Patents

Literature

51results about How to "Precise control of heating time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

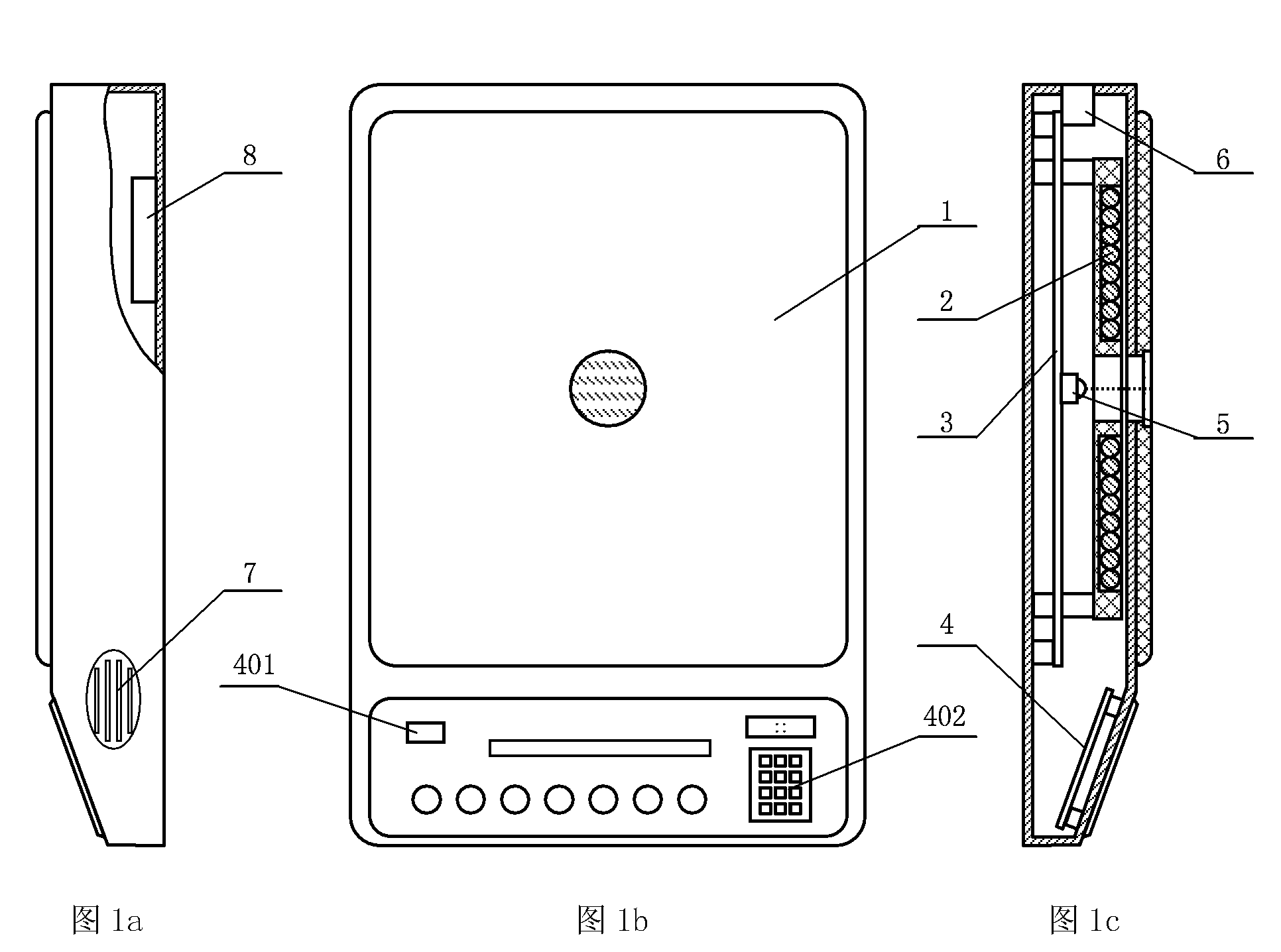

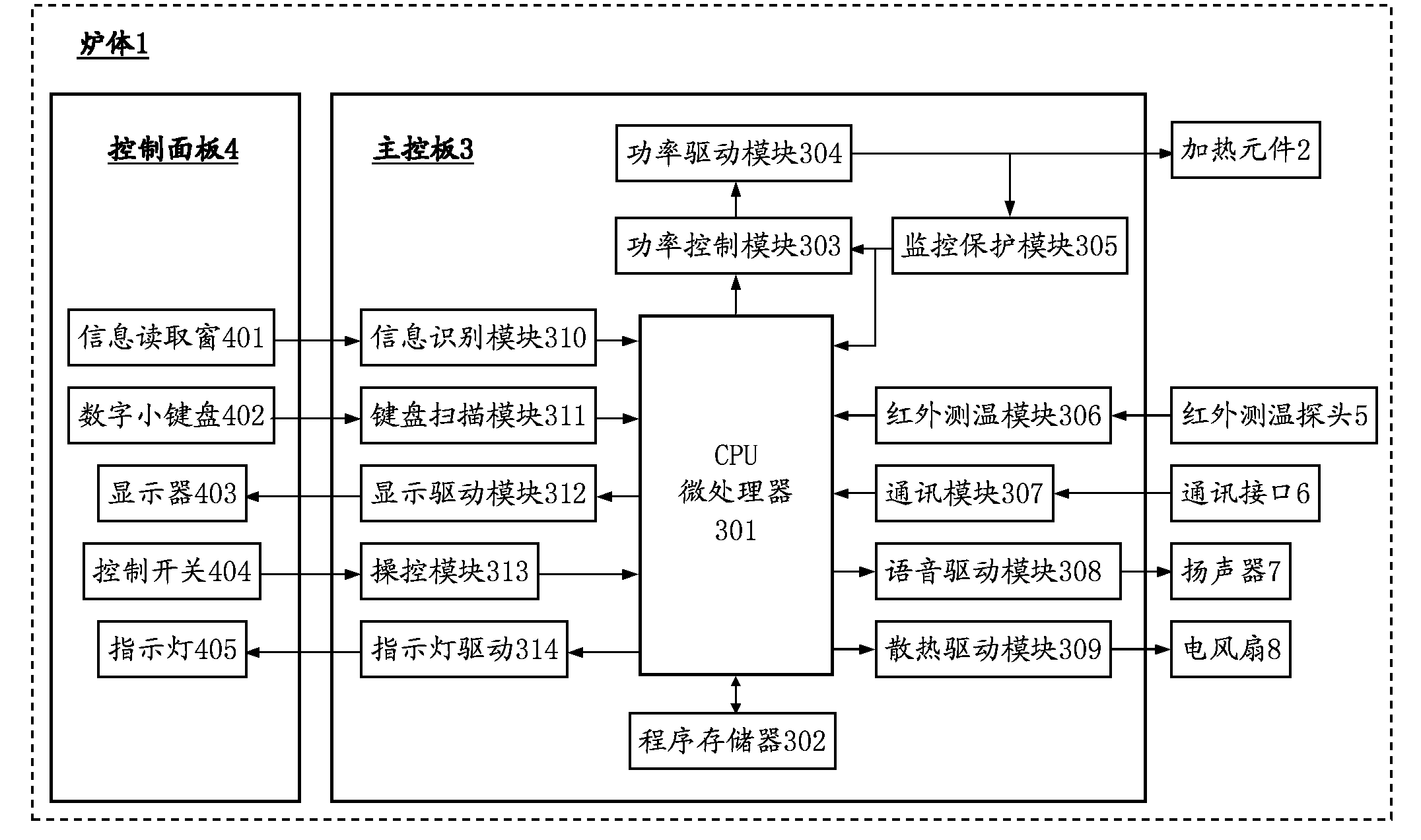

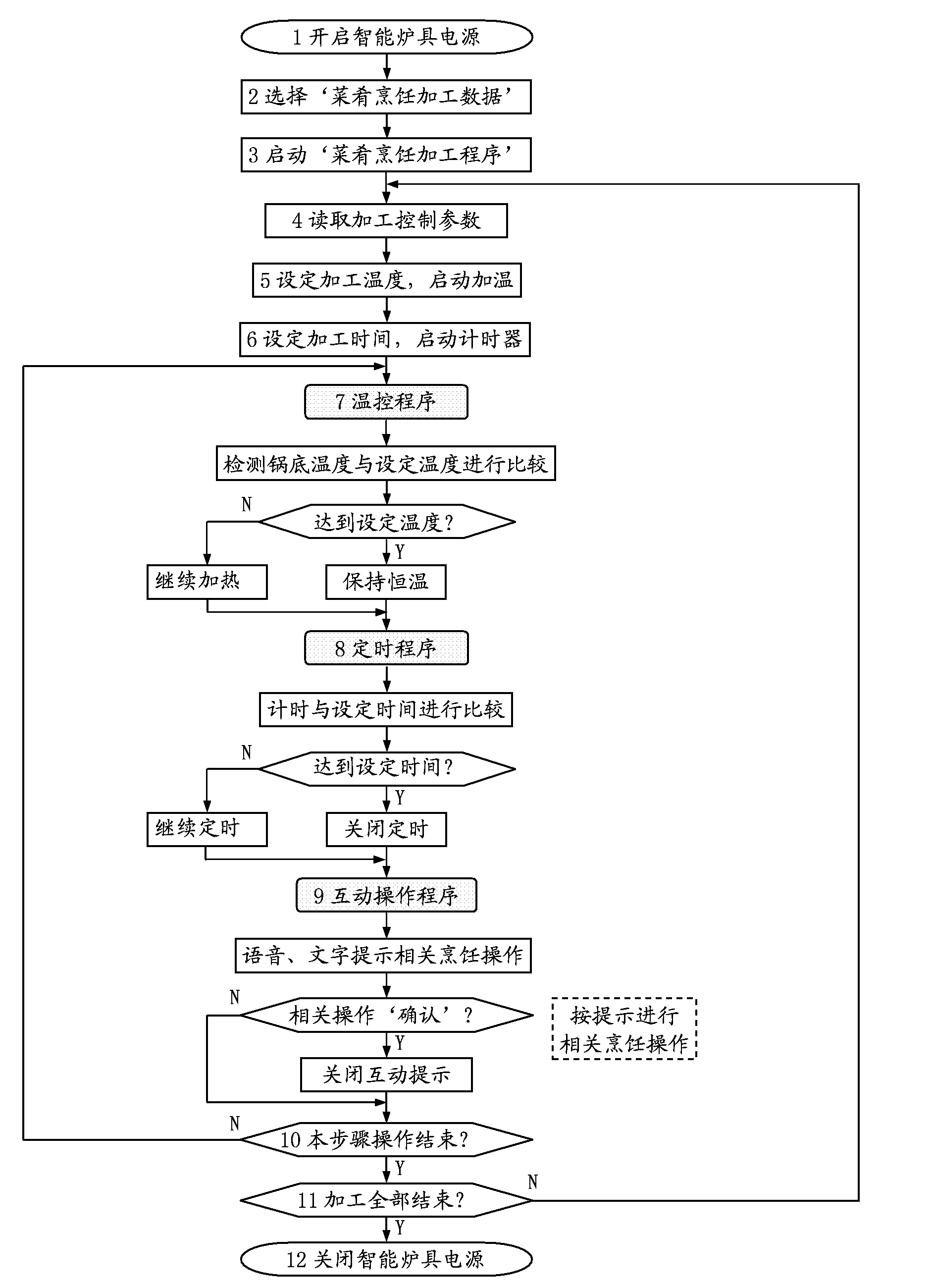

Intelligent cooker interacting with human in cooking and working method

InactiveCN102734846ASolve the contradiction between high enjoyment and low consumption in daily dietReduce labor costsDomestic stoves or rangesLiquid heating fuelAutomatic controlProcess engineering

The invention provides an intelligent cooker interacting with human in cooking and a working method. A main control board of the intelligent cooker comprises a CPU microprocessor and a program memory. Under the control of the CPU microprocessor, ''dish cooking processing data'' are downloaded to a cooking cooker for saving by a wired or wireless communication way. For various dishes, related dish cooking processing data can be called by means of an information reading window, a numeric keypad or a wireless communication mode and the like to realize accurate automatic control of the temperature and time in the cooking process. In the whole cooking processing process, the intelligent cooker is interacted with human through voice, characters and other forms to give hints about when to perform oil adding, dish material pouring, stir-frying, water adding, seasoning adding and other manual operations. Thus, the dish cooking process can meet the requirements of standardized automatic cooking. The intelligent cooker and the working method of the invention can be used for large scale and rapid making of delicious Chinese dishes, and also can drive the rapid development of relevant industries (such as processing, delivery and the like of dish semi-finished products), thus being of profound significance on the development of future information society.

