Method for searching maximum free movement stroke track of electrode in electrosparking of closed blisk

An integral blisk and electric spark technology, applied in electric machining equipment, electrode manufacturing, metal processing equipment, etc., can solve the problems of affecting the efficiency of machining, the influence of search success, and the single form of electrode processing, so as to improve machining efficiency and improve machining efficiency. High efficiency and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

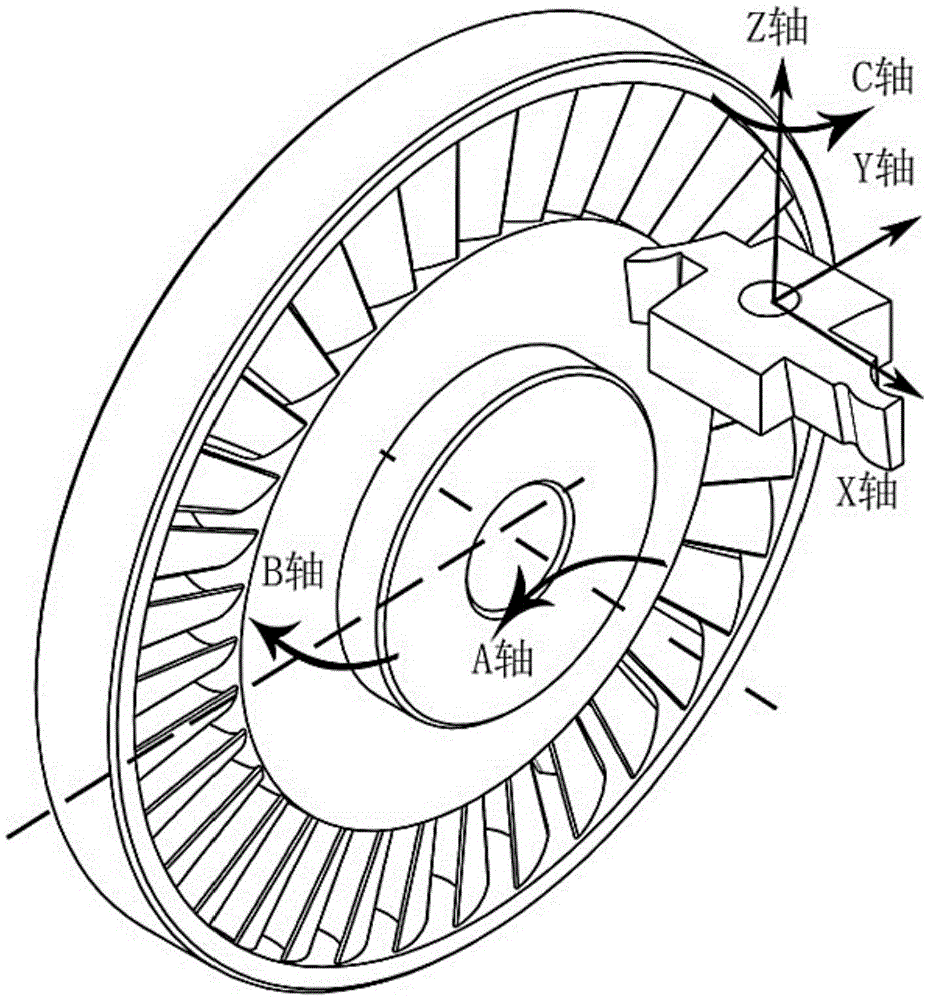

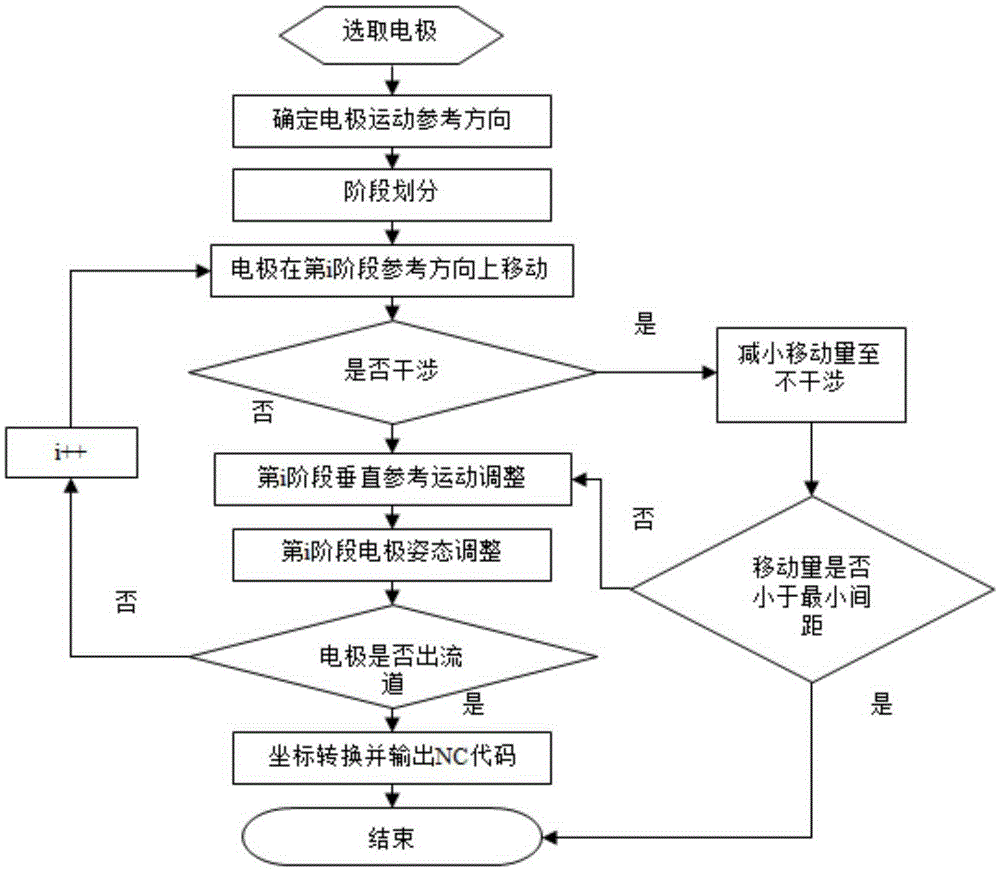

[0028] Such as figure 1 As shown, the definition of each motion axis of the closed integral blisk in EDM is shown, which are respectively moving along the three directions of X, Y, and Z and rotating around the three directions