Full-closed dust-free feeding device

A dust-free, fully enclosed technology, applied in transportation, packaging, conveyors, etc., can solve the problems of large space occupied by conveyor belts, high pollution, inconvenient use, etc., and achieve small space occupation, pollution control, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings.

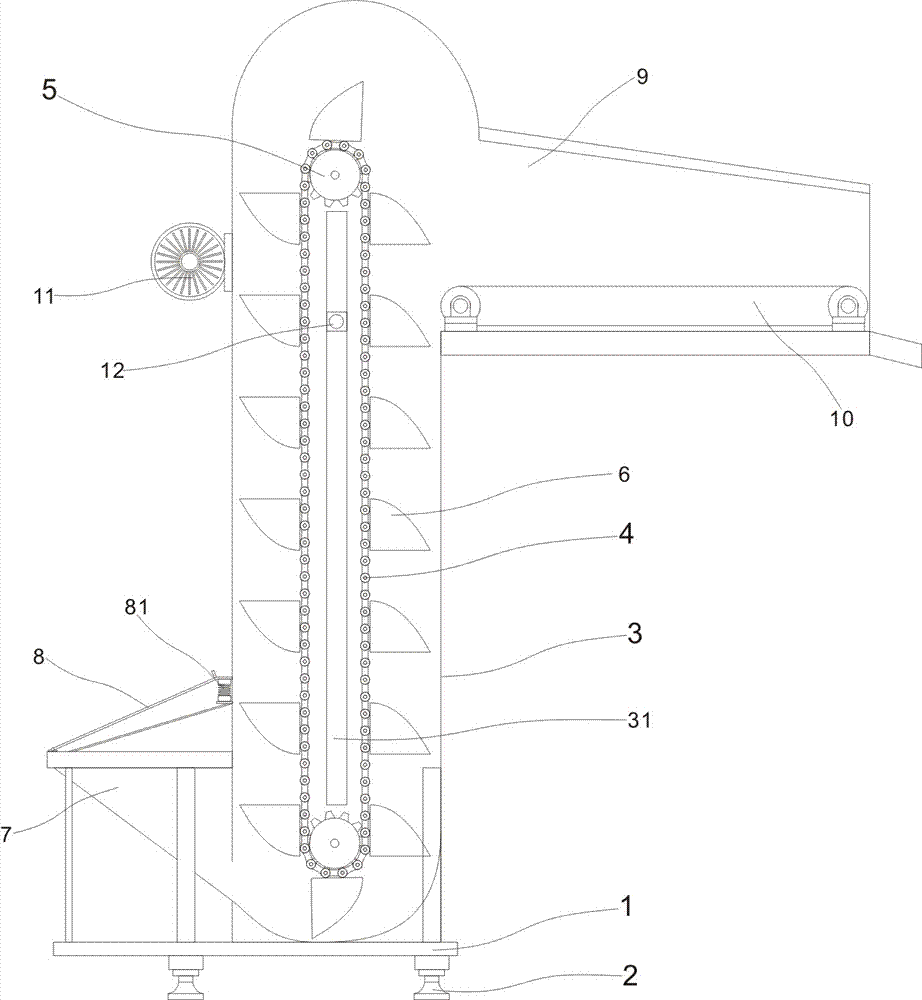

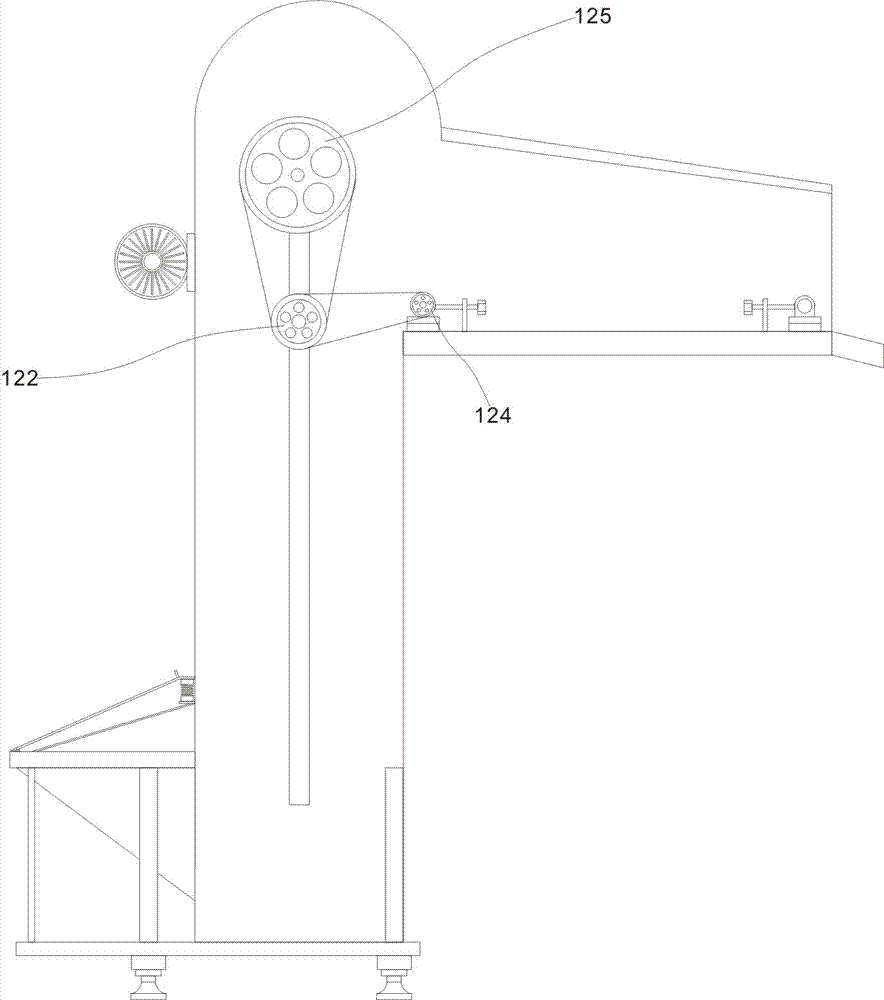

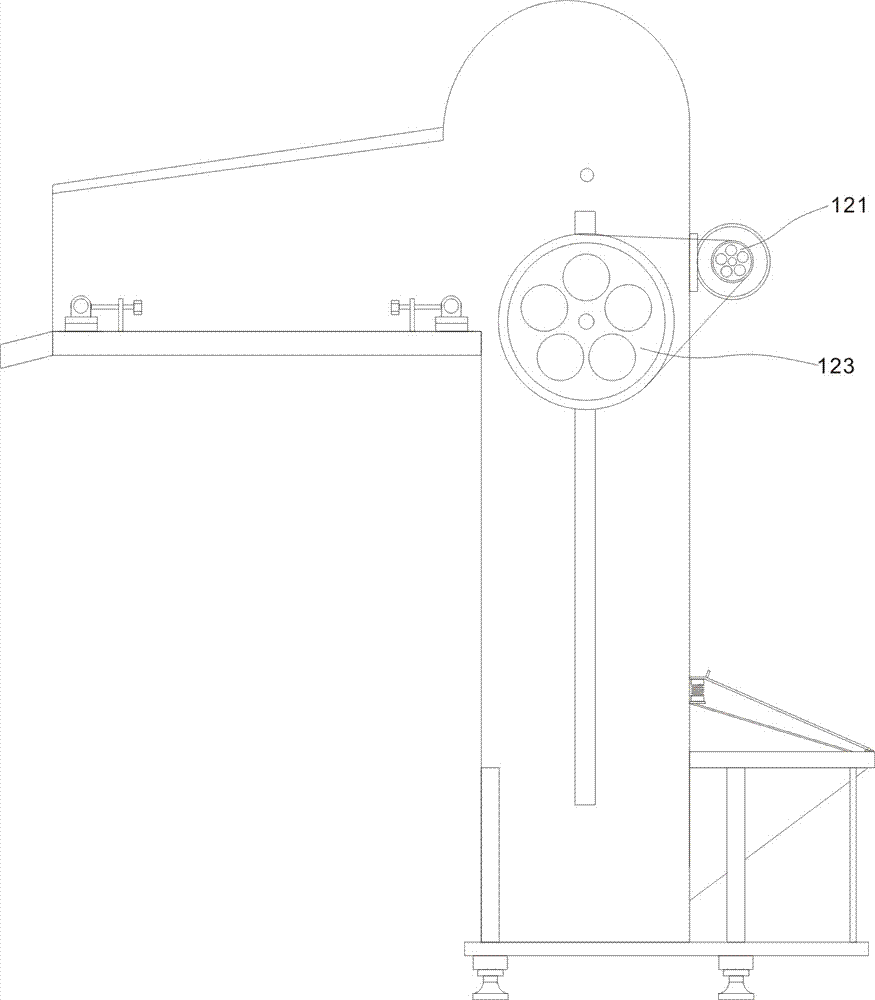

[0020] Such as figure 1 The fully enclosed dust-free feeding device shown includes a frame 1, a support 2, a casing 3, a chain 4, a sprocket 5, an upper hopper 6, a lower hopper 7, a filter screen 8, a side extension arm 9, Conveyor belt 10, electric motor 11.

[0021] The four corners of the bottom of the frame 1 are provided with corresponding supports 2; the case 3 is connected to the upper part of the frame 1, and the position of the case 3 opposite to the two sprockets 5 is provided with a bar hole 31 that penetrates back and forth; The hopper 7 is arranged on the frame 1 at the lower left side of the frame 1. The lower hopper 7 has a through hole leading to the inside of the casing 3; the upper part of the lower hopper 7 is connected with an inclined filter screen 8 , The left side of the filter screen 8 is hinged on the lower hopper 7, and the right side is connected to the outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com