Automatic production and distribution system and method for refrigerator liner

A tank and general assembly tank technology, which is applied in the direction of manufacturing computing systems, instruments, and data processing applications, can solve the problems of difficulty in improving the appearance quality of tanks, high waste of refrigerator tanks, and high labor costs, and achieve improved Production fault tolerance and rapid manufacturing capabilities, solve the problem of misalignment and matching of tanks, and reduce the effect of system distribution failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

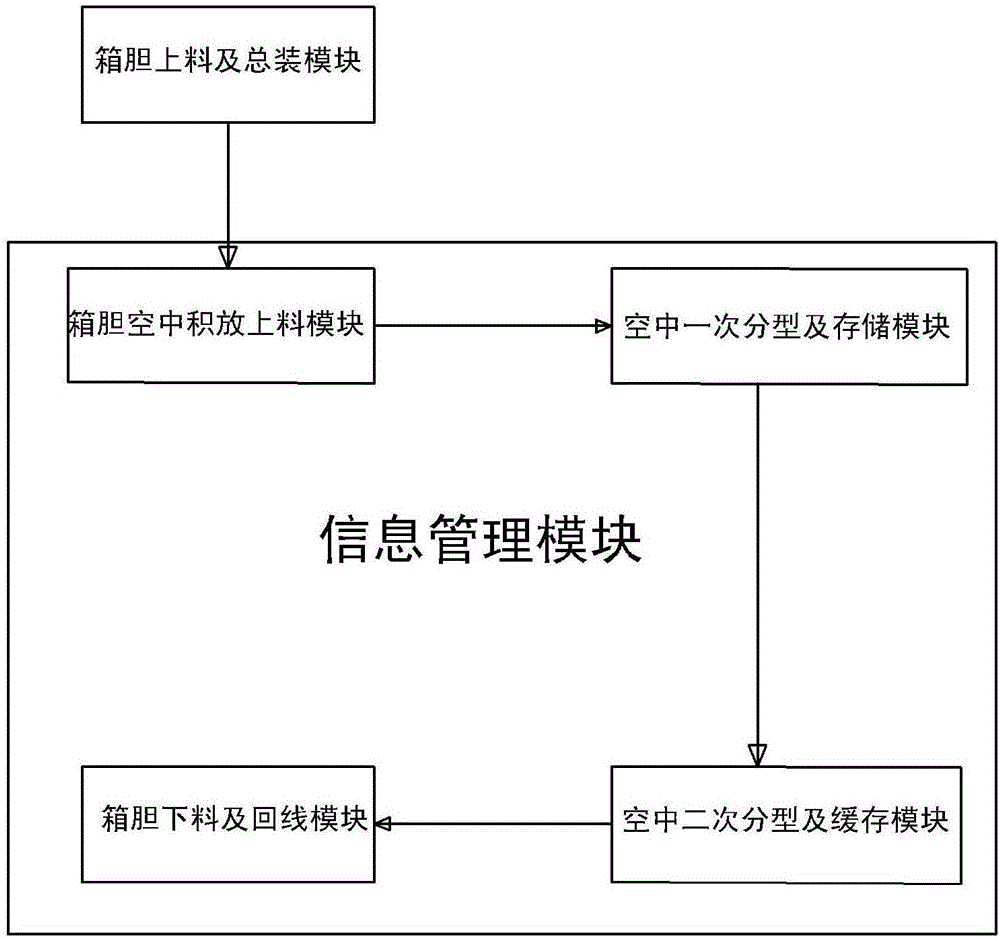

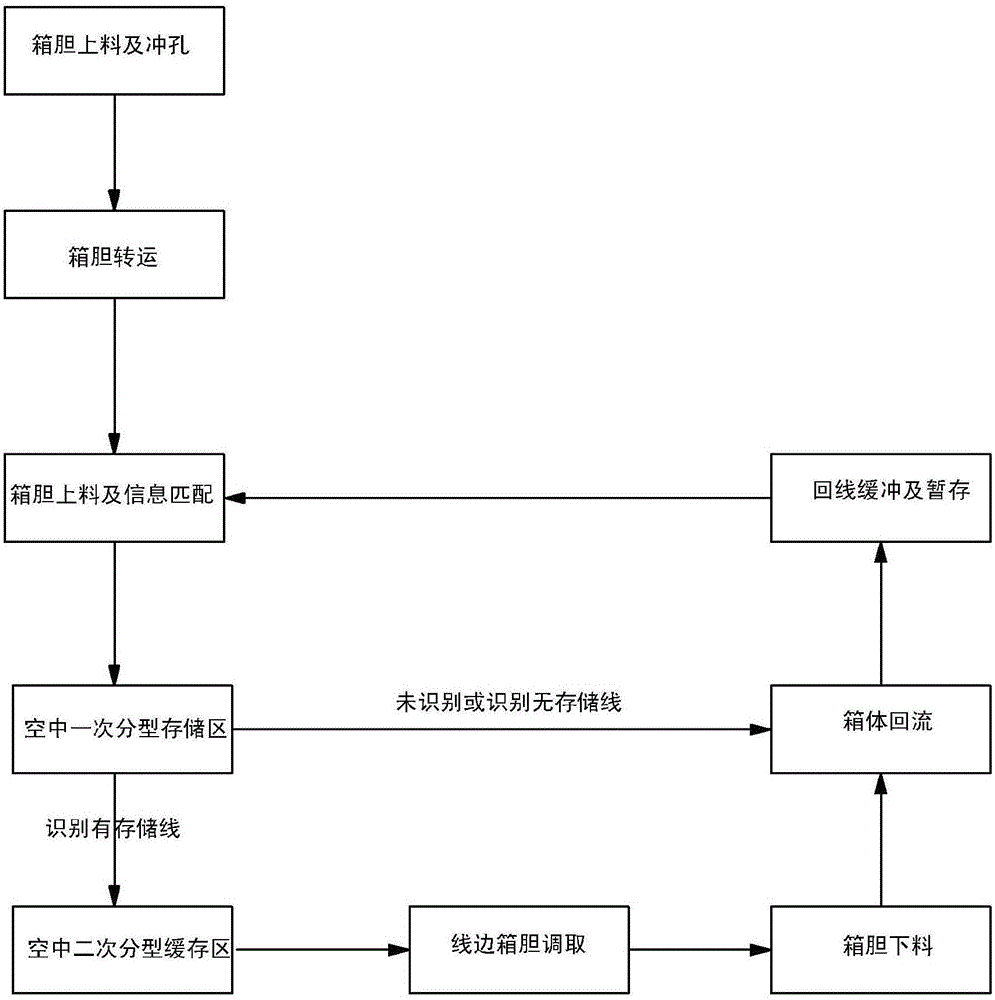

[0035] In this example, if figure 1 As shown, a tank automatic production and distribution system, including: tank feeding and punching module, tank filling and loading module in the air, air one-time classification storage module, air secondary classification buffer module, tank lower The material and return line module and the information management module have realized the highly flexible and system-integrated automatic production and distribution from the blister box liner to the line side box body pre-installation.

[0036] The box liner feeding and assembly module loads the plastic-absorbed box liner on the spot to the belt line, and then automatically transports it to the punching station for punching operations;

[0037] The information management module collects the production information of the day, and sets the classification storage information of the storage line and the cache line according to the tank model to be assembled in the production information of the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com