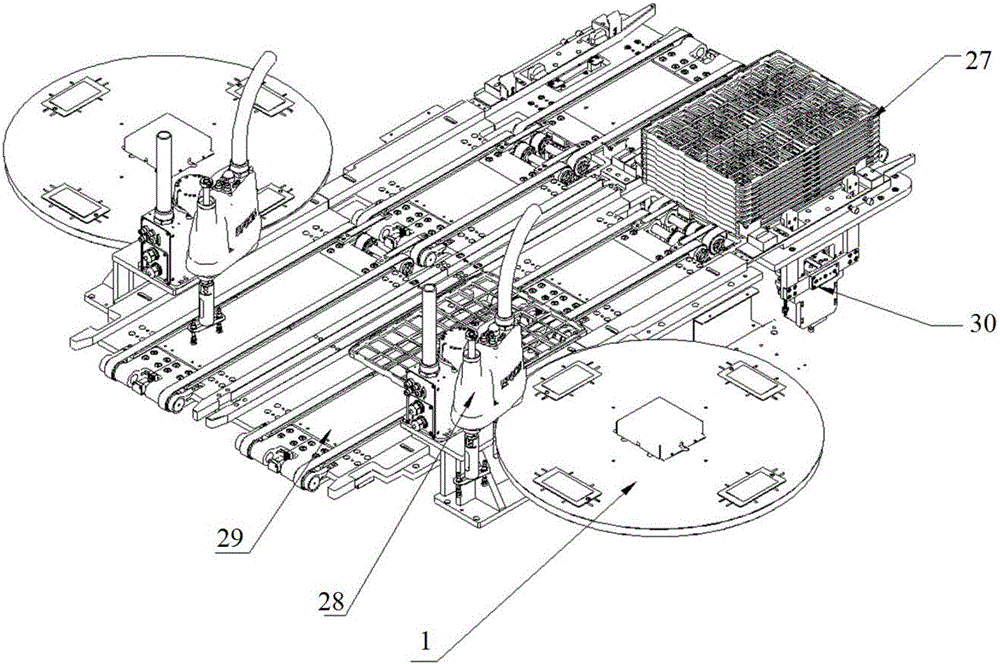

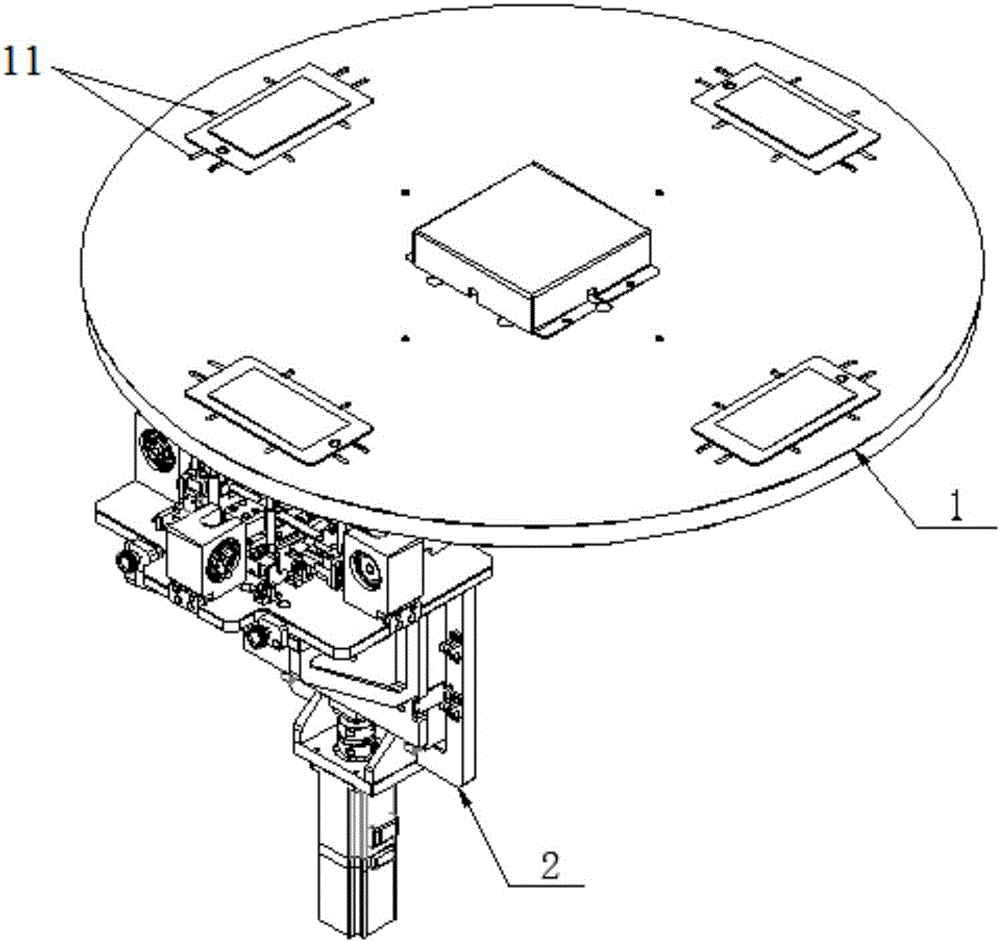

[0031] see figure 1 , the present invention comprises Tray disc conveying device, turntable platform and manipulator, and turntable platform is arranged on one side of Tray dish conveying device, and manipulator is arranged on the same side of turntable platform and is used as the intermediate carrier of conveying panel material between Tray dish conveying device and turntable platform , the Tray tray conveying device includes a front-end conveying part for temporarily storing the Tray tray containing materials and conveying the Tray tray to the next conveying part, for receiving the Tray tray conveyed by the front-end conveying part and conveying it to the next conveying part The middle conveying part and the rear conveying part that receives the middle conveying part and conveys the tray to other processes, the conveying direction of the front conveying part, the middle conveying part and the rear conveying part are the same and they all run independently. There are multiple...

Embodiment 2