Owner:ZHUHAI UNITECH POWER TECH CO LTD

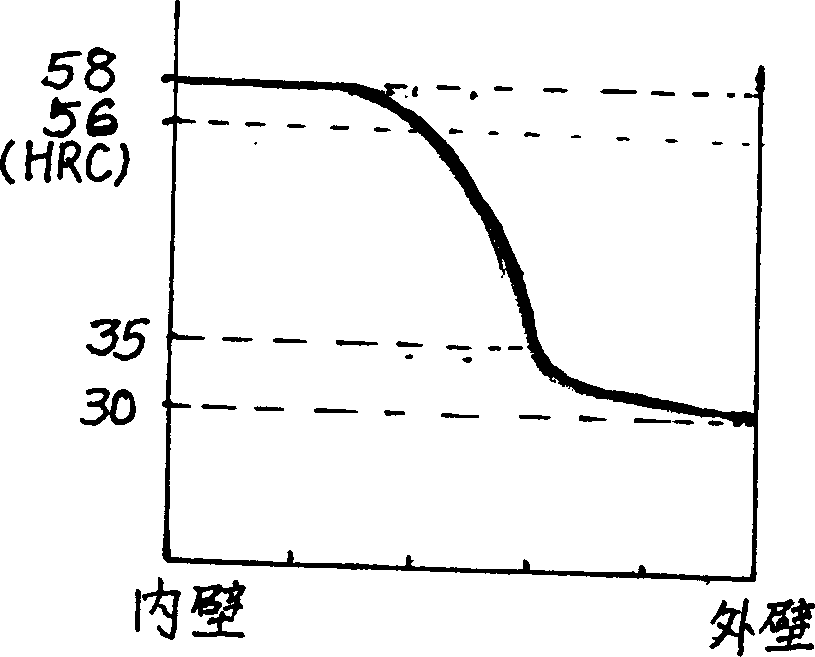

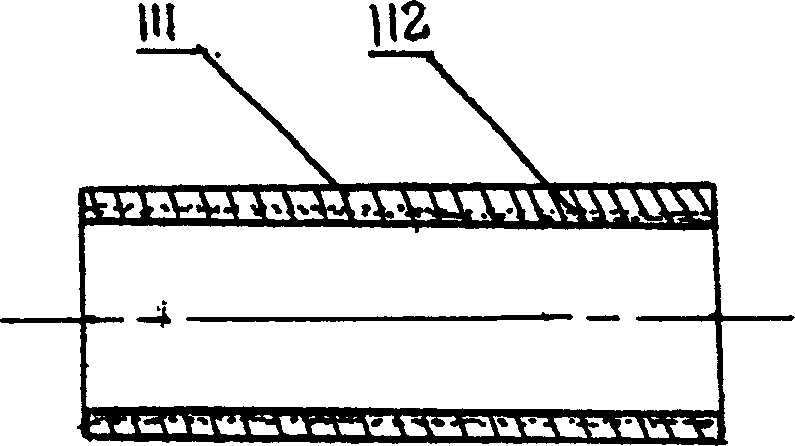

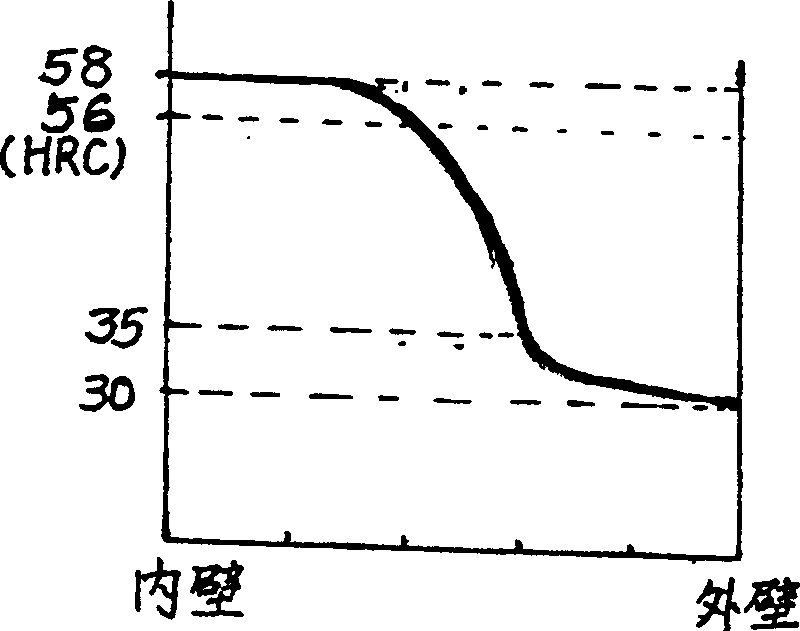

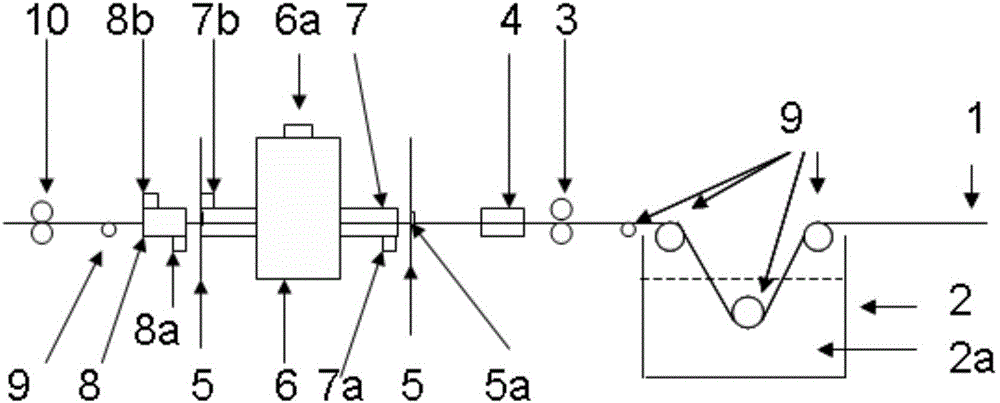

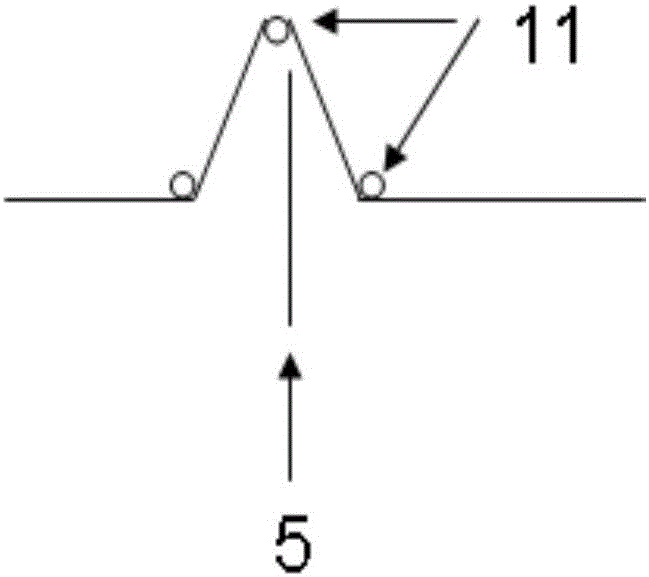

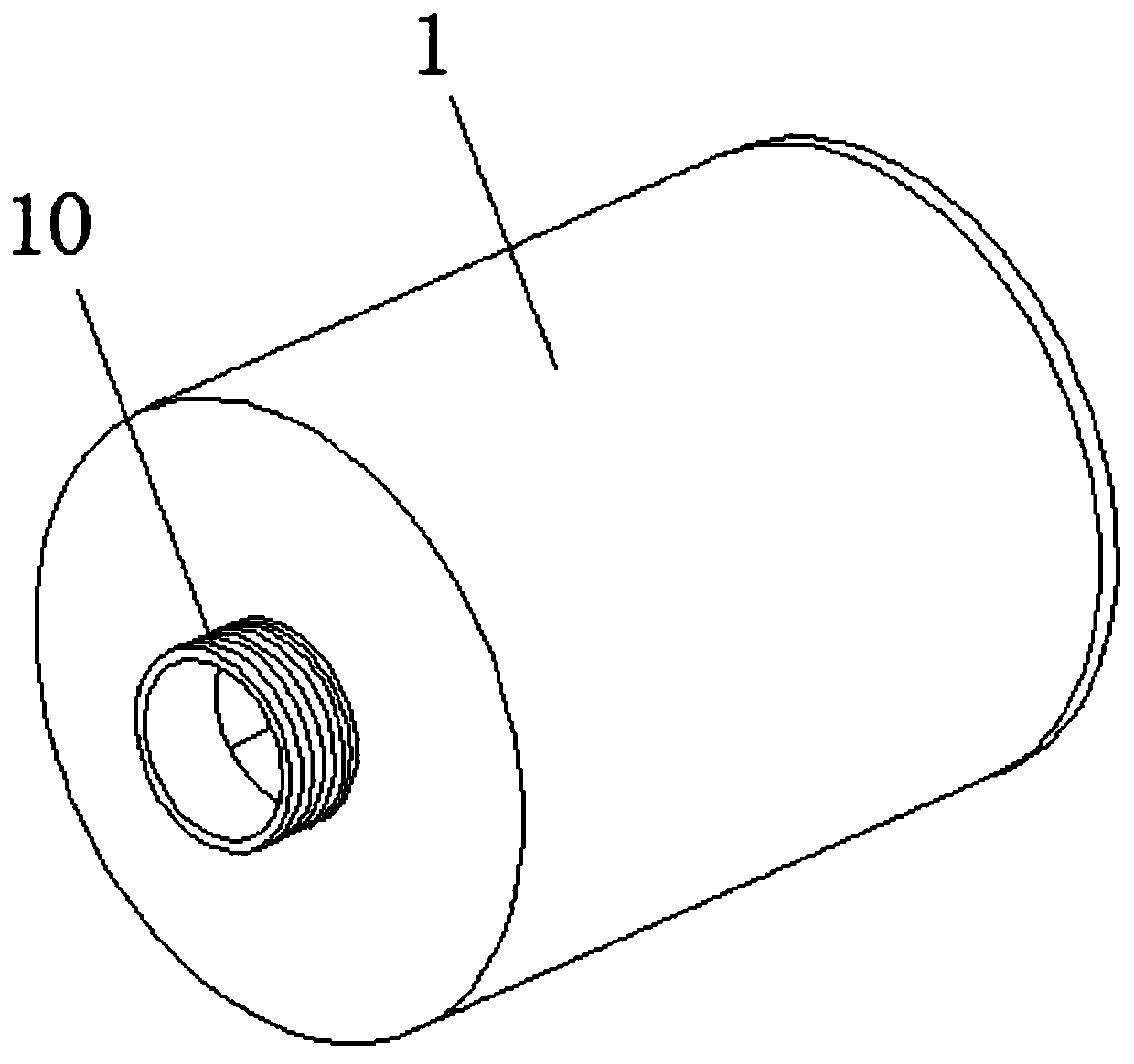

Cylinder shape pipe piece with inner harden layer and production method and equipment

InactiveCN1433942ALarge caliberSave materialIncreasing energy efficiencyFurnace typesFrictional coefficientEngineering

The present invention relates to a cylindrical pipe with internal hardened layer, its production method and special-purpose equipment. Said cylindrical pipe has small wall thickness and long length, its pipe wall has internal layer and external layer with different hardness, the hardness of its internal layer is greater than that of external layer, and said pipe is applicable for conveying material with high frictional coefficient. Its production method adopts the mode utilizing frequency to control pipe movement and proper hardening temp. range, and is special-purpose equipment is simple in structure, stable in operation, and can accurately control hardening temp., pipe moving speed nad depth of hardened layer.

Owner:王克发 +1

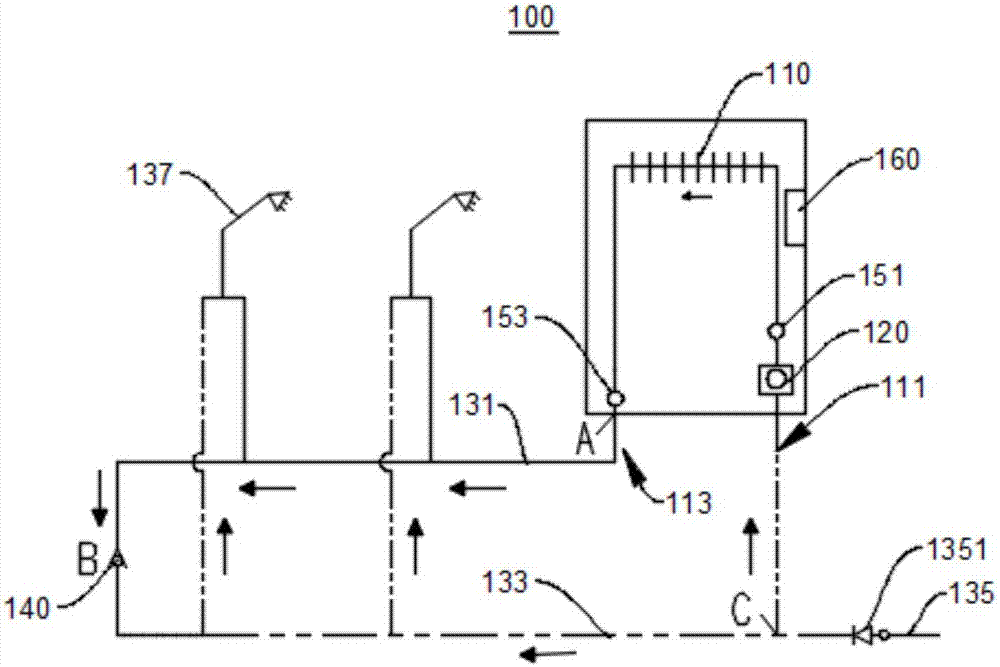

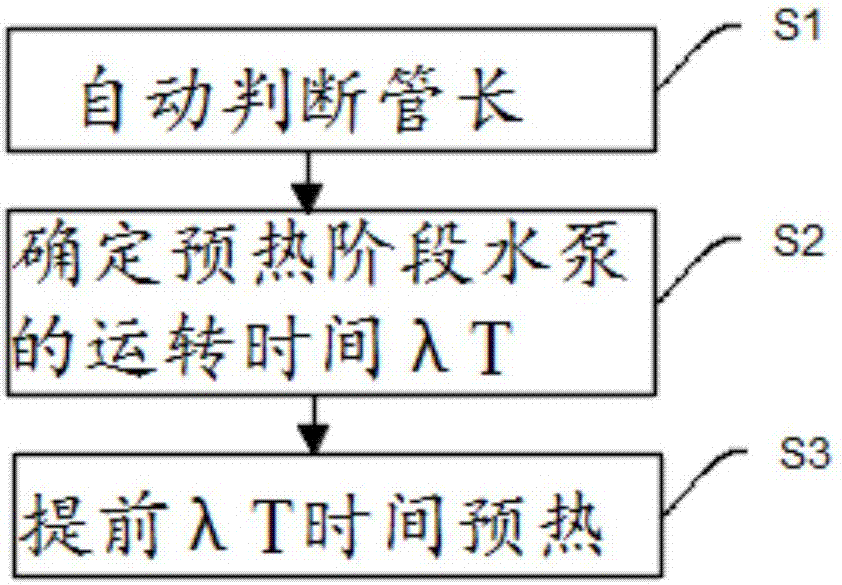

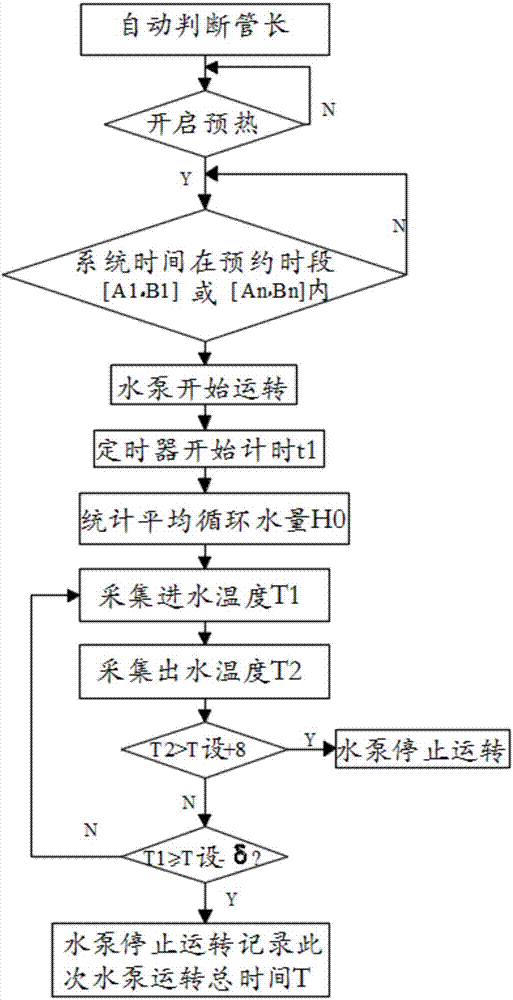

Water heater preheating method and water heater

PendingCN107990560AImprove experienceGuaranteed water temperatureFluid heatersHeating timeAppointment time

The invention provides a water heater preheating method and a water heater and relates to the technical field of water heaters. The water heater preheating method comprises the steps that the length of a water flow pipeline is judged at first, running of a water pump runs and heating of a heater as well as a full-pipeline preheating cycle T allowing the water temperature of the whole water flow pipeline to reach the preset water temperature are determined, then a half-pipeline preheating cycle delta T for heating water in a hot water pipeline to the preset water temperature is determined, after a user starts the preheating function, the water heater starts preheating delta T earlier than the appointment time interval of the user so that the water temperature in the hot water pipeline can meet the preset water temperature when the user uses the water, water is hot instantly when needed, and user experience is improved. According to the water heater provided by the invention, the preheating method is adopted, the water flow pipeline is provided with a one-way valve, the hot water pipeline and a cold water pipeline are separated, and only water in the hot water pipeline is heated whenthe water heater carries out preheating, so that the heating time is shortened, energy consumption is reduced, and user experience is great.

Owner:GUANGDONG MACRO GAS APPLIANCE

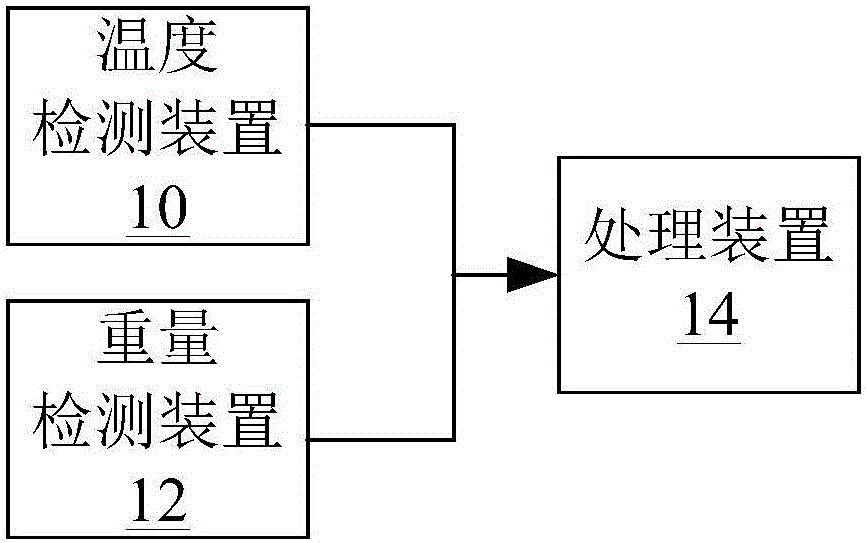

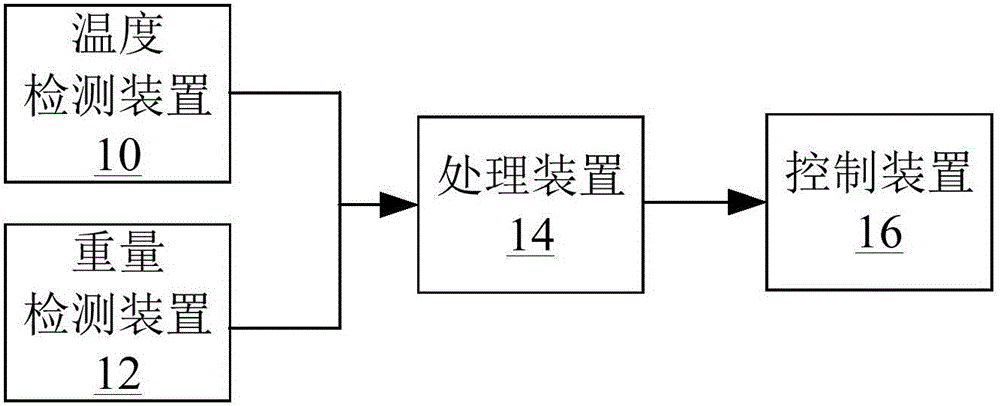

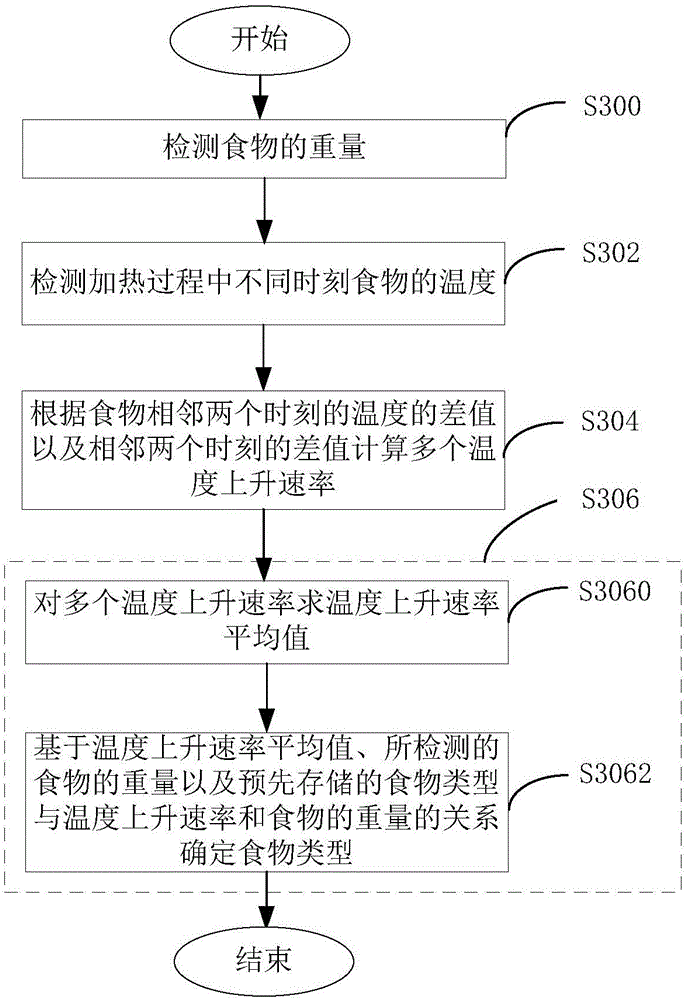

Device and method for determining food type and heating control system and method

ActiveCN105686618APrecise control of heating timeSimple and accurate automatic determinationWarming devicesHeating timeProcess engineering

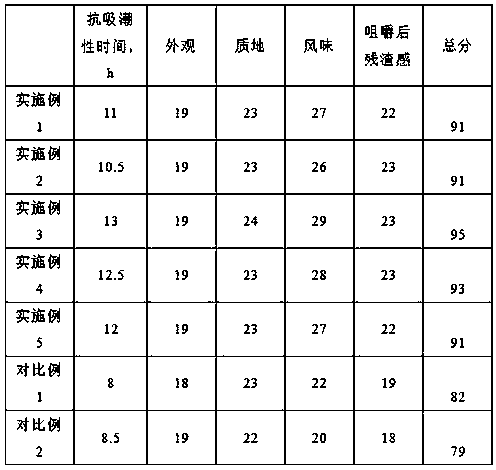

The invention relates to the field of food heating and discloses a device and method for determining a food type and a heating control system and method. The device comprises a temperature detecting device, a weight detecting device and a processing device, wherein the temperature detecting device is used for detecting the temperatures of food at different moments, the weight detecting device is used for detecting the weight of the food, and the processing device is connected with the temperature detecting device and the weight detecting device and used for calculating multiple temperature rising speed rates according to multiple temperatures detected at different moments and moments corresponding to the temperatures and determining the type of the food based on the temperature rising speed rates and the detected weight of the food. Thus, the type of the heated food can be easily, accurately and automatically determined without user participation, and thus precise control over the heating time of the heated food can be better achieved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