of X, Y, and Z; this embodiment The process flow of the method for determining the non-interference feeding trajectory of the electrode is as follows: figure 2 shown.

[0029] The specific steps of this embodiment are as follows:

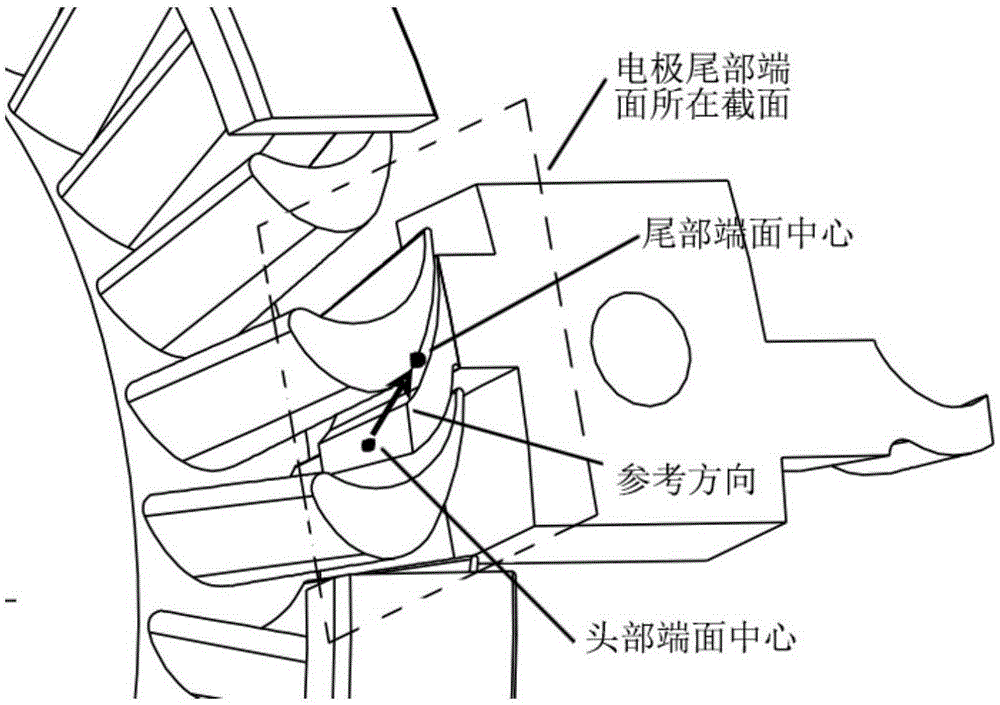

[0030] 1) Determine the reference direction of electrode movement: In the process of closed blisk machining, the most critical factor for the electrode to exit the flow channel is the tendency to move out of the flow channel; generally speaking, from the final movement of the electrode to the flow channel Comparing the position outside the flow channel with the initial position, the amount of movement of the electrode along the direction outward of the flow channel will be greater than the amount of movement in other direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com