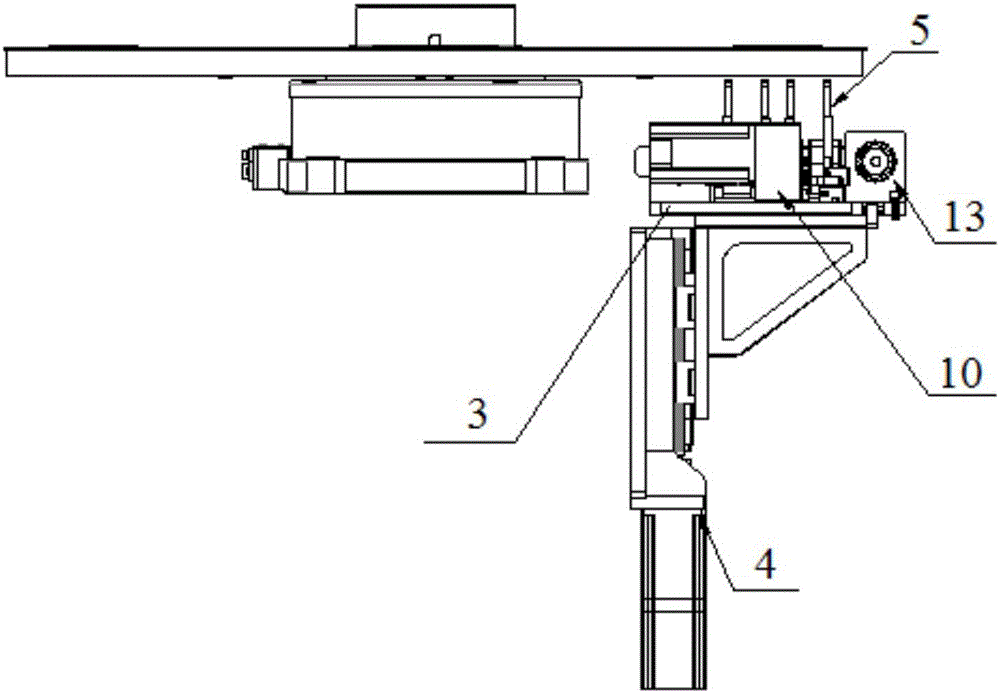

[0048] see Figure 8-9 In this embodiment, in order to further improve work efficiency, each station on the turntable platform is provided with two sub-stations for placing panel materials, and the two sub-stations are arranged in parallel along the first direction;

[0049] The first positioning assembly of this embodiment also includes a first motor, four first connecting seats and a synchronous belt driven by the first motor, the first alignment columns are fixed on the first connecting seats, and the first connecting seats are fixed in pairs On the synchronous belt and driven by the first motor to move relative or opposite to each other in the first direction, the first alignment column is driven by the first connecting seat to respectively clamp the two panels from both sides of the first direction. Panel, in this embodiment, the synchronous belt is wound on the drive wheel connected to the first motor and a corresponding synchronous wheel, and then two of the four connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com