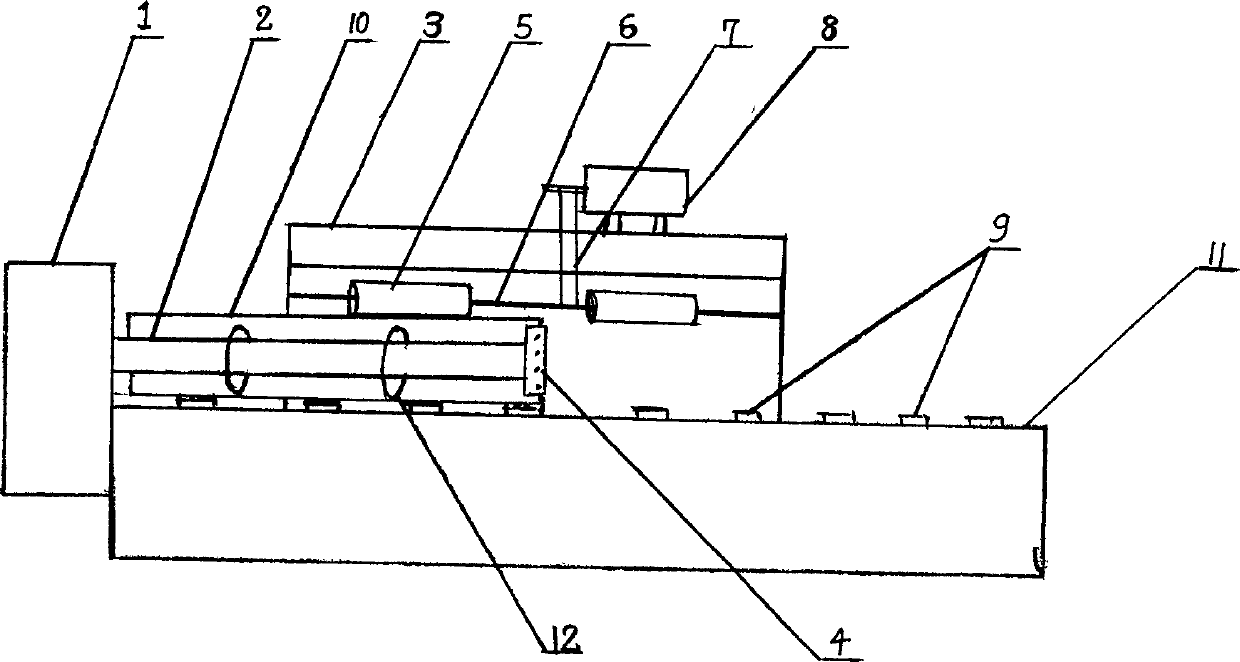

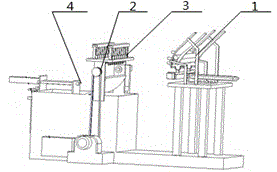

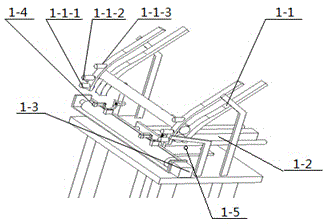

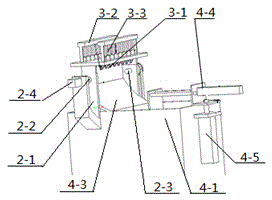

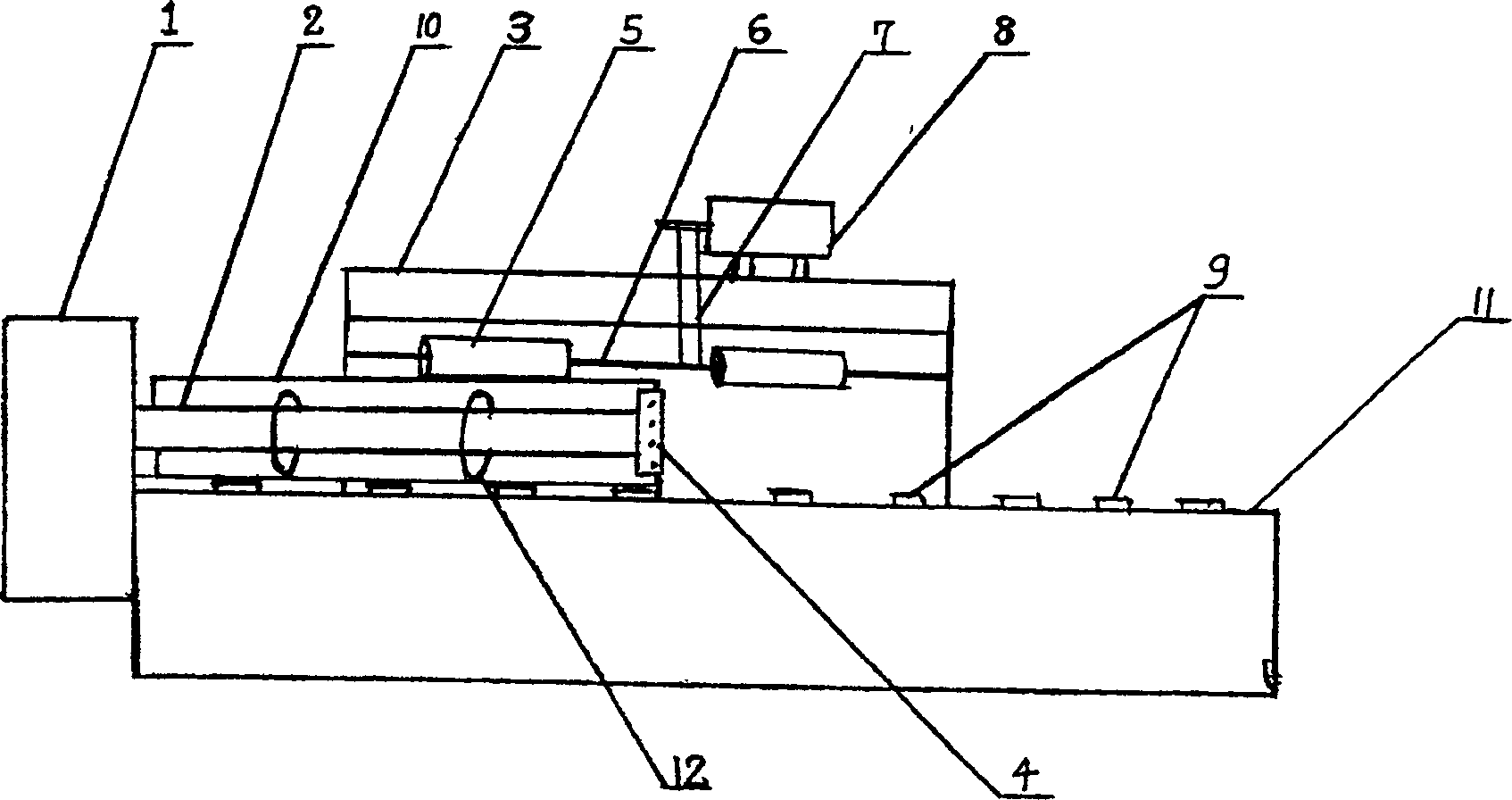

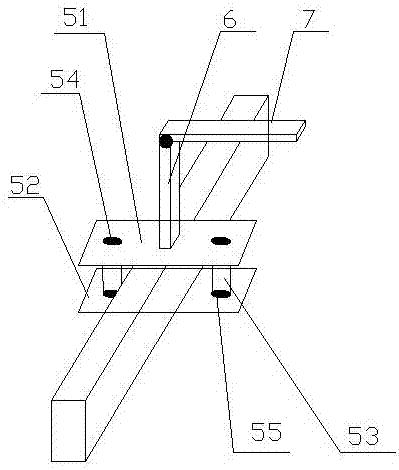

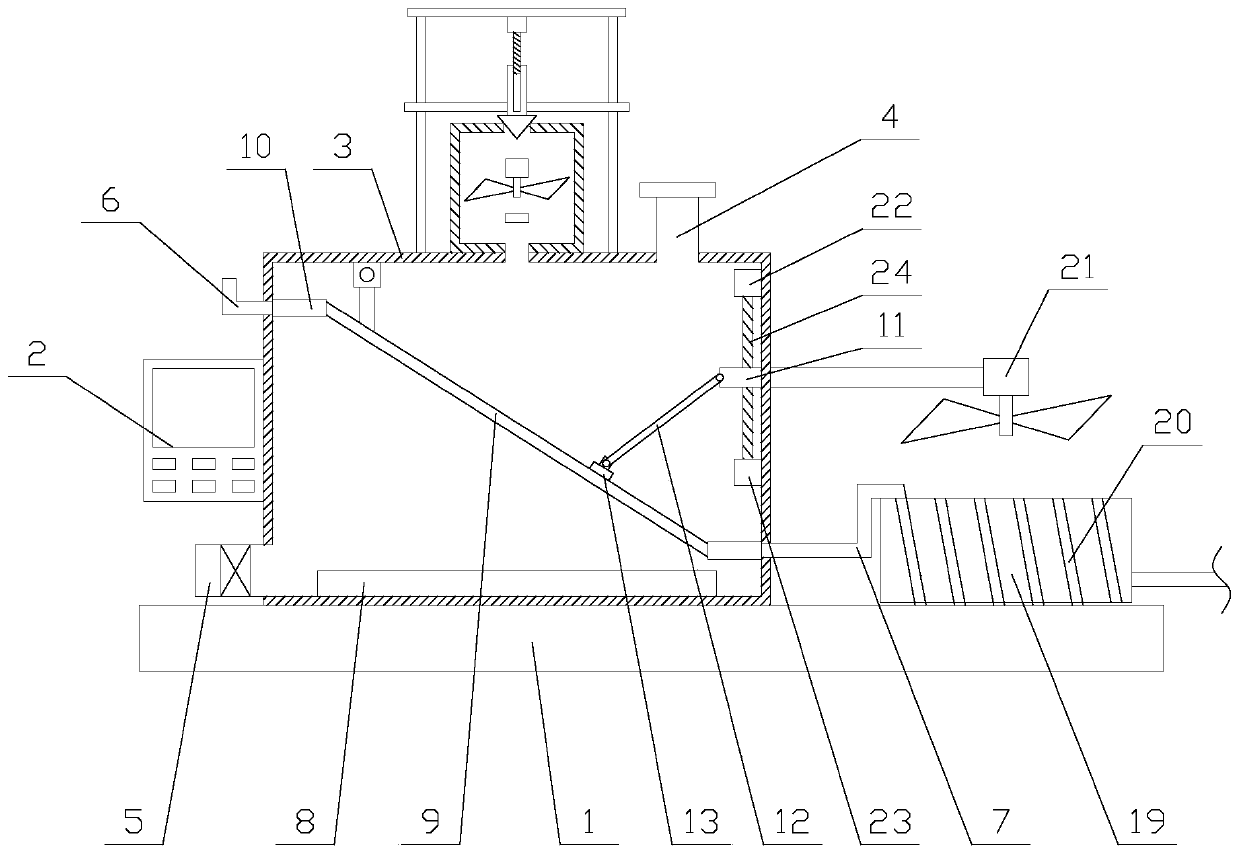

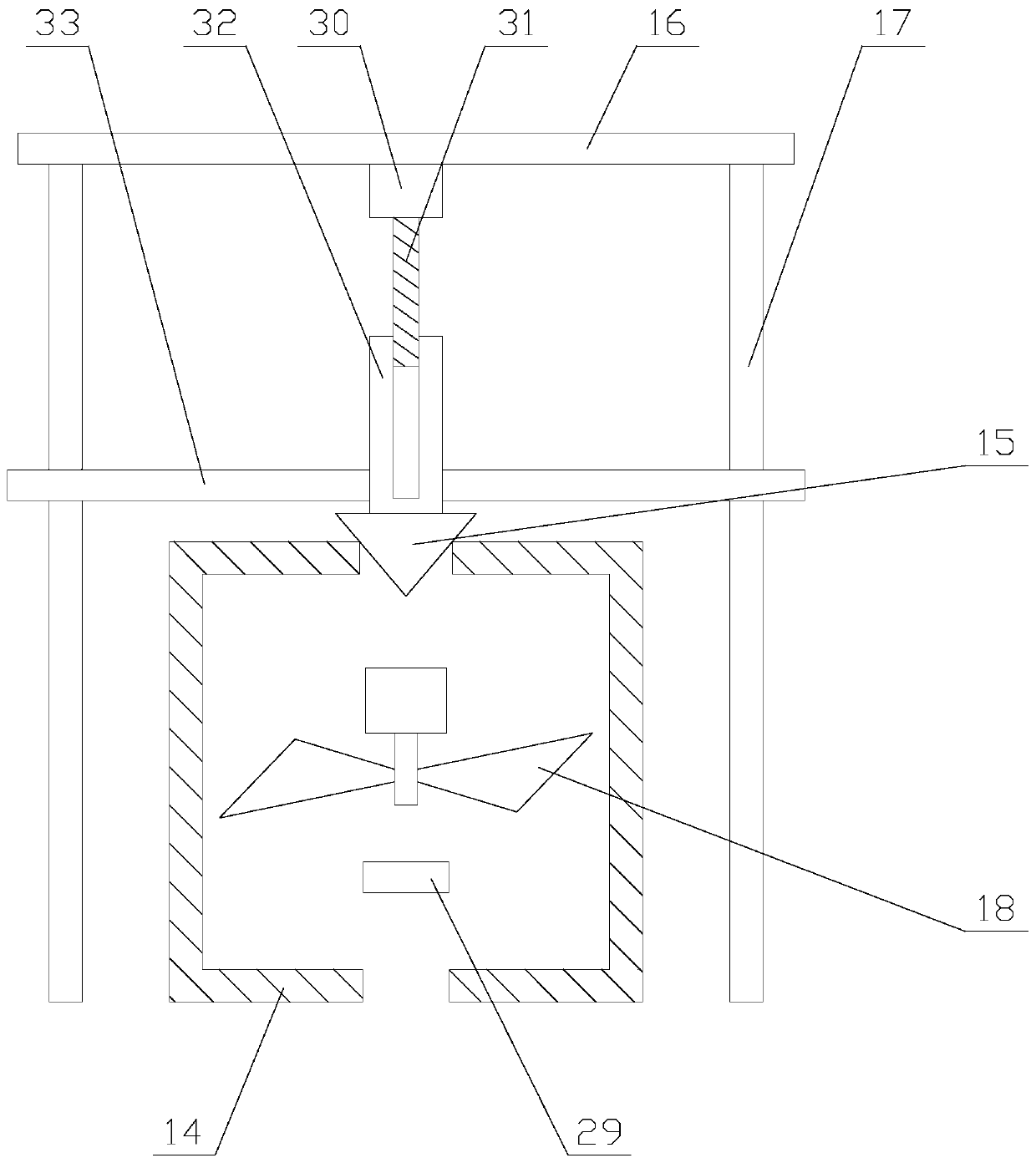

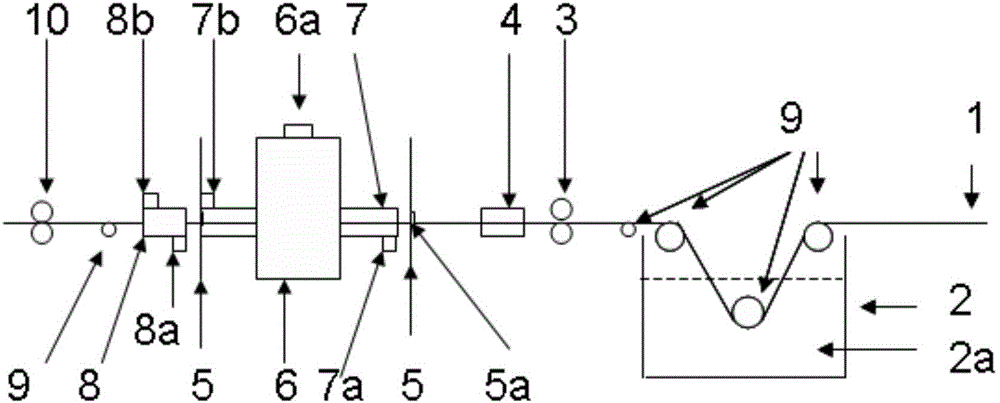

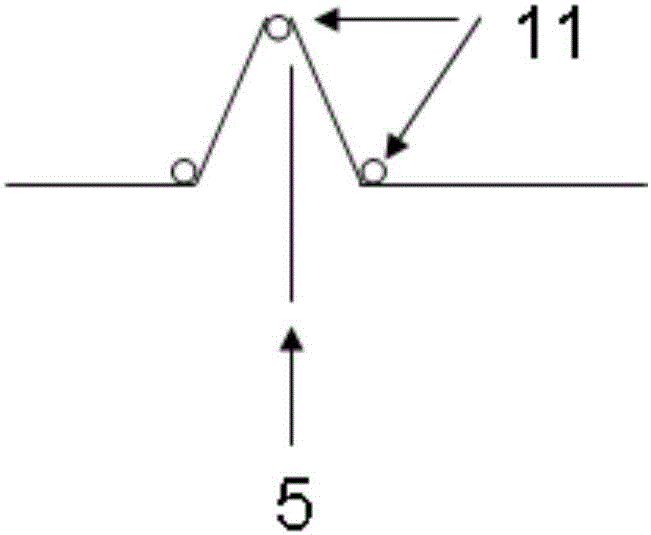

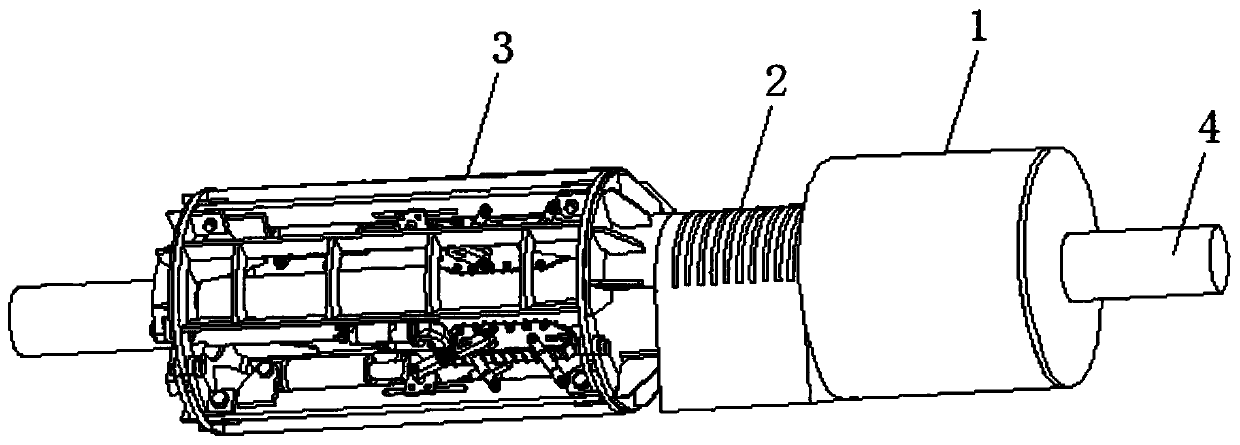

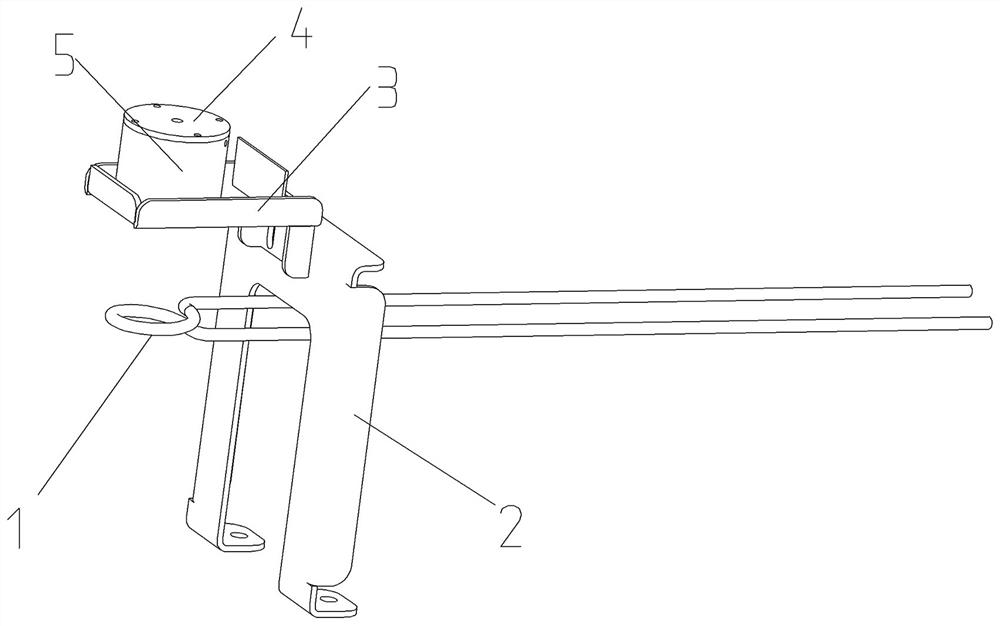

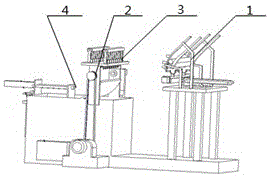

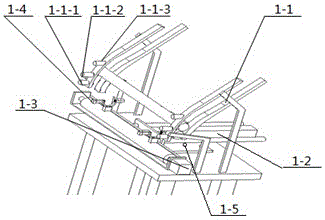

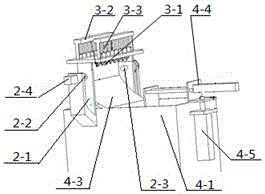

Cam shaft flame hardening automatic heat treatment machine tool and technology

ActiveCN104928458ASimple structureImprove versatilityFurnace typesHeat treatment furnacesEngineeringCam

The invention relates to a cam shaft flame hardening automatic heat treatment machine tool. The machine tool comprises a feeding mechanism, a rotating mechanism, a heating mechanism, a cooling mechanism and a control mechanism controlling all the mechanisms of the machine tool to run cooperatively, wherein the feeding mechanism, the rotating mechanism, the heating mechanism, the cooling mechanism and the control mechanism are arranged on the machine tool in sequence. The invention further discloses a cam shaft flame hardening automatic heat treatment technology. The technology specially comprises the steps of automatic feeding, flame heating and cooling. By the adoption of the cam shaft flame hardening automatic heat treatment machine tool and technology, the technical problem of conducting automatic heat treatment on a cam shaft with the flame hardening heat treatment technology is solved, automatic precise operation is achieved during cam shaft flame hardening, hardening quality and stability are guaranteed, a feeding system and a discharging system of the cam shaft flame hardening automatic machine tool are high in automation degree, and production efficiency and economic effectiveness are further improved.

