Contamination-free feeding and discharging method and apparatus

A technology for flushing devices and disposal bags, which is applied to centrifuges with rotating drums, centrifuges, etc., and can solve problems such as increasing the complexity of things

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

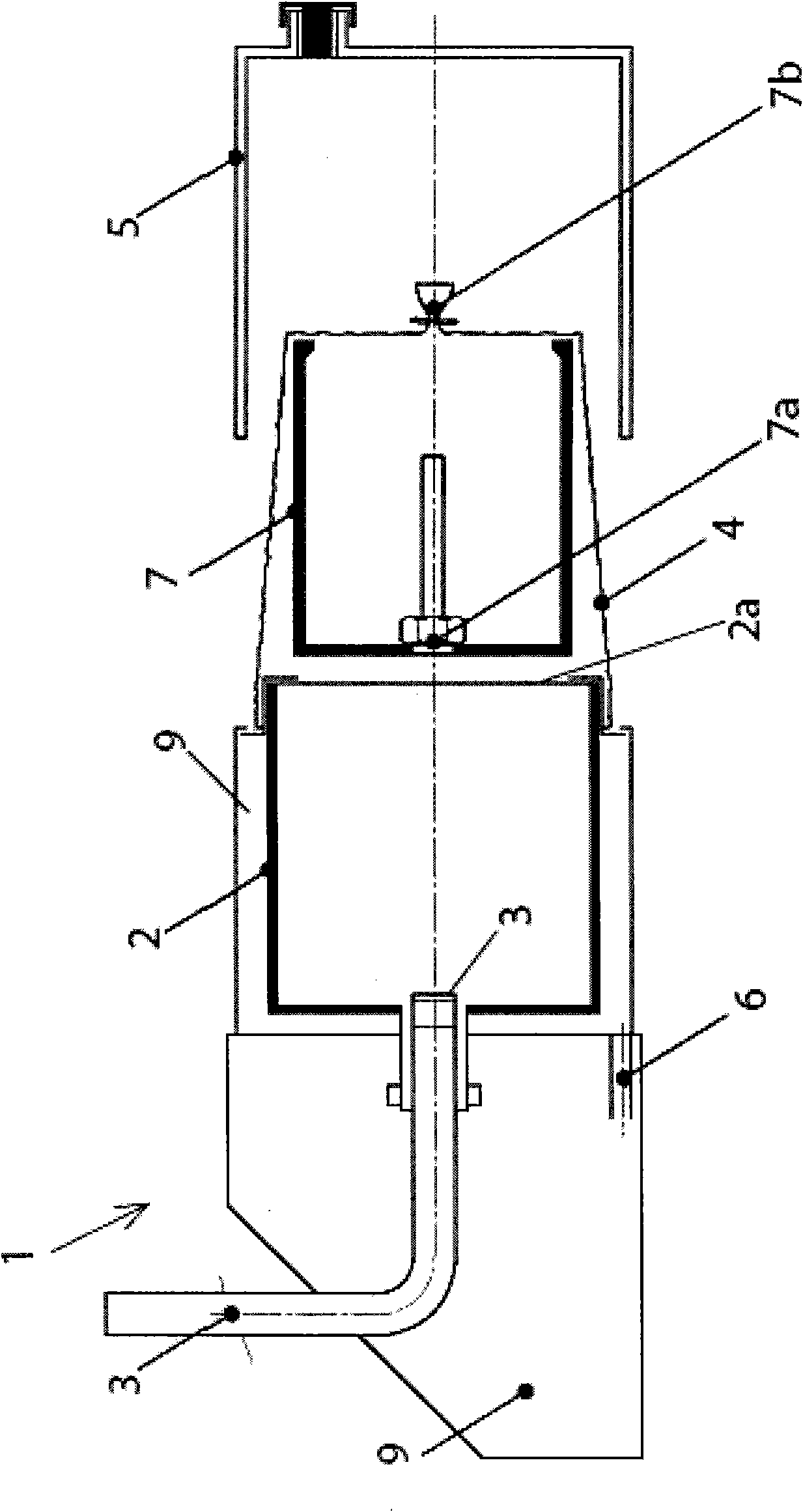

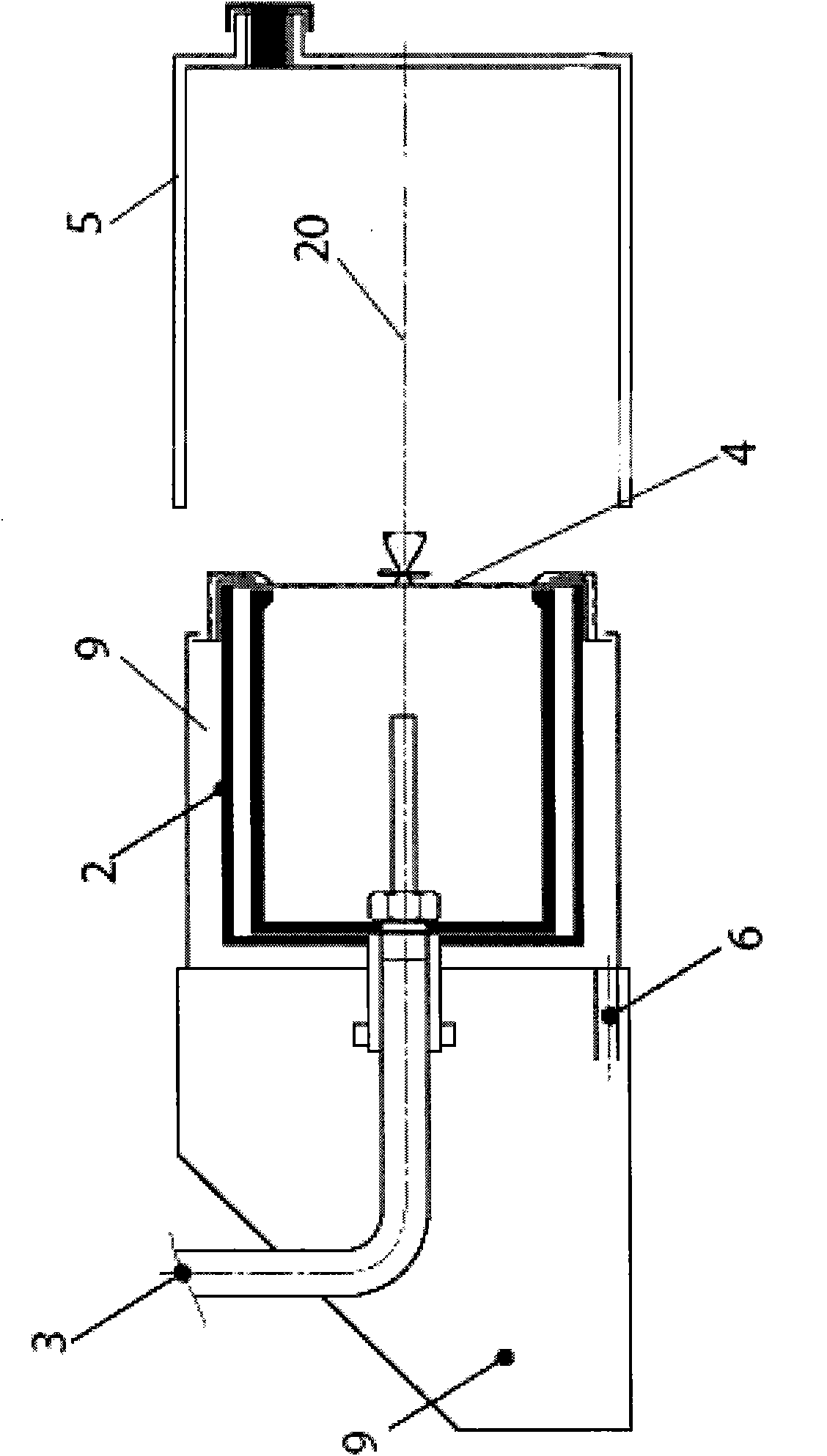

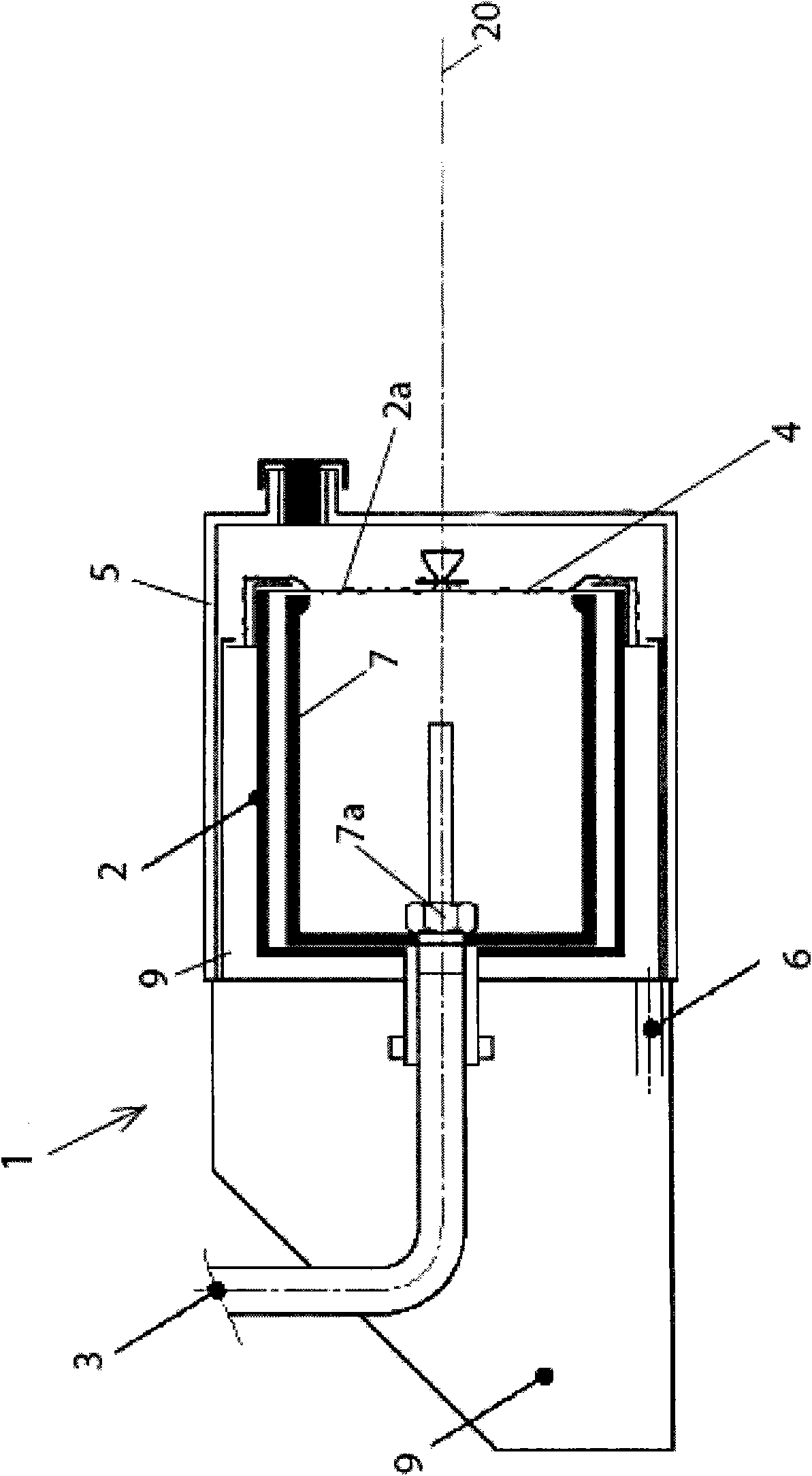

[0046] Centrifuge is best based on image 3 Start description with reference to its complete working status.

[0047] The centrifuge 1 includes a fixed drum shell 9 in which a rotating drum 2 is supported. In this case, the horizontal rotating shaft 20 supports the drum 2. The rotating shaft 20 is cantilevered on the inner side of the drum shell 9, so the drum 2 and the drum shell 9 are uniformly provided with an open side. The right end surface of the drum 2a.

[0048] The inlet 3 for the suspension is on the left closed side of the drum 2, and the suspension is separated into solid and liquid by centrifugal separation.

[0049] Inside the drum 2, there is a stable, cylindrical, and preferably reusable drum insert 7. The drum insert 7 provides the necessary filter function, and the liquid can penetrate its enveloping surface (enveloping surface), but the solids in the suspension cannot pass through. The drum insert 7 and the drum 2 rotate together during operation.

[0050] The rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com