Full-automatic PCB ultraviolet laser cutting machine

An ultraviolet laser, fully automatic technology, applied in laser welding equipment, printed circuits, manufacturing tools, etc., can solve the problems of poor consistency and quality stability, low precision, small area, etc., to reduce labor input and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with schematic diagrams, but is not limited thereto.

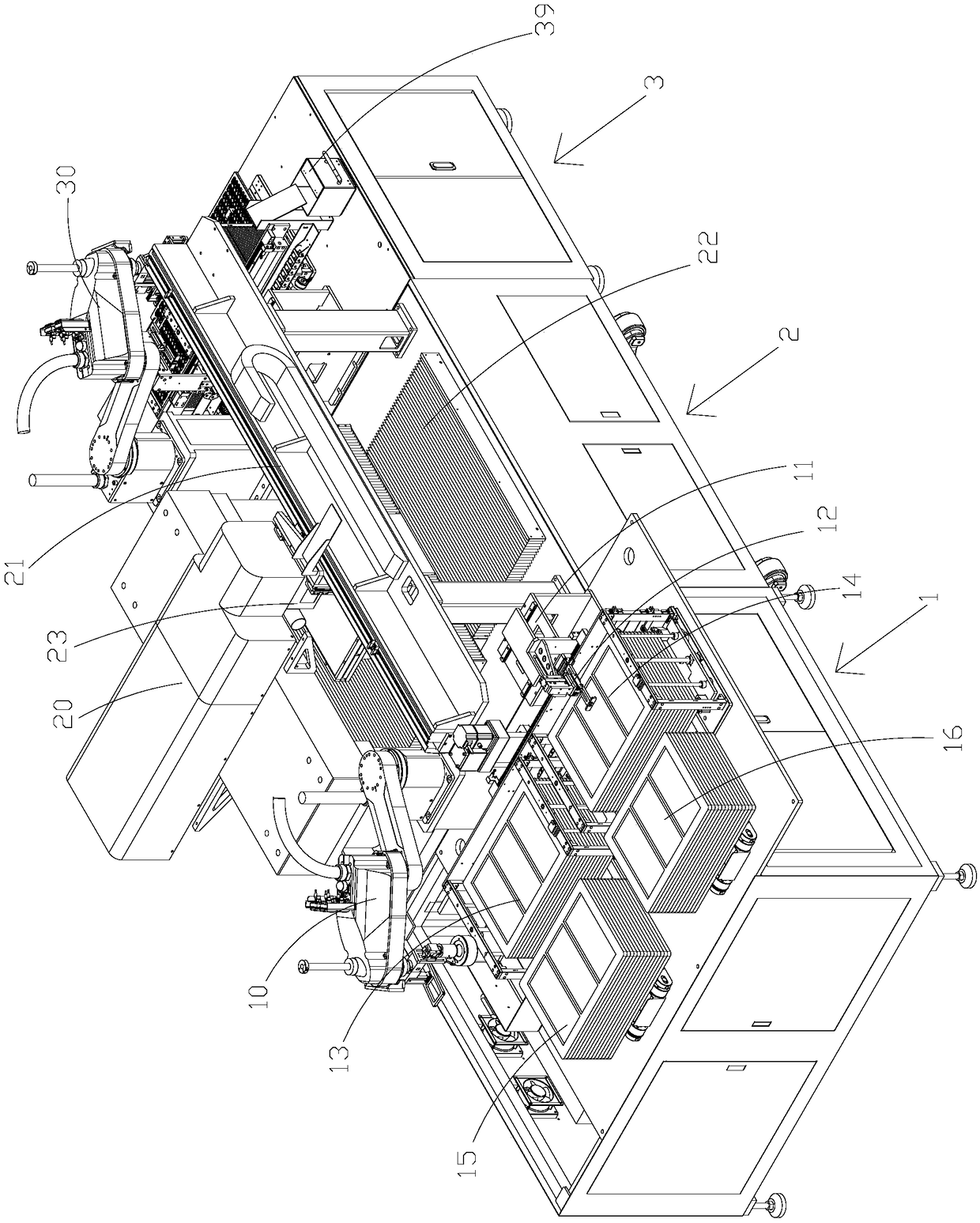

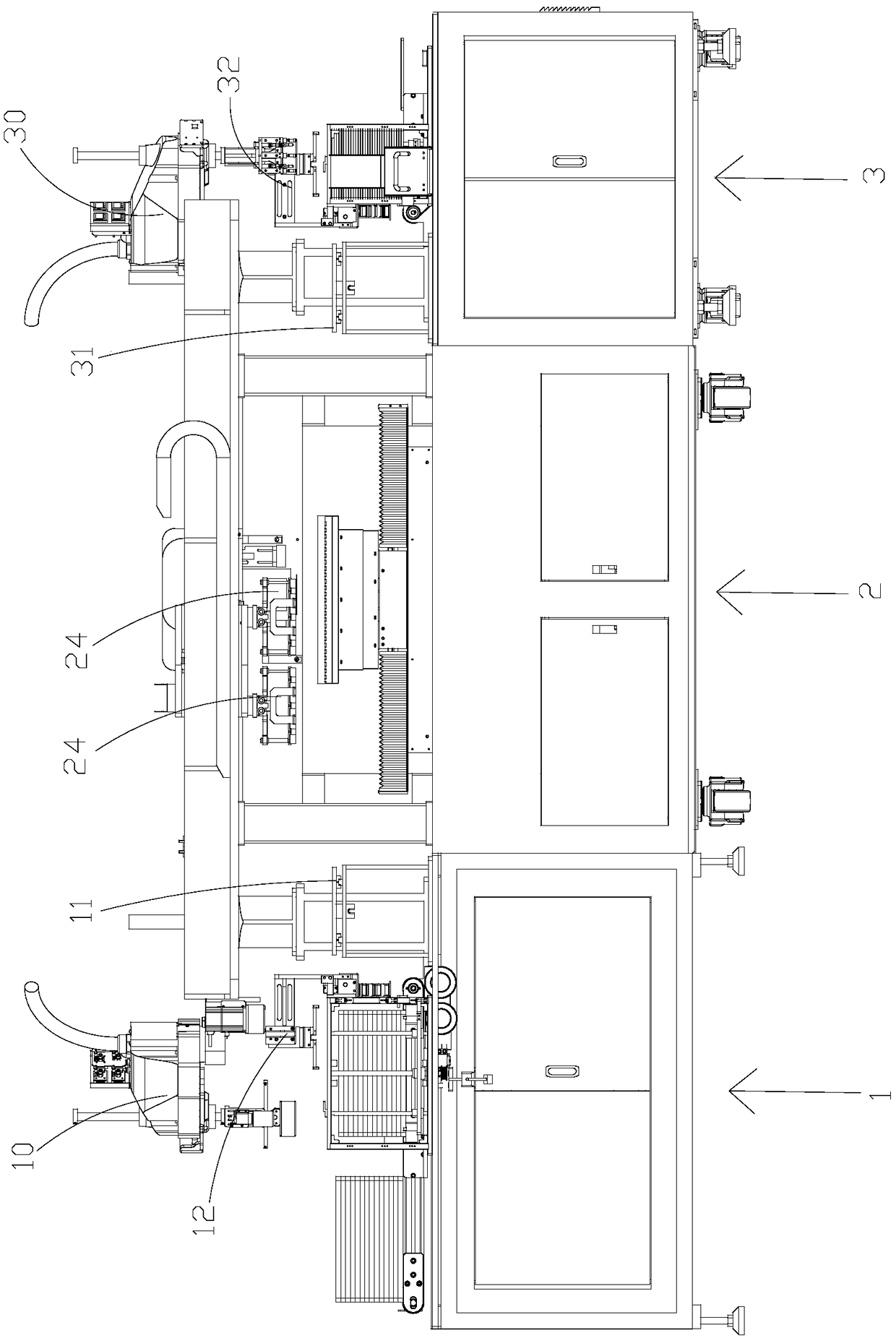

[0025] Such as Figure 1 to Figure 5 As shown, in the present invention, the fully automatic PCB ultraviolet laser cutting molding machine includes a feeding mechanism 1, a cutting mechanism 2 and a feeding mechanism 3, and the cutting mechanism 2 is located between the feeding mechanism 1 and the unloading mechanism 3 , wherein, the feeding mechanism 1 is used to transfer the PCB to be cut and shaped to the cutting mechanism 2 for cutting and shaping, and the unloading mechanism 3 is used to transfer the cut and shaped PCB in the cutting mechanism 2 to enter the next process.

