Real-time detection system for wood microstructure characteristic changes

A technology for microstructure and real-time detection, applied in measurement devices, analysis of materials, strength characteristics, etc., can solve the problems of insufficient material performance, single strain results, and no strain situation, to shorten the image acquisition interval and avoid errors. , Improve the effect of image acquisition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

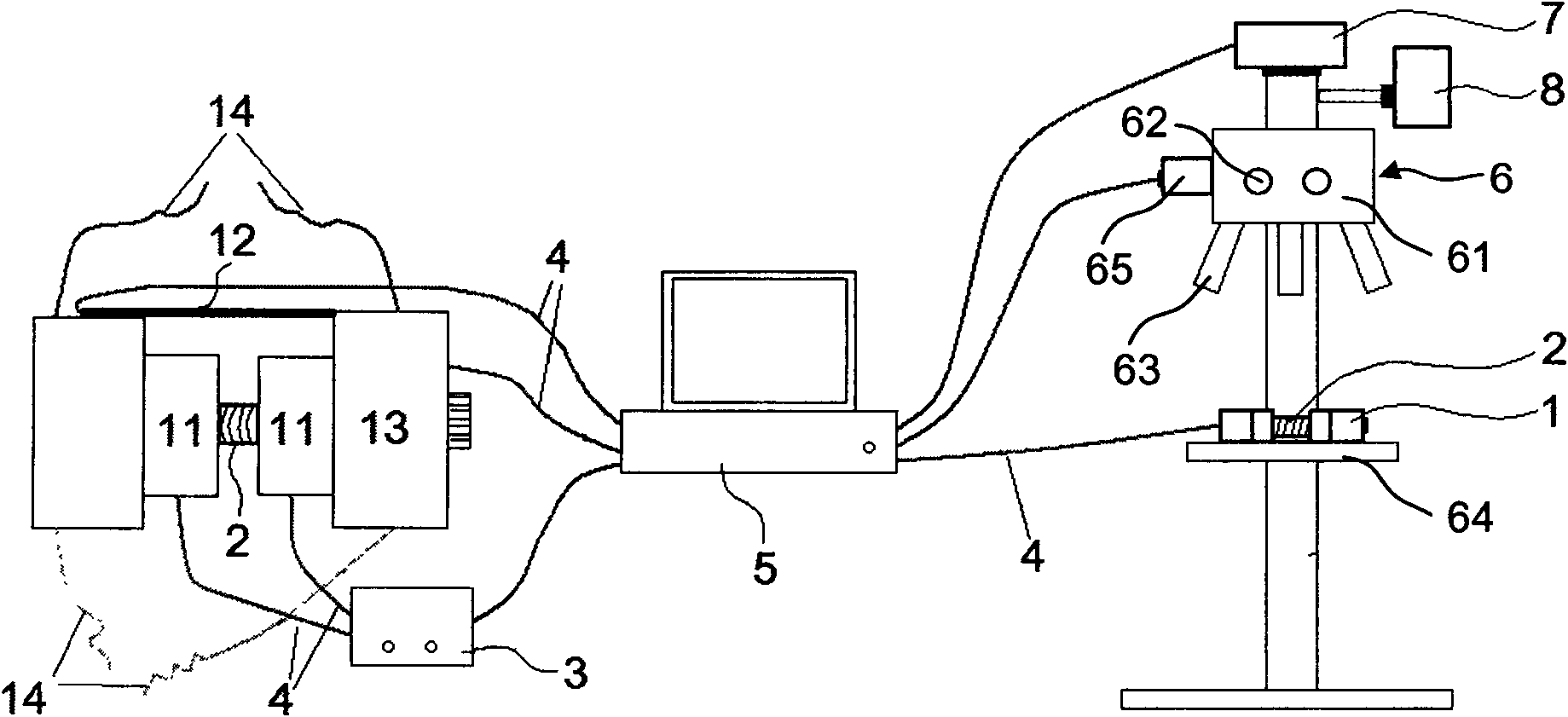

[0034] Such as figure 1 As shown, the present invention includes: a loading unit 1 , a temperature control box 3 , a sensor 4 , a computer 5 (that is, an image processing unit), an optical microscope 6 , a digital camera 7 and a video camera 8 . The loading unit 1 is used to perform mechanical behaviors such as compression, tension, bending, torsion or shearing on the wood 2 to be tested. The temperature control box 3 is connected with the loading unit 1 and the computer 5, and is used to control the temperature of the wood to be inspected (theoretical range -140~600°C). The optical microscope 6 is connected with a digital camera 7, a video camera 8 and a computer 5, and is used for collecting deformation images of the wood surface under pressure or tension. 3 sets of sensors 4, one set is connected with the footage system 12 in the loading unit 1, and is used to measure the overall displacement of the measured timber 2; one set is connected with the load control (pressure co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com