Owner:HEBEI UNIV OF ENG

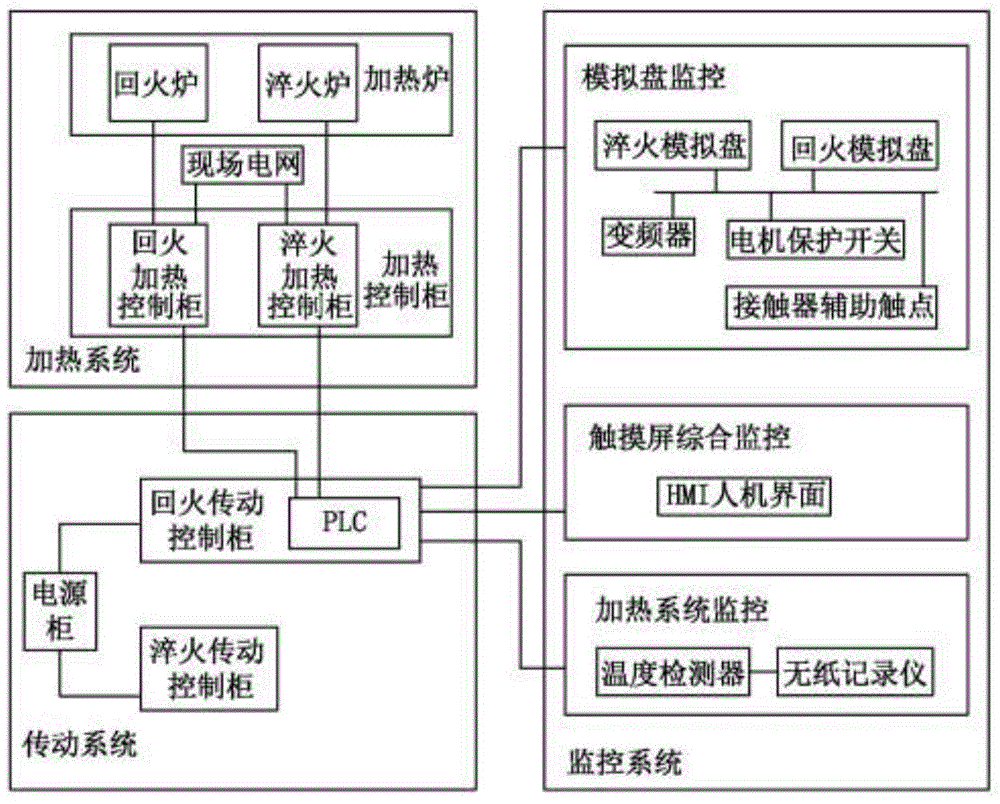

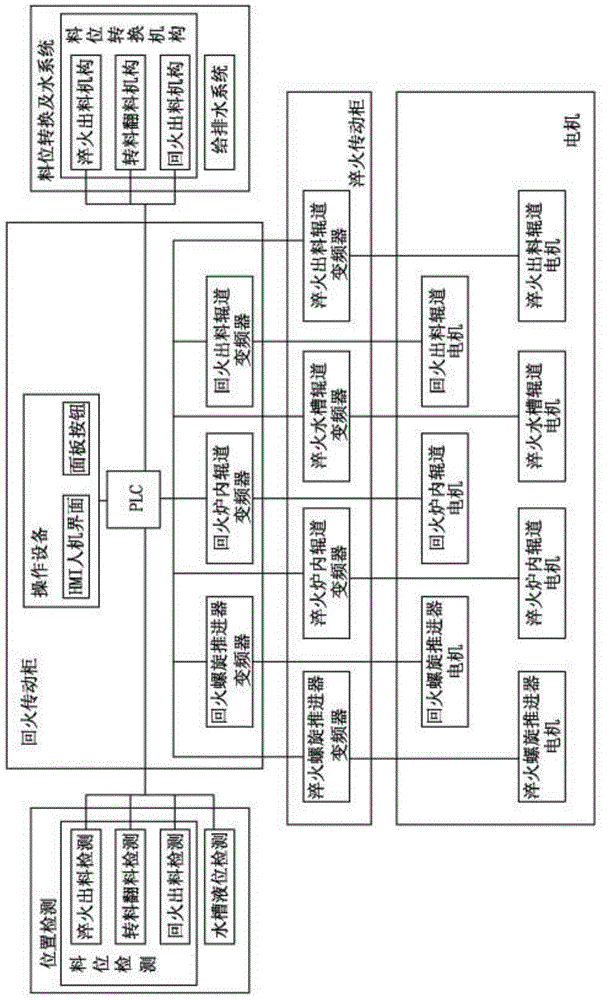

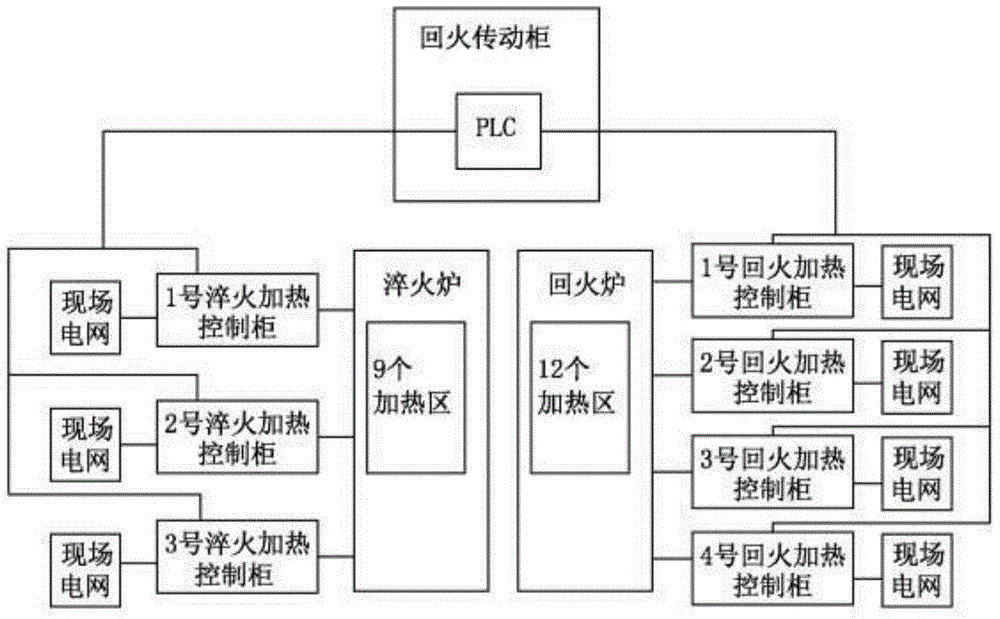

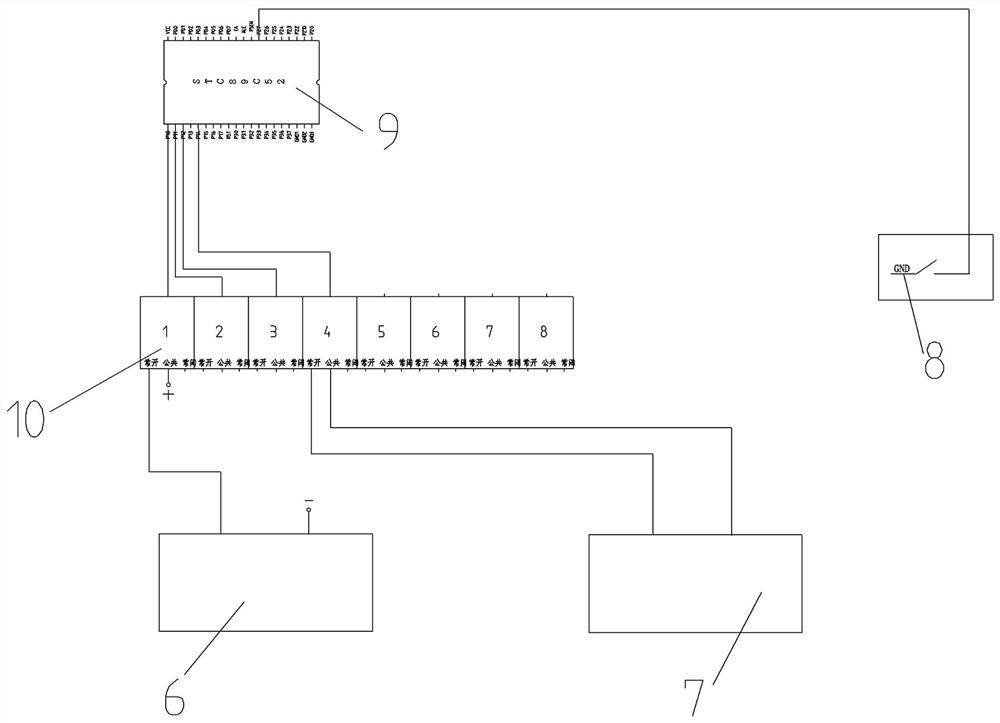

Electrical control system for long bar heating furnace

InactiveCN105112646AImprove versatilityPrecise control of heating timeFurnace typesHeat treatment process controlFrequency changerQuenching

The invention provides an electrical control system for a long bar heating furnace. The system comprises a transmission system, a heating system and a monitoring system, wherein the transmission system comprises a power cabinet, a tempering transmission cabinet, a quenching transmission cabinet, a position detector, a material position switching and water system and motors, wherein a transducer, a PLC and an operating device are arranged in the tempering transmission cabinet and sequentially connected; the transducer is connected with the corresponding motor; the heating system comprises a heating control cabinet and a heating furnace; the monitoring system comprises a simulating plate monitor, a touch screen integral monitor and a heating system monitor; the transmission system, the heating system and the monitoring system are connected through the PLC. According to the system, the heating, quenching and tempering of a workpiece can be automatically carried out; the workpiece heating time can be accurately controlled and adjusted, so that the operators can be greatly decreased, and the labor intensity can be reduced; meanwhile, an automatic production line of the long bar heating furnace can be monitored in real time and remotely diagnosed.

Owner:LUOYANG XINSILU ELECTRIC

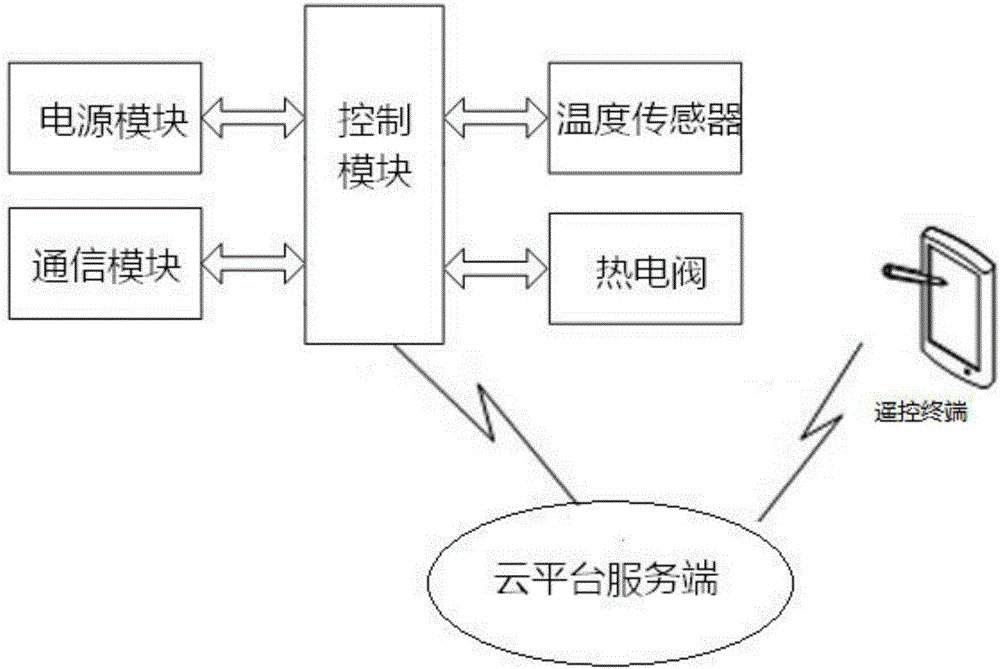

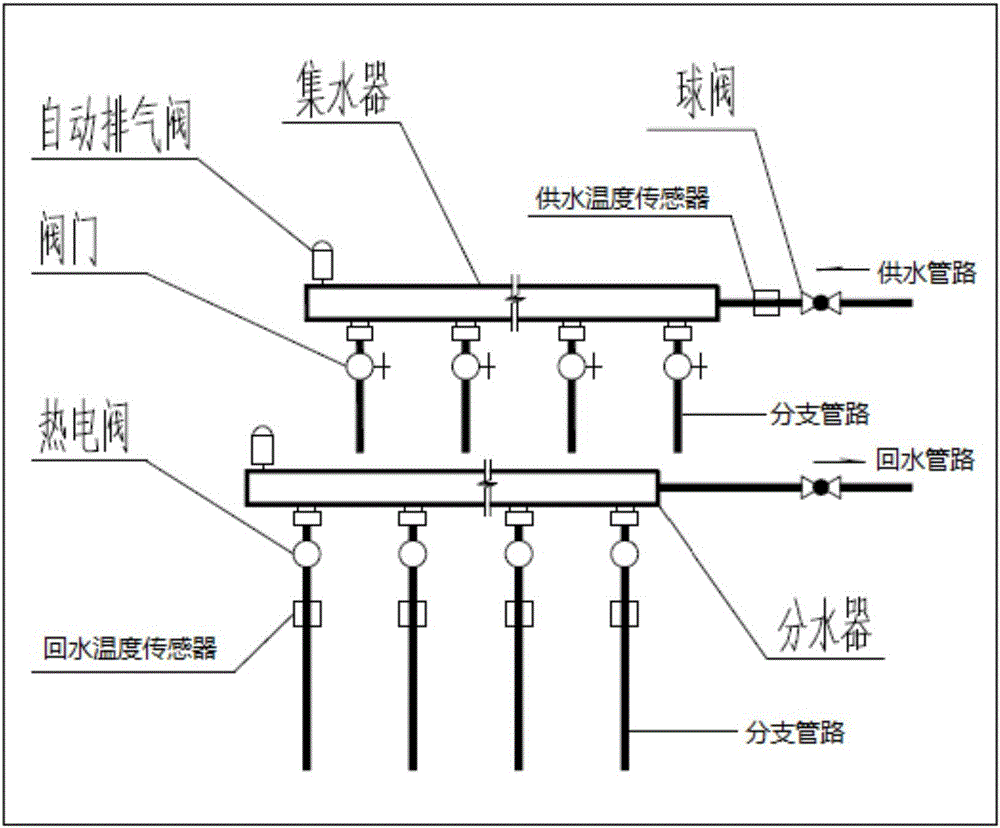

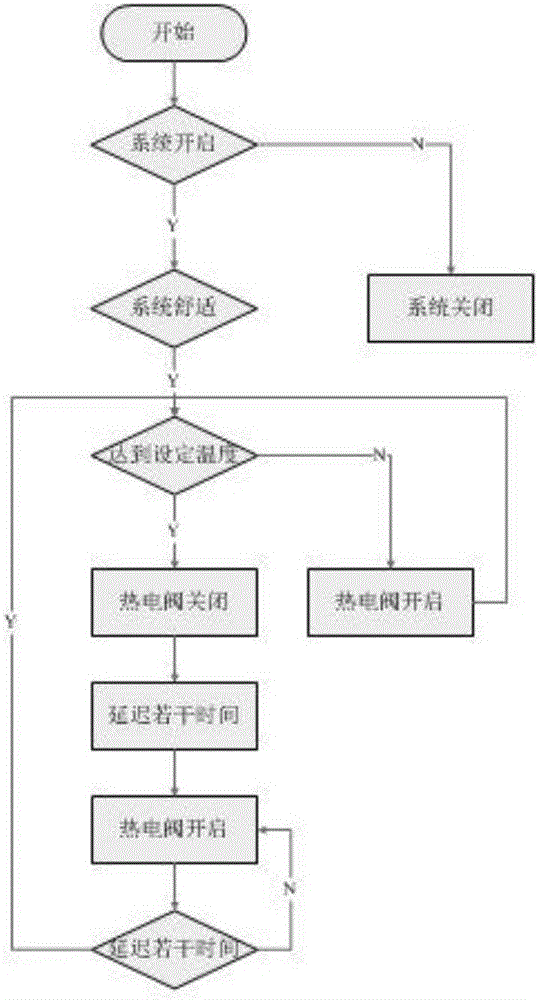

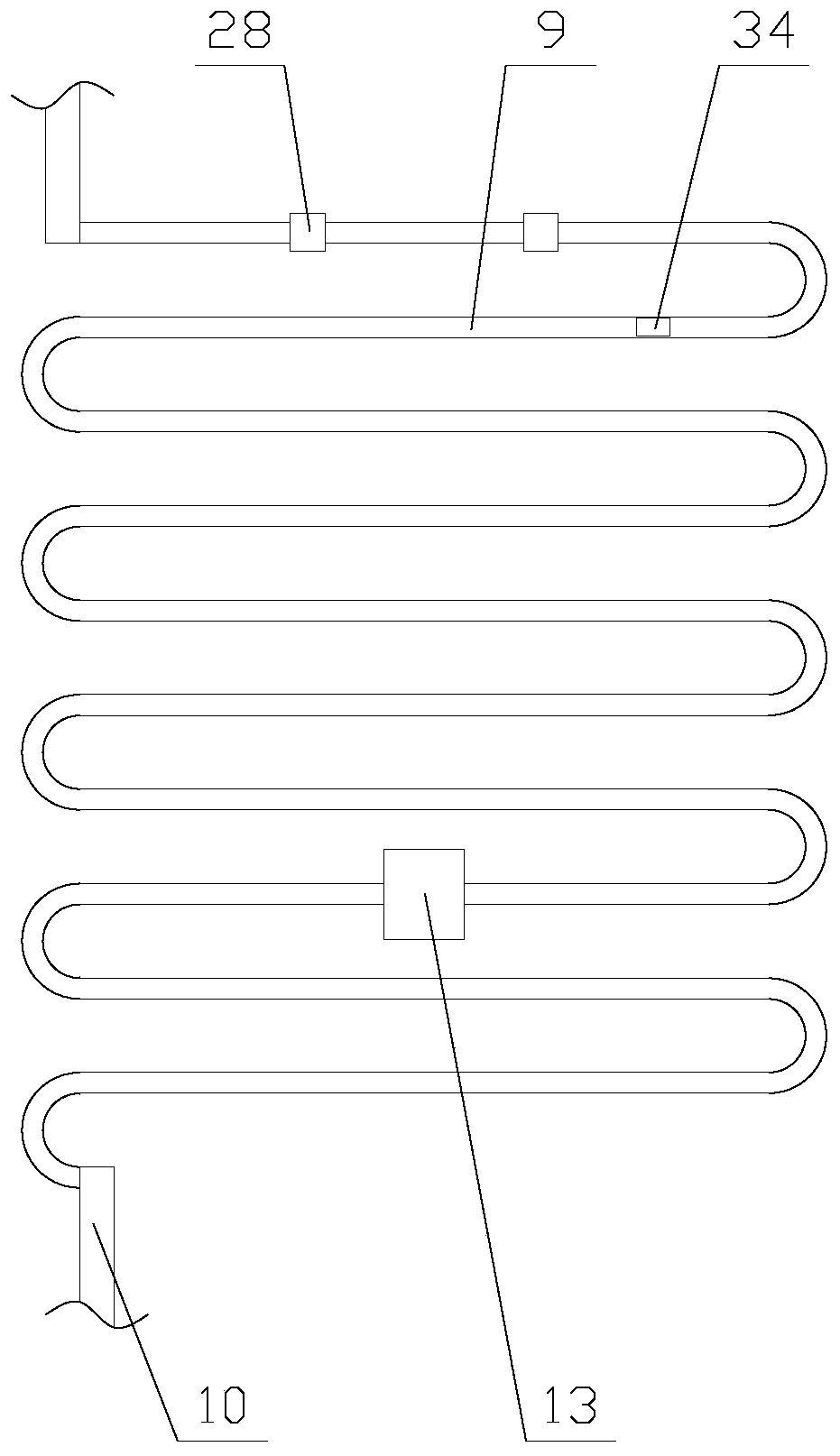

Novel intelligent home heating system and demand control method thereof

InactiveCN105864881APrecise control of heating timeHeating energy saving and high efficiencyLighting and heating apparatusCentral heating componentsRemote controlControl system

The invention discloses a novel intelligent home heating system. The system comprises a cloud platform server, and the cloud platform server is connected with a local control system and a remote control terminal through a public network; the local control system comprises a control module and further comprises a water supply pipeline and a water returning pipeline; the water supply pipeline is divided into a plurality of branch pipelines through a water collecting device, the multiple branch pipelines are communicated with the water returning pipeline through a water distribution device, and the water supply side of the water collecting device and the water returning side of each branch pipeline are each provided with a temperature sensor; and the water returning side of each branch pipeline is further provided with a thermoelectric valve, and the temperature sensors and the thermoelectric valves are all connected with the control module; and the control module is in data communication with the cloud platform server through a communication module. The temperature sensors are used by the system for monitoring inlet water and outlet water temperature in a loop in real time, the real-time delta T is obtained, on the one hand, the delta T is used for detecting the running state of the system, and on the other hand, the system can precisely control the heat supply time according to delta T; and energy-saving efficient heat supply of the system is achieved.

