Dust-free feeding mechanism for mixing machine

A feeding mechanism and mixing machine technology, which is applied in mixers, mixer accessories, and dispersed particle filtration, etc., can solve problems such as harsh working environment, affecting the quality of mixing, and impact of air flow in the hopper, etc., to achieve dust-free feeding and improve The effect of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

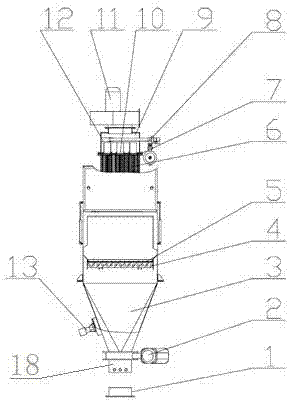

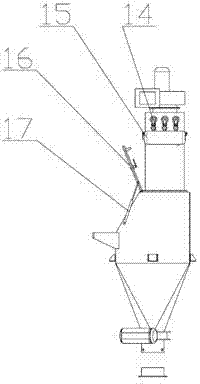

[0019] Such as figure 1 and figure 2 As shown, a dust-free feeding mechanism of a mixing machine includes a feeding bin 3, the bottom of the feeding bin 3 is provided with a discharge port 18 connected to the feeding port 1 of the mixing tank, and a bin cover 16 is provided on one side. The bin cover 16 is connected to the gas spring 17, and the top of the feeding bin 3 is provided with a dust removal port (not marked). The filter cartridge 6 is connected with a filter element mounting frame 7 and a fan mounting frame 9, the filter element mounting frame 7 is equipped with an air filter element 10, the fan mounting frame 9 is equipped with a fan 11, and one side of the fan mounting frame 9 is connected to a guide Wind sleeve 12, the wind guide sleeve 12 communicates with three electromagnetic pulse valves 14, and a sealing gasket 8 is arranged between them, and the electromagnetic pulse valve 14 is connected with an air storage tank 15,

[0020] The feeding bin is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com