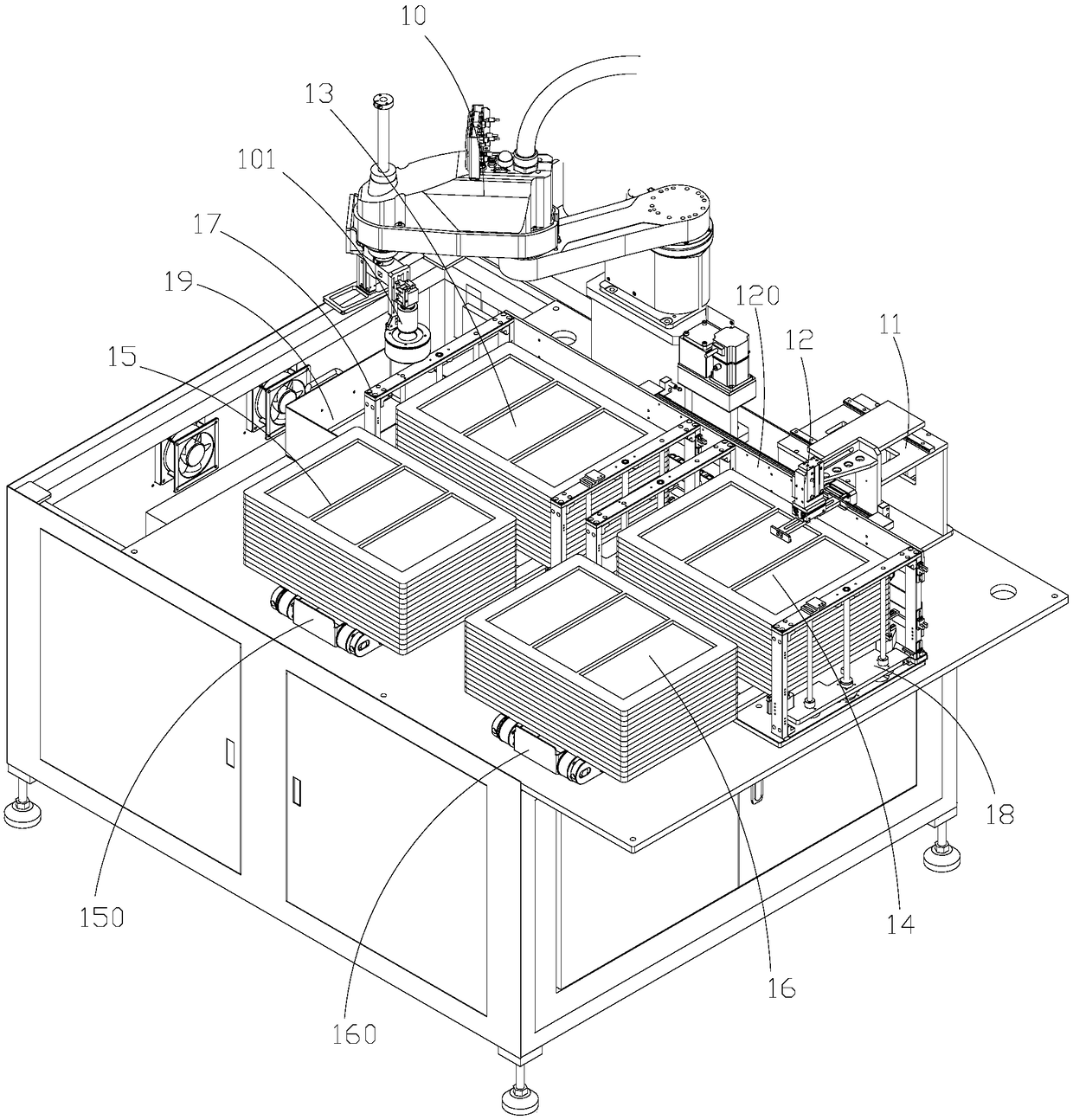

[0026] Such as image 3 As shown, the feeding mechanism 1 includes a feeding manipulator 10, a first jig transfer platform 11, a first tray transfer devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com