Owner:NANJING DENVO ENERGY SAVING TECH CO LTD

Cylinder shape pipe piece with inner harden layer and its production method and equipment

InactiveCN1190617CStable jobUniform speed regulationIncreasing energy efficiencyFurnace typesFrictional coefficientPipe fitting

The present invention relates to a cylindrical pipe with internal hardened layer, its production method and special-purpose equipment. Said cylindrical pipe has small wall thickness and long length, its pipe wall has internal layer and external layer with different hardness, the hardness of its internal layer is greater than that of external layer, and said pipe is applicable for conveying material with high frictional coefficient. Its production method adopts the mode utilizing frequency to control pipe movement and proper hardening temp. range, and is special-purpose equipment is simple in structure, stable in operation, and can accurately control hardening temp., pipe moving speed nad depth of hardened layer.

Owner:王克发 +1

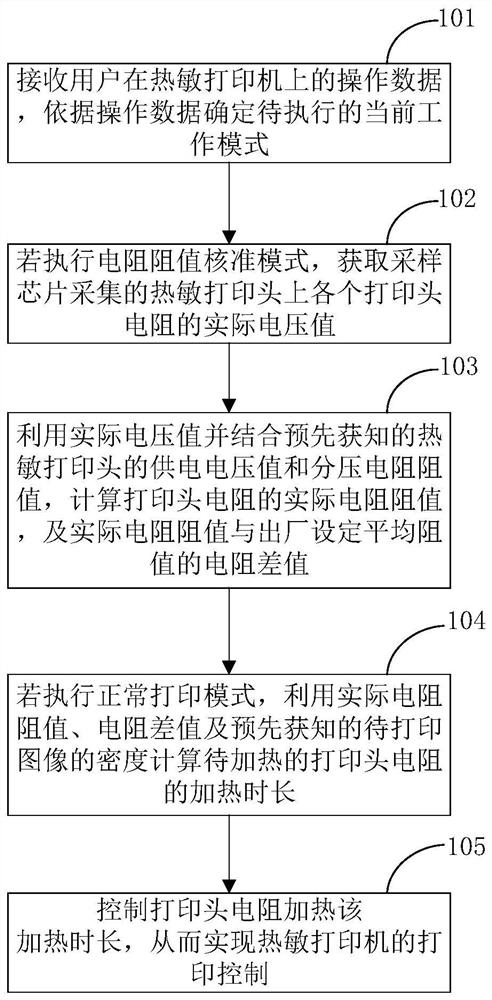

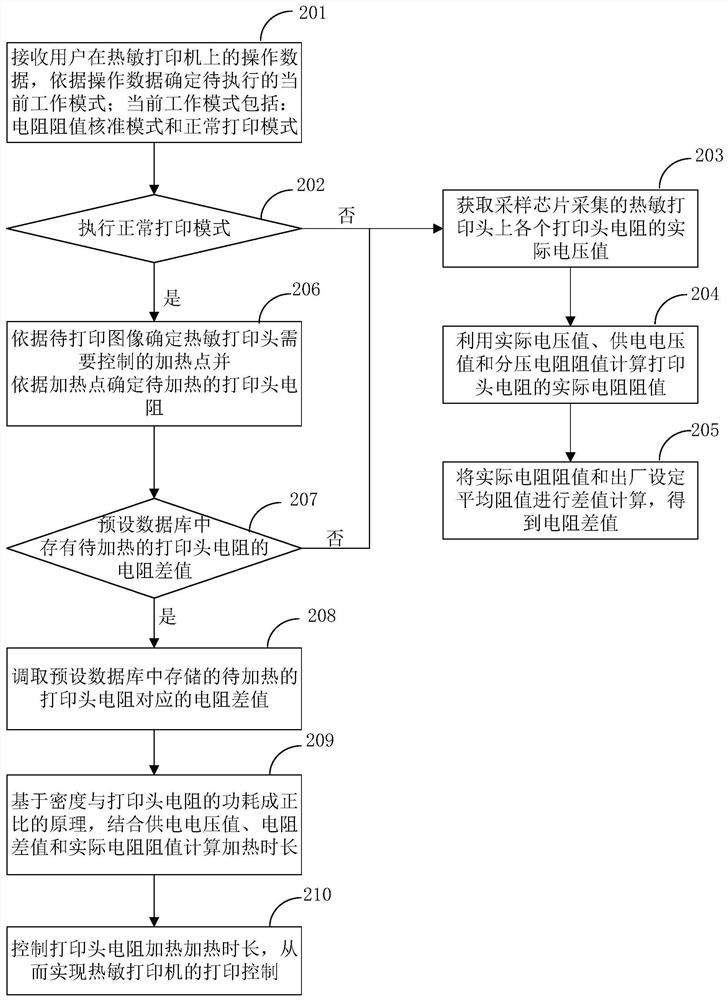

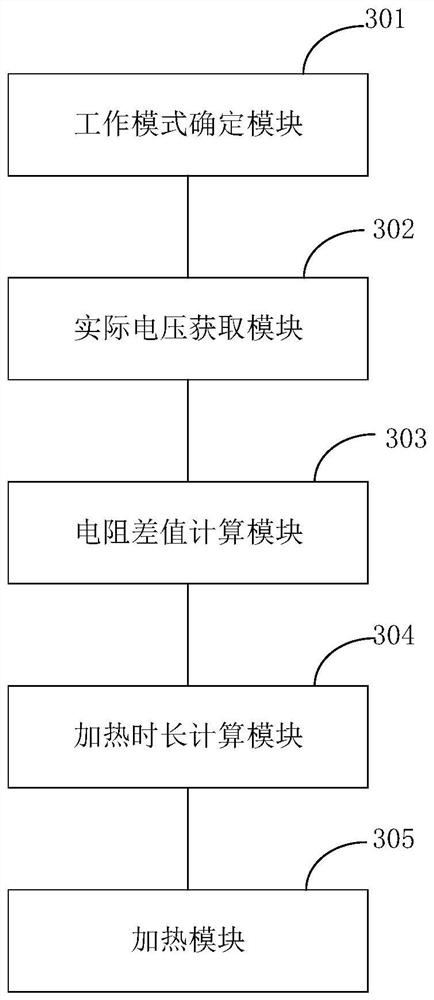

Control method and device of thermal printer, controller and control system.

InactiveCN113334940AEasy to controlAccurate calculation of heating timeOther printing apparatusThermodynamicsControl system

The invention relates to a control method and device of a thermal printer, a controller and a control system. The method comprises the following steps: receiving operation data of a user on the thermal printer, and determining a to-be-executed current working mode according to the operation data, where the current working mode comprises a resistance value approval mode and a normal printing mode; if the resistor resistance value approval mode is executed, obtaining the actual voltage value, collected by the sampling chip, of each printing head resistor; calculating an actual resistance value of a printing head resistor and a resistance difference value between the actual resistance value and a factory set average resistance value by utilizing the actual voltage value and combining a power supply voltage value and a divider resistance value of the thermal printing head; if the normal printing mode is executed, using the actual resistance value, the resistance difference value and the density of the to-be-printed image for calculating the heating duration of the to-be-heated printing head resistor; and controlling the heating duration of resistor heating of the printing head. According to the method, the heating duration of the printing head resistor is accurately controlled, and the error between a printed image and a source image is reduced.

Owner:南阳柯丽尔科技有限公司

Preparation method of graphene foam

The invention discloses a preparation method of graphene foam. The preparation method comprises the following steps: firstly, graphene derivative foam is prepared from a graphene derivative solution; then the graphene derivative foam passes through a microwave heating region at a set speed in a set atmosphere, and the graphene derivative foam is heated to convert graphene derivatives into graphene which is cooled to obtain the graphene foam. The method provided by the invention solves problems of high energy consumption, low yield and graphene derivative foam performance requiring to be improved due to the existing graphene foam needs high temperature vapor deposition, realizes convenient, fast and mass production of the graphene foam material, and is expected to contribute to further development and application of graphene and foam materials.

Owner:SOUTHEAST UNIV

Online temperature detection device

ActiveCN107388841AAccurate and reliable temperature detectionEasy to install and disassembleCharge composition/stateCharge treatment typeTemperature measurementEngineering

The invention belongs to the technical field of heating temperature measurement and control in sintering body firing technologies, and particularly relates to an online temperature detection device. The online temperature detection device comprises a kiln car entering and exiting a kiln, and at least one fixing base is arranged among outer frames of the kiln car; a telescopic vertical rod is arranged on each fixing base, one end of each telescopic vertical rod is fixed to the corresponding fixing base, the other end of each telescopic vertical rod is connected with one end of a corresponding telescopic transverse rod, the other end of each telescopic transverse rod is provided with a temperature detector installing hole, a temperature detector is installed in each temperature detector installing hole, the output ends of the temperature detectors are connected with a controller, and the output end of the controller is connected with a displayer. According to the online temperature detection device, the structure is simple, the actual temperature of sintering bodies located at different positions of the kiln car can be detected in real time, and the qualification rate of finished products is greatly increased.

Owner:郑州登电科诚新材料有限公司

Preparation method of graphene thin film

The invention discloses a preparation method of a graphene thin film. A graphene derivative and inorganic non-metal plane carrier composite material passes through a microwave heating region at a set speed for the first time so as to precisely control the heating time and the cooling chance, so that heating nonuniformity caused by difference among different regions of microwave heating is inhibited and mechanical continuous production is easily realized; moreover, a microwave technology capable of heating quickly and a microwave absorption characteristic and a high heat conducting capacity of the graphene derivative are combined, and meanwhile, by virtue of the characteristics that the inorganic non-metal plane carrier is high-temperature resistant and heat of the surface graphene derivative layer is easily and quickly exchanged and transferred, the graphene derivative layer coated on the surface of a carrier can be quickly converted into a graphene layer, and then the graphene layer and the carrier are separated to obtain the graphene thin film which has a good electric conducting ability. The graphene thin film prepared by the method is excellent in performance and can make contribution to further development and application of conductive thin films and graphene materials.

Owner:SOUTHEAST UNIV

Electromagnetic heating reaction kettle rotary kiln

ActiveCN105258495AAchieve multiple positioningImprove utilization efficiencyRotary drum furnacesWaste heat treatmentEngineeringElectromagnetic shielding

The invention discloses an electromagnetic heating reaction kettle rotary kiln. The electromagnetic heating reaction kettle rotary kiln comprises a charging barrel. Vertexes are induced by means of an electromagnetic heating coil in a charging barrel shell through electromagnetic induction, so that the charging barrel is heated. The reaction kettle rotary kiln further comprises a cooling device. A connecting pipe of the cooling device is communicated with the electromagnetic heating coil, so that the electromagnetic heating coil is cooled from the interior. The reaction kettle rotary kiln further comprises a charging barrel stabilizing device which can prevent the charging barrel from shaking leftwards, rightwards, forwards and backward, and a cooling device used for cooling the charging barrel stabilizing device and the electromagnetic heating coil, an exhaust device used for exhausting waste gas generated during ore heating, a support device used for installing a kiln body, a voltage transformation system used for supplying power to the electromagnetic heating coil, and a center control device which is connected with all the other devices and used for controlling operation of all the other devices. The electromagnetic heating reaction kettle rotary kiln has the advantages that through induction heating, the energy utilization efficiency is high; by adjusting the speed of the charging barrel and the speed of a conveying pipe, the generated waste gas can be treated effectively, and safety construction is guaranteed, the stability is high, and maintenance is convenient.

Owner:ANHUI GUANHUA GOLD TECH

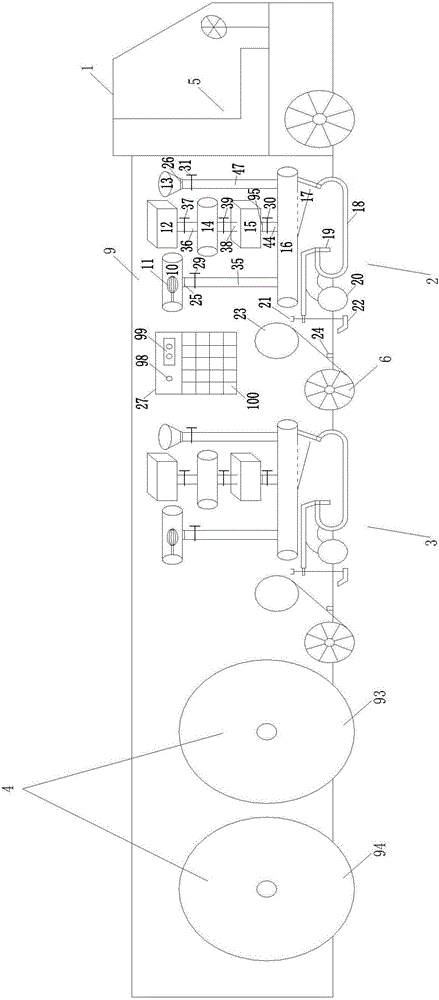

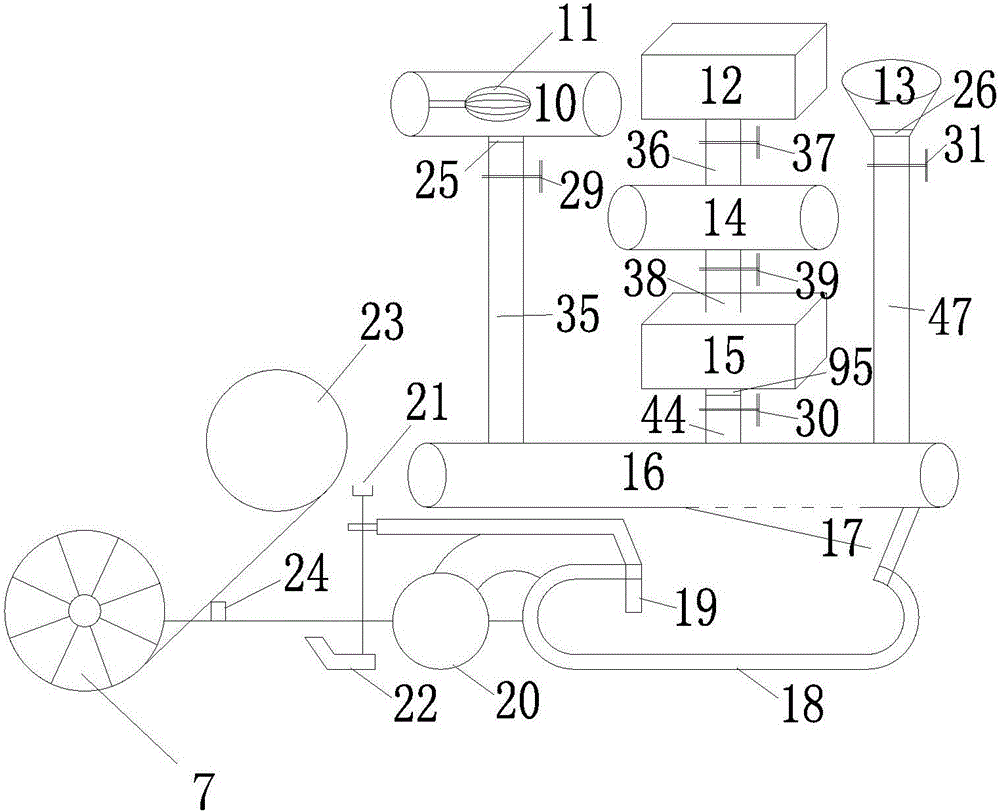

Double-layer stress absorption band integrated construction train

InactiveCN106012783APrecise control of stirring rateSimple structureRoads maintainenceRoad engineeringData acquisition

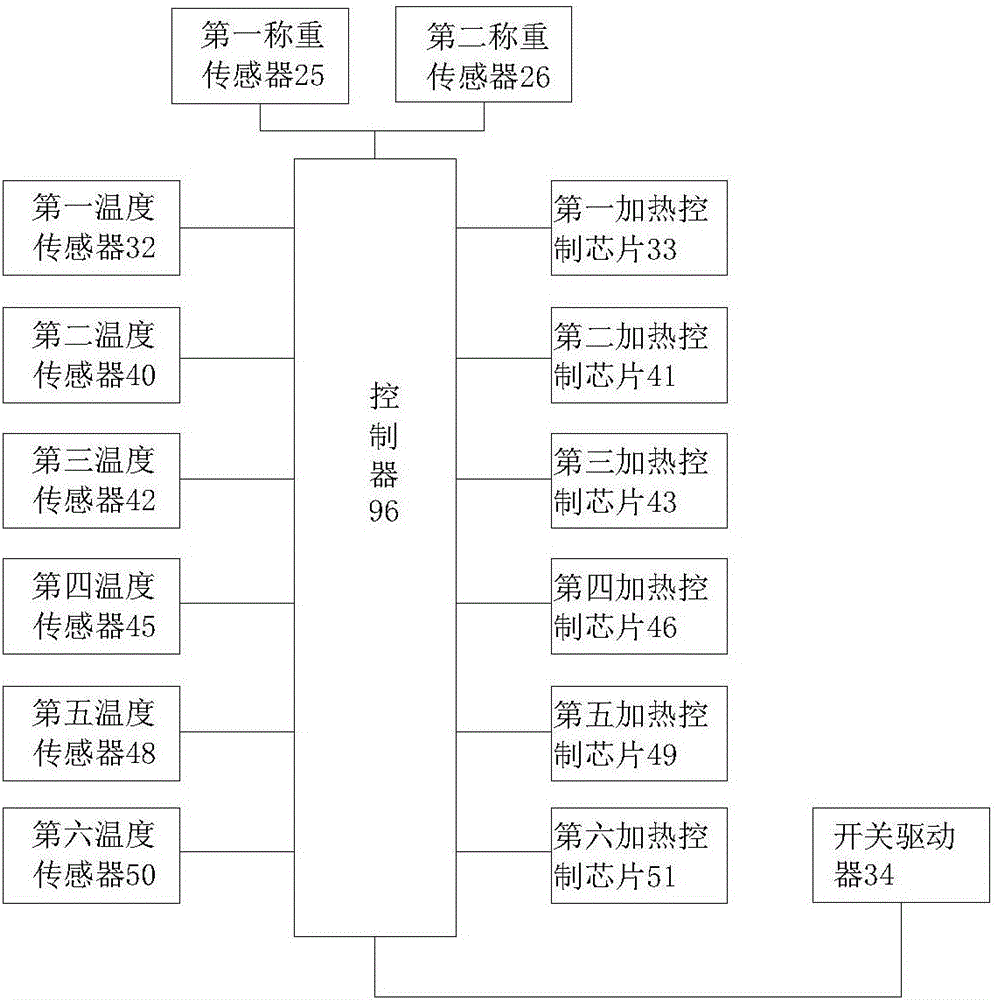

The invention belongs to the field of road engineering, and relates to a double-layer stress absorption band integrated construction train. The double-layer stress absorption band integrated construction train comprises a train body and a carriage which is dragged by the train body; a first stress absorption band preparation and pavement device, a second stress absorption band preparation and pavement device and a compacting device are arranged in the carriage in the axial direction of the carriage in sequence; a data acquisition and control device which is connected with the first stress absorption band preparation and pavement device and the second stress absorption band preparation and pavement device is also arranged in the carriage; the data acquisition and control device comprises a control box; a controller, and a heating control chip and a switch driver which are respectively connected with the controller are arranged in the control box. The double-layer stress absorption band integrated construction train has the advantages that the structure is simple, the design is reasonable, the use and operation are convenient, the use effect is good, the preparation and pavement of a double-layer stress absorption band can be completed conveniently and quickly, and the preparing and paving processes are easy to control.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Fruit and vegetable seasoning and preparation method thereof

The invention relates to a fruit and vegetable seasoning and a preparation method thereof, and belongs to the technical field of seasonings. The method comprises the steps of preprocessing raw materials, preparing fruit enzymes, and preparing the fruit and vegetable seasoning. The seasoning is natural, safe and delicious in taste and has the unique and rich fruit and vegetable flavor; by adoptingno animal raw materials, fat and protein contents contained in existing chicken powder products are greatly lowered, and the phenomenon that a user carries out obesity due to chicken powder is avoided; meanwhile, no sodium glutamate is adopted, so that the requirement of people for health is met; the heating time of the fruit and vegetable products and the fruit enzymes is accurately controlled, loss of flavored substances is avoided as much as possible, the fruit enzyme and the fruits and vegetables are efficiently fused, and the produced seasoning is more comfortable in taste, free of bitterness and overflowing in fruit fragrance; the preparation method is simple and reliable and facilitates industrial production.

