Super plasticity extruding and forming device for micro parts

A technology of extrusion forming and superplasticity, which is applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of small extrusion strokes, achieve uniform extrusion speed, precisely control extrusion precision, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

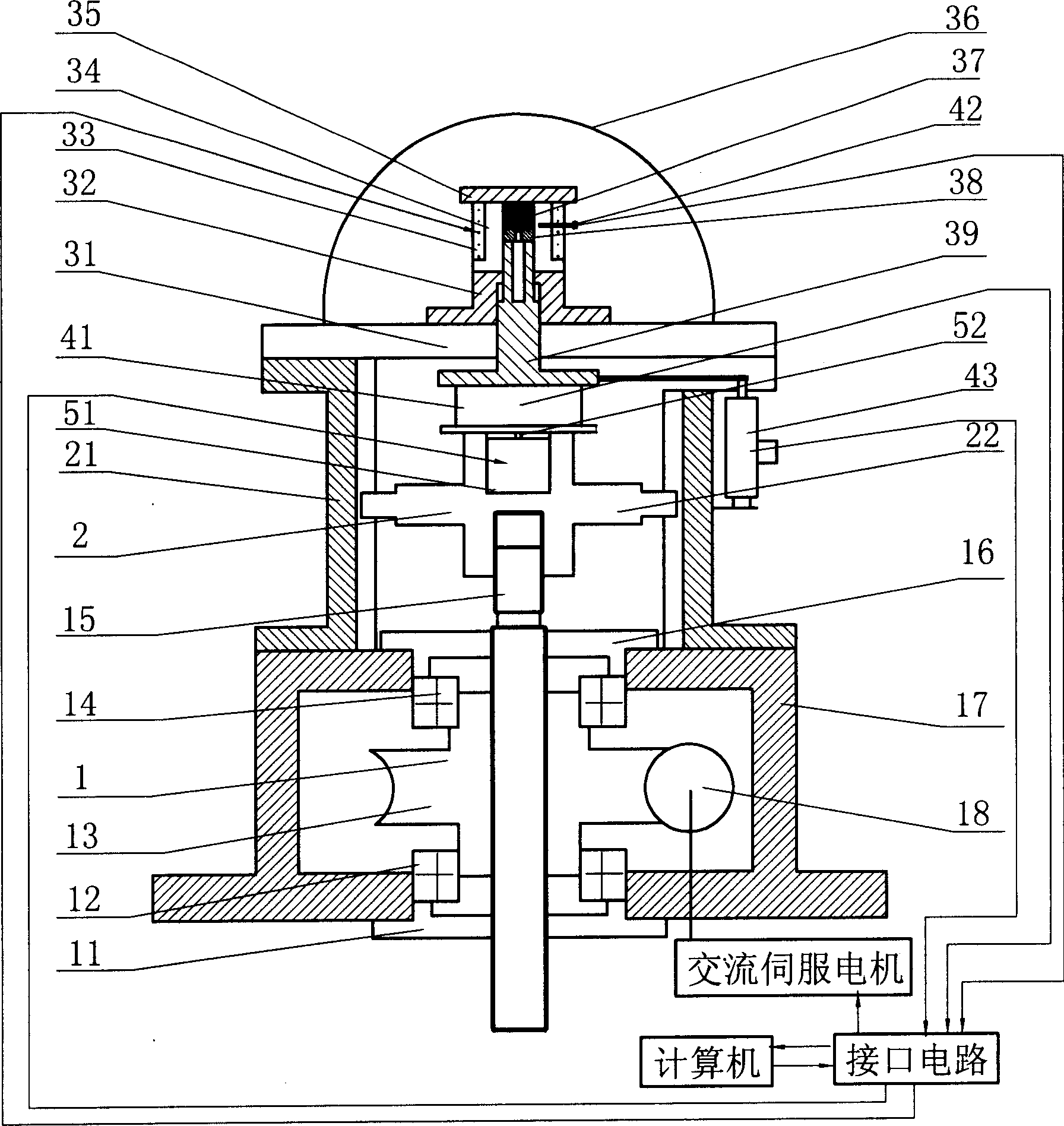

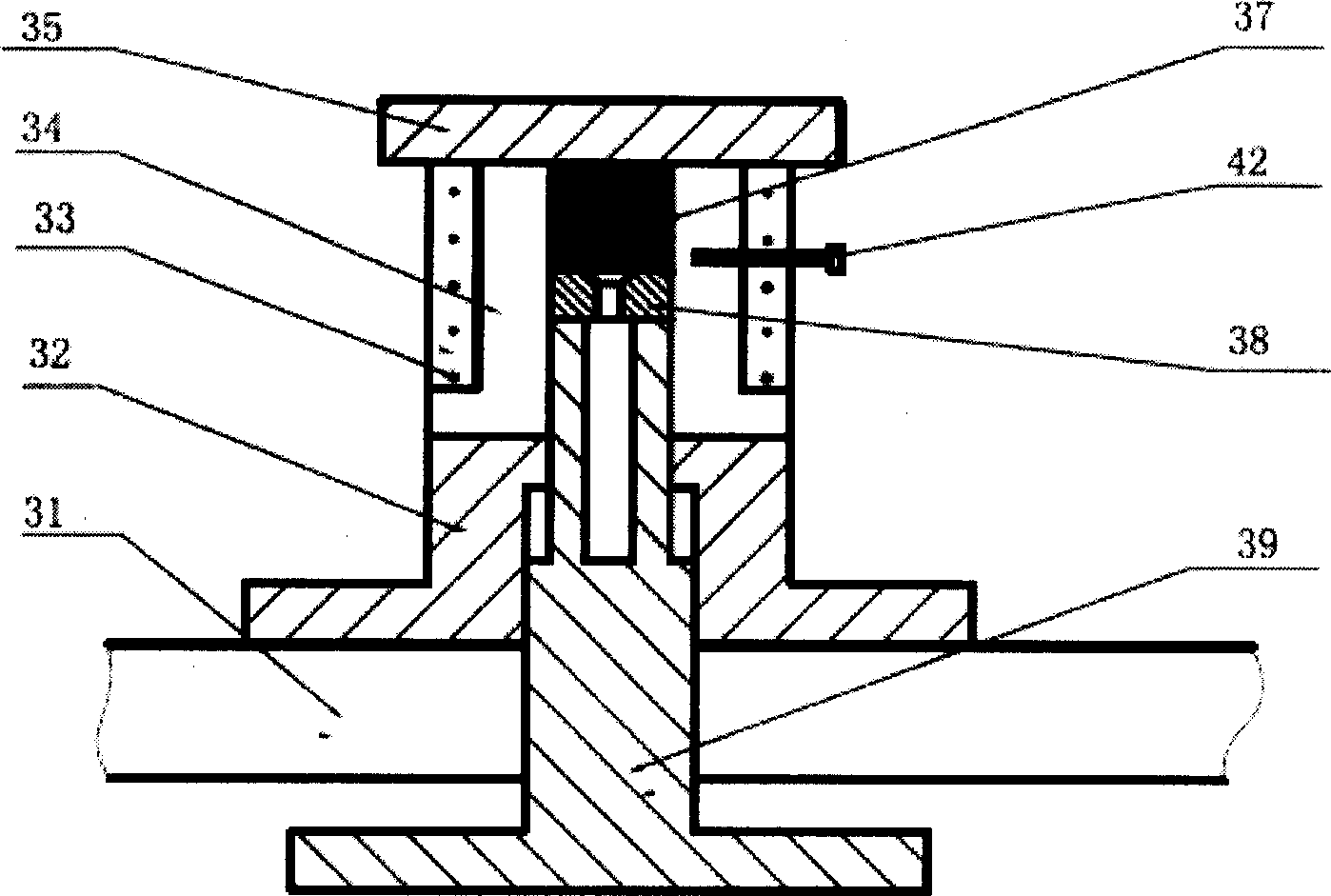

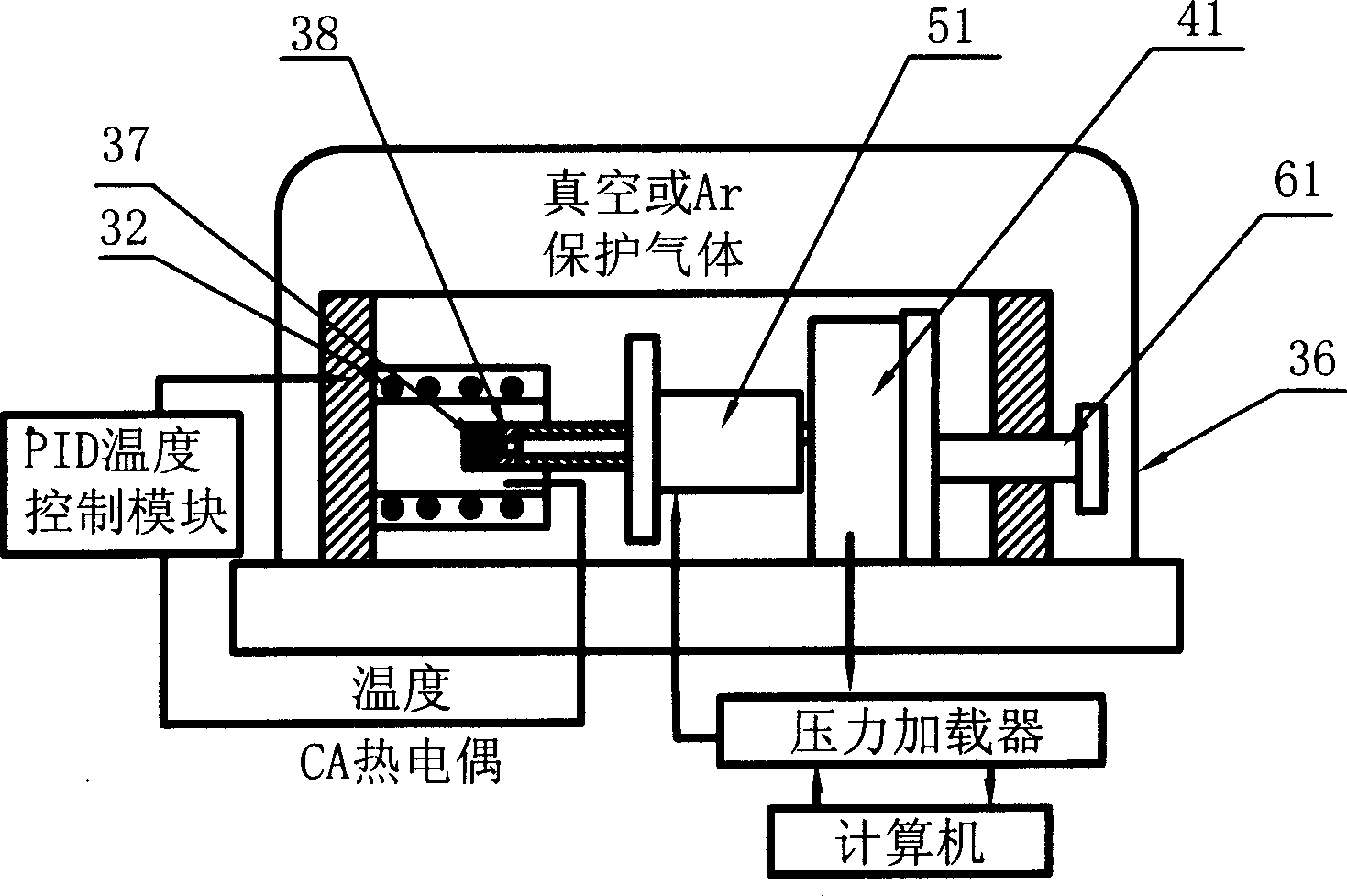

[0018] refer to Figure 1~3 , the present invention consists of a deceleration mechanism, a guiding mechanism, a forming mechanism and a sensor assembly. Speed reduction mechanism comprises lower bearing cover 11, lower bearing 12, worm gear nut 13, upper bearing 14, screw rod 15, upper bearing cover 16, reduction box casing 17 and worm screw 18. The worm wheel nut 13 is connected with the reduction box body 17 through the upper and lower bearings, the screw rod 15 is screwed with the worm wheel nut 13, the inner rings of the lower bearing 12 and the upper bearing 14 are in interference fit with the worm wheel nut 13, and the outer rings of the lower bearing 12 and the upper bearing 14 are in interference fit. The ring is in interference fit with the reduction box casing 17.

[0019] The guide mechanism includes a guide rail 21 and a differential nut 22 . The guide rail 21 is fixedly connected to the reduction box body 17, four bosses are evenly distributed on the outer ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com