Aluminum-piece nylon coating machine and coating method

A technology of nylon coating and aluminum parts, applied in the direction of coating, liquid coating device on the surface, pretreatment surface, etc., to achieve the effect of uniform temperature and low strength damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

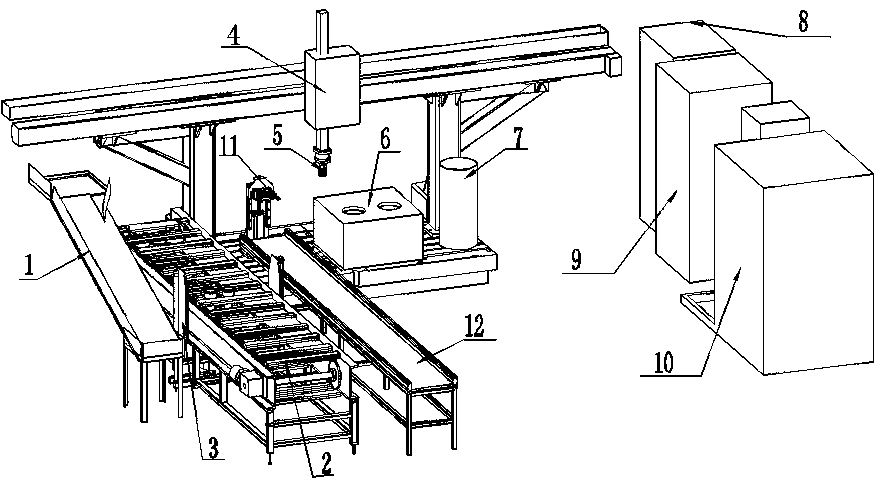

[0030] The present invention as figure 1 , 2 , 3 shown.

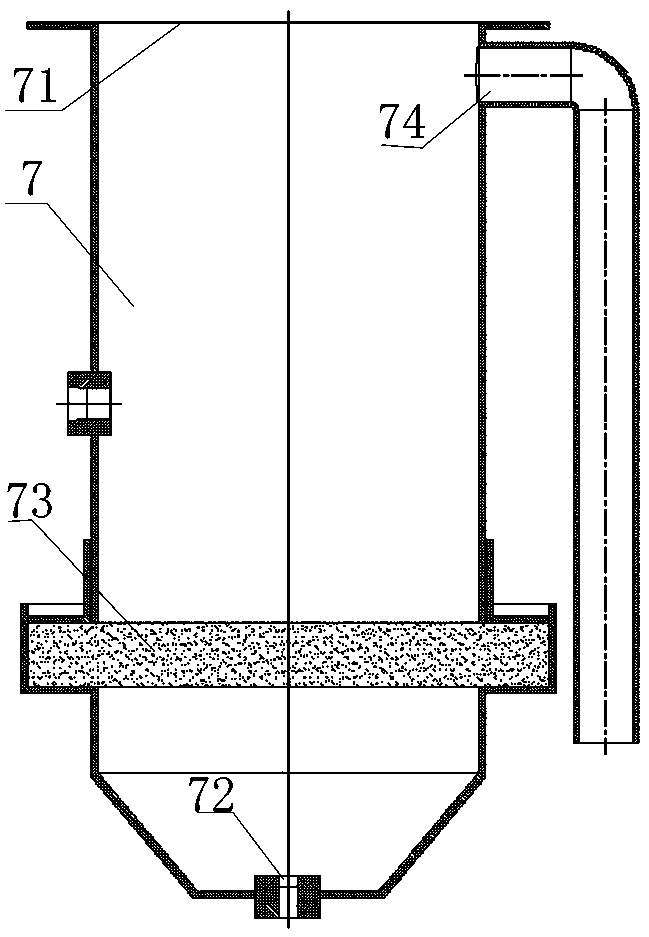

[0031] A nylon coating machine for aluminum parts, including a feeding conveyor 2, a primer coating mechanism 3 is provided on both sides of the feeding conveyor 2, and a truss 4 and a manipulator 5 are provided at the tail end of the feeding conveyor 2 , an intermediate frequency heating furnace 6 and a nylon powder box 7 are arranged under the truss 4; a numerical control electric control console 8, an intermediate frequency heating cabinet 9 and a cooling water tower 10 are arranged outside the truss 4;

[0032] Among them, the CNC electric control console 8 provides wires to connect to the feeding conveyor 2, the primer coating mechanism 3, the nylon powder box 7, the truss 4 and the manipulator 5;

[0033] The intermediate frequency heating furnace 6 and the intermediate frequency heating cabinet 9 are connected and cooled by a cooling water tower 10 .

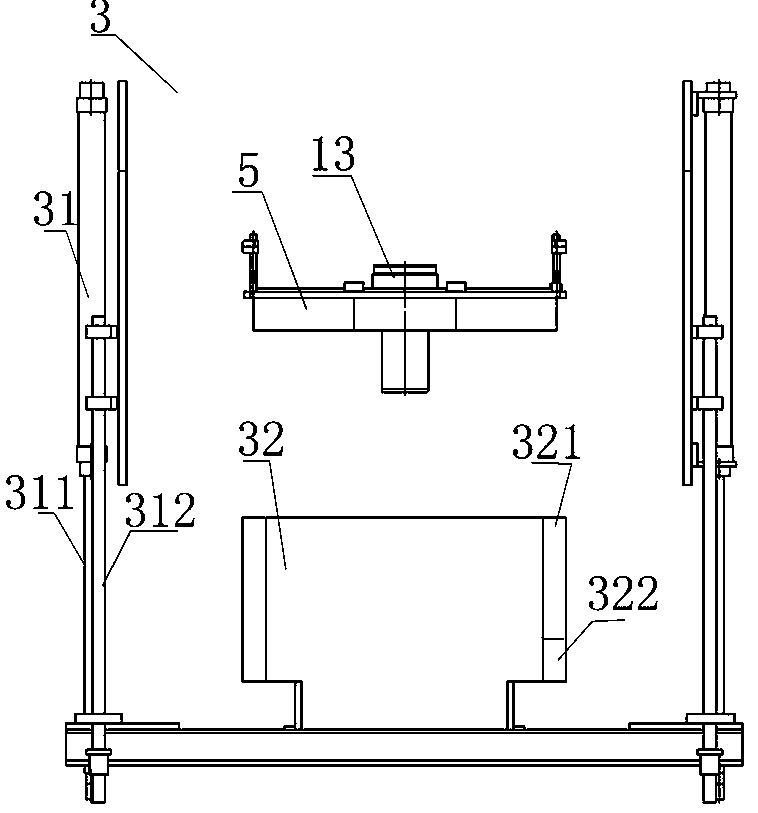

[0034] The described priming mechanism 3 includes a liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com