Owner:赵站锋

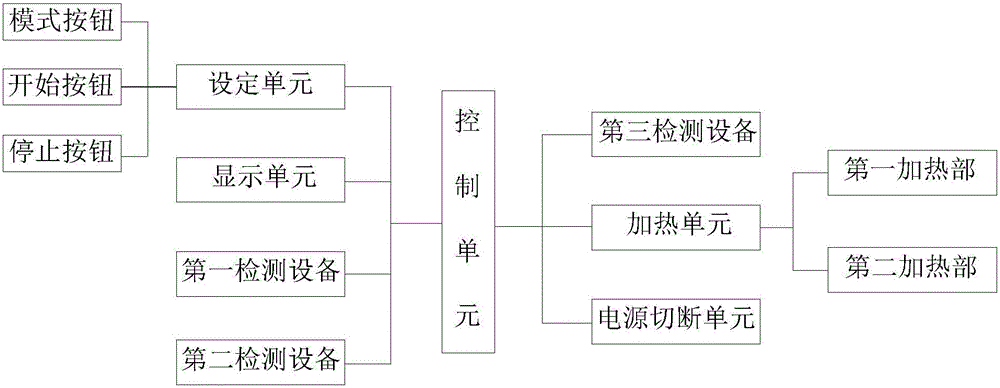

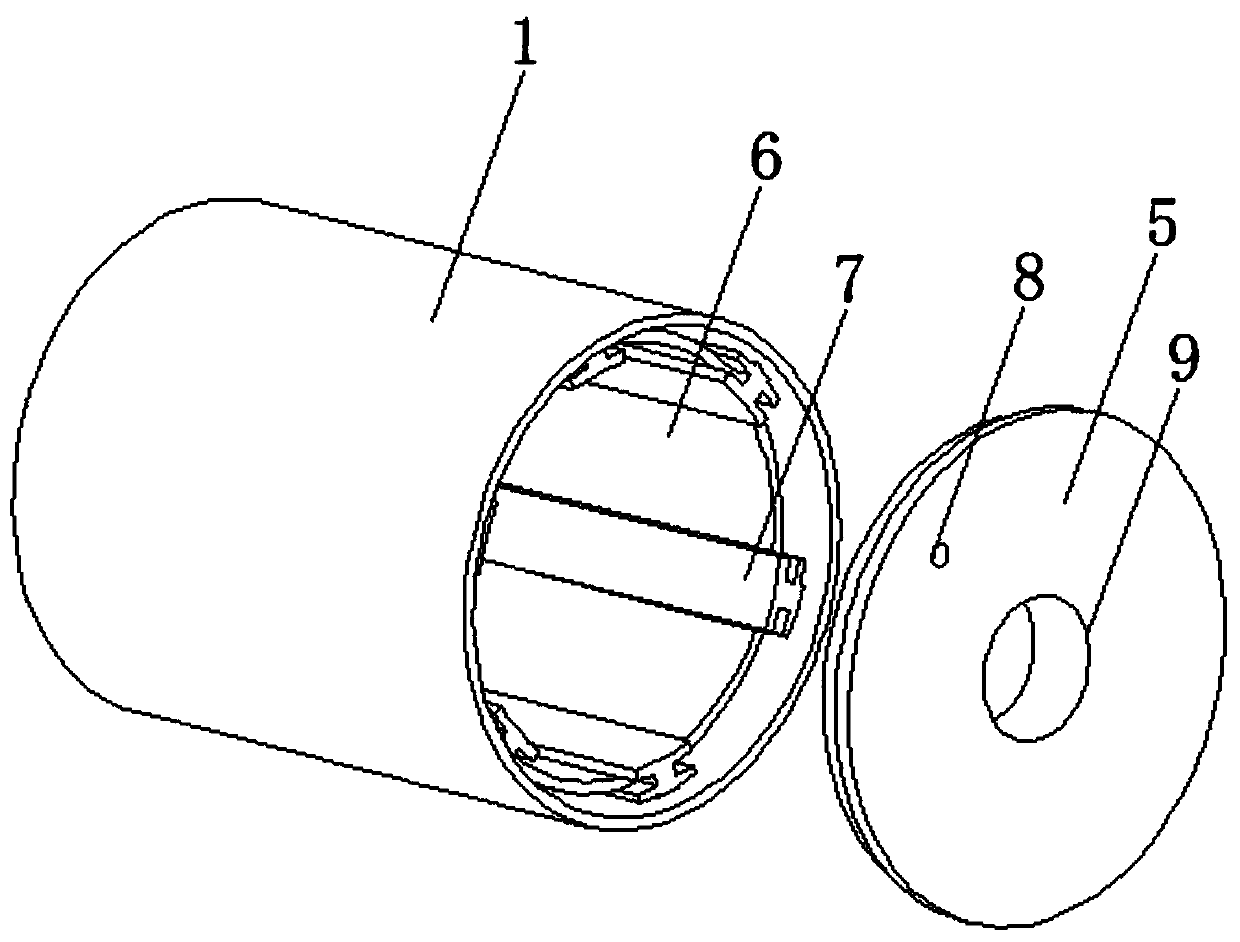

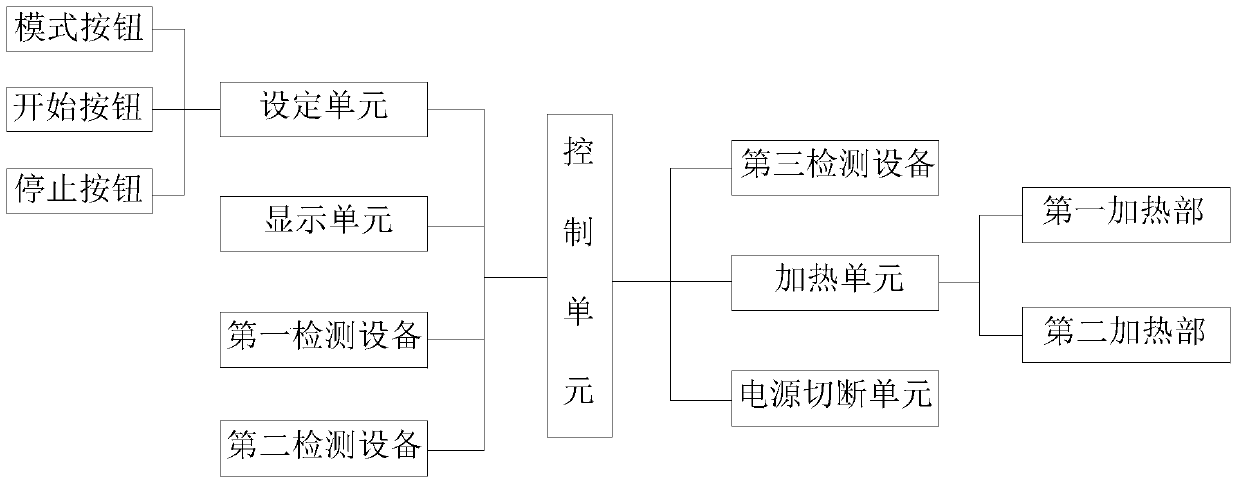

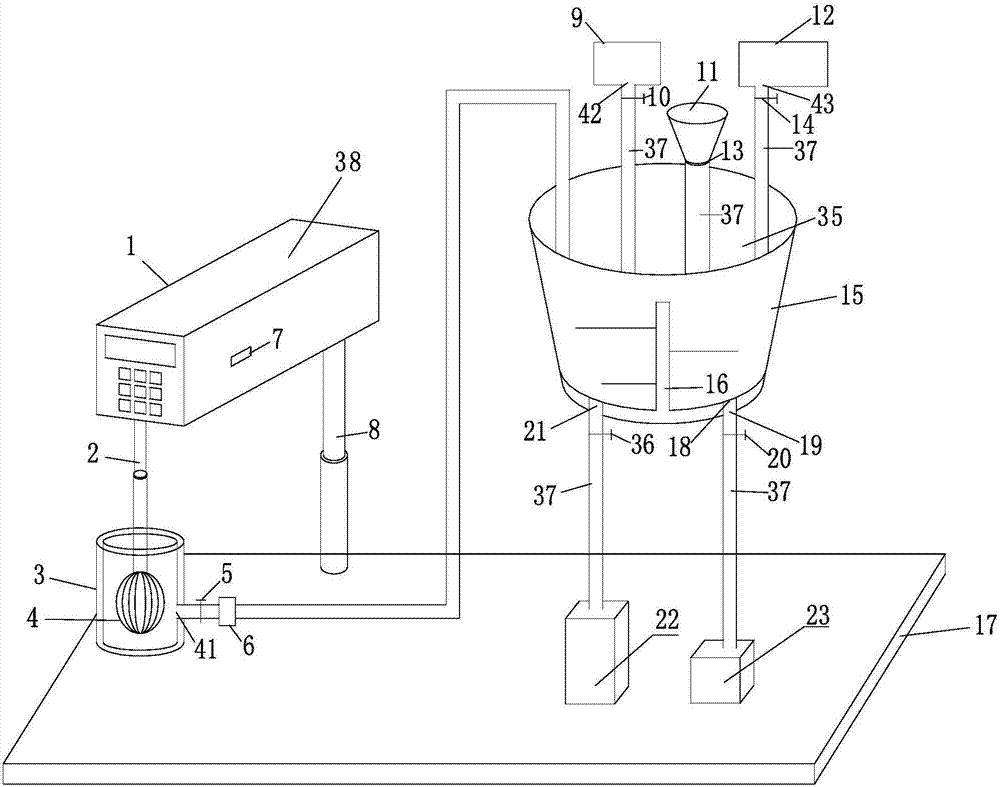

Intelligent control system of microwave oven

ActiveCN106102201AEasy to operateImprove experienceDomestic stoves or rangesLighting and heating apparatusMicrowave ovenCentral unit

The invention discloses an intelligent control system of a microwave oven. The intelligent control system comprises an oven body, an oven cavity, a heating unit and a control unit, wherein the oven body is provided with a setting unit and a display unit; a tray, second testing equipment and third testing equipment are arranged in the oven cavity; the tray is provided with first testing equipment; the control unit obtains a preset working mode which is collected by a mode button and selected by a user and a test value of the first testing equipment, and selects running time of the microwave oven in the preset working mode according to the test value; the control unit stores the running time in the control unit, obtains the test value of the second testing equipment and compares the test value with a preset value stored in the control unit; the control unit controls the heating unit to work according to a comparison result; and meanwhile, the control unit obtains image information, which is shot by the third testing equipment, of an object arranged on the tray, and transmits the image information to the display unit for display.

Owner:宣城加特林机械有限公司

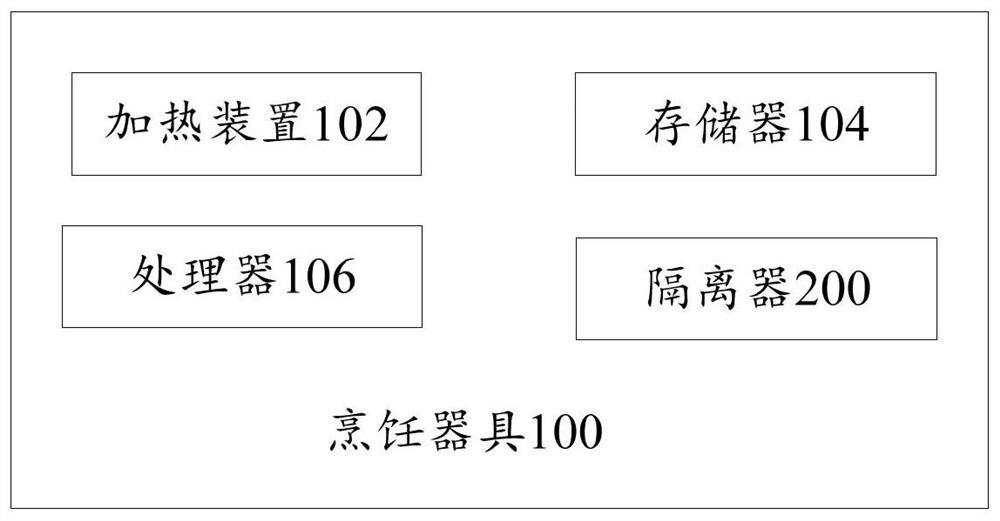

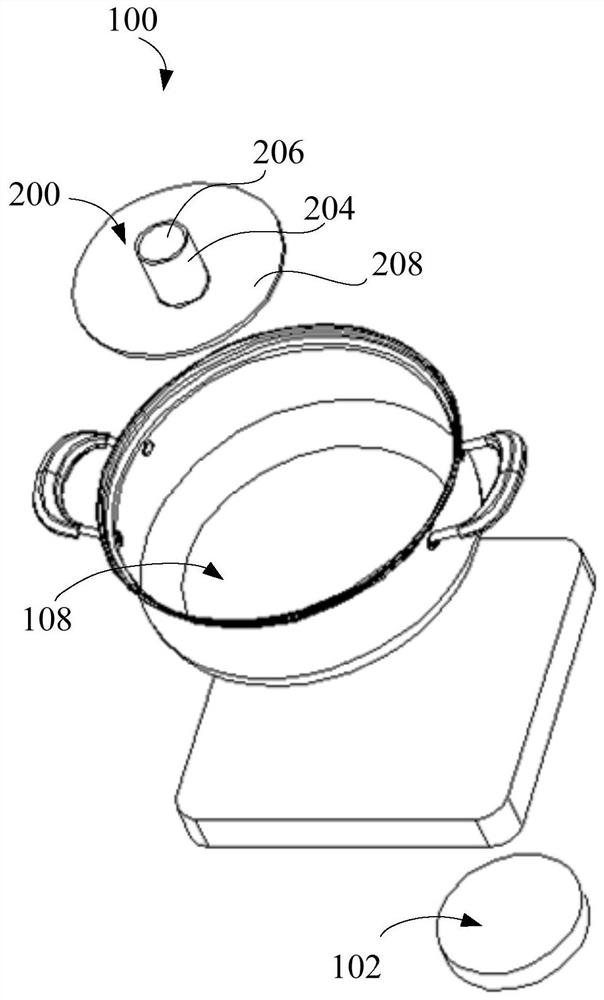

Cooking utensil, control method of cooking utensil and computer readable storage medium

ActiveCN113142968AGuaranteed cooking effectLittle influence of temperatureCooking insertsTime-controlled ignitorsIsolatorSteam cooking

The invention provides a cooking utensil, a control method of the cooking utensil and a computer readable storage medium. The cooking utensil comprises a pot; an isolator which is contained in the cookware, and the isolator and the cookware are matched to define a first chamber; a heating device configured to supply heat to the first chamber; a memory configured to store a computer program; and a processor which is configured to execute a computer program to implement so as to obtain cooking parameters, and determines first heating power and second heating power of the heating device according to the cooking parameters; and after the heating device is controlled to operate at the first heating power, the heating device is controlled to operate at the second heating power. According to the cooking utensil provided by the invention, quick steam discharging and segmented heating of the heating device are realized, a good steam cooking effect is favorably ensured, requirements of special cooking functions can be met, and the application range of the product is expanded.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

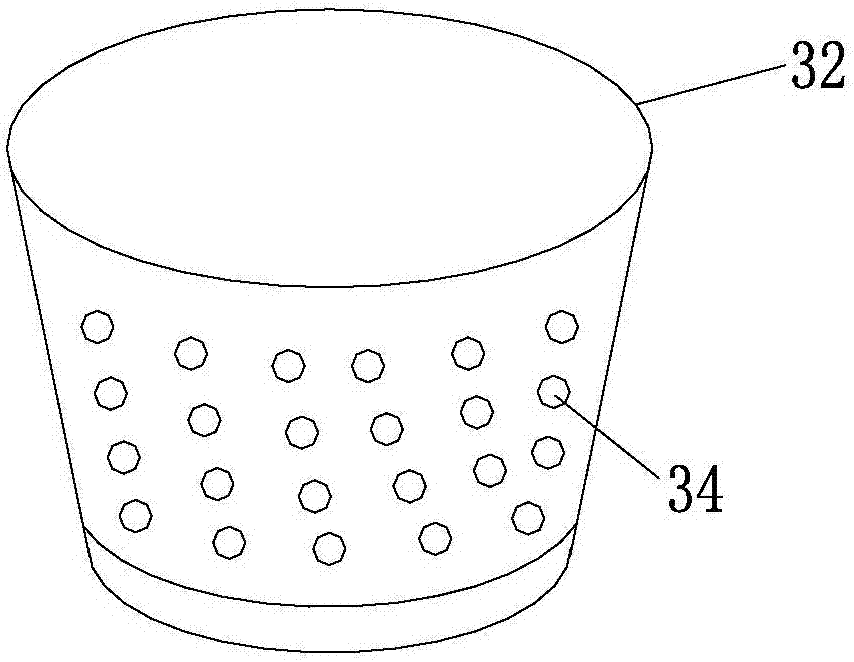

Pasteurization equipment for milk disinfection, having function of accurate regulating

InactiveCN110037106APrecise control of heating timeReduce pressureMilk preservationHeating timePasteurization

The invention relates to pasteurization equipment for milk disinfection, having a function of accurate regulating. The pasteurization equipment comprises a base, a controller, a water tank, a water filling pipe, a drain pipe, a pressure reducing mechanism, a liquid inlet pipe, a liquid outlet pipe and a heat dissipation mechanism, wherein a speed regulating mechanism and a heater are arranged in the water tank; the speed regulating mechanism comprises a heating pipe, a hinging assembly, a steering assembly and two hoses; the steering assembly comprises a lifting unit, a lifting block, a connecting rod and a connecting plate; and the pressure reducing mechanism comprises a pressure reducing box, a blocking block, a seal assembly, a top plate and two supporting rods. According to the pasteurization equipment for milk disinfection, having the function of accurate regulating disclosed by the invention, through the pressure reducing mechanism, the pressure intensity in the water tank is reduced, so that the boiling point temperature of water in the water tank is reduced, and the situation that the water temperature is too high, and nutrient substances of the milk run off is avoided; moreover, the flow rate of the milk in the heating pipe is regulated by the speed regulating mechanism, so that the heating time of the milk is accurately controlled, favorable sterilization and disinfection effect is guaranteed, and the practicality of the equipment is improved.

