Self-locking protective mounting device with doubly-vertical explosive welding effects

An explosive welding, double-vertical technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of difficult effective control of process parameters, difficult quality control, large impact damage, etc., to achieve energy saving and environmental protection and The effects of sustainable development, improvement of quality and production efficiency, and reduction of secondary effect hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

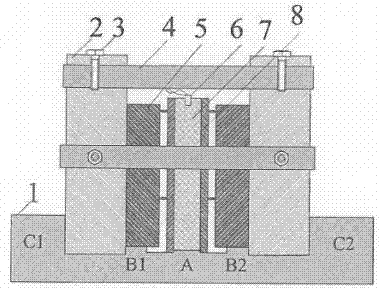

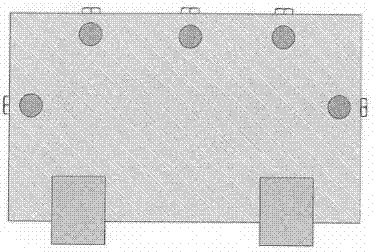

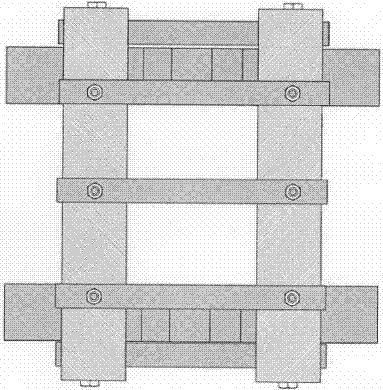

[0028] implemented as figure 1 , figure 2 , image 3 As shown, self-locking protection is carried out for the double-vertical explosive welding of two pairs of stainless steel / steel composite plates with specifications of (2+22) mm×1500mm×3000mm.

[0029] 1. Double-vertical explosive welding adopts an ultra-low charge of 15mm, the mass ratio is 0.736, the distance between the base and cladding plates is 7mm, and the amount of explosive is 52.5kg.

[0030] 2. The compound plate is 10mm higher than the base plate, the height of the boss A is 2mm, and the height of the bosses B1 and B2 is 5mm; the size of the protective plate is 300mm×2000mm×4000mm; the length of the pole is 360mm, the radius is 6mm; the radius of the locking nail is 3.5mm .

[0031] 3. The final explosion welding effect is that the composite rate of the composite plate is 100%, the protective device is not damaged, and the detonation shock wave and noise are significantly weakened.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com