Owner:齐宽宽

Preparation method for compound metal fiber

ActiveCN106758135AImprove conductivityAvoid corrosionRadio/micro wave fibre treatmentMicrowaveGraphene derivatives

The invention discloses a preparation method for a compound metal fiber. The method comprises the following steps: firstly, combining a microwave technique capable of quickly heating with the microwave absorbing characteristic of graphene ramification and the microwave eddy heating characteristic of the metal fiber surface, and meanwhile, combining the high thermal conductance of the graphene with the characteristic of easiness in quickly exchanging and transferring the heat of the graphene layer, quickly converting the graphene ramification coated on the surface of the metal fiber into graphene with low energy consumption, thereby obtaining the compound metal fiber with excellent electric conduction and corrosion resistance. The preparation method can make a contribution to the further development and application of the metal fiber and the graphene material.

Owner:SOUTHEAST UNIV

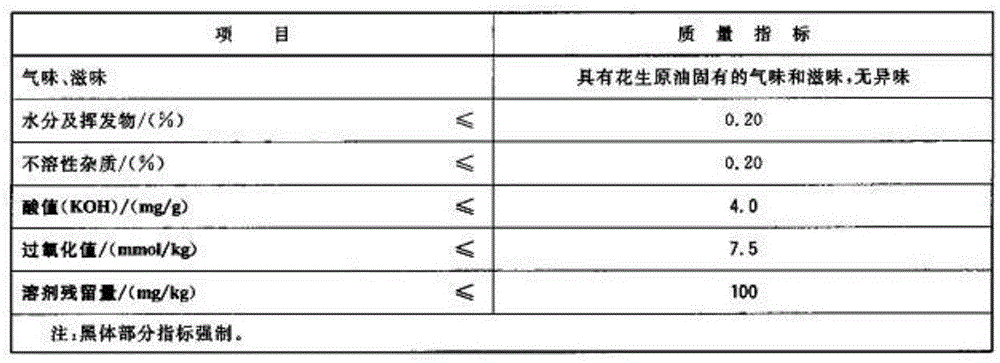

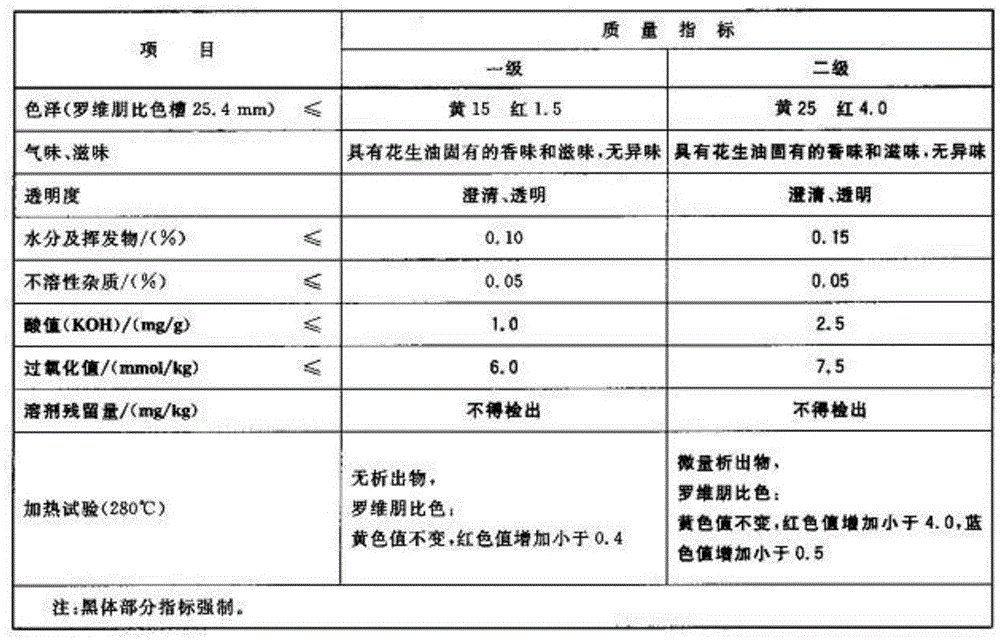

Method for preheating presser to press out vegetable oil with strong aroma

InactiveCN105482892AAvoid charringPrevent spoilageFatty-oils/fats productionCooking & bakingVegetable oil

The invention specifically relates to a method for preheating a presser to press out vegetable oil with strong aroma, which belongs to the technical field of pressing of a vegetable oil material. According to the method, the presser is preheated, hot air with a temperature of more than or equal to 110 DEG C and less than 190 DEG C is used to bake a vegetable oil material, and then normal pressing is carried out. To better improve product quality, the invention also provides an approach of baking the vegetable oil material by using hot air with a temperature of more than 190 DEG C at first so as to allow the surface of the vegetable oil material to approach or reach a critical charring state and then delivering the vegetable oil material to the press which is not preheated for pressing, and through such operation, the presser is preheated in passing; then the temperature of the hot air for baking the vegetable oil material is reduced, and a normal pressing procedure is carried out; and the presser can continuously works without interruption. Moreover, as the hot air is used for baking the vegetable oil material during pressing, hot air temperature and baking time can be accurately controlled, so the vegetable oil material can be completely prevented from charring and deterioration under the condition of high temperature; and thus, the quality of the vegetable oil is improved.

Owner:区钊金

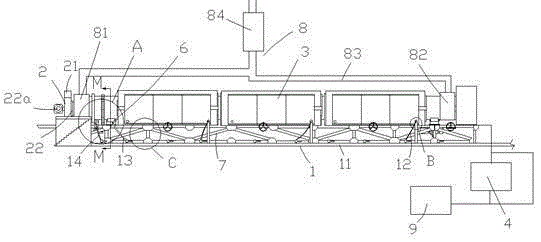

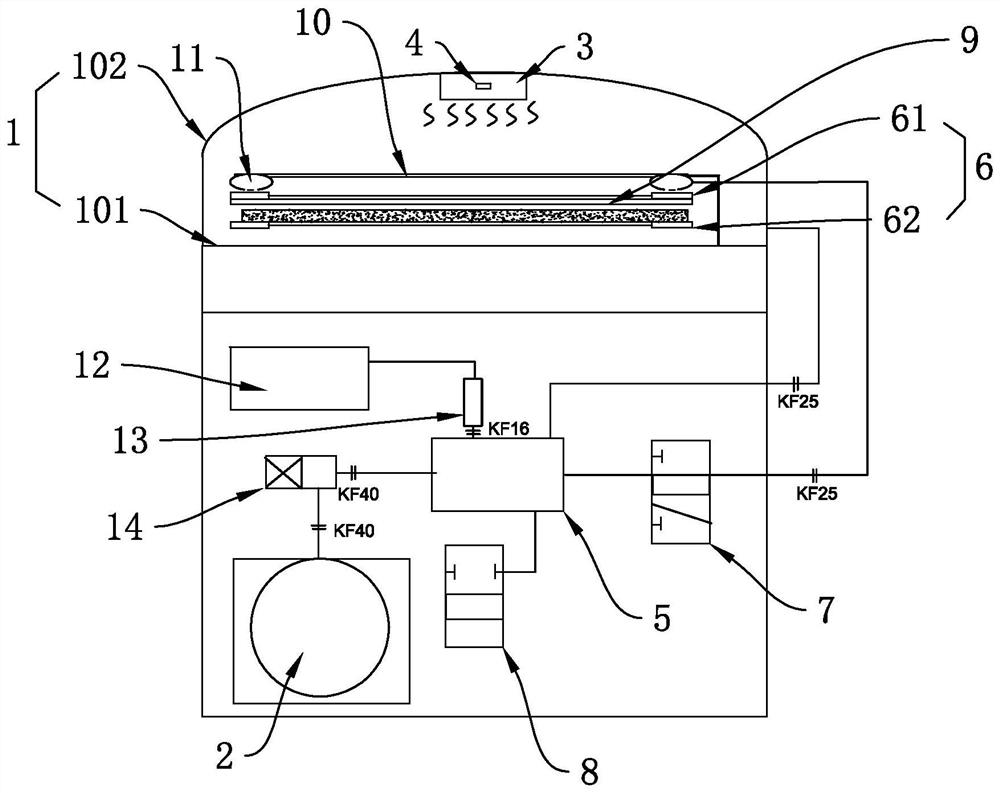

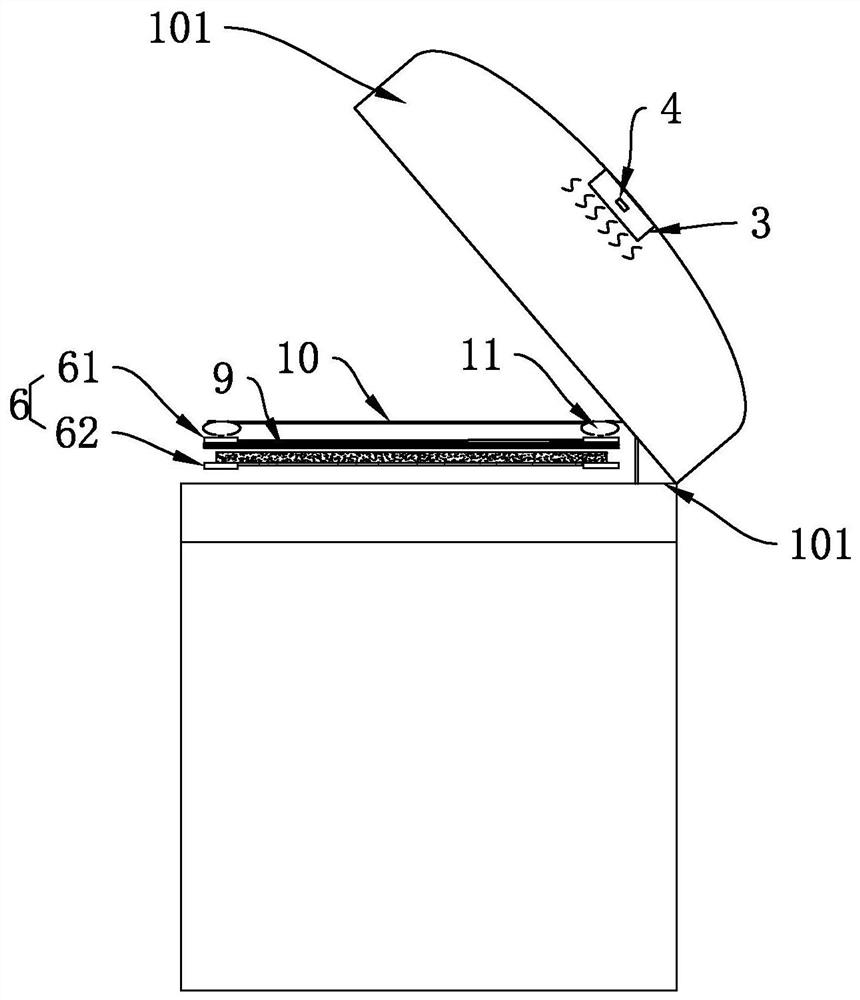

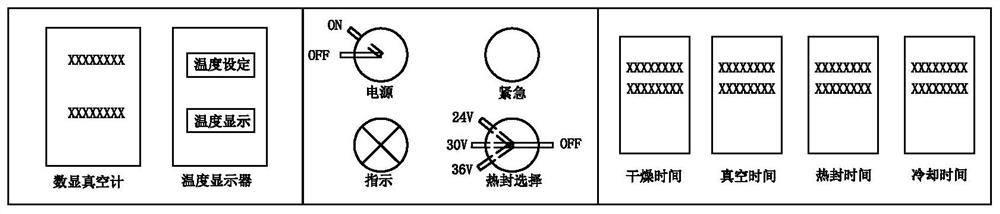

Vacuum insulation panel manufacturing machine with microwave drying device

InactiveCN111645915AGreat suctionHeating inertia is smallDrying solid materials with heatPackaging under vacuum/special atmosphereProcess engineeringPumping vacuum

The invention discloses a vacuum insulation panel manufacturing machine with a microwave drying device, and relates to the technical field of vacuum insulation panel manufacturing machinery. The vacuum insulation panel manufacturing machine comprises a vacuum chamber, a vacuum pump, a microwave emitter, an infrared temperature sensor, a time relay and a heat sealing unit, wherein vacuumizing treatment is carried out through the vacuum pump, and a vacuum insulation panel is heated through the microwave emitter, so that the vacuum insulation panel is heated by using electromagnetic waves in a vacuum environment. The vacuum insulation panel manufacturing machine is simple in structure, vacuumizing of the vacuum chamber is achieved in a short time, a certain vacuum degree is maintained, the vacuum heat insulation panel is rapidly heated by the electromagnetic waves, the moisture of the vacuum heat insulation panel is evaporated, the moisture removing process of the vacuum heat insulation panel is greatly simplified, and the manufacturing efficiency of the vacuum heat insulation panel is improved.

Owner:SHANGHAI MARITIME UNIVERSITY

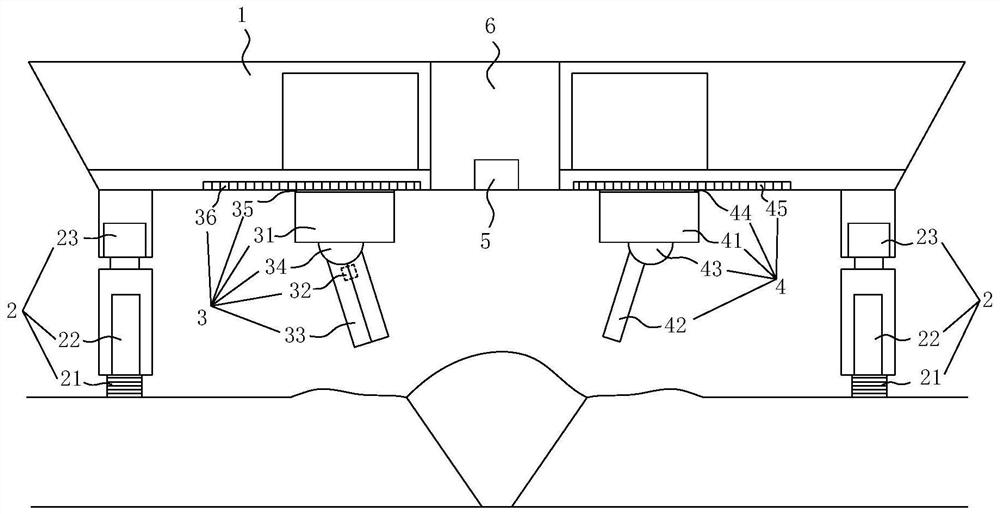

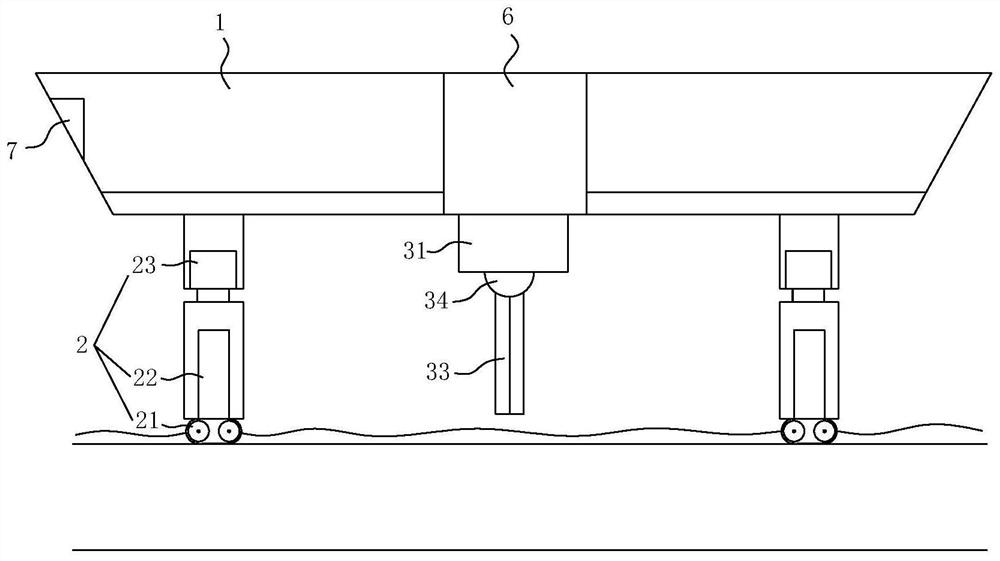

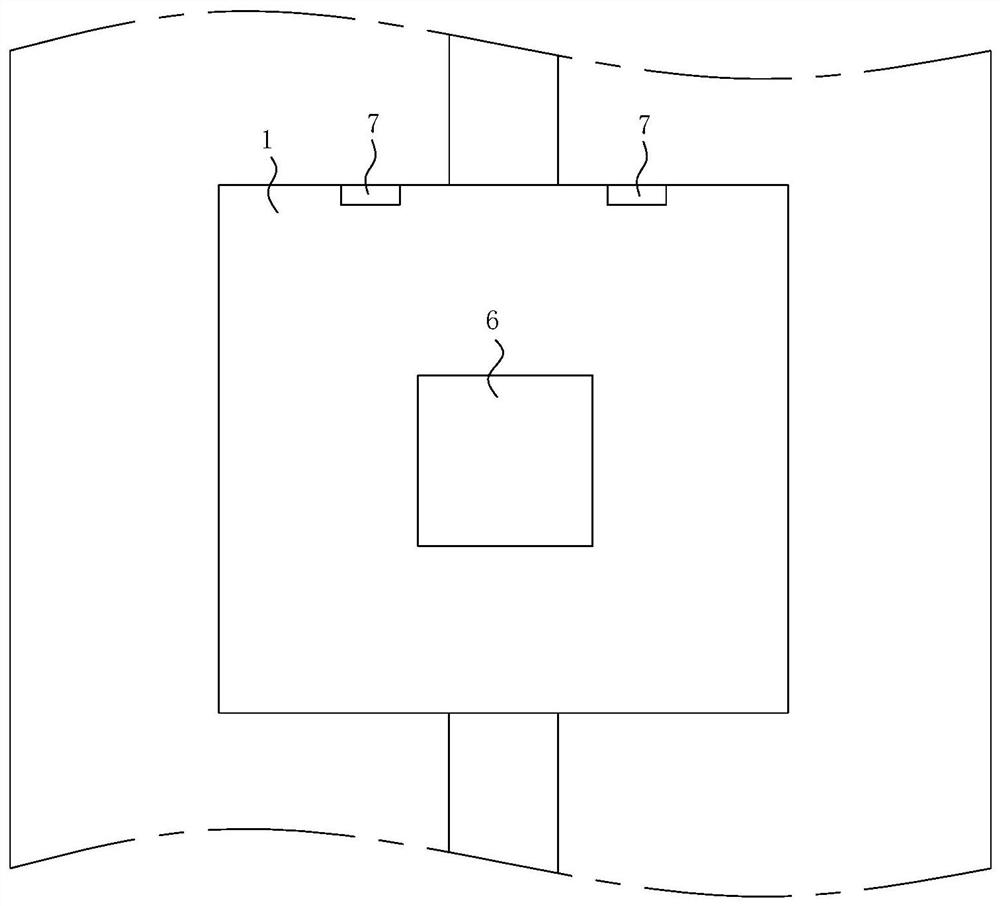

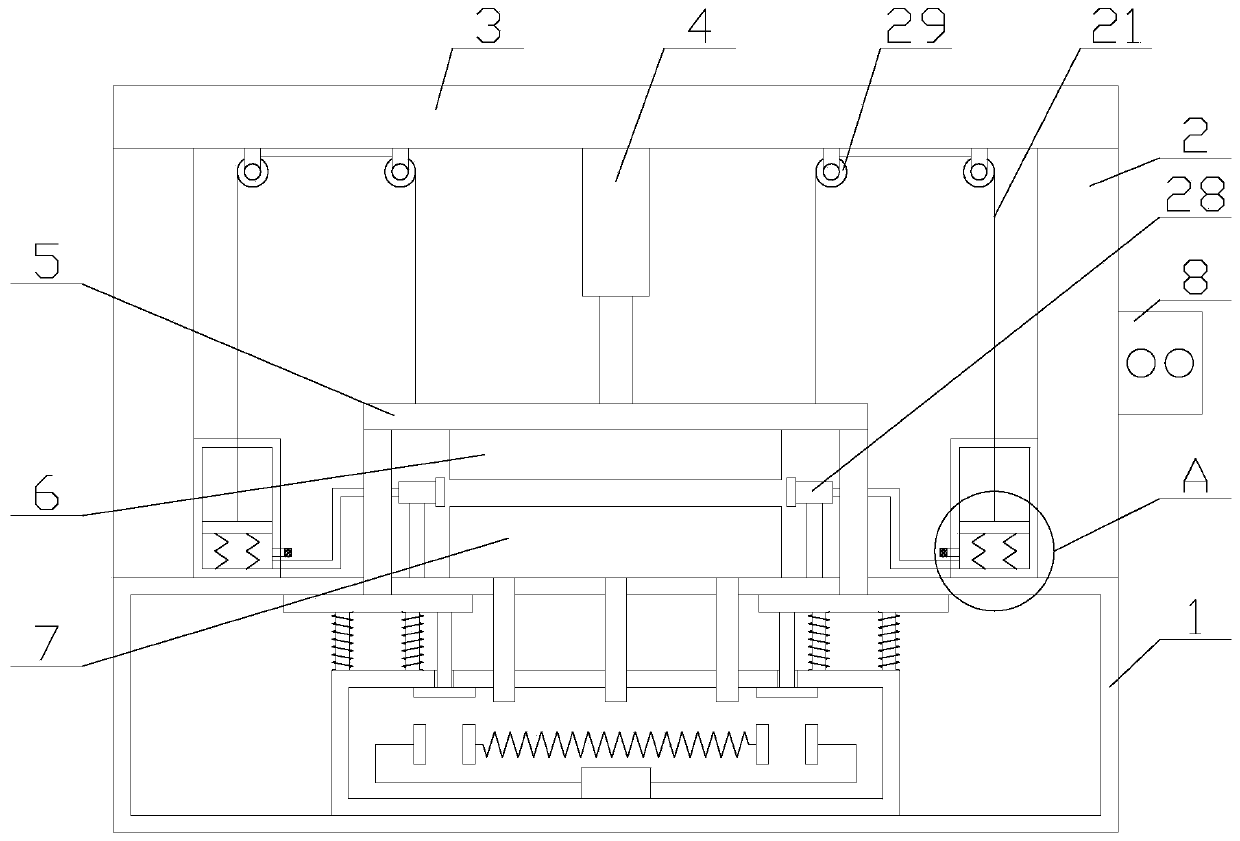

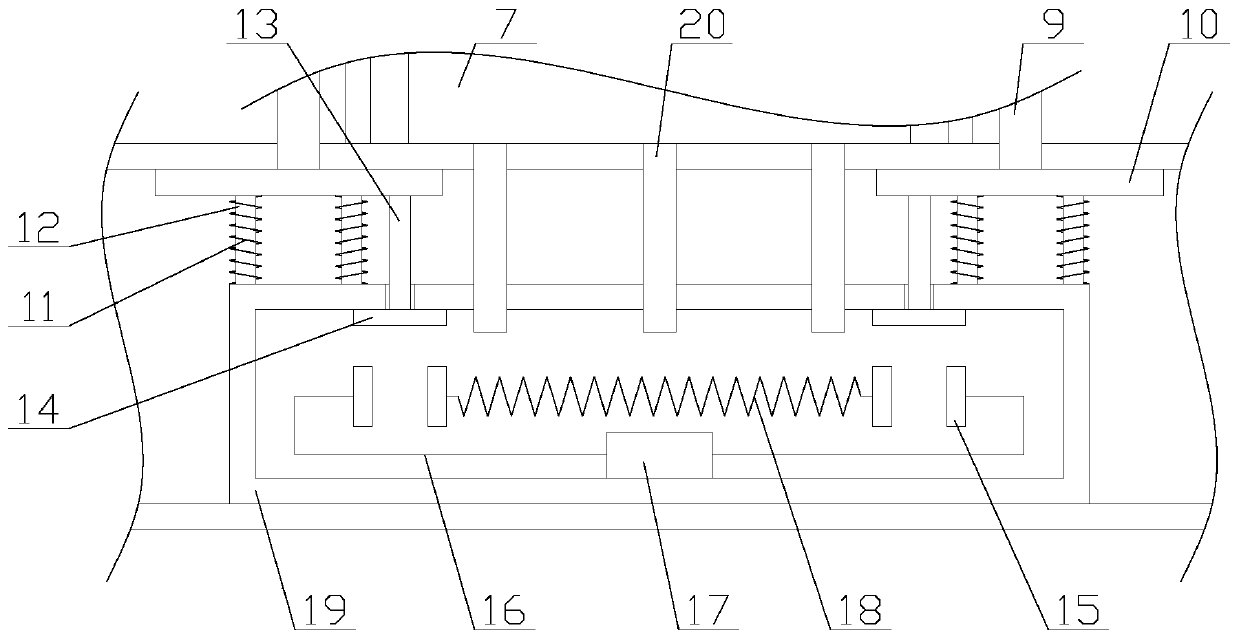

Weld joint treatment device

ActiveCN113042945APrecise temperature controlPrecise control of heating timeWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringManual handling

The invention relates to the technical field of ship manufacturing, and particularly discloses a weld joint treatment device. The weld joint treatment device comprises a device body, a moving assembly, a heating assembly, a cooling assembly, a temperature detector and a controller, wherein the device body is arranged above a weld joint of a ship plate, the moving assembly, the heating assembly, the cooling assembly and the temperature detector are arranged on the side face, close to the ship plate, of the device body, the controller is arranged on the device body, the moving assembly, the heating assembly, the cooling assembly and the temperature detector are all in communication connection with the controller, the moving assembly can drive the device body to move along the weld joint, the heating assembly, the cooling assembly and the temperature detector directly face the weld joint, the heating assembly is used for heating the weld joint, the cooling assembly is used for cooling the weld joint, and the temperature detector is used for collecting the real-time temperature of the weld joint. According to the weld joint treatment device, manual operation is not needed, personal injury to operators is reduced, the temperature and heating time of the weld joint can be accurately controlled, and the stability of the weld joint processed finished product is improved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Compression molding system with heat dissipating function

InactiveCN111376424AReduce the chance of deformationSpeed up circulationCompression moldingHeating time

The invention relates to a compression molding system with a heat dissipating function. The compression molding system comprises a compression molding device. The compression molding device comprisesa working table, a top plate, an air cylinder, a supporting plate, an upper die, a lower die and two supporting rods, and further comprises a heating mechanism and two cooling mechanisms. Each coolingmechanism comprises a spraying nozzle, a fixing rod, a connecting pipe, an air input pipe, an air inflator, a piston, a pulling wire and a plurality of first springs. The heating mechanism comprisesa heating box, an electric heating wire, a battery, a cable, two control assemblies, two transmission assemblies, two connecting rods and a plurality of heat conducting fins. According to the compression molding system with the heat dissipating function, air is blown to a machined workpiece, the ventilation speed of the air around the workpiece is increased, the cooling effect is improved, thus time for workpiece forming is shortened, the working efficiency is improved, by means of the heating mechanism, heating time can be controlled precisely, the situation that the workpiece is still heatedafter compression molding, the probability of workpiece deformation is reduced, and the compression molding quality is improved.

Owner:曹燕红

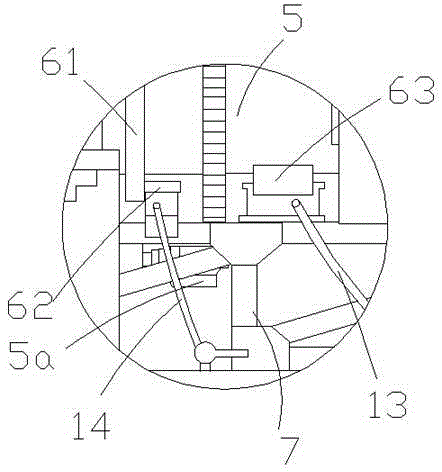

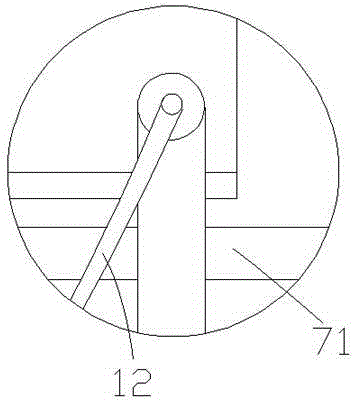

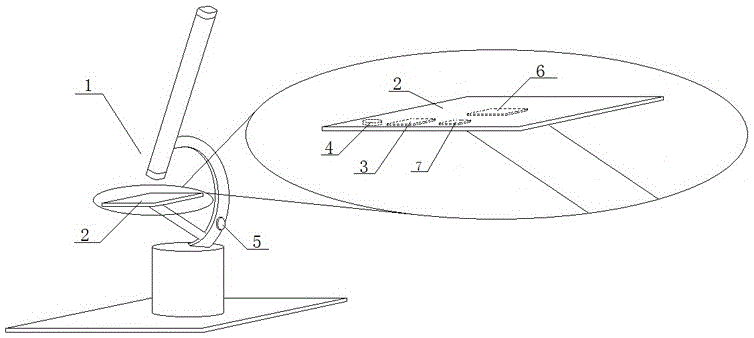

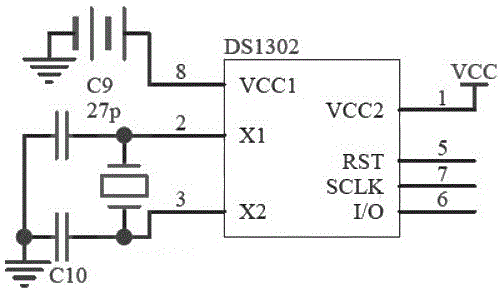

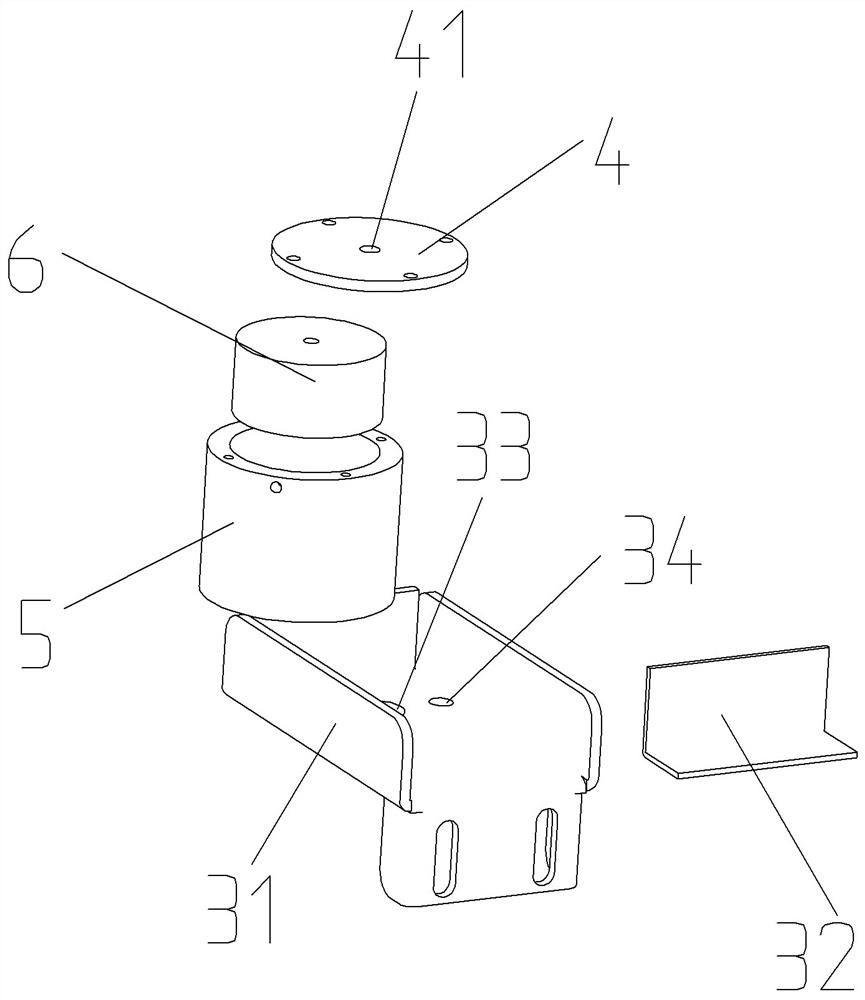

High-efficiency intelligent heating type microscope

The invention relates to a high-efficiency intelligent heating type microscope which comprises a microscope body (1). The microscope body (1) comprises a specimen tray (2) and a control module (3). The microscope body (1) further comprises a power supply (4), a control button (5), an electric heating module (6) and a clock circuit (7) respectively connected with the control module (3). The specimen tray (2) is made of heat conduction materials. The control module (3), the power supply (4) and the clock circuit (7) are arranged on the lower surface of the specimen tray (2) respectively through a thermal insulation layer. The electric heating module (6) is arranged on the lower surface of the specimen tray (2) in a tightly attached way. The high-efficiency intelligent heating type microscope adopting the specimen tray (2) made of heat conduction materials as a basis achieves specimen heating operations through the designed electric heating module (6) via the specimen tray (2). The storage requirements of special specimens are satisfied. The specimen observation data accuracy is greatly improved.

Owner:SUZHOU OUKELUO ELECTRONICS TECH

Heater for shaping of polyester rope and operation method of heater

InactiveCN110552099AShaping speed is fastEasy to controlTextiles and paperElectric machineryPolyester

The invention discloses a heater for shaping of a polyester rope and an operation method of the heater. The heater comprises a heating cylinder, six clamping plates are welded to the inner circumference face of the heating cylinder, and an arc heating plate is installed between every two clamping plates; a cooling box is connected to one end of the heating cylinder, a second motor is installed atthe bottom of the cooling box, a heat dissipation fan is installed at the output shaft end of the second motor, and a conveying mechanism is connected to the end, away from the heating cylinder, of the cooling box. According to the heater, the distances between the inner side faces of all the heating plates and the surface of the polyester rope are identical, so that the surface of the polyester rope is evenly heated; through the heat dissipation fan, the polyester rope shaped just now is cooled, softening of the polyester rope is eliminated accordingly, the situation that during operation ofthe conveying mechanism, due to too large pull force of the polyester rope, the polyester rope deforms is avoided, and the effect of shaping the polyester rope is guaranteed; through the conveying mechanism, it can be effectively guaranteed that the polyester rope passes through the heating cylinder at the constant speed, and accordingly the time of heating all the parts of the polyester rope is identical.

Owner:安徽嘉明新材料科技有限公司

An intelligent control system for a microwave oven

ActiveCN106102201BEasy to operateImprove experienceDomestic stoves or rangesLighting and heating apparatusMicrowave ovenRunning time

The invention discloses an intelligent control system of a microwave oven. The intelligent control system comprises an oven body, an oven cavity, a heating unit and a control unit, wherein the oven body is provided with a setting unit and a display unit; a tray, second testing equipment and third testing equipment are arranged in the oven cavity; the tray is provided with first testing equipment; the control unit obtains a preset working mode which is collected by a mode button and selected by a user and a test value of the first testing equipment, and selects running time of the microwave oven in the preset working mode according to the test value; the control unit stores the running time in the control unit, obtains the test value of the second testing equipment and compares the test value with a preset value stored in the control unit; the control unit controls the heating unit to work according to a comparison result; and meanwhile, the control unit obtains image information, which is shot by the third testing equipment, of an object arranged on the tray, and transmits the image information to the display unit for display.

Owner:宣城加特林机械有限公司

Quenching heating device and workpiece fixing unit thereof

PendingCN112853056AEasy to guideSimple structureFurnace typesIncreasing energy efficiencyHeating timeEngineering

The invention relates to a quenching heating device and a workpiece fixing unit thereof. The workpiece fixing unit comprises an electromagnetic chuck, a guiding direction and a control module, wherein the electromagnetic chuck is used for being arranged above a corresponding induction heating coil so as to adsorb and fix a to-be-quenched workpiece; the guiding direction of the guiding structure extends in the vertical direction; the guiding structure is used for guiding the to-be-quenched workpiece mounted in the induction heating coil in a penetrating mode to move upwards so that the to-be-quenched workpiece can be adsorbed and fixed by the electromagnetic chuck when the electromagnetic chuck is powered on to work, and guiding the to-be-quenched workpiece to move downwards so as to penetrate through the induction heating coil to fall into quenching liquid when the electromagnetic chuck is powered off; and the control module is used for controlling the electromagnetic chuck to be powered off after the induction heating coil is powered on to heat the to-be-quenched workpiece and set heating time is passed. The control module is used for controlling the electromagnetic chuck to be powered off after the set heating time, so that the heating time can be accurately controlled, the quenching quality can be effectively guaranteed, and the quenching heat treatment effect is improved.

Owner:XJ ELECTRIC +2

Camshaft flame quenching automatic heat treatment machine tool and technology

ActiveCN104928458BSimple structureImprove versatilityFurnace typesHeat treatment furnacesEngineeringCam

The invention relates to a cam shaft flame hardening automatic heat treatment machine tool. The machine tool comprises a feeding mechanism, a rotating mechanism, a heating mechanism, a cooling mechanism and a control mechanism controlling all the mechanisms of the machine tool to run cooperatively, wherein the feeding mechanism, the rotating mechanism, the heating mechanism, the cooling mechanism and the control mechanism are arranged on the machine tool in sequence. The invention further discloses a cam shaft flame hardening automatic heat treatment technology. The technology specially comprises the steps of automatic feeding, flame heating and cooling. By the adoption of the cam shaft flame hardening automatic heat treatment machine tool and technology, the technical problem of conducting automatic heat treatment on a cam shaft with the flame hardening heat treatment technology is solved, automatic precise operation is achieved during cam shaft flame hardening, hardening quality and stability are guaranteed, a feeding system and a discharging system of the cam shaft flame hardening automatic machine tool are high in automation degree, and production efficiency and economic effectiveness are further improved.

Owner:HEBEI UNIV OF ENG

Method for improving surface quality of medium-thick plates

InactiveCN108393360AReduce oxidation burnAutomatic and precise control of furnace temperatureWork cooling devicesWork heating devicesPositive pressureSystem pressure

The invention provides a method for improving the surface quality of medium-thick plates. The method comprises the steps that a burner adopts pulse combustion control, a combustion control model is set, and the heating time of a slab is controlled within a set range; the air-fuel ratio is controlled to be not more than 2:1 according to the calorific value of coal gas; and it is ensured that the furnace pressure in a heating furnace is micro positive pressure, and the furnace pressure is controlled within 5-6 Pa. A high-pressure water descaling pump station adopts two kinds of system pressure of 25 MPa and 30 MPa, and switching is conducted according to the different steel grades during using; the 25 MPa system pressure is adopted for the ordinary steel grade; and the 30 MPa system pressureis adopted for high alloy steel. An intermediate blank cooling system is arranged on an intermediate blank holding roller way in front of a finishing mill, and an intermediate blank is subjected to water-cooling at the cooling speed of 3-5 DEG C / s. According to the method for improving the surface quality of the medium-thick plates, the oxidation combustion loss of the slab in the heating furnacecan be reduced, primary oxidized scales on the surface of the slab are effectively removed, the holding time of the intermediate blank during rolling is shortened, and producing of secondary oxidizedscales is inhibited.

Owner:ANGANG STEEL CO LTD

An integrated preparation device and method for esterified bio-asphalt

ActiveCN105771855BSimple structureReasonable designProcess control/regulationWorking-up pitch/asphalt/bitumen by chemical meansAlcoholDrive motor

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com